Page 1

Entero™ System Installation/

Troubleshooting Guide

®

®

©

1999 Bose Corporation

Troubleshooting Guide

Part Number: 251763 Rev. c

Page 2

CONTENTS

Audience ........................................................................................................................................... 3

Safety Information............................................................................................................................ 4

Electrostatic Discharge Sensitive (ESDS) Device Handling ........................................................ 4

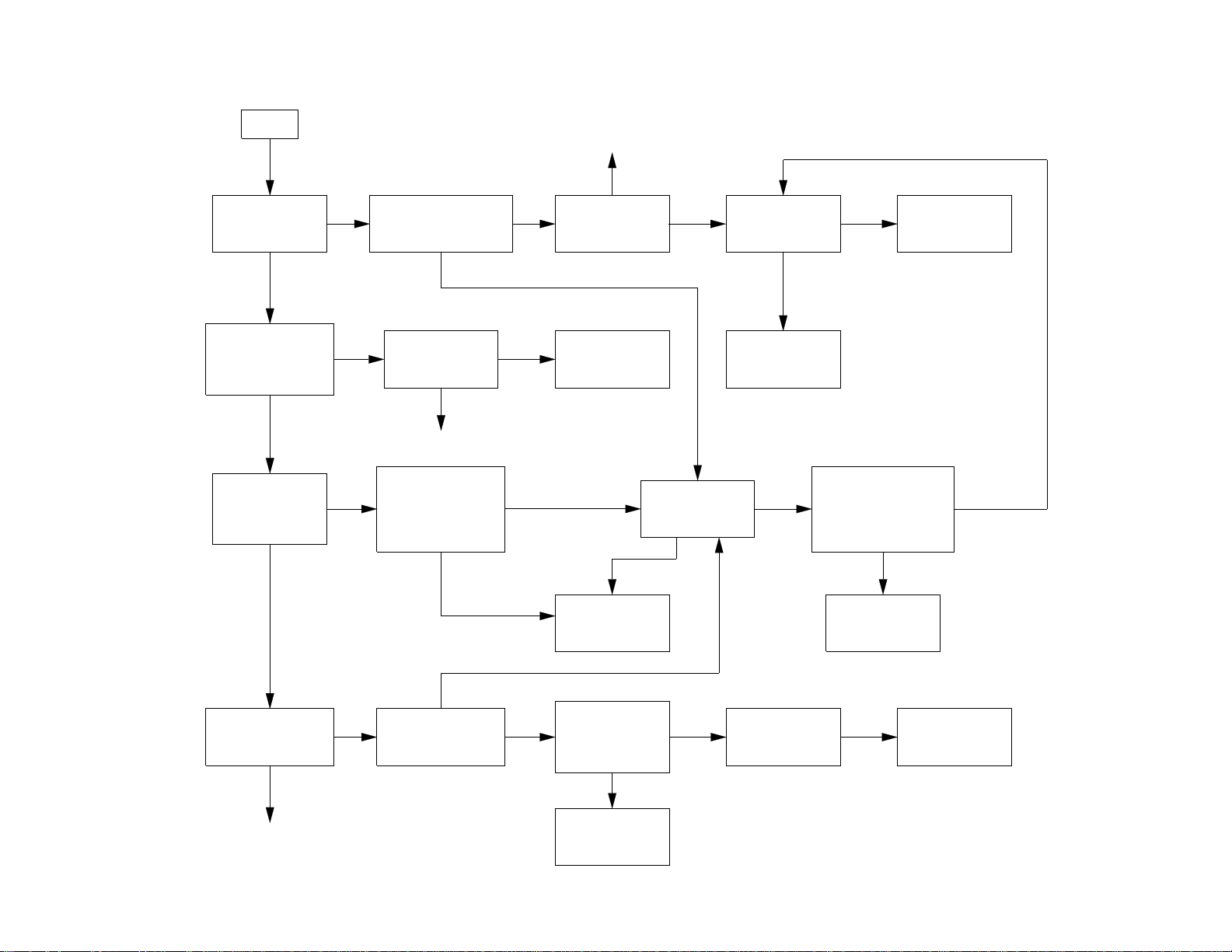

Entero™ System Installation Flow Chart....................................................................................... 5

Entero System Troubleshooting Flow Chart ................................................................................. 6

Entero Computer Related Problems Troubleshooting Flow Chart.............................................. 7

Entero Network Troubleshooting Flow Chart................................................................................ 8

Entero Hardware Troubleshooting Flow Chart.............................................................................. 9

Section 1: PCC-10 Laptop PC Network Adapter Card Information.......................................10-19

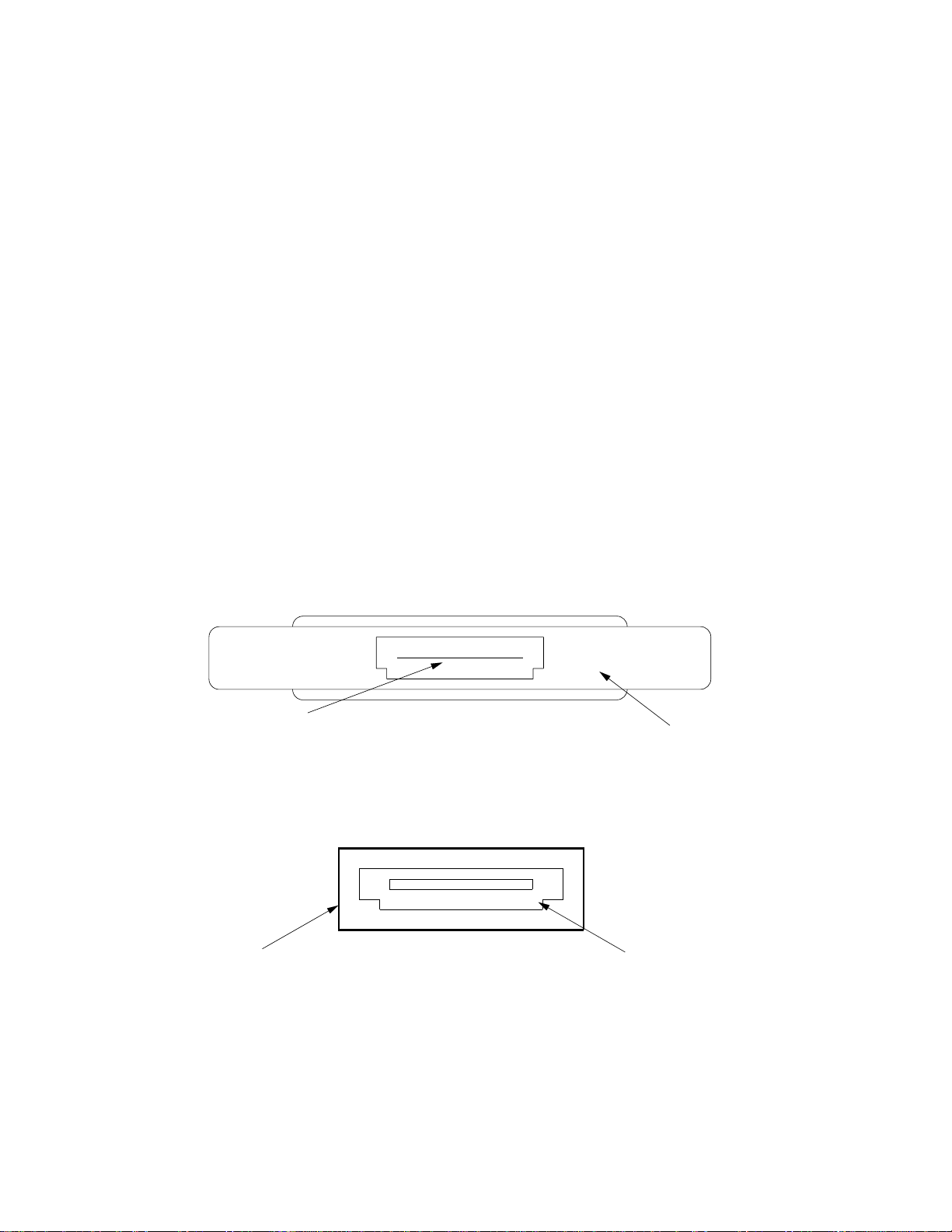

Figure 1.1. PCC-10 Card Network Port Connector (not to scale) .................................................. 18

Figure 1.2. PCC-10 Card Network Cable Connector (not to scale) ............................................... 18

Figure 1.3. PCC-10 Card Network Port Electrical Interface ........................................................... 19

Table 1.1. PCC-10 Network Port Electric Interface Description ..................................................... 19

Section 2: PCNSI Desktop PC Network Adapter Interface Card Information ...................... 20-27

Figure 2.1 PCNSI Card Mechanical Layout and Interfaces ........................................................... 20

Table 2.1 PCNSI Card Interfaces................................................................................................... 20

Table 2.2 SMX-Compatible Transceivers....................................................................................... 21

Figure 2.2 Setting the PCNSI Base Address with switch S1.......................................................... 22

Figure 2.3 PCNSI Default Base Address Setting ........................................................................... 22

Table 2.3 Typical I/O Address Usage in PC-Compatibles .............................................................. 22

Table 2.4 Typical Interrupt Request Usage in PC-Compatibles ..................................................... 24

Section 3: FTT-10A Network Information................................................................................28-33

Figure 3.1 Block Diagram of a LonWorks

Figure 3.2 FFT-10A Free Topology Network Diagram.................................................................... 29

Table 3.1 Cable Types and Typical Parameters............................................................................. 30

Table 3.2 Free Topology Network Specifications ........................................................................... 31

Section 4: Echelon® Model 71000 Router Information........................................................... 34-41

Figure 4.1 Sample Router Installation............................................................................................ 34

Figure 4.2 Router Assembly Using the Router Core Module ......................................................... 35

Figure 4.3 Echelon Model 71000 Router Diagram......................................................................... 36

Table 4.1 Model 71000 Router Interfaces ...................................................................................... 37

Figure 4.4. RJ-45 Connector Pin-out Diagram............................................................................... 38

Figure 4.5 Network Termination Circuits for TP/XF and TP/RS485 Networks ............................... 39

Table 4.2 Power Supply Characteristics......................................................................................... 40

Figure 4.6 Model 71000 Routing Mounting Bracket Fabrication Diagram ..................................... 41

Section 5. K11 and K12 Keypad Information.......................................................................... 42-46

Figure 5.1 K11 and K12 Keypads for Entero System..................................................................... 42

Figure 5.2 K12 Keypad and Cover................................................................................................. 43

Figure 5.3 K11 and K12 Keypad Base Module Front View (without keypad)................................. 45

Figure 5.4 K11 and K12 Keypad Schematic Diagram.................................................................... 46

Section 6: Junction Box and Wiring Guidelines ......................................................................... 47

Figure 6.1 Typical Topology for 78kbps, 1.25Mbps, and RS-485 Networks................................... 47

Figure 6.2 Typical Network Topology for Free Topology Networks ................................................ 48

Figure 6.3 Stub Junction Box Wiring Diagram ............................................................................... 49

Figure 6.4 Local Loop Terminal Junction Box Diagram.................................................................. 50

Section 7: SE-16 Audio Processor Disassembly/Assembly Procedures ................................. 51

Section 8: General Troubleshooting ............................................................................................ 52

Service LED Behavior............................................................................................................... 52-53

Figure 8.1 Service LED Behavior Diagram .................................................................................... 52

Section 8: General Troubleshooting ............................................................................................ 53

Section 9: Reference Information............................................................................................ 54-56

®

Device on a Twisted-Pair Network .............................. 28

2

Page 3

AUDIENCE

This Installation/Troubleshooting Guide is intended for anyone who is installing, maintaining, or

troubleshooting a Bose® Entero™ System; as well as an aid for instructors setting up a training

course on the Entero System.

It contains information about the various components that make up an Echelon® LonWorks

network as they pertain to the Bose Entero System. This includes computer setup

information; Echelon Network Interface Card information; network wiring, router, and junction

box information; and flow charts to direct you to the appropriate service manual for Bose

hardware.

It is not intended to be a definitive answer to any and all problems that can be encountered

when using an Entero system. It is intended to help point you in the direction where you can

find answers to your installation and troubleshooting problems.

Note: Your Entero System as installed may or may not include some of the items as described

in this document.

®

CAUTION: The components listed in this Installation/Troubleshooting Guide

contain no user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service centers or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE® CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER AND SHALL NOT

BE REPRODUCED OR USED FOR ANY OTHER PURPOSE.

3

Page 4

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics or

by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer. Use the

following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

1492 (71). With the unit AC switch first in the ON position and then in OFF position, measure

from a known earth ground (metal waterpipe, conduit, etc.) to all exposed metal parts of the

unit (antennas, handle bracket, metal cabinet, screwheads, metallic overlays, control shafts,

etc.), especially any exposed metal parts that offer an electrical return path to the chassis. Any

current measured must not exceed 0.5 milliamp. Reverse the unit power cord plug in the outlet

and repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a

jumper wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3)

Measure the resistance with an ohmmeter between the jumpered AC plug and each exposed

metallic cabinet part on the unit. When the exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2 Megohms. When there is no return path to

the chassis, the reading must be "infinite". If it is not within the limits specified, there is the

possibility of a shock hazard, and the unit must be repaired and rechecked before it is returned

to the customer .

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

4

Page 5

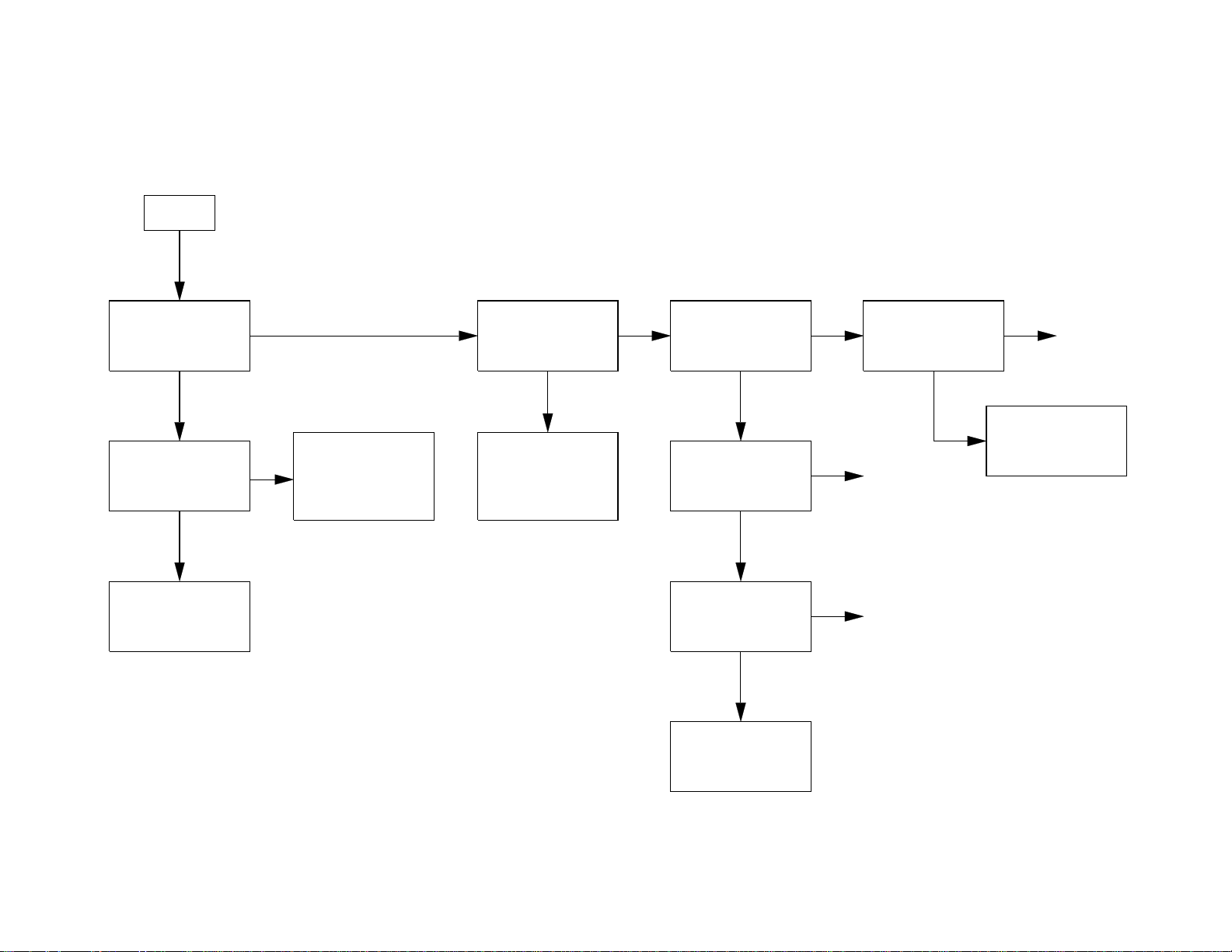

Entero™ System Installation Flow Chart

START

System Design

1. Determine the audio and control requirements

2. Design the network

3. Generate the Entero™ System equipment list

4. Determine the special power requirements

System

Installation

1. Follow the guidelines for cable lengths, types,

and terminations

Network

Commissioning

1. Set up the PC

2. Install the routers

3. Add and configure devices in the Entero System software.

4. Check the network commissioning

Device

Programming

1. Define and set up the device finder and custom views in Entero

2. Add the master controls required

3. Add the On/Off controls required

4. Add mapped faders

5. Consolidate control functions

6. Set up snapshots

7. Program Contact Closure Interfaces

5

Page 6

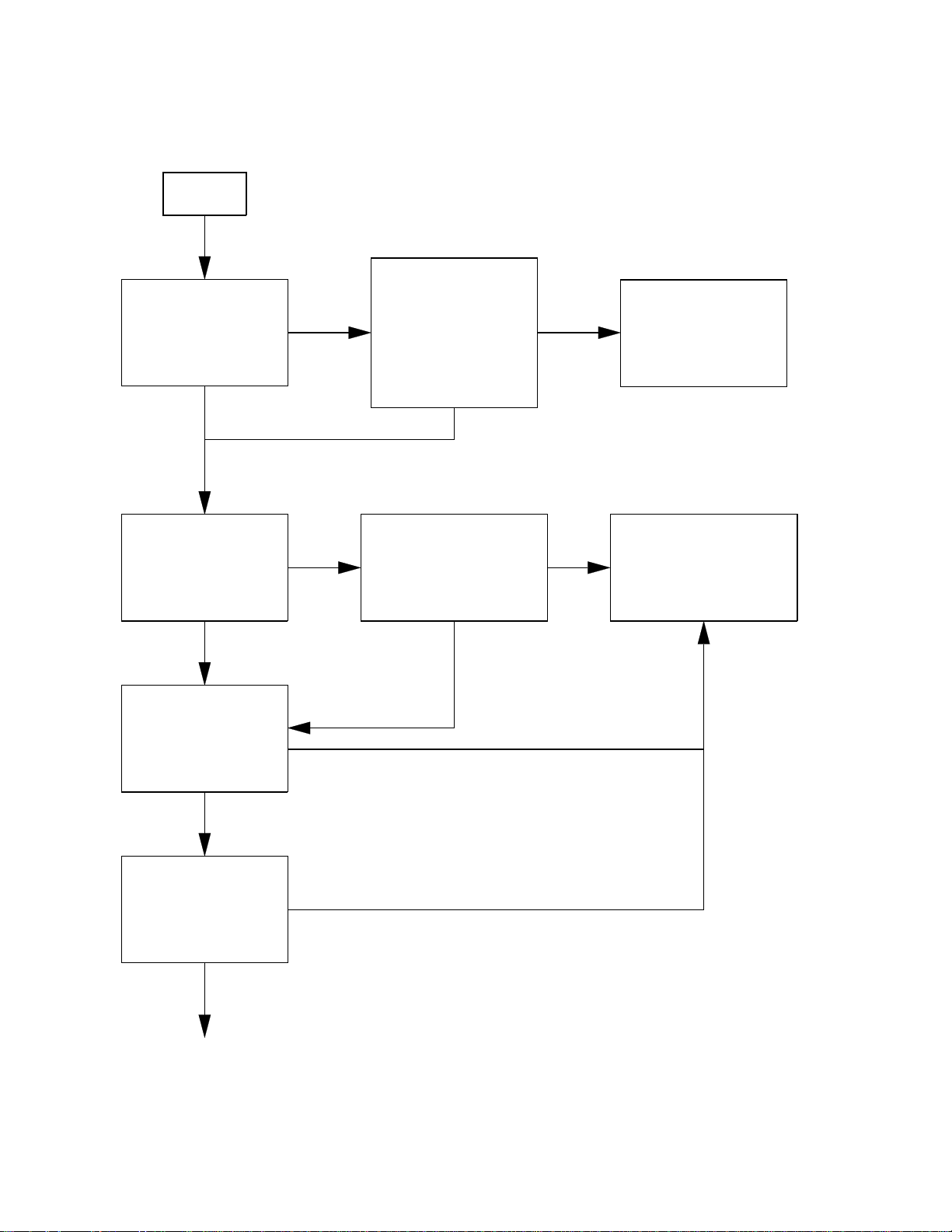

Entero™ System Troubleshooting Flow Chart

START

Is the system

working

properly?

No

Does the

computer boot-up

properly?

Yes

Can you

communicate

with all of the nodes

on the network?

Yes

Yes

No

No

Can you control

the system using

the GUI?

No

Go to the

Computer-Related

Problems T/S

Flow Chart

Go to the

Network T/S

Flow Chart

Done

Yes

Does the hardware

in each section

respond to the

GUI and/or keypad?

Yes

Is clear-sounding

audio coming out of

each speaker?

Yes

Done

No

No

Go to the

Hardware T/S

Flow Chart

6

Page 7

START

Entero™ Computer Related Problems Troubleshooting Flow Chart

Does the computer

boot up properly?

No

Does the computer

7

have AC Mains

power?

No

Restore AC Mains

power.

Yes

Computer failure.

Yes

all necessary

Repair and

re-install

software.

Does the Entero™

System software

open properly?

No

Re-install the

Entero System

software and all

system-specific

files.

Yes

Does the Echelon

Network Interface

Card work

properly?

No

Re-install LNS

software.

Verify software

configuration. OK?

No

Hardware failure,

verify setup and

configuration.

OK?

No

Replace Echelon

Network Interface

Card

®

Yes

Yes

Yes

Can you control

all sections of

the system

using Entero?

No

Done

Done

Yes

Done

Go to the network

trouble-shooting

flow-chart.

Page 8

Entero™ Network Troubleshooting Flow Chart

START

Check router

Can you

communicate

with all of the

sections of the

network?

No

hardware and

configuration

in the Entero™

System software

for the affected

section(s). OK?

Yes

Yes

No

Check the wiring,

connections,

and terminations

for the

affected section(s).

Do all of the nodes

in each section

respond?

Yes

Can you control

the hardware on

the node

using the GUI?

Yes

Is clear-sounding

audio

coming from

each loudspeaker?

No

No

No

Verify affected

node's configuration

in Entero.

Does the node

respond?

Yes

No

Go to the Hardware

Troubleshooting

Flow Chart

Yes

Done

8

Page 9

START

Are the SE-16

audio processors in

the affected section

working properly?

Yes

Using Entero, verify

signal flow through all

channels of the affected

No

SE-16 processor. OK?

Yes

No

Done

Yes

Reconfigure the

affected SE-16

module in Entero.

OK?

No

Does the

affected SE-16

channel have a

clean input signal?

Yes

No

Entero™ Hardware Troubleshooting Flow Chart

Check the source

hardware

and cabling

Can you control and

monitor the amplifiers

in the affected section

using the Entero™

system software?

Yes

9

Is a clean audio

signal coming out

of each amplifier

in the affected

section?

Yes

Is clear-sounding

audio coming out of

each loudspeaker in

the affected section?

Yes

No No

No

No

Reconfigure the

affected ACM-1

in the Entero

software.OK?

Yes

Done

Using the Entero

software, verify

that the operating

parameters of the

affected amplifier

are within limits. OK?

Yes

No

Is a clean audio

signal coming from

the amplifier that is

driving the speaker?

manual for repair.

No

from the amplifier

to the loudspeaker.

Yes

Refer to the

ACM-1 service

Refer to the

1600/1800VI

service manual

for repair.

Check the wiring

and connectors

OK?

No

manual for repair.

Does the

affected amplifier

have a clean input

signal?

Yes

Replace/repair the

Yes

Refer to the

SE-16 service

No

defective

loudspeaker.

Does the SE-16

audio processor

driving the amplifier

have a clean output

signal on that channel?

Yes

Refer to the

1600/1800VI

service manual

for repair.

Refer to the

appropriate service

manual for repair.

No

Done

Repair/replace

defective

wiring.

Page 10

Section 1: PCC-10 Laptop PC Network Adapter Card Information

PCC-10 Network Adapter Card Installation Process

Note: Installation of the PCC-10 software must precede insertion of a PCC-10 card into a PC

Card Type II (PCMCIA) slot.

Failure to install the software before inserting the card will render the card unusable until the

software and card are removed, and then reinstalled in the correct order.

The six steps of the installation process are as follows:

• Install Windows PCMCIA driver if not currently installed. A Windows

®

PCMCIA driver must

be installed prior to PCC-10 card installation. Under Windows 95, the PC Card driver is

installed automatically when the PC Card drive is installed. (if this is not present, please

consult your Windows 95 documentation).

• If you have purchased the LonManager

®

PCC-10 Protocol Analyzer, install the protocol

analyzer applications following the instructions provided in the LonManager Protocol User's

Guide. Note that you cannot use the LonManager ISA Protocol Analyzer card and a PCC-10

card in the same PC.

• Install the PCC-10 driver software as described below.

• Insert the PCC-10 card as described later in this section.

• Attach the PCC-10 network card cable.

• Install the LonWorks

Note: If the LonManager Protocol Analyzer software is installed after installing the PCC-10

card software, the PCC-10 card software must be re-installed.

PCC-10 Network Adapter Card Software Installation

®

Network Services (LNS) software, if needed.

Prior to installation, ensure that the computer is running the Windows 95 Operating System.

The PCC-10 software cannot be installed from DOS or a DOS shell.

1. Close all open programs.

2. Insert the installation diskette into the PC.

3. Click the START button on the Windows 95 task bar and select the RUN command.

4. When prompted for a program name, enter the following:

a:\SETUP.EXE

If necessary, replace a: with the drive letter that corresponds to the drive containing the

PCC-10 installation diskette.

5. When prompted with a list of languages, click on the desired language. A checkmark will

appear to the left of the language to be installed.

10

Page 11

Section 1: PCC-10 Laptop PC Network Adapter Card Information

PCC-10 Network Adapter Card Software Installation (continued)

6. When prompted for a destination directory, enter the desired installation directory. By default

®

this directory is c:\lonworks, unless previous LonWorks

products have been installed and

registered a different path in the Windows® Registry. The path may be modified using the

Browse button; however, if a directory other than c:\lonworks is chosen, the PCC-10 images path will have to be specified to enable use of the PCC-10 card. This is accomplished

during PCC-10 configuration.

7. When the 16-bit Applications Support prompt appears, select "Yes" to enable the use of

16-bit applications with the PCC-10 card. This causes the installation program to add references to the DOS CONFIG.SYS file for the 'stub' device drivers named PCCLON1 and

PCCLON2. This allows existing 16-bit applications, such as the LonManager® Protocol

Analyzer's channel interface maker tool, to recognize these device names and use the PCC-10

card as a network interface. If the PC has more than two PC card slots, two additional stub

device drivers can be created manually. To do so, add the following lines to the CONFIG.SYS

file:

DEVICE=C:\LONWORKS\BIN\LDVSTUB.SYS /D:PCCLON3

DEVICE=C:\LONWORKS\BIN\LDVSTUB.SYS /D:PCCLON4

There is a limit of four (4) PCC-10 cards on a single PC.

To access the PCC-10 card, the "PCCLONn" network interface naming convention must be

used, rather than the "LONn" naming convention used with other Echelon® products. Use of

this naming convention will direct the software to use the PCC-10 card device driver under

Windows rather than attempting to access the device under DOS.

Once this driver is installed and active, existing 16-bit Windows applications can access the

PCC-10 card using the ldv_open(), ldv_close(), ldv_read(), and ldv_write()

functions provided by the WLDV.DLL file.

The installation software installs a new WLDV.DLL file, replacing any previous versions of the

file. The updated WLDV.DLL file is fully backward compatible with previous versions.

8. If the installation software discovers the SYSTEM.INI entry that loads the ISA-bus driver,

ECHLMPA.386, it will comment out the entry and display the message:

"SETUP has modified your SYSTEM.INI file by removing the following

entry: device=echlmpa.386."

It is not possible to use the ISA-bus protocol analyzer card and the PCC-10 card on the

same PC.

9. The installation software for the Windows 95 version will issue a prompt to add a DOS

virtual-mode device driver file named LDVVDD.SYS to the DOS CONFIG.SYS file to support

DOS applications to be used in a Windows 95 DOS shell/window. The following line is added

to the CONFIG.SYS file:

DEVICE=C:\LONWORKS\BIN\LDVVDD.SYS /D1

11

Page 12

Section 1: PCC-10 Laptop PC Network Adapter Card Information

PCC-10 Network Adapter Card Software Installation (continued)

10. Installation is complete. At the prompt to restart the computer, remove the PCC-10

®

installation diskette and restart the computer. Note that Windows

will not recognize the

PCC-10 card until the computer is restarted.

Windows 95 Warning

Some Windows 95 computer systems come equipped with hardware (such as a CDROM

drive) that use its own card and socket services. These services replace those provided by

Windows 95, and may contain incompatibilities that prevent the PCC-10 card from functioning.

One example is SystemSoft's CardWorks™ PCMCIA drivers, which are packaged with the

Axonix ProMedia™ Portable CDROM Drive. To allow the PCC-10 card to operate with these

drivers, some of its services must be disabled by commenting out the lines in the PC's

CONFIG.SYS file that contain the following instructions:

C:\CARDWORK\SSTOPIC.EXE, C:\CARDWORK\ATADRV.EXE,

C:\CARDWORK\MTAA.EXE, C:\CARDWORK\MTAB.EXE,

C:\CARDWORK\MTI1.EXE, C:\CARDWORK\MTI2P.EXE,

C:\CARDWORK\MTATM.EXE, C:\CARDWORK\MTHB2.EXE,

C:\CARDWORK\MTSRAM.EXE, C:\CARDWORK\MTTDRV.EXE,

C:\CARDWORK\FTL.EXE, C:\CARDWORK\CARDID.EXE,

C:\CARDWORK\AXONIXXR.EXE

PCC-10 Network Adapter Card Software Removal

To remove the PCC-10 software, use the Uninstall control panel as follows:

1. Close the "LonWorks® Plug n' Play" control panel, if it is open.

2. Choose the "Add/Remove Programs" icon from the Control Panel folder.

3. Select "LonWorks PCC-10" from the list under the Install/Uninstall tab.

4. Click the "Add/Remove..." button.

5. Confirm file deletion at the prompt. Most of the PCC-10 software will be removed

automatically.

6. The LonWorks Plug n' Play control panel must be removed manually. Close the Control

Panel folder if it is open. Rename C:\Windows\System\Pcc10cfg.cpl to

C:Windows\System\Pcc10cfg.cpx, (where C: is the drive containing the Windows

folder), then remove the file Pcc10cfg.cpx by placing it in the Recycle Bin. It is not

necessary to empty the Recycle Bin at this time.

Windows will not allow deletion of Pcc10cfg.cpl because it is registered as a control panel.

Renaming the file circumvents this Windows 95 restriction.

7. If necessary, edit the CONFIG.SYS file to remove any references to the LDVSTUB.SYS

driver.

12

Page 13

Section 1: PCC-10 Laptop PC Network Adapter Card Information

PCC-10 Laptop Network Card Hardware Installation

Note: If the software has not been installed, please install it first using the procedures outlined

earlier in this section. The Windows

without the software installed.

The PCC-10 card conforms to the Personal Computer Memory Card International Association's

(PCMCIA) standard for hot plug-in. The PCC-10 card will not be harmed if it is inserted into, or

removed from, a PC Card (PCMCIA) slot that conforms to this standard, whether the

computer is on or off. In addition, the PCC-10 card is recognized as a UL Listed Accessory

and is designed to be used with UL Listed equipment.

Do not force the PCC-10 card into the PC card slot. The PCC-10 card is keyed and can only

be inserted one way into the PC card slot. In a Windows 95 environment, insertion of the

PCC-10 card will cause the operating system to produce two brief tones: a low tone followed

by a higher tone. Extracting the card will produce the tones in reverse order: high then low. If a

device's properties window is open in the System Control Panel, the tones will be produced

after the window is closed to confirm that the device is inserted correctly. Additionally, a PC

Card icon may appear in the status area to the right of the Windows 95 taskbar.

®

operating system will not recognize the PCC-10 card

• If the computer was rebooted after installation of the software, insert the PCC-10 card into

an open PC card slot. Otherwise, reboot the computer before insertion.

• Under Windows 95, the device driver for the PCC-10 card is not loaded until the first

PCC-10 card is recognized. Likewise, when the last PCC-10 card is removed, the device

driver is unloaded, thus freeing any system resources it was using.

• Each PCC-10 card requires a single, dedicated interrupt request (IRQ) and four contiguous

bytes of I/O address space starting on a modul0-4 based address.

• Removal of a PCC-10 card while an application is using the card will result in a loss of

communication with the device, which cannot be restored by re-inserting the card. Some

applications will display unusual behavior, and will not properly function. Any application

using the PCC-10 card must be restarted if, a PCC-10 card has been removed during use

to ensure proper operation of the device and software.

• Under Windows 95, the first time a PCC-10 card is inserted into a running PC, a window will

appear with the words "Echelon Corp.-PCC-10". Another window will appear stating that the

Windows operating system is building a new database from the device information installed

by the PCC-10 installation diskette. The new hardware can be configured when the PC has

finished writing the device information.

13

Page 14

Section 1: PCC-10 Laptop PC Network Adapter Card Information

®

PCC-10 Card Hardware Revisions under Windows

95

If a different, or newer, version of the PCC-10 card is inserted into the PC Card slot, a

"New Hardware Found" window may be presented. In this event, a prompt will appear to select

which driver should be installed for the new hardware. If the new hardware states that it is the

"PCC-10 LonWorks® Network Interface", then choose the Windows default driver. This is the

driver that is installed on the PC during the PCC-10 software installation. If the driver has a

different name, you must be sure you have installed the proper software for that card. If not,

click Cancel, remove the card, and then install the software for that card.

If the Windows default driver choice cannot be selected (or is shown in gray), the PCC-10

Card may have been erroneously inserted before the software was installed and the system

rebooted. In this case, click Cancel, remove the PCC-10 Card if it is in a PC Card slot, then

follow the Windows 95 Network Adapter Card Software Removal Procedure discussed earlier.

Reinstall the PCC-10 software, reboot the system, and then insert the PCC-10 Card.

If cancel or an option other than Windows default driver is chosen, follow the instructions

indicated for that selection below:

Cancel

If the Cancel button is accidentally selected, remove the PCC-10 card and re-insert it.

This action will cause the New Hardware Found window to be displayed again.

Choose the Windows default driver.

Do Not Install a Driver

If this option is chosen, the PCC-10 software must be re-installed to use the PCC-10 card.

This screen will only be presented once.

Driver from Disk

Do not select this option. If this option is selected inadvertantly, a prompt will ask for a diskette

containing the driver. Since the PCC-10 software installation diskette does not include a driver

in a readable form, no driver will be found. In this case, cancel the request, remove the

PCC-10 card, and re-insert it. This will cause the New Hardware Found window to be

displayed again. Choose the Windows default driver.

Select from a List

Do not select this option. If this option is selected inadvertantly, a list of drivers is displayed

which does not contain the required driver. In this event, cancel the request, remove the

PCC-10 card, and re-insert it. This action will cause the New Hardware Found window to be

displayed again. Choose the Windows default driver.

14

Page 15

Section 1: PCC-10 Laptop PC Network Adapter Card Information

®

Configuring and Testing the PCC-10 Card under Windows

95

PCC-10 Configuration

PCC-10 card configuration is accomplished using the LonWorks® PCC-10 control panel. Open

the control panel by selecting the "LonWorks Plug n' Play" icon in the Control Panel folder

located in the My Computer folder on the Windows 95 Desktop.

The LonWorks PCC-10 control panel is divided into three parts: a device selection area, a

general settings area, and a control section. The device selection area contains configuration

settings and diagnostic controls that are specific to an individual PCC-10 card and its device

driver. The general settings area contains settings for all PCC-10 cards used with the computer. The control section contains buttons for accepting or canceling the changes made in the

control panel, as well as a Help button.

PCC-10 Initialization

In most cases, PCC-10 card initialization occurs automatically upon insertion. Manual initialization will be required following software installation to a directory other than C:\lonworks, or

moving of the PCC-10 system images.

To manually initialize the PCC-10 card, verify that the control panel's System Image Path entry

is correct, then click the Apply button.

An error will be reported if an attempt is made to modify the transceiver type before the

PCC-10 card is initialized. Testing the card with the Diagnostics button, as suggested by the

error message, produces the diagnosis: "Image file not found". In this case, return to

the control panel's main dialog box, and manually initialize the PCC-10 card.

Device Specific Settings

The PCC-10 specific options consist of the following controls:

Device Selected

This setting controls which PCC-10 card is selected for configuration. The PCCLON1 and

PCCLON2 drivers are installed by the installation software. If additional drivers have been

manually installed, one or both of PCCLON3 and PCCLON4 will also be available.

Automatic Flush Cancel

This setting controls whether the device driver will automatically force the network interface

(for the selected PCC-10 card) to leave the post-reset flush state whenever it is reset. The

post-reset flush state prevents any inbound or outbound network traffic following a reset. If this

box is not checked, it is up to the client application to manage this state. If it is checked, the

device driver will automatically allow network traffic to resume. The default is checked.

15

Page 16

Section 1: PCC-10 Laptop PC Network Adapter Card Information

®

Configuring and Testing the PCC-10 Card under Windows

95 (continued)

Device Specific Settings (continued)

NI Application

This setting controls the type of image or application to be used. (When using the

LonManager® Protocol Analyzer software with the PCC-10 Protocol Analyzer card, this

selection is handled automatically). A PCC-10 card can only hold one image at a time.

Loading a new image will replace the currently loaded image. The choices for these images

are determined by the image files (.NBI extension) found in the system image path specified

under General Settings. Some of the possibilities include the following:

• PCC10L7, the basic network interface application image

• NSIPCC, the Network Services Interface application image.

Transceiver...

This control panel opens the PCC-10 Transceiver dialog box. Choosing this control will retrieve

the transceiver configuration of the selected PCC-10 card. If there is no PCC-10 currently

inserted in a PC card slot, a message appears under Windows 95 stating that the operating

system has removed, or has not loaded, the PCC-10 device driver.

The default transceiver is an FT-10 compatible transceiver that is built into the PCC-10 card.

Other standard transceiver configurations and a custom configuration may be selected using

the Transceiver selection box. The Custom Properties controls are not accessible unless the

Custom transceiver type is selected. If an error is received while modifying the Transceiver

type, choose the Apply button, then proceed to modify the Transceiver type.

The PCC-10 card will be configured for the selected Transceiver when either the OK button or

Apply button is chosen. While either button will configure the PCC-10 card, the OK button will

also close the PCC-10 Transceiver window. To implement the changes, the PCC-10 card will

reset whenever the transceiver configuration is changed.

The information in the Custom Properties area reflects the current configuration within the

PCC-10 card. It will not change until a transceiver is selected, and then configured by using the

OK or Apply buttons.

When configuring a custom transceiver or adding custom parameters for a standard transceiver, the values used in the Custom Properties Raw Data edit boxes must be entered as

hexadecimal byte values separated by dashes. Further explanation of Raw Data values can be

found in the LonBuilder® User's Guide.

16

Page 17

Section 1: PCC-10 Laptop PC Network Adapter Card Information

®

Configuring and Testing the PCC-10 Card under Windows

95 (continued)

General Settings

The PCC-10 generic options consist of the following controls:

System Image Path

This control specifies the full directory path for the PCC-10 system images. This path is set by

the PCC-10 Installation Software but may be modified by the user.

Layer2 and Layer6 Buffering

This setting controls the number of 4Kbyte operating system pages that are allocated for

message buffering within the driver. The Layer2 setting is used by the LonManager® PCC-10

Protocol Analyzer only and generally should not be modified. The Layer6 setting is used for all

other system images. The default setting of Layer2 buffering is 20 pages, and the default

setting of Layer6 buffering is 6 pages. These values should be appropriate for most applications; embedded systems may need to change the number of buffering pages.

Enable PC Card Reset

This switch controls whether the PCC-10 card's PC Card hardware reset line is enabled. With

the reset line enabled, the PCC-10 card operates in full compliance with the PCMCIA PC Card

Standard, Release 2.1. However, this mode of operation reduces the card's resistance to

electrostatic discharge (ESD) by making it susceptible to spurious resets introduced on the

reset line by the host PC.

Disabling the reset line provides the full ESD resistance, without otherwise affecting card

performance.

The default setting is unchecked, i.e., the PC Card reset is disabled.

17

Page 18

Section 1: PCC-10 Laptop PC Network Adapter Card Information

PCC-10 Laptop Network Card Electrical Interface

This section provides information about the electrical characteristics of the PCC-10 card.

Included is an overview of the electrical design of the interface for the external transceivers

and details about connecting the card's internal FT-10 compatible transceiver to a network.

Network Port

The PCC-10 has a 15-pin network port connector for interfacing with a free topology or link

power channel, and for connecting external transceiver pods.

Figure 1.1 shows the numbering scheme of the 15-pin Hirose male connector on the PCC-10

card. The top of the the PCC-10 card is the side with the product label. Figure 1.2 shows the

pin-out of the mating female Hirose NX30TA-15PAA connector to which the network wiring or

transceiver pod is connected. The Hirose connector plug should be protected with a cover

(Hirose NX-15T-CV1).

Note: As listed in Table 1.1 on the next page, pins 14 and 15 of the connector are the FT-10

Network connection pins. This is where you would connect to your twisted-pair network. They

are polarity insensitive.

Top

115

Hirose Connector:

CL234-0004-5

Bottom

PCC-10 Card

Figure 1.1. PCC-10 Card Network Port Connector (not to scale)

1

Hirose Plug Cover:

NX-15T-CV1

15

Hirose Connector

Plug: NX30TA-15PAA

Figure 1.2. PCC-10 Card Network Cable Connector (not to scale)

18

Page 19

Section 1: PCC-10 Laptop PC Network Adapter Card Information

PCC-10 Laptop Network Card Electrical Interface (continued)

Cable

Connector

FT-10

Compatible

Transceiver

+5V Power

Switch and

Current Limit

Circuit

E

S

D

C

L

A

M

P

C

K

T

R

R

R

R

R

R

R

R

1

1

1

1

1

NoCon

1

1

1

15

(FT_NetA)

14

(FT_NetB)

(GND/Shield)

13

(GND/Shield)

12

(Vcc)

11

(Vcc)

10

(Buff_CP0)

9

(Buff_CP1)

8

7

(Buff_CP2)

(Buff_CP3)

6

(Buff_CP4)

5

4

NC

(~Sense_Pod_Reset)

3

2

(~Drive_Pod_Reset)

1

(~Pod_Sense)

Hirose CL234-

Figure 1.3. PCC-10 Card Network Port Electrical Interface

The R1 resistors used in the PCC-10 card buffer the CPx lines to and from the Neuron

Chip, and have a value of 82 Ohms ± 5%.

Pin Signal Type Description

1 ~Pod_Sense Digital Input Port Connection Indicator

2 ~Drive_Pod_Reset Digital Output Reset Line for External Transceiver

3 ~Sense_Pod_Reset Digital Input External Transceiver Reset Indicator

4 No Conn No connection

5 Buf_CP4 Digital Input/Output Buffered Neuron Chip CP4 Line

6 Buf_CP3 Digital Input/Output Buffered Neuron Chip CP3 Line

7 Buf_CP2 Digital Output Buffered Neuron Chip CP2 Line

8 Buf_CP1 Digital Output Buffered Neuron Chip CP1 Line

9 Buf_CP0 Digital Input Buffered Neuron Chip CP0 Line

10 Vcc Power Output +5Vdc Supply

11 Vcc Power Output +5Vdc Supply

12 GND Shield Ground

13 GND Shield Ground

14 FT_NetB FT-10 Network FT-10 Network Connection B

15 FT_NetA FT-10 Network FT-10 Network Connection A

®

3150

Table 1.1. PCC-10 Network Port Electric Interface Description

19

Page 20

Section 2: PCNSI Desktop PC Network Adapter Interface Card Information

General Information

The PCNSI Network Interface Card is a half-length ISA card that allows a desktop computer to

access a LonWorks control network for installation, configuration, monitoring, and control

functions.

®

Note: The PCNSI Network Interface Card must be used with a LonWorks

SMX compatible

transceiver in order to be able to access the network. This transceiver is not included with the

PCNSI card, and must be purchased separately and installed onto the PCNSI card. A list of

compatible transceivers is shown later in this section.

The PCNSI card includes an NSI-10 module with a Neuron® 3150 Chip, a PROM with the

NSI-10 firmware, and support circuitry for the NSI-10 interface registers and memory control.

It communicates with the attached host computer through an 8-bit bi-directional data register

and an 8-bit status/control register; a single address bit selects the appropriate register. If

desired, the host can enable interrupts on the card for a variety of status conditions. Interrupts

can be configured by software to one of six PC interrupt requests (IRQs).

PCNSI Interface Card Layout

The following figure shows the layout of the connectors and user-accessible switches and

indicators for the PCNSI Interface Card.

1

SMX-

Compatible

Transceiver

P3

1 0

S1

Service

JP1

Transceiver

Expansion

DS1

NSI-10

Module

9876543X

I/O Address

P2 P1

Figure 2.1 PCNSI Card Mechanical Layout and Interfaces

Designation Function

P1, P2 PC ISA bus connectors

P3 SMX-compatible transceiver connector

S1 I/O address selection switches

JP1 Service pin connector

DS1 Service LED

Table 2.1 PCNSI Card Interfaces

20

Page 21

Section 2: PCNSI Desktop PC Network Adapter Interface Card Information

P1 and P2 ISA Bus Connectors

The pinout of the P1 and P2 connectors is the standard pinout for the ISA bus used in

IBM-compatible PCs. The interface card must be installed in a 16-bit slot.

SMX-Compatible Transceivers

®

A transceiver daughter card conforming to the LonWorks

SMX specification must be attached

at connector P3. The SMX-compatible transceivers listed in table 2.2 are available from

Echelon®, and are suitable for use with the PCNSI card.

Product Name Echelon Model

Number

TPM/XF-78 Twisted Pair Modular Transceiver 77010

TPM/XF-1250 Twisted Pair Modular Transceiver 77030

TPM/RS485 Twisted Pair Modular Transceiver 77050

FTM-10 Free Topology Modular Transceiver 77040

PLM-10 Spread Spectrum Power Line Transceiver 77090

PLM-21 C Band Power Line Transceiver 77160

PLM-30 A Band Power Line Transceiver 77180

Table 2.2 SMX-Compatible Transceivers

Note: The Power Line Transceivers listed in the above table require an external coupling

circuit to connect to the power line medium. Packaged coupling circuits for standard AC mains

power lines should be ordered with the SMX-compatible transceivers for power line media.

P3 SMX Connector Terminal

The SMX compatible transceiver is connected to the PCNSI Interface Card at the P3

connector. The PCNSI Interface card may be operated only with an SMX-compatible

transceiver attached.

Service Pin Access

The service pin of the Neuron® Chip is accessible directly at JP1. Pin 2 of this header is

connected to the ~Service pin of the Neuron Chip, and Pin 1 is GND. Shorting Pin 1 to Pin 2

will cause the PC Interface card to generate a service pin message. If the service LED at

location DS1 is off, the PCNSI network interface is in the configured state. If the service LED is

flashing, the PCNSI is in the unconfigured state. If the service LED is continuously on, the

PCNSI is in the applicationless state, or the Neuron Chip has detected a hardware failure.

I/O Address Selection Switches

PC Interface cards occupy a block of 8 addresses in the I/O space of the host PC. The base

address of this block may be set with the DIP switches located at S1. If another device is

allocated to an address in the range of the addresses, neither device will work properly. To set

the base address of the PCNSI registers, set the switches at S1 according to bits 3 through 9

of the address. Figure 2.2 shows the relationship of the switches to selected address bits.

Setting a switch to the upper position programs a 1 (one), and the lower position programs a 0

(zero) for the corresponding address bit.

21

Page 22

Section 2: PCNSI Desktop PC Network Adapter Interface Card Information

1

0

Address bit

Figure 2.2 Setting the PCNSI Base Address with switch S1

9 8 7 6 5 4 3 X

1 1 0 1 0 1 0 X

1

0

Address bit

Figure 2.3 PCNSI Default Base Address Setting

The default assignment for the PCNSI block of addresses is 350 to 357 hex. The default switch

setting is shown in figure 2.3. The black shading indicates the switch position; the shading

shows the side that is pushed in. Always check the switch settings before installing the card, as

the switches may have inadvertantly been moved.

Address Selection Considerations

As an aid in selecting an appropriate I/O address for PC Interface cards, table 2.3 lists

commonly used I/O addresses for PC peripheral devices, as well as alternative switch settings

for S1 in the event of address conflicts. Be careful not to choose an alternate address that will

cause a conflict in your PC.

I/O Address Range Typical Use S1 Switch Settings

0000 - 01FF Reserved for PC motherboard hardware

0200 - 0207 Joystick Input 1 0 0 0 0 0 0 0

0220 - 022F Sound Controller 1 0 0 0 1 0 0 0

0278 - 027B LPT3 Parallel Port (If LPT1 & LPT2 installed) 1 0 0 1 1 1 1 0

02F8 - 02FF COM2 Serial Port 1 0 1 1 1 1 1 0

0310 - 0317 LonBuilder Interface Adapter 1 1 0 0 0 1 0 0

0320 - 0327 LonManager Protocol Analyzer 1 1 0 1 0 0 0 0

0330 - 033F MIDI Controller 1 1 0 0 1 1 0 0

0340 - 0347 PCLTA PC LonTalk Adapter 1 1 0 1 0 0 0 0

0350 - 0357 PCNSI PC Interface Card 1 1 0 1 0 1 0 0

0360 - 036B PC Network 1 1 0 1 1 0 0 0

0378 - 037B LPT2 Parallel Port (If LPT1 installed) 1 1 0 1 1 1 1 0

0388 - 038F Sound Controller 1 1 1 0 0 0 1 0

03B4 - 03BA Video Subsystem

03BC - 03BF LPT1 Parallel Port 1 1 1 0 1 1 1 1

03C0 - 03DA Video Subsystem & DAC

03F0 - 03F7 Floppy Disk Controller

03F8 - 03FF COM1 Serial Port 1 1 1 1 1 1 1 0

9 8 7 6 5 4 3 X

9876543x

Table 2.3 Typical I/O Address Usage in PC-Compatibles

22

Page 23

Section 2: PCNSI Desktop PC Network Adapter Interface Card Information

Installing the PCNSI PC Interface Card

ESD Warning: This product contains devices that are sensitive to static electricity. Before

installing or removing a PC Interface Card or the network cables, touch earth ground with your

hand to discharge any static electricity which may have accumulated.

1. Configure the jumpers on the SMX-compatible transceiver as appropriate for the

transceiver selected and the network type it will be used for.

®

For the FTM-10 Free Topology Transceiver (Echelon

model number 77040), the default

setting for the input clock jumpers at JP1 and JP2 is 10MHz, and the Free/Bus jumper at JP3

is open (termination disabled). Set the clock jumpers at JP1 and JP2 to the proper input clock

speed for your network and set the jumper at JP3 to FREE (center pin and Free pin are

jumpered) if you are using Free Topology in your network.

Refer to the documentation provided with the transceiver for proper configuration information,

or refer to the LonWorks® SMX Transceiver Installation Instructions as found on the Echelon

internet web page at http://www.echelon.com.

2. To attach an SMX-compatible transceiver to a PCNSI card, follow these steps.

• Remove the standoff, spacer, and screw attached to the transceiver front bracket.

• Remove the nut from the center threaded post on the rear bracket of the card and discard it.

• Re-install the spacer and standoff removed from the transceiver onto the threaded post.

• Align the 20-pin connector on the transceiver over the 20-pin header on the card.

• Make sure that the transceiver face-plate is aligned properly with the hole in the rear panel,

and press the connector down firmly in place.

• Re-install the screw through the SMX-compatible transceiver and into the standoff.

3. Identify a 16-bit (ISA) slot in your PC with room for a half-length card. Remove the

corresponding blank panel from the rear of your PC, saving the screw. Insert the card in the

slot, making sure that the edge connectors are fully mated, and the slot in the rear panel

mounting lug of the card is lined up with the threaded hole in the PC chassis. Replace the

screw to hold the card firmly in place.

4. Physically attach the transceiver to a LonWorks network medium. The network connectors

are transceiver-specific. Refer to the SMX transceiver installation document for more details

on attaching the transceiver to the network. If you are installing a PLM-10, PLM-20, or

PLM-30 Power Line transceiver, connect the appropriate external power line coupler

between the transceiver and the power mains.

Interrupt Request (IRQ) Setting

The PCNSI Network Interface Card requires an IRQ setting for it to operate. During setup,

choose a setting that is not being used by another device in the PC. The default setting for the

PCNSI card is IRQ 15, but you may also use IRQ 5, 9, 10, 11 or 12 if needed. The specified

IRQ must not be used by another device. If you experience problems using the network card,

try removing all other devices from the PC or changing the IRQ for the card. Table 2.4 lists

commonly used IRQs for PC peripheral devices.

23

Page 24

Section 2: PCNSI Desktop PC Network Adapter Interface Card Information

Interrupt Request Typical Use

IRQ5 LPT2 Parallel Port, Sound Cards

IRQ9 Redirected from IRQ2, LAN Adapter 1

NodeBuilder setup default

IRQ10 LonManager Protocol Analyzer driver default

IRQ11 LonManager Protocol Analyzer setup default

IRQ12 PS/2-style Mouse

IRQ15 PC LonTalk Adapter and PCNSI driver default

Table 2.4 Typical Interrupt Request Usage in PC-Compatibles

Troubleshooting the PCNSI Network Interface Card

The following is a list of common problems with the setup and use of the PCNSI card.

Addressing problems

Assigning an address is easy, although it may take several tries to find one that works.

Fortunately, there are a lot of potential addresses. Earlier in this section you will find

information about how to use the DIP switches to select an address, as well as information

about various adapters and the addresses they typically use. If you know exactly which

addresses are used in your PC, just set the DIP switches to an unused address. If the PCNSI

card does not have a unique address on the PC, the computer will attempt to communicate

with the PCNSI card incorrectly.

When the computer is booted and the driver for the PCNSI card is loaded, the PCNSI card

®

holds its Neuron

Chip reset after power-on. The driver will configure the Neuron Chip's clock

rate and unreset the Neuron Chip. The Service LED should flash several times. The key for

troubleshooting is whether the Service LED ever goes off after being turned on. If it ever goes

off, it means that the card is being addressed; software is sending out I/O writes that the card

is seeing.

If the Service LED does not behave as indicated, you may have an address conflict. With the

PC powered down, try setting the address DIP switches on the PCNSI card to a different

address, and reboot the computer checking for proper behavior. Watch the Service LED at

DS1. It should be off until the driver loads. It should flash briefly several times and stay off, or

flash briefly several times and then flash at 0.5Hz. If it does not do either of these things, the

card is not being addressed.

If you are still having problems using the PCNSI card, even though it seems that it is being

addressed properly by the PC, you may have two cards with the same address. If another card

on your system stops working when the PCNSI is at this address, then an address conflict is

most likely. The easiest thing to do is to change the address on the PCNSI card; this avoids

having to change the address of the other card. Refer to the information located earlier in this

section about changing the address of the PCNSI card using DIP switch S1.

24

Page 25

Section 2: PCNSI Desktop PC Network Adapter Interface Card Information

Assigning a Unique Interrupt (IRQ)

If you know exactly which interrupts are used in your PC, just set the interrupt of the PCNSI

card to an unused IRQ. The PCNSI card can be configured to use IRQ5, IRQ9, IRQ10, IRQ11,

IRQ12 or IRQ15. The default is IRQ15. If you are low on available IRQs, you can use the LPT2

interrupt request, IRQ5, provided that you do not have two printers.

If you have tried all six interrupts, and none work, remove as many other I/O cards as possible

from your PC and try again. If you find an interrupt that works, try reassigning or disabling the

interrupt of the conflicting card.

If you have two devices in your PC with the same IRQ selected, your PC will either lock up at

boot, or the two devices affected will not operate properly. Verify that each device in your PC is

using a unique IRQ.

®

Windows

95 allows you to check your IRQ assignments and to check for conflicts using

Control Panel. Double-click on My Computer, Control Panel, System. When the System

Properties window opens, click on the Device Manager tab. Make sure that "Computer" at the

top of the list is highlighted, and that the "View devices by type" option is selected. Click the

Properties button. This will open the Computer Properties window. Make sure that the "Interrupt Request (IRQ)" option is selected. Listed will be all of your devices and the IRQs that they

are assigned.

If you close the Computer Properties window and go back to the System Properties window,

you can select the device that you suspect a conflict with, and then click the Properties button.

This will open a window with the information about that device. There are three tabs; General,

Driver, and Resources. Click on the Resources tab. You will see a window called Resource

settings. Listed will be the Interrupt Request (IRQ) and the Input/Output Range (address).

Further down is a box called the Conflicting Device List. If there are any conflicts, they will be

listed here. If there are no conflicts with the device, you will see the message "No conflicts".

If you are having trouble resolving a conflict, you can access Help by clicking on the Start

button on the task bar, and when the menu pops up, select "Help". The Help topics window will

open with the index tab selected. Type a keyword to search for into the window, such as

"hardware conflict". This will bring up an index topic related to resolving hardware conflicts. In

this case, it is "hardware conflict troubleshooter". Click the Display button, and a window with

the Hardware Conflict Troubleshooter will open. This will step you through the process of

resolving a hardware conflict on your PC.

25

Page 26

Section 2: PCNSI Desktop PC Network Adapter Interface Card Information

Diagnostics

®

A number of diagnostic and testing services are provided by the LonWorks

NI Control Panel.

Double-click on My Computer, Control Panel, and then LonWorks NI.This will open the PCLTA/

PCNSI Network Interface Configuration dialog box. Clicking the diagnostics button displays the

Diagnostics dialog box. This dialog box contains buttons for the diagnostic commands and

displays the version number and current status of the device driver. If no adapter is installed in

an ISA-bus slot, the Diagnostics window will display "no driver found". The OK button closes

the dialog box.

The Test button retrieves status and error counts from the adapter. In the box you will see

displayed CRC Errors, TX Timeouts, Lost (App) Messages, Missed (Net) Messages, the Node

State (Configured, Unconfigured, or Applicationless), the number of most recent errors, and

the Reset Cause (reset cause for the Neuron® Chip in the adapter, internal or external).

The Service button causes the adapter to broadcast a service pin message on the network.

The service pin message will not be sent if the adapter is in the post-reset flush state.

The Reset button causes a reset of the Neuron Chip in the adapter, but it does not clear the

Neuron Chip's system image.

The Comm Button

The Comm button verifies communications between the adapter and another node on the

network. This can be a very useful troubleshooting tool. When this function is chosen, a dialog

will appear asking for confirmation of this command, as follows:

This procedure will configure the Network Interface for a zero-length

domain if it is not already configured. Do you want to proceed?

Choosing OK causes the Control Panel to first check the network interface for the configured

state. If it is already in the configured state, it will not be modified further. If it is not in the

configured state, it will install the network interface with a zero-length domain on index 0, a

subnet of 1, and a node ID of 126, and then change its state to configured.

Once the node is in the configured state, the control panel enters the receive/ready state and

displays the following message while waiting for a service pin message from another node on

the network:

Now waiting for a service pin message.

When the service pin is activated on the other node and the service pin message is received,

the control panel sends a request/response diagnostic message to the node that sent the

service pin message. It will repeat this message, referred to as a "ping", once per second until

either the OK or the Quit button is chosen (the Quit button appears in place of the Comm

button).

This series of tests confirms that the adapter can be configured and can communicate with a

node on the network.

26

Page 27

Section 2: PCNSI Desktop PC Network Adapter Interface Card Information

The Comm Button (continued)

The Comm function is intended to eliminate the adapter, the card drivers, the network

connection, the hardware of the other node, and the topology configuration from the list of

possible problem points or points of failure during network troubleshooting. It does not eliminate the possibility that the wrong type of cable medium has been used. Be sure that the cable

type selected is suitable for use in the intended channel topology.

The Comm function also does not eliminate the possibility of poor network termination.

The network wiring may work for this test but may fail if multiple nodes are communicating.

Be sure to verify proper termination when troubleshooting communication problems.

This feature was not designed to work across routers.

Common Resource Problems

The following situations produce an additional drain on system resources that may be hard to

manage. Conflicts arising from these situations can generally be resolved by selectively

disabling devices to free up the required resources.

• COM ports that may not have a connector, but are consuming resources and cannot be

disabled through the BIOS.

• Unused IDE controllers that cannot be disabled through the BIOS.

• Unused/nonexistent PS/2 mouse ports.

• Sound cards that support both 8-bit and 16-bit compatability modes, consuming two IRQs.

An additional problem often associated with sound cards is the improper reporting of I/O

resource usage. This problem may be recognized by examining a device's I/O address allocation for unusual one-byte assignments (since devices typically use more). For example, if a

device's stated I/O range is 0x201-0x201 but its actual range is 0x201-0x204, a conflict will

occur if the adapter is assigned an I/O range of 0x204-0x207. If this problem is suspected,

manually move the adapter's I/O range to a safer location to prevent I/O overlap.

27

Page 28

Section 3: FTT-10A Network Information

General Information

®

uses the FTT-10A Free Topology Network Configuration along with the PCC-10 Type II

Bose

card with FTT-10A transceiver on-board for Laptop PCs, and the PCNSI ISA-bus half-length

network card with an FTT-10A transceiver on-board for use with the Entero™ audio control

network. Each LonWorks® device used in an Entero audio control network uses the Neuron

3150 Chip. The Neuron 3120 Chip is not used in Entero.

®

Clock

Circuit

XCVR.

Service

LED

MAC

CPU

Lines

Reset

Circuit

Net

CPU

Power Supply

Appl.

CPU

I/O LinesCP

Internal Memory

Twisted-pair

Network

Address Lines: A0-A15

Data Lines: D0-D7

Control Lines: ~E, R/~W

LonWorks

Device

External Memory (3150 Chip Only)

Figure 3.1 Block Diagram of a LonWorks Device on a Twisted-Pair Network

The three CPUs interleave accesses to memory for instruction execution and memory read/

write operations. The Neuron 3120 Chip runs completely from internal memory, while the

Neuron 3150 runs from both internal and external memory. For convenience, the division of

tasks among the three CPUs is described briefly here:

MAC CPU: The Media Access Control CPU is responsible for interfacing with the

transceiver. It handles all physical layer transmitting and receiving of

packets, including the p-CSMA algorithm.

Network CPU: The network processor manages the incoming and outgoing message

buffers. It is also responsible for managing the software timers.

Application CPU: The Application processor runs the Neuron C application program.

When a non-MIP device is in the Unconfigured state, the Neuron C

application program does not execute. A non-MIP device must be in

the Configured state for the application to run.

28

Page 29

Section 3: FTT-10A Network Information

General Information (continued)

Configuration States of a Device

A LonWorks device can be in one of the following three firmware states:

1. Applicationless: Only communication parameters are loaded into the device's internal

EEPROM. The Service LED remains continuously ON in this state.

2. Unconfigured: In addition to its communication parameters, the device contains an

application program. The Service LED blinks about once every two

seconds in this state. The device does not yet have information about

its network configuration, such as its network address, network

variable binding information, etc. A non-MIP device does not execute

it's Neuron

®

C application program while it remains in this state. A MIP

device does execute its MIP application when in an Unconfigured

state, so that it can communicate with the MIP's host processor.

3. Configured: In addition to the information from the Unconfigured state, a

Configured device has been assigned its network addresses and

binding information. The Service LED is generally OFF in the

Configured state, and the Neuron C application program is running.

Network Overview

The FTT-10A Free Topology Twisted Pair Transceiver provides a simple, cost effective method

of adding a LonWorks transceiver to any Neuron Chip-based control system. A replacement

for the popular FTT-10 transceiver, the FTT-10A transceiver supports polarity insensitive, free

topology wiring, relieving the installer from using a bus topology. Star, bus, and loop wiring are

all supported by this architecture.

Free topology wiring reduces the time and expense of system installation by allowing the

wiring to be installed in the most expeditious manner. It also simplifies network expansion by

eliminating restrictions on wire routing, splicing, and node placement. FTT-10A transceivers

can be located at any point along the network wiring. Figure 3.2 shows an example of Free

Topology.

Termination

Figure 3.2 FFT-10A Free Topology Network Diagram

29

Page 30

Section 3: FTT-10A Network Information

System Performance and Cable Selection

TP/FT-10 network system and transmission specifications are outlined on the following pages.

Both of these specifications must be met to ensure proper operation.

The system designer may choose a variety of cables, depending on cost, availability, and

performance. Performance may vary with cable type. The transmission specification depends

on such factors as resistance, mutual capacitance, and the velocity of propagation. Currently,

Echelon has documented system performance on the cable types shown in table 3.1.

Cable Type Wire diameter/

Belden 85102, single

AWG

1.3mm/16 28 56 62

R

loop

Ohms/km

Capacitance

nF/km

twisted pair, stranded

19/29, unshielded, 150°C

Belden 8471, single

1.3mm/16 28 72 55

twisted pair, stranded

19/29, unshielded, 60°C

Level IV 22 AWG, twisted

0.65mm/22 106 49 67

pair, typically solid and

unshielded

JY (st) Y 2x2x0.8, 4-wire

0.8mm/20.4 73 98 41

helical twist, solid,

shielded

TIA568A Category 5 24

0.51mm/24 168 46 58

AWG, twisted pair

Table 3.1 Cable Types and Typical Parameters

If a shielded cable is used, the shield should be connected to earth ground via a single

470 kOhm, 1/4 Watt, ≤10%, metal film resistor to prevent static charge build-up.

®

Bose

recommends the use of TIA568A Category 5 wiring for use in the Entero™ System

network.

V

prop

% of c

System Specifications

Up to 64 FFT-10/FFT-10A transceivers are allowed per network segment.

LPT-10 transceivers may be used on network segments with FFT-10/FFT-10A transceivers,

but are subject to additional constraints, particularly on distance. See the Echelon® LPT-10

Users Guide for more information. It is available on-line at the Echelon web page at http://

www.echelon.com.

The average temperature of the wire must not exceed +55°C, although individual segments of

wire may be subjected to as much as 85°C.

30

Page 31

Section 3: FFT-10A Network Information

Transmission Specifications

The free topology transmission specification includes two components which must both be met

for proper system operation. The distance from each transceiver to all other transceivers and

to the termination (including the LPI-10 termination, if used) must not exceed the maximum

node-to-node distance. If multiple paths exist, e.g., a loop topology, then the longest path

should be used for the calculations. The maximum total wire length is the total amount of wire

connected per segment. See table 3.2 for these specifications.

Cable Type Maximum node-to-node

distance

Maximum total wire

length

Belden 85102 500 meters 500 meters

Belden 8471 400 meters 500 meters

Level IV 22 AWG 400 meters 500 meters

JY (st) Y 2x2x0.8 320 meters 500 meters

TIA568A Category 5 250 meters 450 meters

Table 3.2 Free Topology Network Specifications

Cable Termination

The FFT-10 network segment requires termination for proper data transmission performance.

A total termination impedance of approximately 52.3 Ohms is required.

In a Free Topology segment, only one termination is required, and it may be placed anywhere

on the segment. There are two choices for the termination.

1. Resistor, 105 Ohms ± 1%, 1/8W, connected across the twisted pair wires.

2. LPI-10 Link Power Interface, with jumper at "2 CPLR" setting.

31

Page 32

Section 3: FTT-10A Network Information

Troubleshooting an FFT-10A Network

Noise on Real-World Networks

When a network is installed in a real-world environment (as opposed to the development lab

environment), it is exposed to several noise sources that can make network communications

more difficult.

Power Line Noise and Ground Shifts: The "Safety" or "Earth" ground difference in voltage can

have a DC component, but more often the voltage varies at the power line rate (50 Hz or 60

Hz), with an amplitude that can reach many 10's of volts, or higher. DC shifts and power line

frequency noise are naturally rejected by the transformer-coupled transceivers in FFT-10

devices. Link Power LPT-10 devices are required to be "floating" with respect to their local

Earth ground reference.

High Frequency Burst Noise: When the network cable is run near DC motors or other sources

of burst noise, common mode voltage noise can be coupled into the twisted pair. Even though

this burst noise has frequency components within the communication band of the network, the

common-mode rejection of the coupling transformer used in the FTT-10 transceiver is usually

sufficient to prevent significant impairment of communication.

Common Network Wiring Problems

Symptom Possible Cause

Devices work fine on a

small network, but

communication fails on a

large network installation.

The network wire,

terminations, etc. all seem to

be within Echelon's design

rules, and the network

management software

seems to be configuring the

devices correctly, but some

device communications are

still unreliable.

1. Verify that the rules for wire type, length, termination, etc. given in

the Transceiver's Users Guides have been followed.

2. When communication on a large network is a problem, suspect bad

connections, bad terminations, extra capacitive loading of some kind

(like transient protection devices not listed in the User's Guides), or

noise sources coupling into the network. Also make sure that the

network addressing and configuration of the devices is correct.

1. If a few devices have communication problems no matter where

they are moved on the network, suspect a bad network connector or

a bad device. If devices have problems only when moved to certain

spots in the network, suspect transmission line problems (like a

broken termination), or point noise sources near the failure spots.

2. If a hardware reason for the failures is not apparent, use a Protocol

Analyzer to watch network traffic for addressing anomalies that might

indicate network management problems.

32

Page 33

Section 3: FTT-10A Network Information

Common Problems with FTT Networks

Symptom Possible Cause

A device cannot

communicate on an FTT

network.

The device can transmit, but

not receive; for example,

LonBuilder tool install

succeeds, but nothing else

works.

The device communicates

fine on short networks, but

does not communicate on a

"full-size" network

installation.

First make sure that the wire, connections, and terminations are

correct. Then use Service pin presses to generate transmit packets,

so that the CP line waveforms can be checked. Another device on

the network can be used to generate incoming traffic to the device

under test in order to check the CP line waveforms in receive mode.

Finally, the analog waveforms on the network can be checked for

clues about the lost communication.

Suspect an incorrect clock configuration for an FTT-10:

- Check CSO and TXD/CS1 connections for FTT-10.

- Reset the device by manually grounding the reset line. If the device

recovers, suspect an incorrect reset circuit or transient protection

circuit implementation. See the FTT-10 User's Guide for correct

circuit implementation.

An incorrect clock configuration on the FTT-10's CSO and CS1 pins

will usually result in the FTT-10 transmitting a very distorted

waveform, even into a small, lightly-loaded network. An FTT-10 with

an incorrect clock configuration will not receive packets from the

network.

Make sure that the total wire length and type agree with the

specifications in the FTT User's Guide. Suspect an overloaded

network, or incorrect wire substitution.

Check the termination(s). Incorrect or broken terminations will make

communication integrity dependent upon a device's position on the

network.

When attempting to transmit

a packet, the device's CP

lines do not behave

correctly.

An FTT-10 device that uses

a DC-DC converter power

supply has a high CRC

error rate, and has trouble

receiving packets on

heavily loaded networks.

Check the devices to be sure that no extra capacitance is being

connected to the network other than the standard FTT circuit. A

common error is to add high-capacitance transient protection devices

(like zeners) across the network connection.

The FTT-10 uses Single Ended mode for the CP lines CPO, CP1

and CP2 are RXD, TXD, and TXEN, respectively. If the device is

incorrectly configured for differential mode or special purpose mode,

the CP lines will not function correctly for controlling the FTT-10.

Suspect that DC-DC switching noise is interfering with the 78kbps

communication band of the FTT-10. Check the switching frequency of

the DC-DC; if it is 1MHz, it is not likely the source of the problem. If it

is 50-100kHz, interference with communication is possible. The FTT10 has good power supply rejection in the communication band, so

the most likely noise coupling mechanism is magnetic. Make sure the

DC-DC switching inductor is not adjacent to the FTT-10 transceiver

and its transformer. The transformer used on the FTT-10 rejects

magnetic noise coupling well, so the DC-DC inductor would need to

be fairly close to cause a problem. Try re-orienting or moving the DCDC inductor to see if the comm problem goes away.

33

Page 34

Section 4: Echelon® Model 71000 Router Information

Introduction

LonWorks

®

routers connect two communications channels, and route LonTalk® messages

between them. They support the installation of both small and large networks with dozens

to thousands of nodes.

The following figure illustrates a typical installation with free topology, power line, and 78kbps

bus topology channels connected to a 1.25Mbps backbone twisted pair channel using three

routers. Because of the routers, the applications on all six nodes in this example can

communicate transparently as if they were installed on a common channel.

TP/XF-1250 Backbone Channel

TP/XF-1250 to

TP/FT-10 Router

TP/FT-10 Channel 1

TP/XF-1250 to

PL-10 Router

PL-10 Channel 2 TP/XF-78 Channel 3

TP/XF-1250 to

TP/XF-78 Router

Node 1 Node 2 Node 3 Node 4 Node 5 Node 6

Figure 4.1 Sample Router Installation

Routers are used to:

•

Extend the limits of a single channel.

A router may be used to add a channel to a LonWorks

network to support additional nodes or extend the maximum channel length. Multiple routers

may be added, depending on the capacity or distance needed.

•

Interface different communication media, or bit rates, in a LonWorks network.

For example,

it may be desirable to trade data rate for distance on portions of the network, or to use a

1.25Mbps backbone twisted pair channel to connect several 78bps free topology and link