Bosch TW25-1USC-FXXXNA, TW35-1USC-FXXXNA, TW49-1USC-FXXXNA, TW61-1USC-FXXXNA, TW71-1USC-FXXXNA Installation, Operation And Maintenance Manual

...

TW Series

Water to Water

Installation, Operation and Maintenance Manual

6720220047 (2016/02)

2 | Table of contents TW Series Water to Water

TABLE OF CONTENTS

Key to Symbols.................................................................. 3

Safety Warnings ................................................................ 3

Model Nomenclature.......................................................... 4

Standard TW package ........................................................ 5

General Description ..................................................... 5

Moving and Storage ........................................................... 5

Initial Inspection .......................................................... 5

Location ..................................................................... 5

Installation.........................................................................5

Piping ............................................................................... 6

Electrical .......................................................................... 6

Safety Devices and the UPM Controller ........................... 7

Options............................................................................. 9

Heat Recovery Package (HRP) ....................................... 9

DPS Water Flow Proving ............................................... 9

Pump Relay................................................................. 9

Comfort Alert Module ................................................... 9

Heat Recovery Package ................................................... 10

Water Tank Preparation .............................................. 10

HR Water Piping ........................................................ 10

Water Tank Refill........................................................ 10

Initial Start-Up........................................................... 10

Sequence Of Operation .................................................... 11

Cooling Mode ............................................................ 11

Heating Mode............................................................ 11

Sequence Of Operation Flow........................................12

Auto Changeover Mode................................................17

Unit Protection...........................................................17

Manual Lockout................................................................18

Lead-Lag...................................................................18

Pump Cycling.............................................................18

Operating Instructions......................................................18

User Interface............................................................18

UP Button..................................................................18

Down Button..............................................................18

LED Indicators............................................................19

User Adjustable Settings Chart..........................................19

Setting up the controller................... .................................19

Initial Configuration..........................................................20

Unit Check-out sheet........................................................21

Troubleshooting ..............................................................22

Unit Troubleshooting...................................................22

Confort Alert Module-Flash Codes.................................23

HRP Troubleshooting.................. .................................24

Unit Lockouts ............................................................ 24

Electrical Data Table ........................................................ 25

UPM Board LED Indicators.................................................25

Water Quality Table..........................................................26

Wiring Diagrams ..............................................................27

Dimensional Drawings......................................................33

Terminology ....................................................................36

Application Considerations .............................................. 13

Well Water Systems ................................................... 13

Cooling Tower/Boiler Systems ..................................... 13

Geothermal Systems .................................................. 14

System Checkout ............................................................ 15

Considerations...........................................................15

Unit Start-Up ................................................................... 16

Maintenance ................................................................... 16

Decommissioning.............................................................16

Water To Water Unit Controller..........................................16

Features....................................................................16

Unit Sensors.....................................................................16

Water Sensor.............................................................16

Changeover Sensor.....................................................16

Modes Of Operation..........................................................16

Off Mode...................................................................16

Heating Mode.............................................................16

Cooling Mode.............................................................17

TW Series Water to Water6720220047 (2016/02) Subject to change without prior notice

Key to Symbols | 3TW Series Water to Water

KEY TO SYMBOLS

Warnings

Warnings in this document are identified by

a warning triangle printed against a grey

background. Keywords at the start of the

warning indicate the type and seriousness

of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be used in

this document:

• NOTICE indicates a situation that could result in

damage to property or equipment.

• CAUTION indicates a situation that could result in

minor to medium injury.

• WARNING indicates a situation that could result in

sever injury or death.

• DANGER indicates a situation that will result in

severe injury or death.

Important Information

This symbol indicates important information where

there is no risk to property or people.

SAFETY WARNINGS

WARNING: Installation and servicing of this

equipment can be hazardous due to system

pressure and electrical components. Only

trained and qualified personnel should

install, repair, or service the equipment.

DANGER: Before performing service or

maintenance operations on the system, turn

off main power to the unit. Electrical shock

could cause personal injury or death.

WARNING: When working on equipment,

always observe precautions described in

the literature, tags, and labels attached to

the unit. Follow all safety codes. Wear

safety glasses and work gloves. Use a

quenching cloth for brazing, and place a fire

extinguisher close to the work area.

NOTICE: All refrigerant discharged from this

unit must be recovered WITHOUT

EXCEPTION. Technicians must follow

industry accepted guidelines and all local,

state, and federal statutes for the recovery

and disposal of refrigerants. If a compressor

is removed from this unit, refrigerant circuit

oil will remain in the compressor. To avoid

leakage of compressor oil, refrigerant lines

of the compressor must be sealed after it is

removed.

NOTICE: To avoid equipment damage, DO

NOT use these units as a source of heating

or cooling during the construction process.

Doing so may affect the unit’s warranty. The

mechanical components and filters will

quickly become clogged with construction

dirt and debris, which may cause system

damage.

NOTICE: To avoid the release of refrigerant

into the atmosphere, the refrigerant circuit

of this unit must be serviced only by

technicians who meet local, state, and

federal proficiency requirements.

6720220047 (2016/02)Revised 02-16

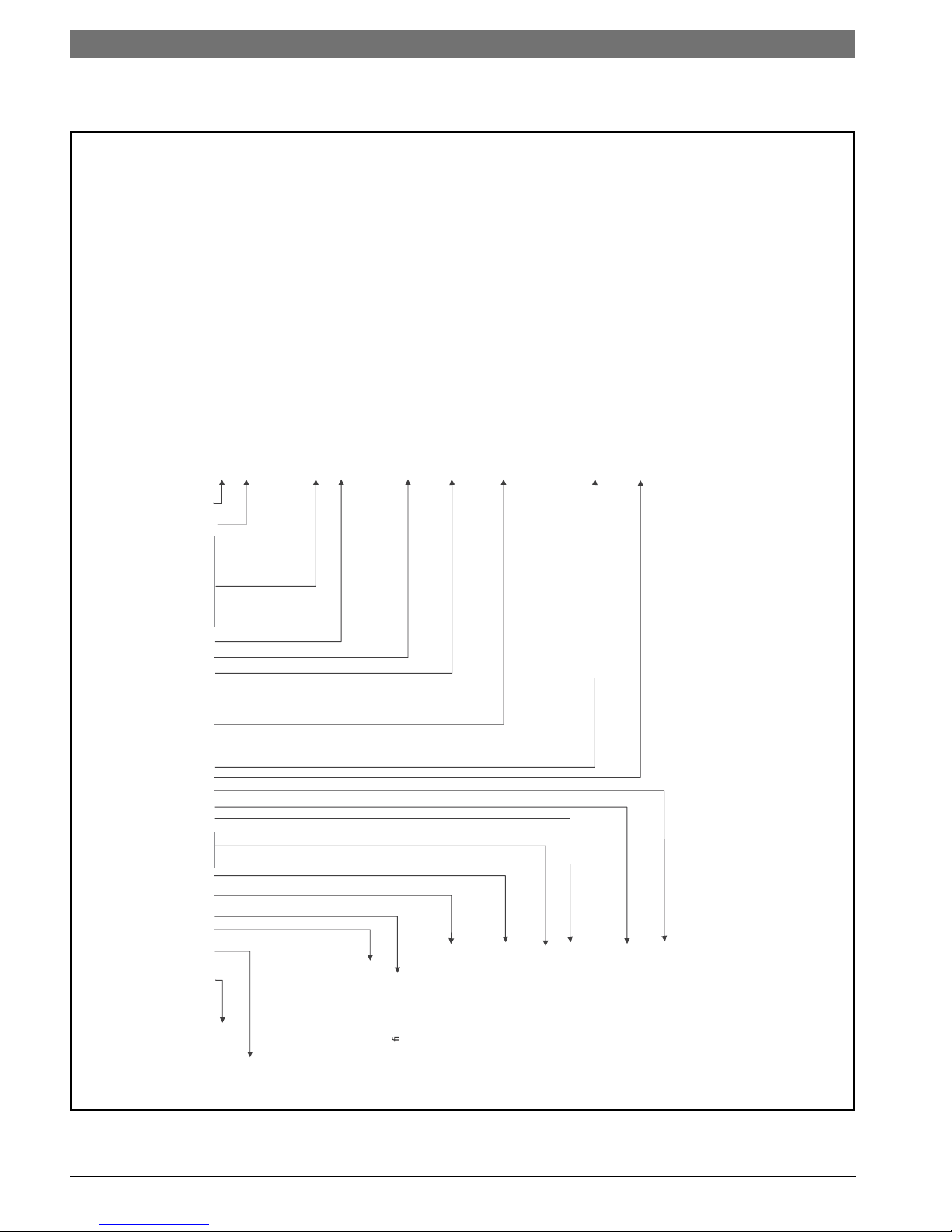

4 | Model Nomenclature TW Series Water to Water

TW25-1CSN-FXXXCA-XKGAEXXXX 7X XX

X

XXXXX SB A

TW Code String Rev Level

Size Standard/Spec ial

035

049

061

122

Controls

Voltage X - Standard

1208-230/60/1 M - DDC - Multi-Protocol (BacNET, Modbus, N2)

L - DDC - LonWorks

Cabinet Con

guration

US - Unit Mounted Controller Transformer

Source Side Coax Options Refrigeration Circu it Options

C - Copper X - None

N - Cupro-Nickel D - Heat Recovery Package

Water Connections General Electrical Opti ons (up to 5 available per u nit)

F - Front A - EMS relay

y

X - N/A H - Flow proving switch

N - Comfort Alert

Load Side Coax Op tions X - As default for non used electrical codes

N - Cupro-Nickel Application

G - EXTENDED RANGE (Geothermal)

Revision Level

Cabinet Construction

K - Pre Paint Steel / 1/2" Standard 1.5LB Dual Density Fiberglass / EQ

Electric Heat

X - None

MODEL NOMENCLATURE

E - Pump/val ve rela

025 SS - Standard

071 X - N/A

CS - Remote Control led 7 - 75 VA

C - Copper

A - Current

TW Series Water to Water6720220047 (2016/02) Subject to change without prior notice

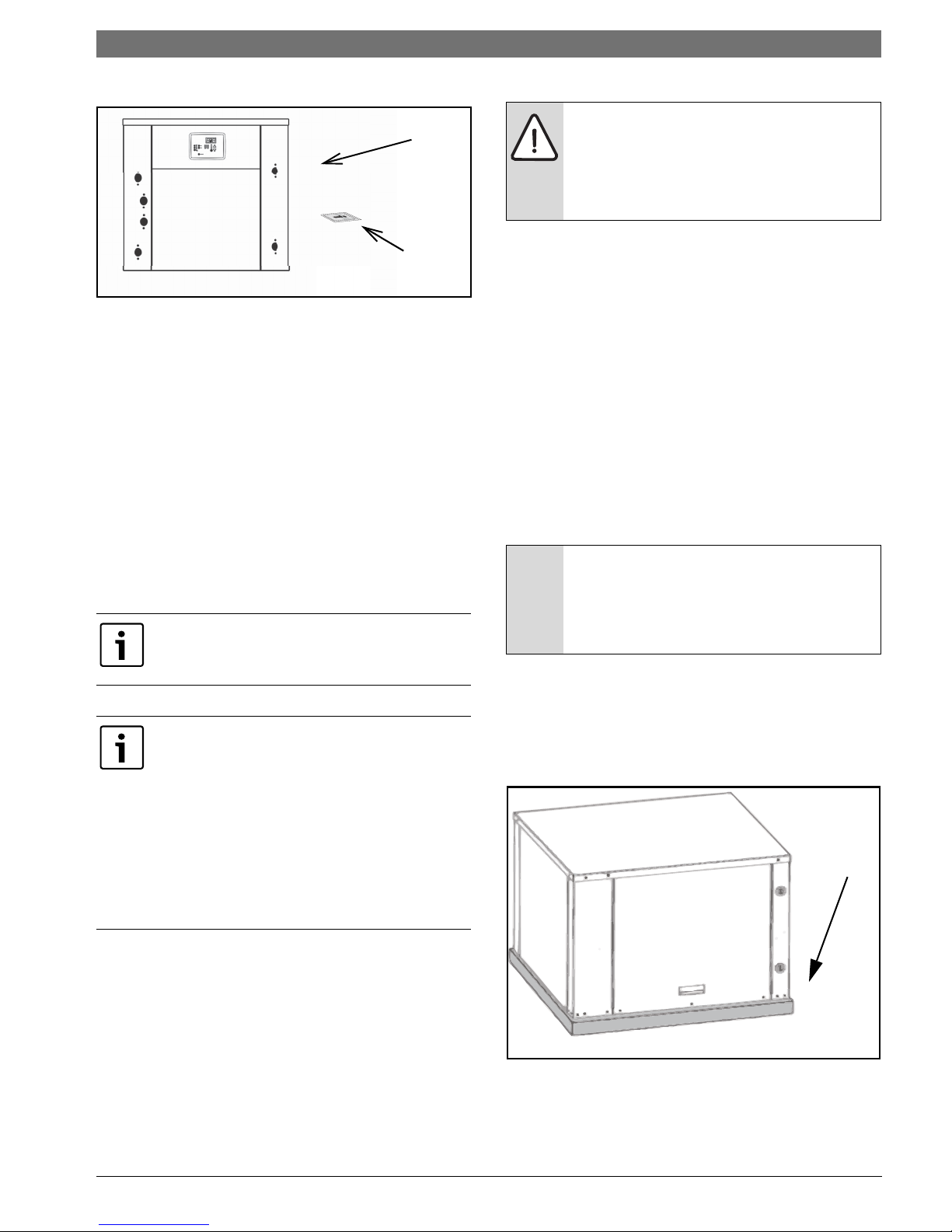

STANDARD TW PACKAGE

1

2

VIBRATION

PAD FULL

Figure # 1

[1] TW Series Water-to-Water

[2] Installation and Operation Manual

General Description

TW Series Water-to-Water Heat Pumps provide the best

combination of performance and efficiency available. All

units are performance certified to American Heating and

Refrigeration Institute (AHRI) ISO Standard 13256-2. All

TW Water-to-Water Heat Pumps conform to UL1995

standard and are certified to CAN/CSA C22.2 No 236 by

Intertek-ETL. The Water-to-Water Heat Pumps are

designed to operate with entering fluid temperature

source between 30°F to 90°F in the heating mode and

between 50°F to 110°F in the cooling mode on the

source side

Heat Pump operating under extreme conditions will

have limitation on fluid flow rates and/or

temperatures.

50°F Minimum Entering Water Temperature (EWT)

is recommended for well water applications with

sufficient water flow to prevent freezing. Antifreeze

solution is required for all closed loop applications.

Cooling Tower/Boiler and Geothermal applications

should have sufficient antifreeze solution to protect

against extreme conditions and equipment failure.

Frozen water coils are not covered under warranty.

Other equivalent methods of temperature control are

acceptable.

Standard TW Package | 5TW Series Water to Water

WARNING: For Storage if unit stacking is

required, stack unit as follows:

Do not stack units larger than 6 tons. For

units less than 6 tons, no more than three

high

Initial Inspection

Be certain to inspect all cartons or crates on each unit as

received at the job site before signing the freight bill.

Verify that all items have been received and that there

are no visible damages; note any shortages or damages

on all copies of the freight bill. In the event of damage or

shortage, remember that the purchaser is responsible

for filing the necessary claims with the carrier.

Concealed damages not discovered until after removing

the units from the packaging must be reported to the

carrier within 24 hours of receipt.

Location

Locate the unit in an indoor area that allows easy access

to the panels, and has enough room for service

personnel to perform maintenance or repair. Provide

sufficient room to make fluid and electrical

connection(s).

NOTICE: These units are not approved for

outdoor installation; therefore, they must

be installed within a conditioned space

inside the structure. Do not locate in areas

that are subject to freezing.

INSTALLATION

The TW series unit should be mounted level on a

vibration absorbing pad slightly larger than the base to

minimize vibration transmission to the building

structure, It is not necessary to anchor the unit to the

floor.(Figure #2).

MOVING AND STORAGE

If the equipment is not needed for immediate

installation upon its arrival at the job site, it should be

left in its shipping carton and stored in a clean, dry area.

Units must only be stored or moved in the normal

upright position as indicated by the “UP” arrows on each

carton at all times.

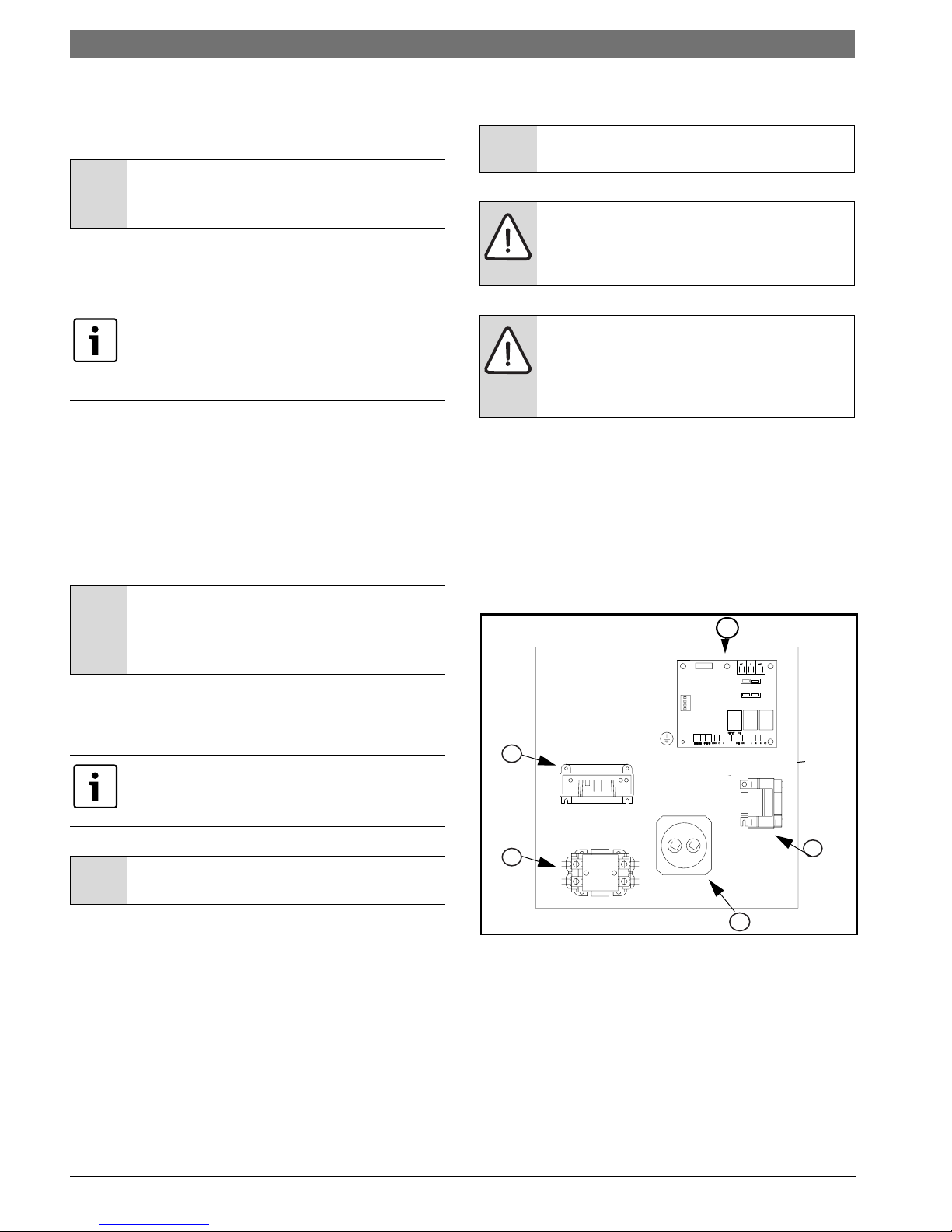

Figure # 2

6720220047 (2016/02)Revised 02-16

6 | Piping TW Series Water to Water

1

2

3

4

5

6

5

PIPING

Supply and return piping must be as large as the unit

connections on the heat pump (larger on long runs).

NOTICE: Never use flexible hoses of a

smaller inside diameter than that of the

fluid connections on the unit.

TW units are supplied with either a copper or optional

cupro-nickel Water to refrigerant Heat Exchanger.

Copper is adequate for ground water that is not high in

mineral content.

Proper testing is recommended to assure the well

water quality is suitable for use with water source

equipment. When in doubt, use cupro-nickel.(See

Water Quality Table on page #28)

In conditions anticipating moderate scale formation or in

brackish water a cupro-nickel heat exchanger is

recommended.

Both the supply and discharge water lines will sweat if

subjected to low water temperature. These lines should

be insulated to prevent damage from condensation. All

manual flow valves used in the system must be ball

valves. Globe and gate valves must not be used due to

high pressure drop and poor throttling characteristics.

NOTICE: Never exceed the recommended

water flow rates as serious damage or

erosion of the water-to-refrigerant heat

exchanger could occur.

ELECTRICAL

Refer to electrical component box layout. (Figure #3)

NOTICE: Field wiring must comply with

local and national electric codes.

WARNING: Power to the unit must be

within the operating voltage range indicated

on the unit nameplate or on the

performance data sheet.

WARNING: Operation of unit on improper

line voltage or with excessive phase

imbalance will be hazardous to the unit,

constitutes abuse and may void the

warranty.

Properly sized fuses or HACR circuit breakers must be

installed for branch circuit protection. See unit

nameplate for maximum fuse or breaker size.

The unit is provided with a concentric knock-out for

attaching common trade sizes of conduit, route power

supply wiring through this opening. Always connect the

ground lead to the grounding lug provided in the control

box and power leads to the line side of compressor

contactor as indicated on the wiring diagram (Figures on

Pg#27 To 34).

Always check carefully for water leaks and repair

appropriately. Units are equipped with female pipe

thread fittings. Consult Unit Dimensional Drawings.

Teflon tape sealer should be used when connecting

water piping connections to the units to insure

against leaks and possible heat exchanger fouling.

NOTICE: Do not overtighten the

connections.

Flexible hoses should be used between the unit and the

rigid system to avoid possible vibration. Ball valves

should be installed in the supply and return lines for unit

isolation and unit water flow balancing. (See Water

Quality Table on Page#26)

Figure # 3

[1] Comfort Alert Module (Option)

[2] Compressor contactor

[3] Capacitor

[4] Auxiliary Relay (DP/DT)

[5] Unit Protection Module (UPM)(CS Option)

TW Series Water to Water6720220047 (2016/02) Subject to change without prior notice

Electrical | 7TW Series Water to Water

1

2

3

4

5

6

7

9

10

11

1213

17

14

15

16

8

For Reference

only

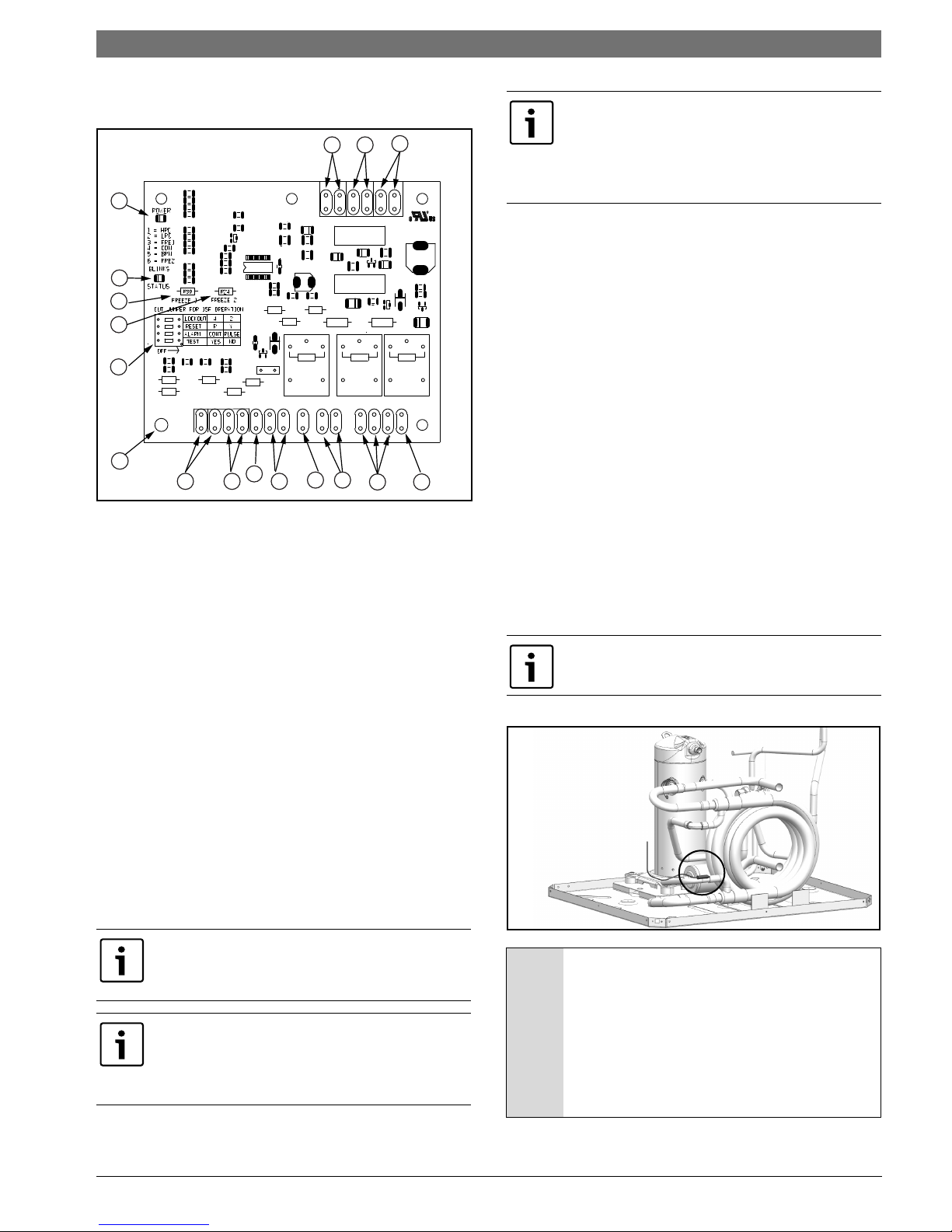

Safety Devices and the UPM Controller

[1] Board Power Indicator

[2] UPM Status LED Indicator

[3]Water Source Coil Freeze Protection Temperature

Selection [R30]

[4] Load Water Coil Freeze Protection Temperature

Selection [R24]

[5] UPM Board Settings

[6] Source Coax Freeze Connection (Freeze 1)

[7] Load Coax Freeze Connection (Freeze 2)

[8] LCD Unit Display Connection

[9] 24VAC Power Input

[10] Compressor Contact Output

[11] High Pressure Switch Connection

[12] Call for Compressor Y1

[13] Low Pressure Switch Connection

[14] 24VAC Power Common

[15] Condensate overflow Sensor (not applicable on

TW)

[16] Dry Contact

[17] UPM Ground Standoff

Figure # 4

If the unit is being connected to a thermostat with a

malfunction light, this connection is made at the unit

malfunction output or relay. Refer to Figure #4.

If the thermostat is provided with a malfunction light

powered off of the common (C) side of the

transformer, a jumper between “R” and “COM”

terminal of “ALR” contacts must be made.

If the thermostat is provided with a malfunction li ght

powered off of the hot (R) side of the transformer,

then the thermostat malfunction light connection

should be connected directly to the (ALR) contact on

the unit’s UPM board.

The TW Series has an optional factory installed Unit

Protection Module (UPM) that controls the compressor

operation and monitors the safety controls that protect

the unit.

Safety controls include the following:

• High pressure switch located in the refrigerant

discharge line and wired across the HPC terminals

on the UPM.

• Low pressure switch located in the unit refrigerant

suction line and wired across terminals LPC1 and

LPC2 on the UPM.

• Water side freeze protection sensor, mounted close

to condensing water coil, monitors refrigerant

temperature between condensing water coil and

thermal expansion valve. If temperature drops

below or remains at freeze limit trip for 30 seconds,

the controller will shut down the compressor and

enter into a soft lockout condition. The default

freeze limit trip is 26°F, however this can be

changed to 15°F by cutting the R30 or Freeze1

resistor located on top of DIP switch SW1 (Refer to

Figure #4, item [3] for resistor location), Refer to

Figure #5 for sensor location

.

UPM Board Dry Contacts are Normally Open (NO)

Figure # 5

NOTICE: If unit is employing a fresh water

system (no anti-freeze protection), it is

extremely important to have the Freeze1

R30 resistor set to 26°F in order to shut

down the unit at the appropriate leaving

water temperature and protect your heat

pump from freezing if a freeze sensor is

included.

6720220047 (2016/02)Revised 02-16

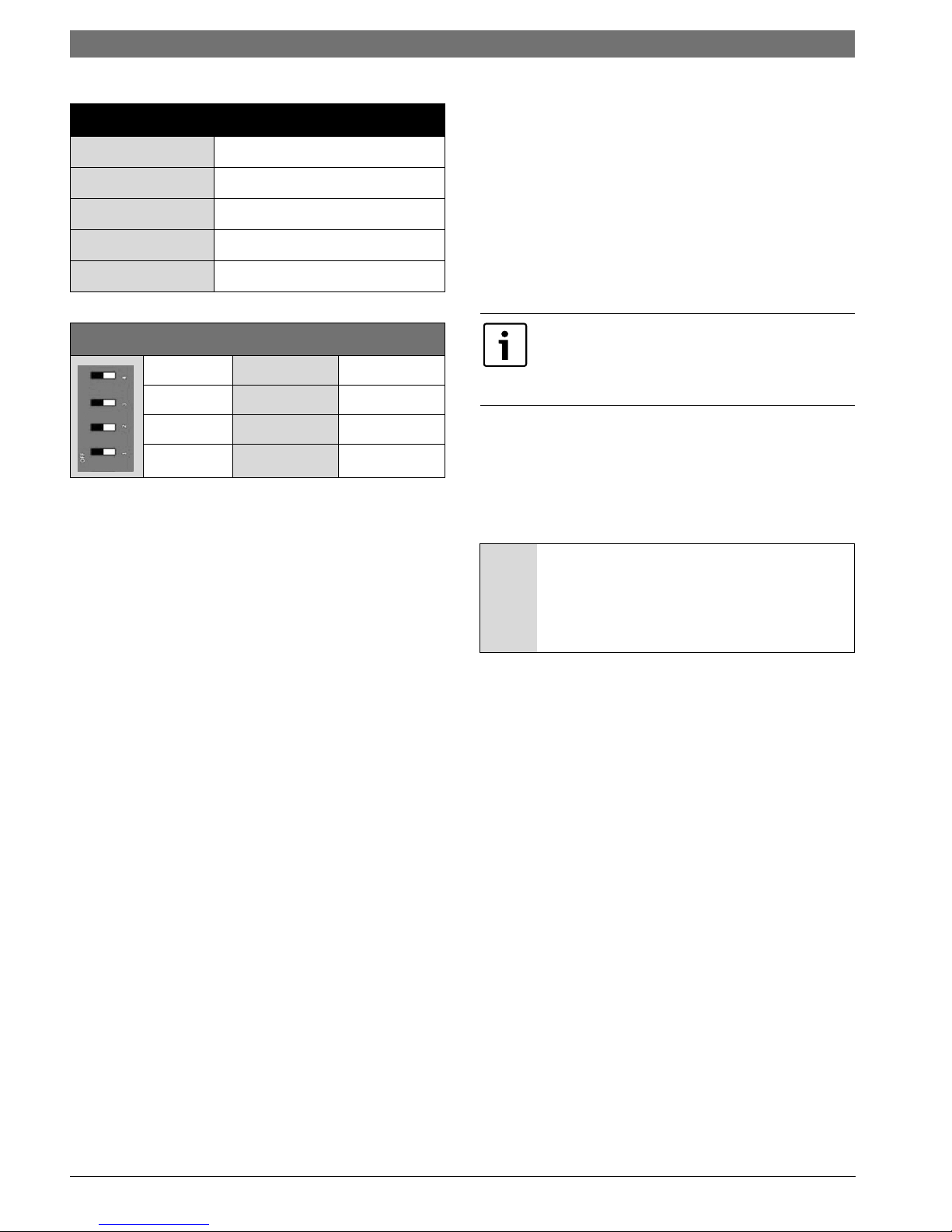

8 | Electrical TW Series Water to Water

• MALFUNCTION OUTPUT: Alarm output is Normally

UPM Board Factory Default Settings

TEMP

LOCKOUT

RESET

ALARM

TEST

26°F

2

Y

PULSE

NO

Open (NO) dry contact. If pulse is selected the alarm

output will be pulsed. The fault output will depend

on the dip switch setting for "ALARM". If it is set to

"CONST", a constant signal will be produced to

indicate a fault has occurred and the unit requires

inspection to determine the type of fault. If it is set

to "PULSE", a pulse signal is produced and a fault

code is detected by a remote device indicating the

fault. See L.E.D Fault Indication below for blink code

explanation. The remote device must have a

malfunction detection capability when the UPM

board is set to "PULSE".

UPM DIP SWITCH DEFAULT POSITION

lockout 42

reset

alarm

test

The UPM Board includes the following features:

• ANTI-SHORT CYCLE TIMER: 5 minute delay on

break timer to prevent compressor short cycling.

• RANDOM START: Each controller has an unique

random start delay ranging from 270 to 300 seconds

on initial power up to reduce the chance of multiple

unit simultaneously starting at the same time after

power up or after a power interruption, thus

avoiding creating large electrical spike.

• LOW PRESSURE BYPASS TIMER: If the compressor

is running and the low pressure switch opens, the

controller will keep the compressor ON for 120

seconds. After 2 minutes if the low pressure switch

remains open, the controllers will shut down the

compressor and enter a soft lockout. The

compressor will not be energized until the low

pressure switch closes and the anti-short cycle time

delay expires. If the low pressure switch opens 2-4

times in 1 hour, the unit will enter a hard lockout. In

order to exit hard lockout power to the unit would

need to be reset.

• BROWNOUT/SURGE/POWER INTERRUPTION

PROTECTION: The brownout protection in the UPM

board will shut does the compressor if the incoming

power falls below 18 VAC. The compressor will

remain OFF until the voltage is above 18 VAC and

ANTI-SHORT CYCLE TIMER (300 seconds) times out.

The unit will not go into a hard lockout.

RY

Cont pulse

yes no

If 24 VAC output is needed, R must be wired to

ALR-COM terminal; 24 VAC will be available o the

ALR-OUT terminal when the unit is in the alarm

condition.

• DISPLAY OUTPUT: The Display output is a pulse

output connected to the Unit Diagnostic Display

(UDD) and it pulses 24VAC when the unit is in an

lockout alarm condition.

• TEST DIP SWITCH: A test dip switch is provided to

reduce all time delays settings to 10 seconds during

troubleshooting or verification of unit operation.

NOTICE: Operation of unit in test mode can

lead to accelerated wear and premature

failure of components. The "TEST" switch

must be set back to "NO" after

troubleshooting/servicing.

• FREEZE SENSOR: The default setting for the freeze

limit trip is 26°F (sensor number 1); however this

can be changed to 15°F by cutting the R24 resistor

located on top of the DIP switch SW1. Since freeze

sensor 2 is dedicated to monitor the load side coil it

is recommended to leave the factory default setting

on the board. The UPM controller will constantly

monitor the refrigerant temperature with the sensor

mounted close to the condensing water coil

between the thermal expansion valve and water coil.

If temperature drops below or remains at the freeze

limit trip for 30 seconds, the controller will shut the

compressor down and enter into a soft lockout

condition. Both the status LED and the Alarm

contact will be active. The LED will flash (three (3)

times) the code associated with this alarm

condition. If this alarm occurs 2 times (or 4 if Dip

switch is set to 4) within an hour the UPM controller

will enter into a hard lockout condition. It will

constantly monitor the refrigerant temperature with

the sensor mounted close to the evaporator

between the

thermal expansion valve and

TW Series Water to Water6720220047 (2016/02) Subject to change without prior notice

Options | 9TW Series Water to Water

evaporator coil as shown in Figure #5. If

temperature drops below or remains at the

limit trip for 30 seconds, the controller will shut the

compressor down and enter into a soft lockout

condition. Both the status LED and the Alarm

contact will be active. The LED will flash (six (6)

times) the code associated with this alarm

condition. If this alarm occurs 2 times (or 4 if Dip

switch is set to 4) within an hour the controller will

enter into a hard lockout condition.

NOTICE: Freeze sensor will not guard

against the loss of water. Flow switch is

recommended to prevent unit from running

if water flow is lost or reduced.

• INTELLIGENT RESET: If a fault condition is initiated,

the 5 minute delay on break time period is initiated

and the unit will restart after these delays expire.

During this period the fault LED will indicate the

cause of the fault. If the fault condition still exists or

occurs 2 or 4 times (depending on 2 or 4 setting for

Lockout dip switch) before 60 minutes, the unit will

go into a hard lockout and requires a manual lockout

reset.

• LOCKOUT RESET: A hard lockout can be reset by

turning the unit thermostat off and then back on

when the “RESET” dip switch is set to “Y” or by

shutting off unit power at the circuit breaker when

the “RESET” dip switch is set to “R”.

freeze

OPTIONS

Number of factory installed options are available on TW

Series of Heat Pumps. The following details the purpose,

function and components of each option.

Heat Recovery Package (HRP)

The heat recovery package is a factory installed option

on TW series heat pumps. The HRP can be used to heat

potable water during unit operation using waste heat

from the compressor discharge gas. In some cases the

HRP can provide most or all of the hot water

requirements for a typical home.

The HRP consists of three major components:

• Double wall, vented refrigerant to water heat

exchanger

• Circulating pump

• Control circuit

The heat exchanger is rated for use with potable water

and is acceptable for use as a domestic water heating

device in most building codes.

The pump circulates water between the domestic hot

water tank and HRP heat exchanger in the Heat Pump.

The control circuit ensures that the HRP only operates

when there is available heat from the compressor and

when the water is within a safe temperature range of

below 140 deg F.

When the heat pump compressor operates, the HRP will

monitor the temperature of the discharge gas from the

compressor. Once discharge gas is hot enough to

provide useful heat to the domestic water tank, the

circulating pump will be enabled, drawing water from

the tank, through the HRP heat exchanger and then

depositing the heated water back into the tank. If the

water temperature reaches 140 deg F, the circulating

pump is disabled to prevent over heating of the

domestic water. The HRP is provided with an on/off

switch in case the end user desires that the HRP be

inactivated (typically during the winter months when

space heating is most important).

NOTICE: If heat recovery unit is installed in

an area where freezing may occur, the unit

must be drained during winter months to

prevent heat exchanger damage. Heat

exchanger ruptures that occur due to

freezing will void the heat recovery package

warranty along with the heat pump

warranty.

DPS Water Flow Proving

The DPS water flow proving switch is a factory installed

option available for the WW series. The DPS prevents

compressor operation if there is inadequate water flow

through the water to refrigerant heat exchanger in the

heat pump.

The DPS operates by monitoring the water side pressure

drop across the water to refrigerant heat exchanger.

When the pressure drop between the water in and water

out lines reaches a pre-set value, compressor operation

is enabled.

Pump Relay

The factory installed pump relay can be used to energize

a supply pump or solenoid valve when there is a call for

compressor operation. This relay can be used to switch

either high or low voltage power.

Comfort Alert Module

The Comfort Alert diagnostics module (CADM) is a

breakthrough innovation for troubleshooting heat pump

system failures. (Figure #6)

Figure # 6

6720220047 (2016/02)Revised 02-16

10 | Heat Recovery Package TW Series Water to Water

By monitoring and analyzing data from the compressor

and the thermostat demand, the module can accurately

detect the cause of electrical and system related failures

without any sensors. A flashing LED indicator

communicates the ALERT code and guides the service

technician more quickly and accurately to the root cause

of a problem.

This module does not provide safety protection! The

Comfort Alert module is a monitoring device and

cannot shut down the compressor directly.

When an abnormal system condition occurs, the

Comfort Alert module displays the appropriate ALERT

and/or TRIP LED.

The yellow ALERT LED will flash a number of times

consecutively, pause and then repeat the process.

To identify a Flash Code number, count the number of

consecutive flashes.

Every time the module powers up, the last ALERT Flash

Code that occurred prior to shut down is displayed for

one minute.Heat Recovery Package

HEAT RECOVERY PACKAGE

Water Tank Preparation

1. Turn off electrical or fuel supply to the water heater.

2. Attach garden hose to water tank drain connection

and run other end of hose out doors or to an open

drain.

3. Close cold water inlet valve to water heater tank.

4. Drain tank by opening drain valve on the bottom of

the tank, then open pressure relief valve or hot

water faucet.

5. Once drained the tank should be flushed with cold

water until the water leaving the drain hose is clear

and free of sediment.

6. Close all valves and remove the drain hose.

7. Install HR water piping.

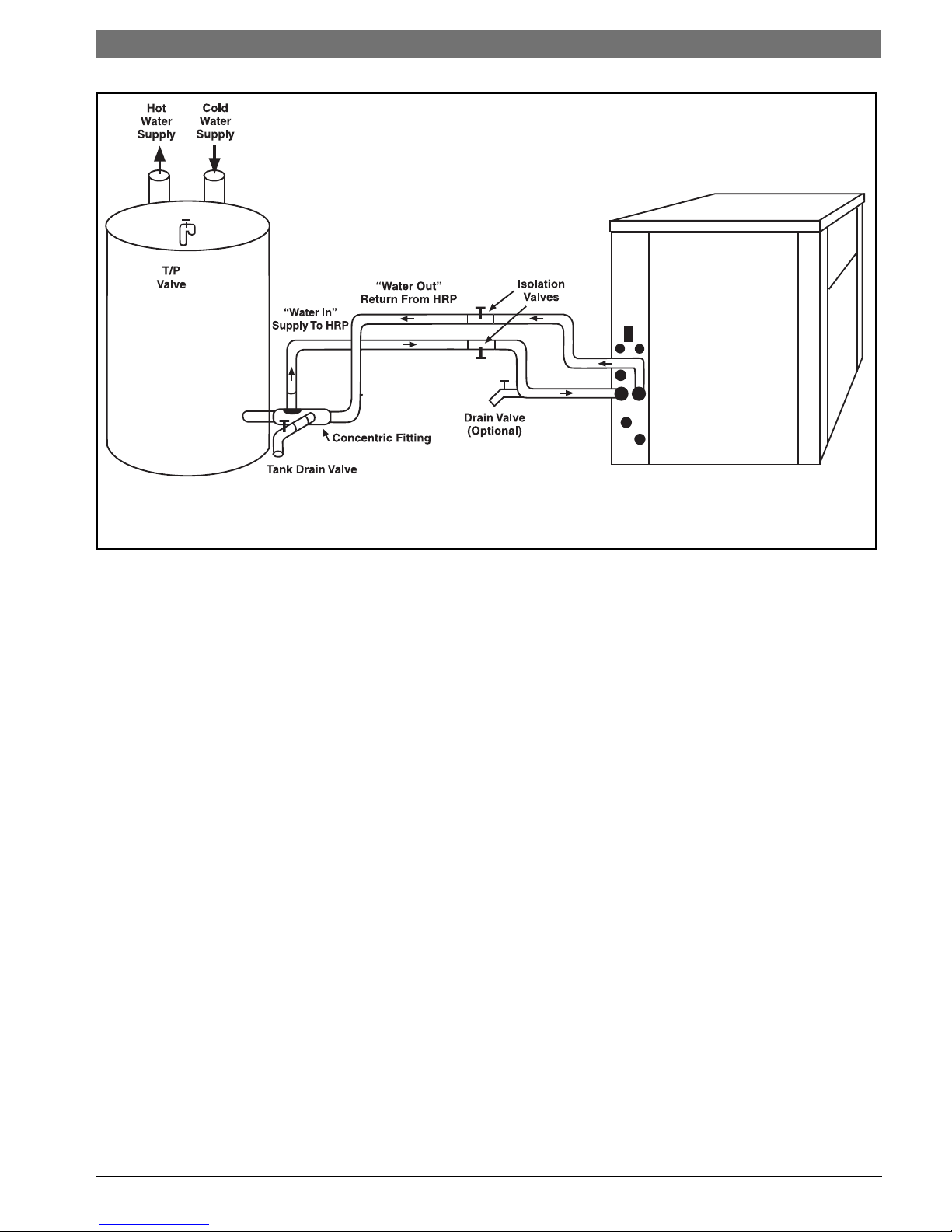

Concentric water fitting (p/n 8733907119) is

recommended.

(See Figure # 7)

HR Water Piping

All hot water piping MUST be a minimum of 3/8t O.D.

copper tube to a maximum distance of fifteen (15) feet.

For distances beyond fifteen feet but not exceeding sixty

(60) feet use 1/2” copper tube. Separately insulate all

exposed surface of both connecting water lines with 3/

8” wall closed cell insulation. Install isolation valves on

supply and return to the heat recovery. (Figure # 7)

3. Depress the hot water tank pressure relief valve

handle to ensure there is no air remaining in the

tank.

4. Carefully inspect all plumbing for water leaks.

Correct as required.

5. Purge all air from HR by depressing the schrader

valve on the HR Unit. Allow all air to bleed out until

water appears at the valve.

6. Before restoring the power or fuel supply to the

water heater, adjust the temperature setting on the

tank thermostat(s) to ensure maximum utilization of

the heat available from the refrigeration system and

conserve the most energy. On tanks with both upper

and lower elements and thermostats, the lower

element should be turned down to 100° F, while the

upper element should be adjusted to 120° F.

Depending upon the specific needs of the customer,

you may need to adjust the upper element

differently. On tanks with a single thermostat lower

the thermostat setting to 120° F or the “LOW”

position. After thermostat adjustments are

completed, replace access cover and restore

electrical or fuel supply to water heater.

NOTICE: All piping from HRP to domestic

water tank must be copper or any metal of

stronger alloy.

Initial Start-Up

NOTICE: Make sure all valves in heat

recovery water piping system are open.

NEVER OPERATE HR PUMP DRY.

1. Turn on the heat pump. The HR pump should not run

if the compressor is not running

2. Turn HR switch to the “ON” position. The pump will

operate if entering water temperature to HR is

below 120° F.

3. The temperature difference between the water

entering and leaving the heat recovery should be 5°

to 15° F.

4. Allow the unit to operate for 20 to 30 minutes to

ensure it is functioning properly. The pump should

shut off when the water temperature entering the

heat recovery reaches 120°F.

Water Tank Refill

1. Open the cold water supply to the tank.

2. Open a hot water faucet to vent air from the system

until water flows from the faucet, then close.

TW Series Water to Water6720220047 (2016/02) Subject to change without prior notice

Sequence of operation | 11TW Series Water to Water

NOTE: Diagram for illustration purposes only.

Ensure access to Heat Pump is not restricted.

Figure # 7

SEQUENCE OF OPERATION

Cooling Mode

Energizing the “O” terminal energizes the unit reversing

valve thus placing the unit into cooling mode. T

When the thermostat calls for first stage cooling (Y1) the

loop pump or solenoid valve if present is energized and

the first stage of compressor capacity starts.

When the thermostat calls for second stage cooling (Y2)

the second stage (or full compressor capacity) is

initiated. Once the thermostat is satisfied, the

compressor shuts down accordingly

Heating Mode

The first two stages of heating (Y1 & Y2) operate in the

same manner as cooling, but with the reversing valve deenergized. Once the thermostat is satisfied, the

compressor shuts down,

6720220047 (2016/02)Revised 02-16

Loading...

Loading...