Bosch TW060-3CSC-FXX, TW060-3USC-FXX, TW060-3CSN-FXX, TW060-3USN-FXX Installation And Maintenance Manual

Installation and Maintenance Manual

TW Series

Water to Water

6 720 220 047

Revised 03-11

©Copyright 2011 Bosch, Inc All rights reserved

Table of Contents

TW Series / Water to Water

TABLE OF CONTENTS

Model Nomenclature .................................................................................... 3

Initial Inspection .......................................................................................... 4

Installation ................................................................................................... 4

Electrical ...................................................................................................... 5

Piping .......................................................................................................... 5

Cooling Tower / Boiler Applications ............................................................. 6

Well Water Systems ...................................................................................... 7

Earth Coupled Geothermal Systems ............................................................ 7

Typical Load Side Applications ..................................................................... 7

Water to Water Unit Controller ..................................................................... 8

Modes Of Operation .................................................................................... 8

Unit Protection ............................................................................................. 9

User Adjustable Setting Chart .................................................................... 11

Setting Up The Controller .......................................................................... 11

Initial Conguration ................................................................................... 12

System Check-Out...................................................................................... 13

Unit Start-Up .............................................................................................. 13

Heat Recovery Package .............................................................................. 14

Operating Pressures .................................................................................. 16

Chiller Mode .......................................................................................... 16

Boiler Mode ........................................................................................... 16

Wiring Diagrams ......................................................................................... 17

Two Phase - Single Stage ....................................................................... 17

Two Phase - Single Stage Solid State Unit Controller ............................. 18

Unit Check-Out........................................................................................... 19

Trouble Shooting ........................................................................................ 20

3

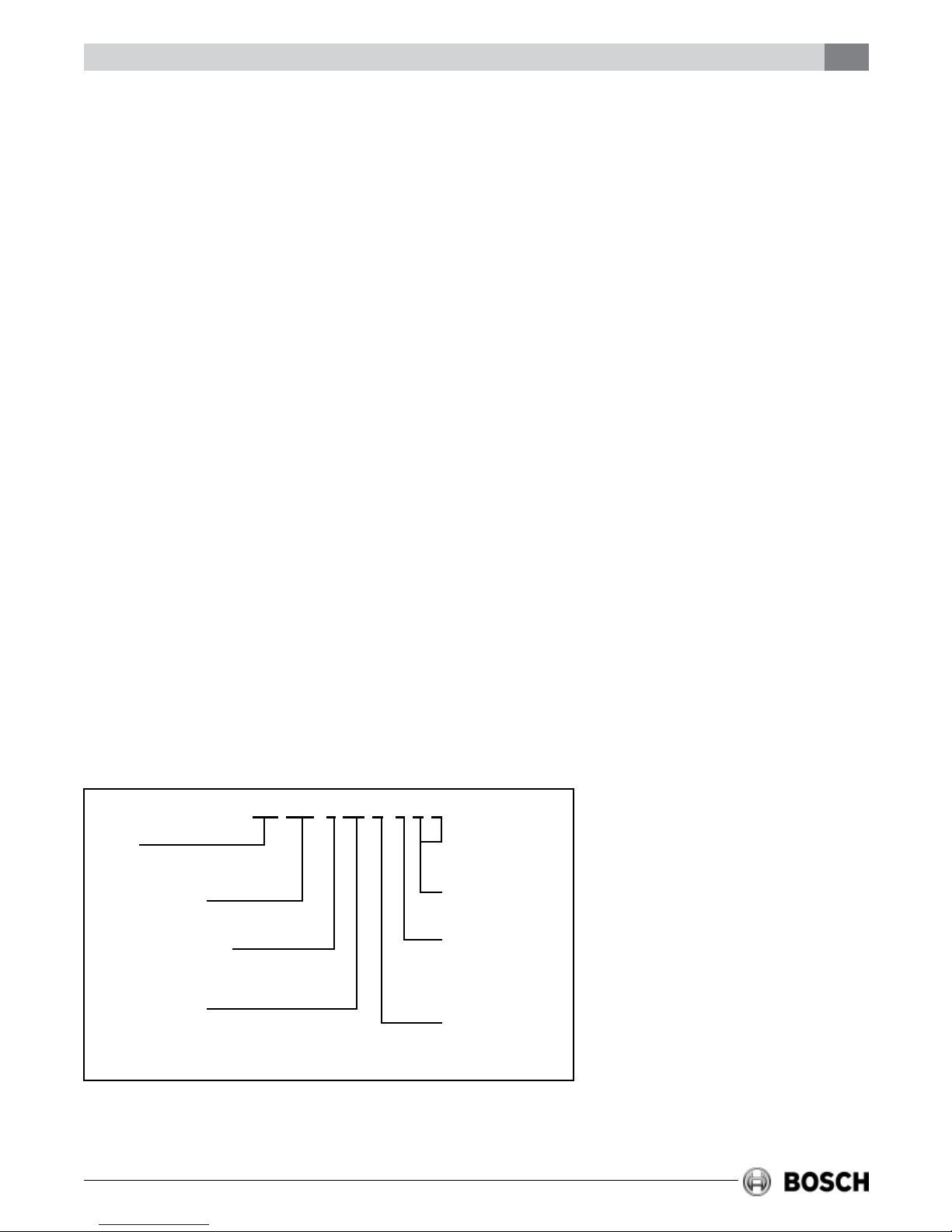

MODEL NOMENCLATURE

TW 060 - 3 CS C - F X X

MODEL:

TW=WATER TO WATER R-410A

NOMINAL CAPACITY:

THOUSANDS OF BTUH - COOLING

VOLTAGE DESIGNATIONS:

1- 208-230/1/60

CONTROL OPTIONS:

CS: WATER-TO-WATER UNIT NO CONTROLS

US: WATER-TO-WATER UNIT MOUNTED CONTROLLER

Revised 03-11 Subject to change without prior notice

NOT APPLICABLE

WATER CONNECTION

LOCATION

F-FRONT

WATER COIL OPTIONS

C-COPPER

N-CUPRO-NICKEL

6 720 220 047

4

TW Series / Water to Water

Initial Inspection

INITIAL INSPECTION

Be certain to inspect all cartons or crates on each

unit as received at the job site before signing the

freight bill. Verify that all items have been received

and that there is no visible damage; note any

shortages or damage on all copies of the freight

bill. In the event of damage or shortage, remember

that the purchaser is responsible for ling the

necessary claims with the carrier. Concealed

damage not discovered until after removing the

units from the packaging must be reported to the

carrier within 24 hours of receipt.

GENERAL DESCRIPTION

The Water-to-Water series unit is a heat pump that

provides the best combination of performance and

efciency available. Safety devices are built into

each unit to provide the maximum system

protection possible when the unit is properly

installed and maintained.

The Water-to-Water series units are Underwriters

Laboratories (UL) and (cUL) listed for safety. The

Water-to-Water series units are designed to operate

with entering source liquid temperature between

25° F and 110° F. (see specications data sheets

for limits).

For well water applications, the minimum

source EWT is 50˚ F, with sufcient water ow

to prevent freezing. Antifreeze solution is

required for all closed loop applications.

Cooling Tower/Boiler and Earth Coupled (Geo

Thermal) applications should have sufcient

antifreeze solution to protect against extreme

conditions and equipment failure. Frozen water

coils are not covered under warranty.

components. Only trained and qualied personnel

should install, repair, or service the equipment.

Before performing service or maintenance

operations on the system, turn off main power

to the unit. Electrical shock could cause

personal injury or death.

TW Series R-410A refrigerant systems operate

at higher pressures than standard R-22

systems. Do not use R-22 service equipment or

components on R-410A equipment.

When working on equipment, always observe

precautions described in the literature, tags, and

labels attached to the unit. Follow all safety codes.

Wear safety glasses and work gloves. Use a

quenching cloth for brazing, and place a re

extinguisher close to the work area.

LOCATION

The unit should be centrally located with respect to

the distribution system. The unit should be

installed in an indoor area that allows easy removal

of the access panels, and has enough room for

service personnel to perform maintenance or

repair. Provide sufcient room to make uid, and

electrical connections. These units are not

approved for outdoor installation; therefore, they

must be installed inside the conditioned structure.

Do not locate in areas that are subject to freezing.

INSTALLATION

The Water-to-Water series unit should be mounted

level on a vibration absorbing pad slightly larger

than the base to minimize vibration transmission to

the building structure. It is not necessary to anchor

the unit to the oor.

MOVING AND STORAGE

If the equipment is not needed for immediate

installation upon its arrival at the job site, it should

be left in its shipping carton and stored in a clean,

dry area. Units must only be stored or moved in the

normal upright position as indicated by the “UP”

arrows on each carton at all times.

SAFETY CONSIDERATIONS

Installation and servicing of this equipment can be

hazardous due to system pressure and electrical

6 720 220 047

VIBRATION PAD

FULL SIZE

If the unit is installed on a oor over a crawl space,

it should not rest on long, unsupported oor joists.

Vibrations may be created in the joists with the

crawl space acting as an amplier box resulting in

undesirable noise. A drain pan is recommended

Subject to change without prior notice Revised 03-11

Minimal System Volume

TW Series / Water to Water

5

where water released during start-up or

maintenance could cause damage below the unit.

MINIMAL SYSTEM VOLUME

Bosch recommends that the total uid volume in the

system be not less than 6 gallons per nominal ton of

cooling capacity on both the load and source sides.

ELECTRICAL

Always disconnect power to the unit before

servicing to prevent injury or death due to

electrical shock.

All eld wiring must comply with local and national

re, safety and electrical codes. Power to the unit

must be within the operating voltage range

indicated on the unit’s nameplate. On three phase

units, phases must be balanced within 2%.

Properly sized fuse or HACR circuit breakers must

be installed for branch circuit protection. See

equipment rating plate for maximum size. The unit

is supplied with an opening for attaching conduit.

Be certain to connect the ground lead to the

ground lug in the control box. Connect the power

leads as indicated on the unit wiring diagram

(Refer to Figure #6).

PIPING

Supply and return piping must be as large as the

unit connections on the heat pump (larger on long

runs). Never use exible hoses of a smaller inside

diameter than that of the water connections on

the unit. The Water-to-Water series units are

supplied with either a copper or optional cupronickel condenser. Should your well driller express

concern regarding the quality of the well water

available or should any known hazards exist in

your area, we recommend proper testing to assure

the well water quality is suitable for use with

water source equipment. In conditions

anticipating moderate scale formation or in

brackish water a cupro-nickel heat exchanger is

recommended.

Galvanized pipe or ttings are not recommended

for use with these units due to the possible

galvanic corrosion.

Both the supply and discharge water lines will

sweat if subject to low water temperature. These

lines should be insulated to prevent damage from

condensation.

All manual ow valves used in the system must be

ball valves. Globe and gate valves must not be

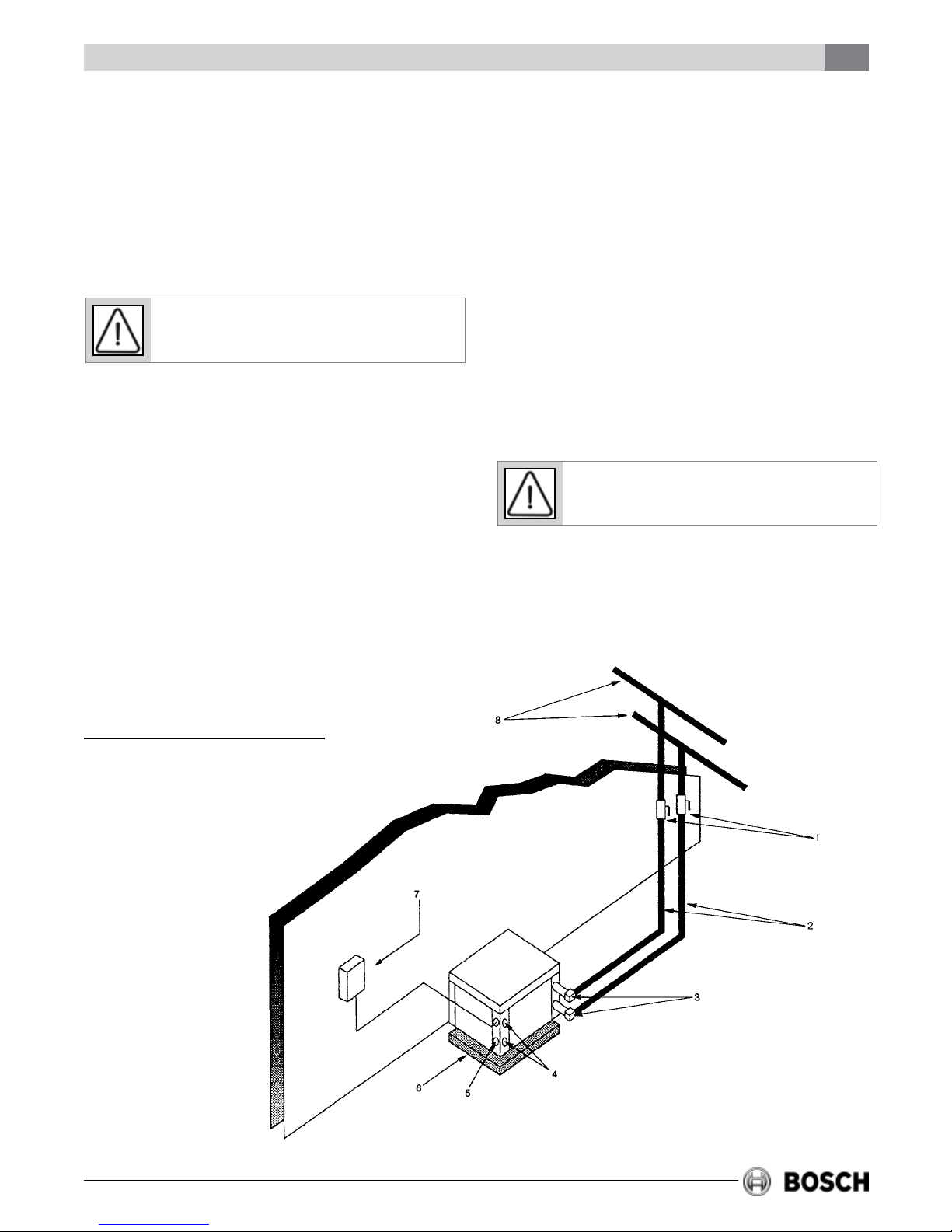

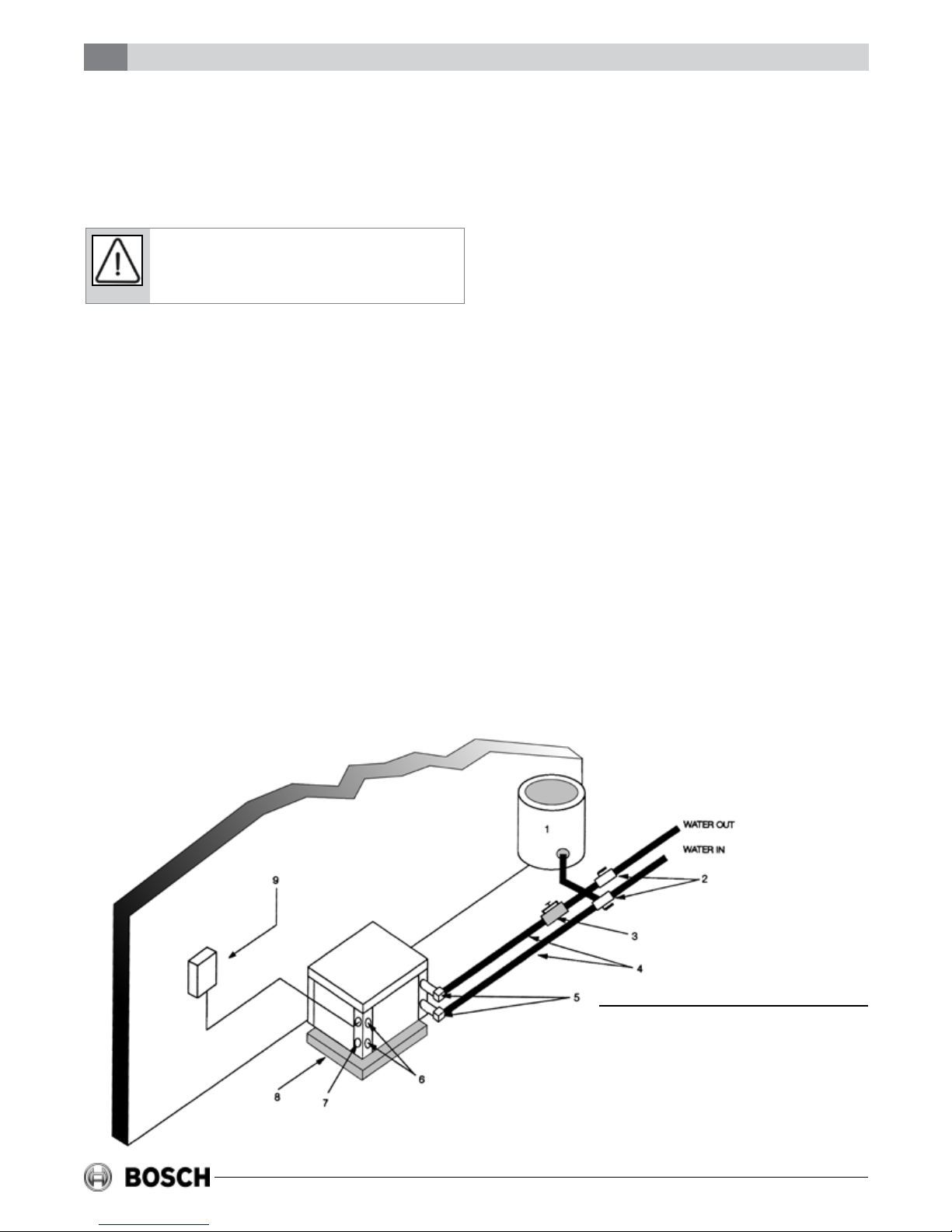

COOLING TOWER/BOILER APPLICATION

(SOURCE SIDE)

1. BALL VALVES

2. HOSE KITS

3. P/T PLUGS

4. LOAD SIDE CONNECTIONS*

5. LOW VOLTAGE CONTROL CONNECTION*

6. VIBRATION PAD

7. LINE VOLTAGE DISCONNECT

8. SUPPLY AND RETURN LINES OF

CENTRAL SYSTEM

* NOTE: Water and electrical connection locations vary depending on model. Connect as required per unit labels.

Figure #1

Revised 03-11 Subject to change without prior notice

6 720 220 047

6

TW Series / Water to Water

Cooling Tower / Boiler Application

used due to high pressure drop and poor throttling

characteristics.

Never exceed the recommended water ow rates.

Serious damage or erosion of the water to

refrigerant heat exchanger could occur.

Improper heat exchanger uid ow due to piping,

valving or improper pump operation is hazardous

to the unit and constitutes abuse which will void

the heat exchanger and compressor warranty.

Always check carefully for water leaks and repair

appropriately. Units are equipped with female pipe

thread ttings. Consult the specication sheets for

sizes. Thread sealant should be used when

connecting water piping connections to the units to

insure against leaks and possible heat exchanger

fouling. Do not overtighten the connections.

Flexible hoses should be used between the unit and

the rigid system to avoid possible vibration. Ball

valves should be installed in the supply and return

lines for unit isolation and unit ow balancing.

COOLING TOWER / BOILER

APPLICATION (Figure #1)

To assure adequate cooling and heating

performance, the cooling tower and boiler uid

loop temperature should be maintained between

50° F to 100° F. In the cooling mode, heat is

rejected from the unit into the condenser water

loop. A cooling tower provides evaporative cooling

to the loop water; thus, maintaining a constant

supply temperature to the unit. When utilizing an

open cooling tower, chemical water treatment is

mandatory to ensure the water is free of corrosive

materials. A secondary heat exchanger (plate frame

between the unit and the open cooling tower) may

also be used. It is imperative that all air is

eliminated from the closed loop side of the heat

exchanger to prevent condenser fouling.

In the heating mode, heat is absorbed from the

condenser water loop to the unit. A boiler can be

utilized to maintain the loop within the proper

temperature range. In milder climates a “ooded

tower” concept is often used. This concept involves

adding make-up water to the cooling tower sump to

maintain the desired loop temperature. No unit

should be connected to the supply or return piping

until the water system has been completely cleaned

and ushed to remove any dirt, piping chips or

other foreign material. Supply and return hoses

should be connected together during this process

to ensure the entire system is properly ushed.

After the cleaning and ushing has taken place, the

unit may be connected to the water loop and should

have all valves wide open.

Pressure/temperature ports are recommended in

both the supply and return lines for system ow

balancing. Water ow can be accurately set by

measuring the refrigerant-to-water heat exchangers

* NOTE: Water and electrical connection locations vary

depending on model. Connect as required per unit labels.

6 720 220 047

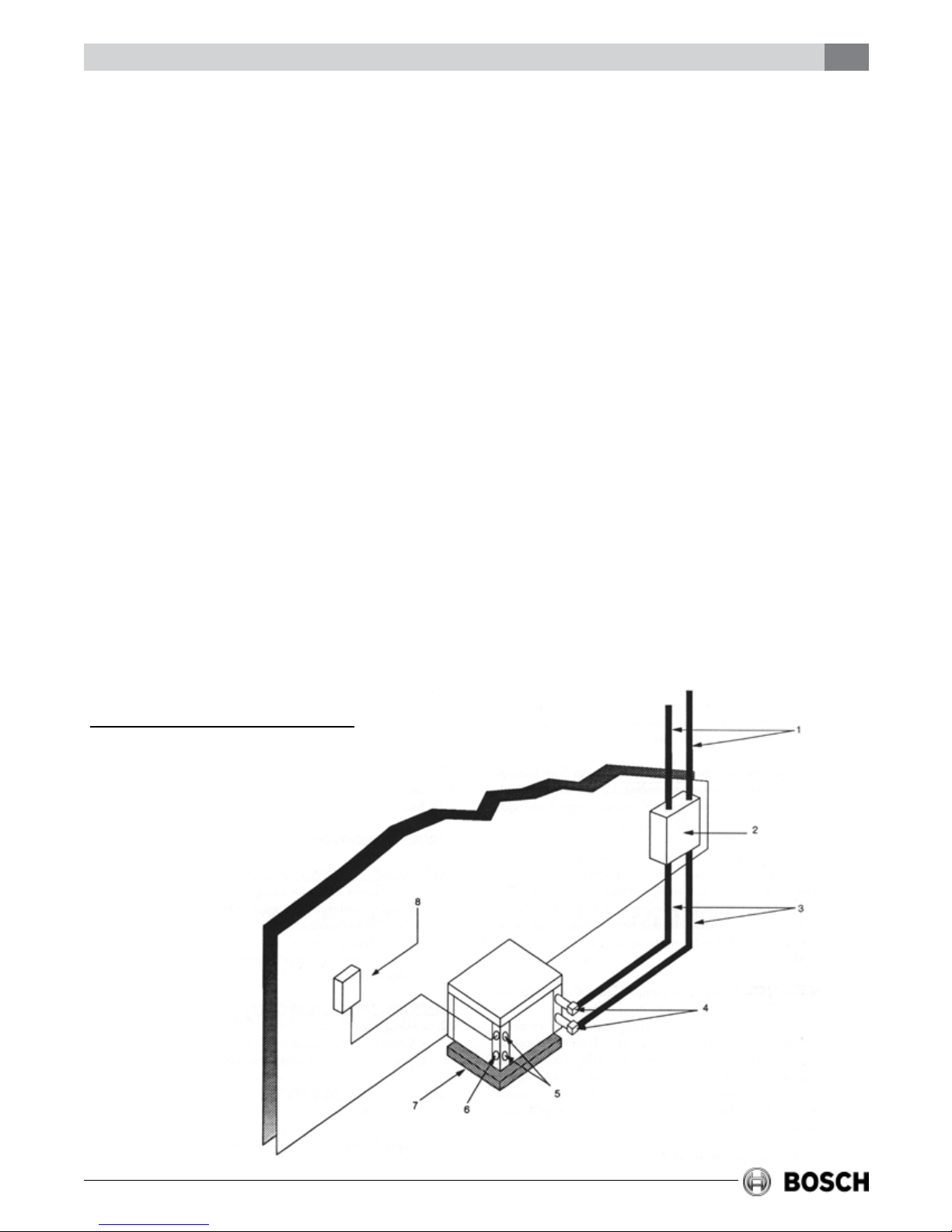

WELL WATER APPLICATION (SOURCE SIDE)

1. PRESSURE TANK

2. BALL VALVES

3. SOLENOID VALVE (SLOW CLOSING)

4. HOSE KIT

5. P/T KIT

Figure #2

Subject to change without prior notice Revised 03-11

6. LOAD SIDE CONNECTIONS*

7. LOW VOLTAGE CONTROL CONNECTION*

8. VIBRATION PAD

9. LINE VOLTAGE DISCONNECT

Well Water Systems

TW Series / Water to Water

7

water side pressure drop. See specication sheets

for water ow and pressure drop information.

WELL WATER SYSTEMS (Figure #2)

Water quantity should be plentiful, between 1.5

and 3.0 gpm per ton of cooling, and of good quality.

To avoid the possibility of freezing in the heating

mode, the well water should be above 50˚F.

Water pressure must always be maintained in the

heat exchanger by placing a water control valve on

the outlet of the water-to-water unit. A bladder type

expansion tank may be used to maintain pressure

on the system. All solenoid valves should be slow

closing to avoid water hammer.

The discharge water from the water-to-water unit is

not contaminated in any manner and can be

disposed of in various ways depending on the local

codes (i.e. discharge well, dry well, storm sewer,

drain eld, stream, pond, etc.) Pilot operated or

slow closing valves are recommended to reduce

water hammering.

EARTH COUPLED GEOTHERMAL

SYSTEMS (Figure #3)

Closed loop and pond applications require

specialized design knowledge. No attempt at these

installations should be made unless the dealer has

received specialized training.

Utilizing the Ground Loop Pumping Package

(GLP), makes the installation easy. Anti-freeze

solutions are utilized when entering loop

temperatures drop below 50˚F or where piping

will be routed through areas subject to freezing. A

ow rate between 2.5 to 3.0 gpm per nominal ton

of cooling is recommended for this application.

See GLP Pump Curve for sizing information.

TYPICAL LOAD SIDE APPLICATIONS

There are many load side applications for which

the water-to-water heat pump/ liquid chiller is

ideally suited.

SOME TYPICAL USES ARE AS

FOLLOWS

Hydronic baseboard heating, hydronic in-slab oor

heating, forced air fan coil heating or cooling, ice

and snow melting, heating potable water, (when

allowed by code) heating swimming pool and spa*,

process uid heating or cooling.

When specifying load side uid volume it is

important to consider the heat pump output

capacities and ow rates. Insufcient load side

uid volume may cause unstable heat pump

operation (short cycling). Pressure/temperature

ports should be used to set ow rates.

EARTH COUPLED APPLICATION (SOURCE SIDE)

1. POLYBUTYLENE OR POLYETHELENE WITH

INSULATION

2. GROUND LOOP PUMPING PACKAGE (GLP)

3. GROUND LOOP CONNECTION KIT

4. P/T PLUGS

5. LOAD SIDE CONNECTIONS*

6. LOW VOLTAGE CONTROL CONNECTION*

7. VIBRATION PAD

8. LINE VOLTAGE DISCONNECT

Figure #3

* NOTE: Water and electrical connection locations vary depending

on model. Connect as required per unit labels.

Revised 03-11 Subject to change without prior notice

6 720 220 047

8

TW Series / Water to Water

Water to Water Unit Controller

*A water-to-water series Heat Pump/Liquid Chiller

can be utilized for direct pool/spa heating without a

secondary heat exchanger. In this application

cupro-nickel heat exchangers must be used.

Automatic chemical feeders must never be installed

up stream of the unit. An external bypass should be

installed to avoid over-owing the heat exchanger

to prevent coil erosion. The pool pH levels and

chemical balances must be maintained to avoid

possible heat exchanger damage.

WATER TO WATER UNIT CONTROLLER

(OPTIONAL)

Bosch’s water to water heat pump controller offers a

low cost, simple solution to the control of a water to

water heat pump unit. The control is congurable to

provide cooling only, heating only or auto change over

control strategies based on the application of the unit

in a given system.

Features:

• Selectable mode of operation. Cooling, Heating or

Auto Changeover.

• Adjustable temperature differential for heating

and cooling set point.

• Adjustable auto changeover set point with adjust-

able dead band setting.

• Intelligent auto reset of a fault condition avoids

nuisance hard lockouts.

• LED display of control temperature and set

points.

• ˚F or ˚C Display.

• 50\60 Hertz operation.

• Brown out low voltage protection

All of the unit’s safeties are tied back into the

controller for system protection.

UNIT SENSORS

The unit controller is provided with two sensors:

Water Sensor: This sensor will control unit

operation in the cooling or heating mode based on

the water temperature on the load side. It may be

eld mounted for example on the return water line

or in a water tank when provided with a eld

supplied immersion well. The location will depend

on the specic requirements of the job.

Changeover Sensor: This sensor will put the unit in

either the heating or cooling mode depending on

the set point. It may be mounted in a location that

would be indicative if the unit should be in either

the heating or cooling mode, for example outdoors.

The sensor may be located up to 1000 feet from the

unit (additional eld supplied wiring required).

MODES OF OPERATION

The controller will memorize the last mode used

before power is removed and will run in that mode

after it is turned on. In all modes the control will

display temperature degree differential setting for ve

seconds once it is powered and this setting may be

adjusted during this time. Thereafter the display will

switch to the monitored water temperature. When

switching from one mode to another the set point (the

decimal point is used to distinguish it from water

temperature) for the new mode is displayed for 5

seconds and then monitored water temperature.

During this time the set point may be adjusted.

• Pump operation congurable for continuous or

cycling operation with the compressor.

• Compressor lead-lag operation on units with dual

compressors.

• Malfunction output and service LED can be set to

steady or pulsing to indicate fault condition.

• Color LED’s indication of mode of operation.

• Set point retention in non volatile memory in the

event of a power failure.

• Five minute delay on break or power interruption

for compressor short cycling protection.

6 720 220 047

OFF MODE

In the OFF mode all outputs are disabled and mode

indication LED’s will be off.

The control will rst display temperature

differential setting with the ability for the user to

adjust it and then will display “OFF” and nally

water temperature.

HEATING MODE

When the unit is operated in the heating mode and

the controlled water temperature is below the set

point minus the differential setting, terminal Y1 will

close and the unit will operate (rst stage

Subject to change without prior notice Revised 03-11

Loading...

Loading...