Page 1

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento

y seguridad

RA1200

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Parlez-vous français? ¿Habla español?

See page 2 Voir page 22 Ver página 42

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll Free Number: Appel gratuit : Número de teléfono gratuito:

1-877-BOSCH99 (1-877-267-2499) http://www.boschtools.com

BM 2610909346 5/03 5/12/03 11:52 AM Page 1

Page 2

-2-

Read and understand the tool manual and these instructions for the use of

this table with your router. Failure to follow all instructions listed below may

result in serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep bystanders, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with

a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified

electrician to install a polarized outlet. Do

not change the plug in any way. Double

Insulation eliminates the need for the

three wire grounded power cord and

grounded power supply system. Before

plugging in the tool, be certain the outlet

voltage supplied is within the voltage marked

on the nameplate. Do not use “AC only”

rated tools with a DC power supply.

Avoid body contact with grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is grounded. If

operating the power tool in damp locations

is unavoidable, a Ground Fault Circuit

Interrupter must be used to supply the

power to your tool. Electrician’s rubber

gloves and footwear will further enhance

your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the

cord to carry the tools or pull the plug

from an outlet. Keep cord away from

heat, oil, sharp edges or moving parts.

Replace damaged cords immediately.

Damaged cords increase the risk of electric

shock.

When operating a power tool outside, use

an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor

use and reduce the risk of electric shock.

Refer to “Recommended sizes of Extension

Cords” in the Accessory section of this

manual.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry,

or long hair can be caught in moving parts.

Keep handles dry, clean and free from oil

and grease.

Avoid accidental starting. Be sure switch

is “OFF” before plugging in. Carrying tools

with your finger on the switch or plugging in

tools that have the switch “ON” invites

accidents.

Remove adjusting keys or wrenches

before turning the tool “ON”. A wrench or

a key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of the

tool in unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must

be used for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand

or against your body is unstable and may

lead to loss of control.

Do not force tool. Use the correct tool for

your application. The correct tool will do

!

WARNING

Power Tool Safety Rules

BM 2610909346 5/03 5/12/03 11:52 AM Page 2

Page 3

-3-

the job better and safer at the rate for which

it is designed.

Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the

risk of starting the tool accidentally.

Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely

to bind and are easier to control. Any

alteration or modification is a misuse and

may result in a dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop

a periodic maintenance schedule for your

tool.

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be

suitable for one tool, may become

hazardous when used on another tool.

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk

of electric shock or injury. Certain cleaning

agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage

plastic parts.

BM 2610909346 5/03 5/12/03 11:52 AM Page 3

Page 4

-4-

Unplug tool before setting up in table,

making adjustments or changing bits.

Accidental start-up of the tool can cause injury.

Fully assemble and tighten all the fasteners

required for this table and mounting the

router. Also remember to occasionally check

the stand and make sure it is still tight. A loose

stand is unstable and may shift in use and

cause serious injury.

Before operating make sure the entire unit is

placed on a solid, flat, level surface. Serious

injury could occur if tool is unstable and tips.

Never stand on the table or use as ladder or

scaffolding. Serious injury could occur if the

table is tipped or the cutting tool is accidentally

contacted. Do not store materials on or near

the table such that it is necessary to stand on

the table or its stand to reach them.

Never use dull or damaged bits. Sharp bits

must be handled with care. Damaged bits

can snap during use. Dull bits require more

force to push the workpiece, possibly causing

the bit to break.

Match the appropriate bit and its speed to

your application. Do not use bits that have a

cutting diameter that exceeds the capacity

of the tool. Overloading the tool can lead to

personal injury or tool failure.

Never start the tool when the bit is engaged

in the material. The bit cutting edge may grab

the material causing loss of control of the

workpiece.

Router bits are intended for wood, wood

products and plastic only. Be sure the

workpiece does not contain nails, etc. before

routing. Cutting a nail or the like can cause the

carbides to be dislodged, fly toward the operator

side, and possibly strike you or bystanders.

Feed the workpiece against the rotation of

the bit. The bit rotates counter-clockwise as

viewed from the top of table. Feeding the

work in the wrong direction will cause the

workpiece to "climb" up on the bit and may lead

to loss of control during operation.

Never place hands near the spinning bit.

Use push sticks, vertical and horizontally

mounted feather boards (spring sticks) and

other jigs to hold down the workpiece and

keep your hands away from the spinning

blade. Router cuts are blind cuts but the bit still

protrudes through the table and you must be

aware of the position of your hands relative to

the spinning bit.

We do not recommend cutting material that

is warped, wobbly or otherwise unstable. If

this situation is unavoidable, always cut the

material with the concave side against the

table. Cutting the material with the concave

side up or away from table may cause the

warped or wobbly material to roll; causing you

to lose control, kickback and serious personal

injury may result.

Use the adjustable fence in straight cutting

applications. When routing along an entire

edge of the work, the fence, fence faces, and

outfeed support shims will help maintain

stability.

When the table is used without the fence,

piloted bits (or "bearing bits") must be used.

Piloted bits are used when routing internal and

external contours on a workpiece. The bearing

of the piloted bit assists in maintaining control of

the workpiece. Whenever possible, the starter

pin should also be used.

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely

tightened. Loose adjustment devices can

unexpectedly shift, causing loss of control,

loose rotating components will be violently

thrown.

Never touch the bit during or immediately

after the use. Contact with a spinning bit will

cause injury and after use the bit is too hot to be

touched by bare hands.

Use only Bosch replacement parts. Any

others may create a hazard.

Safety Instructions for Large Router Table

BM 2610909346 5/03 5/12/03 11:52 AM Page 4

Page 5

-5-

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Symbols

0

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed by

the Canadian Standards

Association.

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters Laboratories.

This symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

This symbol designates

that this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

Laboratories.

BM 2610909346 5/03 5/12/03 11:52 AM Page 5

Page 6

Model number: RA1200

Voltage rating:

120 V 60Hz

Amperage rating: 15 A

FOR USE WITH BOSCH ROUTER

MODELS:

1601A, 1602A, 1604A, 1606A, 1613,

1613EVS, 1613AEVS, 1617, 1617EVS, and

1619EVS.

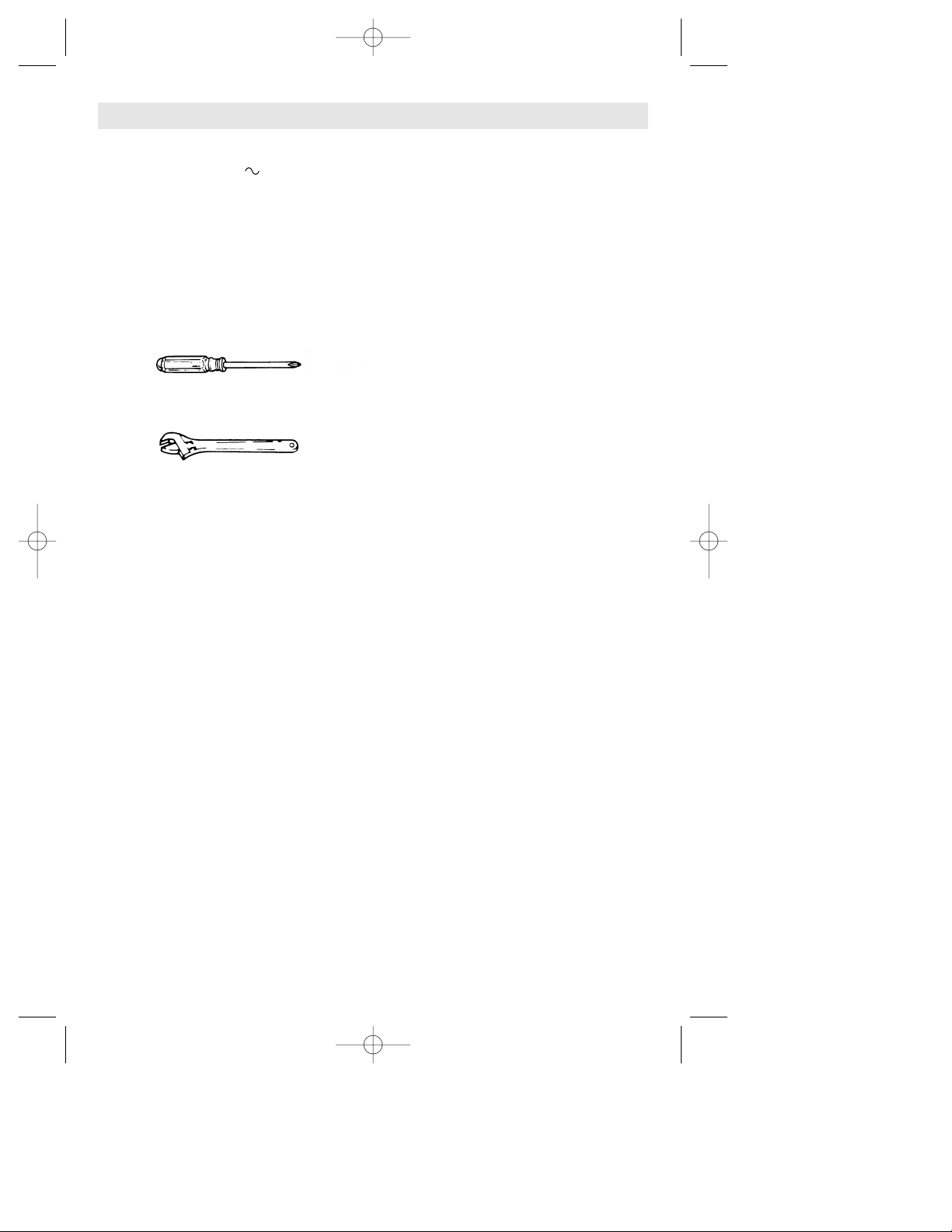

TOOLS REQUIRED:

BEFORE YOU ASSEMBLE THIS

ROUTER STAND:

Sort out and account for all parts to make sure

that you have all necessary materials to

assemble your stand. Do not discard packing

material until all parts are accounted for.

PARTS FOR STAND ASSEMBLY

Qty. Part Description

(1) Table Assembly

(1) Power Switch

(2) Power Switch Screw

(6) Nylon Leveler Screw

(6) Spring

PARTS FOR ROUTER MOUNTING

Qty. Part Description

(1) Mounting Plate

(4) 1/4"-20 x 1 1/2" Machine Screw

(4) 1/4" Washer

(4) 1/4" Nut

(4) 4mm x 20mm Machine Screw

(4) 10-24 3/4" Machine Screw

(4) Corner Snugger

(4) 10-24 Screw

(4) Lock Nut

PARTS FOR FENCE ASSEMBLY

Qty. Part Description

(1) Aluminum Fence

(2) Fence Face

(4) 3/8” x 2” Carriage Bolt

(6) 3/8” Female Wing Knob

(2) 3/8” x 2-1/2” Carriage Bolt

(2) 1/32" Shim

(4) 1/16" Shim

(1) Vacuum Port

(2) 10-24 Vacuum Port Screw

(1) Clear Blade Guard

(2) Featherboard

(2) Threaded Rod

(8) Knurled Steel Nut

(2) Nut

(8) Washer

OTHER PARTS FOR ASSEMBLY

Qty. Part Description

(2) Insert Rings

(1) Starter Pin

(2) Featherboard Mounts

(2) Nylon Spacer Washer

(2) 1/4" Wing Knob

(1) Auxiliary Guard

-6-

Router Table Assembly

Phillips Screwdriver

Adjustable Wrench

BM 2610909346 5/03 5/12/03 11:52 AM Page 6

Page 7

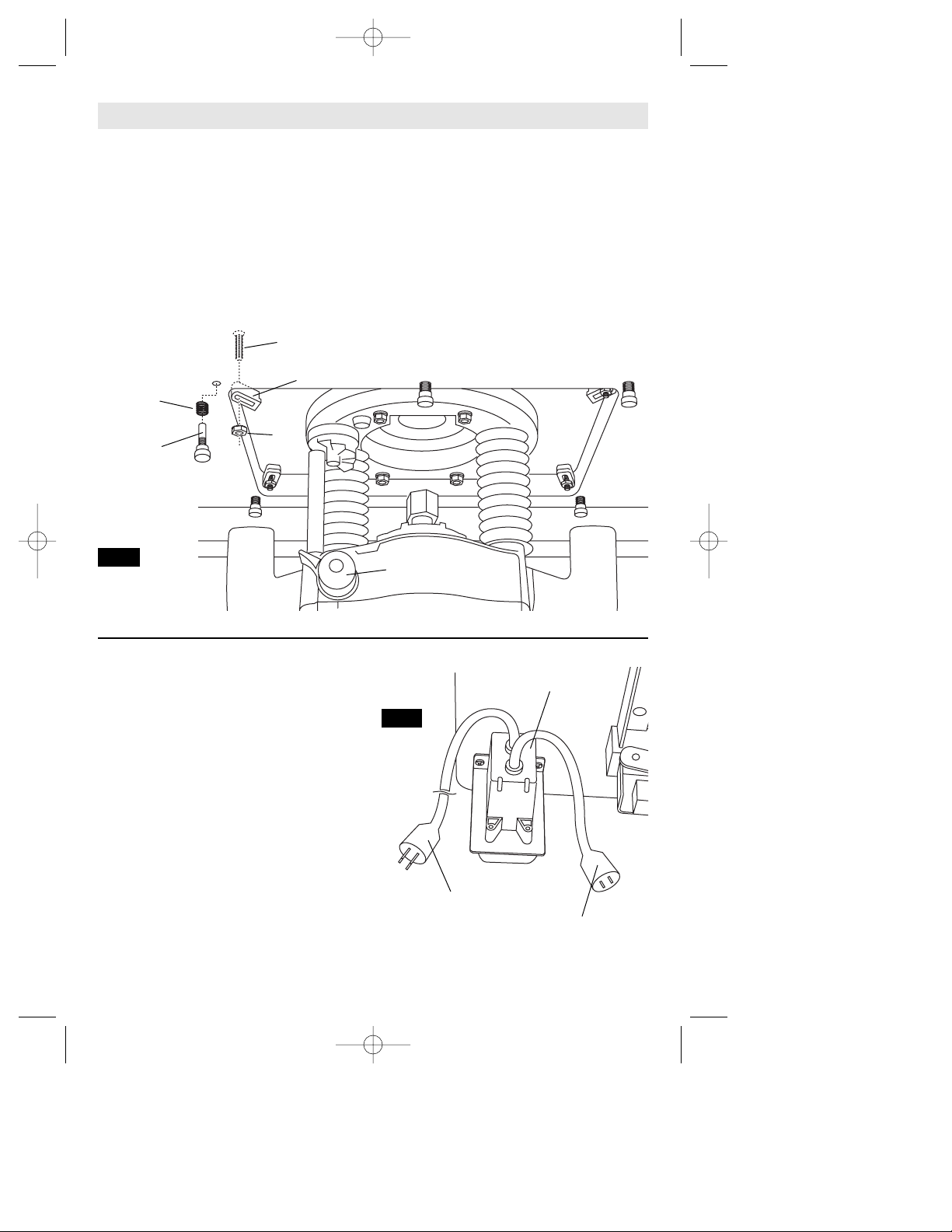

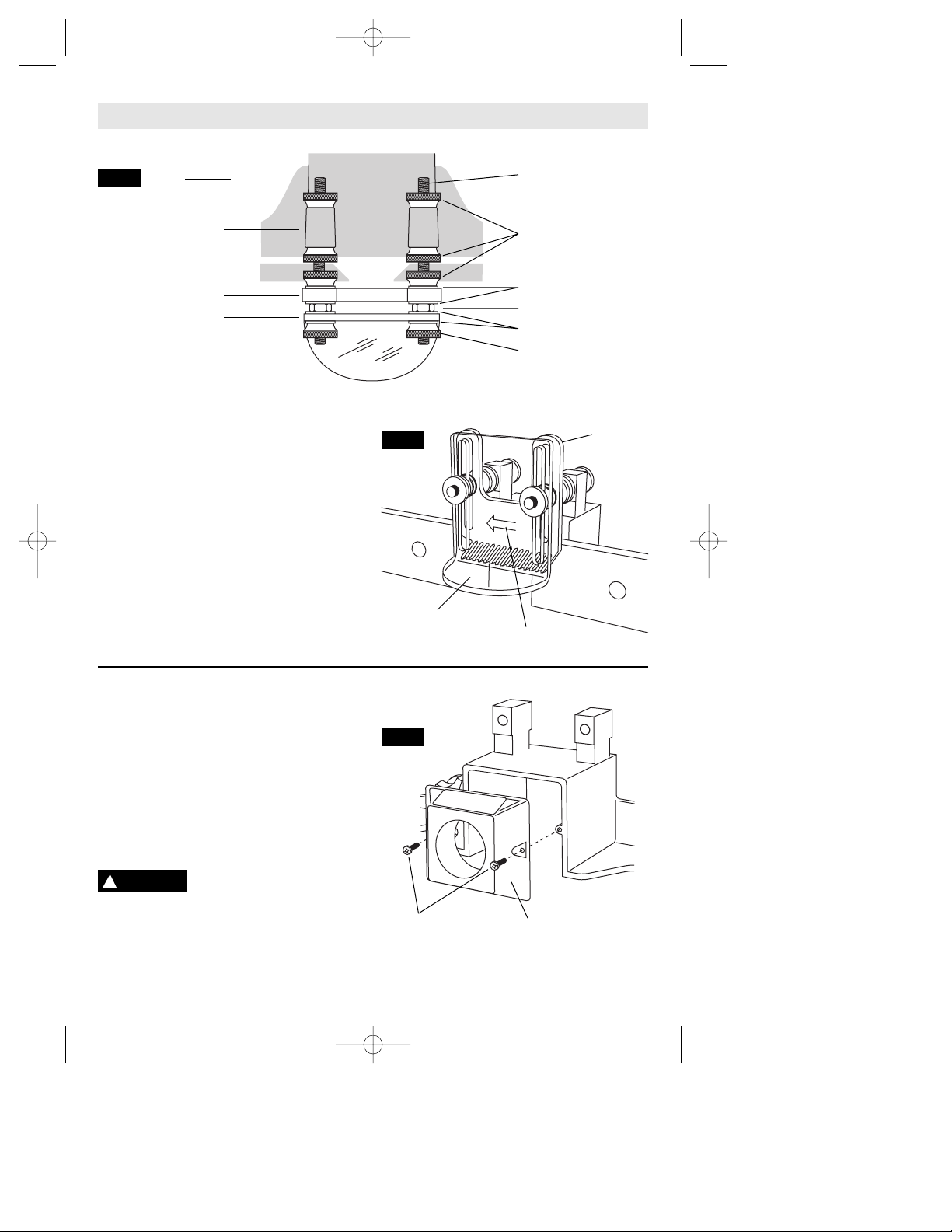

INSTALL POWER SWITCH

Lay the table upside down on a smooth surface.

Place switch bracket’s holes over pre-drilled

holes on front underside of table with the red

switch facing out. Using a No. 2 Phillips

screwdriver, drive the two #10 wood screws

through the bracket and into the predrilled holes

to affix the switch. Do not over-tighten because

this could strip the holes. (Fig. 1).

SET UP TABLE

1. Unfold router table legs until they are fully

extended and the leg braces spring into the

locked position (Fig. 2).

2. Position yourself at the front or rear of the

table.

3. Using the opening for the mounting plate and

the bottom edge of the tabletop, lift the table

to its upright position.

4. Locate the table on a level or nearly-level

surface. Stabilize the table by rotating the

leveler foot up or down until all four legs

contact the floor. The table must not be able

to rock or tilt (Fig. 3).

-7-

Router Table Assembly

FIG. 1

FIG. 2

FIG. 3

POWER

SWITCH

POWER

SWITCH

TABLE

LEG BRACES

LEVELER FOOT

PREDRILLED

HOLES

#10 WOOD

SCREWS

BM 2610909346 5/03 5/12/03 11:52 AM Page 7

Page 8

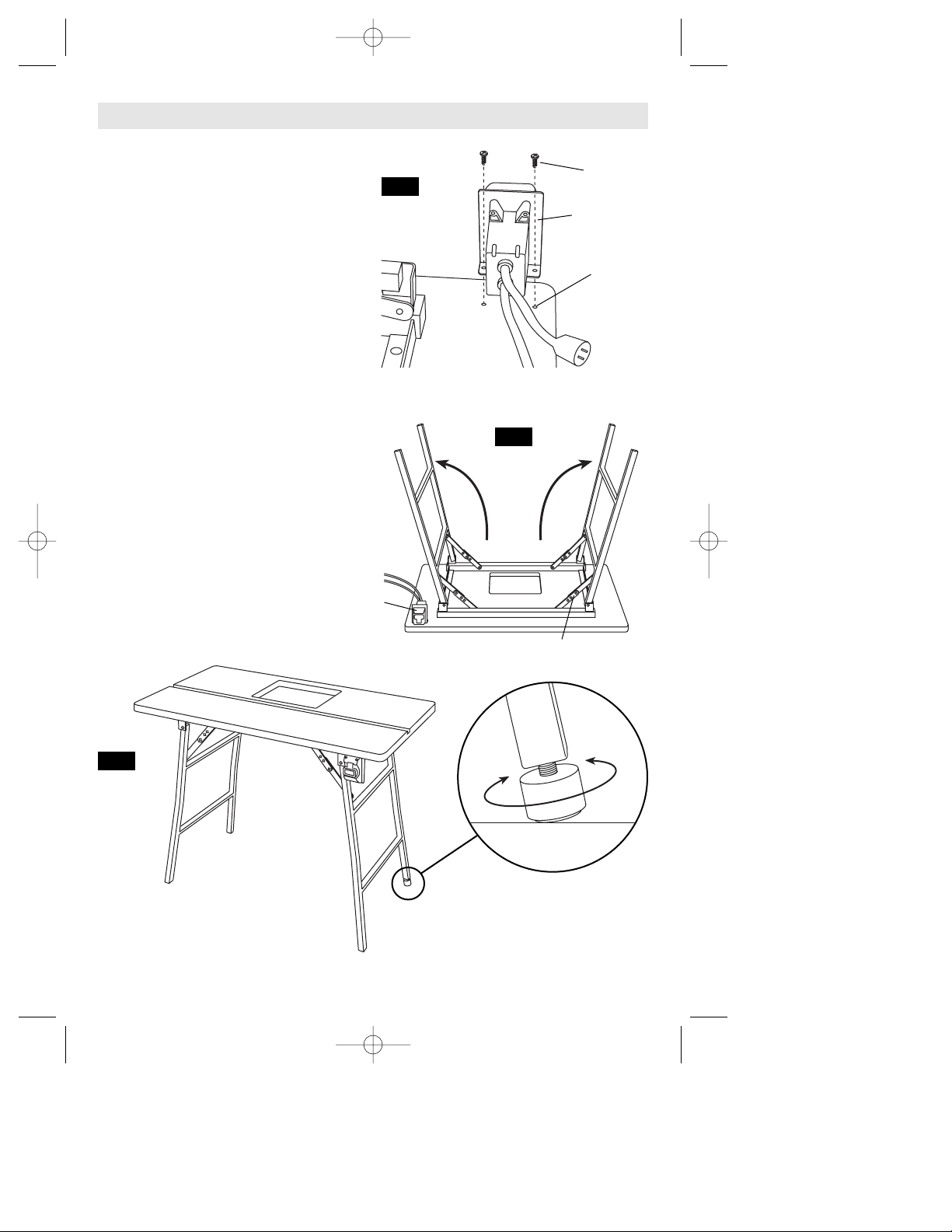

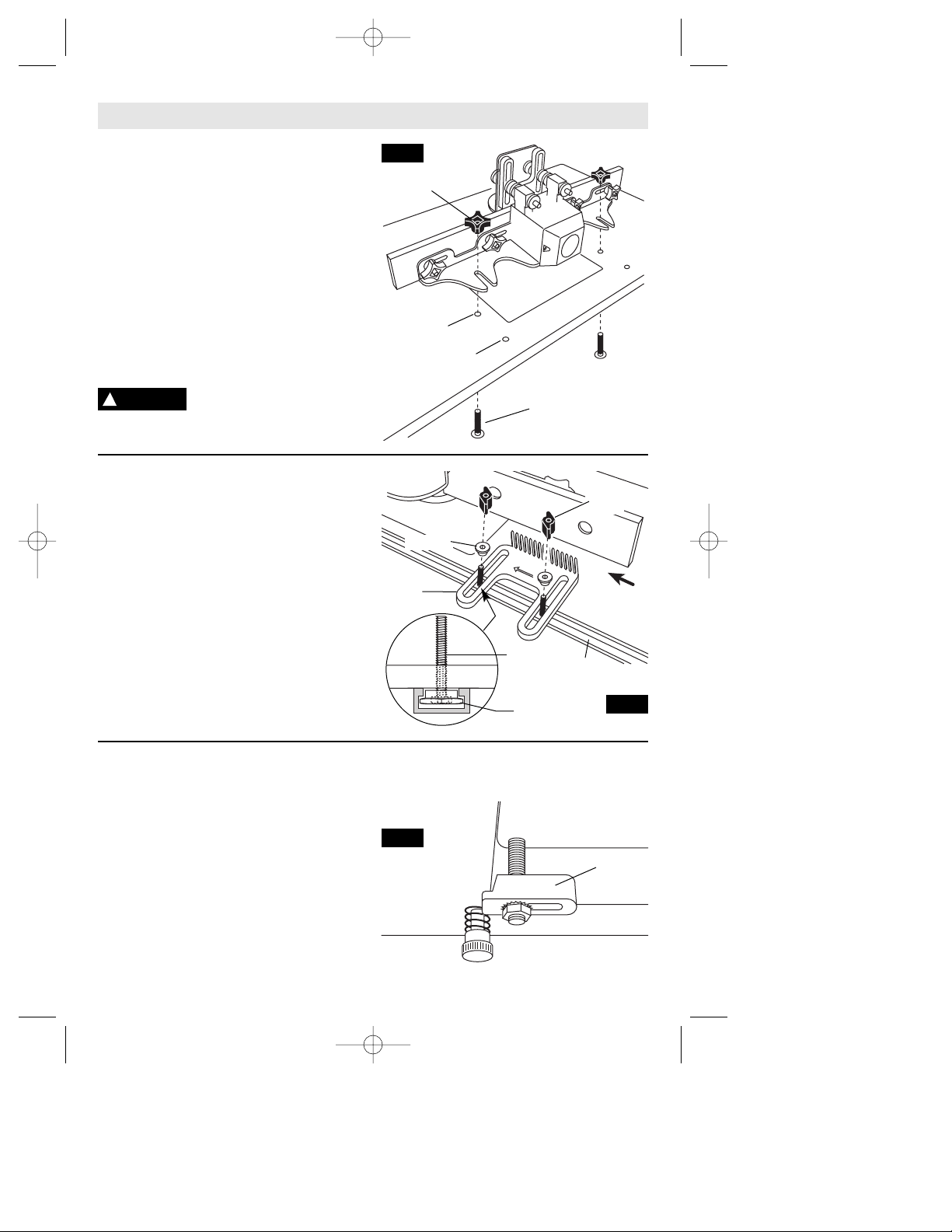

ATTACH ROUTER TO MOUNTING PLATE

1. Remove the black phenolic sub-base from

your Bosch router (Fig. 4).

2. If your router has its own dust extraction hood

that mounts to the top of the metal router

base and you want to use it under the router

table, this is a convenient time to install it.

3. Using the chart below, determine the

hardware (included) needed and mount type

for your Bosch router.

• For the 1601A, 1602A, 1604A, 1606A, and

the 1617 series routers, the screws are

driven into threaded holes in the router’s

base (mount type 1).

• For the 1613 and 1619 series routers: the

screws go all the way through the base

and are fastened with washers and nuts

(mount type 2).

The top and front of the mounting plate is

determined by the location of the guide pin

holes. These holes are to the right of the bit

opening.

4. Refer to the mounting plate illustration (Fig.

6) on page 9, and align the appropriate

mounting plate holes for your Bosch router to

the router base holes. Make sure that the

depth adjustment controls on the router face

the front of the mounting plate.

5. Mount your Bosch router to the mounting

plate (Fig. 5).

6. Once the router has been mounted to the

mounting plate, install the desired router bit

as per the router’s instruction manual.

-8-

Router Table Assembly

FIG. 4

FIG. 5

REMOVE

SUB-BASE

DEPTH

ADJUSTMENT

Bosch Required Mount

Router Model Hardware Type

1601A, 1602A, 4mm x 20mm phillips

1

1604A, 1606A machine screws (4)

1613,

1/4"-20 x 1-1/2" phillips machine

1613EVS,

screws, washers and nuts (3)

2

1613AEVS

1617, 10-24 x 3/4" phillips

1

1617EVS, machine screws (3)

1/4"-20 x 1-1/2" phillips machine

1619EVS

screws, washers and nuts (4)

2

MOUNT TYPE 1

MOUNT TYPE 2

MOUNTING PLATE

ROUTER BASE

MOUNTING PLATE

ROUTER BASE

BM 2610909346 5/03 5/12/03 11:52 AM Page 8

Page 9

-9-

Router Table Assembly

TOP FRONT OF PLATE

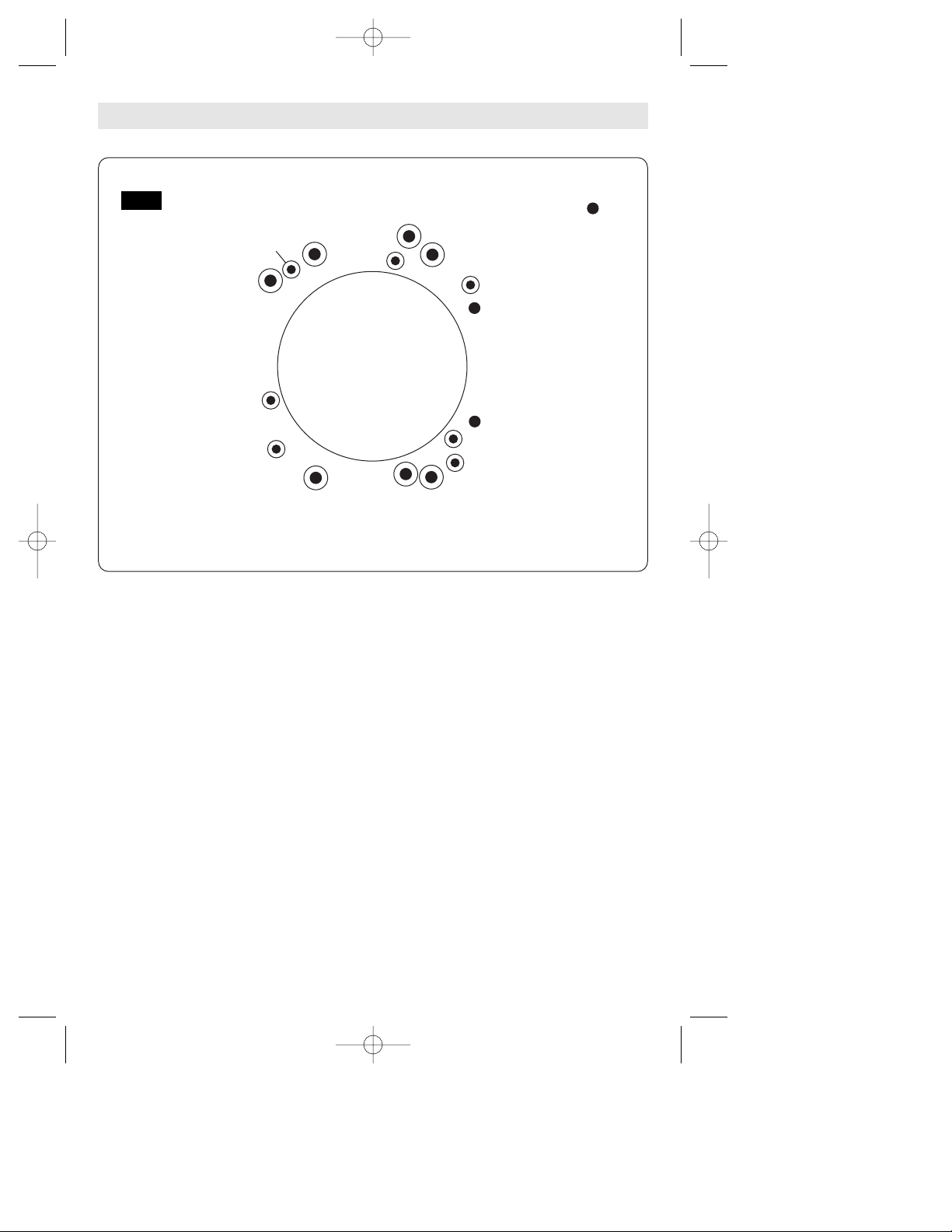

FIG. 6

BM 2610909346 5/03 5/12/03 11:52 AM Page 9

1601A, 1602A, 1604A, 1606A

1613 SERIES

1617 SERIES

1601A, 1602A, 1604A, 1606A

1619EVS

1619EVS

1617

SERIES

SERIES

1613 SERIES

1613

1619EVS

1601A, 1602A, 1604A, 1606A

STARTER PIN HOLE

STARTER PIN HOLE

1617 SERIES

1601A, 1602A, 1604A, 1606A

1619EVS

STARTER PIN

STORAGE HOLE

Page 10

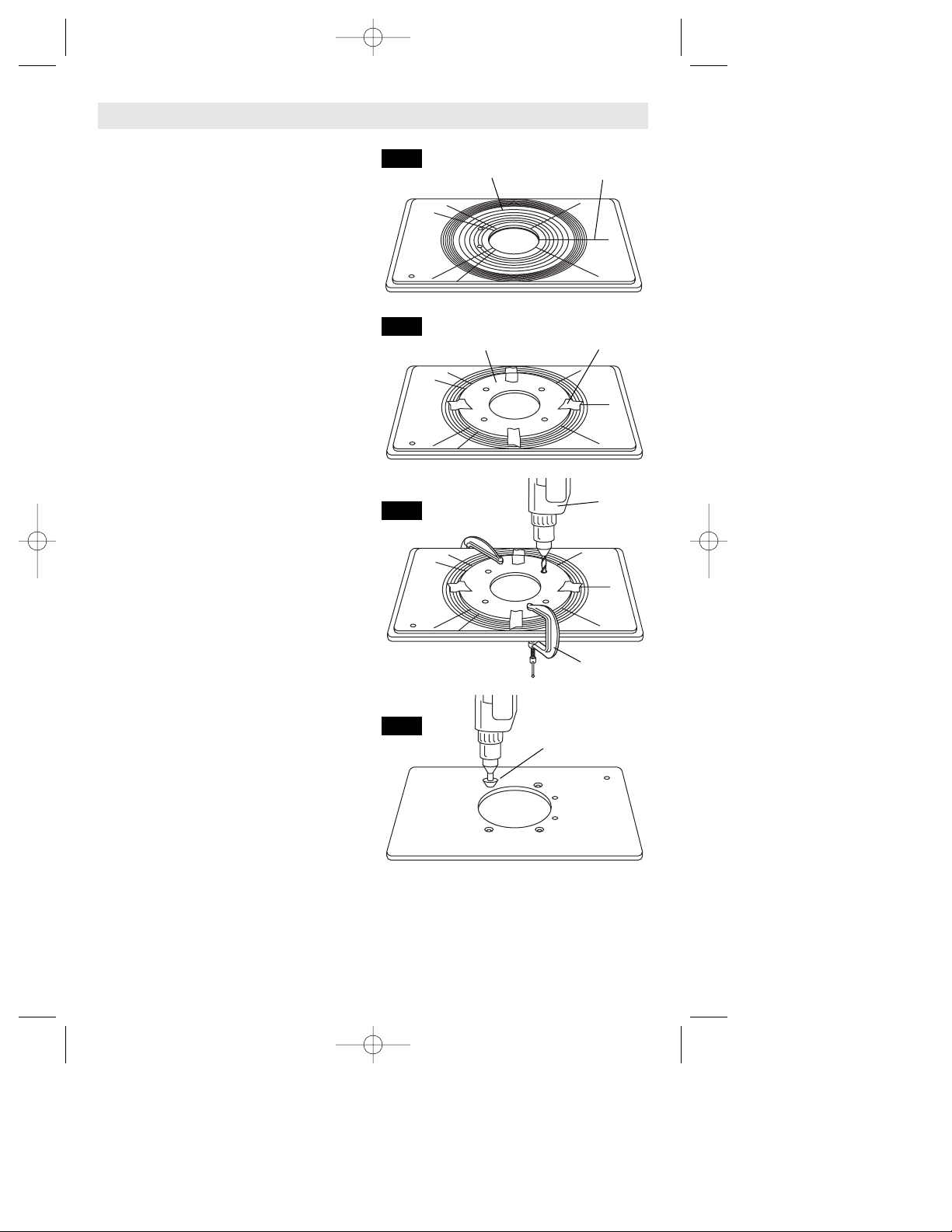

DRILLING HOLES IN THE

MOUNTING PLATE

(Only necessary if the holes in your router’s

base don’t line up with factory drilled holes in

the mounting plate.)

You can drill additional holes in the RA1200

mounting plate or purchase a blank RA1250

Bosch mounting plate from your Bosch dealer.

Your router’s sub-base will be your drilling

pattern.

1. Orient the mounting plate for drilling. The

bottom of the plate, which has concentric

rings, should be facing up. The guide-pin hole

should be just to the left of the opening. The

nearest edge of the plate is the front edge of

the plate. (Fig. 7)

2. Decide how you want your router positioned

under the table. These are the things to

consider:

• Location of router depth adjustment

controls

• Location of router speed control.

• Location of router depth lock lever.

• Location of router handles. If the router is

very large and you want to rotate it slightly

to allow the handles to easily fit though the

opening, make sure the handles will not hit

the table frame at any depth setting.

3. Remove router’s sub-base.

4. Using the concentric rings on the underside

of the mounting plate, center your router’s

sub-base. Line up the mounting holes on the

radial lines. Use tape to hold the sub-base in

position (Fig. 8).

Note: Make sure that the intended locations

for your mounting holes do not run into the

holes for the router table’s guide pin or the

factory-drilled mounting holes for Bosch

routers.

5. Firmly clamp the sub-base to the mounting

plate using no-mar wood clamps or "C"

clamps. To avoid any slippage, don’t use

spring clamps (Fig. 9).

6. Place a piece of scrap wood under the

mounting plate below drilling location. Drill

through the mounting plate using a drill bit of

the same size as the holes in your router’s

sub-base (Fig. 9).

7. Remove the clamps and sub-base. Turn the

mounting plate over.

8. Countersink the new holes using a singleflute countersink at a slow speed to achieve a

clean cut (Fig. 10). Use a drill press if

available. Make sure the screw heads are

sub-flush when installed.

-10-

FIG. 7

FIG. 9

FIG. 10

Router Table Assembly

FIG. 8

CONCENTRIC RINGS

ROUTER SUB-BASE

CLAMPS

SINGLE-FLUTE

COUNTERSINK

DRILL OR

DRILL

PRESS

RADIAL

LINES

TAPE

BM 2610909346 5/03 5/12/03 11:52 AM Page 10

Page 11

CONNECT THE ROUTER AND THE

ROUTER TABLE SWITCH

To prepare for use of the switch, (Fig. 12)

1. Make sure the router switch and the router

table switch are both turned off.

2. Plug the router table switch cord into wall

outlet.

3. Plug the router into the "pigtail" socket on the

router table switch.

4. Turn the router’s own switch to "ON" and

activate lock-on button, if it has one.

5. Use the router table switch to start and stop

the router.

This switch has a 15 amp rating and is intended

only for turning the router "ON" and "OFF". Do

not use it to operate additional equipment, such

as a vacuum cleaner.

-11-

Router Table Assembly

FIG. 11

FIG. 12

PLUG ROUTER INTO

THIS SOCKET

TABLE

POWER SWITCH

PLUG INTO

WALL OUTLET

DEPTH

ADJUSTMENT

INSTALL ROUTER/PLATE

IN ROUTER TABLE

1. Place the router/plate assembly into the

router table. Orient the mounting plate so that

the depth adjustment controls on the router

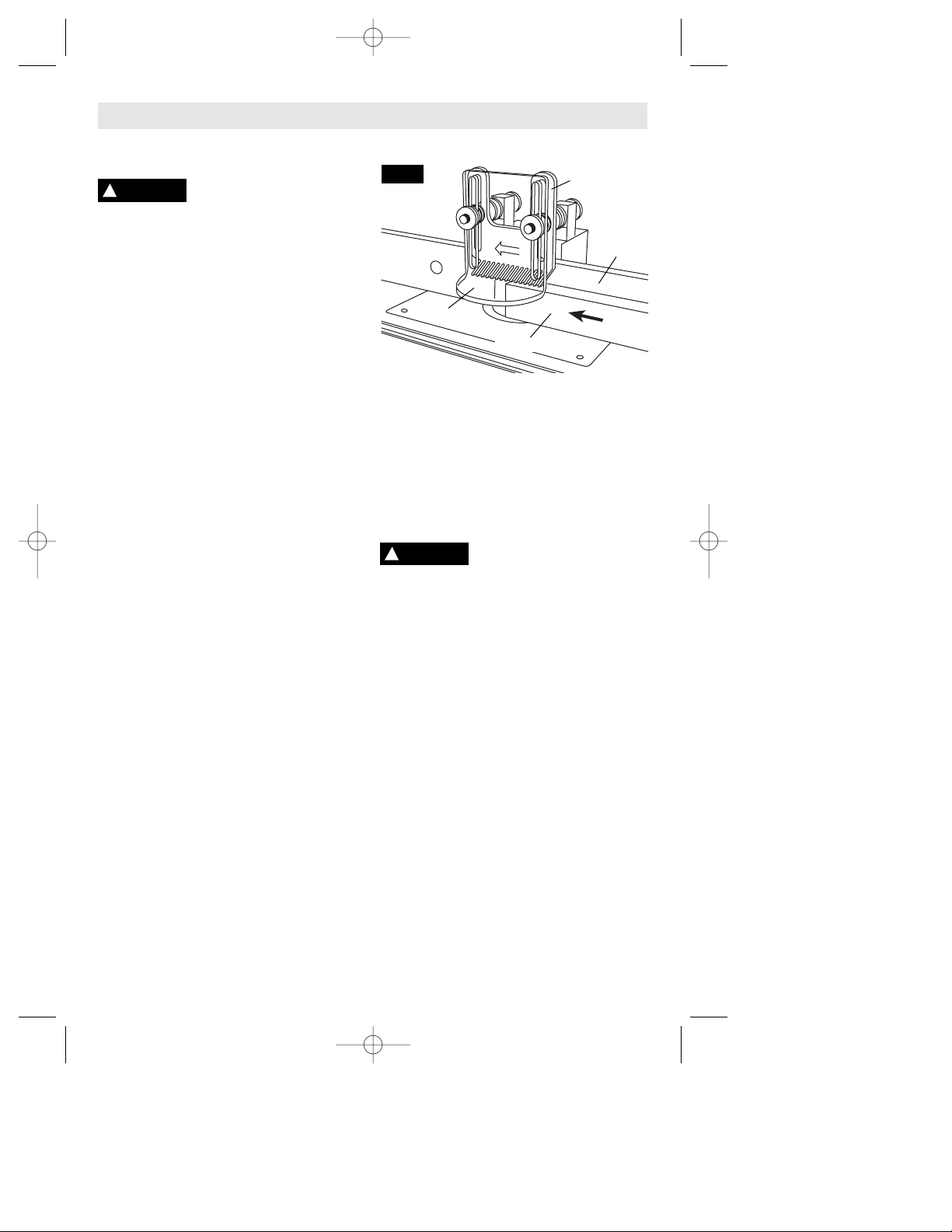

face the front side of the table (Fig. 11).

2. Install the six nylon mounting plate leveling

screws with springs into the six holes around

the mounting plate opening. Adjust the

mounting plate height so that it is level and

even with the table. A turn to the right raises

the mounting plate, and a turn to the left

lowers the plate. Mounting plate must be

level with table surface for proper

performance. Make sure that all of the

leveling screws are adjusted to be snug

against the mounting plate. (Fig. 11)

3. Assemble mounting plate snuggers using

10-24 screws and lock nuts to the four

corners of the mounting plate. To hold the

plate in position, push snuggers into corners

and tighten. (Fig. 11)

SNUGGER

LOCK

NUT

10-24 SCREW

LEVELING

SCREW

SPRING

BM 2610909346 5/03 5/12/03 11:52 AM Page 11

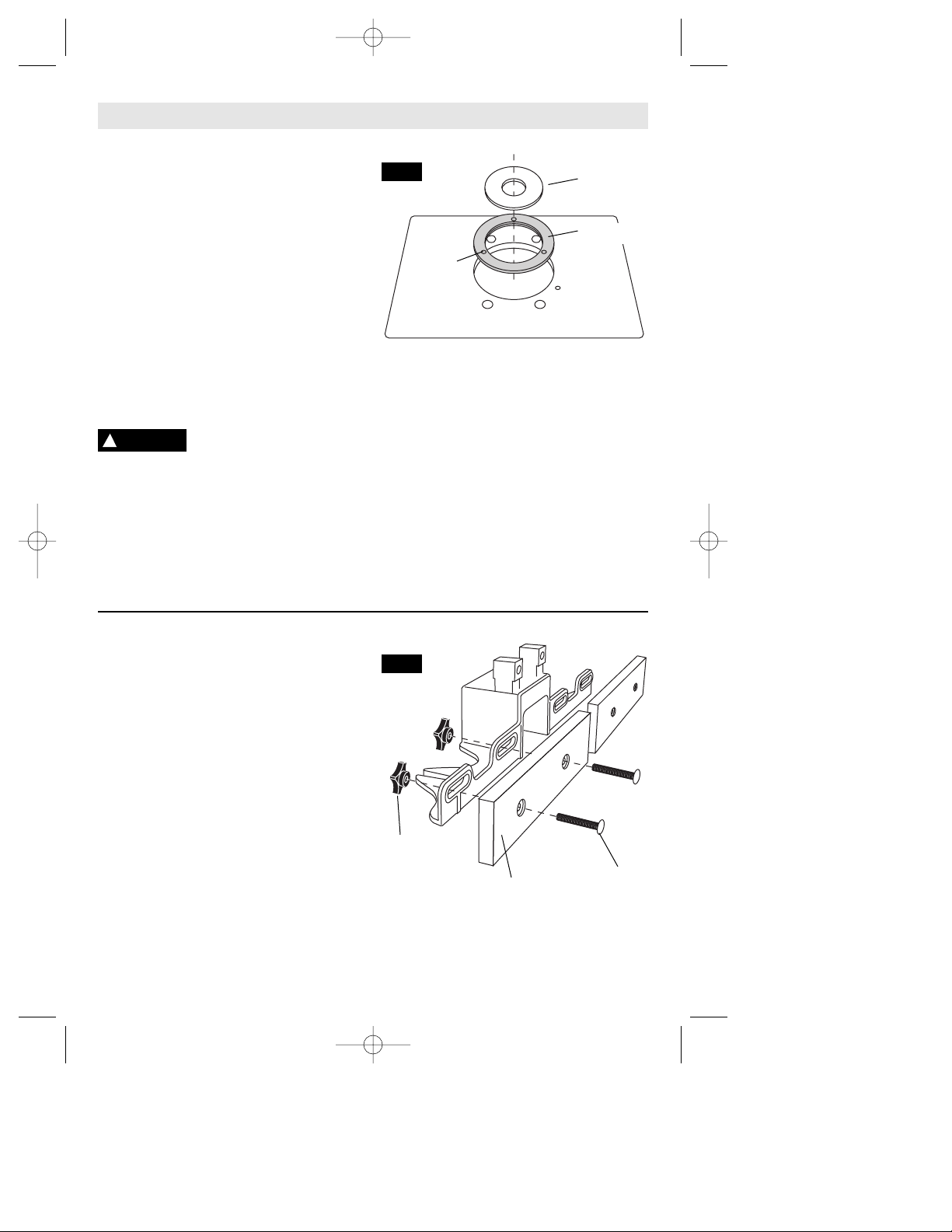

Page 12

ATTACHING FENCE FACES TO FENCE

Using 3/8" x 2" carriage bolts and black wing

knobs, tighten the fence faces against fence.

The fence faces are symmetrical and can be

installed on either side of the fence with either

end of the face facing center. (Fig. 14)

INSERT RINGS

When smaller diameter router bits are used, use

the mounting plate’s throat insert rings to

provide additional support to the workpiece as it

nears the bit and minimize the amount of debris

that falls through the throat opening. (Fig. 13)

The rings are designed to fit snugly to stay in

place and remain level. Considerable force may

be required to install and remove the rings.

• To insert the outer ring, press it into the

mounting plate. Make sure the tabs on the

ring goes into one of the notches in the

mounting plate.

• To insert the inner ring, press it into the outer

ring (considerable force may be required).

• To remove, tap out from the back side with a

soft mallet or piece of wood.

Don't pry them out or they

may be damaged. If you

want a slightly looser fit, lightly sand the outside

diameter of each ring.

• When removing the inner ring, it may be

necessary to press down on the outer ring.

-12-

Router Table Assembly

FIG. 14

FIG. 13

3/8" X 2"

CARRIAGE

BOLT

STARTER

PIN HOLES

OUTER RING

WING

KNOB

FENCE

FACE

INNER RING

!

CAUTION

BM 2610909346 5/03 5/12/03 11:52 AM Page 12

Page 13

VACUUM PORT

To minimize the amount of debris and dust in

the work area, always connect a vacuum

cleaner to the router table. The vacuum port

opening is sized to connect to standard 2-1/2"

vacuum hoses.

Orient the vacuum port such that the internal

positioning ribs are on the top and sides and the

warning is on the top. Attach vacuum port using

the two 10-24 screws. Insert the end of the hose

into the port. (Fig. 17)

Do not reach into area of

the bit while the router is

plugged in.

FIG. 15

THREADED ROD

KNURLED STEEL NUT

WASHERS

WASHERS

NUT

FEATHERBOARD

TOP VIEW

FENCE

CLEAR BIT GUARD

KNURLED STEEL NUTS

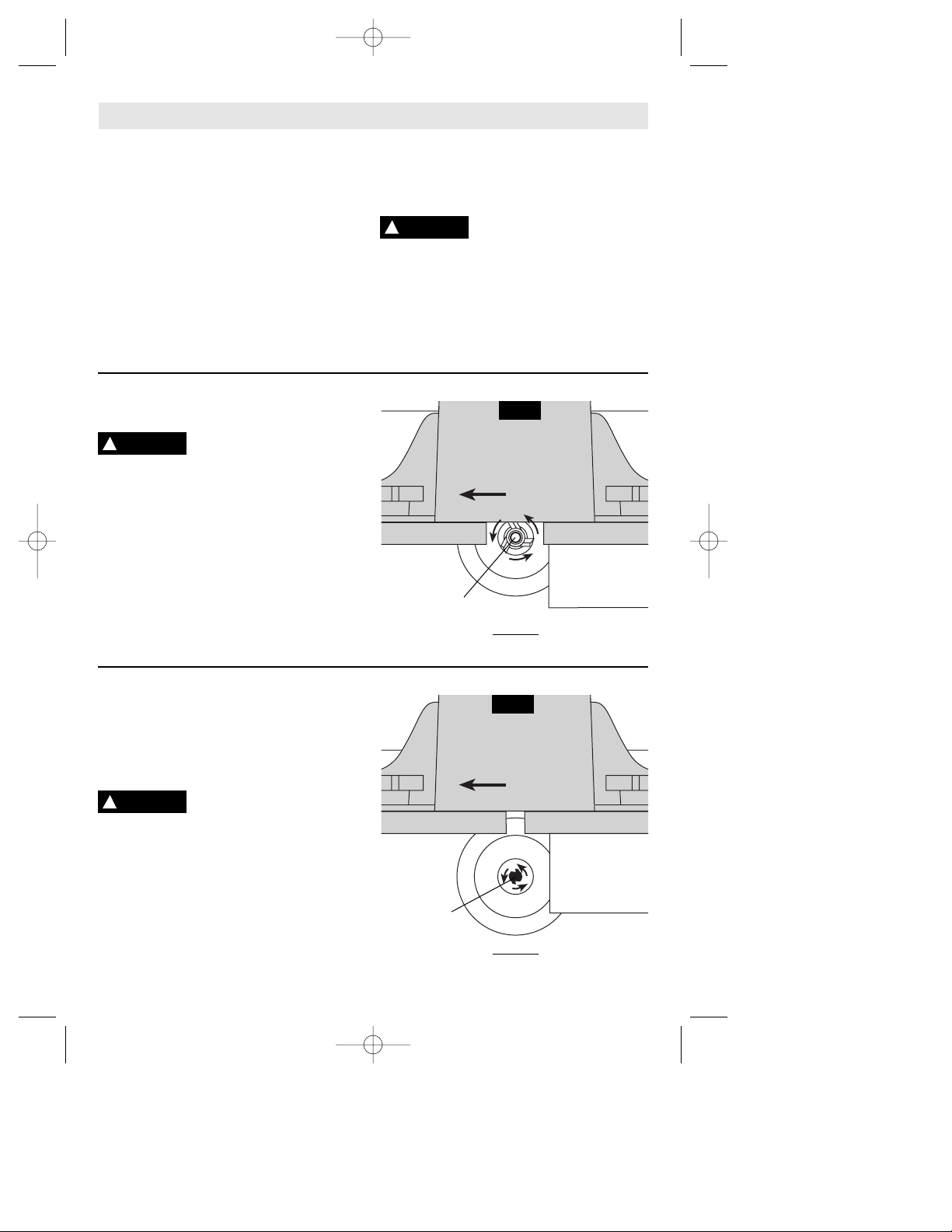

ASSEMBLE VERTICAL FEATHERBOARD

AND GUARD SYSTEM

This system makes it easy to correctly position

the clear bit guard and the vertical featherboard,

which helps keep the workpiece pressed

against the table and reduces the possibility and

intensity of kickback.

This system is especially beneficial when

routing small pieces. Following figures 15 & 16,

assemble the vertical featherboard and guard

system. Note in particular the orientation of

featherboard and the knurled steel knobs. The

“feathers” should point in the feed direction.

(The two featherboards are the same and either

one can be used as the vertical featherboard.)

-13-

Router Table Assembly

FIG. 17

FIG. 16

10-24

SCREWS

VACUUM PORT

FENCE

CLEAR BIT GUARD

FEED DIRECTION

FEATHER

BOARD

!

WARNING

BM 2610909346 5/03 5/12/03 11:52 AM Page 13

Page 14

PREPARING THE ROUTER TABLE FOR

TRANSPORTATION AND/OR STORAGE

To prepare the table for transportation and

storage:

1. Remove fence.

2. Remove the mounting plate and router.

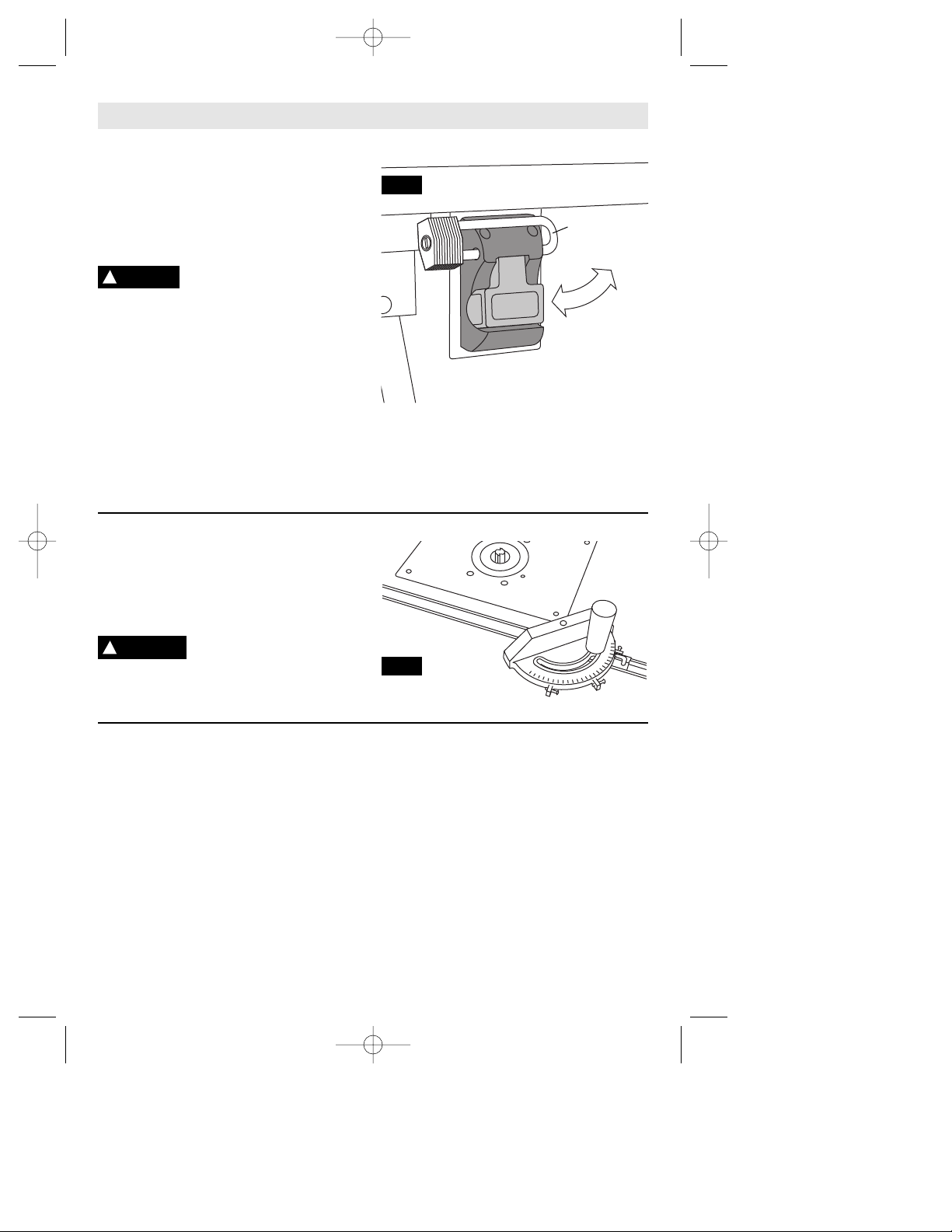

3. Fold up table legs: Make sure the cord stays

clear of the legs. Fold in the leg on the power

switch side first. Push in the leg brace lock

buttons, push leg braces in, then fold down

legs.

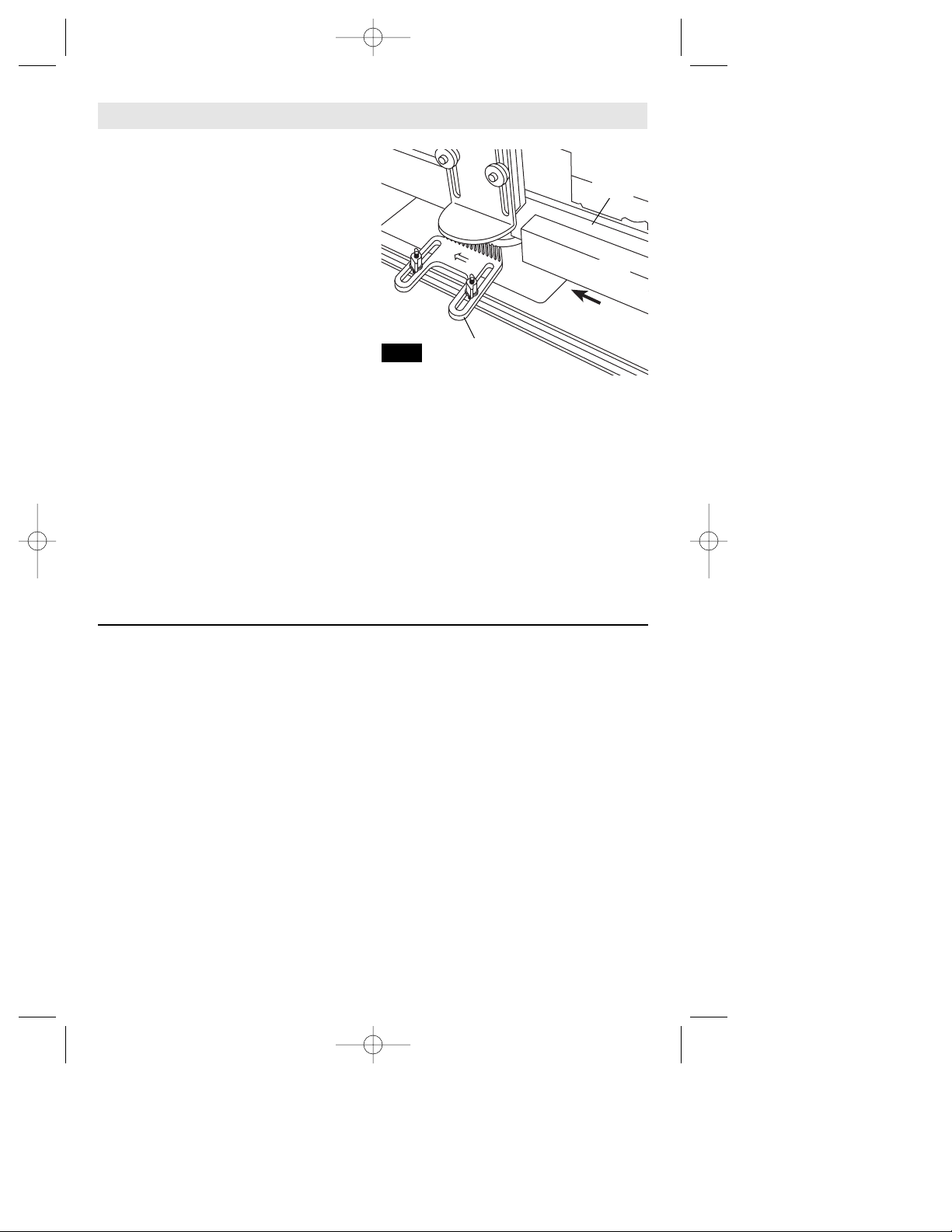

4. After removing the router for the mounting

plate, you can securely store the mounting

plate to the router table by using the back

end of the corner snuggers (Fig. 20)

HORIZONTAL FEATHERBOARD ASSEMBLY

The horizontal featherboard helps keep the

workpiece pressed against the fence and

reduces the possibility and intensity of kickback.

It is especially beneficial when routing small

pieces.

To install:

1. Screw a bolt into each of the two hex nuts so

that bolt heads are recessed and tightened

into the bottom of the nuts.

2. Slide the two hex nut and bolt assemblies

into the track from the right end. Attach the

second of the two matching featherboards to

the bolts using the nylon spacer washers and

small wing knobs. Position the feathers so

that they point in the feed direction (Fig. 19).

ATTACHING FENCE TO TABLE

Attach fence to table using the two 3/8" x 2-1/2"

carriage bolts and two wing knobs provided.

When securing the fence assembly in place, it

may be necessary to reach under the table to

provide finger pressure to stop the bolt from

spinning. Or you can tap each bolt with a mallet

so that its neck becomes slightly embedded in

the hole.

Figure 18 illustrates the assembled fence for

most operations, which uses the front set of

holes.

For making cuts in the middle of the workpiece,

such as slotting cuts, the fence can be mounted

using the rear set of holes.

Use extra caution when

positioning the fence for

slotting cuts, due to the increased exposure

of the spinning bit before and after the cut.

-14-

Router Table Assembly

FIG. 18

3/8" X 2-1/2"

CARRIAGE

BOLT

WING KNOB

FRONT HOLE

REAR HOLE

FIG. 20

!

WARNING

SNUGGER

MOUNTING PLATE

UNDERSIDE

OF TABLE

WING

KNOB

FEATHER

BOARD

FEED

DIRECTION

TRACK

HEX NUT

BOLT

WASHER

FIG. 19

BM 2610909346 5/03 5/12/03 11:52 AM Page 14

Page 15

Operating Instructions

-15-

POSITIONING THE FENCE FOR

EDGE FORMING STRAIGHT PIECES

For safe operation and

quality routing results when

edge-forming straight pieces, the workpiece,

fence, and router bit must be positioned

according to these guidelines:

• The workpiece must be positioned against

the fence faces and must slide smoothly

along the faces.

• If a piloted (or “bearing”) bit is used, the front

of the bearing should be even with the front

of the fence faces.

POSITIONING THE FENCE FOR

SLOTTING CUTS

Slotting cuts are made in the middle of the

workpiece, such as grooves and dados. Mount

the fence to the table using the front or rear set

of holes, as appropriate (Fig. 22).

For safe operation and

quality results when

slotting, the workpiece and router bit must

be positioned as follows:

• Only non-piloted bits can be used.

• The bit must not cut though the top of the

workpiece.

• Always feed the workpiece from right to left.

!

WARNING

!

WARNING

ROUTER PREPARATION

Install the desired bit into the router according

the router’s instructions. (It is often easier to do

this when the router and mounting plate

assembly have been removed from the router

table.)

Install or remove insert rings as appropriate to

minimize the opening without touching the

desired bit.

Adjust the router bit to the desired height

according the router’s instructions.

POSITIONING THE FENCE FACES

The fence faces can be moved left and right to

properly position the faces for the desired

operation. Loosen the fence face wing knobs.

For safe operation and to

avoid tear-out on the

workpiece, position the faces as closely as

possible to the bit without touching the bit.

Once the proper location has been determined,

secure the faces in place by tightening the wing

knobs behind the fence (Fig. 14).

Additional fence face sets are available from

your Bosch dealer.

!

WARNING

FIG. 21

FIG. 22

WORKPIECE

WORKPIECE

DIRECTION

OF FEED

DIRECTION

OF FEED

BIT

BEARING

NON-BEARING

BIT

TOP VIEW

TOP VIEW

FENCE FACE

FENCE FACE

FENCE FACE

FENCE FACE

BM 2610909346 5/03 5/12/03 11:52 AM Page 15

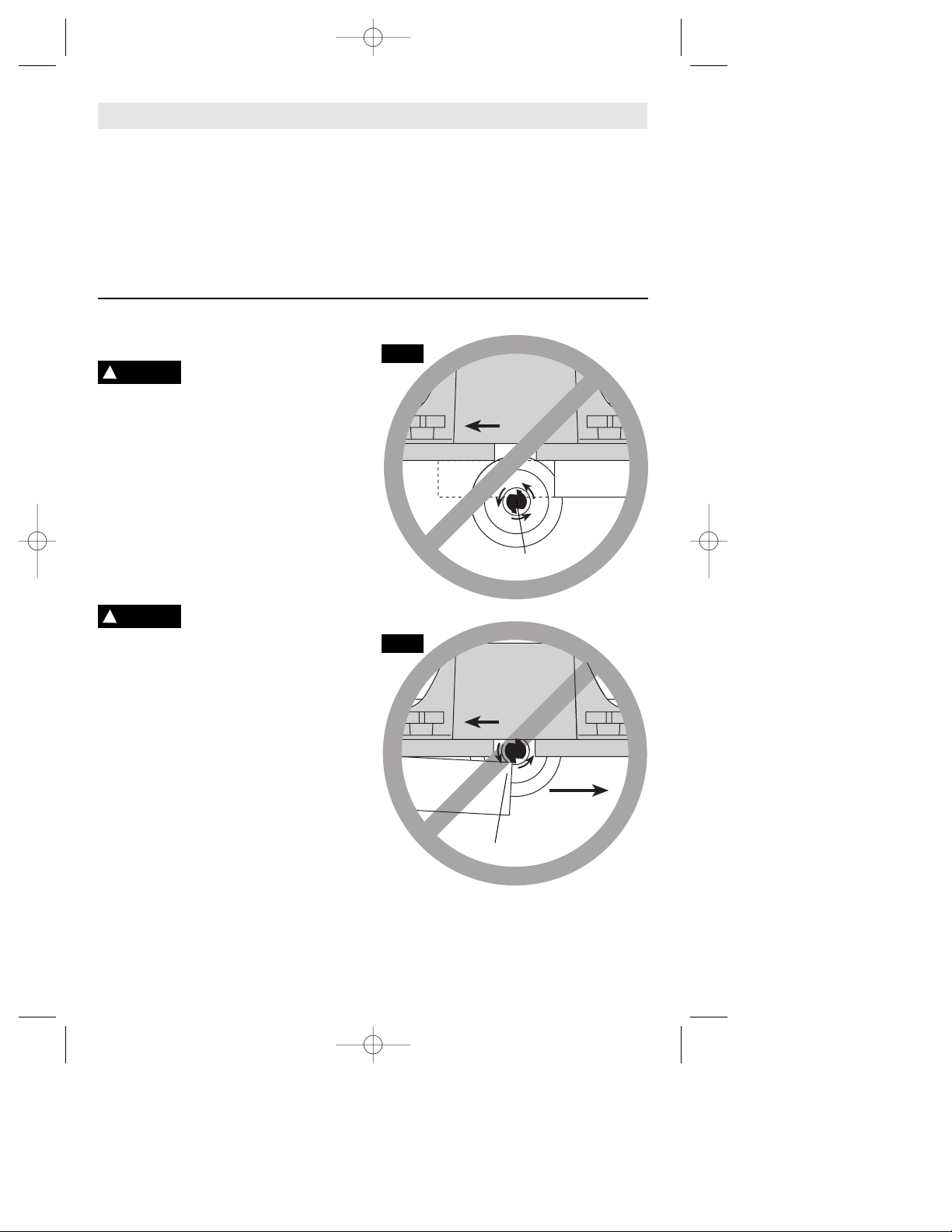

Page 16

IMPROPER FENCE LOCATION AND

WORKPIECE FEED

The fence and/or workpiece

are improperly located

anytime it would result in:

• The front of the bit is exposed during the

actual cutting (Fig. 23).

• “Climb-cutting” - The bit must not enter the

workpiece in the same direction as the feed

direction, which is likely to cause the

workpiece to "climb" and may lead to loss of

control during operation (Fig. 24).

"Fence Traps": One type of improper fence

location warrants special attention: "Fence

traps" happen when the fence is positioned so

far back that front side (power switch side) of

the workpiece would be behind the router bit.

Fence traps are dangerous

for two reasons:

• Exposure of the bit on the front side (power

switch side) of the workpiece.

• Likeliness of climb cut, which can cause loss

of control.

Figure 23 shows a fence trap.

Do not feed the workpiece from left to right:

(Fig. 24)

• It would cause climb-cutting.

• It would be difficult to keep the workpiece

against the fence faces because the bit

rotation would push the workpiece away from

the fence.

-16-

Operating Instructions

FIG. 23

FIG. 24

!

WARNING

!

WARNING

WORKPIECE

EXPOSED BIT

WORKPIECE

CLIMB-CUTTING

DIRECTION

OF FEED

CORRECT

DIRECTION

OF FEED

INCORRECT

DIRECTION

For slots that require multiple passes to achieve

the desired total width, make each subsequent

pass using a right-to-left feed. This helps push

the workpiece against the fence. Adjust the

fence and workpiece for subsequent passes as

follows:

- To widen the slot on the side that is on the

front side (power switch side), simply move

the fence farther back as required to widen

the slot.

- To widen the slot on the side that is closest to

the fence, first turn the workpiece around,

then move the fence farther back as required

to widen the slot.

BM 2610909346 5/03 5/12/03 11:52 AM Page 16

Page 17

POSITIONING THE VERTICAL

FEATHERBOARD AND BIT GUARD

The vertical featherboard

and guard are essential for

proper safety and performance and must

always be used (except when using the

starter pin and auxiliary guard instead of the

fence.)

Once the fence is secured in the desired

position, do the following:

1. Place the workpiece on the table against the

fence faces near the bit.

2. Loosen the knurled steel knobs in front and

back of the raised areas of fence housing to

allow the featherboard and guard to move

front-to-back.

3. Move the featherboard and guard assembly

forward or back as needed so that the

featherboard is centered over the cutting

area. When using small bits to route the edge

of the workpiece, this means the fence

should be placed against or near the fence

faces. For larger bits, the featherboard should

be positioned farther away from the fence.

4. Tighten the four knurled steel knobs against

the fence housing.

5. Loosen the knurled knobs behind the

featherboard.

6. Press the featherboard down enough to keep

the workpiece pressed against the table and

to create a slight drag on the workpiece.

7. While continuing to press down on the

featherboard, tighten the knurled steel knobs

to secure the featherboard at this level.

8. Loosen the front two sets of knurled steel

knobs

9. Lower the guard vertically about 1/8" above

the top of the workpiece.

10. Secure the guard with the front two sets of

knurled steel knobs.

Repeat steps 1-10 after any adjustments to the

bit, fence, or workpiece.

Before switching on the

router, make sure that all of

the knurled steel knobs on the featherboard

and guard are secured tightly so that

nothing moves unexpectedly or falls into the

spinning bit.

-17-

Operating Instructions

FIG. 25

!

WARNING

!

WARNING

GUARD

FEATHERBOARD

FEED

DIRECTION

FENCE

FACE

WORKPIECE

BM 2610909346 5/03 5/12/03 11:52 AM Page 17

Page 18

HORIZONTAL FEATHERBOARD

The horizontal featherboard greatly improves

performance and should be used whenever

possible (except when routing a workpiece that

is too wide to use the horizontal featherboard or

when using the starter pin and auxiliary guard

instead of the fence). It is especially beneficial

when routing small workpieces. (Fig. 26)

1. Loosen the featherboard wing knobs.

2. Move the horizontal featherboard assembly in

the track until the "feathers" are centered in

front of the bit.

3. Press the featherboard in against the

workpiece enough to keep the workpiece

pressed against the table and create a slight

drag on the workpiece.

4. While continuing to press on the

featherboard, tighten the small wing knobs to

secure the featherboard.

Two or more horizontal featherboard

assemblies placed at even intervals along the

miter slot provide enhanced guidance. This is

especially beneficial when routing long

workpieces and/or using large bits, such as

panel-raising bits. Additional featherboards

fasteners are available separately.

-18-

Operating Instructions

FIG. 26

FEATHERBOARD

FEED

DIRECTION

FENCE

FACE

WORKPIECE

FEEDING THE WORKPIECE

When using the fence, ALWAYS feed the

workpiece from right to left. The correct feed

direction is also shown on fence housing and on

the featherboards, when they have been

properly installed. (Fig. 25)

Whenever possible, use a push stick (not

included) to push the workpiece, especially

when working with narrow pieces.

(See "Using the Guide Pin for Edge Forming of

Curves" for details on feeding when guide pin is

used.)

RATE OF FEED

When routing or doing related work in wood and

plastics, the best finishes will result if the depth

of cut and feed rate keep the motor operating at

high speed. Feed the workpiece at a rate that

does not cause a significant change in the

router RMP. Soft materials require a faster feed

rated than hard materials.

The router may stall if improperly used or

overloaded. Reduce feed rate to prevent

possible damage to the tool.

BM 2610909346 5/03 5/12/03 11:52 AM Page 18

Page 19

ON-OFF SWITCH

Your router should be turned "ON" and "OFF"

using the router table switch.

This switch has a 15 amp rating is intended only

for turning the router "ON" and "OFF". Do not

use it to operate additional equipment, such as

a vacuum cleaner.

Always keep the workpiece

away from the bit when

turning the unit on or off. Contact the bit with

the workpiece only after the router has reached

the full desired speed, and remove the

workpiece before turning it off. Operating in this

manner will prolong switch and motor life and

will greatly increase the quality of your work.

Before turning the table’s switch on, make sure

router’s own switch is set to its "ON" position.

TO TURN THE TOOL "ON": Lift the switch to

turn the unit "ON".

TO TURN THE TOOL "OFF": Press the switch

in to turn it "OFF".

When the router table is not in use, we suggest

locking the switch in the off position with a lock

(not included).

-19-

Operating Instructions

OFFSETTING THE OUTFEED FENCE

AND JOINERY

When trimming the entire edge of a thin

workpiece, the outfeed fence face can be

moved forward to provide the necessary

support to prevent workpiece chatter. The

outfeed fence can also be moved forward for

joinery, which is the process of making flat,

square and straight mating edges.

Using a router table for jointing has several

advantages over other methods, such as using

a freestanding power jointer, though it cannot

completely replace a power jointer.

• Small and short pieces of wood can be safely

and successfully routed because the opening

between the faces can be adjusted down to a

minimum.

• Because routers spin much faster than typical

jointers, the cut quality is much better. This is

especially useful on types of woods that are

prone to tear-out.

Shims are provided to easily and accurately

position the outfeed fence forward and to

provide the necessary support.

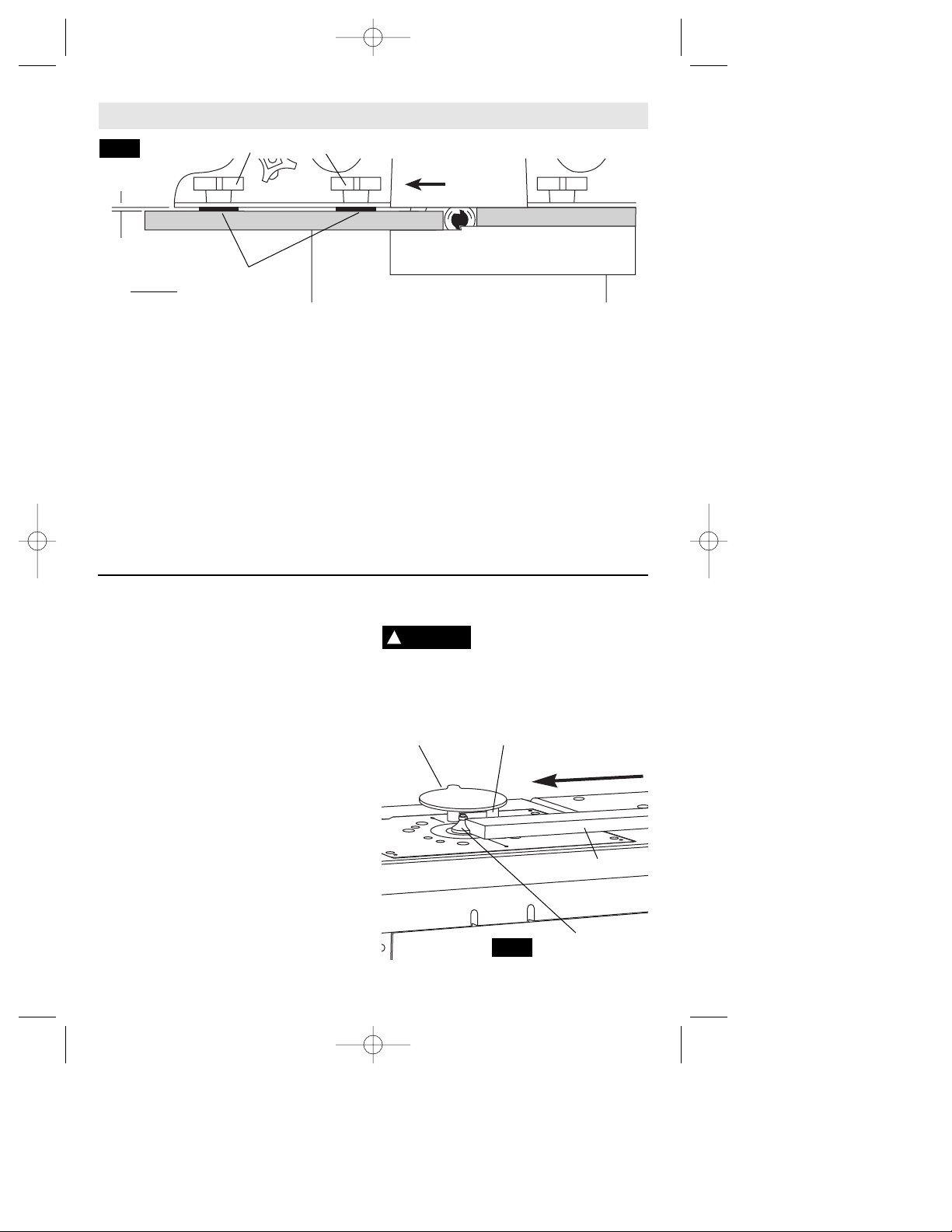

OPTIONAL MITER GAUGE

The Bosch table saw miter gauge can also be

inserted into the track in the middle of the table.

(A T-slot miter gauge can also be used.) A miter

guide will allow angled workpieces to be

precisely guided across the table. (Fig. 27)

Do not use the miter gauge

and the fence at the same

time.

30

45

60

75

90

75

60

45

30

FIG. 27

!

WARNING

FIG. 28

ON

OFF

LOCK

(NOT INCLUDED)

!

CAUTION

BM 2610909346 5/03 5/12/03 11:52 AM Page 19

Page 20

USING THE STARTER PIN FOR

EDGE FORMING OF CURVES

The starter pin is used instead of the fence for

operations that involve routing curves in the

workpiece. When edge forming curves or

complex shapes you must use bits that have

pilot bearings.

The red insert ring has a threaded brass insert

for attaching the auxiliary guard.

Attach the auxiliary guard to the mounting plate

by threading a #10-32x3/8” truss head machine

screw through the hole in the guard post and

into the threaded insert in the red insert ring.

Align the guard with the hole in the mounting

plate so it is over the bit and tighten.

• Always use the auxiliary guard when routing

with the starter pin.

• When using the starter pin, the feed direction

of the workpiece is always right to left across

the front of the bit (Fig. 30).

• Set the workpiece against the front of the

starter pin and swing it slowly into the bit.

• While routing, make sure the workpiece is

always in contact with the bit’s pilot bearing.

Always use the auxiliary

guard when routing with the

starter pin. Keep fingers at least 6” away

from spinning bit. Do not attempt to route

small workpieces. Serious injury can occur

if you contact the spinning bit.

-20-

Operating Instructions

PREPARING THE ROUTER AND

TABLE FOR OFFSET OUTFEED

1. Install a 1/2" diameter straight bit or spiral bit

in your router, because they are the strongest

bits and have the least potential for deflecting.

To further minimize the potential for

deflection, use a bit with the shortest possible

cutter height that is sufficient to do the job.

2. Loosen the outfeed fence knobs.

3. Slide both fence faces towards the bit to

minimize the space between the faces and

router bit.

4. To properly offset the outfeed fence,

determine the desired offset. Two (2) 1/32"

shims and four (4) 1/16" shims are included.

Place the desired combination of metal shims

over the outfeed fence bolts between the

fence faces and the aluminum fence. The

same shim configuration must be placed

behind each of the bolts.

5. Use a straight edge to ensure the front of

outfeed fence face is even with the front of

the router bit.

6. Tighten the fence clamping knobs. Readjust if

necessary. Remove straight edge when

done.

7. Tighten the vertical featherboard, bit guard,

and horizontal featherboard in the proper

positions.

8. Switch on the router and begin.

If the cut does not stay straight throughout the

entire length of the workpiece, stop the router and

realign the outfeed fence face to the router bit.

FIG. 29

WORKPIECE

FENCE FACE

FENCE FACE

TOP VIEW

FEED

DIRECTION

SHIMS

OUTFEED FENCE KNOBS

OFFSET

AUXILIARY

GUARD

STARTER

PIN

FEED

DIRECTION

WORKPIECE

PILOT

BEARING BIT

!

WARNING

FIG. 30

BM 2610909346 5/03 5/12/03 11:52 AM Page 20

Page 21

-21-

Service

Preventive maintenance

performed by unauthorized

personnel may result in misplacing of internal

wires and components which could cause

serious hazard. We recommend that all tool

service be performed by a Bosch Factory

Service Center or Authorized Bosch Service

Station.

Cleaning

To avoid accidents always

disconnect the tool from the

power supply before cleaning or performing

any maintenance. The tool may be cleaned

most effectively with compressed dry air.

Always wear safety goggles when cleaning

tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not attempt to clean by inserting pointed objects

through openings.

Certain cleaning agents and

solvents damage plastic

parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents,

ammonia and household detergents that contain

ammonia.

!

WARNING

!

WARNING

Maintenance

!

CAUTION

Accessories

If an extension cord is

necessary, a cord with

adequate size conductors that is capable of

carrying the current necessary for your tool

must be used. This will prevent excessive

voltage drop, loss of power or overheating.

Grounded tools must use 3-wire extension

cords that have 3-prong plugs and receptacles.

NOTE: The smaller the gauge number, the heavier

the cord.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

!

WARNING

Tool’s

Ampere

Rating

Cord Size in A.W.G.

Wire Sizes in mm

2

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Cord Length in Feet Cord Length in Meters

Featherboards *

Outfeed Shims *

Mounting Plate *

Corner Snuggers *

Fence Faces *

Routers **

Push Stick **

Miter Gauge **

Vacuum Hose **

Router Bits **

On/Off Switch *

(*= standard equipment)

(**= optional accessories)

BM 2610909346 5/03 5/12/03 11:52 AM Page 21

Page 22

-22-

Vous devez lire et comprendre toutes les instructions. Le non-respect, même partiel,

des instructions ci-après entraîne un risque de choc életrique, d'incendie et/ou de

blessures graves.

CONSERVEZ CES INSTRUCTIONS

AVERTISSEMENT

!

Aire de travail

Veillez à ce que l'aire de travail soit propre et bien

éclairée. Le désordre et le manque de lumière

favorisent les accidents.

N'utilisez pas d'outils électriques dans une

atmosphère explosive, par exemple enprésence de

liquides, de gaz ou de poussières inflammables. Les

outils électriques créent des étincelles qui pourraient

enflammer les poussières ou les vapeurs.

Tenez à distance les curieux, les enfants et les

visiteurs pendant que vous travaillezavec un outil

électrique. Ils pourraient vous distraire et vous faire

faire une fausse manoeuvre.

Sécurité électrique

Les outils à double isolation sont équipés d'une

fiche polarisée (une des lames est pluslarge que

l'autre), qui ne peut se brancher que d'une seule

façon dans une prise polarisée. Si la fiche n'entre

pas parfaitement dans la prise, inversez sa position

; si elle n'entre toujours pasbien, demandez à un

électricien qualifié d'installer une prise de courant

polarisée. Ne modifiez pas la fiche de l'outil. La

double isolation élimine le besoin d'un cordon

d'alimentationà trois fils avec mise à la terre ainsi que

d'une prise de courant mise à la terre. Avant de

brancher l'outil, assurez-vous que la tension de la

prise correspond, à celle indiquée sur la plaque

signalétique. N'utilisez pas d'outils prévus pour

courant alternatif seulement avec une source de

courant continu.

Évitez tout contact corporel avec des surfaces mises

à la terre (tuyauterie, radiateurs, cuisinières,

réfrigérateurs, etc.). Le risque de choc électrique est

plus grand si votre corps est encontact avec la terre.Si

l'utilisation de l'outil électrique dans un endroit

humide est inévitable, un disjoncteur de fuite à la terre

doit être utilisé pour alimenter votre outil. Des

chaussures et des gants en caoutchouc d'électricien

contribueront à accroître davantage votre sécurité

personnelle.

N'exposez pas les outils électriques à la pluie ou à

l'eau. La présence d'eau dans un outil électrique

augmente le risque de choc électrique.

Ne maltraitez pas le cordon. Ne transportez pas

l'outil par son cordon et ne débranchez pas la fiche

en tirant sur le cordon. N'exposez pas le cordon à la

chaleur, à des huiles, à des arêtes vives ou à des

pièces en mouvement. Remplacez immédiatement

un cordon endommagé. Un cordon endommagé

augmente le risque de choc électrique.

Lorsque vous utilisez un outil électrique à

l'extérieur, employez un prolongateur pour

l'extérieur marqué « W-A » ou « W ». Ces cordons

sont faits pour être utilisés à l'extérieur et réduisent le

risque de choc électrique. Reportez-vous aux «

Dimensions recommandées des cordons de rallonge

» dans la section Accessoires de ce manuel.

Sécurité des personnes

Restez alerte, concentrez-vous sur votre travail et

faites preuve de jugement. N'utilisez pas un outil

électrique si vous êtes fatigué ou sous l'influence de

drogues, d'alcool ou de médicaments. Un instant

d'inattention suffit pour entraîner des blessures

graves.

Habillez-vous convenablement. Ne portez ni

vêtements flottants ni bijoux. Confinez les cheveux

longs. N'approchez jamais les cheveux, les

vêtements ou les gants des pièces en mouvement.

Des vêtements flottants, des bijoux ou des cheveux

longs risquent d'être happés par des pièces en

mouvement. Gardez les poignées sèches, propres et

exemptes d'huile et de graisse.

Méfiez-vous d'un démarrage accidentel. Avant de

brancher l'outil, assurez-vous que son interrupteur

est sur ARRÈT. Le fait de transporter un outil avec le

doigt sur la détente ou de brancher un outil dont

l'interrupteur est en position MARCHE peut mener tout

droit à un accident.

Enlevez les clés de réglage ou de serrage avant de

démarrer l'outil. Une clé laissée dans une pièce

tournante de l'outil peut provoquer des blessures.

Ne vous penchez pas trop en avant. Maintenez un

bon appui et restez en équilibre entout temps. Un

bonne stabilité vous permet de mieux réagir à une

situation inattendue.

Utilisez des accessoires de sécurité. Portez toujours

des lunettes ou une visière. Selon les conditions,

portez aussi un masque antipoussière, des bottes de

sécurité antidérapantes, un casque protecteur et/ou un

appareil antibruit.

Utilisation et entretien des outils

Immobilisez le matériau sur une surface stable au

moyen de brides ou de toute autre façon adéquate.

Le fait de tenir la pièce avec la main ou contre votre

corps offre une stabilité insuffisante et peut amener un

dérapage de l'outil.

Ne forcez pas l'outil. Utilisez l'outil approprié à la

tâche. L'outil correct fonctionne mieux et de façon

plus sécuritaire. Respectez aussi la vitesse de travail

qui lui est propre.

Règles de Sécurité Générales

BM 2610909346 5/03 5/12/03 11:52 AM Page 22

Page 23

-23-

N'utilisez pas un outil si son interrupteur est bloqué.

Un outil que vous ne pouvez pas commander par son

interrupteur est dangereux et doit être réparé.

Débranchez la fiche de l'outil avant d'effectuer un

réglage, de changer d'accessoire oude ranger

l'outil. De telles mesures préventives de sécurité

réduisent le risque de démarrage accidentel de l'outil.

Rangez les outils hors de la portée des enfants et

d'autres personnes inexpérimentées. Les outils sont

dangereux dans les mains d'utilisateurs novices.

Prenez soin de bien entretenir les outils. Les outils

de coupe doivent être toujours bien affûtés et

propres. Des outils bien entretenus, dont les arêtes

sont bien tranchantes, sont moins susceptibles de

coincer et plus faciles à diriger.Toute altération ou

modification constitue un usage erroné et peut causer

un danger.

Soyez attentif à tout désalignement ou coincement

des pièces en mouvement, à tout bris ou à toute

autre condition préjudiciable au bon fonctionnement

de l'outil. Si vous constatez qu'un outil est

endommagé, faites-le réparer avant de vous en

servir. De nombreux accidents sont causés par des

outils en mauvais état. Élaborez un calendrier

d'entretien périodique de votre outil.

N'utilisez que des accessoires que le fabricant

recommande pour votre modèle d'outil. Certains

accessoires peuvent convenir à un outil, mais être

dangereux avec un autre.

Réparation

La réparation des outils électriques doit être confiée

à un réparateur qualifié. L'entretien ou la réparation

d'un outil électrique par un amateur peut avoir des

conséquences graves. Ainsi, des fils internes peuvent

être mal placés ou pincés, des ressorts de rappel de

protecteur peuvent être montés erronément.

Pour la réparation d'un outil, n'employez que des

pièces de rechange d'origine. Suivez les directives

données à la section « Réparation » de ce manuel.

L'emploi de pièces non autorisées ou le non-respect

des instructions d'entretien peut créer un risque de

choc électrique ou de blessures. Certains agents

nettoyants tels qu'essence, tétrachlorure de carbone,

ammoniac, etc., peuvent abîmer les pièces en

plastique.

BM 2610909346 5/03 5/12/03 11:52 AM Page 23

Page 24

-24-

Veuillez lire et comprendre le mode d’emploi de

votre machine et les instructions d’utilisation de

cette table avec votre défonceuse. Si vous ne

respectez pas toutes les consignes qui suivent, vous

risquez des blessures corporelles graves.

Débranchez la machine avant de déployer la table,

de faire des réglages ou de changer de fer. Tout

démarrage intempestif de la machine risque de causer

des blessures.

Assemblez complètement et serrez tous les

éléments de fixation de cette table et ceux requis

pour y monter la défonceuse. N’oubliez pas

également de contrôler périodiquement le pied pour

vous assurer qu’il est toujours serré. Desserré, il

serait instable et risquerait de bouger pendant

l’utilisation, ce qui pourrait causer des blessures

graves.

Avant toute utilisation, assurez-vous que l’unité est

entièrement positionnée sur une surface ferme,

plate et de niveau. Il y a risque de blessures graves

si la machine est instable et bascule.

Ne montez jamais sur la table et ne vous en servez

jamais comme échelle ou échafaudage. Il y a

risque de blessure grave si la table bascule ou si vous

touchez accidentellement le fer. Ne stockez pas de

matériaux sur la table ou à proximité de celle-ci de

telle sorte qu’il serait nécessaire de grimper sur la

table ou sur son pied pour les atteindre.

N’utilisez jamais de fer émoussé ou abîmé.

Manipulez les fers aiguisés avec précaution. Les

fers abîmés risquent de casser pendant l’utilisation.

Les fers émoussés nécessitent qu’on pousse plus fort

sur la pièce ce qui risque de les briser.

Utilisez le fer et la vitesse qui conviennent à la

tâche à effectuer. N’utilisez pas de fer dont le

diamètre est supérieur à la capacité de la machine.

Il y a risque de blessure grave ou de panne de la

machine si celle-ci est surchargée.

Ne démarrez jamais la machine avec le fer en

contact avec la pièce. Le tranchant du fer risque de

happer la pièce, et vous pourriez en perdre le

contrôle.

Les fers de défonceuse sont conçus exclusivement

pour le bois, les produits à base de bois et les

plastiques. Vérifiez que la pièce ne contient aucun

clou etc. avant de toupiller. Si on coupe un clou ou

similaire, les pastilles carbure risquent de se déloger,

d’être projetées vers l’utilisateur et de le frapper ou de

frapper un tiers.

Poussez la pièce contre le sens de rotation du fer.

Le fer tourne en sens anti-horaire vu du dessus de

la table. Si on pousse la pièce dans le mauvais sens,

elle risque d’être happée par le fer, ce qui peut

résulter en une perte de contrôle pendant le

toupillage.

N’approchez jamais les mains du fer en rotation.

Utilisez des baguettes pour pousser la pièce, des

planches en éventail montées horizontalement ou

verticalement (planches à ressort) ou d’autres

montages pour la tenir afin de maintenir vos mains

à distance du fer en rotation. Lors du toupillage le

fer ne dépasse pas de la planche mais il dépasse

quand même de la table et il est important de toujours

connaître la position de vos mains par rapport au fer

en rotation.

Nous vous conseillons de ne pas toupiller de pièces

déformées, tordues ou autrement instables. Si

vous ne pouvez pas faire autrement, toupillez

toujours la pièce avec le côté concave tourné vers

le bas (contre la table). Si on toupille avec le côté

concave tourné vers le haut (opposé à la table), la

pièce déformée ou tordue risque de rouler et de

causer une perte de contrôle. Il y a risque de rebond

et de blessures corporelles graves.

Utilisez le guide réglable pour les toupillages

droits. Lors du toupillage le long d’un chant d’une

pièce, le guide et le coin de support réglables

permettent de stabiliser la pièce.

Si vous utilisez la table sans le guide, il faut utiliser

des fers pilotés (ou fers à roulement). Les fers

pilotés sont utilisés pour toupiller des contours

internes ou externes sur une pièce. Le roulement des

fers pilotés permet de maintenir le contrôle de la

pièce. Autant que possible, il faut également utiliser le

goujon d’appui.

Après avoir changé de fer ou effectué un réglage,

assurez-vous que l’écrou de douille et tous les

systèmes de réglages sont fermement serrés.

Desserré, un système de réglage risque de bouger de

manière inattendue, résultant en une perte de

contrôle. Quant aux pièces tournantes desserrées,

elles risquent d’être violemment éjectées.

Ne touchez jamais le fer pendant l’utilisation ou

immédiatement après. Vous vous blesseriez si vous

touchiez un fer en rotation. Après usage, le fer est

trop chaud pour pouvoir le toucher à main nue.

Utilisez exclusivement des pièces de rechange

Bosch. Toute autre pièce risque de présenter un

danger.

Consignes de sécurité pour table de toupillage

BM 2610909346 5/03 5/12/03 11:52 AM Page 24

Page 25

-25-

Symboles

IMPORTANT : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et

apprendre leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de

façon plus efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules,

etc.

n

0

Vitesse à vide Vitesse de rotation, à vide

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

minute etc., par minute

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de

l, ll, lll, ... position. Un nombre plus élevé signifie

une vitesse plus grande.

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif Type ou caractéristique du courant

ou continu

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre Borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

d'avertissement.

Sceau Ni-Cad RBRC™ Désigne le programme de recyclage des piles

Ni-Cad.

0

Ce symbole signifie que cet

outil est approuvé par

Underwriters Laboratories.

Ce symbole signifie que cet

outil est approuvé par

l'Association canadienne de

normalisation.

Ce symbole signifie que

cet outil est approuvé

conformément aux normes

canadiennes par Underwriters

Laboratories.

Ce symbole

signifie que

cet outil se

conforme aux

normes

mexicaines

NOM.

Ce symbole signifie que cet outil

est approuvé par Underwriters

Laboratories et qu’il a été

homologué selon les normes

canadiennes par Underwriters

Laboratories.

BM 2610909346 5/03 5/12/03 11:52 AM Page 25

Page 26

Numéro de modèle : RA1200

Tension nominale : 120 V 60Hz

Courant nominal : 15 A

POUR L'USAGE AVEC LES MODÈLES DE

DÉTOUREUSE BOSCH:

1601A, 1602A, 1604A, 1606A, 1613, 1613EVS,

1613AEVS, 1617, 1617EVS, 1613AEVS, 1617,

1617EVS, et 1619EVS.

OUTILS NECESSAIRES :

AVANT D’ASSEMBLER VOTRE TABLE DE

TOUPILLAGE :

Triez et comptez toutes les pièces pour vous assurer

que vous avez tous les matériaux nécessaires à

l’assemblage de la table. Ne jetez pas les matériaux

d’emballage avant d’avoir compté toutes les pièces.

PIÈCES POUR L’ASSEMBLAGE DE LA TABLE

Qté Description de la pièce

(1) Ensemble de table

(1) Interrupteur d’alimentation

(2) Vis de l’interrupteur

(6) Vis de mise à niveau en nylon

(6) Ressort

PIÈCES POUR MONTER LA DEFONCEUSE

Qté Description de la pièce

(1) Plaque de montage

(4) Vis à machine 1/4 po –20 x 1-1/2 po

(4) Rondelle de 1/4 po

(4) Ecrou de 1/4 po

(4) Vis à machine de 4 mm x 20 mm

(4) Vis à machine No 10-24 x 3/4 po

(4) Bride de coin

(4) Vis No 10-24

(4) Ecrou de blocage

PIÈCES POUR L’ASSEMBLAGE DU GUIDE

Qté Description de la pièce

(1) Guide en aluminium

(2) Contre-guide

(4) Boulon à tête ronde de 3/8 po x 2 po

(6) Bouton à ailette femelle de 3/8 po

(2) Boulon à tête ronde de 3/8 po x 2-1/2 po

(2) Cale de 1/32 po

(4) Cale de 1/16 po

(1) Raccord d’aspiration

(2) Vis No 10-24 du raccord d’aspiration

(1) Capot transparent du fer

(2) Planche en éventail

(2) Tige filetée

(8) Ecrou moleté en acier

(2) Ecrou

(8) Rondelle

AUTRES PIÈCES D’ASSEMBLAGE

Qté Description de la pièce

(2) Anneaux réducteurs

(1) Goujon d’appui

(2) Montez de planche en éventail

(2) Rondelle entretoise en nylon

(2) Bouton à ailette de 1/4 po.

(1) Capot auxiliaire

-26-

Assemblage de la table de toupillage

Tournevis Phillips (cruciforme)

Clé à molette

BM 2610909346 5/03 5/12/03 11:52 AM Page 26

Page 27

-27-

MONTAGE DE L’INTERRUPTEUR D’ALIMENTATION

Posez la table à l’envers sur une surface lisse. Placez

les trous du support de l’interrupteur en face des

avant-trous situés sous la table à sa partie avant.

L’interrupteur rouge doit être tourné vers l’extérieur.

Enfilez les deux vis à bois No 10 par les trous du

support et à l’aide d’un tournevis Phillips No 2,

vissez-les dans les avant-trous pour fixer

l’interrupteur. Ne serrez pas top fort pour éviter de

foirer les trous. (Fig. 1).

DEPLIAGE DE LA TABLE

1. Dépliez les pieds de la table à fond de manière à ce

que les renforcements des pieds s’enclenchent

dans leur position verrouillée (Fig. 2).

2. Placez-vous à l’avant ou à l’arrière de la table.

3. Servez-vous de l’orifice de la plaque de montage et

du bord inférieur du dessus de table pour relever la

table et la remettre à l’endroit.

4. Positionnez la table sur une surface de niveau ou

quasiment de niveau. Stabilisez-la en vissant ou en

dévissant la vis de mise à niveau de manière à ce

que les quatre pieds touchent le sol. La table ne

doit pas branler ou pouvoir basculer (Fig. 3).

Assemblage de la table de toupillage

FIG. 1

FIG. 2

FIG. 3

INTERRUPTEUR

D’ALIMENTATION

INTERRUPTEUR

D’ALIMENTATION

TABLE

SUPPORTS DE PIED

VIS DE MISE À NIVEAU

AVANTTROUS

VIS À BOIS

NO 10

BM 2610909346 5/03 5/12/03 11:52 AM Page 27

Page 28

-28-

MONTAGE DE LA DEFONCEUSE SUR LA

PLAQUE DE MONTAGE

1. Enlevez la sous-embase noire en phénolique de

votre défonceuse Bosch (Fig. 4).

2. Si votre défonceuse est dotée de son propre

capuchon d’aspiration monté sur le dessus de

l’embase en métal de la défonceuse et que vous

désirez l’utiliser sous la table de toupillage, c’est le

moment de l’installer.

3. A l’aide du tableau ci-dessous, déterminez la

boulonnerie (fournie) nécessaire et le type de

montage convenant à votre défonceuse Bosch.

• Pour les défonceuses des gammes 1601A,

1602A, 1604A, 1606A, et 1617 les vis se vissent

dans les trous taraudés de l’embase de la

défonceuse (montage de type 1).

• Pour les défonceuses des gammes 1613 et

1619, les vis traversent complètement l’embase

et sont maintenues à l’aide de rondelles et

d’écrous (montage de type 2).

Le dessus et l’avant de la plaque de montage sont

déterminés par la position des trous du goujon

d’appui. Ces trous se trouvent à droite de l’ouverture

pratiquée pour le fer.

4. Veuillez-vous référer à l’illustration de la plaque de

montage (Fig. 6) à la page 9 et alignez les trous de

la plaque de montage convenant à votre

défonceuse Bosch en face de ceux de l’embase de

la défonceuse. Assurez-vous que les systèmes de

réglage de la profondeur de votre défonceuse sont

tournés vers l’avant de la plaque de montage.

Assemblage de la table de toupillage

FIG. 4

FIG. 5

ENLEVEZ LA

SOUS-EMBASE

REGLAGE DE

PROFONDEUR

Modèle de Boulonnerie Type de

défonceuse Bosch nécessaire Montage

1601A, 1602A, 4 vis à machine Phillips

1

1604A, 1606A 4 mm x 20 mm

1613,

3 écrous, rondelles et vis à machine

1613EVS,

Phillips de 1/4 po -20 x 1-1/2 po

2

1613AEVS

1617, 3 vis à machine Phillips

1

1617EVS, No 10-24 x 3/4 po

1619EVS 4 écrous, rondelles et vis à machine

Phillips de 1/4 po – 20 x 1-1/2 po

2

MONTAGE DE TYPE 1

MONTAGE DE TYPE 2

PLAQUE DE MONTAGE

EMBASE DE LA

DEFONCEUSE

PLAQUE DE MONTAGE

EMBASE DE LA

DEFONCEUSE

BM 2610909346 5/03 5/12/03 11:53 AM Page 28

Page 29

-29-

Assemblage de la table de toupillage

DESSUS AVANT DE LA PLAQUE

FIG. 6

TROUS DE

RANGEMENT DU

GOUJON D’APPUI

5. Fixez votre défonceuse Bosch sur la plaque de

montage (Fig. 5).

6. Après avoir fixé la défonceuse à la plaque de

montage, installez le fer désiré selon les

instructions se trouvant au mode d’emploi de la

défonceuse.

TROUS DE GOUJON D’APPUI

TROUS DE GOUJON D’APPUI

BM 2610909346 5/03 5/12/03 11:53 AM Page 29

1613 SERIES

1601A, 1602A, 1604A, 1606A

1613 SERIES

1619EVS

1617

SERIES

1617 SERIES

1601A, 1602A, 1604A, 1606A

1619EVS

1613

SERIES

1619EVS

1601A, 1602A, 1604A, 1606A

STARTER PIN HOLE

STARTER PIN HOLE

1617 SERIES

1601A, 1602A, 1604A, 1606A

1619EVS

STARTER PIN

STORAGE HOLE

Page 30

-30-

PERÇAGE DE TROUS DANS LA PLAQUE

DE MONTAGE

(Nécessaire uniquement si les trous de l’embase de

votre défonceuse ne tombent pas en face des trous

percés en usine dans la plaque de montage.)

Il est possible de percer des trous supplémentaires dans

la plaque de montage RA1200 ou d’acheter une plaque

de montage Bosch non percée RA1250 auprès de votre

revendeur Bosch.

La sous-embase de votre défonceuse vous servira de

gabarit de perçage.

1. Orientez la plaque de montage pour la percer. Le

dessous de la plaque doté d’anneaux concentriques

doit être tourné vers le haut. Le trou du goujon

d’appui doit être juste à gauche de l’orifice. Le bord

avant de la plaque est vers vous. (Fig. 7)

2. Décidez de la position de votre défonceuse sous la

table. Il vous faut considérer ce qui suit :

• L’emplacement des systèmes de réglage de la

profondeur de la défonceuse.

• L’emplacement de la commande de vitesse de la

défonceuse.

• L’emplacement du levier de blocage de la

profondeur de la défonceuse.

• L’emplacement des poignées de la défonceuse. Si

la défonceuse est de taille importante et que vous

voulez la tourner légèrement pour permettre aux

poignées de passer aisément par le trou, assurezvous que les poignées ne risquent pas de toucher

la table quel que soit le réglage de la profondeur.

3. Enlevez la sous-embase de la défonceuse.

4. En vous aidant des anneaux concentriques situés sur

le dessous de la plaque de montage, centrez la sousembase de votre défonceuse. Alignez les trous de

fixation sur les traits radiaux. Fixez la sous-embase en

place avec du ruban adhésif (Fig. 8).

Remarque : Assurez-vous que les emplacements

choisis pour les trous de montage n’interfèrent pas

avec les trous de goupille de guidage de la table de

toupillage ou avec les trous percés en usine pour les

défonceuses Bosch.

5. Bridez fermement la sous-embase contre la plaque de

montage à l’aide de serre-joints à bois qui ne rayent

pas ou de serre-joints en «C ». Afin d’éviter tout

mouvement, n’utilisez pas de pinces à ressort (Fig. 9).

6. Mettez une chute de bois sous la plaque de montage

en dessous de l’emplacement des perçages. Percez la

plaque avec un foret du même diamètre que les trous

de la sous-embase de votre défonceuse (Fig. 9).

7. Enlevez les serre-joints et la sous-embase et

retournez la plaque de montage.

8. Fraisez les nouveaux trous à l’aide d’un foret à fraiser

à une seule cannelure en tournant à basse vitesse afin

d’usiner proprement (Fig. 10). Utilisez une perceuse

sensitive si vous en avez une. Assurez-vous que les

têtes des vis ne risquent pas de dépasser au-dessus

de la surface de la plaque.

FIG. 7

FIG. 9

FIG. 10

Assemblage de la table de toupillage

FIG. 8

ANNEAUX CONCENTRIQUES

SOUS-EMBASE DE

LA DEFONCEUSE

SERRE-JOINTS

FORET À FRAISER À

UNE SEULE

CANNELURE

PERCEUSE

OU

PERCEUSE

SENSITIVE

TRAITS

RADIAUX

RUBAN

ADHESIF

BM 2610909346 5/03 5/12/03 11:53 AM Page 30

Page 31

MONTAGE DE LA PLAQUE DE MONTAGE SUR LA

PLAQUE DE TOUPILLAGE

1. Placez le sous-ensemble défonceuse et plaque de

montage dans la table de toupillage. Orientez la

plaque de montage de manière à ce que les

systèmes de réglage de profondeur de la défonceuse

soient tournés vers l’avant de la table (Fig. 11).

2. Installez les six vis de mise à niveau en Nylon et les

six ressorts de la plaque de montage dans les six

trous situés autour de l’orifice de la plaque de

montage. Réglez la hauteur de la plaque de montage

de manière à ce qu’elle soit de niveau et qu’elle

affleure la table. Tournez vers la droite pour soulever

la plaque de montage et vers la gauche pour

l’abaisser. La plaque de montage doit affleurer la

surface pour que la machine fonctionne

correctement. Assurez-vous que toutes les vis de

mise à niveau touchent la plaque de montage

(Fig. 11).

3. Montez les brides de coin de la plaque de montage à

l’aide des vis No 10 –24 et des écrous de blocage

aux quatre coins de la plaque de montage. Pour

maintenir la plaque en position, poussez les brides

de coin dans les coins et serrez les vis. (Fig. 11).

-31-

BRANCHEMENT DE LA DEFONCEUSE ET DE

L’INTERRUPTEUR DE LA TABLE DE TOUPILLAGE

Pour préparer l’interrupteur, (Fig. 12)

1. Assurez-vous que la gâchette de la défonceuse et

que l’interrupteur de la table de toupillage sont tous

deux sur la position arrêt.

2. Branchez le cordon de l’interrupteur de la table de

toupillage sur une prise murale.

3. Branchez la défonceuse sur la prise pendante de

l’interrupteur de la table de toupillage.

4. Mettez la gâchette de la défonceuse sur la position

‘MARCHE’ (‘ON’) et enclenchez le bouton de blocage

sur marche de la gâchette s’il existe.

5. Utilisez l’interrupteur de la table de toupillage pour

démarrer et arrêter la défonceuse.

Le courant nominal de cet interrupteur est de 15 Amp. Il

est conçu pour être utilisé uniquement pour démarrer et

arrêter la défonceuse. Ne l’utilisez pas pour commander

des appareils supplémentaires tels qu’un aspirateur.

Assemblage de la table de toupillage

FIG. 11

FIG. 12

BRANCHEZ LA

DEFONCEUSE SUR

CETTE PRISE

INTERRUPTEUR

D’ALIMENTATION DE LA TABLE

BRANCHEZ SUR

UNE PRISE

MURALE

REGLAGE DE

PROFONDEUR

BRIDE DE COIN

ECROU DE

BLOCAGE

VIS NO 10-24

VIS DE

MISE À

NIVEAU

RESSORT

BM 2610909346 5/03 5/12/03 11:53 AM Page 31

Page 32

-32-

FIXATION DES CONTRE-GUIDES

SUR LE GUIDE

A l’aide des boulons à tête ronde de 3/8 po x 2 po et

des boutons à ailettes noirs, serrez les contre-guides

contre le guide. Les contre-guides sont symétriques.

Ils peuvent être installés des deux côtés du guide avec

l’une ou l’autre des extrémités des contre-guides

dirigée vers le centre. (Fig. 14)

ANNEAUX REDUCTEURS

Quand vous utilisez des petits fers, servez-vous des

anneaux réducteurs qui s’insèrent dans l’orifice de la

plaque de montage afin de mieux supporter la pièce

près du fer et de minimiser la quantité de copeaux qui

tombent par l’orifice. (Fig. 13)

Les anneaux sont conçus pour s’ajuster légèrement

serrés de manière à ce qu’ils ne bougent pas et

restent de niveau. Il se peut qu’une force importante

soit nécessaire pour monter et démonter les anneaux.

• Pour insérer l’anneau externe, enfoncez-le dans la

plaque de montage. Assurez-vous que les

languettes de l’anneau pénètrent dans une des

encoches de la plaque de montage.

• Pour insérer l’anneau interne, enfoncez-le dans

l’anneau externe. (Il se peut qu’une force

importante soit nécessaire).

• Pour enlever les anneaux, sortez-les en tapotant

sur l’envers avec un maillet doux ou un morceau

de bois.

Ne pas tenter de les arracher de

leur logement car vous

risqueriez de les endommager. Si vous désirez un

ajustement légèrement plus libre, poncez légèrement

le diamètre extérieur de chaque anneau.

Pour enlever l’anneau interne, il se peut qu’il faille