Page 1

Installation Instructions

Guide d'installation

Manual de instalación

Slide-in Electric Ranges with European Convection

fr Cuisinières électriques à encastrer

es Estufas eléctricas empotrables

Page 2

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Before Calling Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Questions?

1-800-944-2904

www.boschappliances.com

5551 McFadden Ave.

Huntington Beach, CA 92649

We look forward to hearing from you!

Page 3

Safety

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Important Safety

Instructions

Appliance Handling Safety • Do not lift appliance by door handle. Remove the door for easier handling and

Safety Codes and Standards • This appliance complies with one or more of the following Standards:

Electric Safety • Before you plug in an electrical cord, be sure all controls are in the OFF posi-

• Warning: If the information in this manual is not followed exactly, fire or shock

may result causing property damage or personal injury.

• WARNING: Do not repair or replace any part of the appliance unless specifically recommended in the manuals. Improper installation, service or maintenance can cause injury or property damage. Refer to this manual for

guidance. All other servicing should be done by a qualified technician.

installation. See instructions in Use and Care Manual.

• Unit is heavy and requires at least two people or proper equipment to move.

• Hidden surfaces may have sharp edges. Use caution when reaching behind

or under appliance.

UL 858, The Standard for the Safety of Household Electric Ranges

UL 923, The Standard for the Safety of Microwave Cooking Appliances

UL 507, The Standard for the Safety of Electric Fans

ANSI Z21.1-2000, The American National Standard for Household Cooking Gas Appliances

CAN/CSA-C22.2 No. 113-M1984 Fans and Ventilators

CAN/CSA-C22.2 No. 61-M89 Household Cooking Ranges

It is the responsibility of the owner and the installer to determine if additional requirements and/or standards apply to specific installations.

tion.

• For appliances equipped with a cord and plug, do not cut or remove the

ground prong. It must be plugged into a matching grounding type receptacle

to avoid electrical shock. If there is any doubt as to whether the wall receptacle is properly grounded, the customer should have it checked by a qualified

electrician.

• If required by the National Electrical Code (or Canadian Electrical Code), this

appliance must be installed on a separate branch circuit.

• Only a power-supply cord kit rated for this appliance and marked "for use with

ranges" shall be used.

• Installer - show the owner the location of the circuit breaker or fuse. Mark it for

easy reference.

• Important - Save these instructions for the local electrical inspector's use.

• Before installing, turn power OFF at the service panel. Lock service panel to

prevent power from being turned ON accidentally.

• Be sure your appliance is properly installed and grounded by a qualified technician. Installation, electrical connections and grounding must comply with all

applicable codes.

Related Equipment Safety • Warning: All ranges can tip. Injury to persons could result. Install anti-tip

device packaged with range. Verify that the anti-tip devices are engaged. See

installation instructions.

English 1

Page 4

Installation

Before You Begin

• Remove all tape and packaging before using the appliance. Destroy the packaging after unpacking the appliance. Never allow children to play with packaging material.

• Never modify or alter the construction of the appliance. For example, do not

remove leveling legs, panels, wire covers or anti-tip brackets/screws.

• To eliminate the risk of burns or fire by reaching over heated surface units,

cabinet storage space located above the surface units should be avoided. If

cabinet storage is to be provided, the risk can be reduced by installing a hood

that projects horizontally a minimum of 5 inches beyond the bottom of the

cabinet.

• Verify that cabinets above the cooktop are a maximum of 13" (330 mm) deep.

Tools and Parts Needed • 40 or 50 Amp Power Supply Cord Kit (depending on local code)

Note: Not necessary for Canadian installations

• Measuring Tape

• Phillips Head Screwdriver

• 1-1/4” (31.8 mm) Wrench

•Pencil

• T-20 Torx Screwdriver

• Screws (2) and Anchors (2) for Anti-Tip Bracket (Style will vary depending on

mounting surface)

•Level

• Drill and Drill Bit

• Soapy Water

• Safety Gloves and Goggles

• Tape (Optional)

• Cloth or Cardboard (Optional - to Protect Floor)

Additional Parts Needed For Hard Wire Installations

• Flexible Conduit

• Torque Wrench

• Note: Power Supply Cord Kit Not Necessary For Hard Wire Installations

Parts Included • Anti-Tip Bracket

• Foam Tape

• Terminal Lugs (For Use With Hard Wire Installations) (not necessary for

Canadian installations)

English 2

Page 5

General Information

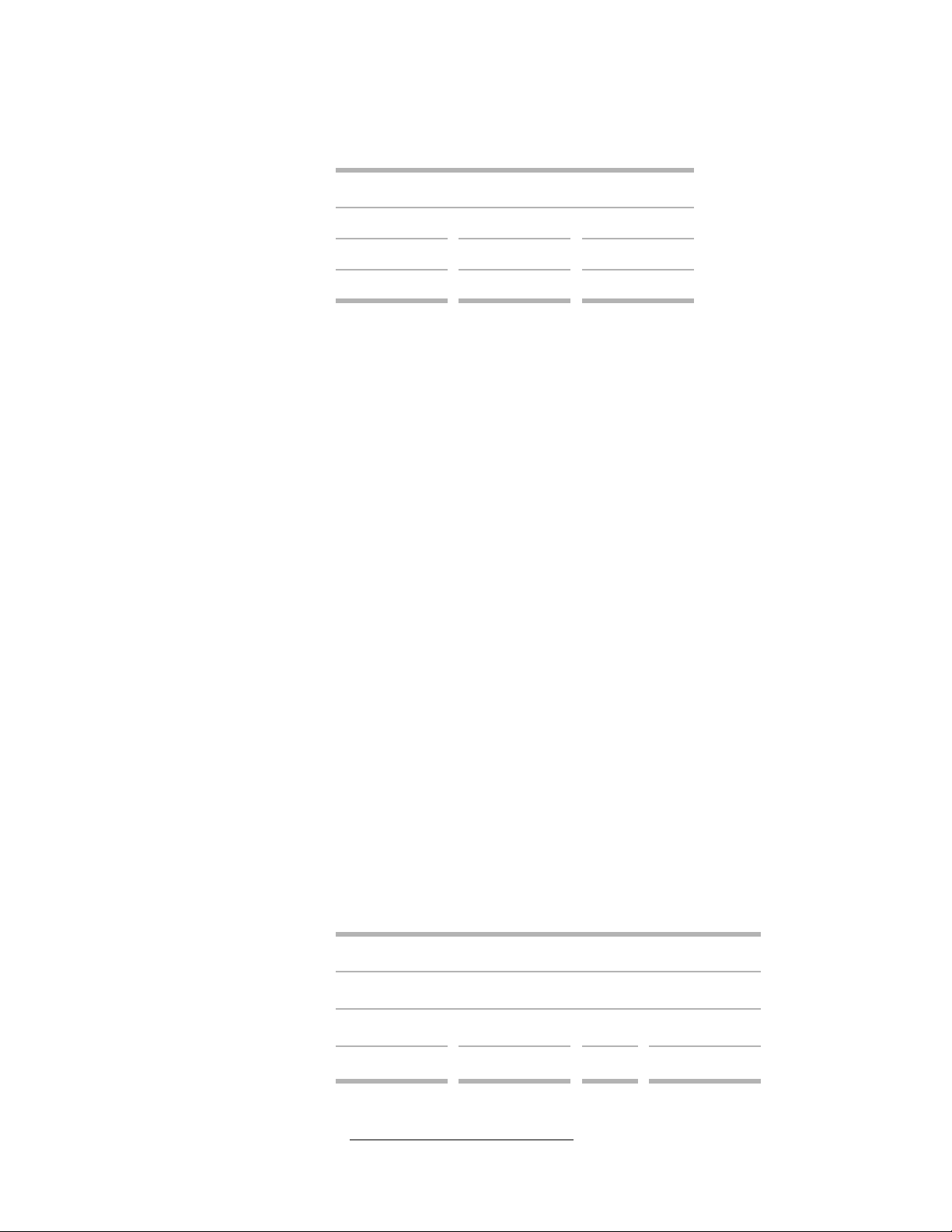

Overall Dimensions

Table 1: Overall Dimensions

Dimension Inches centimeters

Height

Width

Depth

36 91.44 cm

29 5/16” 74.55 cm

25 5/8” 65.09 cm

Level For best results, cabinets, countertops walls and floors in the installation location

should be as level and plumb as possible. Variance may cause damage to countertops and floors during installation, could jeopardize the seal around the cooktop

and may adversely affect cooking and baking performance.

Tips Tape warming drawer shut to keep it from opening while installing the range.

During installation, place a portion of the box or a piece of cloth under the range to

protect floors.

To make range lighter and easier to handle remove door (see instructions in Use

and Care manual).

Preparation

Electrical Requirements Refer to data plate for more information. See “Product Data Plate” on page 17 for

data plate location.

We recommend that the range be installed with a power cord set (not supplied).

The electrical rating of the power cord set must be 120/240 volt, 40 or 50

amperes

1

minimum (depending on local code). The power cord set shall be marked “For

Use with Ranges.” Always use a new power cord.

Note: In Canada, the range is shipped from the factory with the range cord

already installed.

Ranges are dual rated for use on either 120/240 VAC or 120/208 VAC. Check the

data plate for the kW rating. Reference the kW rating in the table below to deter-

mine amperage requirements.

Table 2: Electrical Specifications

kW Rating Hz Amps Req’d

120/240V 120/208V

13

13.8

9.8

60

10.4 60

40 or 50

40 or 50

a

a

a. Varies by location. Check local codes.

1.Not needed for Canadian installations

English 3

Page 6

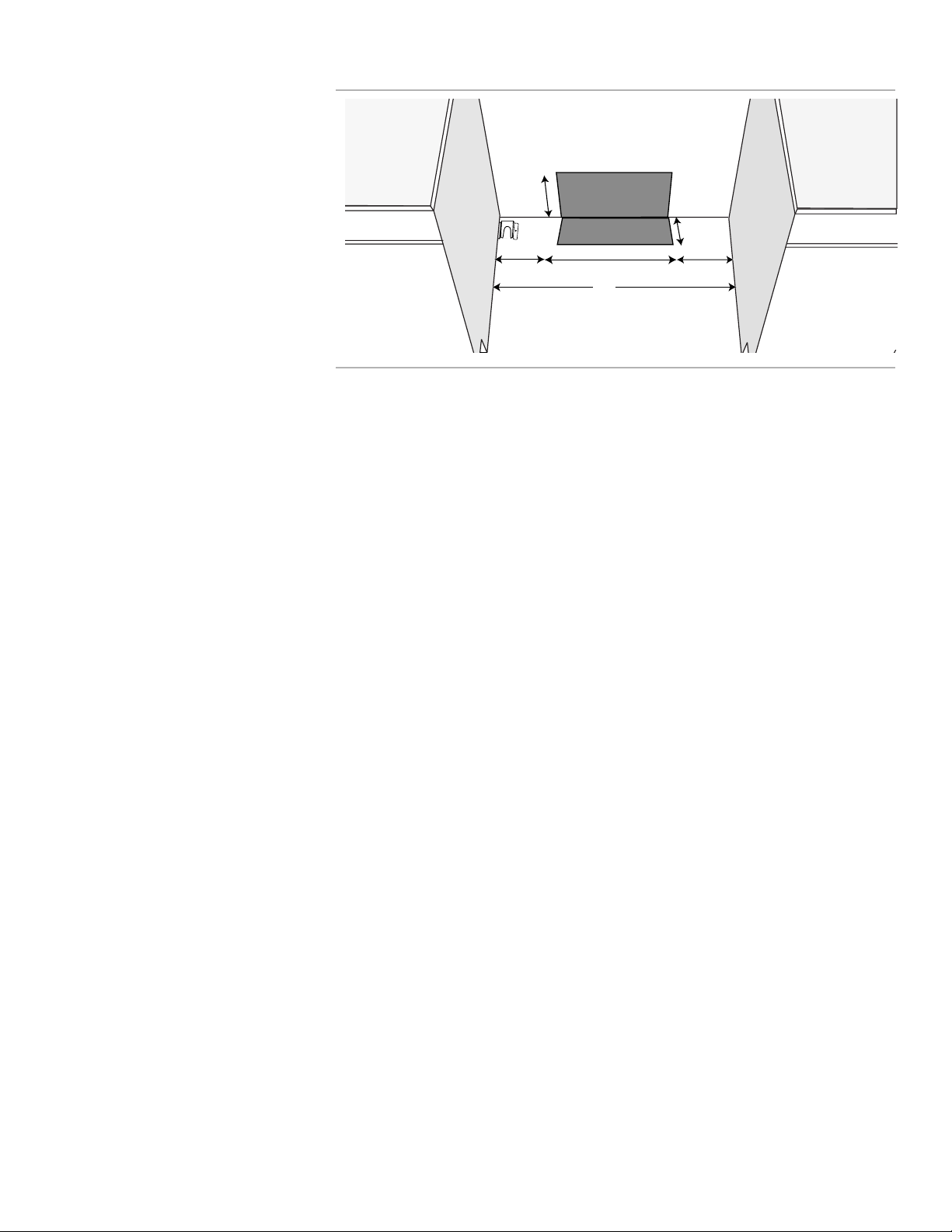

The electrical outlet must be located in the shaded space in Figure 3.

7 1/2”

(190.5 mm)

3 1/2”

(88.9 mm)

4 1/2”

(114.3 mm)

21” (533.4 mm)

30”

(762 mm)

4 1/2”

(114.3 mm)

Figure 1: Cooktop Clearances

Verify that wiring to house is adequate

Contact your local utility company to verify that the present electric service to your

home is adequate. In some instances, the size of the wiring to the house and service switch must be increased to handle the electrical load demanded by the

range.

Verify that wiring inside house is adequate

Most wiring codes require a separate circuit with separate disconnect switch and

fuses either in the main entrance panel or in a separate switch and fuse box.

The range requires a minimum of a three wire 120/240 or 120/208 volt, 40 or 50

AMP, 60 Hz AC circuit. Check local codes for proper amperage ratings.A four wire

connection is preferred.

Most local building regulations and codes require that electrical wiring be done by

licensed electricians. Be sure to install your range according to the electric codes

in place in your region.

Cabinet Requirements This unit is designed for installation near adjacent walls and projecting surfaces

constructed of combustible materials.

English 4

Page 7

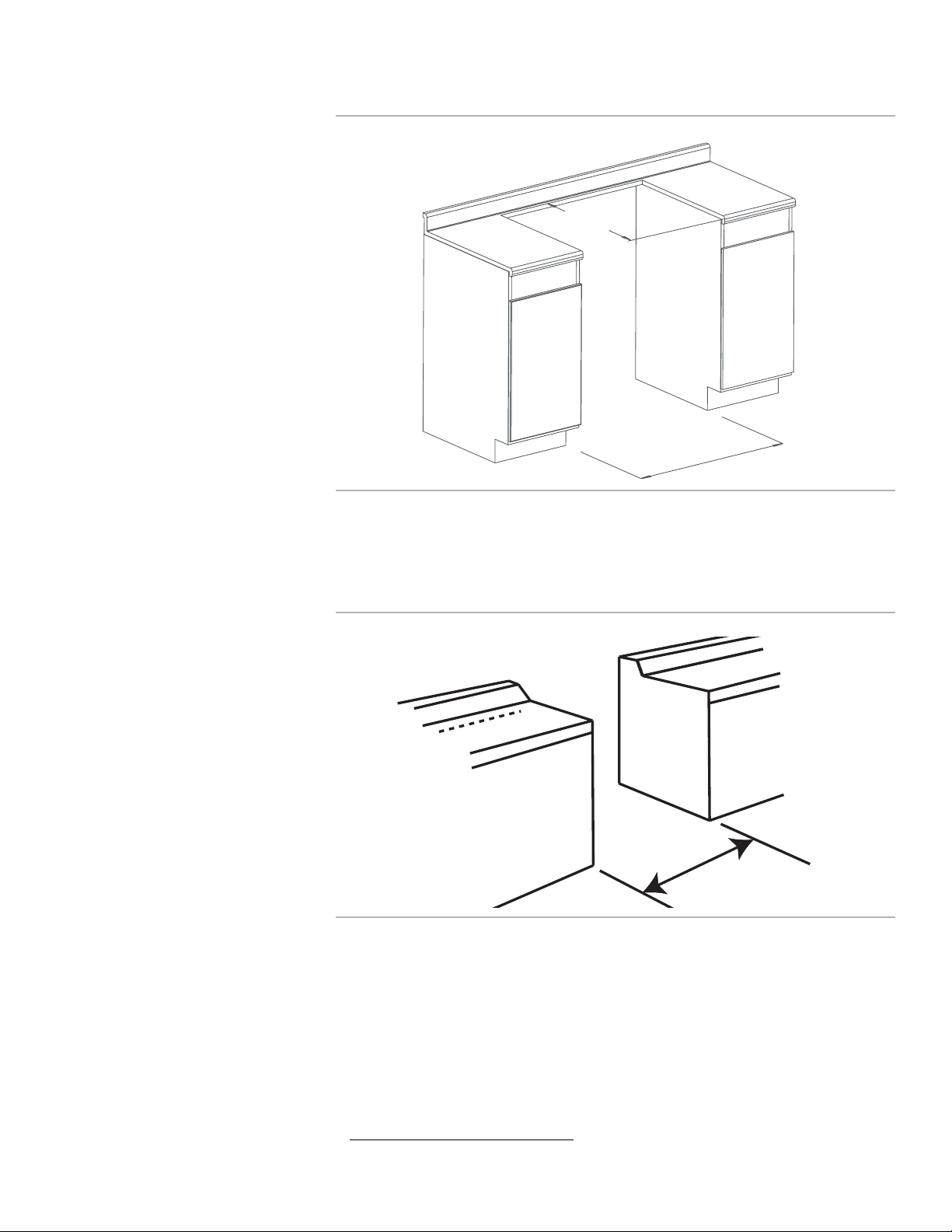

Allow a minimum of 30 inches between cabinets where range is to be installed

See Figure 2: Cutout Requirements for more information..

23 1/16"

(585.4 mm)

30" (762 mm)

Figure 2: Cutout Requirements

1

.

Note: The slide-in range can also replace a freestanding range. In this case, ver-

ify that the opening is at least 30 inches.

Figure 3: Cutout Requirements - Replacing a Free-Standing Model

1

30" (76.2 cm) min

.

1.In Canada, a clearance of 12 mm from range sidewall to cabinet is required.

English 5

Page 8

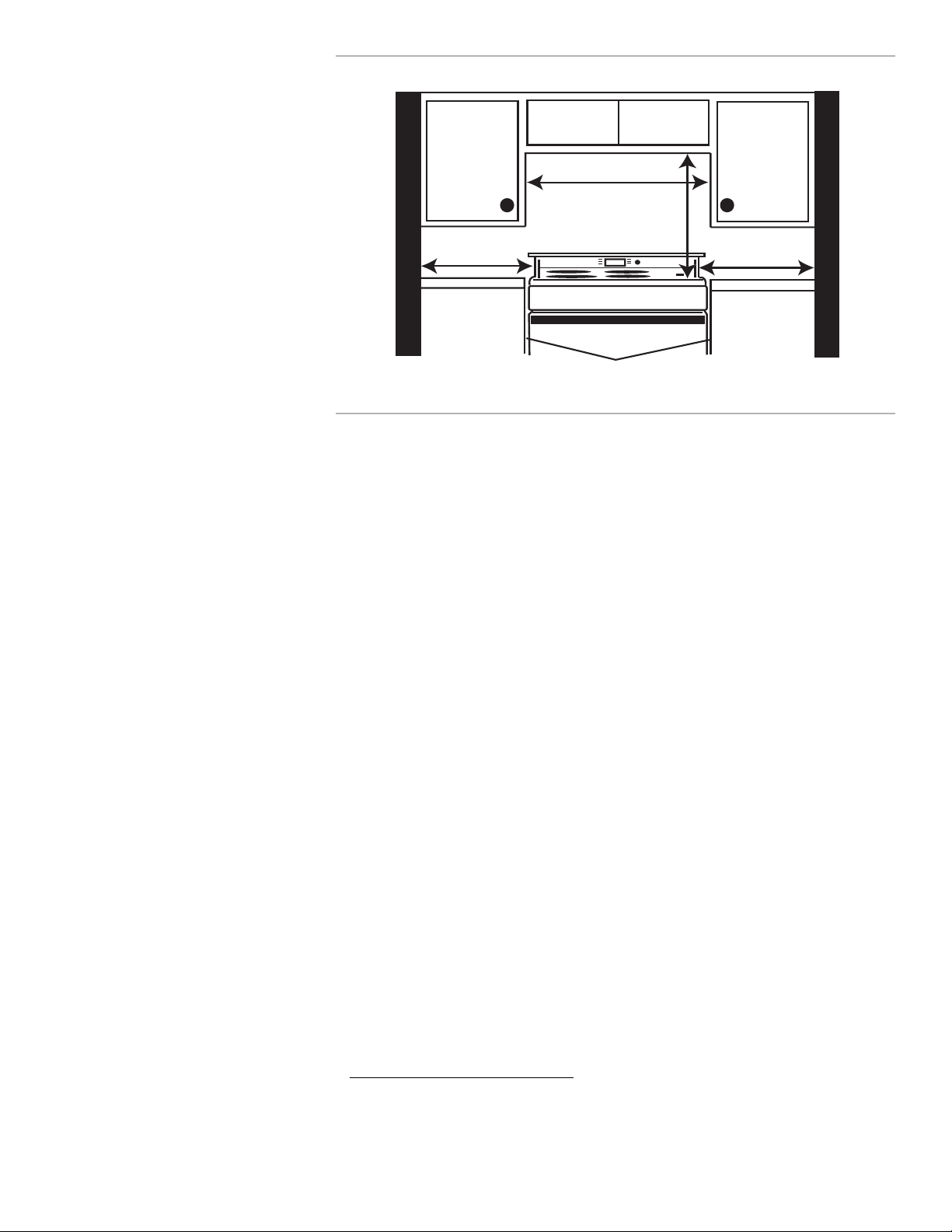

30" (76.2 cm)

min. centered

4" (10.2 cm)

min.

Required Clearance

30" (76.2 cm) min.

no clearance required

(12 mm clearance required in Canada)

1

4" (10.2 cm)

min.

Figure 4: Cabinet Preparation

From cooktop to materials above: There must be a minimum clearance of 30

inches between the top of the cooking surface and the bottom of an unprotected

wood or metal cabinet. See Figure 4: Cabinet Preparation.

24 inches is acceptable when the bottom of the wood or metal cabinet is protected

by (a) not less than 1/4" of flame retardant material which must be covered with

(b) not less than No. 28 MSG sheet metal, 0.015 inch stainless steel’ or 0.024 inch

aluminum or copper.

From range walls to adjacent materials: See Figure 4: Cabinet Preparation. No

clearance is required from unit walls to adjacent vertical combustible walls on

rear, right or left.

2

Clearance from range top to adjacent vertical walls must be at least 4”.

Note: Some cabinet finishes cannot survive the temperatures allowed by U.L.,

particularly self-cleaning ovens; the cabinets may discolor or stain. This is most

noticeable with laminated cabinets.

Prepare Walls and Floor

Seal any holes in the walls or floor. Remove any obstructions (extra electrical or

gas connections, etc.) so that range will rest against wall properly.

Countertop Requirements Countertops must be smooth and level.

Mounting Requirements Install Anti-Tip Bracket

1.Instructions were determined using standard American cabinets. Standard base cabinets measure 36" high x 24" deep. Cabinets over the cooking surface and cabinets adjacent to those over

the cooking surface measure 13 inches deep from backwall. If nonstandard cabinets are used,

care should be taken to alter dimensions accordingly.

2.In Canada, a clearance of 12 mm from range sidewall to cabinet is required.

English 6

Page 9

1. Adjust height of range and level by rotating the adjustable leg supports on the bottom of the range, using 1-1/4" wrench.

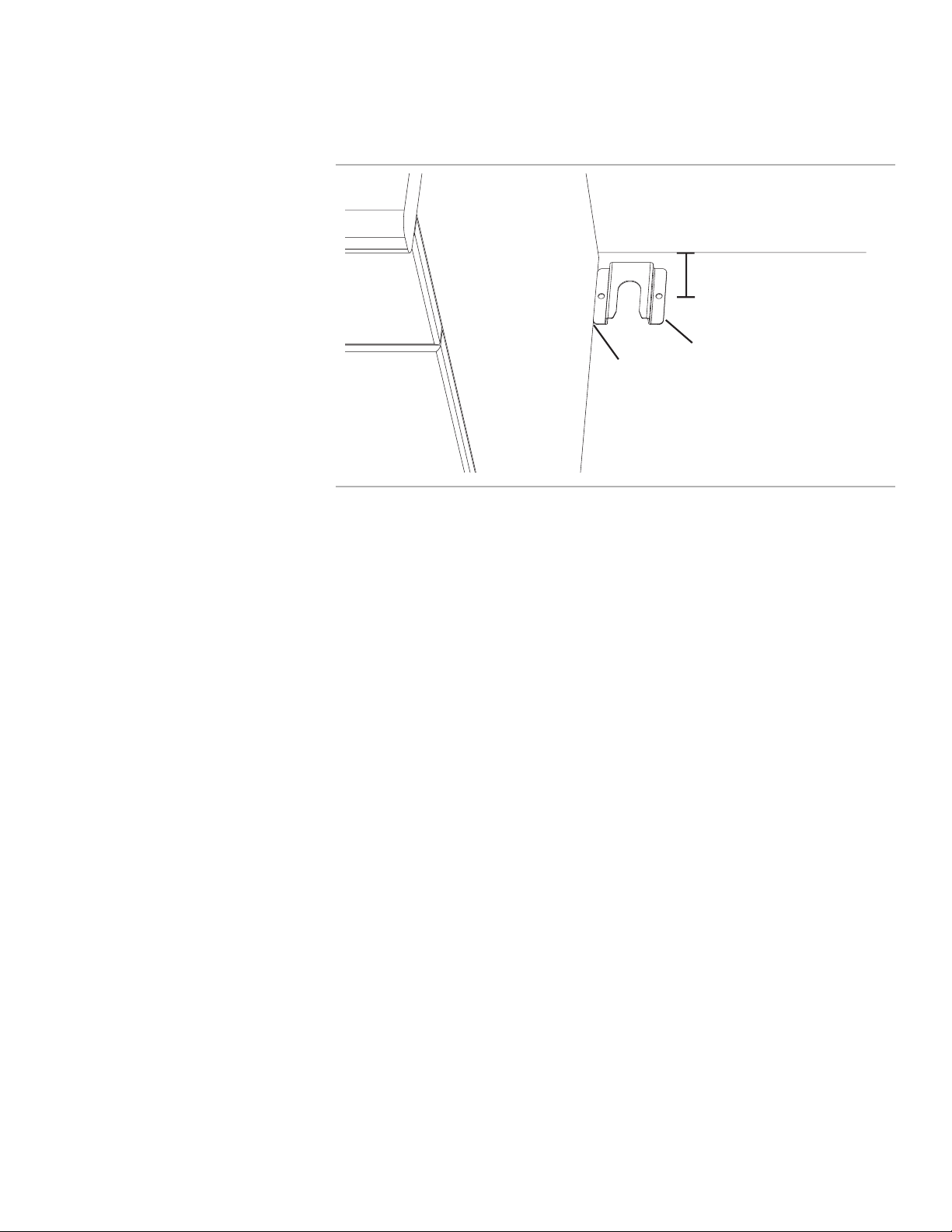

2. Measure to locate bracket position as shown in See Figure 5: Anti-Tip Bracket.

3. Secure bracket with 2 screws adequate for mounting surface (i.e., for wood floor use wood screws, for concrete floor use concrete anchors and screws).

rear wall

cabinet wall

flush against

cabinet wall

1 9/16" (39.7 mm)

from rear wall to center of screw hole

floor

anti-tipping

device

Figure 5: Anti-Tip Bracket

Ventilation Recommendations We strongly recommend the installation of a ventilation hood above this appli-

ance. For most kitchens a certified hood rating of not less than 300 CFM is recommended. The range hood must be installed according to instructions furnished

with the hood.

Installation Procedure

Apply Foam Tape Apply foam tape to underside of cooktop trim in one continuous piece.

Note: DO NOT use caulk or glue/adhesive of any kind.

Install Backwall Trim Note: This step is only required if the countertop does not connect behind the

range (i.e.; when replacing a free-standing range). See “Cabinet Requirements”

on page 6 for more information

English 7

Page 10

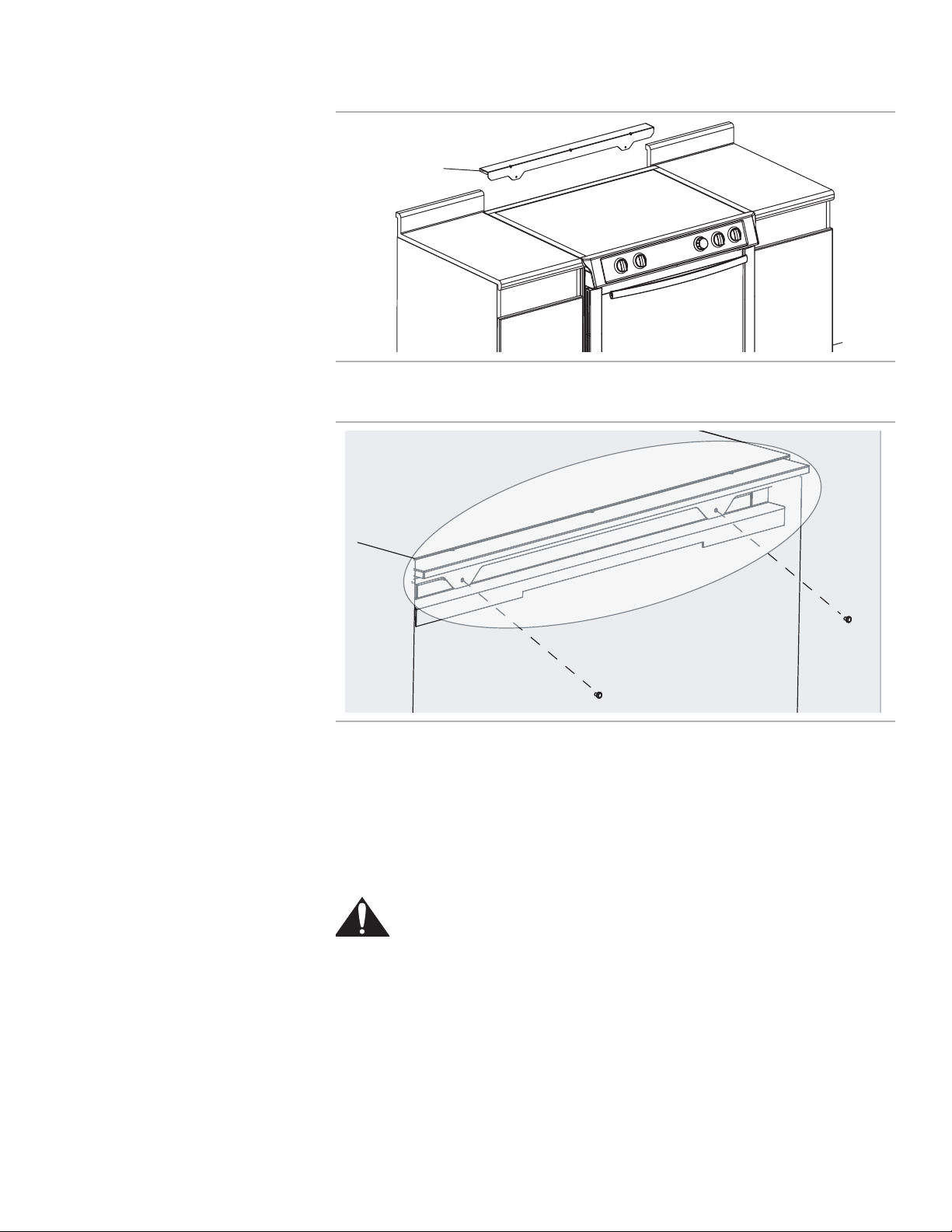

Install 2 screws through holes in trim and in range backwall. See Figure 6: Backwall Trim Strip and Figure 7: Install Backwall Trim Strip

Backwall

Trim Strip

Figure 6: Backwall Trim Strip

Back of Range

Figure 7: Install Backwall Trim Strip

Connect Electric - Range Cord

Install Strain Relief Warning: The strain relief provided with your range cord must be properly

Note: In Canada, the range is shipped from the factory with the range cord

already installed. Continue to “Complete the installation” on page 15.

For installations other than those in Canada, connect the range cord at the terminal block (See next page for detailed instructions). Access the terminal block by

removing the cover in the lower right hand corner of the range back panel.

installed.

Place strain relief in knockout below terminal block. See Figure 8: Strain Relief

Knockout. Feed range cord through hole and strain relief up to terminal block.

Allow for slack in the cord between the strain relief and terminal block. Once cord

English 8

Page 11

length/ slack has been adjusted, attach strain relief per instructions included with

l

l

strain relief.

Tip: The knockout panel below the terminal block can be removed from

the range to install the strain relief: Remove knockout panel from range,

install strain relief in panel and reattach. DO NOT remove entire range

back panel.

Figure 8: Strain Relief Knockout

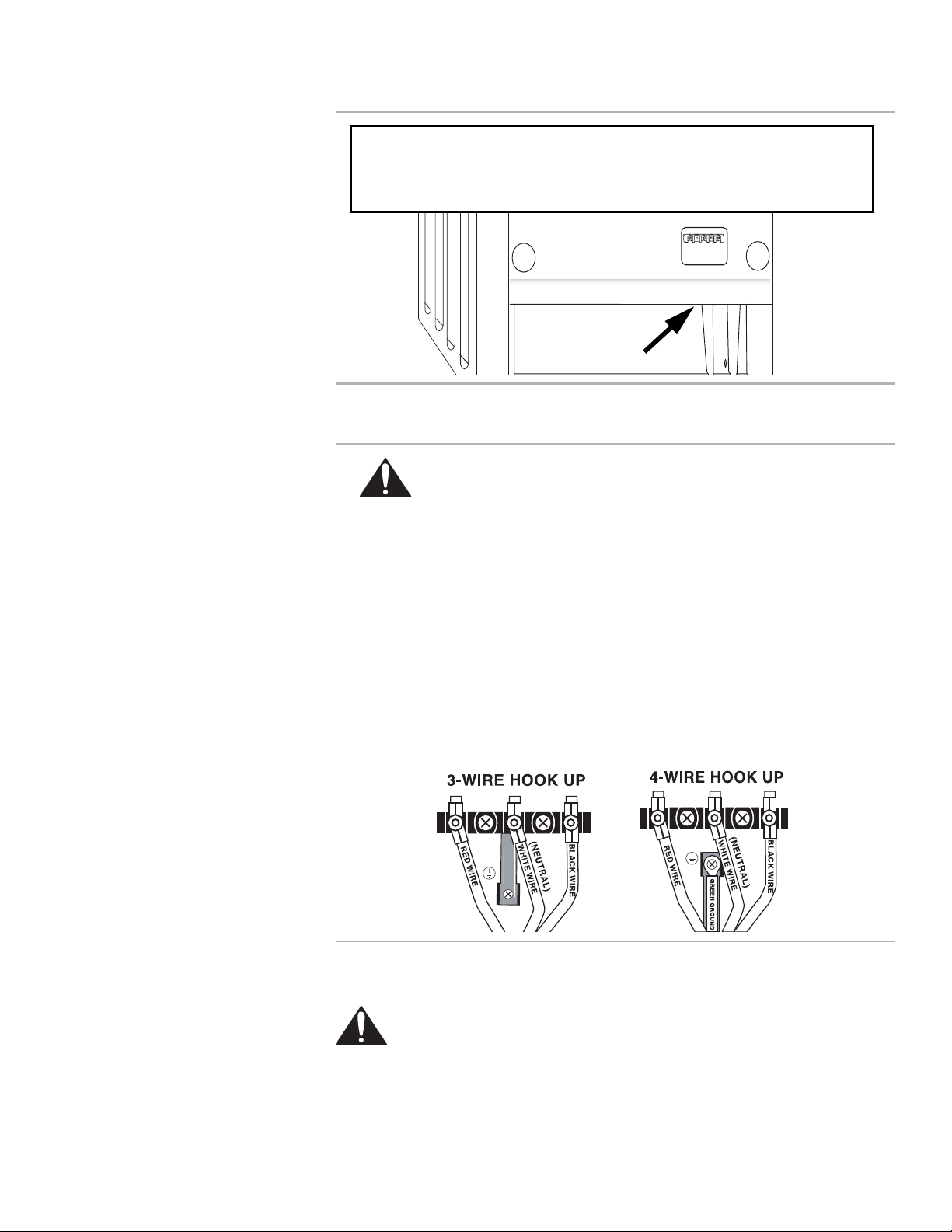

Warning: Risk of Electric Shock or Fire. Frame grounded to neutral

through a ground strap. Grounding through the neutral conductor is prohibited

for new branch-circuit installations (1996 NEC), mobile homes, and recreationa

vehicles, or in an area where local codes prohibit grounding through the neutra

conductor.

For installations where grounding through the neutral conductor is prohibited,

(a) disconnect the link from the neutral, (b) use grounding terminal or lead to

ground unit, (c) connect neutral terminal to lead branch circuit neutral in usual

manner (when the appliance is to be connected by means of a cord kit, use 4conductor cord for this purpose).

Use only cord kits rated 125/250 volts (minimum), 40 or 50 amperes (depending on local code) and labeled “For Use with Ranges”. Strain relief provided

with cord must be installed per instructions

Figure 9: Grounding Requirements

Warning: To prevent electrical shock, the grounding prong on the range

cord should not be cut or removed under any circumstances. It must be plugged

into a matching grounding type receptacle and connected to a correctly polarized

240- Volt circuit. If there is any doubt as to whether the wall receptacle is properly

grounded, have it checked by a qualified electrician.

English 9

Page 12

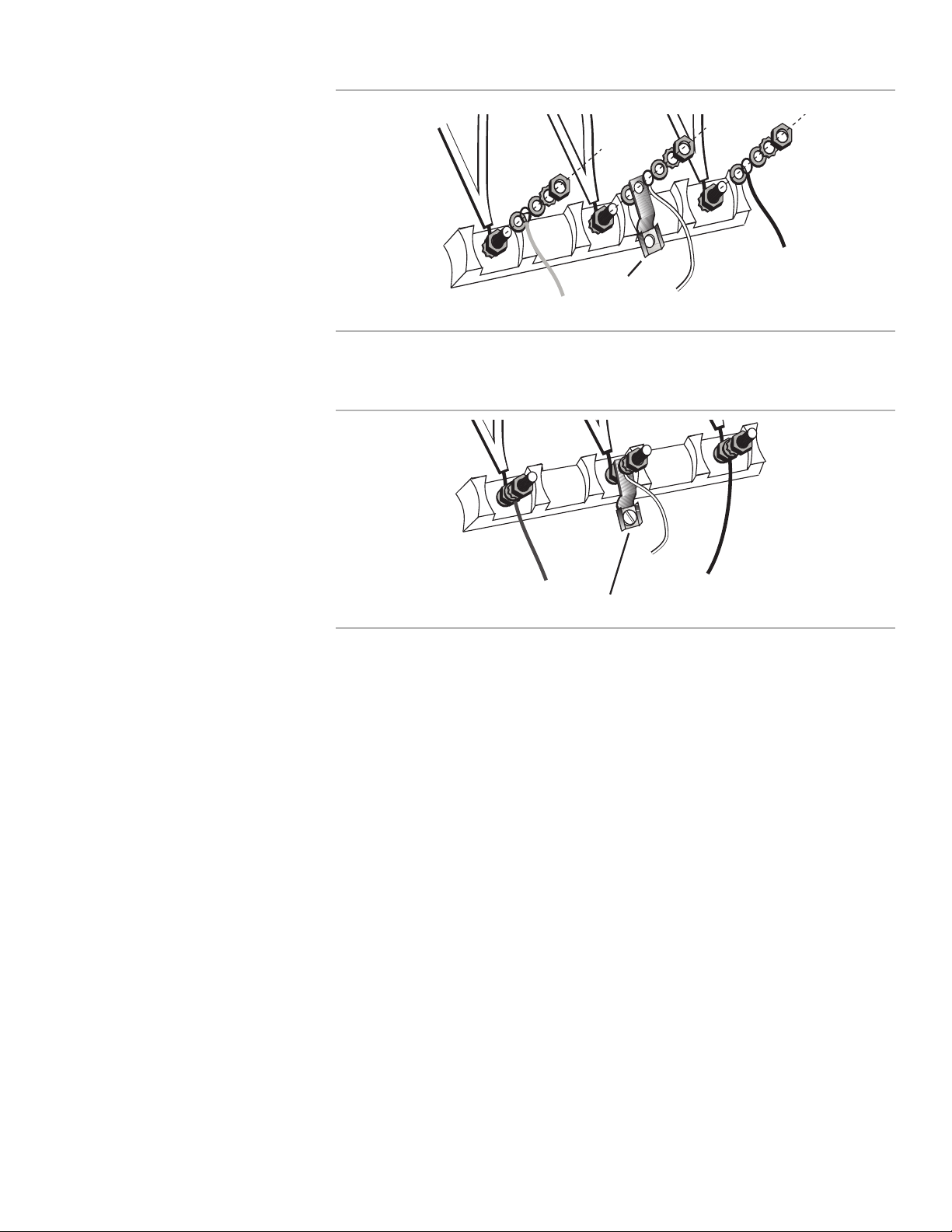

Four Wire Range Cord Connection (Recommended Method)

1. Disconnect electrical power at breaker box.

2. Remove the terminal block cover to expose the terminal block

Figure 10: 4 Wire Connection

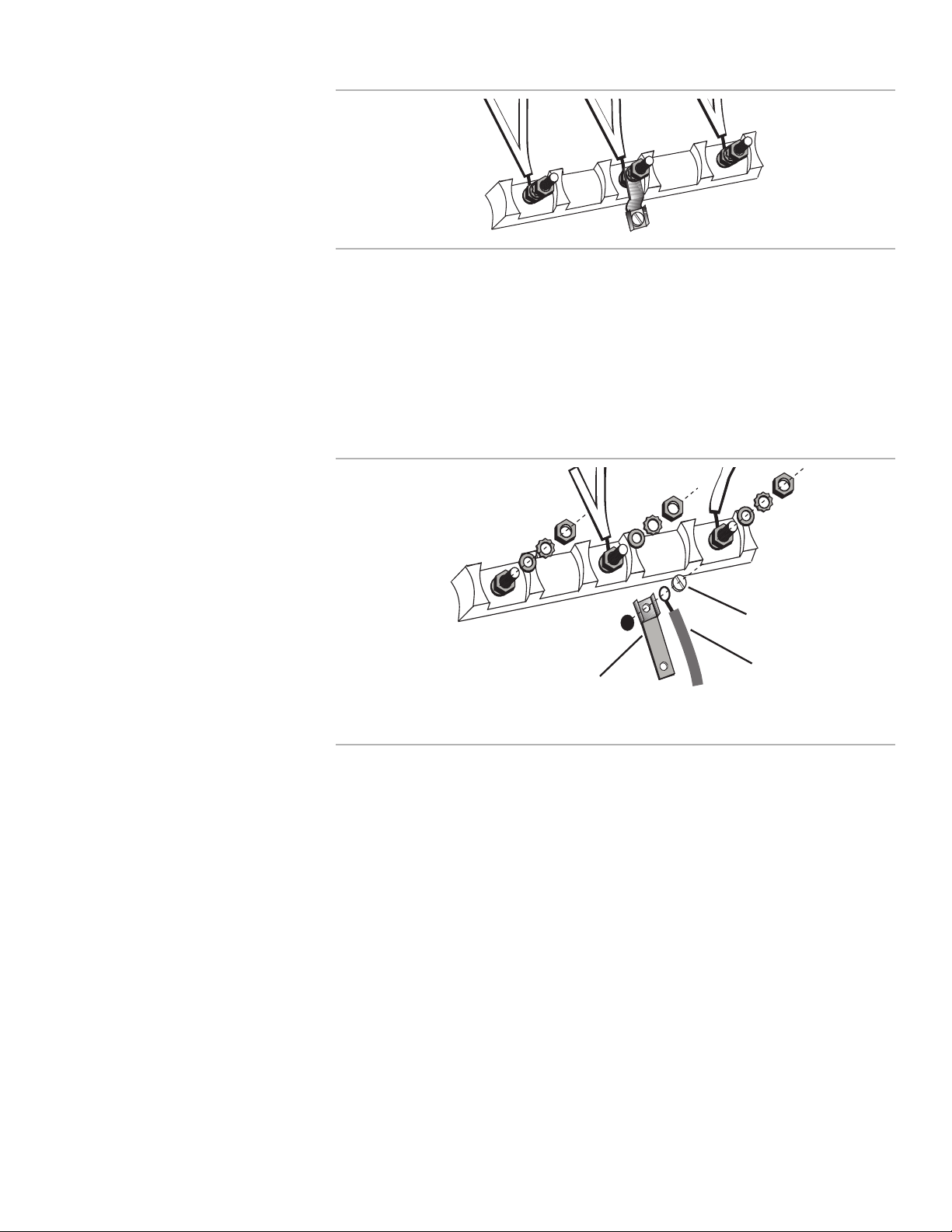

3. Remove top nut, star washer, and round washer from each post.

Note: DO NOT remove last round washer, last nut or internal wiring leads.

4. Remove screw from bottom end of ground strap.

5. Remove ground strap from center post, rotate so that wide end is at top and attach wide end to range through hole below junction box. Attach green wire on top of ground strap. Tighten Screw.

green ground screw

ground strap

Figure 11: Four Wire Range cord Connection - Ground Strap and Wire

ground wire

6. Attach red wire, round washer, star washer and nut IN THIS ORDER to left post.

7. Attach white wire, round washer, star washer and nut IN THIS ORDER to center post.

English 10

Page 13

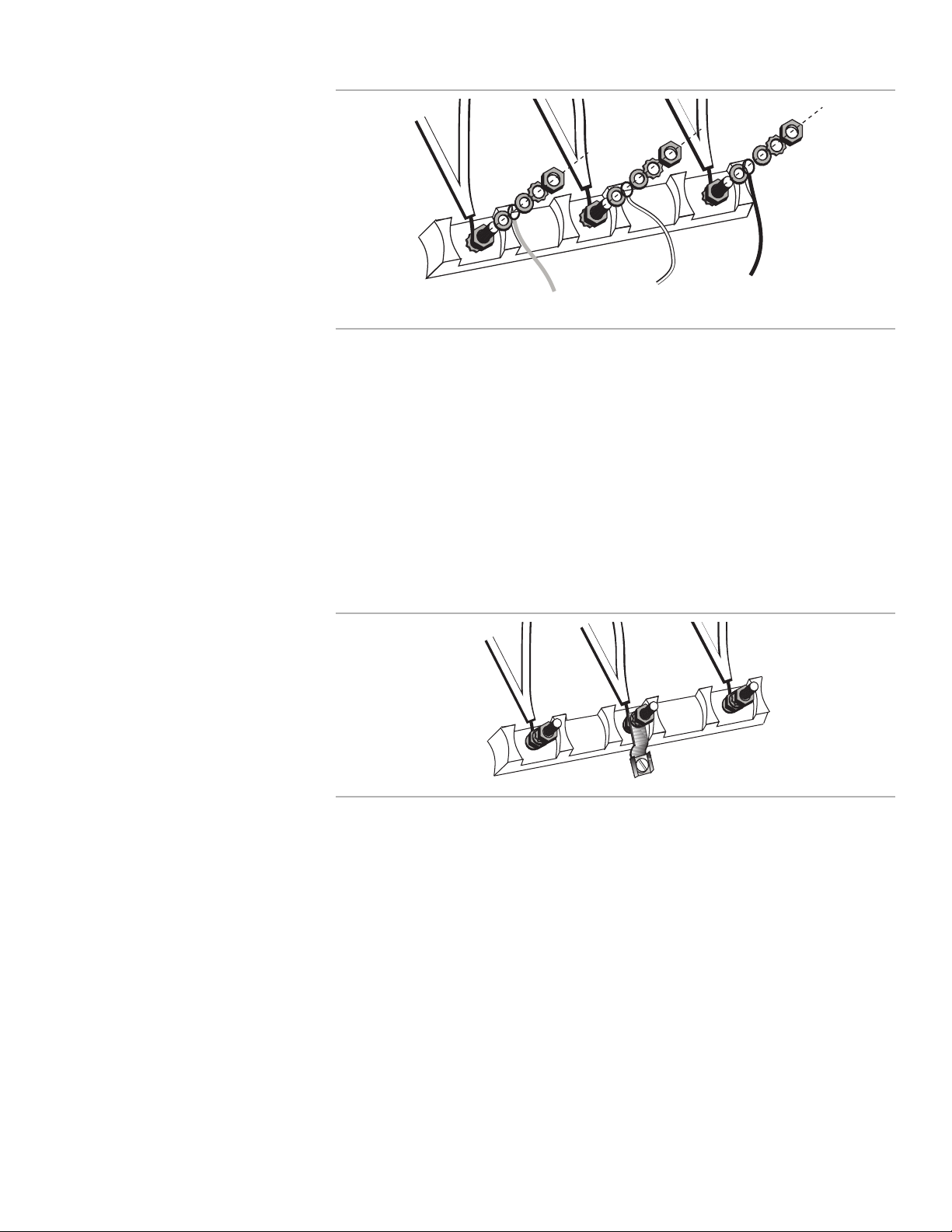

8. Attach black wire, round washer, star washer and nut IN THIS ORDER to right post.

red

Figure 12: Four Wire Range Cord Connection (continued)

white

black

9. Tighten all connections securely and replace terminal block cover.

10. Properly secure strain relief (see previous section).

Note: DO NOT plug in range at this time.

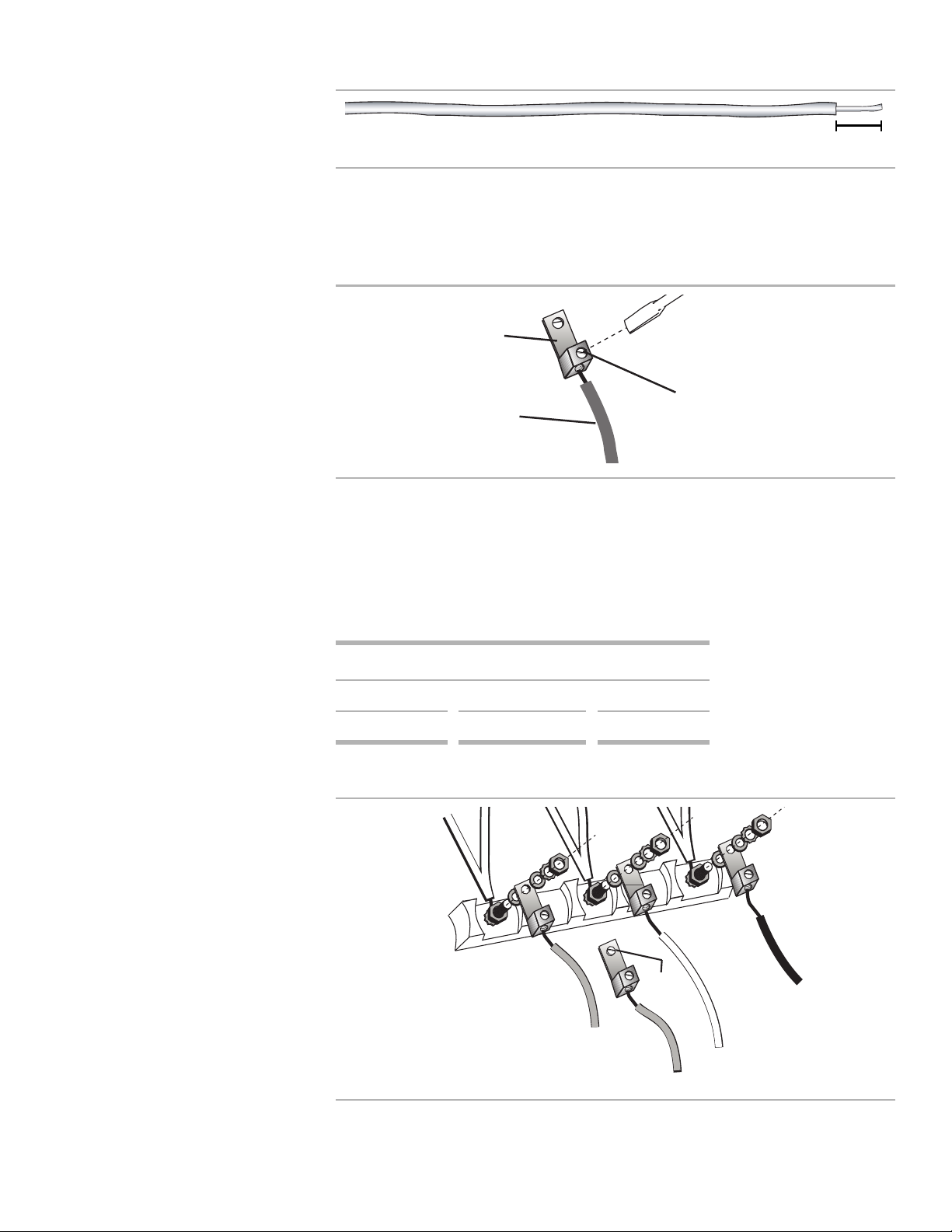

Three Wire Range Cord Connection The Four Wire Connection (above) is preferred, but where local codes and ordi-

nances permit grounding through neutral and where conversion to four wire is

impractical, the unit may be connected to the power supply via a three wire connection.

1. Disconnect electrical power at breaker box.

2. Remove the terminal block cover to expose the terminal block.

Figure 13: Terminal Block

3. Remove top nut, star washer, and round washer from each post.

Note: DO NOT remove last round washer, last nut or internal wiring leads.

4. Attach white wire, round washer, star washer and nut IN THIS ORDER on top of ground strap on center post.

5. Attach red wire, round washer, star washer and nut IN THIS ORDER to left post.

English 11

Page 14

6. Attach black wire, round washer, star washer and nut IN THIS ORDER to right post.

black

ground strap

red

white

Figure 14: Three Wire Connection

7. Tighten all connections securely and replace terminal block cover.

Connect Electric - Flexible Conduit Connection

Four Wire Flexible Conduit Connection

green ground screw

Figure 15: Completed Three Wire Range Cord Connection

8. Properly secure strain relief. See “Install Strain Relief” on page 8 for detailed instructions.

The range can also be connected via flexible conduit. If using this method, always

use the lugs supplied.

Note: In Canada, the range is shipped from the factory with the range cord

already installed. Continue to “Complete the installation” on page 15.

1. Disconnect electrical power at the breaker box.

2. Remove the terminal block cover to expose the terminal block.

3. Remove the top nut, star washer, and round washer from each post.

Note: DO NOT remove last round washer, last nut or internal wire leads.

4. Remove screw from bottom end of ground strap.

5. Remove ground strap from center post. Discard.

6. Attach one terminal lug (packaged with this manual) through hole below terminal block with ground screw.

7. Place one terminal lug (packaged with this manual) on each post. Replace the star washer and round washer and secure with 20 inch pounds of torque.

English 12

Page 15

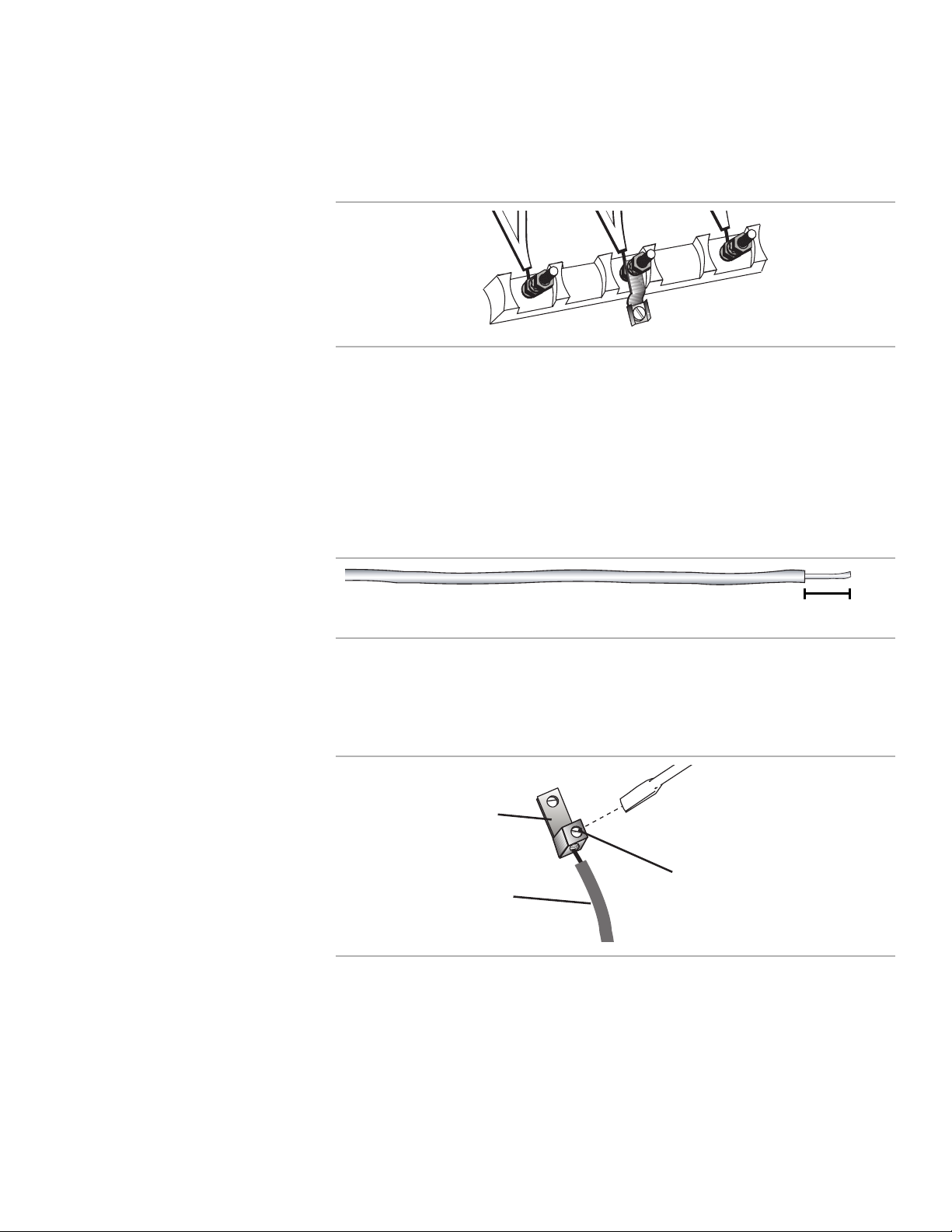

8. Strip 3/8 (9.53 mm) inches of insulation from the end of the wire.

3/8 “

Figure 16: Wire Stripping

9. Insert the insulated grounding wire into the lug below the terminal block.

10. Insert stripped end of white wire into the center lug. Secure the clampingscrew.

lug

wire

clamping screw

Figure 17: Attaching Wire to Lug

11. Insert stripped end of red wire into the left lug. Secure clamping screw.

12. Insert black wire into the right lug. Secure clamping screw. Tighten each clamping screw with the appropriate torque (see table).

Table 3: Appropriate Torque Levels for Aluminum or Copper Wire

Gauge Torque (in./lbs.) Torque (Nm)

6

8

35 3.95

25 2.82

13. Properly secure flexible conduit at knockout on angle and at supply side junction box. The wiring is now complete.

green

red wire

ground

screw

green ground wire

white wire

black wire

Figure 18: Completed Four Wire Flexible Conduit Connection

English 13

Page 16

Note: DO NOT plug in range at this time.

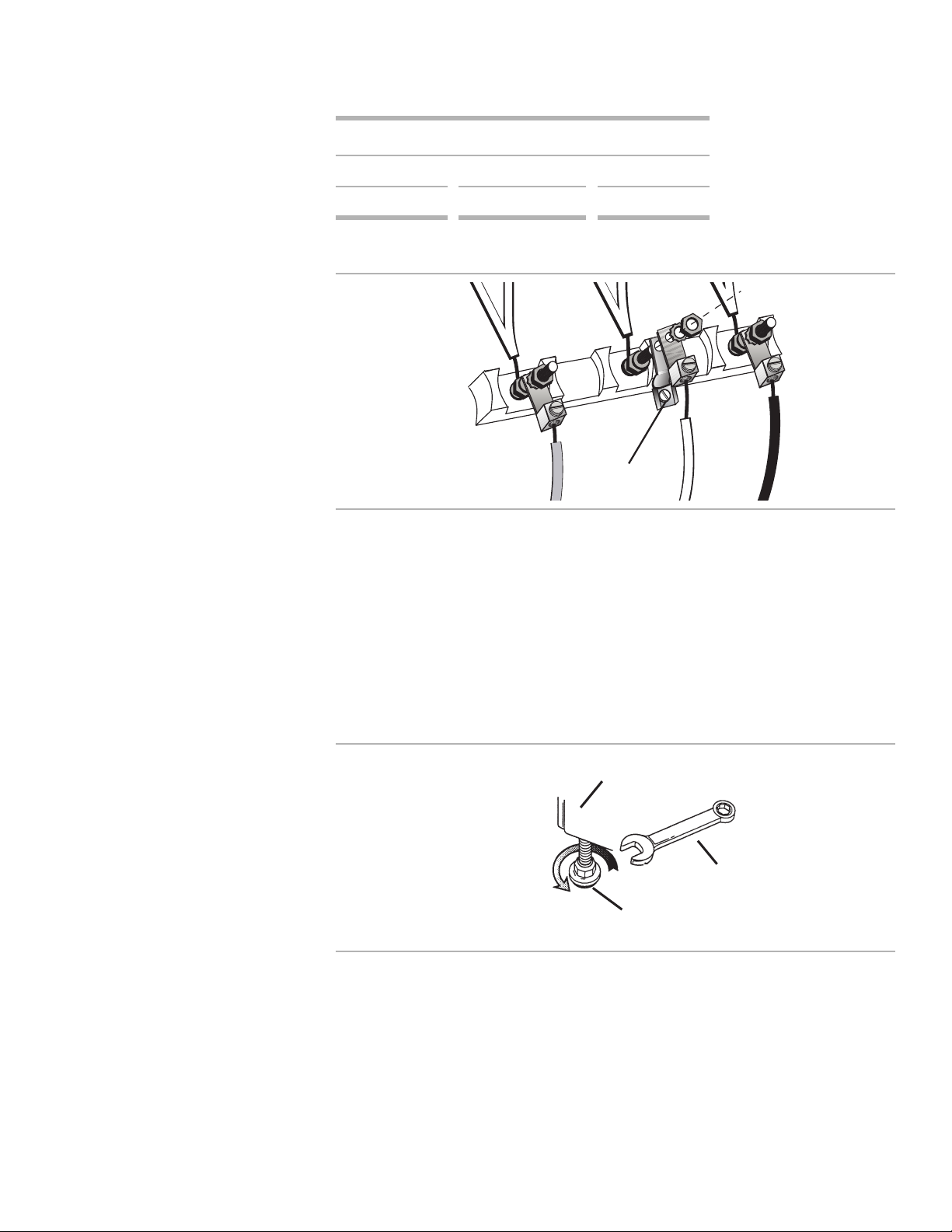

Three Wire Flexible Conduit Connection

The Four Wire Connection is preferred, but where local codes and ordinances

permit grounding through neutral and/or conversion to four wire is impractical, unit

may be connected to the power supply via a three wire connection.

1. Disconnect electrical power at the breaker box.

2. Remove the terminal block cover to expose the terminal block.

Figure 19: Terminal Block

3. Remove the top nut, star washer, and round washer from each post.

Note: DO NOT remove last round washer, last nut or internal wire leads.

4. Place one terminal lug (packaged with this manual) on each post. Replace the star washer and round washer and secure with 20 inch pounds of torque.

5. Strip 3/8 (9.53 mm) inches of insulation from the end of each wire.

3/8 “

Figure 20: Wire Stripping

6. Insert stripped end of white wire into the center lug on top of the ground strap. Secure the clamping screw. .

lug

wire

clamping screw

Figure 21: Attaching Wire to Lug

7. Insert stripped end of red wire into the left lug. Secure clamping screw.

8. Insert stripped end of black wire into the right lug. Secure clamping screw.

English 14

Page 17

9. Tighten each clamping screw with the appropriate torque (See table below).

Table 4: Appropriate Torque Levels for Aluminum or Copper Wire

Gauge Torque (in./lbs.) Torque (Nm)

6

8

35 3.95

25 2.82

10. Properly secure flexible conduit at knockout panel on range and at supply side junction box. The wiring is now complete.

green ground screw

Figure 22: Completed Three Wire Flexible Conduit Connection

Note: DO NOT plug in range at this time.

Complete the installation

Adjust Levelling Legs 1. Line up range in front of opening.

2. Measure back left corner of opening from floor to top of countertop.

3. Measure back left corner of range to bottom of cooktop trim. Use a wrench to adjust leveling leg until this height is the same as the corner dimension.

4. Repeat in right back corner.

5. Adjust front leveling legs so that the bottom of the cooktop trim is ½" higher

than the corresponding countertop surface.

drawer

wrench

adjustable leg

Figure 23: Adjust the Front Leveling Leg

Slide Range into Opening 1. Plug in power cord.

2. Dampen countertop and foam tape with soapy water.

English 15

Page 18

3. Slide range into opening, being careful not to damage countertops, floors, or the range drawer front. Do not apply pressure to cooktop when sliding into position.

Tip: Remove the drawer to prevent damage.

Check Back of Range for Proper Installation

Adjust Front of Range for Proper Installation

1. When properly installed, the cooktop trim around the back of the range will rest lightly on the countertop.

2. There should not be any gap between the countertop and the trim; however,

the weight of the range must not rest on the countertop. Look under the range

to verify that both back legs are resting solidly on the floor. Also verify that the

left range leg is under the anti-tip bracket.

Caution: Verify that the weight of the range is not resting on the counterrop. This

could result in damage to the countertop and the appliance.

3. If the back legs are not resting solidly on the floor or the left leg is not under the anti-tip bracket, slide range out, adjust legs and slide back in.

1. Adjust front leveling legs so that the cooktop trim rests snugly against the countertop all the way around.

2. Verify that both front legs are resting solidly on the floor.

3. Use a level to verify that the range is level and plumb.

Test the Installation

Turn on Power at Breaker Caution: If the display flashes and beeps, the polarity of the wiring may be

reversed. Reversed polarity can damage the range and can result in electrical

shock hazard. Immediately switch off power at the breaker and return to “Connect

Electric - Range Cord” on page 8.

Service

Before Calling Service

English 16

See Use and Care Manual for troubleshooting information. Refer to the Warranty

in the Use and Care Manual.

To reach a service representative, see the contact information at the front of the

manual. Please be prepared with the information printed on your product data

plate when calling.

Page 19

Product Data Plate The data plate shows the model and serial number. Refer to the data plate on the

appliance when requesting service. It is located on the frame near the drawer.

Open the drawer to view it.

Data Plate

Figure 24: Data Plate

English 17

Page 20

Table des matières

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Avant de commencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Marche à suivre d'installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Avant d'effectuer un appel de service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Questions?

1.800.944.2904

www.boschappliances.com

5551 McFadden Ave.

Huntington Beach, CA 92649

Nous attendons vos nouvelles !

Page 21

Sécurité

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

LIRE ET CONSERVER CES INSTRUCTIONS

Instructions de sécurité

importantes

Sécurité pour manipuler l'appareil • Ne pas soulever l'appareil par la poignée. Enlever la porte pour faciliter la

Normes et codes de sécurité • Cet appareil est conforme avec une ou plusieurs des normes

• Avertissement : si l'information de ce guide n'est pas suivie exactement, il

peut en résulter un choc électrique ou un incendie pouvant causer des dommages à la propriété ou des blessures.

• AVERTISSEMENT : ne pas réparer ni remplacer les pièces de l'appareil à

moins que cela ne soit spécifiquement recommandé dans les guides. Une

installation, un service ou un entretien inadéquat peut causer des dommages

à la propriété ou des blessures. Consulter ce guide. Tout autre service doit

être effectué par un technicien qualifié.

manutention et l'installation. Voir les instructions du guide d'utilisation et

d'entretien.

• L'appareil est lourd et il faut au moins deux personnes ou un équipement

approprié pour le déplacer.

• Certaines surfaces présentent des bords tranchants. Faire attention en allant

derrière ou sous l'appareil.

UL 858, norme pour la sécurité des cuisinières électriques domestiques

UL 923, norme pour les appareils de cuisson micro-ondes

UL 507, norme pour les ventilateurs électriques

ANSI Z21.1-2000, norme nationale américaine pour appareils de cuisson

à gaz domestiques

CAN/CSA-C22.2 n° 113-M1984 ventilateurs

CAN/CSA-C22.2 n° 61-M89 cuisinières domestiques

Il incombe au propriétaire et à l'installateur de déterminer si des

exigences et ou normes additionnelles s'appliquent aux installations

spécifiques.

Sécurité électrique • Avant de brancher l'appareil, s'assurer que tous les contrôles sont en position

arrêt.

• Pour les appareils dotés d'un cordon et d'une fiche, ne pas couper ni enlever

la broche de mise à la terre. Il doit être branché sur une prise mise à la terre

appropriée pour éviter les chocs électriques. En cas de doute concernant la

mise à la terre adéquate de la prise, la faire vérifier par un électricien qualifié.

• Si requis par le Code national d'électricité (ou le code canadien d'électricité),

cet appareil doit être installé sur un circuit terminal séparé.

• Seul un nécessaire de cordon d'alimentation coté pour cet appareil et marqué

" pour utilisation avec cuisinières " peut être utilisé.

• Installateur - indiquer au propriétaire l'emplacement du coupe-circuit ou du

fusible. Le noter à des fins de références.

• Important - conserver pour utilisation par l'inspecteur en électricité local.

• Avant l'installation, mettre l'alimentation hors circuit au panneau de service, le

verrouiller pour éviter la mise en circuit accidentelle.

Français 1

Page 22

• S'assurer que l'appareil est installé et mis à la terre adéquatement par un

technicien qualifié. L'installation, les connexions électriques et la mise à la

terre doivent être conformes à tous les codes applicables.

Sécurité relative à l'équiement • Avertissement : toute cuisinière peut basculer et causer des blessures.

Installer le dispositif anti bascule fourni avec l'appareil. S'assurer que le dispositif est bien enclenché. Voir les instructions d'installation.

• Enlever tout ruban et emballage avant d'utiliser l'appareil. Jeter l'emballage.

Ne jamais laisser les enfants jouer avec le matériel d'emballage.

• Ne jamais modifier ni changer la fabrication de l'appareil. Par exemple, ne pas

enlever les pieds niveleurs, panneaux, fils, couvercles ni dispositifs anti bascule/vis.

• Pour éliminer le risque de brûlures ou d'incendie en passant par dessus une

surface chaude, il serait préférable d'éviter le rangement au-dessus de l'appareil. S'il y a un espace de rangement, le risque peut être réduit en installant

une hotte à projection horizontale de 5 po minimum du bas de l'armoire.

• S'assurer que les armoires au-dessus de la surface de cuisson ont un minimum de 13 po (330 mm) de profondeur.

Installation

Avant de commencer

Outils et pièces nécessaires

• Nécessaire d’alimentation 40 ou 50 amp (selon les codes locaux)

• Ruban à mesurer

• Tournevis à lame Phillips

• Clé 1 1/4 po (31,8 mm)

•Crayon

• Tournevis T-20

• Vis (2) et ancrages (2) pour fixation anti bascule (style variant selon la surface

• Niveau

• Perceuse et mèches

• Eau savonneuse

• Gants et lunette de sécurité

• Ruban adhésif (optionnel)

• Carton ou chiffon (optionnel pour protéger le plancher)

Remarque : non nécessaire pour les installations au Canada

d’installation)

Pièces additionnelles nécessaires pour installation à raccordement fixe

• Conduit flexible

• Clé dynamonmétrique

• Remarque : nécessaire de cordon d’alimentation non nécessaire pour installation à raccordement fixe

Pièces comprises • Fixation anti bascule

• Ruban mousse

Français 2

Page 23

Généralités

Dimensions hors tout

• Cosses (pour installation à raccordement fixe) (non nécessaires pour installation au Canada)

Tableau 1: Dimensions hors tout

Dimension Poids Centimèters

Hauteur

Largeur

Profondeur

Niveau Pour de meilleurs résultats, les armoires, plans de travail, murs et plancher de

l'emplacement doivent être le plus de niveau possible. Une variation peut causer

des dommages au plan de travail et plancher pendant l'installation et pourrait

nuire au joint de l'appareil et modifier la cuisson et le rendement.

Conseils Apposer du ruban adhésif au tiroir réchaud pour le garder fermé pendant l'installa-

tion de la cuisinière.

Pendant l'installation, placer une portion de la boîte ou autre sous la cuisinière

afin de protéger le plancher.

Pour alléger l'appareil et en faciliter la manutention, enlever la porte (voir les

instructions dans le guide d'utilisation et d'entretien).

36 91,44 cm

29 5/16 po 74,55 cm

25 5/8 po 65,09 cm

Préparation

Exigences électriques Consulter la plaque signalétique pour plus de détails. Voir “Plaque signalétique” à

la page 17 pour l'emplacement.

Nous recommandons que la cuisinière soit installée avec un nécessaire de cor-

don d'alimentation (non fourni)

être de120/240 volts, 40 ou 50 ampères minimum (selon les codes locaux). Le

nécessaire de cordon d'alimentation doit être marqué " pour utilisation avec cuisinières ". Toujours utiliser un nouveau cordon d'alimentation.

Remarque : au Canada, la cuisinière est expédiée de l'usine avec le cordon déjà

en place.

1.Non nécessaire pour les installations au Canada.

1

. La cote électrique du cordon d'alimentation doit

Français 3

Page 24

Les cuisinières sont une cote jumelée pour une utilisation avec le 120/240 VAC

ou 120/208 CAV. Vérifier la plaque signalétique pour la cote kW. Voir la cote kW

dans le tableau ci-dessous pour déterminer les exigences d'ampérage.

Tableau 2: Données techniques électriques

kW Cote Hz Amps Requis

120/240V 120/208V

13 9.8 60

13.8

10.4 60

40 or 50

40 or 50

a

a

a. Varie selon les régions, vérifier les codes locaux.

La prise électrique doit être située dans la zone ombragée, figure 3.

7 1/2 po

(190,5 mm)

3 1/2 po

(88,9 mm)

4 1/2 po

(114,3 mm)

21 po (533,4 mm)

30 po

(762 mm)

4 1/2 po

(114,3 mm)

Figure 1: Dégagements de la surface de cuisson

Vérifier si le câblage résidentiel est adéquat

Communiquer avec la compagnie d'électricité locale pour s'assurer que le service

électrique de la résidence est adéquat. Dans certains cas, le calibre du câblage

de la résidence et l'interrupteur de service doivent être augmentés pour supporter

la charge électrique requise par la cuisinière.

Vérifier si le câblage intérieur de la maison est adéquat

La plupart des codes de câblages requiert un circuit séparé avec un interrupteur

de débranchement séparé et fusibles au panneau de service principal ou un interrupteur séparé et une boîte à fusibles.

La cuisinière requiert un circuit minimum de trois fils 120/240 ou 120/208 volts, 40

ou 50 amp., 60 Hz c.a. Vérifier les codes locaux concernant la cote d'ampérage

appropriée. La connexion à 4 fils est recommandée.

La plupart des codes et règlements de construction locaux requièrent que le

câblage électrique soit effectué par un électricien qualifié. S'assurer d'installer la

cuisinière conformément aux codes électriques de la région.

Exigences pour l’armoire Cet appareil est conçu pour une installation près de murs adjacents et surfaces

projetées fabriqués de matériaux combustibles

Français 4

Page 25

Allouer un minimum de 30 po entre les armoires où la cuisinière est installée

Voir figure 2: Exigences de découpe for more information..

23 1/16 po

(585,4 mm)

30 po (762 mm)

Figure 2: Exigences de découpe

1

.

Remarque : la cuisinière à encastrer peut aussi remplacer une cuisinière amov-

ible. Dans ce cas vérifier que l'ouverture a au moins 30 po.

30 po (76,2 cm) min

Figure 3: Exigences de découpe - remplacement d'un modèle amovible

1

.

1.Au Canada, un dégagement de 12 mm depuis le mur de la cuisinière à l'armoire est requis.

Français 5

Page 26

4 po (10,2 cm

min

30 po (76,2 cm

min. centré

30 po (76,2 cm) min

)

)

4 po(10,2 cm

)

min

aucun dégageme

la pa

Dégagement requis

nt requis (dégagement 12 mm de

roi de l’appareil à l’armoire requis au

Figure 4: Préparation d'armoire

1

Canada

)

De la surface de cuisson aux matériaux au-dessus : Il doit y avoir un dégagement

minimum de 30 po entre le haut de la surface de cuisson et le bas d’une armoire

en métal ou en bois non protégé. Voir figure 4: Préparation d'armoire.

24 po sont acceptables lorsque le bas d'armoire en bois ou en métal sont protégées par (a) pas moins de 1/4 po de matériaux ignifuges qui doivent être recouverts avec (b) une feuille en métal de pas moins de n° 28 MSG, acier inoxydable

0.015 po ou 0.024 po d'aluminium ou de cuivre.

Depuis les murs de la cuisinière aux matériaux adjacents : Voir figure 4: Préparation d'armoire. Aucun dégagement n'est nécessaire depuis les murs de l'appareils

aux murs combustibles verticaux adjacents sur l'arrière, gauche ou droite.

2

Le dégagement de la cuisinière aux murs verticaux adjacents doit être d'au moins

4 po.

Remarque : certains finis d'armoires ne peuvent supporter les températures permises par U.L., particulièrement avec four autonettoyant ; les armoires peuvent

décolorer ou tacher. Ceci est plus remarquable avec les armoires laminées.

Préparer murs et planchers

Sceller tout trou dans les murs et plancher. Enlever toute obstruction (connexions

électriques ou de gaz additionnelles, etc.) afin que la cuisinière soit adéquatement

appuyée au mur.

Exigences de plan de travail Le plan de travail doit être uni et de niveau.

Exigences de fixation Installer le dispositif anti bascule

1.Les instructions ont été déterminées avec des armoires de type américain standard. Les armoires de base standard mesurent 36 po de haut x 24 po de profondeur. Les armoires au-dessus de

la surface de cuisson et celles adjacentes mesurent 13 po de profondeur du mur arrière. Si des

armoires non standard sont utilisées, il faut prendre et modifier les dimensions adéquatement.

2.Au Canada, un dégagement de 12 mm du mur de la cuisinière à l'armoire est requis.

Français 6

Page 27

1. Ajuster la hauteur de la cuisinière et mettre de niveau en tournant les pieds

réglables au bas de la cuisinière à l'aide d'une clé 1 ¼ po.

2. Mesurer pour placer le dispositif. Voir figure 5: Dispositif anti bascule.

3. Fixer avec 2 vis appropriées pour la surface d'installation (ex. : pour plancher en bois, utiliser des vis à bois, pour le ciment, utiliser des ancres et des vis). .

Mur arrière

Paroi d’armoire

Contre paroi

d’armoire

1 9/16 po (39,7 mm)

depuis le mur arrière au centre du trou à vis

plancher

Fixation

anti bascule

Figure 5: Dispositif anti bascule

Recommandation de ventilation Nous recommandons l'installation d'une hotte au-dessus de l'appareil.

Pour la plupart des cuisines, une hotte certifiée ayant une cote de pas moins de

300 pi3/min est recommandée. La hotte doit être installée selon les instructions

fournies avec l'appareil.

Marche à suivre d'installation

Apposer du ruban mousse Apposer du ruban mousse sur le côté inférieur de la garniture de surface de cuis-

son en une pièce continue.

Remarque : NE PAS utiliser de calfeutrage ni de colle/adhésif que ce soit.

Garniture de dosseret Remarque : cette étape est requise seulement si le plan de travail n'est pas relié

derrière la cuisinière (par exemple, lorsque l'on remplace une cuisinière amovible)

Voir “Exigences pour l’armoire” à la page 4 pour plus de détails.

Français 7

Page 28

Installer deux vis par les trous de la garniture et le dosseret de la cuisinière.Voir

Voir figure 6: Bande de garniture de dosseret et Figure 7: Installer la bande de

garniture de dosseret

Bande de

garniture

de dosseret

.

Figure 6: Bande de garniture de dosseret

Connexion électrique cordon de cuisinière

Installation du réducteur de tension

le dos de la cuisinière

Figure 7: Installer la bande de garniture de dosseret

Remarque : au Canada, la cuisinière est expédiée de l’usine avec un cordon

d’alimentation déjà installé. Poursuivre à “Compléter l'installation” à la page 16.

Pour les installations autres qu'au Canada, brancher le cordon de la cuisinière au

bloc de bornes. (voir la page suivante pour plus de détails). Accéder au bloc de

bornes en enlevant le couvercle dans le coin inférieur droit du panneau arrière de

la cuisinière.

Avertissement : le réducteur de tension fourni avec le cordon de la cuisinière doit être installé.

Placer un réducteur de tension dans le trou à estamper sous le bloc de bornes.

Voir figure 8: Trou à estamper du réducteur de tension. Alimenter le cordon par le

trou et le réducteur de tension vers le bloc de bornes. Laisser assez de cordon

Français 8

Page 29

entre le réducteur de tension et le bloc de bornes. Une fois la longueur ajustée,

,

e

e

fixer le réducteur de tension selon les instructions fournis avec le réducteur.

Conseil : le panneau à estamper (sous le bloc de bornes) peut être enlevé

de la cuisinière pour installer le réducteur de tension. Enlever le panneau de

la cuisinière, installer le réducteur de tension sur le panneau, puis remettre

en place. NE PAS enlever complètement le panneau arrière de l’appareil.

Figure 8: Trou à estamper du réducteur de tension

Avertissement : Risque de choc électrique ou d’incendie. Le cadre

mis à la terre au neutre par le conducteur de terre. La mise à la terre par le con

ducteur neutre est interdit pour les nouvelles installations de circuit terminal

(1996 NEC), maisons mobiles et véhicules récréationnels ou dans les endroits

où les codes interdisent la mise à la terre par un conducteur neutre.

Pour les installations où la mise à la terre par le conducteur neutre est interdite

(a) débrancher le lien du neutre, (b) utiliser la borne de terre ou le fil pour mettr

l’appareil à la terre, (c) brancher la borne neutre sur le fil neutre du circuit termi

nal de la façon habituelle (lorsque l’appareil doit être branché par un nécessair

de cordon, utiliser un cordon à 4 fils).

Utiliser seulement les nécessaires de cordon cotés 125/250 volts (minimum),

50 ampères et étiquetés « Pour utilisation avec cuisinière ». Le réducteur de

tension fourni avec le cordon doit être installé selon les instructions fournies

avec le cordon.

CONNEXION à 3 FILS

FIL ROUGE

FIL BLANC

NEUTRE

CONNEXION à 4 FILS

FIL NOIR

FIL ROUGE

FIL BLANC

NEUTRE

FIL NOIR

Figure 9: Exigences de mise à la terre

Avertissement : pour éviter les choc électriques, la broche de mise à la

terre du cordon ne doit pas, en aucun cas, être coupée ni enlevée. Elle doit être

branchée sur une prise mise à la terre correspondante et branchée sur un circuit

240 volts adéquatement polarisé. En cas de doute concernant la mise à la terre,

communiquer avec un électricien qualifié.

Français 9

Page 30

Connexion du cordon à 4 fils (méthode recommandée)

1. Débrancher l’alimentation électrique au disjoncteur.

2. Enlever le couvercle du bloc de bornes pour exposer le bloc de borne..

Figure 10: Connexion à 4 fils

3. Enlever l’écrou supérieur, rondelle étoile et rondelle ronde de chaque tige.

Remarque : NE PAS enlever la dernière rondelle ronde, dernier écrou ou fils de

câblage interne.

4. Enlever la vis au bas de l’extrémité du conducteur de terre.

5. Enlever le conducteur de terre de la tige centrale, tourner afin que l’extrémité

large soit au haut et fixer l’extrémité large à la cuisinière par le trou sous la

boîte de jonction. Fixer le fil vert sur le dessus du conducteur de terre. Serrer

la vis.

Vis de mise à la terre verte

Conducteur de terre

Figure 11:

Connexion de cuisinière – conducteur de terre et fil

Fil de mise à la terre

6. Fixer le fil rouge, rondelle ronde, rondelle étoile et écrou DANS CET ORDRE sur la tige gauche.

7. Fixer le fil blanc, rondelle ronde, rondelle étoile et écrou DANS CET ORDRE sur la tige centrale.

Français 10

Page 31

8. Fixer le fil noir, rondelle ronde, rondelle étoile et écrou DANS CET ORDRE sur la tige droite..

rouge

Figure 12: Connexion de cuisinière à 4 fils (suite)

blanc

noir

9. Serrer toutes les connexions adéquatement et remettre le couvercle du bloc de bornes.

10. Bien fixer le réducteur de tension (voir rubrique précédente).

Remarque : NE PAS brancher l’appareil à ce moment.

Connexion de cuisinière à 3 fils La connexion à 4 fils est préférable, mais là où les codes et règlements permet-

tent la mise à la terre par le neutre et où la conversion à 4 fils n’est pas pratique,

l’appareil peut être branché sur l’alimentation électrique par une connexion à 3

fils.

1. Débrancher l’alimentation électrique au disjoncteur.

2. Enlever le couvercle du bloc de bornes pour exposer le bloc de borne.

Figure 13: Bloc de bornes

3. Enlever l’écrou supérieur, rondelle étoile et rondelle ronde de chaque tige.

Remarque : NE PAS enlever la dernière rondelle ronde, dernier écrou ou fils de

câblage interne.

4. Fixer le fil blanc, rondelle ronde, rondelle étoile et écrou DANS CET ORDRE sur le dessus du conducteur de terre sur la tige centrale

5. Fixer le fil rouge, rondelle ronde, rondelle étoile et écrou DANS CET ORDRE sur la tige gauche

Français 11

Page 32

6. Fixer le fil noir, rondelle ronde, rondelle étoile et écrou DANS CET ORDRE sur la tige droite.

noir

Conducteur

rouge

de terre

blanc

Figure 14: Connexion à 3 fils

7. Serrer toutes les connexions adéquatement et remettre le couvercle du bloc de bornes..

Connexion électrique conduit flexible

Connexion de conduit flexible à 4 fils

Vis de mise à la terre verte

Figure 15: Connexion à 3 fils complétée

8. Bien fixer le réducteur de tension Voir “Installation du réducteur de tension” à la page 8 pour plus de détails.

La cuisinière peut être branchée par l'entremise d'un conduit flexible. Si l'on utilise

cette méthode, toujours utiliser les cosses fournies.

Remarque : au Canada, la cuisinière est expédiée de l’usine avec un cordon

d’alimentation déjà installé. Poursuivre à “Compléter l'installation” à la page 16.

1. Débrancher l’alimentation électrique au disjoncteur.

2. Enlever le couvercle du bloc de bornes pour exposer le bloc de borne.

3. Enlever l’écrou supérieur, rondelle étoile et rondelle ronde de chaque tige.

Remarque : NE PAS enlever la dernière rondelle ronde, dernier écrou ou fils de

câblage interne.

4. Enlever la vis de l’extrémité inférieure du conducteur de terre.

5. Enlever le bloc de bornes de la tige centrale. Jeter.

6. Fixer une cosse (fournie avec ce guide) par le trou sous le bloc de bornes avec la vis de mise à la terre.

7. Placer une cosse (fournie avec ce guide) sur chaque tige. Remettre la rondelle étoile et la rondelle ronde et fixer avec une force de 20 po/lb.

Français 12

Page 33

8. Dégainer 3/8 po (9,53 mm) d’isolant de l’extrémité du fil..

3/8 po (9,53 mm)

Figure 16: Dégainer le fil

9. Insérer le fil de mise à la terre isolé sur la cosse sous le bloc de bornes.

10. Insérer l'extrémité dénudée du fil de mise à la terre blanc isolé dans la cosse centrale. Fixer avec une vis à pince..

Cosse

fil

Vis de serrage

Figure 17: Fixer le fil à la cossel

11. Insérer l'extrémité dénudée du fil rouge dans la cosse gauche. Fixer avec la vis à pince.

12. Insérer le fil noir dans la cosse droite. Fixer avec la vis à pince. Serrer chaque vis à pince avec une force appropriée (voir tableau).

Tableau 3: Niveau de force approprié pour fil aluminium ou cuivre

Calibre Force (po/lb Force (Nm

6

8

35 3,95

25 2,82

Français 13

Page 34

13. Fixer adéquatement le conduit flexible au trou à estamper en angle et à la boîte de jonction, côté alimentation. Le câblage est complété.

Vis de

mise à la

terre verte

fil rouge

fil blanc

Fil de mise à la

terre verte

Figure 18: Connexion de conduit flexible à 4 fils complétée

fil noir

Connexion de conduit flexible à 3 fils

Remarque : NE PAS brancher l’appareil à ce moment.

La connexion à 4 fils est préférable, mais là où les codes et règlements permet-

.

tent la mise à la terre par le neutre et où la conversion à 4 fils n’est pas pratique,

l’appareil peut être branché sur l’alimentation électrique par une connexion à 3

fils.

1. Débrancher l’alimentation électrique au disjoncteur.

2. Enlever le couvercle du bloc de bornes pour exposer le bloc de borne.

Figure 19: Bloc de bornes

3. Enlever l’écrou supérieur, rondelle étoile et rondelle ronde de chaque tige.

Remarque : NE PAS enlever la dernière rondelle ronde, dernier écrou ou fils de

câblage interne.

Français 14

4. Placer une cosse (fournie avec ce guide) sur chaque tige. Remettre la rondelle étoile et la rondelle ronde et fixer avec une force de 20 po/lb.

Page 35

5. Dégainer 3/8 po (9,53 mm) d’isolant de l’extrémité du fil..

3/8 po (9,53 mm)

Figure 20: Dégainer le fil

6. Insérer l’extrémité dégainée du fil blanc dans la cosse centrale. Fixer avec une vis de serrage..

Cosse

fil

Vis de serrage

Figure 21: Fixer le fil à la cosse

7. Insérer l’extrémité dégainée du fil rouge sur la cosse gauche. Fixer avec une vis de serrage.

8. Insérer l’extrémité dégainée du fil noir dans la cosse droite. Fixer avec une vis de serrage.

9. Serrer chaque vis de serrage avec une force appropriée (voir le tableau).

Tableau 4: Niveau de force approprié pour fil aluminium ou cuivre

Calibre Force (po/lb Force (Nm

6

8

35 3,95

25 2,82

10. Fixer adéquatement le conduit flexible au trou à estamper en angle et à la boîte de jonction, côté alimentation. Le câblage est complété.

Vis de mise

à la terre verte

Figure 22: Conduit flexible à 3 fil compléte

Remarque : NE PAS brancher l’appareil à ce moment.

Français 15

Page 36

Compléter l'installation

Régler le niveau des pieds 1. Aligner la cuisinière devant l'ouverture.

2. Mesurer le coin arrière gauche de l'ouverture depuis le plancher au haut du plan de travail.

3. Mesurer le coin arrière gauche de la cuisinière au bas de la garniture de surface de travail. Utiliser une clé pour régler le niveau du pied jusqu'à ce que

cette hauteur soit la même que celle du coin. .

tiroir

Figure 23: Régler les pieds niveleurs avant

4. Répéter avec le coin arrière droit.

5. Régler les pieds niveleurs avant afin que le bas de la garniture de surface de

cuisson soit ½ po plus haut que la surface du plan de travail correspondante.

Cl é

pied réglable

Glisser la cuisinière en place 1. Brancher le cordon d'alimentation.

2. Humidifier le plan de travail et le ruban mousse avec de l'eau savonneuse. .

3. Faire glisser la cuisinière dans l'ouverture en faisant attention à ne pas endommager le plan de travail, plancher ou le devant du tiroir de la cuisinière. Ne pas appliquer de pression à la surface de cuisson au moment de mettre en place.

Conseil : enlever le tiroir pour éviter tout dommage.

Vérifier le dos de la cuisinière pour une installation adéquate

Régler le devant de la cuisinière pour une installation adéquate

1. Lorsque bien installée, la garniture de surface de cuisson autour du dos de la cuisinière repose légèrement sur le plan de travail.

2. Il ne devrait pas y avoir d'espace entre le plan de travail et la garniture ; toutefois, le poids de la cuisinière ne doit pas reposer sur le plan de travail.

Regarder sous l'appareil afin de vérifier si les deux pieds arrière sont solidement au sol. Vérifier si le pied gauche de la cuisinière est inséré sous le dispositif anti bascule.

Attention : s'assurer que le poids de la cuisinière ne repose pas sur le plan de

travail. Ceci peut endommager le plan de travail et l'appareil.

3. S les pieds arrière ne sont pas solidement au sol ou que le pied gauche n'est pas sous le dispositif anti bascule, sortir la cuisinière, régler les pieds et remettre en place.

1. Régler les pieds niveleurs avant afin que la garniture de surface de cuisson repose bien contre le plan de travail tout autour.

2. S'assurer que les deux pieds avant sont solidement au sol.

3. Utiliser un niveau pour vérifier si la cuisinière est bien de niveau.

Français 16

Page 37

Vérifier l'installation

Mettre en circuit au coupe-circuit Attention : si l'affichage clignote et émet un bip, la polarité du câblage peut être

inversée. Une polarité inversée peut endommager la cuisinière et causer un risque de choc électrique. Fermer l'alimentation au coupe-circuit et retourner à

.“Connexion électrique - cordon de cuisinière” à la page 8.

Service

Avant d'effectuer un appel de service

Voir le guide de dépannage du guide d'utilisation et d'entretien. Consulter la

garantie.

Pour communiquer avec un représentant de service, voir l'information au début du

guide. Avoir l'information imprimée sur la plaque signalétique sous la main avant

de téléphoner.

Plaque signalétique La plaque signalétique donne les numéros de modèle et de série. La consulter au

moment de faire un appel de service. Elle est située sur le care près du tiroir.

Ouvrir le tiroir pour la voir

Plaque signalétique

.

Figure 24: Plaque signalétique

Français 17

Page 38

Tabla de Contenidos

Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Antes de comenzar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Procedimiento de Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Servicio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Antes de llamar al servicio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

¿Preguntas?

1-800-944-2904

www.boschappliances.com

5551 McFadden Ave.

Huntington Beach, CA 92649

¡Estamos a sus órdenes!

Page 39

Seguridad

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

LEA Y GUARDE ESTAS INSTRUCCIONES

Instrucciones Importantes

de Seguridad

Seguridad al manejar el aparato • No levante el aparato por la agarradera de la puerta. Quite la puerta para

Códigos de seguridad y normas • Este aparato cumple con una o más de las siguientes normas:

• Advertencia: El hecho de no observar con exactitud la información en este

manual puede causar un incendio o una descarga eléctrica y provocar

lesiones o daños a la propiedad.

• ADVERTENCIA: No repare o reemplace ninguna parte del aparato a menos

que se recomienda específicamente en los manuales. La instalación, servicio

o mantenimiento no apropiado puede causar lesiones o daños a la propiedad.

Consulte este manual como guía. Contrate a un técnico calificado para todos

los demás servicios.

facilitar el manejo y la instalación. Vea las instrucciones en el manual de uso

y cuidado.

• La unidad está pesada y requiere al menos de dos personas o de un equipo

apropiado para moverla.

• Las superficies ocultas pueden tener bordes filosos. Tenga cuidado cuando

meta la mano detrás o abajo del aparato.

UL 858, La norma para la seguridad de estufas electrodomésticas

UL 923, La norma para aparatos (hornos) de microondas

UL 507, La norma para la seguridad de ventiladores eléctricos

ANSI Z21.1-2000, La norma americana nacional para aparatos

domésticos de cocina que funcionan con gas

CAN/CSA-C22.2 No. 113-M1984 Ventiladores

CAN/CSA-C22.2 No. 61-M89 Estufas domésticas

Es la responsabilidad del propietario y del instalador determinar si aplican

requerimientos y/o normas adicionales a instalaciones específicas.

Seguridad eléctrica • Antes de enchufar un cable eléctrico, asegúrese que todos los controles

estén en la posición OFF (Apagado).

• No corte la clavija de tierra en aparatos que incluyen un cable con enchufe.

Se debe enchufar en una tomacorriente aterrizada que coincida con el

enchufe para evitar una descarga eléctrica. Si tiene alguna duda con

respecto a si la tomacorriente está puesta a tierra correctamente, el cliente

debería contratar a un eléctrico calificado para revisarla.

• Si el Código Eléctrico Nacional (o el Código Eléctrico de Canadá) lo requiere,

se debe instalar este aparato en un circuito derivado separado.

• Se debe utilizar solamente un cable apropiado de alimentación eléctrica para

este aparato y marcado "para uso con estufas".

• Instalador - enseñe al propietario el lugar del cortacircuitos o de la caja de

fusibles. Márquelo para futuras referencias.

• Importante - Guarde estas instrucciones para el uso del inspector eléctrico.

• Antes de instalar el aparato, apague la corriente en el panel de servicio. Bloquee el panel de servicio para evitar que se prenda la corriente accidentalmente.

Español 1

Page 40

• Asegúrese de que su aparato esté instalado y aterrizado correctamente por

un técnico calificado. La instalación, las conexiones eléctricas y la puesta a

tierra deben cumplir con todos los códigos aplicables.

Seguridad del equipo • Advertencia: Todas las estufas pueden volcarse. Esto puede causar

lesiones. Instale el dispositivo antivolcadura que se incluye con la estufa.

Verifique que los dispositivos antivolcadura estén enganchados. Vea las

instrucciones de instalación.

• Quite las cintas adhesivas y materiales de empaque antes de usar el aparato.

Destruya el cartón y las bolsas de plástico después de desempacar el

aparato. Nunca permita que los niños jueguen con el material de

empaque.Nunca modifique o altere la construcción del aparato. Por ejemplo,

no quite las patas de nivelación, paneles, alambres, cubiertas o dispositivos

antivolcadura/tornillos.Para eliminar el riesgo de sufrir quemaduras o de

causar un fuego cuando trata de alcanzar cosas arriba de las unidades

superficiales calientes, se debe evitar el espacio de almacenamiento en gabinetes arriba de las unidades superficiales. Cuando se tiene que proporcionar

este espacio de almacenamiento, se puede reducir el riesgo al instalar una

campana que salga horizontalmente un mínimo de 5 pulgadas (127 mm)

arriba del fondo del gabinete.

• Verifique que los gabinetes arriba de la parrilla tengan una profundidad

máxima de13" (330 mm).

Instalación

Antes de comenzar

Herramientas y partes que se necesitan

• Juego de cable de alimentación eléctrica de 40 o 50 amps (depende del

código local) (Nota: no se necesita para instalaciones en Canadá)

• Cinta de medir

• Destornillador de cabeza Phillips (de cruz)

• Llave inglesa de 1-1/4” (31.8 mm)

•Lápiz

• Destornillador de cabeza Torx T-20

•

Tornillos (2) y anclas (2) para el soporte antivolcadura (El estilo varía dependiendo de

la superficie de montaje

• Niveleta

• Taladro y broca

• Agua con jabón

• Guantes y lentes de seguridad

• Cinta (Opcional)

• Trapo o cartón (Opcional - para proteger el piso)

)

Partes adicionales que se necesitan para instalaciones permanentes

Español 2

• Conducto flexible

• Llave inglesa

• Nota: No se necesita el kit del cable de alimentación eléctrica con instalaciones permanentes

Page 41

Partes incluidas • Soporte antivolcadura

• Cinta de espuma

• Terminales de orejeta (Se usan con instalaciones permanentes) (no se

necesitan para instalaciones en Canadá)

Información general

Dimensiones generales

Tabla 1: Dimensiones generales

Dimensiones Pulgadas Centímetros

Altura

Ancho

Profundidad

Nivel Para lograr mejores resultados, las paredes y los pisos de los gabinetes y de la

cubierta deben ser lo más nivelados y desplomados posible en el lugar de la

instalación. Una variación puede dañar las cubiertas y los pisos durante la instalación, podría perjudicar el sello alrededor de la parrilla y puede afectar los

resultados negativamente cuando cocina u hornea.

Consejos Ponga cinta al cajón calentador para evitar que se abra cuando instala la estufa.

Durante la instalación, coloque una parte de la caja o un pedazo de tela debajo

de la estufa para proteger los pisos.

Quite la puerta para facilitar el manejo de la estufa (vea las instrucciones en el

manual de uso y cuidado).

36 91.44 cm

29 5/16” 74.55 cm

25 5/8” 65.09 cm

Preparación

Requerimientos eléctricos Consulte la placa con información para más detalles. Vea la “Placa con datos del

producto” en página 16 para ubicar la placa de información.

Recomendamos instalar la estufa con un cable de alimentación (no se incluye).

La capacidad eléctrica del cable de alimentación debe ser 120/240 volts, 40 o 50

amperes mínimo (dependiendo del código local). El cable de alimentación eléctrica debe estar marcado “Para uso con estufas.” Siempre use un cable de alimentación nuevo.

Nota: En Canadá se envía la estufa desde la fábrica con el cable de alimentación

ya instalado.

Las estufas funcionan con doble voltaje ya sea con 120/240 VAC o 120/208 VAC.

Revise la placa de información para la capacidad en kW. Tome referencia de la

capacidad kW en la tabla abajo para determinar los requerimientos del amperaje.

1.No se necesita para instalaciones en Canadá

Español 3

1

Page 42

Tabla 2: Especificaciones eléctricas

Régimen de kW Hz

AMPS

Requeridos

120/240V 120/208V

13 9.8 60

13.8

10.4 60

40 or 50

40 or 50

a

a

a. Varía por lugar. Revise los códigos locales.

La tomacorriente debe quedar ubicada en el espacio sombreado en la Figura 3.

7 1/2”

(190.5 mm)

3 1/2”

(88.9 mm)

4 1/2”

(114.3 mm)

21” (533.4 mm)

30”

(762 mm)

4 1/2”

(114.3 mm)

Figura 1: Espacios libres para los gabinetes

Verificar que el cableado a la casa sea apropiado

Contacte a su proveedor local de electricidad para verificar que el servicio eléctrico actual en su casa sea el adecuado. En algunos casos, se debe aumentar el

tamaño del cableado a la casa y al interruptor de servicio para poder manejar la

carga eléctrica exigida por la estufa.

Verificar que el cableado adentro de la casa sea apropiado

La mayoría de los códigos de cableado requieren un circuito separado con un

desconectador y fusibles separados ya sea en el panel de la entrada principal o

en una caja separada de interruptores y fusibles.

La estufa requiere mínimo un circuito de tres cables de 120/240 o 120/208 volts,

40 o 50 AMP, 60 Hz AC. Revise los códigos locales para el amperaje apropiado.

Una conexión con cuatro cables es preferible.

La mayoría de los códigos locales de construcción requieren que un eléctrico

autorizado realice el cableado eléctrico. Asegúrese de instalar su estufa conforme

a los códigos eléctricos que aplican en su región.

Requerimientos para los gabinetes Esta unidad está diseñada para una instalación cerca de paredes adyacentes y

las superficies salientes que son hechas de materiales combustibles.

Español 4

Page 43

Permita un mínimo de 30 pulgadas (762 mm) entre los gabinetes donde se va a

1

instalar la estufa

. Vea Figura 2: Requerimientos del recorte para más infor-

mación.

23 1/16"

(585.4 mm)

30" (762 mm)

Figura 2: Requerimientos del recorte

Nota: La estufa deslizable puede sustituir también a una estufa autoestable. En

este caso, verifique que la abertura sea de al menos 30 pulgadas (762 mm).

30" (76.2 cm) min

Figure 3: Requerimientos del recorte - sustituir un modelo autoestable

1

.

1.En Canadá se requiere un espacio libre de 12 mm de la pared lateral de la estufa al gabinete.

Español 5

Page 44

30” (76.2 cm)

mínimo centrado

4” (10.2 cm)

mín

30” (76.2 cm) mínim

o

4” (10.2 cm)

mín

no se requiere espacio libre (en Canadá, se requiere un

espacio lib

Requerimiento para espacio libre

re de 12 mm del costado de la estufa al gabine

Figura 4: Preparación para los gabinetes

1

e.)

t

Desde la parrilla a los materiales arriba: Debe haber un espacio libre mínimo de

30 pulgadas entre la parte superior de la superficie de cocinar y el fondo de un

gabinete de madera o metal no protegido. Vea Figura 4: Preparación para los

gabinetes.

24 pulgadas (610 mm) son aceptables cuando el fondo del gabinete de metal o

madera está protegido por (a) no menos de 1/4” de material retardante al fuego

que debe estar cubierto con (b) no menos de chapa No. 28 MSG, con un grueso

de 0.015 pulgadas (4 mm) de acero inoxidable o 0.024 pulgadas (6 mm) de aluminio o cobre.

Desde las paredes de la estufa a los materiales adyacentes: Vea Figura 4:

Preparación para los gabinetes. No se requiere ningún espacio libre desde las

paredes de la unidad a las paredes verticales adyacentes combustibles en la

parte trasera, izquierda y derecha.

2

El espacio libre desde la parte superior de la estufa a las paredes verticales adyacentes debe ser al menos 4”.

Nota: El acabado de algunos gabinetes no puede sobrevivir las temperaturas

permitidas por U.L. para aparatos electrodomésticos, sobre todo los hornos de

autolimpieza; los gabinetes pueden perder su color o mancharse. Esto se nota

aún más con gabinetes laminados.

Preparar las paredes y los pisos

Selle cualquier orificio en las paredes o el piso. Quite cualquier obstrucción (conexiones eléctricas o de gas adicionales) de modo que la estufa pueda descansar

correctamente contra la pared.

1.Se determinaron las instrucciones en base a gabinetes americanos estándar. Los gabinetes estándar de piso miden 36” (910 mm) de altura x 24” (610 mm) de profundo. Los gabinetes arriba de

la superficie de cocinar y los gabinetes junto a los que están arriba de la superficie de cocinar

miden 13” (330 mm) de profundo de la pared trasera. Cuando se usan gabinetes no estándar, tenga cuidado de modificar las dimensiones correctamente.

2.En Canadá se requiere un espacio libre de 12 mm desde la pared lateral de la estufa hasta el

gabinete.

Español 6

Page 45

Requerimientos para cubiertas Las cubiertas deben quedar suaves y niveladas.

de l

ificio de t

ill

Requerimientos de montaje Instalar el soporte antivolcadura

1. Ajuste la altura de la estufa y nivélela girando las patas ajustables en la parte inferior de la estufa, usando una llave de 1-1/4".

2. Tome medidas para localizar la posición del soporte como se indica en Vea Figura 5: Soporte antivolcadura.

3. Fije el soporte con 2 tornillos apropiados para la superficie de montaje (i.e., para un piso de madera use tornillos para madera, para un piso de concreto use anclajes y tornillos para concreto).

pared trasera

pared del gabinete

a ras contra la

pared del gabinete

1 9/16“ (39.7 mm)

a pared trasera al centro del or

piso

dispositivo

antivolcadura

orn

o

Figura 5: Soporte antivolcadura

Recomendaciones de ventilación Recomendamos fuertemente instalar una campana de ventilación arriba de esta

estufa. Para la mayoría de cocinas se recomienda una campana con un régimen

eléctrico nominal no menor de 300 CFM. La campana debe ser instalada de acuerdo a las instrucciones incluidas con ésta.

Procedimiento de Instalación

Aplicar cinta de espuma Aplique cinta de espuma a la parte inferior de la moldura de la parrilla en una sola

pieza continua.

Nota: NO use junta calafateada o pegamento/adhesivo de ningún tipo.

Instalar la moldura de la pared trasera

Nota: Se requiere este paso solamente cuando la cubierta no está conectada

detrás de la estufa (i.e.; cuando reemplaza una estufa autoestable).

Vea ‘Requerimientos para los gabinetes” en página 4 para más información.

Instale 2 tornillos a través de los orificios en la moldura y en la pared trasera de la

estufa. Vea Figura 6: Tira de la moldura de la pared trasera y Figura 7: “Instalar la

tira de la moldura de la pared trasera”

.

Español 7

Page 46

Tira de la

moldura de

la pared

trasera

Figura 6: Tira de la moldura de la pared trasera

Trasera de la estufa

Figura 7: Instalar la tira de la moldura de la pared trasera

Conexión eléctrica - Cable de la estufa

Nota: En Canadá, se envía la estufa desde la fábrica con el cable de alimen-

tación eléctrica instalado. Sigue al “Terminar la instalación” en página 15.

Para instalaciones fuera de Canadá, conecte el cable de alimentación de la estufa al bloque de terminales (Vea la siguiente página para instrucciones detalladas). Acceda al bloque de terminales abriendo la tapa en la esquina derecha

inferior del panel trasero de la estufa.

Instalar el prensacables Advertencia: Se debe instalar correctamente el prensacable que

viene incluido con el cable de la estufa.

Coloque el prensacable en el agujero ciego abajo del bloque de terminales.

Figura 8: Agujero ciego del prensacable.

Ponga el cable de la estufa a través del

Vea

agujero y del prensacable hasta el bloque de terminales. Permita un poco de juego

en el cable entre el prensacable y el bloque de terminales. Una vez que haya ajus-

Español 8

Page 47

tado la longitud/el juego del cable, fije el prensacable de acuerdo a las instruc-

E

ciones incluidas con éste.

Consejo: Se puede quitar el panel botador de la estufa (abajo del bloque

de terminales) para instalar el prensacable Quite el panel botador de la

estufa, instale el prensacable en el panel y vuelva a fijarlo. NO quite todo

el panel trasero de la estufa.

Figura 8: Agujero ciego del prensacable

Advertencia: Riesgo de una descarga eléctrica o un fuego. El bastidor

está conectado a neutral a través de un cable de tierra. Se prohibe la conexión

a tierra a través del conductor neutral para instalaciones nuevas con circuito

de derivación (1996 NEC), casas rodantes y vehículos recreativos, o en áreas

donde los códigos locales prohiben el aterrizaje a través del conductor neutral.

Para instalaciones donde se prohibe la conexión a tierra a través del conductor

neutral, (a) desconecte el cable del conductor neutral, (b) use la terminal o el

cable a tierra para aterrizar la unidad, (c) conecte la terminal o el cable neutral

del circuito de derivación del modo normal (cuando el aparato está conectado

mediante un cable de alimentación, use un cable con 4 hilos para este

propósito).

Use sólo cables con capacidad nominal de 125/250 volts (mínima), 50

amperes y marcado “Para uso con estufas”. Se debe instalar el prensacable

incluido con el cable de acuerdo a las instrucciones incluidas.

CONEXIÓN DE 3 HILOS

CABLE ROJO

Advertencia:

Para evitar una descarga eléctrica, no se debe cortar o

CABLE BLANCO

Figura 9: Requerimientos para la puesta a tierra

CABLE NEGRO

CONEXIÓN DE 4 HILOS

CABLE ROJO

CABLE BLANCO

TIERRA VERD

CABLE NEGRO

quitar la espiga de tierra bajo ninguna circunstancia. Se debe enchufar

en una tomacorriente correspondiente y conectar a un circuito de 240

Volts correctamente polarizado. Cuando existe alguna duda con

respecto a si la tomacorriente está correctamente puesta a tierra, contrate a un

eléctrico calificado para checarlo.

Español 9

Page 48

Conexión del cable con cuatro hilos (método recomendado)

1. Desconecte la corriente eléctrica en la caja del cortacircuito.

2. Quite la tapa del bloque de terminales para exponer el bloque de terminales

Figura 10: Conexión de 4 hilos

3. Quite la tuerca superior, la arandela de estrella y la arandela redonda de cada

poste.

Nota: NO quite la última arandela redonda, la última tuerca o los cables internos.

4. Quite el tornillo del extremo inferior de la tira de conexión a tierra.

5. Quite la tira de conexión a tierra del poste central, gire de modo que el

extremo ancho quede arriba y fije el extremo ancho a la estufa a través del

agujero abajo de la caja de conexiones. Fije el cable verde en la parte superior de la tira de conexión a tierra. Apriete el tornillo.

tornillo verde de

conexión a tierra

tira de conexión

a tierra

cable de tierra

Figura 11: Conexión del cable de 4 hilos - Tira y cable de tierra

6. Fije el cable rojo, la arandela redonda, la arandela de estrella y la tuerca EN

ESTE ORDEN al poste izquierdo.

7. Fije el cable blanco, la arandela redonda, la arandela de estrella y la tuerca

EN ESTE ORDEN al poste central.

8. Fije el cable negro, la arandela redonda, la arandela de estrella y la tuerca EN

ESTE ORDEN al poste derecho.

negro

rojo

blanco

Español 10

Figura 12: Conexión del cable de 4 hilos, continuación

Page 49

9. Apriete todas las conexiones bien y reemplace la tapa del bloque de termina-

les.

10. Fije el prensacables correctamente (vea la sección anterior).

Nota: NO enchufe la estufa en este momento.

Conexión del cable con tres hilos La conexión de cuatro hilos es el método preferido, pero donde los códigos

locales permiten la puesta a tierra a través del neutral y/o donde la conversión a

cuatro hilos es algo poco práctico, se puede conectar la unidad a la fuente de alimentación vía una conexión de tres hilos.

1. Desconecte la corriente eléctrica en la caja del cortacircuito.

2. Quite la tapa del bloque de terminales para exponer el bloque de terminales.

Figura 13: Bloque de terminales

3. Quite la tuerca superior, arandela de estrella y arandela redonda de cada poste.

Nota: NO quite la última arandela redonda, la última tuerca o los cables internos.

4. Fije el cable blanco, la arandela redonda, la arandela de estrella y la tuerca EN

ESTE ORDEN en la parte superior de la tira a tierra sobre el poste central.

5. Fije el cable rojo, la arandela redonda, la arandela de estrella y la tuerca EN

ESTE ORDEN al poste izquierdo.

6. Fije el cable negro, la arandela redonda, la arandela de estrella y la tuerca EN

ESTE ORDEN al poste derecho.

negro

tira de conexión

rojo

a tierra

blanco

Figura 14: Conexión de 3 hilos

Español 11

Page 50

7.

)

Apriete todas las conexiones bien y reemplace la tapa del bloque de terminales.

tornillo verde de

conexión a tierra

Figura 15: Conexión terminada del cable de la estufa de 3 hilos

8. Fije el prensacables correctamente. Vea ‘Instalar el prensacables” en

página 8 para màs detalles.

Conexión eléctrica - conducto flexible

Conexión con conducto flexible de cuatro hilos

La estufa se puede conectar también vía conducto flexible. Si utilizando este

método, siempre utiliza las terminales de orejeta suministradas.

Nota: En Canadá, la estufa está transportado del fábrica con el conducto flexible

ja instaló. Continúe a “Terminar la instalación” en página 15.

1. Desconecte la corriente eléctrica en la caja del cortacircuito.

2. Quite la tapa del bloque de terminales para exponer el bloque de terminales.

3.

Quite la tuerca superior, arandela de estrella y arandela redonda de cada poste

Nota: NO quite la última arandela redonda, la última tuerca o los cables internos.

4. Quite el tornillo del extremo inferior de la tira de tierra.

5. Quite la tira del poste central. Deséchela.

6. Fije una terminal de orejeta (incluida con este manual) a través del agujero

abajo del bloque de terminales con el tornillo de tierra.

7. Coloque una terminal de orejeta (incluida con este manual) en cada poste.

Reemplace la arandela de estrella y la arandela redonda y fíjelos con un