Page 1

Service guide

230 V 1 N~/400 V 3 N~

Split Outdoor unit

6 720 813 707-00.2I

ODU Split 2

ODU Split 4...8

ODU Split 11t...15t

ODU Split 11s...15s

6 720 817 722 (2015/06)

Page 2

Table of contents

Split ODU – 6 720 817 722 (2015/06)

2

Table of contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 2

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Error handling instructions for Split outdoor unit . . . . . . . . . . 3

2.1 Names of units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 List of error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Error code 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.1 Error diagnosis and countermeasure flow chart . . . . . . . 5

2.4 Error code 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4.1 Error diagnosis and countermeasure flow chart . . . . . . . 8

2.5 Error code 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.1 Error diagnosis and countermeasure flow chart . . . . . 11

2.6 Error code 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6.1 Error diagnosis and countermeasure flow chart . . . . . 14

2.7 Error code 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.7.1 Error diagnosis and countermeasure flow chart . . . . . 17

2.8 Error code 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.8.1 Error diagnosis and countermeasure flow chart . . . . . 20

2.9 Error code 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.9.1 Error diagnosis and countermeasure flow chart . . . . . 21

2.10 Error code 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.10.1 Error diagnosis and countermeasure flow chart . . . . . 22

2.11 Error code 41, 44, 45, 46, 48 . . . . . . . . . . . . . . . . . . . 23

2.11.1 Error diagnosis and countermeasure flow chart . . . . . 23

2.12 Error code 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.12.1 Error diagnosis and countermeasure flow chart . . . . . 24

2.13 Error codes 52, 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.13.1 Error code 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.13.2 Error code 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.14 Error code 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.15 Error code 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.16 Error code 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.16.1 Error diagnosis and countermeasure flow chart . . . . . 29

2.17 Error code 62, 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.17.1 Error diagnosis and countermeasure flow chart . . . . . 30

2.18 Error code 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.18.1 Error diagnosis and countermeasure flow chart . . . . . 32

3 Check compressor resistances . . . . . . . . . . . . . . . . . . . . . . . . 34

4 Compressor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5 Check system parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6 Electronic expansion valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7 Fan motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8 Replacement procedure for INV PCB . . . . . . . . . . . . . . . . . . . 39

9 Other pre - checkings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this document:

• NOTICE indicates a situation that could result in damage to property

or equipment.

• CAUTION indicates a situation that could result in minor to medium

injury.

• WARNING indicates a situation that could result in severe injury or

death.

• DANGER indicates a situation that will result in severe injury or

death.

Important information

Additional symbols

1.2 General safety instructions

These installation instructions are intended for plumbers, heating

engineers and electricians.

▶ Read any installation instructions (outdoor unit, heating controls,

etc.) carefully before starting the installation.

▶ Observe the safety instructions and warnings.

▶ Observe national and regional regulations, technical rules and

guidelines.

▶ Record all work carried out.

Intended use

This outdoor unit must only be used as a heat appliance in a sealed hot

water heating system for domestic purposes.

Any other use is considered inappropriate. Any damage that results from

such use is excluded from liability.

Installation, commissioning and servicing

Installation, commissioning and servicing must only be carried out by an

authorised contractor.

▶ Only use original spares.

Electrical work

Electrical work must only be carried out by qualified electricians.

▶ Before starting electrical work:

– Isolate all poles of the mains voltage and secure against

reconnection.

– Using suitable means, test that the power supply is disconnected.

▶ Also see connection diagrams of other system components.

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

This symbol indicates important information where

there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

Page 3

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

3

Handling refrigerant

The air to water outdoor unit is filled with R410A refrigerant.

▶ Only qualified and authorised refrigeration engineers may work on

the refrigerant circuit.

▶ For all work with refrigerant, wear suitable safety gloves and goggles.

What to do if refrigerant leaks

If refrigerant leaks and touches the skin, it can cause frostbite.

▶ In case of a refrigerant leak, never touch any part of the air to water

outdoor unit.

▶ Avoid skin or eye contact with refrigerant.

▶ Seek medical attention if you get refrigerant on your skin or in your

eyes.

▶ If the refrigerant leaks please contact your installer immediately.

Handover to the user

When handing over the heating system, instruct the user in its operation

and operating conditions.

▶ Explain the operation - with particular emphasis on all safety-related

actions.

▶ Explain that conversions and repairs must only be carried out by an

approved contractor.

▶ Point out the need for inspections and maintenance for safe and

environmentally-compatible operation.

▶ The installation and operating instructions must be given to the user

for keeping.

2 Error handling instructions for Split outdoor unit

2.1 Names of units

2.2 List of error codes

Supplier name for ODU BTT name for ODU

AHUW036A2 ODU Split 2

AHUW056A2 ODU Split 4

AHUW076A2 ODU Split 6

AHUW096A2 ODU Split 8

AHUW126A2 ODU Split 11s

AHUW146A2 ODU Split 13s

AHUW156A2/166A2 ODU Split 15s

AHUW128A2 ODU Split 11t

AHUW148A2 ODU Split 13t

AHUW158A2/168A2 ODU Split 15t

Table 2 Names of units

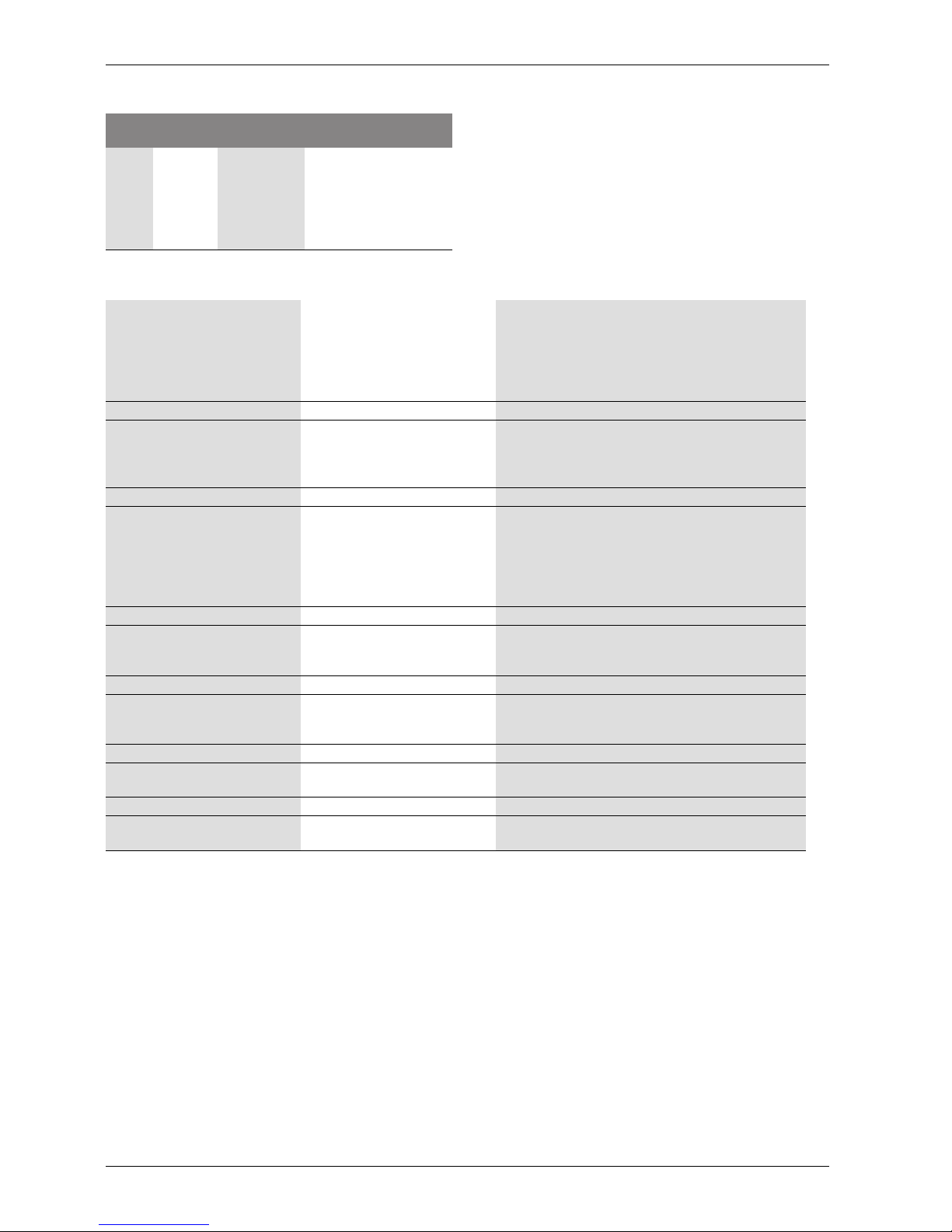

HMI Error code ODU Error code Description Error characteristc Remark

5600, 5601 21 DC Peak (IPM Fault)

IPM = Intelligent Power module

Restart 10x/hour,

then blocked

Compressor broken or too much refrigerant in

compressor

5602, 5603 22 CT 2 (Max CT) Restart after

problem has

vanished

Inverter current > 14 A

5604, 5605 23 DC Link Voltage is low or high Restart after

problem has

vanished

Direct voltage

1~: <140 VDC or >480 (3kW: 420) VDC

3~: <320VDC or >780VDC

5610, 5611 26 Problem in DC Compressor

positioning

Restart 10x/hour,

then blocked

Wrong orientation of compressor connections

(UVW)

5612, 5613 27 PSC Fault Restart 10x/hour,

then blocked

High current IGBT (check reactor)

5616, 5617 29 High current at Compressor

phases

Restart 10x/hour,

then blocked

5618, 5619 32 Temperature at discharge-pipe is

too high

Restart after

problem has

vanished

Hot gas temperature TH5 >105 °C (check

refrigerant load)

5666, 5667 35 Low Pressure error Restart 3x/hour,

then blocked

Low Pressure < 0 kPa

( – 49.5 °C)

5622, 5623 41 Problem in discharge-pipe

temperature sensor

Direct shut-down Sensor TH5 broken (200k >25 °C)

5662, 5663 43 High-pressure sensor (Open/

Short)

Direct shut-down LP/HP sensor broken

5624, 5625 44 Problem in ambient temperature

sensor

Direct shut-down Sensor TH7 broken (10k >25 °C)

5626, 5627 45 Problem in condenser-middle-pipe

temperature sensor

Direct shut-down Sensor TH8 broken (5k >25 °C)

5628, 5629 46 Problem in suction-pipe

temperature sensor

Direct shut-down Sensor TH4 broken (5k >25 °C)

Table 3 Error codes

Page 4

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

4

2.3 Error code 21

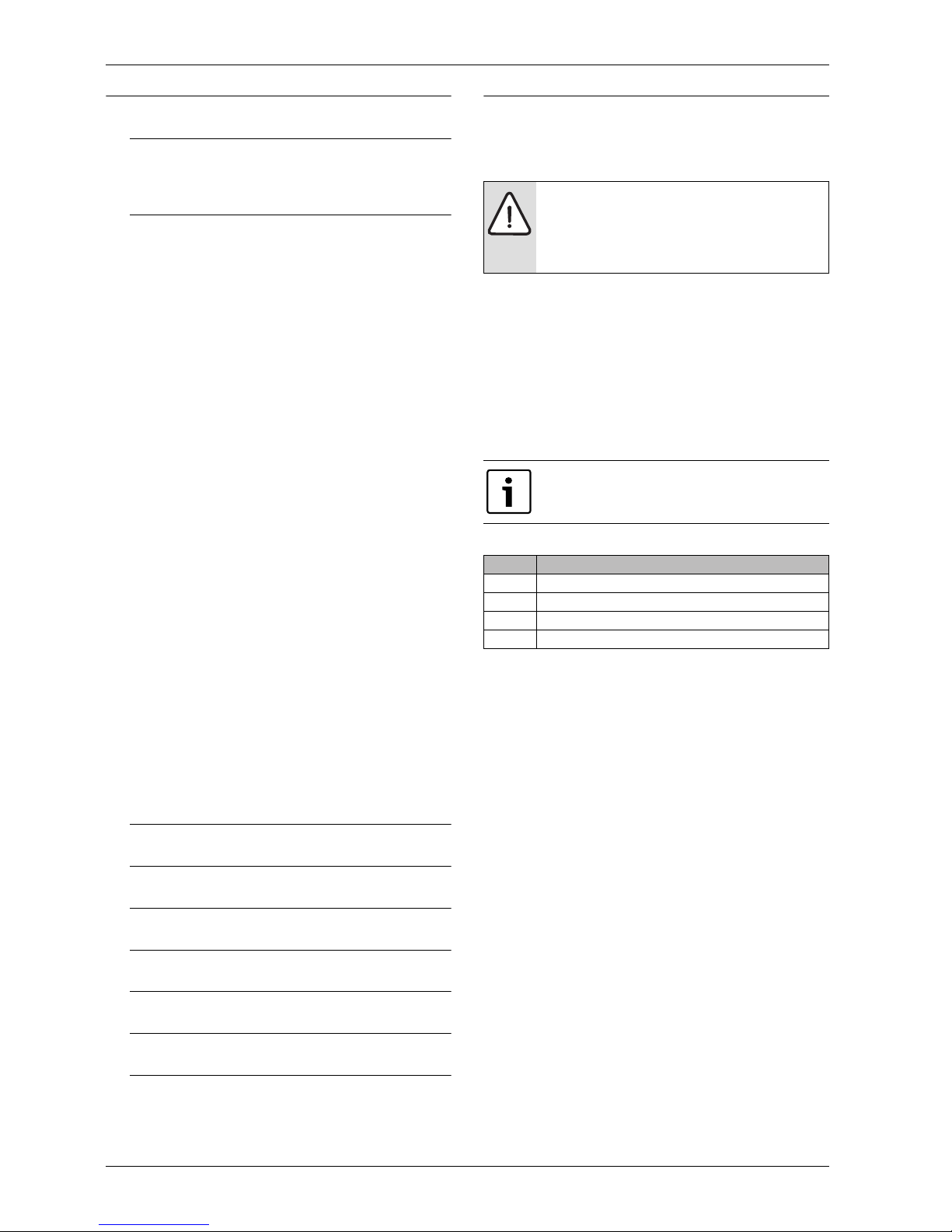

Fig. 1 Resistance measurement on compressor

[1] Compressor

[2] Copper pipe

5664, 5665 48 Cond. Out-pipe Th Error (Open/

Short)

Direct shut-down Sensor TH6 broken (5k >25 °C)

5632, 5633 52 Bad communication between

Inverter-PCB and Main-PCB

Restart 3x/hour,

then blocked

Wiring between Mainboard and Inverter board

damaged (3~ phase only)

5634, 5635 53 Bad communication between Can-

PCB and Main-PCB

Direct shut-down Wiring between Mainboard and CAN-PCB

damaged

5636, 5637 54 Phase sequence incorrect Restart 10x/hour,

then blocked

only 2 phases or incorrect rotation field

(3~ phase only)

5668, 5669 55 CAN Communication error (CAN-

PCB <=> Installerboard)

Direct shut-down Wiring between CAN-PCB and Indoor unit

damaged

5638, 5639 60 EEPROM Checksum mismatched Direct shut-down Change EEPROM

5640, 5641 61 Temperature at condenser-pipe is

too high

Restart after

problem has

vanished

Condensing temperature >65.3°C (4199 kPa)

{Heating}

Condensing temperature >64.2

°C(4101 kPa)

{Cooling}

5642, 5643 62 Temperature at heat sink is too

high

Restart after

problem has

vanished

Heat sink temperature >85 °C

5646, 5647 65 Problem in heatsink temperature

sensor

Direct shut-down Heat sink sensor / Inverter-PCB broken

5670, 5671 67 ODU BLDC fan lock Restart 10x/hour,

then blocked

Fan blocked

HMI Error code ODU Error code Description Error characteristc Remark

Table 3 Error codes

When the outdoor unit (ODU) is blocked the error can be

acknowledged by power ON/OFF.

Display

code

Title Cause of error

Check point & Normal

condition

21 DC PEAK

(IPM fault)

-Instant over

current

-Over rated

current

-Poor insulation

of IPM

-An instant over current in

the U,V,W phase

-Comp lock

-The abnormal connection of

U,V,W

-Over load condition

-Overcharging of refrigerant

pipe length

-Outdoor fan has stopped

-Poor insulation of

compressor

Table 4 Error code 21

ODU model Resistance () at 25 °C

ODU Split 4

ODU Split 6

ODU Split 8

U-V

0.628

V-W

0.628

W-U

0.628

ODU Split 11s

ODU Split 13s

ODU Split 15s

U-V

0.438

V-W

0.438

W-U

0.438

ODU Split 11t

ODU Split 13t

ODU Split 15t

U-V

0.845

V-W

0.845

W-U

0.845

Table 5 Resistance between phases

V

U

W

6 720 817 722-01.1I

1

2

1

Page 5

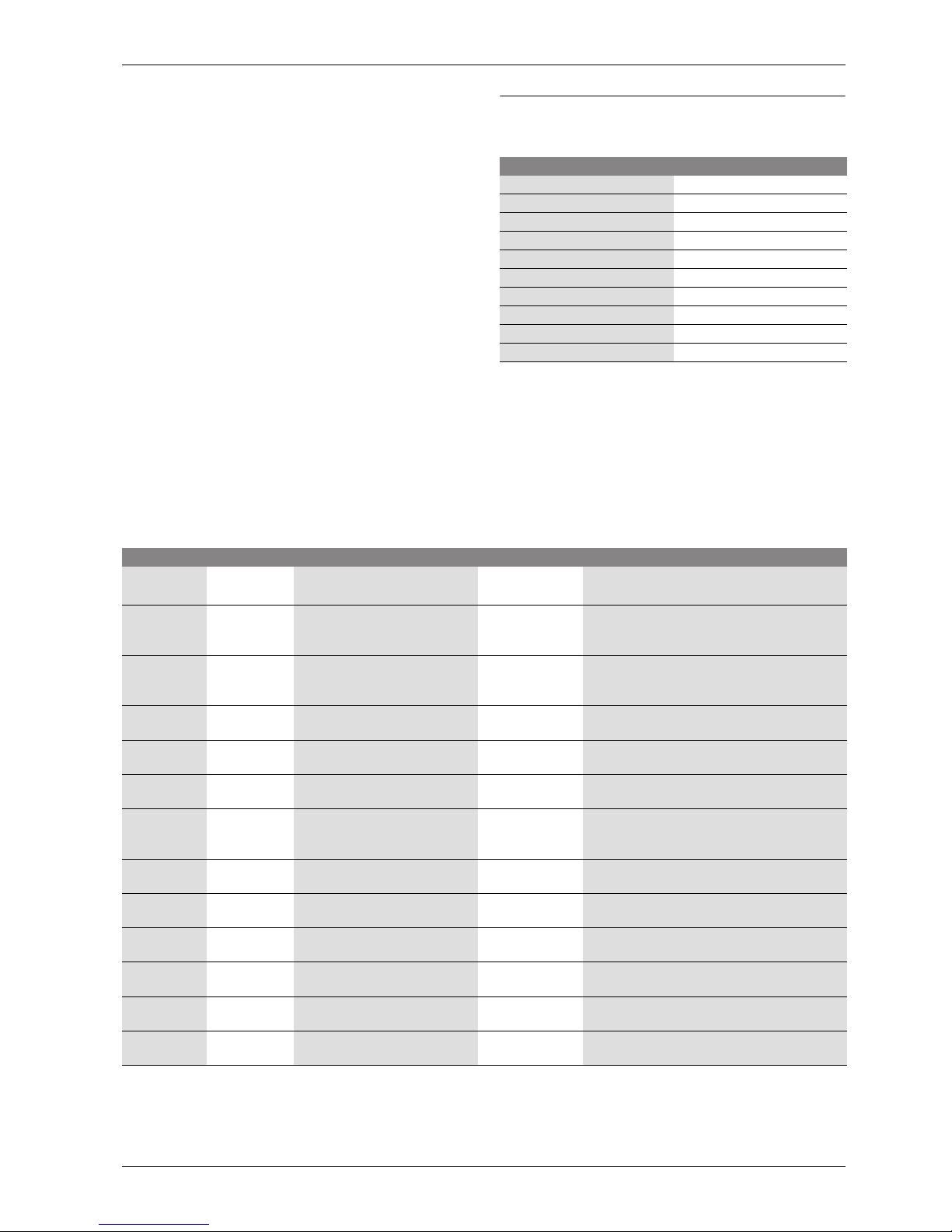

2.3.1 Error diagnosis and countermeasure flow chart

ODU Split 4, 6 and 8

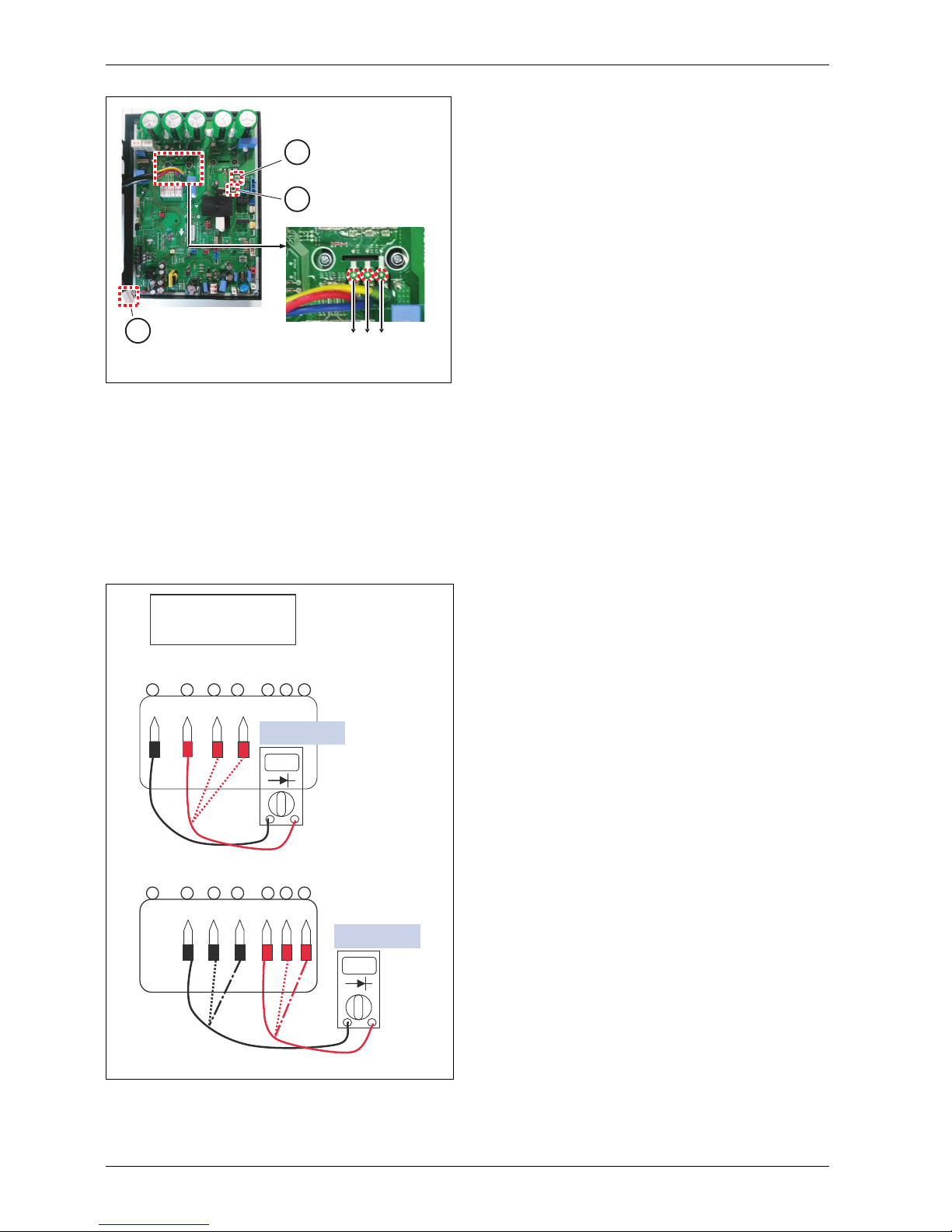

Fig. 2 ODU Split 4, 6, 8

1. Wait until PCB (Inverter) DC voltage is discharged after main

power is shut off.

2. Pull out V, W, U COMP connector.

3. Set multi tester to resistance mode.

4. If the value between P and N terminal of IPM is short (0) or open

(hundreds M), PCB (Inverter) needs to be replaced, IPM is

damaged.

5. Set the multi tester to diode mode.

6. In case measured value is different from the table, PCB (Inverter)

needs to be replaced. PCB (Inverter) is damaged.

Fig. 3 PFC_IPM check

ODU Split 11s, 13s, 15s

Is installation condition normal? No -> 1. Check pipe clogging / distortion

2. Check covering (unit)

3. Check EEV connector assembly condition / normal

operation

4. Check refrigerant pressure

-> Reassemble or manage if abnormality found

Yes

Are the resistance between each phase

and insulation resistance of inverter

compressor normal?

No ->

1. Check resistance between each terminal of compressor

2. Check insulation resistance between compressor terminal

and pipe

-> Replace compressor if abnormality is found

Yes

Is compressor wire connection

condition normal?

No -> 1. Check inverter PCB assembly 1 U,V,W connector

cennection condition

2. Check wire disconnection and wiring

3. Check compressor terminal connection condition (bad

contact)

-> Reassemble if abnormality is found

Yes

Is inverter PCB assembly 1 normal? No -> 1. Check inverter PCB assembly 1 IPM normality

-> Replace inverter PCB assembly 1

Yes

Recheck power and installation

condition

Table 6 Error diagnosis and countermeasure chart

SPM3

27 26 25 24 23 22 21

P W V U Nw Nv Nu

6 720 817 722-02.1I

27 26 25 24 23 22 21

P W V U Nw Nv Nu

0.4 ~ 0.6 V

P W V U Nw Nv Nu

27 26 25 24 23 22 21

0.4 ~ 0.6 V

PFC_IPM check

U, V, W ‘ R S T

6 720 817 722-03.1I

Page 6

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

6

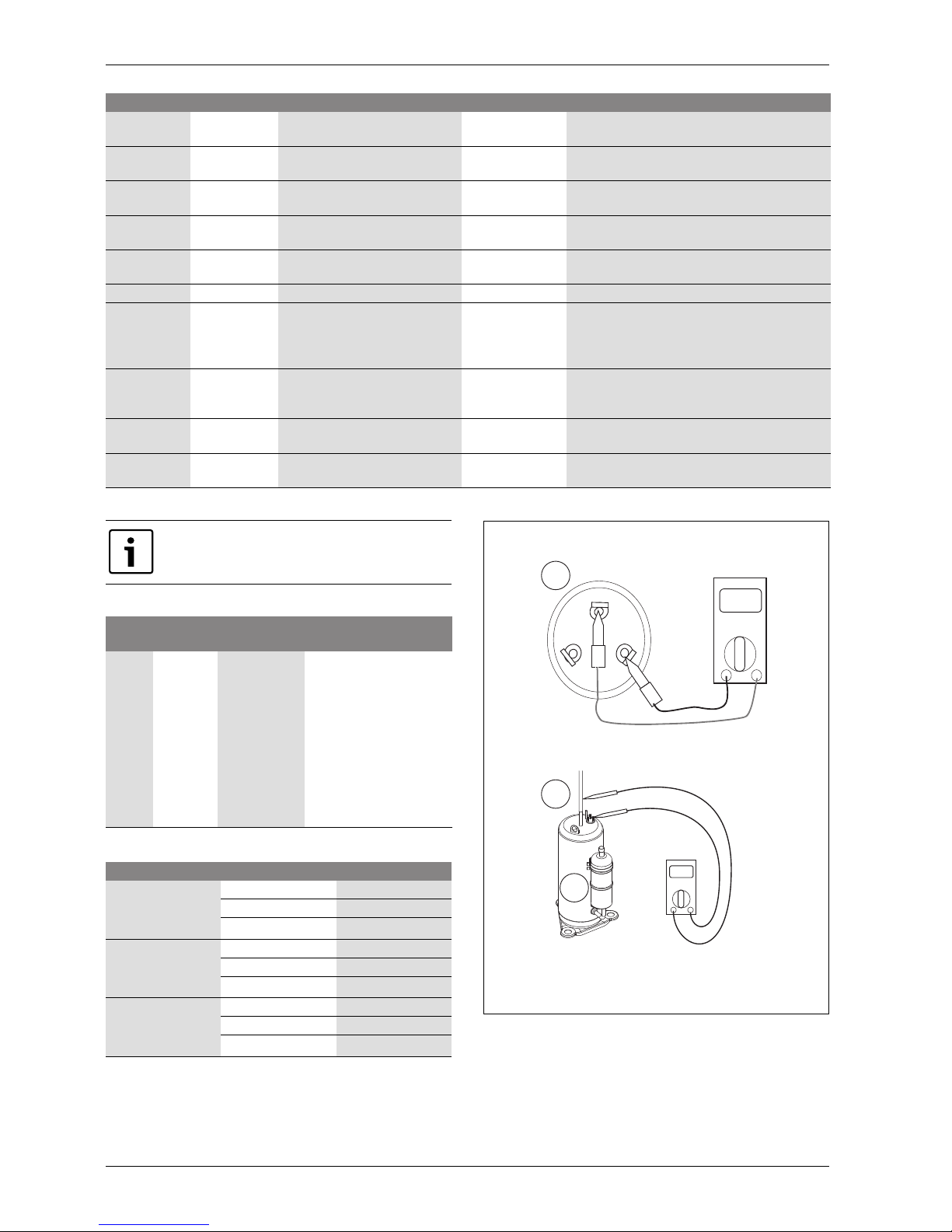

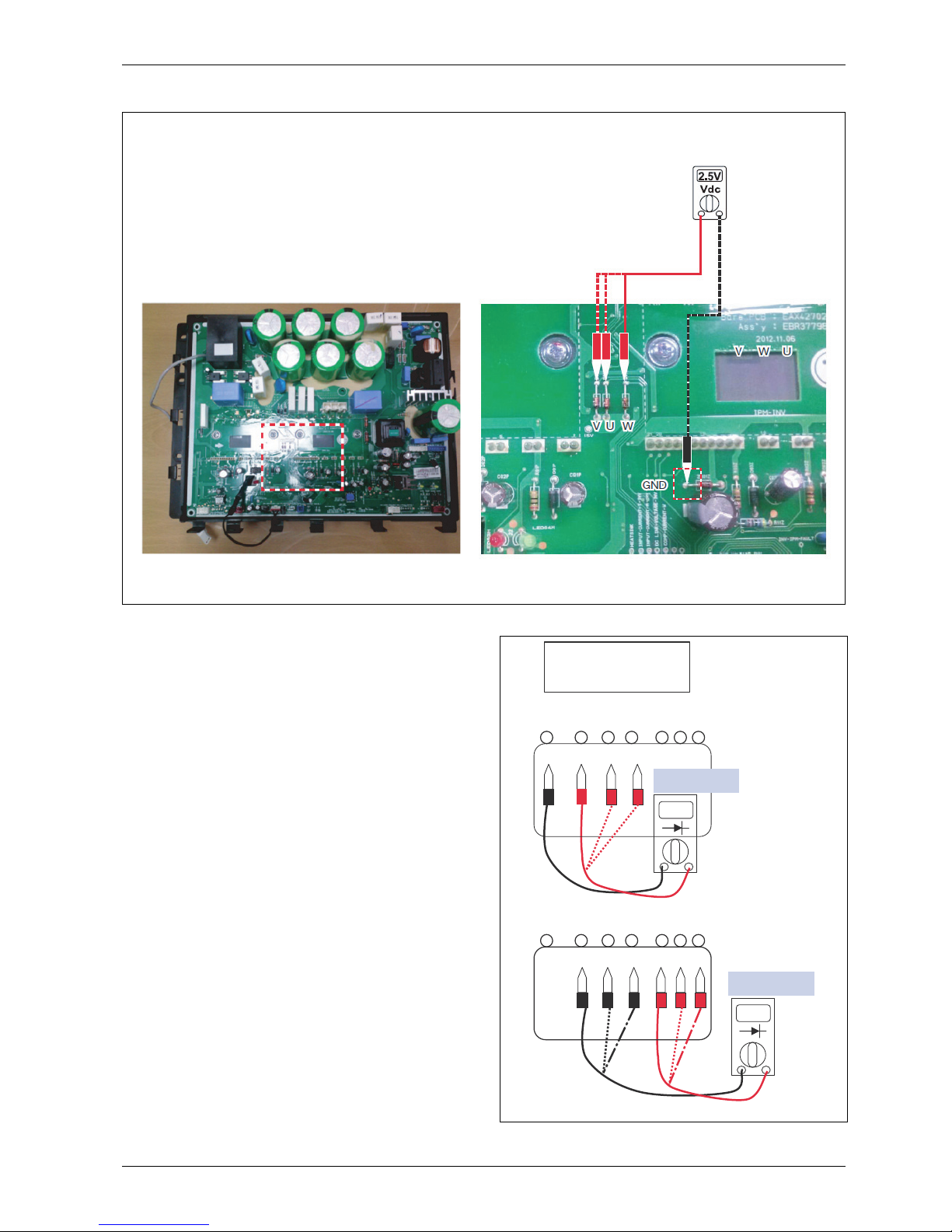

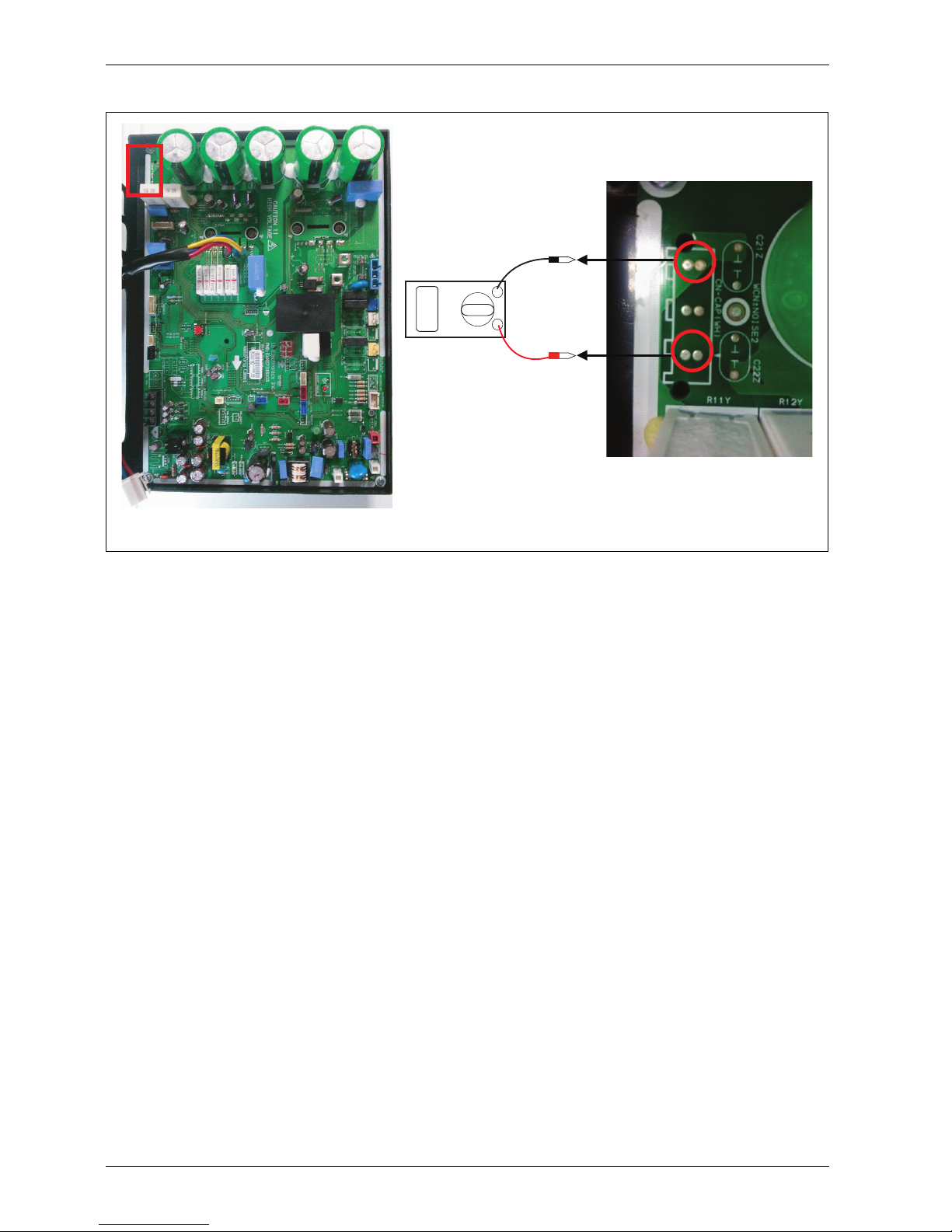

Fig. 4 ODU Split 11s, 13s, 15s

1. Wait until PCB (Inverter) DC voltage is discharged after main power

is shut off.

2. Pull out V, W, U COMP connector.

3. Set multi tester to resistance mode.

4. If the value between P and N terminal of IPM is short (0) or open

(hundreds M), PCB (Inverter) needs to be replaced, IPM is

damaged.

5. Set the multi tester to diode mode.

6. In case measured value is different from the table, PCB (Inverter)

needs to be replaced. PCB (Inverter) is damaged.

Fig. 5 PFC_IPM check

1

2

3

UVW

6 720 817 722-04.1I

27 26 25 24 23 22 21

P W V U Nw Nv Nu

0.4 ~ 0.6 V

P W V U Nw Nv Nu

27 26 25 24 23 22 21

0.4 ~ 0.6 V

PFC_IPM check

U, V, W ‘ R S T

6 720 817 722-03.1I

Page 7

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

7

ODU Split 11t, 13t, 15t

Fig. 6 ODU Split 11t, 13t, 15t

1. Wait until PCB (Inverter) DC voltage is discharged after main power

is shut off.

2. Pull out V, W, U COMP connector.

3. Set multi tester to resistance mode.

4. If the value between P and N terminal of IPM is short (0) or open

(hundreds M), PCB (Inverter) needs to be replaced, IPM is

damaged.

5. Set the multi tester to diode mode.

6. In case measured value is different from the table, PCB (Inverter)

needs to be replaced. PCB (Inverter) is damaged.

Fig. 7 PFC_IPM check

6 720 817 722-05.1I

27 26 25 24 23 22 21

P W V U Nw Nv Nu

0.4 ~ 0.6 V

P W V U Nw Nv Nu

27 26 25 24 23 22 21

0.4 ~ 0.6 V

PFC_IPM check

U, V, W ‘ R S T

6 720 817 722-03.1I

Page 8

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

8

2.4 Error code 22

2.4.1 Error diagnosis and countermeasure flow chart

Check Point

1. Check the power source (230V 15%).

2. Check that the fan operation is right.

3. Check the current.

4. Check the install condition.

5. Check the CT sensor output signal.

Display

code

Title Cause of error

Check point & Normal

condition

22 Max. C/T -Input Over

Current

1. Malfunction of

Compressor

2. Blocking of Pipe

3. Low Voltage Input

4. Refrigerant, Pipe length,

Blocked

Table 7 Error code 22

Is installation condition normal? No -> 1. Check pipe clogging / distortion

2. Check covering (unit)

3. Check EEV connector assembly condition / normal

operation

4. Check refrigerant pressure

-> Reassemble or manage if abnormality found

Yes

Are the resistance between each phase

and insulation resistance of inverter

compressor normal?

No -> 1. Check resistance between each terminal of compressor

2. Check insulation resistance between compressor terminal

and pipe

-> Replace compressor if abnormality is found

Yes

Is compressor wire connection

condition normal?

No -> 1. Check connection between PCB assembly and bridge diode

(misconnection, disconnection)

2. Check wire disconnection and wiring

3. Check compressor terminal connection condition (bad

contact)

-> Reassemble if abnormality is found

Yes

Is inverter PCB assembly 1 power

connection normal?

No -> 1. Check connection between PCB assembly 1 and bridge

diode (misconnection, disconnection)

-> Wiring again if abnormality is found

Yes

Is input voltage normal? No -> 1. Check L~N phase is 230V 15%

-> Check connection condition and wiring if power is

abnormal

Yes

Is PCB assembly 1 normal? No -> 1. Check PCB assembly 1 IPM normality

-> Replace inverter PCB assembly

Yes

Recheck power and installation

condition

Table 8 Error diagnosis and countermeasure chart

Page 9

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

9

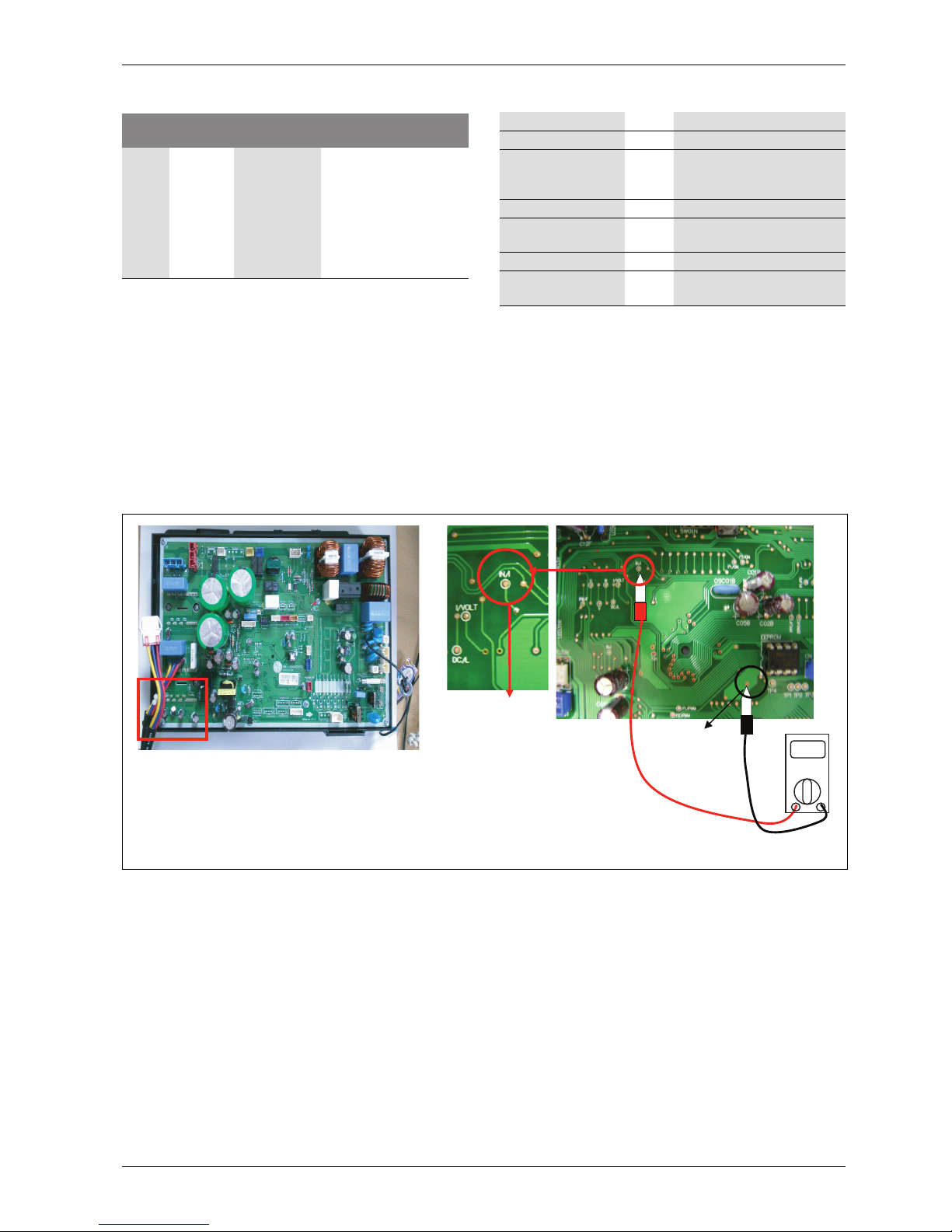

ODU Split 4, 6, 8

Fig. 8 ODU Split 4, 6, 8

▶ Check output of the CT sensor: DC 2.5 0.2V

ODU Split 11s, 13s, 15s

Fig. 9 ODU Split 11s, 13s, 15s

[1] Inverter PCB

[2] CT sensing check point

▶ Check output pin 2.3 of the CT sensor: DC 2.5 0.2V

IN/I

GND

Black

Red

Vdc

6 720 817 722-06.1I

1

2

3

Vdc

6 720 817 722-07.1I

1 2

Page 10

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

10

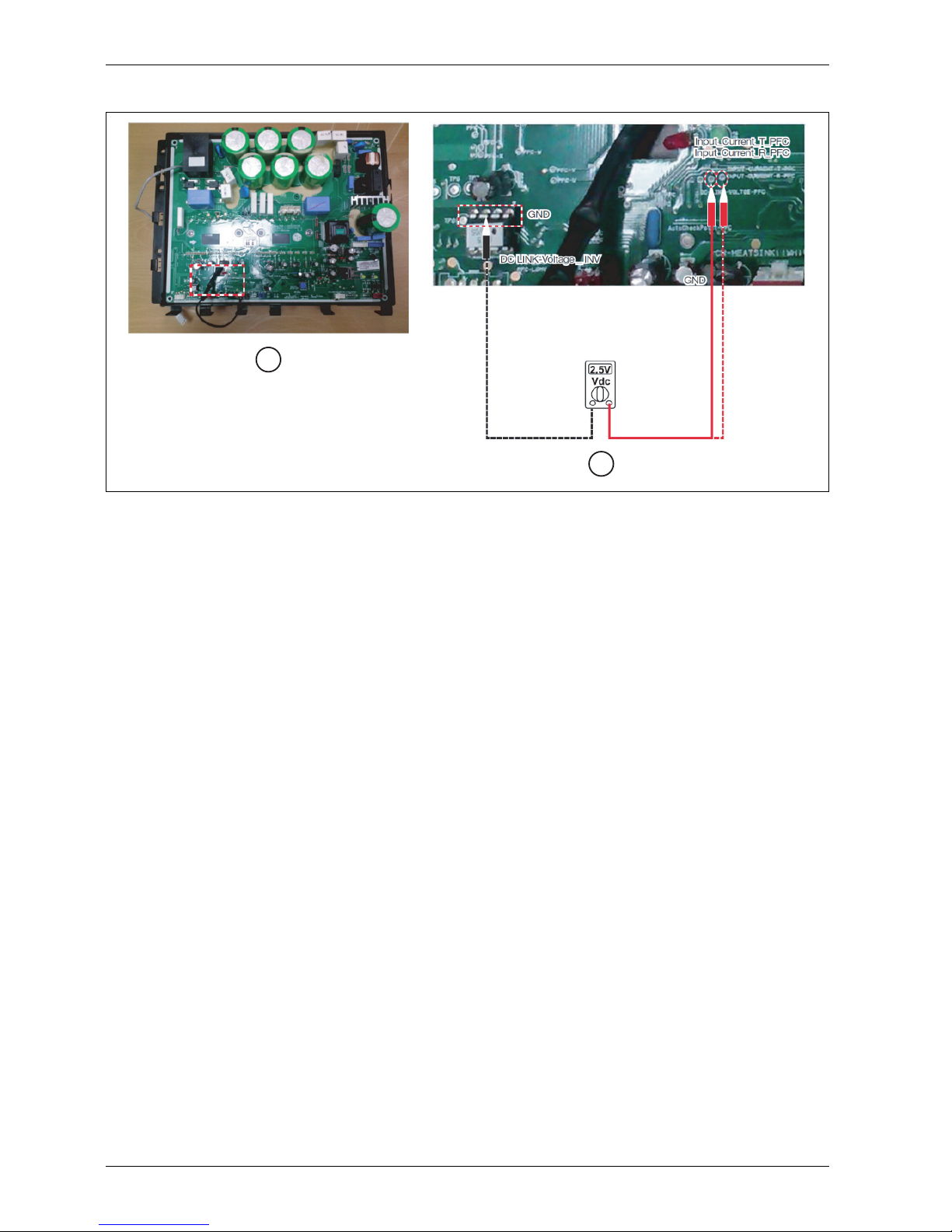

ODU Split 11t, 13t, 15t

Fig. 10 ODU Split 11t, 13t, 15t

[1] Inverter PCB

[2] CT sensing check point

▶ Check input current T_PFC and R_PFC

▶ Check output of the CT sensor: DC 2.5 0.2V

6 720 817 722-08.1I

1

2

Page 11

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

11

2.5 Error code 23

2.5.1 Error diagnosis and countermeasure flow chart

Check Point

1. Check the WCN_P(L), P(N) connection condition ate the main PCB

(heater). Refer to wiring diagram.

2. Check the DC link voltage at no operation of compressor (280V).

3. Check the DC link voltage at operation of compressor (340V).

4. Check the DC link sensing signal (AHBW**6AO): 2.4~2.8V

(Graphic 12).

5. Check the DC link sensing signal (AHBW**8AO): 0.4~0.6V

(Graphic 13).

ODU Split 4, 6, 8

Fig. 11 ODU Split 4, 6, 8

Display

code

Title Cause of error

Check point & Normal

condition

23 DC link High

/ Low

voltage

• DC link

voltage is

above

420Vdc

• DC link

voltage is

below

140Vdc

1. Check CN_(L), CN_(N)

connection

2. Check input voltage

3. Check PCB DC link

voltage sensor parts

Table 9 Error code 23

Is input voltage normal? No -> 1. Check power input voltage

Yes

Is inverter PCB

assembly 1 power

connection normal?

No ->

1. Check power connection state

Yes

Is PCB (Inverter)

normal?

No -> 1. Replace PCB assembly 1

Yes

Recheck power and

installation condition

Table 10 Error diagnosis and countermeasure chart

IN/I

GND

Vdc

6 720 817 722-09.1I

Page 12

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

12

ODU Split 11s, 13s, 15s

Fig. 12 ODU Split 11s, 13s, 15s

Vdc

P

GND

6 720 817 722-10.1I

Page 13

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

13

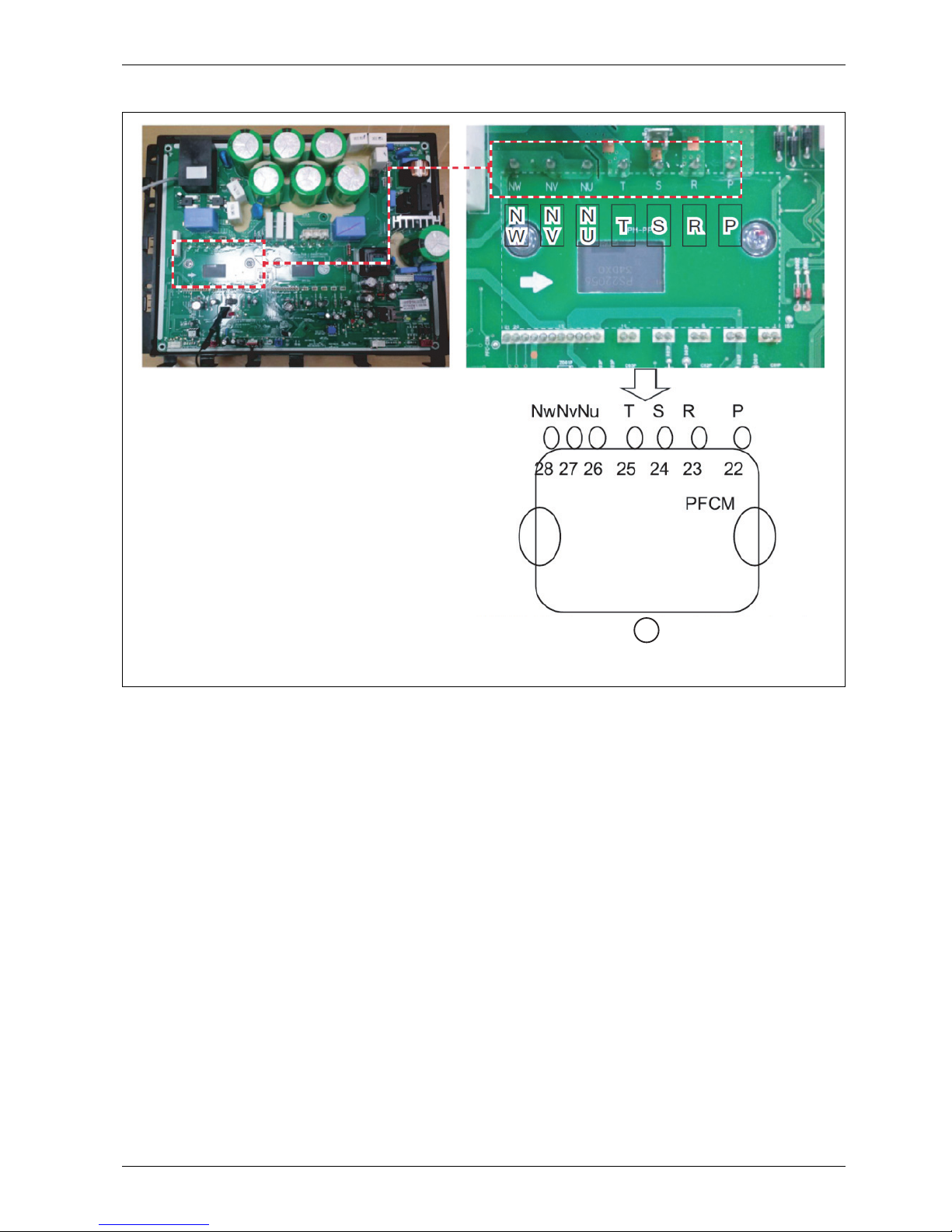

ODU Split 11t, 13t, 15t

Fig. 13 ODU Split 11t, 13t, 15t

[1] PFCM pin arrangement and pin numbers

6 720 817 722-11.1I

1

Page 14

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

14

2.6 Error code 26

2.6.1 Error diagnosis and countermeasure flow chart

Display

code

Title Cause of error

Check point & Normal

condition

26 DC

compressor

position

• Compressor

starting

failure

1. Check the connection of

comp wire “U,V,W”

2. Malfunction of

compressor

3. Check the component of

“IPM”, detection parts

Table 11 Error code 26

Is installation condition

normal?

No -> 1. Check pipe clogging /

distortion

2. Check covering (Indoor /

Outdoor unit)

3. Check EEV connector

assembly condition / normal

operation

4. Check refrigerant pressure

-->Reassemble or manage if

abnormality found

Yes

Are the resistance

between each phase

and insulation

resistance of inverter

compressor normal?

No ->

1. Check resistance between

each terminal of compressor

2. Check insulation resistance

between compressor terminal

and pipe

--> Replace compressor if

abnormality is found

Yes

Is compressor wire

connection condition

normal?

No -> 1. Check inverter PCB assembly

U,V,W connector connection

condition

2. Check wire disconnection and

wiring

3. Check compressor terminal

condition condition (bad

contact)

--> Reassemble if abnormality is

found

Yes

Is inverter PCB

assembly normal?

No -> 1. Check inverter PCB assembly

IPM normality

--> Replace inverter PCB assembly

Yes

Recheck power and

installation condition

Table 12 Error diagnosis and countermeasure chart

Page 15

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

15

ODU Split 4, 6, 8

Fig. 14 ODU Split 4, 6, 8

[1] CT sensing check point

[2] WVC connector check

ODU Split 11s, 13s, 15s

Fig. 15 ODU Split 11s, 13s, 15s

U, V, W

GND

Vdc

U V W

6 720 817 722-12.1I

1

2

U

W

V

GND

6 720 817 722-13.1I

Page 16

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

16

ODU Split 11t, 13t, 15t

Fig. 16 ODU Split 11t, 13t, 15t

6 720 817 722-14.1I

Page 17

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

17

2.7 Error code 27

2.7.1 Error diagnosis and countermeasure flow chart

PFCM module checking method

1. Set the multi tester to diode mode

2. Check short circuit between input signal pins which are placed below

PFC module

3. Replace PCB assembly 1 if it is short circuit between pins except

number 4, 5 pins.

Display

code

Title Cause of error

Check point & Normal

condition

27 DC

compressor

position

• Compressor

starting

failure

1. Check the connection of

comp wire “U,V,W”

2. Malfunction of

compressor

3. Check the component of

“IPM”, detection parts

Table 13 Error code 27

Is installation condition

normal?

No -> 1. Check pipe clogging /

distortion

2. Check covering (Indoor /

Outdoor unit)

3. Check EEV connector

assembly condition / normal

operation

4. Check refrigerant pressure

-->Reassemble or manage if

abnormality found

Yes

Is input voltage normal? No -> 1. Check that L-N phase voltage is

230 15% (1~)

2. Check that R-S-T-N phase

voltage is 380 15% (3~)

--> Check connection condition

and wiring if power is abnormal

Yes

Is AC input wire

connection condition

normal?

No -> 1. Check L-N connection

condition

2. Check wire disconnection and

wiring

--> Reassemble if abnormality

found

Yes

Is compressor wire

connection condition

normal?

No -> 1. Check PCB assembly U,V,W

connector connection

condition

2. Check wire disconnection and

wiring

3. Check compressor terminal

connection condition (bad

contact)

--> Reassemble if abnormality is

found

Yes

Is PCB assembly 1

normal?

No -> 1. Check PCB assembly 1 PFCM

normality

--> Replace PCB assembly 1

Yes

Recheck power and

installation condition

Table 14 Error diagnosis and countermeasure chart

CAUTION: PFCM module number 4 and 5 pins are

internal short state.

Page 18

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

18

ODU Split 4, 6, 8

Fig. 17 ODU Split 4, 6, 8

[1] Short circuit check point

[2] After turning off the main power; R24N between the ends of the

resistance will be measured to 620~670

6 720 817 722-15.1I

1

2

Page 19

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

19

ODU Split 11s/t, 13s/t, 15s/t

Fig. 18 ODU Split 11s/t, 13s/t, 15s/t

[1] ODU Split 11t/13t/15t

[2] ODU Split 11s/13s/15s

[3] Short circuit check point

6 720 817 722-16.1I

PT S R

N

U

N

V

N

W

1

2

3

Page 20

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

20

2.8 Error code 29

2.8.1 Error diagnosis and countermeasure flow chart

Display

code

Title Cause of error

Check point & Normal

condition

29 Inverter

compressor

over

current

• 1~ODU:

inverter

compressor

input current

is 30A

• 3~ODU:

inverter

compressor

input current

is 24A

1. Overload operation (pipe

clogging/covering/EEV

defect/ refrigerant

overcharge)

2. Compressor damage

(insulation damage /

motor damage)

3. Input voltage low

4. ODU PCB assembly 1

damage

Table 15 Error code 29

Is installation condition

normal?

No -> 1. Check pipe clogging /

distortion

2. Check covering (outdoor unit)

3. Check EEV connector

assembly condition / normal

operation

4. Check refrigerant pressure

-->Reassemble or manage if

abnormality found

Yes

Are the resistance

between each phase

and insulation

resistance of inverter

compressor normal?

No ->

1. Check resistance between

each terminal of compressor

(0.188 7%

2. Check insulation resistance

between compressor terminal

and pipe (over 50 M)

--> Replace compressor if

abnormality is found

Yes

Is compressor wire

connection condition

normal?

No -> 1. Check PCB assembly 1 U,V,W

connector connection

condition

2. Check wire disconnection and

wiring

3. Check compressor terminal

connection condition (bad

contact)

--> Reassemble if abnormality is

found

Yes

Is input voltage normal? No -> 1. Check U-V, V-W, W-U phase is

220~240 V 10%

--> Check connection condition

and wiring if power is abnormal

Yes

Is PCB assembly 1

normal?

No -> 1. Check PCB assembly 1 IPM

normality

--> Replace inverter PCB assembly

Yes

Recheck power and

installation condition

Table 16 Error diagnosis and countermeasure chart

Page 21

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

21

2.9 Error code 32

2.9.1 Error diagnosis and countermeasure flow chart

Inspecting inverter compressor discharge sensor

1. Set multi-tester to resistance measurement mode.

2. Measure the resistance between inverter discharge sensor

connector pins.

3. Measure resistance value of 200k10%, 25 °C basis.

4. Check if the sensor insulation is damaged, measure the resistance

between sensor connector pin and unit assembly pipe (1M or

more)

Fig. 19 CN_TH3 connector

[1] CN_TH3 (red 4pin connector)

Display

code

Title Cause of error

Check point & Normal

condition

32 High

temperatur

e in

discharge

pipe of the

inverter

compressor

• Overload

operation

(outdoor fan

constraint,

screened,

blocked

• Poor INV

comp

discharge

sensor

• LEV

connector

displaced /

poor LEV

assembly

1. Check outdoor fan

constraint / screened /

flow structure

2. Check refrigerant leakage

3. Check if the sensor is

normal

4. Check the status of EEV

assembly

Table 17 Error code 32

Is the heating water flow

sufficient?

No -> 1. Check that the heating water

circulation pump is working

2. Check that the heating water

flow rate is sufficient

3. Check preassure gauge

(1.5~2.5 bar)

-->Remove cause of error

Yes

Is there enough

refrigerant?

No -> 1. Check refrigerant leakage

2. Supply refrigerant if not

enough

Yes

Is the EEV properly

assembled?

No -> 1. Check the status of PCB

(inverter) EEV1 assembly

2. Check the status of EEV

assembly

3. Check PCB (inverter) IPM

input signal connectors shortcircuit

--> Refer to CH21 trouble

shooting method

Yes

Is the inverter

compressor sensor

normal?

No -> 1. Check the sensor assembly

status

2. Check if the sensor is broken:

measure resistance

200k10% (25 °C basis)

Table 18 Error diagnosis and countermeasure chart

6 720 817 722-17.1I

1

Page 22

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

22

2.10 Error code 35

2.10.1 Error diagnosis and countermeasure flow chart

Display

code

Title Cause of error

Check point & Normal

condition

35 Low

pressure

error

• Excessive

decrease of

pressure

1. Defective low pressure

sensor

2. Defective unit fan

3. Deformation because of

damage of refrigerant

pipe

4. Defective unit EEV

5. Covering / clogging (unit

covering during cooling

mode / unit filter clogging

during heating mode)

6. SVC valve clogging

7. Defective unit PCB

(inverter)

8. Defective unit pipe sensor

Table 19 Error code 35

Are communication

cable / piping normal?

No -> 1. Check communication / piping

correction

Yes

Is amount of refrigerant

normal?

No -> 1. Check for pipe crack or trace of

refrigerant leakage

2. Weld / reconnect the cracked

portion

3. Adjust the amount of /

recharge refrigerant

Yes

Is the strainer OK?

1)

1) If the temperature difference between inlet and outlet of strainer is so large that

frost or ice formation can be seen or confirmed then clogging of strainer should

be checked (Notice: it is not full ice forming of strainer, in case that there is not at

inlet portion but at outlet portion)

No -> 1. Replace the strainer

Yes

Are the value of manifold

gauge and pressure

sensor the same?

(Is the low pressure

value actually low?)

No ->

1. Replace the pressure sensor

Yes

• Check unit LEV

• Check unit PCB

(inverter)

• Check unit

installation

conditions

Table 20 Error diagnosis and countermeasure chart

Page 23

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

23

2.11 Error code 41, 44, 45, 46, 48

2.11.1 Error diagnosis and countermeasure flow chart

Fig. 20 Check sensor

[1] Unplugged; check the resistance (10k)

[2] Plugged; check the voltage (2.5V DC)

Display

code

Title Cause of error

Check point & Normal

condition

41 D-pipe

sensor

(inverter)

• Open / short

• Soldered

poorly

• Internal

circuit error

1. Bad connection of

thermistor connector

2. Defect of thermistor

connector (open / short)

3. Defect of outdoor PCB

(inverter)

44 Air sensor • Open / short

• Soldered

poorly

• Internal

circuit error

1. Bad connection of

thermistor connector

2. Defect of thermistor

connector (open / short)

3. Defect of outdoor PCB

(inverter)

45 Condenser

Mid-pipe

sensor

• Open / short

• Soldered

poorly

• Internal

circuit error

1. Bad connection of

thermistor connector

2. Defect of thermistor

connector (open / short)

3. Defect of outdoor PCB

(inverter)

46 Suction

pipe sensor

• Open / short

• Soldered

poorly

• Internal

circuit error

1. Bad connection of

thermistor connector

2. Defect of thermistor

connector (open / short)

3. Defect of outdoor PCB

(inverter)

48 Condenser

out-pipe

sensor

• Open / short

• Soldered

poorly

• Internal

circuit error

1. Bad connection of

thermistor connector

2. Defect of thermistor

connector (open / short)

3. Defect of outdoor PCB

(inverter)

Table 21 Error code 35

Is sensor connected to

PCB (inverter)

correctly?

No -> 1. Connect sensor to PCB

(inverter) correctly

Yes

Is sensor value correct? No -> 1. Replace sensor

Yes

• Replace

corresponding PCB

(inverter)

Table 22 Error diagnosis and countermeasure chart

V

6 720 817 722-18.1I

1 2

Page 24

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

24

2.12 Error code 43

2.12.1 Error diagnosis and countermeasure flow chart

Fig. 21 HP sensor characteristics

[1] Pressure sensor

[2] High pressure sensor: 0~5 MPa, Vout 0.5~3.5 V

Display

code

Title Cause of error

Check point & Normal

condition

43 High

pressure

sensor

error

• Abnormal

value of

sensor (open

/ short)

1. Bad connection of

connector PCB (inverter)

2. Bad connection high

pressure connector

3. Defect of connector PCB

(inverter) (open/short)

4. Defect of PCB (inverter)

Table 23 Error code 43

Is pressure sensor OK? No -> 1. Replace the pressure sensor

Yes

Is sensor connected to

PCB (inverter)

correctly?

No -> 1. Connect sensor to PCB

(inverter) correctly

Yes

After replacement of

outdoor unit main PCB

(inverter) is the system

also abnormal?

No ->

END

Yes

• Replace

corresponding PCB

(inverter)

Table 24 Error diagnosis and countermeasure chart

1

2

6 720 817 722-22.1I

Page 25

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

25

2.13 Error codes 52, 53

Fig. 22 Error codes 52, 53

2.13.1 Error code 52

Inverter PCB

Main/ODU PCB

CANboard

Installerboard

CH52

No Error

1

2

3

CH53

??

Situation Description

Error code that is sent to

Installerboard by CAN

Waiting time of

communication before

error is generated

1 No communication between

INV-PCB and ODU-PCB

(380V / 3~units)

CAN-PCB receives error

code from ODU-PCB but

Inverter-PCB does not

respond

52

30 seconds

2 No communication between

ODU-PCB and CAN-PCB

CAN-PCB does not receive

signals from ODU-PCB

53 10 seconds

3 No communication between

CAN-PCB and Installerboard

CAN-PCB does not send

signals to Installerboard

55 ODU shuts down after 1~3

seconds from recognizing

CAN communication error

Table 25 Error codes 52, 53

Display

code

Title Cause of error

Check point & Normal

condition

52 PCB

communica

tion error

• Checking the

communicati

on state

between

main PCB

and inverter

PCB

1. Generation of noise

source interfering with

communication

Table 26 Error code 52

Is transmission LED

(Yellow) of inverter

compressor PCB on?

No -> Is noise filter or fuse normal?

▶ NO: Replace noise filter or fuse

-or-

▶ YES: Replace inverter

compressor PCB

Yes

Is transmission cable

connected correctly?

No -> 1. Re-connect transmission cable

Yes

Is main PCB normal? No -> 1. Replace main PCB

Yes

• Replace inverter

compressor PCB

Table 27 Error diagnosis and countermeasure chart

Page 26

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

26

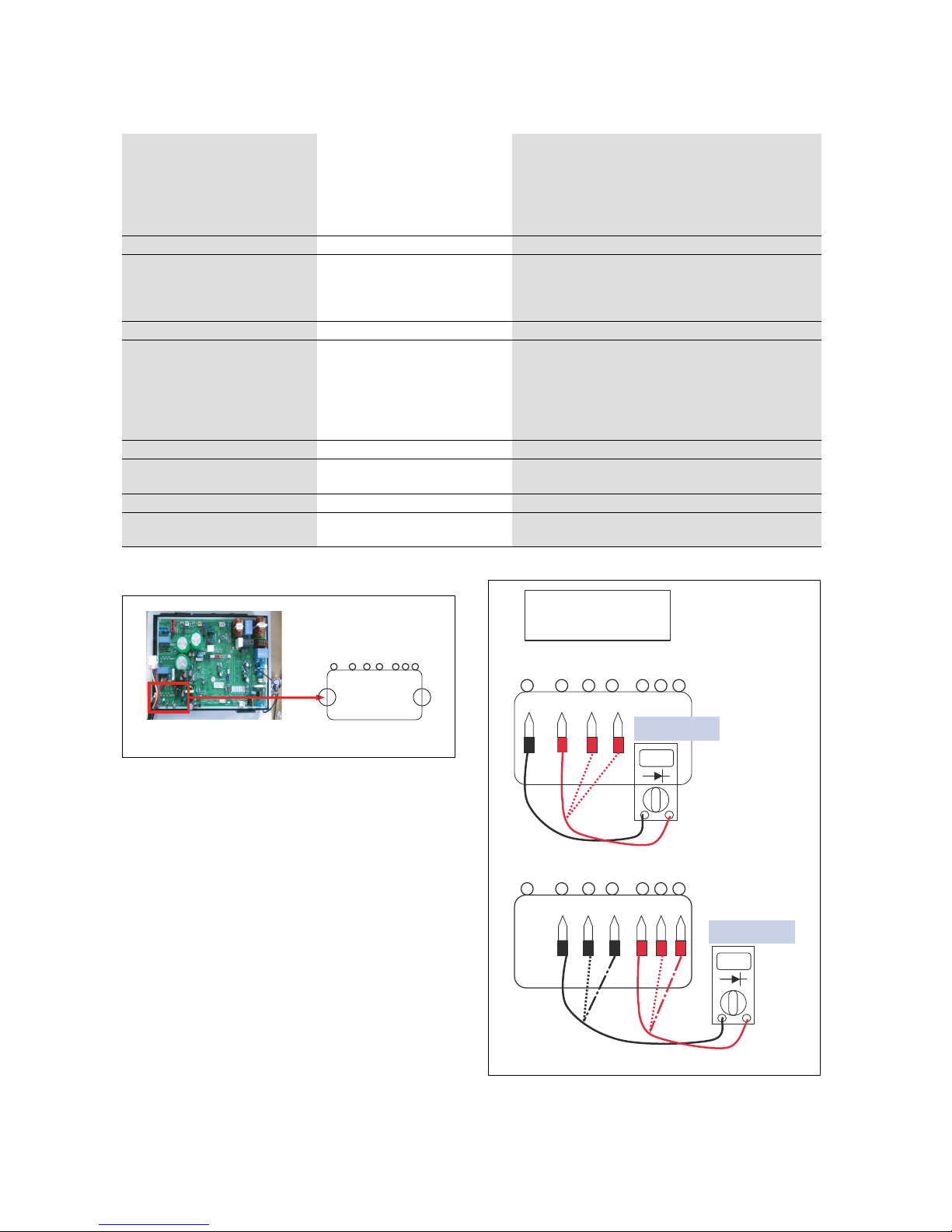

ODU Split 11t, 13t, 15t

Check point

▶ Check the transmission connector and LED (main and inverter)

Fig. 23 Error code 52 check point ODU Split 11t/13t/15t

[1] Insufficient insertion of wires

[2] Damage of wire coating: Interference with wires or wire coating

damage with chopping

[3] 42/48/60k

[4] Inverter PCB

[5] Main PCB

OK NG

6 720 817 722-21.1I

1

2

3

4 5

Page 27

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

27

2.13.2 Error code 53

Check point

1. Check the input power AC 230V

2. Check that the communication wires are correctly connected. Adjust

the connection of wire confirm the wire of “Live”, “Neutral”.

3. Check the resistance between communication line and GND (normal:

over 2M).

4. Check that the connector for communication is correctly connected.

5. Make sure you have connected to the communication line soldering

(if you do not connect by soldering, a communication error (CH05/

CH53) occurs by noise)

2.14 Error code 54

Fig. 24 Error code 54 diagnosis and countermeasure flow chart

[A] Items for checking

[B] Sub-items for checking

[1] Installation

[2] Fuse damage (R and S phases)

[3] Inverter PCB

[4] Checking N-phase

[5] Checking for power phase loss

[6] Checking for open and reverse phase

[7] AC load

2.15 Error code 60

Check point

▶ Check the EEPROM check sum and direction

Display code Title Cause of error Check point & Normal condition

53 Communication

PCB(Heater)

-->PCB(Inverter)

• Poor communication 1. Power input AC 230V

2. The connector for transmission is disconnected

3. The connection wires are miss-connected

4. The communication line is shorted at GND

5. Transmission circuit of PCB (inverter) is abnormal

6. Transmission circuit of PCB (heater) is abnormal

Table 28 Error code 53

Display

code

Title Cause of error

Check point & Normal

condition

54 Open and

reverse

phase error

• Prevention

of phase

unbalace and

prevention

of reverse

rotation of

constant rate

compressor

1. Main power wiring fault

Table 29 Error code 54

A

B

1

2

3

4 5

6

7

6 720 817 722-34.1I

Display

code

Title Cause of error

Check point & Normal

condition

60 PCB

(inverter)

and main

EEPROM

check sum

error

• EEPROM

access error

and check

sum error

1. EEPROM contact defect /

wrong insertion

2. Different EEPROM

version

3. ODU inverter and main

PCB assembly 1 damage

Table 30 Error code 60

Is EEPROM insertion

normal?

No -> 1. Check EEPROM insert

direction / connection

condition

2. Check EEPROM check sum

-->Replace if abnormality is found

Yes

Is PCB assembly 1

normal?

No -> 1. Replace PCB assembly 1

Yes

Is main PCB assembly 1

normal?

No -> 1. Replace main PCB assembly 1

Yes

• Recheck power and

installation condition

Table 31 Error diagnosis and countermeasure chart

Page 28

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

28

Fig. 25 ODU Split 4/6/8

Fig. 26 ODU Split 11/13/15

[1] ODU Split 11s/13s/15s

[1] ODU Split 11t/13t/15t

6 720 817 722-23.1I

EEPROM

EEPROM

6 720 817 722-24.1I

1

2

Page 29

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

29

2.16 Error code 61

2.16.1 Error diagnosis and countermeasure flow chart

Inspecting condenser pipe sensor

1. Set multi-tester as resistance measurement mode.

2. Measure the resistance between rated speed compressor discharge

sensor connector pins.

3. Measure resistance value of 5k 10% (25 °C basis).

4. Check if the sensor insulation is damaged --> measure the resistance

between sensor connector pin and unit assembly pipe 1M .

Fig. 27 CN-C/PIPE connector

[1] CN-C/PIPE (Violet 3Pin connector)

Display

code

Title Cause of error

Check point & Normal

condition

61 High

temperatur

e in

condenser

pipe

• Overload

operation

(outdoor fan

constraint,

screened,

blocked)

• Unit heat

exchanger

contaminate

d

• EEV

connector

displaced /

poor EEV

assembly

• Poor

condenser

pipe sensor

assembly /

broken

1. Check outdoor fan

constraint / screened /

flow structure

2. Check if refrigerant is

overcharged

3. Check the status of the

EEV assembly

4. Check the status of

sensor assembly

Table 32 Error code 61

Is the unit properly

installed?

No -> 1. Check fan locking

2. Remove blockings around heat

exchanger

3. Maintain distance between

unit and the wall

4. Check pipe folding and

abnormality

5. Check SVC lock

Yes

Is the refrigerant

properly charged?

No -> 1. Check if refrigerant is

overcharged

--> Adjust refrigerant volume

Yes

Is the EEV properly

assembled?

No -> 1. Check the status of PCB

(inverter) CN-EEV1 assembly

2. Check the status of EEV

assembly

--> Reassemble / replace if

abnormality is found

Yes

Is the condenser pipe

sensor normal?

No -> 1. Check the sensor assembly

status

2. Check if the sensor is burned:

measure resistance

-->5k 10% (25 °C basis)

Yes

Recheck power and

installation condition

Table 33 Error diagnosis and countermeasure chart

1

6 720 817 722-35.1I

Page 30

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

30

2.17 Error code 62, 65

2.17.1 Error diagnosis and countermeasure flow chart

▶ Short circuit check: if temperature 130 °C

▶ Open circuit check: if temperature < – 30 °C

System will go in self diagnosis (error 65) is displayed and ODU stops.

Check point

1. Check resistance between no. 19 pin and no. 20 pin of PCB PFC

module

2. Resistance value should be in 7k 10% (at 25 °C).

Fig. 28 Error codes 62, 65 check the PFCM

Display code Title Cause of error Check point & Normal condition

62 Heat sink temp high • Heat sink sensor detected high

temperature (85 °C)

1. Part no. :EBR37798101~09

-Check the heat sink sensor: 10k at 25 °C (unplugged)

-Check the outdoor fan is running correctly

2. Part no. :EBR37798112~21

-Check the soldered condition in the 22, 23 pin of IPM,

PFCM

-Check the screw torque of IPM, PFCM

-Check the spreadable condition of thermal grease on IPM,

PFCM

-Check the outdoor fan is running correctly

65 Heat sink sensor • Connector connection error

• Faulty PCB

• Faulty sensor (Open / Short)

1. Normal resistor: 5k at 25 °C (unplugged)

2. Normal voltage: 2.5Vdc at 25 °C (plugged)

3. Refer to sensor resistance table

Table 34 Error code 61

Is there good screw

torque of IPM, PFCM?

No -> 1. Tighten the screw of IPM,

PFCM

Yes

Is there normal

resistance between 22

and 23 Pin of IPM,

PFCM?

Is there normal thermal

grease on IPM, PFCM?

Is IPM, PFCM normal?

No ->

1. Change the inverter PCB

Yes

Recheck power and

installation condition

Table 35 Error diagnosis and countermeasure chart

27 26 25 24 23 22 21

0.4 ~ 0.6 V

6 720 817 722-36.1I

Page 31

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

31

Fig. 29 Error code 62, 65 check points

[1] ODU Split 4/6/8

[2] PFCM: measuring resistance between no. 19, 20 pin

[3] ODU Split 11s/13s/15s

[4] ODU Split 11t/13t/15t

[5] Heat sink temperature output pin

[IPM]

[PFCM]

1 2ྛ

1 2ྛ

6 720 817 722-25.1I

1

3

2

4

5

Page 32

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

32

2.18 Error code 67

2.18.1 Error diagnosis and countermeasure flow chart

Check point

1. Check voltage between 1pin and 4pin of fan motor connector (tester

diode mode).

2. Voltage value should be in 1V 0.2V.

3. Do not replace all of fan motor and 220 – 240 V~at once.

4. Check error code again, after replacing the abnormal part (fan motor

or PCB) first.

Fig. 30 Error code 67

[1] Fan motor connector

Display code Title Cause of error Check point & Normal condition

67 Fan lock error • Fan RPM is 10 RPM or less for 5

seconds when ODU fan starts or

40 RPM or less after fan starting

1. ODU fan locking

2. Heat sink assembly of PCB assembly 1 condition abnormal

3. Defect of temperature sensing circuit part defect of PCB

(inverter)

Table 36 Error code 67

Is ODU fan motor

assembly condition

normal?

No ->

1. Check ODU fan motor

assembly condition and fan

locking

--> Reassemble or replace if

abnormality is found

Yes

Is ODU fan motor

normal?

No -> 1. Set the multi tester to diode

mode

2. Check voltage between 1pin

and 4pin of fan motor

(1 0.2V)

Yes

Is wire connection of

ODU fan motor wire

normal?

No -> 1. Check wiring between ODU fan

motor and PCB (inverter)

(Check if Hall sensor and

motor output terminal colour is

matched)

--> Reassemble if abnormality is

found

Yes

Is PCB assembly 1

normal?

No -> 1. Replace PCB assembly 1

Yes

Recheck power and

installation condition

Table 37 Error diagnosis and countermeasure chart

6 720 817 722-26.1I

1

Page 33

Error handling instructions for Split outdoor unit

Split ODU – 6 720 817 722 (2015/06)

33

Fig. 31 Error code 67 check points

[1] ODU Split 4/6/8

[2] ODU Split 11s/13s/15s

[3] ODU Split 11t/13t/15t

6 720 817 722-27.1I

2

3

1

Page 34

Check compressor resistances

Split ODU – 6 720 817 722 (2015/06)

34

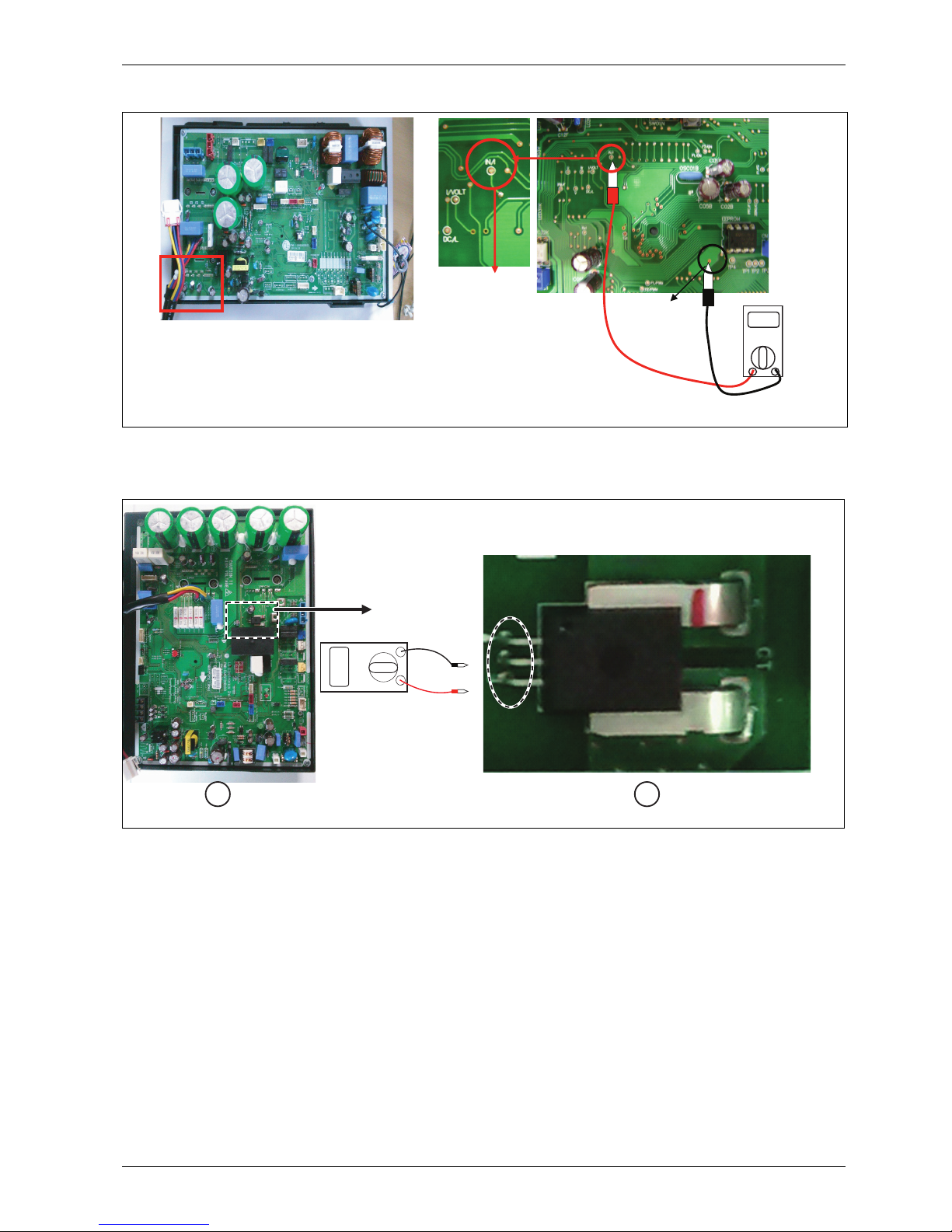

3 Check compressor resistances

To check the resistance of the compressor:

▶ Disconnect the compressor motor plug

▶ Measure the resistance between each coil and ground

▶ The resistance should be more than 2M (at 20 °C)

To check the resistance between the coils:

▶ Disconnect the compressor motor plug

▶ Measure the resistance between the coils

▶ The resistance should be equal

Fig. 32 Check compressor resistances

[1] Compressor

[2] Copper pipe

WARNING: Electric shock!

▶ Even if the ODU is disconnected from power supply,

it takes some time to discharge the remaining

electricity of the electrolytic capacitor. Before

conducting a service or repairing job, switch off the

main power supply and make sure that all LED on the

circuit boards are off.

1

2

1

6 720 817 722-33.1I

Page 35

Compressor replacement

Split ODU – 6 720 817 722 (2015/06)

35

4 Compressor replacement

1. Disconnect the unit from power supply.

2. Detach the motor plug from the compressor.

3. Remove the sound proof covering the faulty compressor.

4. Pump out the refrigerant completely.

5. Disconnect the brazing sections of the suction pipe by using brazing

torch.

6. Remove the three nuts at cushion rubber section to take out the

faulty compressor outside the unit.

7. Install the new compressor in the unit. Be sure to insert the cushion

rubbers before tightening the fixing nuts of the compressor.

8. Remove the rubber caps put on the suction and discharge pipes of

the new compressor to release the sealing nitrogen gas.

9. Braze the suction and discharge pipe to the compressor with brazing

torch.

10.Conduct air tight test to check that the piping system is free from

leakage.

11.Re-connect the power cable to the terminal board of the

compressor.

12.Attach the sound-proof covering to the compressor.

13.Conduct vacuum suction.

14.After completion of vacuum, open the service valves.

15.Charge the unit with the correct amount of refrigerant.

Fig. 33 Compressor replacement

[1] Insert the sound proof counter-clockwise

[2] Suction pipe

[3] Discharge pipe

2

3

1

6 720 817 722-30.1I

Page 36

Check system parameters

Split ODU – 6 720 817 722 (2015/06)

36

5 Check system parameters

6 Electronic expansion valve

Fig. 34 EEV driving circuit

Output pulse sequence

– In valve close state: 1 -->2 -->3 -->4 -->5 -->6 -->7 -->8 -->1

– In valve open state: 8 -->7 -->6 -->5 -->4 -->3 -->2 -->1 -->8

1. If EEV open angle does not change, all of output phase will be OFF.

2. If output phase is different or continuously in the ON state, motor will

not operate smoothly and start vibrating.

Temperature difference between inlet and outlet

depends on water flow rate and exchange-surface of the

heating system.

Symptom Remark

No temperature difference between water inlet and outlet

Power consumption is low (<80% of rated current)

Refrigerant completely leaked

Check cycle

Temperature difference is ok (5-10K)

Power consumption is low (<80% of rated current)

Leakage of refrigerant or clog of cycle

Defective compressor

Temperature difference is ok (5-10K)

Power consumption is high (over rated current)

Too much refrigerant

Temperature difference is ok (5-10K)

Power consumption is in range of rated current (10%)

Normal operation

Table 38 Temperature difference and power consumption

Suction pressure Outlet temperature Reason Result

Higher than normal value Higher than normal value Defective compressor

Defective 4-way-valve

Current is low

Normal value

Too much refrigerant High pressure does not quickly

increase when compressor starts

Lower than normal value Higher than normal value Insufficient amount of refrigerant

(leakage) or clogging

Current is low

Table 39 Pressure and temperature

6 720 817 722-37.1I

Output (Ø ) No. Output state

1 2 3 4 5 6 7 8

Ø 1 ON OFF OFF OFF OFF OFF ON ON

Ø 2 ON ON ON OFF OFF OFF OFF OFF

Ø 3 OFF OFF ON ON ON OFF OFF OFF

Ø 4 OFF OFF OFF OFF ON ON ON OFF

Table 40 Pulse signal output value and valve operation

Page 37

Electronic expansion valve

Split ODU – 6 720 817 722 (2015/06)

37

EEV valve operation

Fig. 35 EEV valve operation

[A] Valve open angle

[P] Pulse

[1] Close

[2] Open

[3] Fully open 1350 pulses

• At power ON, open angle signal of 1400 pulses output and valve

position is set to

If valve operates smoothly, no noise and vibration occur and if valve

is closed. Noise occurs.

• Noise from the EEV can be confirmed by touching the EEV surface

with a screw driver and listening to the EEV noise.

• If liquid refrigerant is in EEV, the noise is lower.

EEV failure check method

2

3

a

1

A

P

6 720 817 722-31.1I

a

Failure mode Diagnosis Repair process Remark

Microcomputer driving circuit

failure

1. Disconnect the EEV connector from

control board and connect testing

LED

2. Main power ON, pulse signal is out

from EEV for 17 seconds. If the LEDs

do not turn on, or are in on state

continuously, then the driving circuit

is abnormal

Check and replace unit control

board

Unit

EEV locking 1. If EEV is locked, in no load state, the driving motor rotate

and clicking sound always occurs

Replace EEV

EEV motor coil short or

misconnection

1. Check the resistance between coil terminal (red-white, redyellow, red-orange, red-blue)

2. If the estimated resistance value is in 52 3 then the EEV

is normal

Replace EEV

1. Check the resistance between coil terminal (brown-white,

brown-yellow, brown-orange, brown-blue)

2. If the estimated resistance value is in 150 10 then the

EEV is normal

Replace EEV

Table 41 EEV failure check method

1K LED

Page 38

Fan motor

Split ODU – 6 720 817 722 (2015/06)

38

Remove and assemble the EEV coil

Fig. 36 Remove and assemble the EEV coil

[1] Remove

[2] Assemble

[3] A part

▶ Grip the A part tightly, and pull coil part upward.

Fig. 37

7 Fan motor

2

1

3

6 720 817 722-32.1I

Checking item Symptom Countermeasure

1. The fan motor does not operate.

Does failure appear again when starting

operation?

2. Large vibration of the fan motor.

1. When power supply is abnormal

• Modify connection status in front or at the

rear of the breaker, or if the power terminal

console are at frosting condition.

• Modify the power supply voltage if it is

beyond specified scope.

2. For wrong wiring

-For following wiring

1. Check connection status.

2. Check contact of the connector.

3. Check that parts are firmly secured by

tightening screws.

4. Check connection of polarity.

5. Check short circuit and grounding.

6. For failure of motor

• Measure winding resistance of the motor

coils.

7. For failure of circuit board

Replace the circuit board in following

procedures if problems occur again when

powering on and if there are no matters

equivalent to items as specified in above 1)

through 4).

Carefully check both connector and grounding

wires when replacing the circuit board.

1. Replace only fan control boards.

If the fan starts, it means that the fan control

board is defect.

2. Replace both fan control board and the main

board.

If the fan starts, it means that the main board

is defect.

Table 42 Fan motor check

Page 39

Replacement procedure for INV PCB

Split ODU – 6 720 817 722 (2015/06)

39

8 Replacement procedure for INV PCB

1. Disconnect the unit from power supply.

2. Disassemble main PCB by unscrewing 2 screws (Figure 1).

3. Disassemble panel assembly (with cooling fan) by unscrewing for

screws (Figure 2).

4. Replace INV PCB assembly (Figure 3). When assembling new INV

PCB assembly with control case, make sure that PCB case is inserted

surely in the slit of control case. Confirm that there is no gap between

INV PCB case and control case (Figure 4).

5. Re-assemble panel assembly and main PCB.

Fig. 38 Replacement of INV PCB

CAUTION: Be sure that INV PCB assembly is firmly

assembled with control case.

If any gap is present, it will cause product malfunction.

▶ Confirm that there is no gap between INV PCB case

and control case (Figure 4).

> .2-2 erugiF <> .1-2 erugiF <

> .4 erugiF <> .2-3 erugiF <> .1-3 erugiF <

< Figure 1. >

6 720 817 722-39.1I

Page 40

Replacement procedure for INV PCB

Split ODU – 6 720 817 722 (2015/06)

40

Fig. 39 INV PCB fan motor connection

[1] Fan motor wire terminal (UP)

[2] Fan motor wire terminal (DOWN)

[3] Main PCB case

[4] To Fan motor

[5] To Fan motor

Attention! After replacing the INV PCB assembly, make

sure that connection of the fan motor wires is correct.

YELLOW

RED

YELLOW

RED

YELLOW

RED

YELLOW

RED

INV. PCB

UP

DOWN

UP

DOWN

2

3

1

5

4

6 720 817 722-40.1I

Page 41

Other pre - checkings

Split ODU – 6 720 817 722 (2015/06)

41

9 Other pre - checkings

▶ Check blockage of refrigerant circuit

Are both check - valves completely open?

▶ Check function of fans

– Check rotation speed

– Check supply voltage

▶ Check function of water pump

– Check rotation speed

– Check supply voltage

▶ Check heat-transfer

– Clean heat-exchangers

▶ Check refrigerant charge

– Sub-cooling very high --> Overfilled

– Refill refrigerant (with gauge)

Page 42

Other pre - checkings

Split ODU – 6 720 817 722 (2015/06)

42

Loading...

Loading...