Bosch MMD 302 Original Instructions Manual

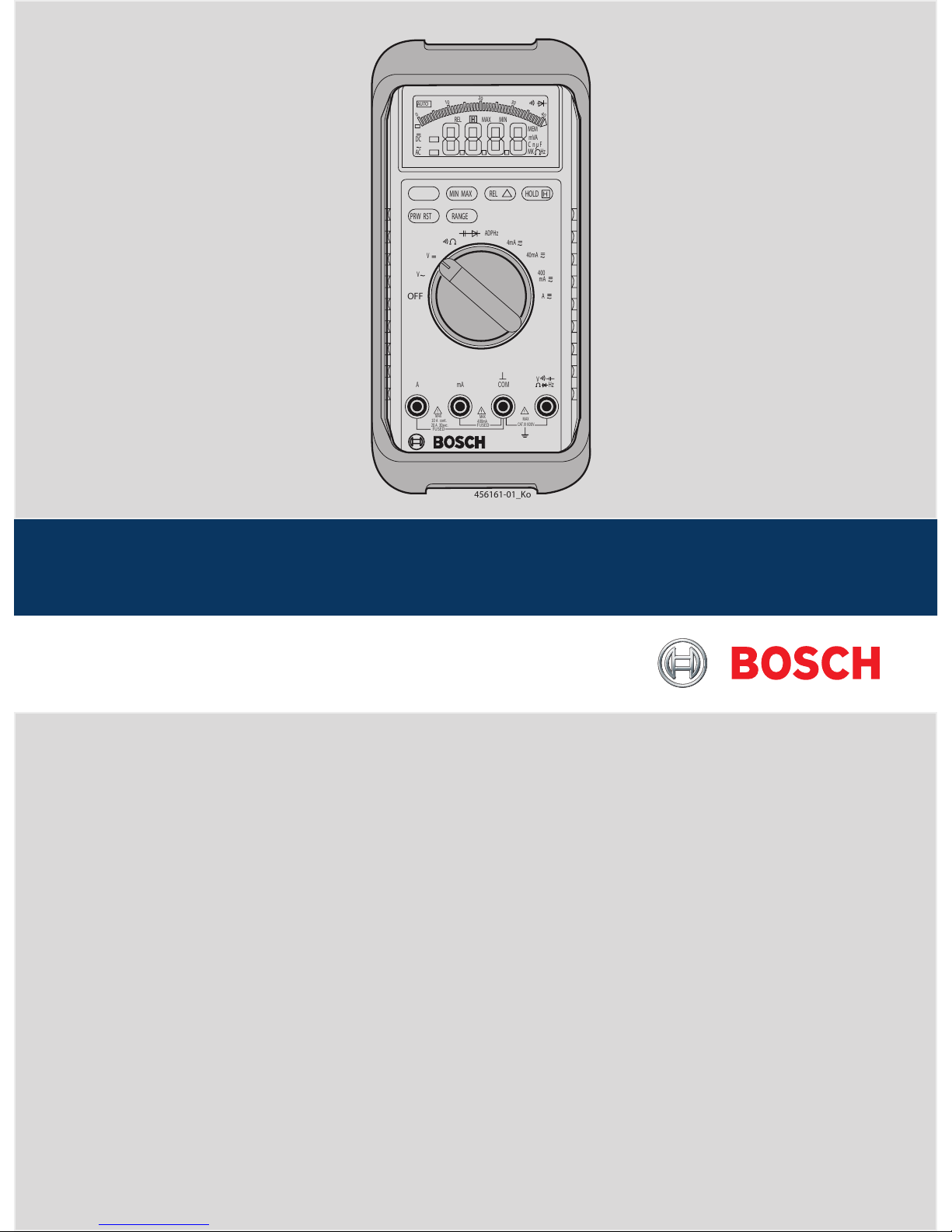

MMD 302

de

Originalbetriebsanleitung

Digital Multimeter

en

Original instructions

Digital Multimeter

fr

Notice originale

Multimètre numérique

es

Manual original

Multímetro digital

it

Istruzioni originali

Multimetro digitale

MIN MAX REL HOLD

RANGE

PRW RST

H

OFF

V

V

ADPHz

4mA

40mA

400

mA

A

A

mA

V

Hz

MAX

CAT.III 600V

DC

AC

REL MAXMIN

MEM

mVA

C n u F

MK Hz

0

10

20

30

40

AUTO

H

456161-01_Ko

COM

MAX

MAX

400mA

FUSED

FUSED

10 A cont.

20 A 30sec.

1 689 979 642 2014-11-03

|

Robert Bosch GmbH

| MMD 302 | 15

en

Contents English

1. Symbols used 16

1.1 In the documentation 16

1.1.1 Warning notices -

Structure and meaning 16

1.1.2 Symbols in this documentation 16

1.2 On the product 16

2. Safety instructions 16

2.1 Risk of electric shocks 16

2.1.1 Low voltages, high voltages 16

2.1.2 High voltages in hybrid vehicles and

electric vehicles as well as their

high-voltage components 17

2.2 Danger of fire, Danger of explosion 17

2.3 Danger of burning 17

2.4 Danger of tripping 17

2.5 Danger of injury, Danger of crushing 18

3. General Information 18

3.1 User profile 18

3.2 Application 18

3.3 Function description 18

3.4 Scope of delivery 18

3.5 Front View, operating elements and

connections 19

3.5.1 LCD 19

3.5.2 Blue function button 19

3.5.3 MIN MAX button 19

3.5.4 REL ∆-button 19

3.5.5 HOLD-button 20

3.5.6 PWR RST-button 20

3.5.7 RANGE-button 20

3.5.8 Measurement-mode switch 20

4. Connection and operation 20

4.1 Alternating and direct current

measurement 20

4.2 Acoustic continuity test and

resistance measurement 20

4.3 Capacitance measurement and

diode test 21

4.3.1 Capacitance measurement 21

4.3.2 Diode test 21

4.4 Frequency measurement 21

4.5 Current measurement 21

4.6 Possible uses of the protective

rubber cover 21

4.6.1 Single-handed multimeter 21

4.6.2 Measurement cables can be wrapped 22

4.6.3 Erecting 22

4.6.4 Protection 22

5. Maintenance 22

5.1 Cleaning 22

5.2 Spare parts and parts subject to wear 22

5.3 LCD difficult to read 22

5.4 0000 appears during current

measurement 23

5.5 Changing the batteries 23

5.6 Changing the fuses 24

6. Technical Data 24

6.1 General data 24

6.2 Measurement category as per EN61010 24

6.3 Meas. range, resolution and accuracy 25

1 689 979 642 2014-11-03

|

Robert Bosch GmbH

16 | MMD 302 | Symbols used

en

1. Symbols used

1.1 In the documentation

1.1.1 Warning notices - Structure and meaning

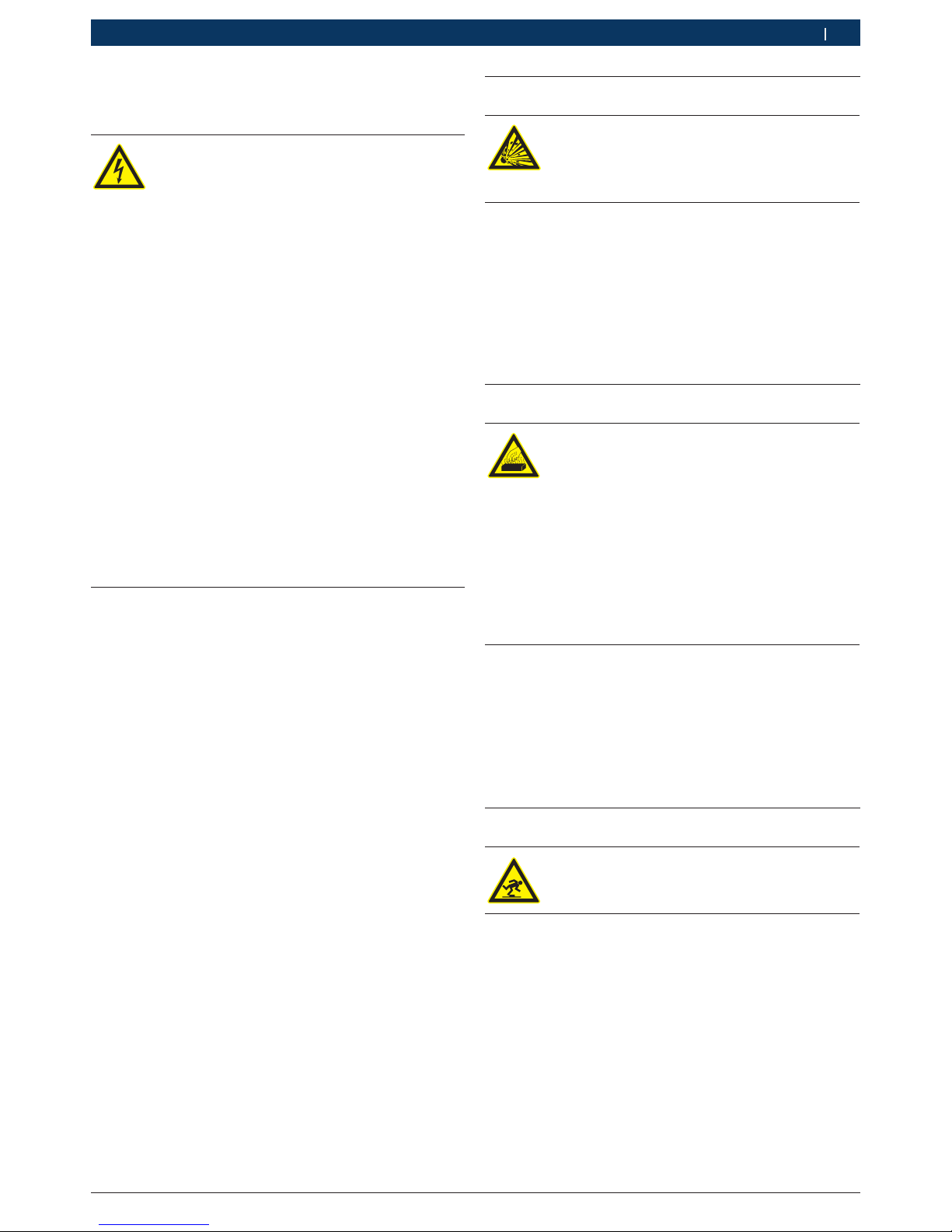

Warning notices warn of dangers to the user or people

in the vicinity. Warning notices also indicate the consequences of the hazard as well as preventive action.

Warning notices have the following structure:

Warning

symbol

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of failure to observe action and information given.

¶ Hazard prevention action and information.

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-observance:

Key word Probability of

occurrence

Severity of danger if instructions not observed

DANGER Immediate impend-

ing danger

Death or severe injury

WARNING Possible impending

danger

Death or severe injury

CAUTION Possible dangerous

situation

Minor injury

1.1.2 Symbols in this documentation

Symbol Designation Explanation

!

Attention Warns about possible property damage.

i

Information Practical hints and other

useful information.

1.

2.

Multi-step

operation

Instruction consisting of several steps.

e

One-step

operation

Instruction consisting of one step.

Intermediate

result

An instruction produces a visible intermediate result.

"

Final result There is a visible final result on com-

pletion of the instruction.

1.2 On the product

! Observe all warning notices on products and ensure

they remain legible.

Instructions for your personal safety and

for the protection of equipment/vehicle

components

2. Safety instructions

2.1 Risk of electric shocks

2.1.1 Low voltages, high voltages

Hazardous voltages occur in both the lighting

system and the electrical system of a motor

vehicle. If contact is made with live parts

(e.g. with the ignition coil), there is a risk of

electric shock from flashover voltages caused

by damaged insulation (e.g. ignition cables

which have been attacked by martens). These

apply to the secondary and primary sides of

the ignition system, the wiring harness with

connectors, lighting system (Litronic) as well

as connection to the vehicle.

Safety measures:

¶ Only connect to a properly grounded outlet.

¶ Only the enclosed or a tested power supply cable is

to be used.

¶ All extension cables must be fitted with shock-proof

contacts.

¶ Do not exceed the voltage limits as specified on the

connection cables.

¶ Any cables with damaged insulation must be re-

placed.

¶ Before connecting it to the vehicle, first connect the

product to the lighting mains and switch on.

¶ Before switching on the ignition connect the (B-)

cable to engine ground or the battery (B–) terminal.

¶ Always switch off the ignition before performing any

work on the electrical system of the vehicle. Intervention includes, for instance, connection to the

vehicle, replacement of ignition system components,

removal of equipment (e. g. alternators), connection

of equipment to a test bench.

¶ Wherever possible, tests and settings should always

be caried out with the ignition switched off and the

engine stationary.

¶ If tests or settings are carried out with the ignition

switched on or the engine running, care must be

taken not to touch any live parts. This applies to all

connection cables and leads as well as to connections of equipment to test benches.

¶ Test connections must always be made using suit-

able connectors (e.g. Bosch testing cable set or

vehicle-specific adapter cables).

¶ Make sure that all test connections are properly

plugged in and secure.

¶ Before disconnecting the (B-) cable from the engine

ground or battery (B–), switch off the ignition.

¶ Never open the enclosures.

Disposal

Dispose of used electrical and electronic

devices, including cables, accessories and

batteries, separately from household waste.

1 689 979 642 2014-11-03

|

Robert Bosch GmbH

Symbols used | MMD 302 | 17

en

2.2 Danger of fire, Danger of explosion

There is a risk of fire and explosion from fuels and fuel vapors when work is performed

on the fuel system or on the mixture control

system.

Safety measures:

¶ Switch off the ignition.

¶ Allow the engine to cool down first.

¶ Avoid naked flames and potential sources of sparks.

¶ Do not smoke.

¶ Collect any leaked fuel.

¶ Always ensure effective ventilation and suction when

working in closed areas.

2.3 Danger of burning

When working on a hot engine, there is a risk

of injury from burning if such components as

the exhaust gas manifold, the turbo-charger,

the Lambda sensor, etc. are touched or if

parts of the body come too close to them.

These components may be heated to tem-

peratures of several hundred degrees Celsius.

Depending on the duration of the exhaust

gas measurements, the sampling probe of the

exhaust gas measuring instrument may also

become extremely hot.

Safety measures::

¶ Always wear protective clothing, e.g. gloves.

¶ Allow the engine to cool down first. This also applies

to auxiliary heating systems.

¶ Keep connecting cables well away from all hot parts.

¶ Do not leave the engine running any longer than

necessary for the test or setting.

2.4 Danger of tripping

When conducting tests or making adjustments, the sensor and connection cables increase the risk of tripping.

Safety measures:

¶ Route the connecting cables such that any risk of

tripping up is prevented.

2.1.2 High voltages in hybrid vehicles and electric vehicles as well as their high-voltage components

If high-voltage components or high-voltage

wires are inexpertly handled, there is a risk of

fatal injury from high voltages and the possible transmission of current through the body.

¶ Deenergization is only to be performed by

a qualified electrician, a qualified electrician for specific tasks (hybrid) or a power

systems engineer.

¶ Work on vehicles with high-voltage com-

ponents is only ever to be performed in

a safe, deenergized condition by persons

with the minimum qualification "Trained to

perform electrical work".

¶ Even after deactivating the high-voltage

vehicle electrical system, the high-voltage

battery may still be live.

¶ Operating condition cannot be established

from any running noise, as the electric machine is silent when stationary.

¶ In gear positions "P" and "N" the engine

or electric motor may start spontaneously

depending on the charge of the high-voltage

battery.

Safety measures:

¶ Never open or damage high-voltage batteries.

¶ On accident vehicles, never touch high-voltage com-

ponents or exposed high-voltage wires before deactivating the high-voltage vehicle electrical system.

¶ Avoid contact with any high-voltage components

and high-voltage wires (orange sheathing) when in

operation.

¶ Secure against unauthorized renewed start-up

(e.g. by means of a padlock).

¶ Always wait at least 10 seconds after deactivating

the high-voltage system.

¶ Visually inspect the high-voltage components and

high-voltage wires for damage. The power systems

engineer responsible should always be immediately

notified of any irregularities, doubts or defects

found.

$ High-voltage components must never exhibit signs

of external damage.

$ The insulation of the high-voltage wiring must be

intact and undamaged.

$ Watch out for any abnormal deformation of the

high-voltage wiring.

Loading...

Loading...