Page 1

LTC 85 00 Series

Instruction Manual

EN

Allegiant Microprocessorbased Video Switcher/

Control Systems

BOSCH

Page 2

EN | iiBosch Security Systems | December 13, 2005

Page 3

Product | Instruction Manual | Important Safeguards

EN | iii

Important Safeguards

1. Read, Follow, and Retain Instructions - All safety

and operating instructions should be read and

followed before operating the unit. Retain instructions

for future reference.

2. Heed Warnings - Adhere to all warnings on the unit

and in the operating instructions.

3. Attachments - Attachments not recommended by

the product manufacturer should not be used, as they

may cause hazards.

4. Installation Cautions - Do not place this unit on an

unstable stand, tripod, bracket, or mount. The unit

may fall, causing serious injury to a person and

serious damage to the unit. Use only manufacturerrecommended accessories, or those sold with the

product. Mount the unit per the manufacturer's

instructions. Appliance and cart combination should

be moved with care. Quick stops, excessive force, or

uneven surfaces may cause the appliance and cart

combination to overturn.

5. Cleaning - Unplug the unit from the outlet before

cleaning. Follow any instructions provided with the

unit. Generally, using a damp cloth for cleaning is

sufficient. Do not use liquid cleaners or aerosol

cleaners.

6. Servicing - Do not attempt to service this unit

yourself. Opening or removing covers may expose

you to dangerous voltage or other hazards. Refer all

servicing to qualified service personnel.

7. Damage Requiring Service - Unplug the unit from

the main AC power source and refer servicing to

qualified service personnel under the following

conditions:

•When the power supply cord or plug is damaged.

• If liquid has been spilled or an object has fallen

into the unit.

• If the unit has been exposed to water and/or

inclement weather (rain, snow, etc.).

• If the unit does not operate normally, when

following the operating instructions. Adjust only

those controls specified in the operating

instructions. Improper adjustment of other controls

may result in damage, and require extensive work

by a qualified technician to restore the unit to

normal operation.

• If the unit has been dropped or the cabinet

damaged.

• If the unit exhibits a distinct change in

performance, this indicates that service is needed.

8. Replacement Parts - When replacement parts are

required, the service technician should use

replacement parts specified by the manufacturer or

that have the same characteristics as the original part.

Unauthorized substitutions may result in fire,

electrical shock or other hazards.

9. Safety Check - Upon completion of servicing or

repairs to the unit, ask the service technician to

perform safety checks to ensure proper operating

condition.

10. Power Sources - Operate the unit only from the type

of power source indicated on the label. If unsure of

the type of power supply to use, contact your dealer

or local power company.

•For units intended to operate from battery power,

refer to the operating instructions.

•For units intended to operate with External Power

Supplies, use only the recommended approved

power supplies.

•For units intended to operate with a limited power

source, this power source must comply with

EN60950. Substitutions may damage the unit or

cause fire or shock.

•For units intended to operate at 24VAC, normal

input voltage is 24VAC. Voltage applied to the

unit's power input should not exceed 30VAC.

User-supplied wiring, from the 24VAC supply to

unit, must be in compliance with electrical codes

(Class 2 power levels). Do not ground the 24VAC

supply at the terminals or at the unit's power

supply terminals.

11. Coax Grounding - If an outside cable system is

connected to the unit, ensure that the cable system is

grounded. U.S.A. models only - Section 810 of the

National Electrical Code, ANSI/NFPA No.70,

provides information regarding proper grounding of

the mount and supporting structure, grounding of the

coax to a discharge unit, size of grounding

conductors, location of discharge unit, connection to

grounding electrodes, and requirements for the

grounding electrode.

12. Grounding - This unit may be equipped with a 3wire grounding plug (a plug with a third pin, for

grounding). This safety feature allows the plug to fit

into a grounding power outlet only. If unable to insert

the plug into the outlet, contact an electrician to

arrange replacement of the obsolete outlet. Do not

defeat the safety purpose of the grounding plug.

• Outdoor equipment should only be connected to

the unit's inputs after this unit has had its

grounding plug connected to a grounded outlet or

its ground terminal properly connected to a ground

source.

• The unit's input connectors must be disconnected

from outdoor equipment before disconnecting the

grounding plug or grounding terminal.

•Proper safety precautions such as grounding should

be followed for any outdoor device connected to

this unit.

13. Lightning - For added protection during a lightning

storm, or when this unit is left unattended and

unused for long periods of time, unplug the unit from

the wall outlet and disconnect the cable system. This

will prevent damage to the unit due to lightning and

power line surges.

Page 4

Product | Instruction Manual | Safety Precautions

EN | ivBosch Security Systems | December 13, 2005

Safety Precautions

Installation should be performed by qualified

service personnel only in accordance with the

National Electrical Code or applicable local

codes.

Power Disconnect. Units with or without

ON-OFF switches have power supplied to the

unit whenever the power cord is inserted into the

power source; however, the unit is operational

only when the ON-OFF switch is in the ON

position. The power cord is the main power

disconnect for all units.

CAUTION: TO REDUCE THE RISK OF

ELECTRIC SHOCK, DO NOT REMOVE COVER

(OR BACK). NO USER SERVICEABLE PARTS

INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

This symbol indicates the presence of

uninsulated “dangerous voltage” within the

product’s enclosure that can cause an electric

shock.

This symbol indicates the presence of

important operating and maintenance

(servicing) instructions in the literature

accompanying the appliance.

For Indoor Product

1. Water and Moisture - Do not use this unit near

water - for example, in a wet basement, in an

unprotected outdoor installation or in any area

classified as a wet location.

2. Object and Liquid Entry - Never push objects of

any kind into this unit through openings, as they

might touch dangerous voltage points or create

short circuits, resulting in a fire or electrical

shock. Never spill liquid of any kind on the unit.

3. Power Cord and Power Cord Protection - For

units intended to operate with 230VAC, 50Hz,

the input and output power cord must comply

with the latest versions of IEC Publication 227 or

IEC Publication 245.

Power supply cords should be routed so they are

not likely to be walked on or pinched. Pay

particular attention to location of cords and plugs,

convenience receptacles, and the point of exit

from the appliance.

4. Overloading - Do not overload outlets and

extension cords; this can result in a risk of fire or

electrical shock.

For Outdoor Product

Power Lines - An outdoor system should not be

located in the vicinity of overhead power lines,

electric lights or power circuits, or where it may

contact such power lines or circuits. When

installing an outdoor system, extreme care should

be taken to keep from touching power lines or

circuits, as this contact might be fatal. U.S.A.

models only - refer to the National Electrical

Code Article 820 regarding installation of CATV

systems.

For Rack-mount Product

1. Ventilation - Do not place this equipment in a

built-in installation or rack, unless proper

ventilation is provided, or the manufacturer's

instructions were followed. The equipment must

not exceed its maximum operating temperature

requirements.

2. Mechanical Loading - When rack-mounting the

equipment, ensure that a hazardous condition is

not created by uneven mechanical loading.

Page 5

Product | Instruction Manual | FCC & ICES Information

EN | v

Sécurité

Attention : l'installation doit exclusivement être réalisée par du

personnel qualifié, conformément au code national d'électricité

américain (NEC) ou au code d'électricité local en vigueur.

Coupure de l'alimentation. Qu'ils soient pourvus ou non d'un

commutateur ON/OFF, tous les appareils reçoivent de l'énergie une

fois le cordon branché sur la source d'alimentation. Toutefois,

l'appareil ne fonctionne réellement que lorsque

le commutateur est réglé sur ON. Le débranchement du cordon

d'alimentation permet de couper l'alimentation des appareils.

AT TENTION : POUR ÉVITER TOUT RISQUE D'ÉLECTROCUTION,

N'ESSAYEZ PAS DE RETIRER LE CAPOT (OU LE PANNEAU

ARRIÈRE). CET APPAREIL NE CONTIENT AUCUN COMPOSANT

SUSCEPTIBLE D'ÊTRE RÉPARÉ PAR L'UTILISATEUR. CONFIEZ

LA RÉPARATION DE L'APPAREIL À DU PERSONNEL QUALIFIÉ.

Ce symbole signale que le produit renferme une « tension

potentiellement dangereuse » non isolée susceptible de

provoquer une électrocution.

Ce symbole invite l'utilisateur à consulter les instructions

d'utilisation et d'entretien (dépannage) reprises dans la

documentation qui accompagne l'appareil.

Sicherheitshinweise

Achtung! Die Installation sollte nur von qualifiziertem

Kundendienstpersonal gemäß jeweils zutreffender

Elektrovorschriften ausgeführt werden.

Unterbrechung des Netzanschlusses. Geräte mit oder ohne

Netzschalter haben Spannung am Gerät anliegen, sobald der

Netzstecker in die Steckdose gesteckt wird. Das Gerät ist jedoch

nur betriebsbereit, wenn der Netzschalter (EIN/AUS) auf EIN

steht. Wenn das Netzkabel aus der Steckdose gezogen wird, ist

die Spannungszuführung zum Gerät vollkommen unterbrochen.

VORSICHT: UM EINEN ELEKTRISCHEN SCHLAG ZU

VERMEIDEN, IST DIE ABDECKUNG (ODER RÜCKSEITE) NICHT

ZU ENTFERNEN. ES BEFINDEN SICH KEINE TEILE IN DIESEM

BEREICH, DIE VOM BENUTZER GEWARTET WERDEN

KÖNNEN. LASSEN SIE WARTUNGSARBEITEN NUR VON

QUALIFIZIERTEM WARTUNGSPERSONAL AUSFÜHREN.

Das Symbol macht auf nicht isolierte „gefährliche Spannung"

im Gehäuse aufmerksam. Dies kann zu einem elektrischen

Schlag führen.

Der Benutzer sollte sich ausführlich über Anweisungen für

die Bedienung und Instandhaltung (Wartung) in den

begleitenden Unterlagen informieren.

Precauciones de Seguridad

Atención: la instalación la debe realizar únicamente personal

cualificado de conformidad con el National Electric Code o las

normas aplicables en su país.

Desconexión de la alimentación. Las unidades con o sin

interruptores de encendido/apagado reciben alimentación

eléctrica siempre que el cable de alimentación esté conectado a

la fuente de alimentación. Sin embargo, la unidad sólo funciona

cuando el interruptor está en la posición de encendido. El cable

de alimentación es la principal fuente de desconexión de todas

las unidades.

PRECAUCIÓN: PARA DISMINUIR EL RIESGO DE DESCARGA

ELÉCTRICA, NO RETIRE LA CUBIERTA (NI LA PARTE

POSTERIOR). NO EXISTEN PIEZAS DE RECAMBIO EN EL

INTERIOR DEL EQUIPO. EL PERSONAL DE SERVICIO

CUALIFICADO SE ENCARGA DE REALIZAR LAS

REPARACIONES.

Este símbolo indica que existen puntos de tensión peligrosos

sin aislamiento dentro de la cubierta de la unidad. Estos

puntos pueden constituir un riesgo de descarga eléctrica.

El usuario debe consultar las instrucciones de funcionamiento y

mantenimiento (reparación) en la documentación que se

suministra con el aparato.

FCC & ICES INFORMATION

(U.S.A. and Canadian Models Only)

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions:

(1)This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired

operation.

NOTE: This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules and ICES-003 of Industry Canada. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential

installation. This equipment generates, uses and can radiate radio

frequency energy, and if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer, or an experienced radio/TV technician for

help.

Intentional or unintentional changes or modifications, not

expressly approved by the party responsible for compliance, shall

not be made. Any such changes or modifications could void the

user’s authority to operate the equipment.The user may find the

following booklet, prepared by the Federal Communications

Commission, helpful: How to Identify and Resolve Radio-TV

Interference Problems. This booklet is available from the U.S.

Government Printing Office, Washington, DC 20402,

Stock No. 004-000-00345-4.

Page 6

Product | Instruction Manual | Safety Precautions

Veiligheidsmaatregelen

Attentie: het apparaat mag alleen door gekwalificeerd personeel

worden geïnstalleerd. De installatie dient in overeenstemming

met de nationale elektrische richtlijnen of de van toepassing

zijnde lokale richtlijnen te worden uitgevoerd.

Spanning uitschakelen. Apparatuur met of zonder

aan-uitschakelaar staat onder spanning zolang de stekker is

aangesloten op de wandcontactdoos. De apparatuur is uitsluitend

in werking als de aan-uitschakelaar aan staat. Het netsnoer is de

"hoofdschakelaar" voor alle apparatuur.

VOORZICHTIG: OPEN DE BEHUIZING OF DE ACHTERKANT

VAN HET APPARAAT NIET. ZO VERMINDERT U HET RISICO

OP ELEKTRISCHE SCHOKKEN. IN HET APPARAAT

BEVINDEN ZICH GEEN ONDERDELEN DIE U ZELF KUNT

REPAREREN. LAAT SERVICE EN ONDERHOUD UITVOEREN

DOOR GEKWALIFICEERD PERSONEEL.

Dit symbool geeft aan dat er binnen in het apparaat

ongeïsoleerde, gevaarlijke spanning aanwezig is die mogelijk

elektrische schokken kan veroorzaken.

De gebruiker dient de bedienings- en onderhoudsvoorschriften

te raadplegen in de documentatie die werd meegeleverd met

het apparaat.

Sicurezza

Attenzione: l'installazione deve essere effettuata esclusivamente

da personale tecnico qualificato in conformità con il National

Electrical Code o con le normative locali vigenti.

Scollegamento dell'alimentazione. Le unità dotate o sprovviste di

interruttori ON-OFF vengono alimentate quando si inserisce il

cavo nella presa dell'alimentazione. L'unità è tuttavia in funzione

solo quando l'interruttore ON-OFF si trova nella posizione ON. Il

cavo di alimentazione costituisce il dispositivo di scollegamento

dell'alimentazione principale per tutte le unità.

AT TE NZ IONE: PER RIDURRE IL RISCHIO DI SCOSSE

ELETTRICHE NON RIMUOVERE LA COPERTURA (O IL

PANNELLO POSTERIORE). L'UNITÀ NON CONTIENE

COMPONENTI INTERNI RIPARABILI DALL'UTENTE. PER

QUALSIASI INTERVENTO, RIVOLGERSI A PERSONALE

TECNICO QUALIFICATO.

Questo simbolo indica la presenza di "tensione pericolosa" non

isolata all'interno del contenitore del prodotto. Ciò comporta un

potenziale rischio di scosse elettriche.

Si consiglia di consultare le istruzioni operative e di

manutenzione (interventi tecnici) contenute nella

documentazione fornita con il dispositivo.

Medidas de Segurança

Atenção: a instalação deve ser executada apenas por técnicos

qualificados da assistência, de acordo com o código eléctrico

nacional ou os códigos locais aplicáveis.

Corte de corrente. As unidades com ou sem interruptores

ON-OFF (ligar/desligar) recebem corrente sempre que o fio de

alimentação está introduzido na fonte de alimentação; contudo, a

unidade apenas está operacional quando o interruptor ON-OFF

está na posição ON. O fio de alimentação destina-se a desligar a

corrente em todas as unidades.

CUIDADO: PARA REDUZIR O RISCO DE CHOQUE

ELÉCTRICO, NÃO RETIRE A TAMPA (OU A PARTE

POSTERIOR). NO INTERIOR, NÃO EXISTEM PEÇAS QUE

POSSAM SER REPARADAS PELO UTILIZADOR. REMETA A

ASSISTÊNCIA PARA OS TÉCNICOS QUALIFICADOS.

Este símbolo indica a presença de "tensão perigosa" não isolada

dentro da estrutura do produto, o que pode constituir risco de

choque eléctrico.

O utilizador deve consultar as instruções de funcionamento

e manutenção (assistência) nos documentos que

acompanham o aparelho.

EN | viBosch Security Systems | December 13, 2005

Page 7

1. Unpacking ........................................................................................................................................................... 1

1.1 Parts List ................................................................................................................................................. 1

2. Service.................................................................................................................................................................. 2

3. Description.......................................................................................................................................................... 3

4. Allegiant Feature Summary Table ................................................................................................................ 5

5. System Components ......................................................................................................................................... 7

5.1 LTC 8501 Series Systems .......................................................................................................................7

6. System Accessory Components...................................................................................................................... 8

6.1 LTC 8540/00 Alarm Interface Unit ......................................................................................................8

6.2 LTC 8568 and LTC 8768 Signal Distribution Units ...........................................................................8

6.3 IntuiKey Series KBD-Universal Keyboard...........................................................................................8

6.4 KBD-Rack Keyboard Mounting Kit......................................................................................................8

6.5 LTC 8555 Series Keyboards ..................................................................................................................9

6.6 LTC 8558/00 Keyboard Extension Cable............................................................................................9

6.7 LTC 8557 Series Keyboard Extension Kits..........................................................................................9

6.8 LTC 8560 and LTC 8561 Series Receiver/Driver Units....................................................................9

6.9 AutoDome Series.....................................................................................................................................9

6.10 LTC 8569, LTC 8570, LTC 8571, LTC 8572 Series Code Merger Units..................................... 10

6.11 LTC 8770 Switcher Follower Series................................................................................................... 10

6.12 LTC 8712 Series Console Port Expander Units ............................................................................... 10

6.13 LTC 8713 Alarm Port Expander Units.............................................................................................. 10

6.14 LTC 8780 Series Data Converter Units............................................................................................. 11

6.15 LTC 8781 Series Data Converter Units............................................................................................. 11

6.16 LTC 8016/90 Bilinx™ Data Interface Unit........................................................................................ 11

6.17 LTC 8785 Series Code Converters .................................................................................................... 11

6.18 LTC 8782 Series Code Translator Units ........................................................................................... 11

6.19 LTC 8059/00 Master Control Software............................................................................................. 12

6.20 LTC 8850/00 Windows Based Graphical User Interface Software................................................ 12

6.21 SFT-INTSRV Allegiant Integration Software ...................................................................................12

6.21.1 Integration Server......................................................................................................................... 12

6.21.2 Virtual Allegiant Satellite Application Software ....................................................................... 12

6.21.3 Allegiant Satellite Software Development Kit........................................................................... 13

6.22 LTC 8506/00 PC-to-Console Port RS-232 Cable............................................................................. 13

6.23 Logging Printer ..................................................................................................................................... 14

7. Installation Procedure .................................................................................................................................... 16

7.1 Main CPU Bay Installation ................................................................................................................. 16

7.2 Video Input Modules........................................................................................................................... 16

7.3 Video Output Modules........................................................................................................................ 17

7.4 CPU Module......................................................................................................................................... 17

7.5 Camera and Monitor Video Connections.........................................................................................18

7.6 Termination Practices .......................................................................................................................... 18

7.6.1 LTC 8500 Series Video Terminations....................................................................................... 18

7.6.2 Monitor Output Video Connections.......................................................................................... 18

8. Optional Accessories Installation ................................................................................................................ 19

8.1 General Accessory Installation............................................................................................................ 19

8.2 Logging Printer Option Installation ................................................................................................... 19

8.3 Computer Interface Installation.......................................................................................................... 20

EN | vii

Page 8

9. Satellite Configuration Installations ........................................................................................................... 21

9.1 Satellite Site “Trunk Line” Monitor Outputs .................................................................................... 21

9.2 Main Site “Trunk Line” Video Inputs ............................................................................................... 22

9.3 Control Data Lines in Satellite Systems............................................................................................. 22

9.4 Satellite Site Programming Requirements ......................................................................................... 22

9.5 Main Site Programming Requirements.............................................................................................. 23

9.6 Special Programming for “Cascaded” Satellite System Configurations......................................... 25

9.7 Alarm Inputs in Satellite Systems ....................................................................................................... 26

10. Feature Selection............................................................................................................................................. 27

11. Main Power Connections............................................................................................................................... 28

12. Video Monitor Display .................................................................................................................................. 29

12.1 Time / Date........................................................................................................................................... 29

12.2 Monitor Title/System Status Display ................................................................................................. 29

12.2.1 Monitor Message .......................................................................................................................... 29

12.2.2 System Status Display .................................................................................................................. 30

13. Factory Default Settings................................................................................................................................. 33

13.1 User Selectable DIP Switch Settings for Main CPU Bay................................................................. 33

13.1.1 Upper CPU DIP Switch S1001................................................................................................... 33

13.1.2 Lower CPU DIP Switch S1002................................................................................................... 34

14. User Information ............................................................................................................................................. 38

14.1 User Priority Levels.............................................................................................................................. 38

14.2 User Priority Access Table .................................................................................................................. 39

15. Alarm Information .......................................................................................................................................... 40

15.1 General .................................................................................................................................................. 40

15.2 Basic Alarm Response Mode .............................................................................................................. 40

15.3 Auto Build Alarm Response Mode .................................................................................................... 40

15.4 Sequence and Display Alarm Response Mode................................................................................. 40

15.5 Alarm Activated Pre-position.............................................................................................................. 41

15.6 Sample Alarm Responses .................................................................................................................... 41

15.7 Alarm Relay Response ........................................................................................................................ 43

16. Keyboard Operation ...................................................................................................................................... 44

16.1 General .................................................................................................................................................. 44

16.2 System Commands............................................................................................................................... 44

16.2.1 Keyboard Log-in Procedure........................................................................................................ 44

16.2.2 Keyboard Log-off Procedure....................................................................................................... 45

16.3 Switcher Commands ............................................................................................................................ 45

16.4 Controlling Camera Movement.......................................................................................................... 45

16.4.1 General .......................................................................................................................................... 45

16.4.2 Focus and Iris Lens Control........................................................................................................ 45

16.4.3 Lock or Unlock Control of a Camera........................................................................................ 45

16.4.4 Lock or Unlock Control of a Monitor ....................................................................................... 46

16.4.5 Recording a Camera Pre-position Scene ................................................................................... 46

16.4.6 Recalling a Camera Pre-position Scene ..................................................................................... 46

16.4.7 Activate/Deactivate Auxiliary Function .................................................................................... 46

16.5 Alarm Commands ................................................................................................................................ 47

16.5.1 Arm/Disarm Individual Alarms ................................................................................................. 47

16.5.2 Arm/Disarm All Alarms.............................................................................................................. 48

EN | viii Bosch Security Systems | December 13, 2005

Page 9

16.5.3 Arm/Disarm Monitor .................................................................................................................. 48

16.5.4 Alarms Acknowledgement .......................................................................................................... 48

16.6 Sequence Control ................................................................................................................................. 48

16.6.1 Load/Clear a Sequence ............................................................................................................... 48

16.6.2 Run a Sequence ............................................................................................................................ 49

16.6.3 Stop a Running Sequence ........................................................................................................... 49

16.6.4 Controlling Sequence Direction ................................................................................................. 49

16.7 Sequence Programming....................................................................................................................... 50

16.7.1 Programming a Simple Camera Sequence................................................................................ 50

16.7.2 Programming a SalvoSwitching Camera Sequence.................................................................. 52

17. Keyboard User Functions .............................................................................................................................. 53

17.1 General Information............................................................................................................................. 53

17.1.1 User Function 1 - Local Keyboard Test..................................................................................... 55

17.1.2 User Function 2 - Show Keyboard Port Number ..................................................................... 56

17.1.3 User Function 3 - Select Keyboard Beeper ON/OFF.............................................................. 56

17.1.4 User Function 4 - Adjust Position of Monitor Overlay............................................................ 56

17.1.5 User Function 5 - Monitor Display Brightness / Status Selection........................................... 56

17.1.6 User Function 6 - Select Monitor Display Option.................................................................... 56

17.1.7 User Function 7 - Set Time ......................................................................................................... 57

17.1.8 User Function 8 - Set Date .......................................................................................................... 57

17.1.9 User Function 9 - Set Camera ID............................................................................................... 57

17.1.10 User Function 10 - Change USER Password............................................................................ 57

17.1.11 User Function 11 - Select Time / Date Format......................................................................... 58

17.1.12 User Function 12 - Default All Monitor Overlays.................................................................... 58

17.1.13 User Function 13 - Print System Configuration Tables ........................................................... 58

17.1.14 User Function 14 - Reserved Function ...................................................................................... 58

17.1.15 User Function 15 - System Reset................................................................................................ 58

17.1.16 User Function 16 - Time Event Enable/Disable....................................................................... 58

17.1.17 User Function 17 - Set Monitor ID ............................................................................................ 58

17.1.18 User Function 18 - Print Sequence............................................................................................. 59

17.1.19 User Function 19 - Select Alarm Response............................................................................... 59

17.1.20 User Function 20 - Select Printer Verbosity.............................................................................. 59

17.1.21 User Function 21 - Designate Alarm Monitor Type ................................................................ 59

17.1.22 User Function 22 - Select Control Code Format...................................................................... 59

17.1.23 User Function 23 - Display CPU Software Version Number ................................................. 60

17.1.24 User Function 24 - Set Positions on All Monitor Displays...................................................... 60

17.1.25 User Function 25 - Set Brightness on All Monitor Displays ................................................... 60

17.1.26 User Function 26 - Set Display Option On All Monitors........................................................ 60

17.1.27 User Function 27 - Select Keyboard Log-in.............................................................................. 60

17.1.28 User Function 28 - Select Console Log-in................................................................................. 61

17.1.29 User Function 29 - Reset RS-232 Parameters to Default......................................................... 61

17.1.30 User Function 30 - Set Console RS-232 Parameters ................................................................ 61

17.1.31 User Function 31 - Set Printer RS-232 Parameters................................................................... 61

17.1.32 User Function 32 - Set Alarm RS-232 Parameters ................................................................... 61

17.1.33 User Function 33 - Display User Number and Priority........................................................... 61

17.1.34 User Function 34 - Camera Indicator ........................................................................................ 62

17.1.35 User Function 35 - Controllable Cameras................................................................................. 62

17.1.36 User Function 36 - Select Crosspoint Data ............................................................................... 62

17.1.37 User Function 37 - R/D Address Mode .................................................................................... 62

17.1.38 User Function 38 - Printer Port Mode ....................................................................................... 62

17.1.39 User Function 39 - Select DIU Interface Port........................................................................... 62

17.1.40 User Function 40 - Reserved Function ...................................................................................... 62

17.1.41 User Function 41 - Set Satellite Communication Format ........................................................ 62

EN | ix

Page 10

17.1.42 User Function 42 - Keyboard Log-in Auto-off Mode............................................................... 64

17.1.43 User Function 43 - CPU Battery Status ..................................................................................... 64

17.1.44 User Function 99 - User Function Index................................................................................... 64

18. Maintenance Information.............................................................................................................................. 65

18.1 Cleaning the Keyboard........................................................................................................................ 65

18.2 AC Line Voltage Input Selection ....................................................................................................... 65

18.3 AC Line Fuse Replacement ................................................................................................................ 66

18.4 Power Supply Fuse Replacement ....................................................................................................... 66

18.5 Replacement of Memory Backup Batteries....................................................................................... 66

19. Character ROM Tables for LTC 8500......................................................................................................... 68

20. Error Messages................................................................................................................................................. 70

21. Troubleshooting Guide.................................................................................................................................. 73

21.1 Main Bay Checkout ............................................................................................................................. 73

21.2 Keyboard Checkout ............................................................................................................................. 73

21.3 Video Monitor Display Checkout ...................................................................................................... 74

21.4 Remote Receiver/Driver Functions Inoperative............................................................................... 74

21.5 No Alarm Response ............................................................................................................................. 74

21.6 CPU Software Version Numbers........................................................................................................ 75

22. Glossary of Terms............................................................................................................................................ 76

Appendix A Satellite Systems ......................................................................................................................... 78

Appendix B Installation Checklists ............................................................................................................... 85

Appendix C Quick Reference Cable Interconnections ............................................................................ 86

Appendix D Main Bay Rear Panel Connector Pin-outs and Cable Pin-out......................................... 88

EN | x Bosch Security Systems | December 13, 2005

Page 11

1Unpacking

This equipment should be unpacked and handled with care. If an item appears to

have been damaged in shipment, notify the shipper. Verify that all parts shown in

the Parts List have been included. If any items are missing, notify your Bosch Security Systems Sales or Customer Service Representative.

The original packing carton is the safest container in which to transport the unit.

Save it for possible future use.

1.1 Parts List

The following table lists the components:

Qty Item

1LTC 8501 Series Main CPU card cage

1LTC 8511/00 CPU module

1LTC 8505 Series Power Supply

1AC power cord (either for 120 VAC or 220 - 240 VAC)

1Fuse kit

1This installation manual

EN | 1

Page 12

2Service

If the unit needs repair, contact the nearest Bosch Security Systems Service Center

for authorization to return and shipping instructions.

Service Centers

•USA

• Phone: 800-366-2283 or 717-735-6638

• Fax: 800-366-1329 or 717-735-6639

•CCTV Spare Parts

• Phone: 800-894-5215 or 408-956-3853 or 3854

• Fax: 408-957-3198

• E-mail: BoschCCTVparts@ca.slr.com

•Canada

• Phone: 514-738-2434

•Europe, Middle East & Asia Pacific Region

• Phone: 32-1-440-0711

For additional information, see www.boschsecurity.com.

EN | 2 Bosch Security Systems | December 13, 2005

Page 13

3Description

This Allegiant video switcher/control system combines both switching and computer technology to provide powerful performance and unique system features for

the security user. Offering full matrix switching capability, this system can be programmed to display the video from any camera on any monitor, either manually or

via independent automatic switching sequences.

The LTC 8500 Series Allegiant system can handle up to 64 cameras and eight (8)

monitors in a full crosspoint configuration. It can also accommodate 128 alarm

points, up to eight (8) system keyboards, a computer system console port, and a logging printer port.

This system can be programmed with up to 60 sequences that can be run independently of each other, in either a forward or reverse direction. Any of the sequences

can utilize the SalvoSwitching capability where any number of system monitors may

be selected to switch as a synchronized group. Using the optional LTC 8059/00

Master Control Software (MCS) package or the LTC 8850/00 Bosch Graphical User

Interface (GUI), sequences can be made to activate and deactivate automatically,

based upon the time of day and the day of week.

The series supports variable speed control and full programming functions of

AutoDome

units provide operators with control of pan, tilt, zoom, multiple pre-positions, four

auxiliaries, autopan, and random scan using conventional camera/lens/housings.

®

Series dome cameras. In addition, support for on-site receiver/driver

With the addition of an external LTC 8540/00 Alarm Interface unit, an external

contact closure or logic level can be used to automatically display any camera. Any

monitor or group of monitors can be set to display cameras under alarm conditions.

The base system contains three (3) built-in alarm response modes: basic, auto-build,

and sequence and display. In addition to these three (3) modes, the PC based software packages offer the ability to combine any or all three (3) standard modes.

Alarm video may be selected to reset either manually or automatically. In addition,

a 16-character alarm title can be selected to appear instead of the camera title during

alarm conditions.

System operation and programming is accomplished using a full-function, ergonomically designed keyboard. Multiple keyboards may be used in the system. Built-in

operator priority levels and the ability to restrict certain operators from controlling

designated functions provide maximum flexibility.

This system includes a 48-character on-screen display for time-date, camera number,

camera ID (16 characters), and monitor (12 characters) or status information. When

programming camera ID and monitor titles, 256 different characters are available.

Enhanced programming and switching features can be obtained by utilizing a standard Windows

LTC 8850/00 GUI Software. A user friendly spreadsheet format provides the ability

to enter camera titles, enter operator names, schedule up to 64 timed events, change

system parameters, program camera sequences, install lockouts, and access the

advanced alarm handling screens with speed and efficiency. The programmed information may then be transferred into the Allegiant system, stored on disk, or printed

from a PC.

®

equipped PC and the optional LTC 8059/00 MCS package or the

The LTC 8850/00 Bosch GUI Software is designed around an intuitive graphicbased interface. This software provides high performance programming, control,

EN | 3

Page 14

and monitoring of all system functions by using on-screen icons to reflect real time

status of the devices controlled by the system.

The LTC 8850/00 GUI Software also provides the ability to monitor system status

events. System alarms, switching functions, sequence events, and keyboard actions

can be viewed in real time on the PC screen and, if desired, logged to the PC hard

drive. The LTC 8850/00 GUI Software can also be used to enable a special onscreen icon for identifying controllable cameras.

The CPU inside these matrix switchers supports powerful macro capabilities. The

macros can be activated using system keyboards, system time event functions, alarm

activations, and via special function icons in the LTC 8850/00 GUI Software.

This system can serve as the master switcher in a SatelliteSwitch configuration. This

innovative feature enables a single master Allegiant system to communicate with

remotely located “Satellite” systems. Any Allegiant system model can serve as a

remote Satellite switcher. This powerful feature permits the design of a distributed

matrix video switching system with control at one central location and individual

control at the local sites. The main control site can view/control local cameras plus

cameras located at any of the remotely distributed Satellite sites. The Satellite sites

can view/control only cameras associated with their own site. When these models

are used in this type of configuration, the main system can access up to 256 cameras

located anywhere in the system.

EN | 4 Bosch Security Systems | December 13, 2005

Page 15

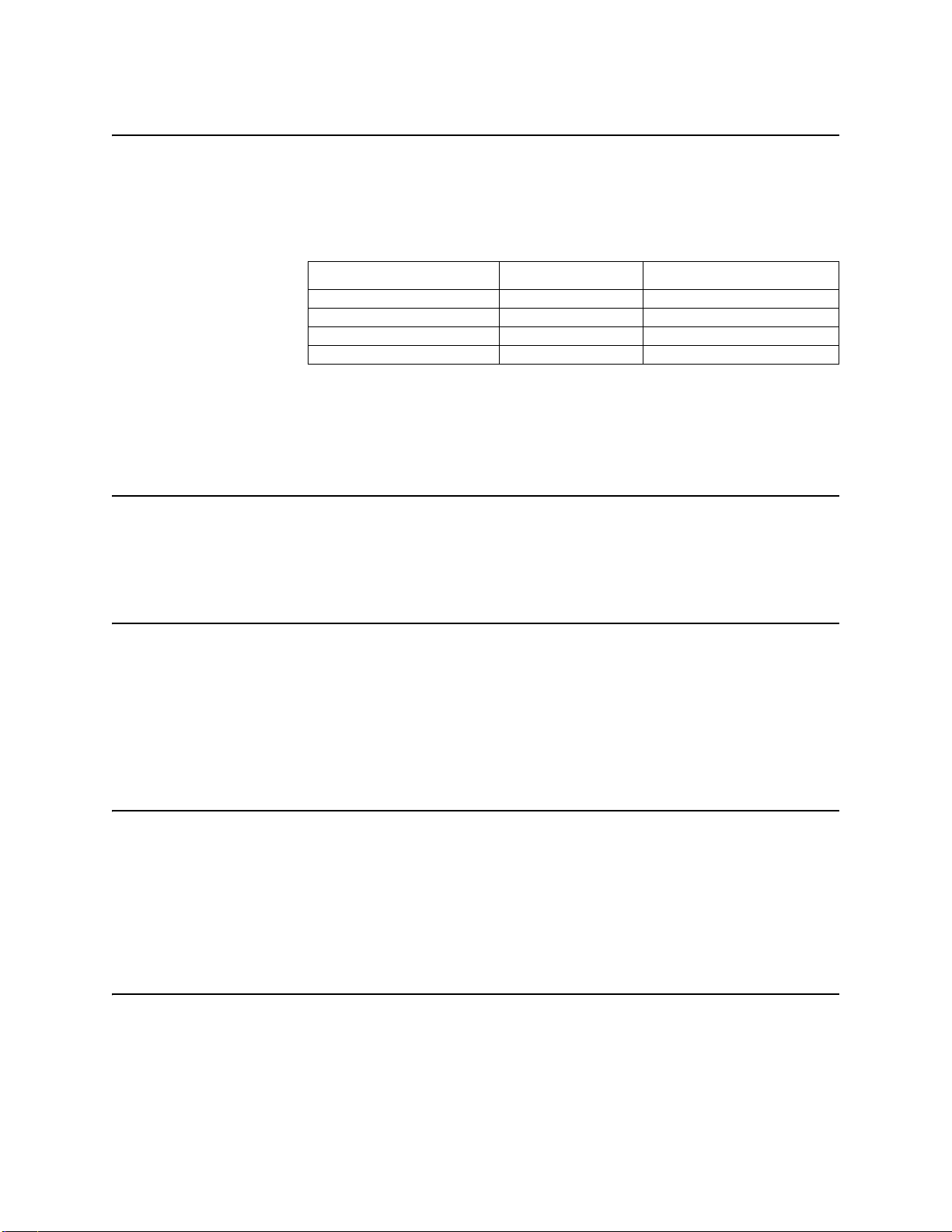

4Allegiant Feature Summary Table

This Allegiant Series system is available in two (2) operating configurations: a base

system and the base system with an optional PC based software package. The base

system includes features required for most switching/controller systems.

The addition of the optional LTC 8059/00 MCS or optional LTC 8850/00 GUI

Software package enables the user to customize the system's configuration using a

menu driven program run on any personal computer using Microsoft

SE, Windows ME, Windows NT

The following table lists available features.

®

, Windows 2000, or Windows XP.

®

Windows 98

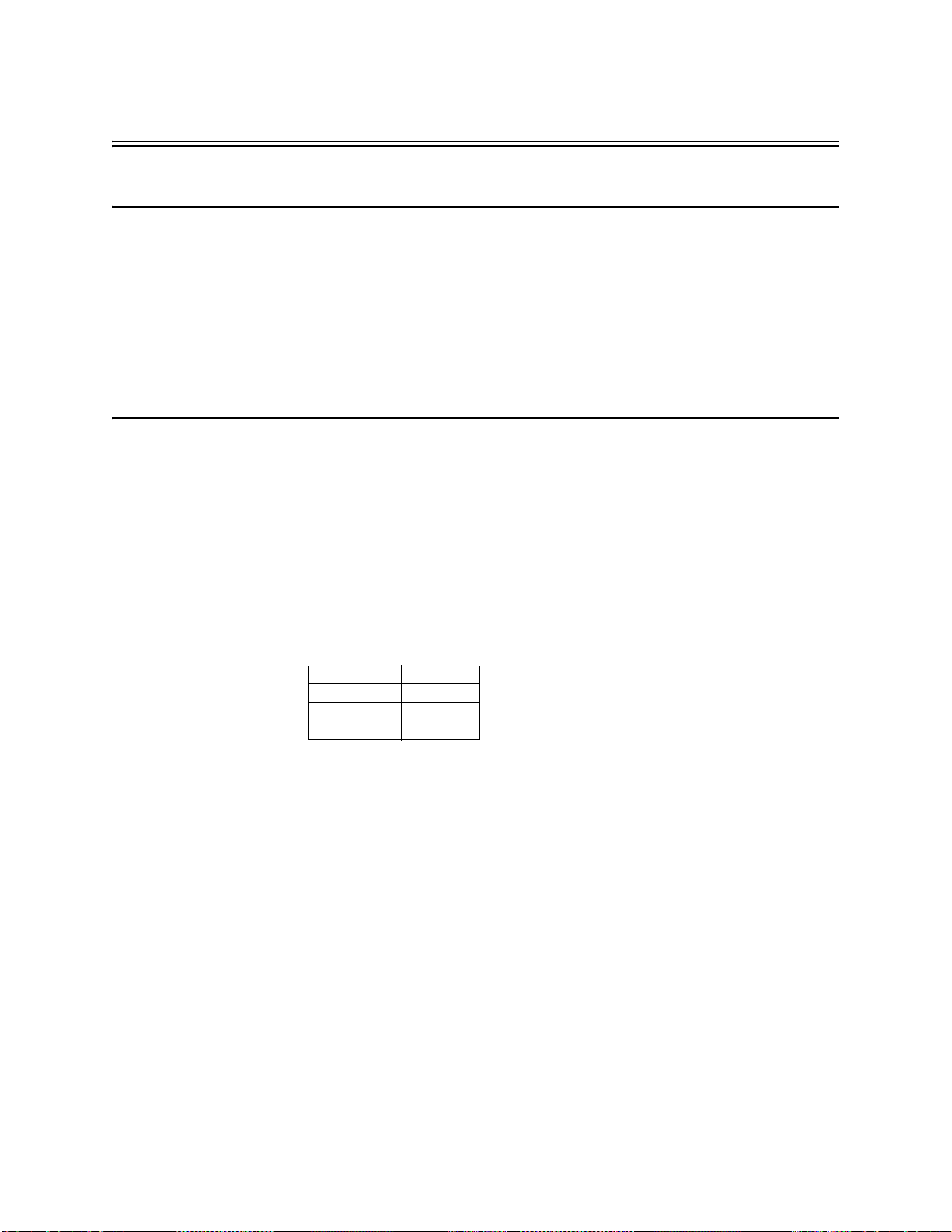

Feature

1. Full camera switching/control on all monitors Y Y

2. Up to eight (8) system keyboards Y Y

3. Up to 64 alarm inputs Y Y

4. Three (3) user-selectable pre-defined alarm response

modes

5. Full control of on-site receiver/drivers Y Y

6. SalvoSwitching feature Y Y

7. 6 0 Pro gr a m m a b le sequences Y Y

8. Alarm call-up of pre-position scenes Y Y

9. RS-232 Interface ports for computer, logging printer, etc. Y Y

10. Ke yb oa rd log- on/log-off function Y Y

11. Us er- selectable password security Y Y

12. 16- Ch ar ac ter camera titles and 12-c hara cter monitor

titles

13. Format sel ection time/date format Y Y

14. Lo ca l keyboard test function Y Y

15. Table and Sequence printout feature Y Y

16. Parameter designation for RS-232 communication Y Y

17. Satellite configurations N Y

18. Re st ri ct us er /keyboard access to cameras N Y

19. Re st ri ct us er/keyboard access to receiver/drivers N Y

20. Restrict user access to keyboard N Y

21. R es tr ic t u se r/keyboard access to monitors N Y

22. Designate user name and ID number N Y

23. Designate zoned alarm call-ups N Y

24. Powerful alarm response features N Y

25. Designate displayed camera number N Y

26. Designate receiver/driver functions on alarm N Y

27. Program 64 time activated events N Y

28. Designate receiver/driver functions in sequences N Y

29. Broadcast monitor messages N Y

30. Alarm title designation N Y

31. Personal computer displayed monitoring of system

status

Base

System

Y Y

Y Y

N Y

With Optional

Allegiant PCBased Software

In addition, this system provides the capability to control on-site receiver/driver

units and the AutoDome Series of integral pan/tilt/zoom/cameras.

EN | 5

Page 16

The LTC 8500 Series system contains a logging printer output port, so an inexpensive RS-232 serial printer or some other form of logging software can be used to

capture log data. This provides a permanent record showing time and date of

changes to system status, such as:

•Incoming alarms

•Acknowledgment of alarms by users

•Loading sequences

•User log-on to keyboard or console port

•Console broadcast message

•Console transfer of system tables

•Activation of time event functions

•Power up reset message

The printer may also be used to provide a hard copy of all system configuration

Ta bl es a nd Sequences.

EN | 6 Bosch Security Systems | December 13, 2005

Page 17

5System Components

5.1 LTC 8501 Series Systems

•LTC 8501 Series Main CPU Bay

A modular equipment bay which contains the system’s microprocessor module

(LTC 8511/0 0), the power supply module (LTC 8505 Series ), and combinations of

video input and video output modules (see below).

•LTC 8521/00 Video Input Module

Individual cards placed in LTC 8501 Series bays to accept inputs from cameras and

other video sources. Each card provides eight (8) video input channels with switch

selectable terminations.

•LTC 8532/00 Video Output Modules

Individual cards placed in LTC 8501 Series bays to provide video outputs to monitors and DVRs. Each card provides two (2) video output channels.

•LTC 8501 Series System Capacities

Up to eight (8) video input modules; eight (8) inputs per module.

LTC 8501 Series Systems

Up to four (4) video output modules; two (2) outputs per module.

To t a l : 6 4 inputs and eight (8) outputs.

Satellite configuration input capacity: 320.

EN | 7

Page 18

6System Accessory Components

The Allegiant Series accessory products provide many optional features to the base

system. A brief description of accessory products is provided below. Complete specification information can be found in respective product data sheets. Applicable

accessories are designed to be compatible throughout the Allegiant Series.

6.1 LTC 8540/00 Alarm Interface Unit

The LTC 8540/00 is an alarm gathering unit which accepts up to 64 dry contact closures or logic level inputs from remote sensing devices such as door contacts, PIRs,

etc. and then reports this alarm information to the main CPU bay. Alarm inputs

may be configured in groups of 32 to accept either normally open or normally

closed contacts. This unit provides eight (8) relay outputs which can be used to drive

external alerting devices, DVR's, and other devices.

6.2 LTC 8568 and LTC 8768 Signal Distribution Units

The signal distribution is a main site control code distribution and line driver units

are available for communicating to receiver/drivers, switcher followers, and Allegiant Satellite systems. The LTC 8568/00 Signal Distribution Unit provides 32 separate outputs for driving up to 256 remote devices. Either “star” or “daisy chain”

wiring configurations may be used. The LTC 8768/00 Signal Distribution unit is

similar to the LTC 8568/00, except that it provides 64 separate outputs for driving

up to 512 remote devices.

6.3 IntuiKey Series KBD-Universal Keyboard

The IntuiKey KBD-UNIVERSAL is a full function keyboard used for control and

programming of the Allegiant Series matrix switchers. Backlit LCD screens provide

a multi-language display of softkey menus and status information. Integral variable

speed joystick and zoom lens controls are standard for operating fixed or variable

speed pan/tilt/zoom equipped cameras. Both Allegiant RS-485 and Allegiant

RS-232 keyboard protocols are supported.

In addition to the Allegiant Series, the KBD-UNIVERSAL model IntuiKey can be

used to simultaneously control Divar Series DVRs, System4 Series multiplexers, and

access ADIM based DVR control screens.

6.4 KBD-Rack Keyboard Mounting Kit

Rack-mounting kit designed to provide vertical, horizontal, or inclined mounting for

IntuiKey keyboards.

EN | 8 Bosch Security Systems | December 13, 2005

Page 19

6.5 LTC 8555 Series Keyboards

The LTC 8555 Series keyboards are compact, full function keyboards for use with

Allegiant Series matrix switchers. LED readouts display real time system status

information. Includes variable speed joystick and zoom lens controls for operating

fixed or variable speed pan/tilt/zoom equipped cameras. The keyboards are available in the following configurations:

Model Number Top Bezel Graphics Communication Protocol

LTC 8 555/00 English RS-485

LTC 8 555/01 Icons RS-485

LTC 8 555/02 English RS-232

LTC 8 555/03 Icons RS-232

The RS-232 model keyboards connect to an Allegiant's console port or to a port

provided by an LTC 8712 Console Expander accessory unit. Up to four (4) may be

connected to a single LTC 8712 unit. When used with dial-up type phone modems,

these keyboards provide rudimentary dialing capability.

6.6 LTC 8558/00 Keyboard Extension Cable

LTC 8555 Series Keyboards

The LTC 8558/00 keyboard extension cable has a six-conductor extension cable

that carries data/power for remote keyboards up to 30 m (100 ft) away from the

main CPU bay.

6.7 LTC 8557 Series Keyboard Extension Kits

The LTC 8557 Series keyboard extension cable is an interface kit used to remote the

IntuiKey Series or LTC 8555 Series keyboards up to 1.5 km (5000 ft) away from the

2

main CPU bay. Customer supplied 0.5 mm

(Belden 9841 or equivalent) required between the main CPU bay site and keyboard

site. Kit provides two (2) junction boxes, interface cable, and appropriate keyboard

power supply.

(24 AWG) shielded-twisted pair

6.8 LTC 8560 and LTC 8561 Series Receiver/Driver Units

These series of on-site receiver/drivers are designed to receive biphase control code

and convert this data into signals for controlling conventional pan/tilt, zoom lenses,

and auxiliary functions. Supplied in an environmentally rated enclosure, these series

of receiver/drivers are available in both basic and full-featured models. This unit

contains integral local test feature, autopan or random scanning, and is available in

several input and output drive voltage versions.

6.9 AutoDome Series

The AutoDome Series comprise an integral camera, a high speed pan/tilt mechanism, a zoom lens, and a receiver/driver system in a compact dome enclosure. Various enclosure mounting options are available for indoor and outdoor applications.

EN | 9

Page 20

6.10 LTC 8569, LTC 8570, LTC 8571, LTC 8572 Series Code Merger Units

These series are control code merger and line driver units used to combine Allegiant

biphase control code from two (up to four with LTC 8570 and LTC 8572 versions)

systems for communicating to AutoDome Series cameras, receiver/drivers,

switcher/followers, and Allegiant Satellite systems.

The LTC 8569, LTC 8570 Series provides 32 separate outputs capable of driving up

to 256 remote devices. The LTC 8 571, LTC 8572 Series provides 64 separate outputs

capable of driving up to 512 remote devices. Either “star” or “daisy chain” wiring

configurations may be used. The unit will accept signal input either from an Allegiant main CPU bay, LTC 8568/00 output, LTC 8780 biphase output, or an output

from another LTC 8569, LTC 8570 Series or LTC 8571, LTC 8572 Series unit. Multiple units may be cascaded to obtain additional outputs.

6.11 LTC 8770 Switcher Follower Series

The LTC 8770 Series is an accessory unit which provides relay contact closures corresponding to cameras displayed on system monitors. The LTC 8770 may be configured to follow manual activations, non-alarmed video, alarmed video, or both. Each

unit provides 24 relay contact outputs. In addition, six (6) functional operating

modes are available, including one user activated test mode.

6.12 LTC 8712 Series Console Port Expander Units

The LTC 8712 Series “expands” an Allegiant system's console port to permit up to

four (4) external computing devices to communicate with the system via RS-232

protocol. Any computing device that can normally communicate directly with an

Allegiant via its RS-232 console port can be used with this port expander. The external devices may consist of PCs running the Allegiant system's MCS package, the

Allegiant GUI, access control systems, Allegiant RS-232 protocol keyboards, or

other devices utilizing the Allegiant system's Command Console Language (CCL).

6.13 LTC 8713 Alarm Port Expander Units

The LTC 8713 Series interfaces to the alarm port of an Allegiant system to permit

additional LTC 8540/00 Alarm Interface units to be connected. In a LTC 8500 system, two (2) LTC 8540/00 units can be connected to a LTC 8713 Series unit providing up to 128 alarm inputs. In LTC 8600 systems, up to eight (8) LTC 8540 Series

units can be connected to three (3) LTC 8713 Series unit providing up to 512 alarm

inputs. In LTC 8800 systems, up to sixteen LTC 8540 Series units can be connected

to five (5) LTC 8713 Series unit providing up to 1024 alarm inputs.

EN | 10 Bosch Security Systems | December 13, 2005

Page 21

6.14 LTC 8780 Series Data Converter Units

The LTC 8780 Series are accessory units that convert the Allegiant system's biphase

control code into RS-232, or converts RS-232 back to biphase code. This provides

the capability of transmitting the control code over conventional RS-232 transmission mediums such as phone modems, fiber optics, microwaves, etc. The unit will

accept the Biphase control code generated by an Allegiant main CPU bay, an

LTC 8568/00 Signal Distribution unit, or an output from an LTC 8569, an

LTC 8 570, an LTC 8571, or an LTC 8572 Series Code Merger unit.

6.15 LTC 8781 Series Data Converter Units

The LTC 8781 Series are accessory units that decode the Allegiant system's encoded

time/date information generated on the biphase control code line and convert it into

an RS-422 GPS format. This time/date information can be used to interface into

external time/date inserter products (such as the Kalatel KTS-53-16), which are

designed to be synchronized via a GPS signal.

6.16 LTC 8016/90 Bilinx™ Data Interface Unit

LTC 8780 Series Data Converter Units

The LTC 8016/90 Allegiant Bilinx Data Interface unit is an accessory used for communicating over-the-coax, with up to 16 Bilinx-capable AutoDome and/or Dinion™

Series cameras. The LTC 8016 provides complete control of pan/tilt/zoom, auxiliaries, and pre-position functions of Bilinx enabled AutoDome Series cameras. In

addition, complete programming of Dinion Series cameras and AutoDomes via

their on-screen menus is supported. Bilinx technology also supports camera-generated event reporting to the Allegiant. This connection allows remote alarm inputs

and motion event data to be sent by the camera to the Allegiant without the need

for additional wiring between the camera site and the main control location. The

LTC 8016 can also be used to transmit Bilinx communications over a number of

video transmission systems. Example devices include fiber optic links and external

balun devices that use CAT5 twisted pair cables for video communication.

6.17 LTC 8785 Series Code Converters

The LTC 8785 Series code converter units are designed for use in older Allegiant

systems that have been upgraded to support 'variable speed' control code protocol.

The LTC 8785 units are used to provide a source of 'fixed speed' control code when

the system is generating the newer 'variable speed' control code preferred by the

AutoDome Series of PTZ cameras. The LTC 8785 would receive the variable speed

control code from the Allegiant via its LTC 8568/00 Signal Distribution unit and

convert it into the appropriate fixed speed control code. The 'fixed speed' control

code outputs from the LTC 8785 Series connect to the older TC8561 Series receiver/

drivers using the existing field cabling.

6.18 LTC 8782 Series Code Translator Units

The LTC 8782 Series Code Translators are accessory units that convert biphase code

to other manufacturers’ control codes, or convert other manufacturers’ codes to

EN | 11

Page 22

biphase. Many of the most popular protocol codes are supported, including Pelco

®

Vicon

and Javelin

, American Dynamics®, Sensormatic®, Kalatel®, Diamond Electronics®,

®

. Fixed and variable speed codes are supported where applicable.

6.19 LTC 8059/00 Master Control Software

The Allegiant LTC 8059/00 MCS brings the familiarity of the personal computer to

those who supervise closed circuit television systems. Running on a Windows based

compatible computer, this software is the human interface that makes it quick and

easy to configure an entire Allegiant system.

With the MCS package, users can set and change an Allegiant's system parameters;

program camera sequences; lock cameras, monitors, remotes, and keyboards from

certain users; and perform many other system control features. Users can also view

system activity with real time monitoring of the system status, and if desired, log this

information to a file stored on the hard drive.

6.20 LTC 8850/00 Windows Based Graphical User Interface Software

The Allegiant LTC 8850/00 GUI Software is a PC-based program designed for

complete control and programming of the Allegiant Series of matrix switchers. With

a mouse click on an icon, operators can easily take control of system hardware

devices, including cameras, monitors, and alarms. Jumping from one map to

another is easily accomplished using special link icons. System Administrators can

easily call-up the included Allegiant LTC 8059/00 MCS module for entering the

Allegiant system's camera titles, sequences, alarm responses, and many other configuration features. Communication between the GUI workstations and an Allegiant

system can be made using an RS-232 link, or via a Windows based-PC network.

®

,

6.21 SFT-INTSRV Allegiant Integration Software

The SFT-INTSRV software CD contains three (3) distinct software packages that

can be used to integrate external devices with an Allegiant system matrix switcher.

Please refer to the following sections for details:

Integration Server

The Integration Server is a versatile software package used to integrate multiple systems that are not ordinarily compatible with each other. This system can include

video switchers, point of sale systems, fire/burglar alarms, Access Control, or HVAC

systems. Devices can be interfaced using any of the following three (3) methods:

serial RS-232 connection, digital I/O card, or directly to an Allegiant Switcher via

the LTC 8059 MCS program. The Integration Server software is programmed to

recognize events as they occur in real time from one or more systems, based upon

one of the three (3) integration methods mentioned above. It then reacts to those

events by sending commands to another system or systems.

Virtual Allegiant Satellite Application Software

The Virtual Allegiant Satellite Application (VASA) is Bosch's strategic product that

allows existing Allegiant customers to transition gradually to pure IP technologies

rather than a total and instantaneous replacement. VASA acts as the integration

EN | 12 Bosch Security Systems | December 13, 2005

Page 23

bridge between an existing Allegiant and the new digital based CCTV system (the

'satellite') that uses digital video encoders and decoders. With VASA, the new IP

technology is totally transparent to the existing Allegiant users who continue to use

their Intuikey CCTV keyboards for video switching and PTZ control on classic analog monitors.

VA S A s u pp o r t s the Allegiant LTC 8100 through the LTC 8900 Series matrix switchers. In addition to PTZ control, VASA provides auxiliary and preposition control of

the IP-based cameras. VASA improves the ROI on existing capital assets, removes

the need for training, and reduces the risk for adopting new technology by incrementally adding to the system. The integration is seamless and the transition is

designed to be imperceptible.

Allegiant Satellite Software Development Kit

The Allegiant Satellite Software Development Kit (SDK) is a fully supported set of

libraries, documentation, and samples targeted at PC-based application software

that is used to control 3rd party CCTV matrix systems or manage IP-based digital

video networks. Since the SDK can be used to create customized solutions for

unique, specific problems, customers looking to integrate an Allegiant matrix system

with products offered by other manufacturers is readily accomplished. For the thousands of existing Allegiant customers, it also provides a bridge to integrate or

expand their systems with IP based products gradually rather than a total and

instantaneous replacement.

LTC 8506/00 PC-to-Console Port RS-232 Cable

When operating in an Allegiant satellite system configuration, an Allegiant master

generates switching and PTZ data that is typically used to control a remote Allegiant

satellite matrix. Using the SDK, the video switching commands and PTZ data from

the master system are converted into an ActiveX interface allowing developers to

easily translate this information into formats used to control other original equipment manufacturer's (OEM) systems. The SDK also supports an ability to translate

repetitive type Allegiant PTZ commands to their indefinite equivalents, resulting in

reduced interface traffic and lower bandwidth demands when controlling IP based

networks.

The level of integration available with the SDK results in a robust interface that provides transparent operation to the existing Allegiant operators. Operators continue

to use their existing CCTV keyboards for selecting video and control of PTZ

devices on the Allegiant monitors. This type of solution improves the return of

investment on existing capital assets, removes the need for training, and reduces the

risk for adopting new technology by incrementally adding to the system.

The SDK is compatible with all models of the Allegiant Series switchers. In addition

to video switching commands and PTZ control, auxiliaries and prepositions are also

supported. The SDK is supplied with five sample applications. Three (3) applications use C++ to demonstrate incorporating the SDK in a console, an ATL, and an

MFC application. In addition, samples using Visual Basic

Framework are included.

6.22 LTC 8506/00 PC-to-Console Port RS-232 Cable

®

, and Microsoft's .NET

The LTC 8506/00 is an RS-232 grade cable with 9-pin D-connectors on each end

that is used to connect an Allegiant's system's console port to a standard PC COM

port. This cable is included in the Allegiant LTC 8059 MCS and the LTC 8850 Allegiant GUI packages. Length is approximately 3 m (10 ft).

EN | 13

Page 24

6.23 Logging Printer

An optional RS-232 serial printer may be connected to this system to provide a permanent record of significant system status changes. Time and date is printed for system events such as alarms, start-up after power failure, sequence loading, operator

log-on/log-off to keyboards, and download of information from the optional MCS.

The printer may also be used to obtain hard copies of all system tables and

sequences.

NOTE The printer port does not provide a standardized pin-out connection. If desired,

a cable can be made up at installation, by following the cable pin-out information provided at the end of this manual.

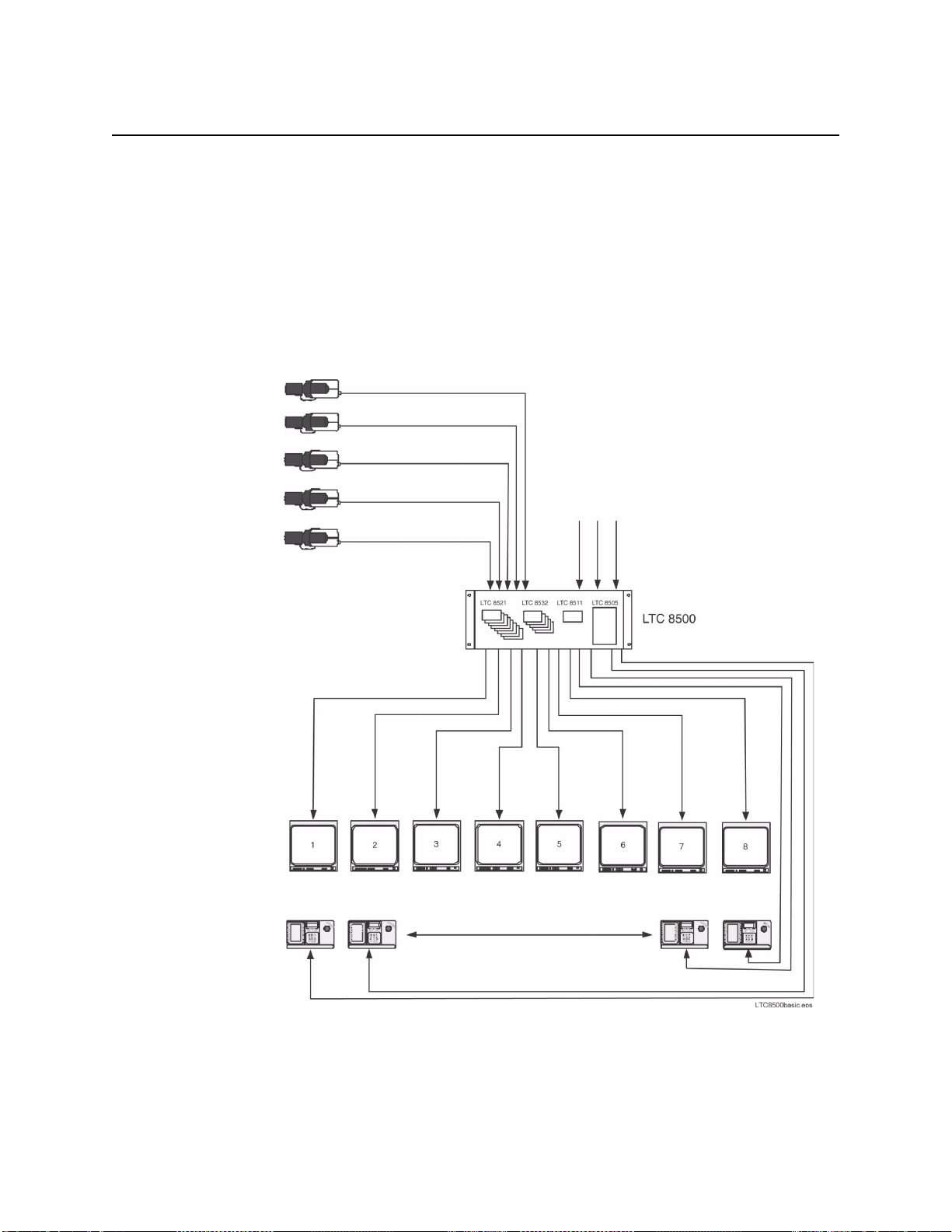

LTC 8500 Series Video Switching Configuration

Supports up to 64

Video Inputs

Main CPU Bay

Supports up to 8

Monitor Inputs

Maximum of 8 Allegiant Keyboards, up to

1.5 k m ( 5000 ft) away using Optional

Remote Hookup Kit

Figure 1: LTC 8500 Series Basic Video Switching Configuration

EN | 14 Bosch Security Systems | December 13, 2005

Page 25

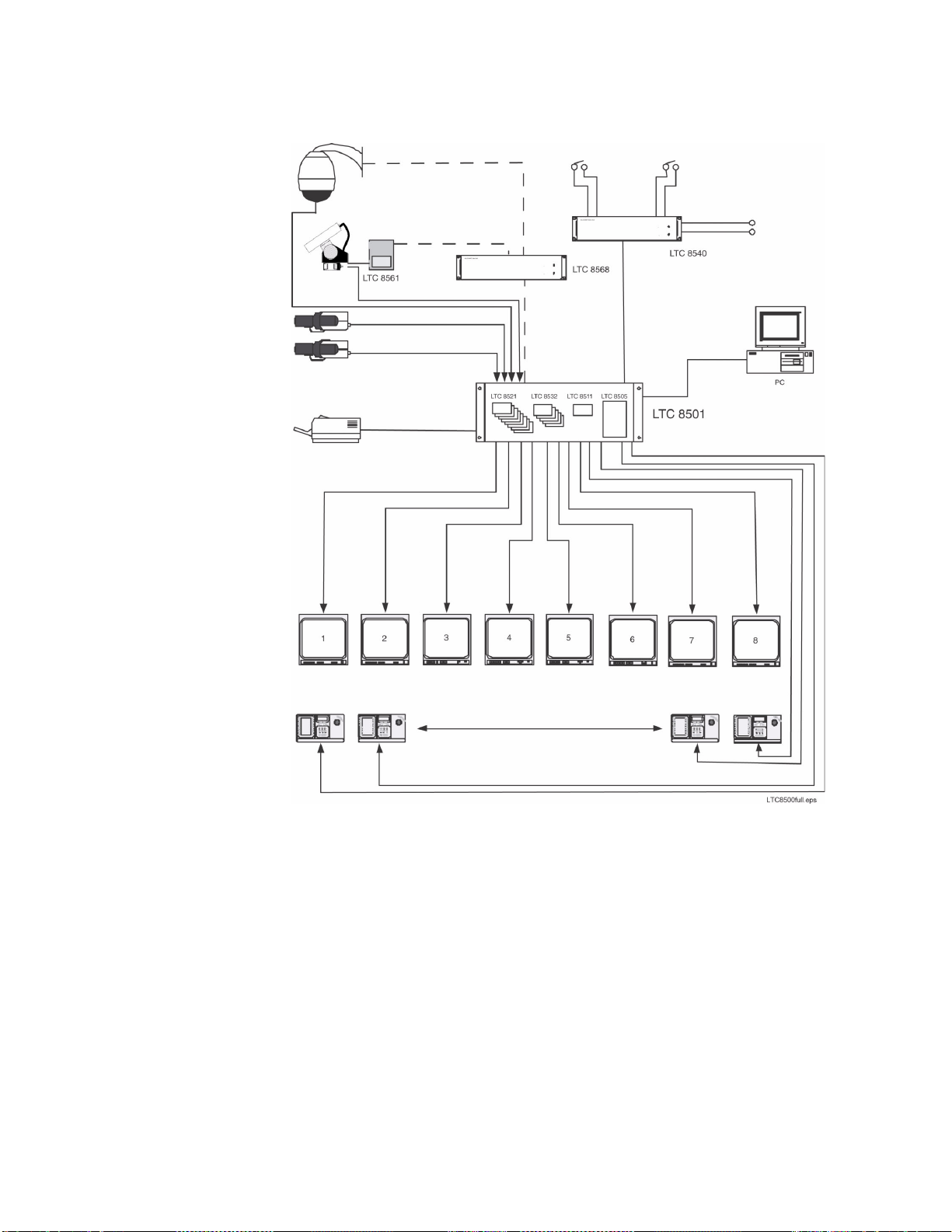

LTC 8500 Series Full Capacity Video Switching Configuration

Typ ica l Auto Do me

Camera

Receiver/Driver

Alarm

Interface

Unit Sup-

ports up to

64 Separate

Alarm Inputs

Main CPU Bay

Supports up to 64

Video Inputs

Signal

Distribution

Unit Supports

up to 32

Seperate

Outputs

Logging Printer

8 Relay

Outputs

Optional LTC 8059/00

MCS or LTC 8850/00

GUI Software

Package can be

Run on a PC

RS-232

Data

Supports up to 8 Monitor Outputs

Maximum of 8 Allegiant Keyboards, up

to 1.5 km (5000 ft) away using Optional

Remote Hookup Kit

Figure 2: LTC 8500 Series Full Capacity Video Switching Configuration

EN | 15

Page 26

7Installation Procedure

7.1 M a i n C P U B a y I n s t a l l a t i o n

Before discarding the shipping cartons, verify that the various pieces of equipment

have no evidence of carrier damage.

CAUTION Do not apply power to the equipment until instructed to do so.

1. Remove the front panel of the main CPU bay by loosening the four (4) corner

fasteners.

2. Install the power supply in far right position of the main CPU bay insuring

proper alignment and seating of the module into the rear mating connector. Verify that the power supply ON/OFF switch is in the OFF position.

3. Install the four (4) screws and star washers (supplied) on the rear panel of the

bay(s) surrounding the power supply line cord to fasten the power supply

securely in place.

CAUTION If the Allegiant card cage is to be transported, the main power supply should be

removed to prevent possible damage to the bay's internal parts.

4. If the bay(s) are to be installed into a standard 19-inch EIA rack, remove the

four (4) rubber bumper foot pads found on the bottom of the bay before installing the unit in the rack. Four (4) holes are provided for mounting the bay(s) in

the rack.

7. 2Video Input Modules

Te r m i n a t ion switches on the Video Input Modules (VIM) must be set to the correct

position prior to installation. If necessary, see Section 7.6 “Termination Practices,” on

page 18 prior to actually installing the VIM on this system.

The appropriate number of VIMs should be installed in the main bay starting with

the left most slot. If less than full capacity is being used, the modules should be

inserted in a left-to-right manner so that the lower camera numbers are used first.

The VIMs are identical and are interchangeable within the designated VIM slots

without having to make any changes to the module.

Figure 3: Typical Video Input Module Insertion

EN | 16 Bosch Security Systems | December 13, 2005

Page 27

7. 3Video Output Modules

Counting from left to right beginning with slot 9, install the appropriate number of

Video Output Modules (VOM) into these slots. If fewer than the maximum number

of VIMs are installed, there will be empty slots between the Input and the Output

Modules, so make sure that the Output Modules are inserted into the correct slots.

All VOMs are identical and are interchangeable within the designated VOM slots.

7. 4CPU Module

Video Output Modules

Figure 4: Typical Video Output Module Insertion

The slot to the left of the power supply in the main CPU bay is reserved for the system CPU module.

NOTE The CPU module contains two (2) lithium batteries mounted on the component

side of the printed circuit board. A red rectangular insulating tag may be

installed in between the top of the batteries and the battery holder clip. This tag

prevents battery drainage during stocking. Remove tag if so equipped.

Figure 5: Typical CPU Module Insertion

Install the main bay CPU at this time.

The circuit board contains two (2) 8-position DIP switches for system configuration

options. The DIP switches can be used to modify certain system operating conditions. Review the Factory Default Settings Section to determine if it is necessary to

change the DIP switches from the factory default positions. For reference, the factory default settings are:

DIP Switch S1001 All OFF

DIP Switch S1002 Switch 5 ON, 7 ON, and 8 ON; All others OFF

EN | 17

Page 28

7. 5Camera and Monitor Video Connections

Refer to Figure 10 on page 28 for the next series of steps.

Connect the system cameras to the appropriate video inputs, but as a minimum connect one known operating camera to video input #1 on the rear of the main CPU

bay. Use only those inputs that correspond to an installed VIM. Also connect

desired monitors to the rear of the main CPU bay, ensuring to connect at least one

monitor to video output #1. The video outputs are the left-most column of BNC

connectors on the rear of the bay. Use only those outputs that correspond to an

installed VOM.

7. 6 Te r m i nation Practices