Bosch ISC-SK10 Installation Manual

1 | Overview

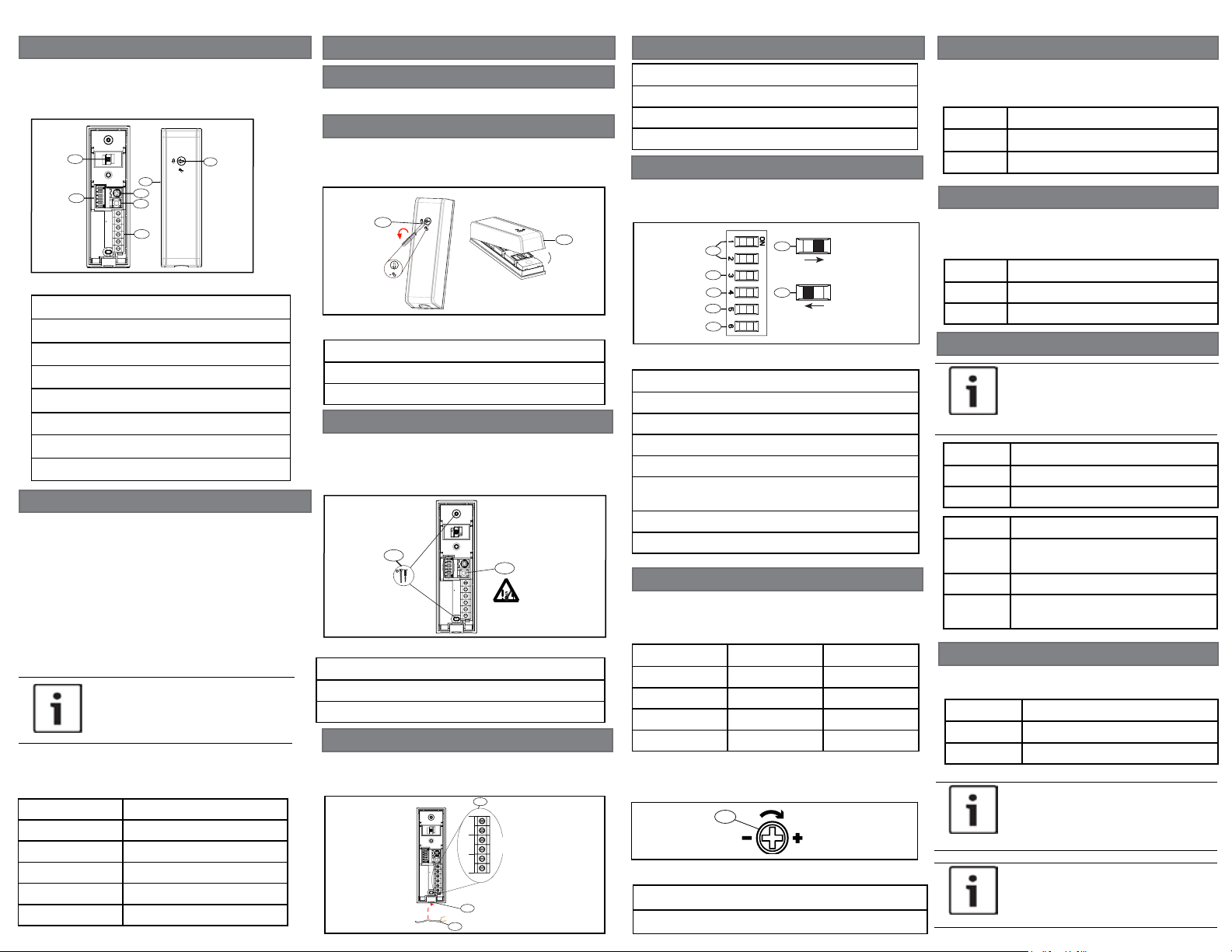

1

2

3

4

5

6

7

The ISC-SK10 is an advanced shock sensor designed

to monitor doors, windows, safes, and ATM

machines. The sensor detects mechanical attacks,

such as blasting, hammering, drilling, and sawing.

Figure 1.1: Sensor overview

Callout ― Description

1 ― LED

2 ― DIP switches

3 ― Sensitivity adjustment POT

4 ― Tamper switch

5 ― Terminal block

6 ― Cover

7 ― Unlock/lock switch

2 | Installation considerations

Install the ISC-SK10 on a door or window surface,

inside a safe, or ATM. Mount the ISC-SK10 on a flat

surface such as metal, glass, concrete, or wood

surfaces.

When installing the sensor, use the included screws

to secure the base to the desired surface, or use an

adhesiveAB glue if screws are not suitable. Do not

use double-sided tape.

Avoid installing in locations where movement and

other manual operations might generate false alarms

due to vibrations or accidental contact.

NOTICE!

The ISC-SK10 is intended for indoor

use only.

Maximum detection range

Use the different detection ranges that are suitable for

the desired surface.

Applications Radius (m)

Concrete 1.5

Brick wall 2.5

Steel 3

Wood 3.5

Glass 3.5

3 | Installation and configuration

3.1 | Hardware installation

Perform the following steps to install the hardware.

3.1.1 | Open cover

1. Insert a slotted screwdriver into the Unlock/lock

switch and turn counter-clockwise 90° to unlock.

2. Pull apart the cover from the base.

1

2

Figure 3.1: Opening cover

Callout ― Description

1 ― Unlocking the switch

2 ― Pull apart base from cover

3.1.2 | Install base

1. Locate desired installation location.

2. Insert supplied screws (two ST2.9x13 mm) into

screw slot locations (or use AB glue) to secure the

base to the desired surface.

1

2

Figure 3.2: Screw locations

Callout ― Description

1 ― Screw locations

2 ― Tamper

3.1.3| Wiring

1. Insert wiring through the grommet.

2. Fasten wires to terminal block and secure with

tie-wrap (included).

Figure 3.3: Mounting the module in the enclosure

1

TAMPER ALARM - 12 +

2

3

Callout ― Description

1 ― Terminal block

2 ― Grommet cut-out area

3 ― Wiring

3.2 | Set DIP switches

Refer to Figure 3.4 for the DIP switch locations and

settings.

1

2

3

4

5

6

7

DIP

Figure 3.4: DIP switch settings

Callout ― Description

1 ― Sensitivity levels (#1 and #2)

2 ― Pulse counting

3 ― Drilling/saw detection (enable/disable)

4 ― LED enable/disable

5 ― Installation mode (this switch enables “Intelligent” mode)

6 ― DIP switch positioning example: ON (open)

7 ― DIP switch positioning example: OFF (closed)

3.2.1| Sensitivity

1. Select the desired sensitivity level (1-4) using

DIP switches #1 and #2. Refer to the table below for

settings.

2. Fine-tune the sensitivity level by turning the POT

adjustment clockwise to increase sensitivity, and

counter-clockwise to descrease the sensitivity.

Figure 3.5: Fine sensitivity adjustment POT

Level DIP#1 DIP#2

High ON ON

High-middle ON OFF

Low-middle OFF ON

Low (default) OFF OFF

1

Callout ― Description

1 ― Fine sensitivity adjustment POT

3.2.2| Pulse counting

Select DIP #3 to set the pulse counting adjustment.

The sensor generates an alarm when certain pulse

countings are reached during the specified time.

DIP #3 Pulse counting time(s)

ON 4

OFF 1 (Default)

3.2.3 | Drilling/saw detection

Select DIP #4 to enable or disable the detection of

drilling or sawing vibrations. Functionality occurs

after sensor is powered up.

DIP #4 Drilling/saw detection

ON Disable

OFF Enabled (default)

3.2.4 | LED descriptions

NOTICE!

The LEDs must be enabled during

installation.

DIP #5 LED function

ON Enabled (default)

OFF Disable

LED Function

Green Indicates an attempt attack was

Red Indicates an alarm was generated.

Red (ON

steady)

detected.

Indicates there is a sensor fault.

3.3 | Installation mode

Select DIP #6 to choose between manual or

intelligent mode.

DIP #6 Installation mode

ON Intelligent

OFF Manual (default)

NOTICE!

Enable the LED and cycle power on the

system before applying the intelligent

installation mode.

NOTICE!

Manual installation is active 20 min

after powering up the system.

3.3.1 | Intelligent installation (recommended)

Perform the following to enable Intelligent Installation.

1. Power down the sensor and select intelligent installation (DIP#6 is set to ON).

DIP #1 DIP #2 DIP #3 DIP #4 DIP #5 DIP #6 POT

OFF OFF OFF OFF ON ON Random

2. Power up and wait for 2 sec. During this period, do not remove or disturb the sensor.

3. Use a suitable instrument to tap or bang within the detection range. During a 3 min duration, the sensor

simulates, and records the maximum shock data. Installer simulates the typical noise to be ignored: printer,

cash dispenser, bumps...etc.

4. After 3 mins, the red LED begins to flash quickly. Set the DIP#6 to OFF. The LED flashes slowly.

5. According to LED status , adjust sensitivity till LED turns OFF steadily.

• LED slow flashing: according to LED slow flashing time(s), set DIP #1 and DIP#2 as stated in the table

below. The LED either turns ON or OFF steadily. If ON steadily, tune the pot slowly till LED turns OFF steadily;

if OFF steady, no adjustment is needed. (Slow flashing LED pattern: 0.5 second ON, 0.5 second OFF, repeat

1-4 times.Then the LED stays off for 2 seconds and restart slow flashing pattern.)

Red LED slow flashing DIP #1 DIP #2

4 times ON ON

3 times ON OFF

2 times OFF ON

1 time OFF OFF

• LED ON Steadily: correct sensitivity level is selected, no need to set DIP #1 or DIP#2. But the POT is

needed to be tuned till LED turns OFF steadily.

• LED OFF Steadily: desired sensitivity is achieved.

6. Power up the system and wait for 2 sec. The sensor starts working.

3.3.2 | Manual installation (Intelligent Install mode disabled)

Perform the following to set the sensitivity manually.

1. Power down the system and select manual installation (DIP#6 is OFF). Select any one of the 4 sensitivity

levels and adjust the sensitivity to desired as steps 2~6. Default is low level, 1 pulse, drilling/saw detection

enabled and LED enabled as stated in the table below.

DIP #1 DIP #2 DIP #3 DIP #4 DIP #5 DIP #6 POT

OFF OFF OFF OFF ON OFF Intermediate

2. Power up and wait for 2 seconds. During this period, the sensor shall not be removed or disturbed.

3. Use a suitable instrument to tap or bang within the detection range. Observe the LED response.

4. If needed, tune the POT slowly with the screwdriver based on the LED response observed in Step 3.

5. Repeat steps 3 and 4 until the desired sensitivity is achieved.

6. Power up again and wait for 2 sec. The sensor starts working.

4 | Specifications

Dimensions 100 mm x 30 mm x 20 mm

Voltage (operating) 9-15 VDC, 12 V nominal

Current

(maximum)

Alarm output NC relay output, 100 mA/30

Tamper switch NC 50 mA/30 VDC

Sensitivity settings 4 adjustment levels

Operating

temperature

Relative humidity 0% to 95% non-condensing

Enclosure

protection

Detection method Digital, triaxial acceleration

(3.93 in x 1.18 in x 0.78 in)

8.5 mA (Standby), 12 mA

(Alarm)

VDC

+14°F to +131°F (-10°C to

+55°C)

IP43

sensor

Shock Sensor

ISC-SK10

en Installation Guide

3.4 | Close the cover

1. Slip the cover into the base slots and close the cover.

2. Turn the slotted screwdriver clockwise 90° to lock in place.

1

Figure 3.6: Closing the cover

2

3

Callout ― Description

1 ― Sensor base

2 ― Sensor cover

3 ― Slotted screwdriver (turning clockwise)

Copyright

This document is the intellectual property of Bosch

Security Systems, Inc. and is protected by copyright.

All rights reserved.

Trademarks

All hardware and software product names used in this

document are likely to be registered trademarks and

must be treated accordingly.

Bosch Security Systems, Inc. product manufacturing

dates

Use the serial number located on the product label and

refer to the Bosch Security Systems, Inc. website at

http://www.boschsecurity.com/datecodes/.

Bosch Security Systems, Inc.

130 Perinton Parkway

Fairport, NY 14450

USA

www.boschsecurity.com

© 2014 Bosch Security Systems, Inc.

F.01U.306.533 | 01 | 2014.09

Loading...

Loading...