Bosch GCM 10 PROFESSIONAL Operating Instructions Manual

À

GCM 10

PROFESSIONAL

Operating instructions

Instrucciones de servicio

Manual de instruções

* Des idées en action.

π—ß◊Õ§Ÿà¡◊Õ°“√„™âß“π

Petunjuk-petunjuk untuk

penggunaan

HıÎng dÕn s¯ dÙng

Instructions d’emploi

29

28

27

1

2

3

4

5

26

25

24

23

22

21

6

7

8

9

10

11

12

1 609 929 E91 • (04.10) PS

1618 171920

15

1314

1

2

29

36

3026 22

35 34

17 213132

A

26

1 609 929 E91 • (04.10) PS

B

2333

13

17

12

C1

C2

C3

37

4

41

D1

16

36

38

39

D2

40

5

1 609 929 E91 • (04.10) PS

16

16

E

27 34

F

30

22

G

H

42

43

19

20 18

I

44

J

45

1 609 929 E91 • (04.10) PS

7

17

1514 1213

K

13

11

L

33

31

23

32

M

O

N

32

47

3

1 609 929 E91 • (04.10) PS

P

R

Q

46

R

33,9°

0

15

30

33,9

45

1 609 929 E91 • (04.10) PS

31,6°

S1 S2

23

T1 T2

32

24

47

35

6

35

1 609 929 E91 • (04.10) PS

1 GENERAL SAFETY RULES

FOR ELECTRIC TOOLS

WARNING

electrical shock, fire and/or serious personal injury.

Save these Instructions!

Work Area

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive atmo

spheres such as in the presence of flammable

liquids, gases, or dust. Power tools generate sparks

which may ignite the dust or fumes.

Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Do not let the electortool continue to run when

not attended switch it off. Do not leave the elec

trotool until the tool has come to a complete stand

still.

Electrical Safety

Before connecting the electrotool, ensure that

the voltage of the power source agrees with that

give on the nameplate or deviates by a maximum

of no more than 10%. If the voltage of the power

source is not compatible with the voltage required by

the electrotool, a serious accident and damage to the

electrotool can result.

Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators.

There is an increased risk of electrical shock if your

body is grounded.

Don't expose power tools to rain or wet condi

tions. Water entering a power tool will increase the

risk of electrical shock.

Do not abuse the cord. N ever use the cord to car

ry the tools or pull the plug from an outlet. Keep

the cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immedi

ately. Damaged cords increase the risk of electrical

shock.

Personal Safety

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a tool while tired or under the influence

of drugs, alcohol, or medication. A moment of in

attention while operating a power tool may result in se

rious personal injury.

Read and understand all in

structions. Failure to follow all in

structions listed below may result in

Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, cloth

ing and gloves away from moving parts. Loose

clothes, jewelry or long hair can become caught in

moving parts.

Avoid accidental starting. Be sure the switch is

off before inserting the plug. Carrying a tool with

your finger on the switch or plugging in a tool that is

switched on invites an accident.

Remove adjusting keys or wrenches before turn

ing the tool on. A wrench or a key that is left attached

to a rotating part of the tool may result in personal in

jury.

Do not overreach. Keep proper footing and bal

ance at all times. Proper footing and balance enable

better control of the tool in unexpected situations.

Use safety equipment. Always wear eye protec

tion. A dust mask, nonskid safety shoes, hard hat, or

hearing protection must be used as appropriate for the

conditions.

Power Tool Handling and Usage

Use clamps or other practical means to secure

and support the work piece on a stable platform.

Holding the work by hand or against your body is un

stable and may lead to loss of control.

Do not force the tool. Use the correct tool for

your application. The correct tool will do the job bet

ter and safer at the rate for which it is designed.

Do not use a tool if the switch does not turn it on

and off. A tool that cannot be controlled with the

switch is dangerous and must be repaired.

Disconnect the plug from the power source be

fore making any adjustments, changing acces

sories or storing the tool. Such preventive safety

measures reduce the risk of starting the tool acciden

tally.

Store tools when not in use out of reach of chil

dren and other inexperienced persons. Tools are

dangerous in the hands of inexperienced users.

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with

sharp cutting edges are less likely to bind and are eas

ier to control.

Check for misalignment or binding of moving

parts, breakage of parts and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many acci

dents are caused by poorly maintained tools.

English–11 609 929 E91 • (04.10) PS

Do not make changes to the electrotool or use it

for purposes other that those described in the

"Intended Use" Section. Any modification is a mis

use and can lead to serious injuries.

Use only accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool, may become hazardous

when used on another tool.

2 SPECIFIC SAFETY RULES

FOR COMPOUND MITER SAWS

Service

Tool repair must be performed only by qualified

repair personnel. Repairs or maintenance performed

by unqualified personnel could result in a risk of injury.

When repairing a tool, use only identical replace

ment parts. Follow instructions in the mainte

nance section of this manual. The use of unautho

rized parts or failure to follow maintenance instructions

may create a risk of shock or injury.

Provide for adequate room lighting at your workplace

or for adequate lighting of the immediate work area.

If the power cable is damaged or cut through while

working, do not touch the cable but pull the power

plug immediately. Never use the machine with a dam

aged cable.

Wear protective glasses and hearing protection.

Dust is generated while working that can be detrimen

tal to health, inflammable or explosive. Suitable protec

tive measure are required.

For example: Some types of dust are considered to be

carcinogenic. Use suitable dust vacuuming and wear

a dust protection mask.

Connect machines that are used outdoors by means

of a fault current circuit breaker (FI) with a maximum

triggering current of 30 mA. Use only an extension ca

ble that is approved for outdoor use.

Always lead the cable to the rear away from the ma

chine.

Before using, mount the electrotool on a flat and sta

bile work surface, e.g., workbench.

Never stand on the electrotool. Serious injuries could

occur when the electrotool tips over or when coming

in contact with the saw blade.

Saw only materials for which the electrotool is ap

proved by the manufacturer.

Ensure that during operation, the swinging guard func

tions properly. It must move freely and be able to

close by itself. It should never be jammed in the open

position.

Put the electrotool in operation only when the working

surface is free of all adjustment tools, wood chips, etc.

and only the piece to be worked is present. Small

pieces of wood or other objects that come in contact

with the rotating saw blade can strike the operator with

high speed.

Always firmly clamp the piece to be worked. The free

ends of long work pieces must be supported. Do not

work with pieces that are to small to clamp.

Never allow another person to hold or support the

work piece while working. Always use a suitable saw

table extension or a work piece attachment.

Do not work with material containing asbestos.

Take hold of the electric tool only by the insulated han

dle when the cutting tool used could come in contact

with hidden wiring or its own power cable. Contact

with voltage carrying wiring can place the metal parts

of the machine also under voltage and lead to an elec

trical shock.

The saw blade must have reached its full rotational

speed before advancing to the work piece.

Keep fingers, hands and arms away from the rotating

saw blade.

Do not reach behind the fence in the area of the saw

blade to hold the work piece, to remove chips or for

any other reason. The distance from your hand to the

rotating saw blade is in this case too small.

Always saw only a single work piece. Work pieces

place one on the other or next to each other cannot be

properly clamped and can cause saw blade blockage

or slip with respect to each other during sawing.

The cutting path must be free from obstacles above

and below. Do not saw wood containing nails,

screws, etc.

If the saw blade becomes blocked, switch off the elec

trotool immediately and pull the power plug. Only

then remove the wedged work piece.

Do not ram the saw blade with force into the work

piece or apply too much pressure when using the

electrotool. Especially avoid catching the saw blade

when working on corners, edges, etc.

English–21 609 929 E91 • (04.10) PS

Be careful when slotting that the saw blade does not

become jammed in the workpiece.

The saw blade becomes very hot while working; do

not take hold of it until it has cooled.

Avoid overloading the motor especially when working

with large work pieces. Apply only light pressure to the

handle when sawing.

Caution! The saw blade continues to run after the

electrotool is switched off.

Protect the saw blade from strikes and shocks. Do not

apply side pressure to the saw blade.

Use only sharp, flawless saw blades. Change

cracked, bent or dull saw blades without delay.

Select a saw blade suitable for the material to be

worked.

Use only saw blades recommended by the manufac

turer of the electrotool.

Observe the instructions of the manufacturer for the

mounting and usage of the saw blade.

Actuate the spindle lock only when the saw blade is at

a standstill.

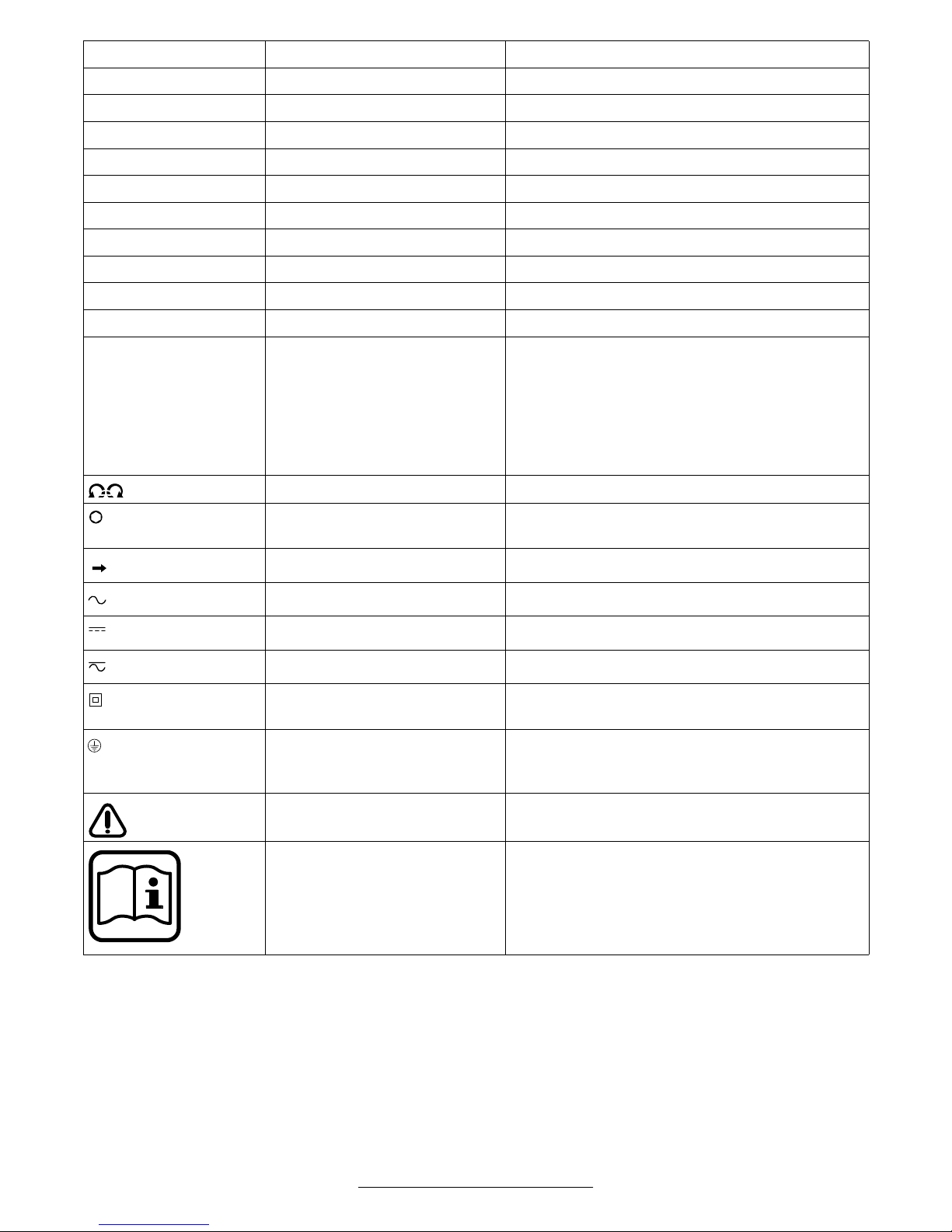

SYMBOLS

Wear protective gloves to avoid injury from the sharp

cutting edges of the saw blade during changing the

saw blade.

Observe the dimensions o f the saw blade. The hole di

ameter must fit the tool spindle without play. Do not

use reducer pieces or adapters.

Observe the maximum allowable speed of the saw

blade.

Saw blades of highly alloyed high speed steel (HSS

steel) are not to be used.

Never use the electrotool without the table insert. Re

place a defective table insert.

Bosch can ensure flawless functioning of the machine

only when original accessories intended for the ma

chine are used.

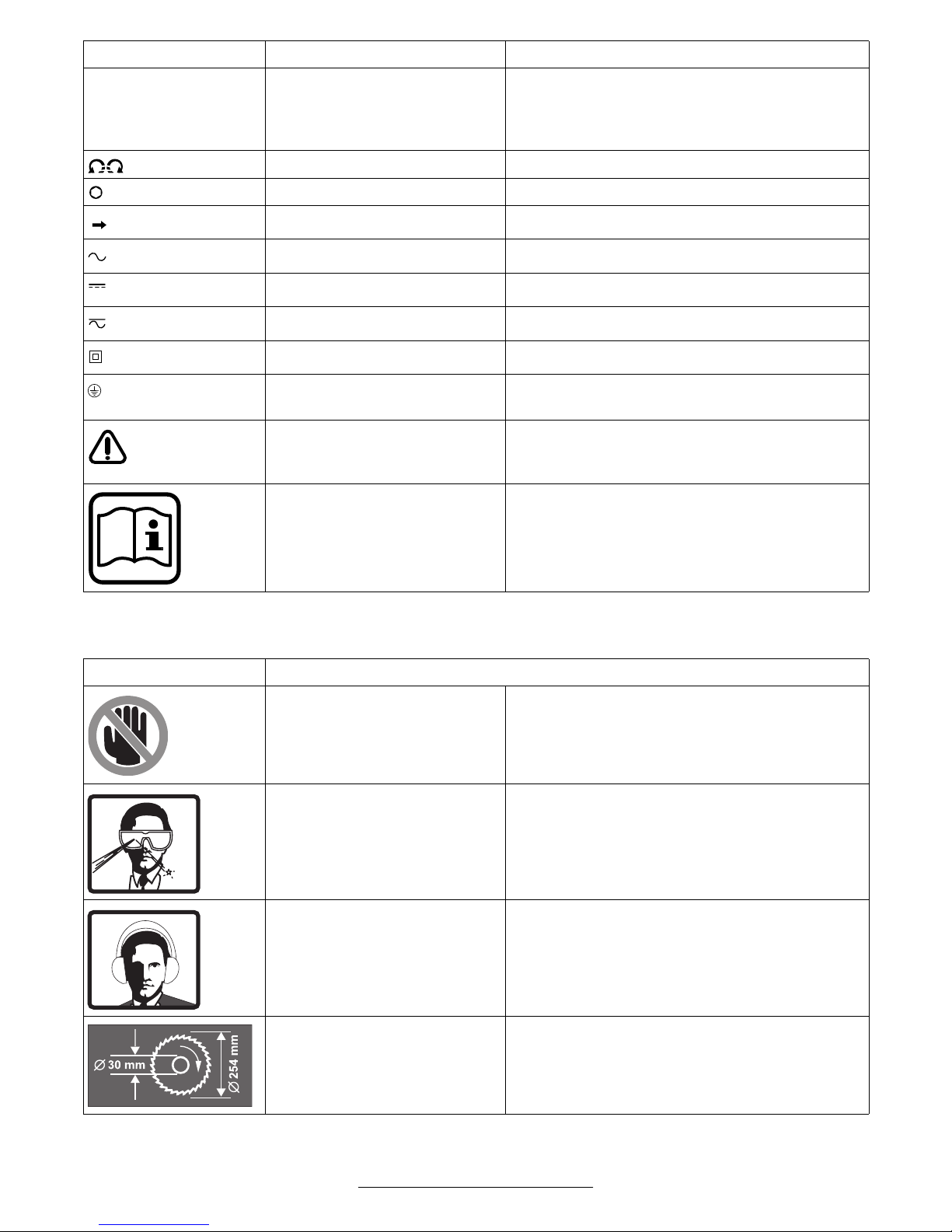

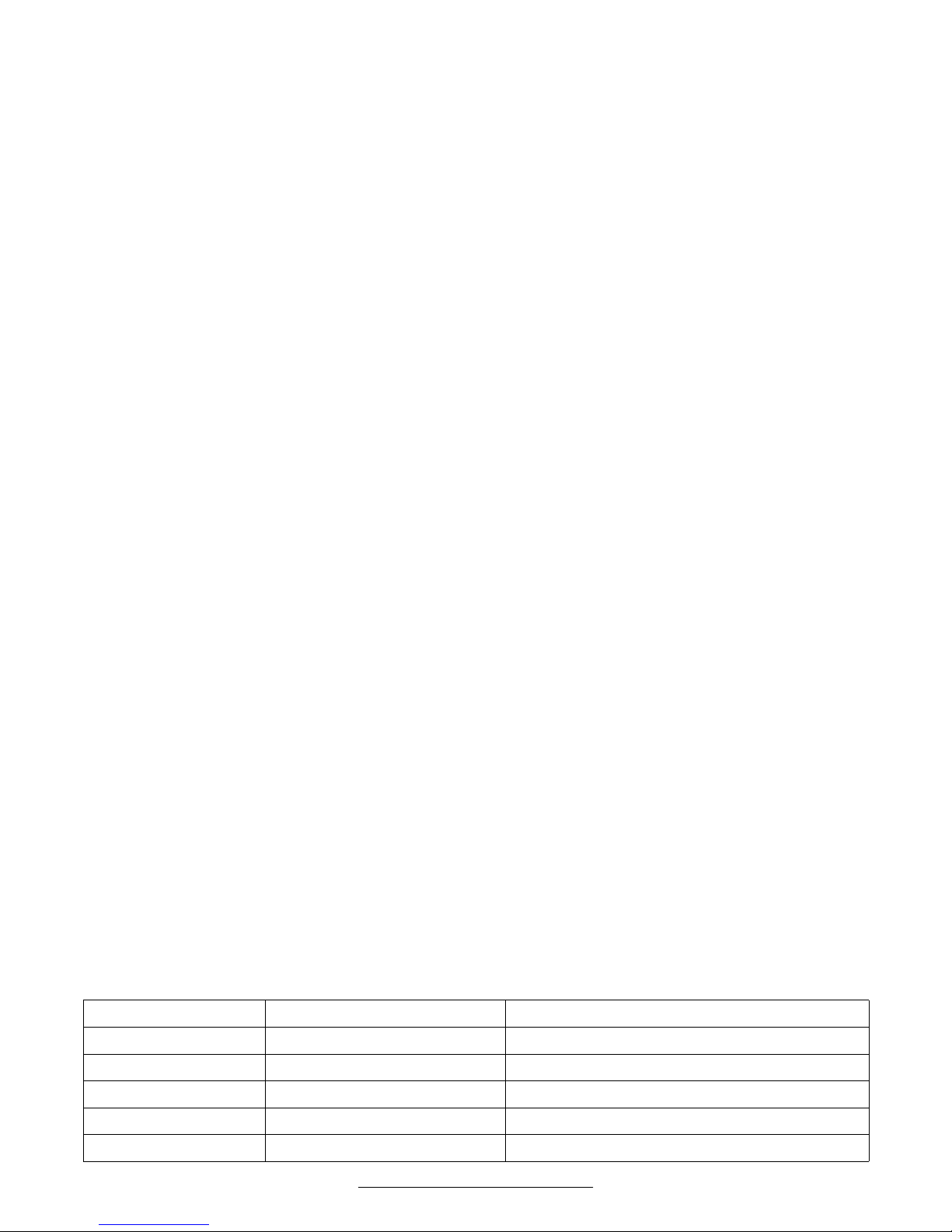

Important notice: Some of the following symbols could have meaning for the use of your tool. Please take note

of the symbols and their meaning. The correct interpretation of the symbols will help you to use the tool in a better

and safer manner.

Symbol Name Meaning

VVolts Voltage

A Amperes Current

Ah Amperehours Capacity, quantity of stored electrical energy

Hz Hertz Frequency (cycles per second)

WWatt Power

Nm Newtonmeter Unit of energy

kg Kilograms Mass, weight

mm Millimetre Length

min/s Minutes/Seconds Time

°C/°F Degrees Celsius/Degrees

Temperature

Fahrenheit

dB Decibel Unit of relative loudness

∅ Diameter Size of drill bits, grinding wheels, etc.

1

min

/n

0

Revolutions per minute/no load

Rotational speed at no load

speed

…/min Revolutions or reciprocation per

minute

0 Off position Zero speed, zero torque...

Revolutions, strokes, surface speed, orbits, etc.

per minute

English–31 609 929 E91 • (04.10) PS

Symbol Name Meaning

SW Wrench width (in mm) Distance between parallel surfaces on fastener el

ements on which the tool must fit on (e.g. hex nuts

or hexhead screws), fit over (e.g. ring wrench) or

fit in (e.g. sockethead screws).

Left rotation/Right rotation Direction of drive rotation

/ Hex socket drive/Square drive Type of tool holder

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates double insulated constructed tools

Protection class I

(Grounding terminal)

Warning symbol Alerts user to warning messages.

Warning symbol Provides information for correct handling, e.g.,

Symbols specifically for this Machine

Symbol Meaning

Warning symbol Danger area! Keep fingers, hands or arms away

Warning symbol Wear protective glasses.

Machines of the protection class I must be ground

ed

Read and understand instructions before opera

tion

read the operating instructions.

from these areas.

Warning symbol Wear hearing protection.

Note symbol Observe the dimensions of the saw blade. The

hole diameter must fit the tool spindle without play.

Do not use reducer pieces or adapters.

English–41 609 929 E91 • (04.10) PS

3 FUNCTION

While reading the operating instruc

tions, refer to the corresponding illus

trations of the electrotool on the front

pages.

Intended Use

The electrotool is intended as a stationary machine for

making straight lengthways and crossways cuts in

wood. Horizontal miter angles of 48° to +48° as well

as vertical bevel angles of 0° to +45° are possible.

Noise/Vibration Information

Measured values are determined according to stan

dard EN 61 029 procedures.

The Aweighted noise levels of the tool are typically:

Sound pressure level: 97 dB(A)

Sound power level: 110 dB(A)

Measurement uncertainty K = 3 dB

Wear ear protection!

The handarm vibration is typically below 2.5 m/s

2

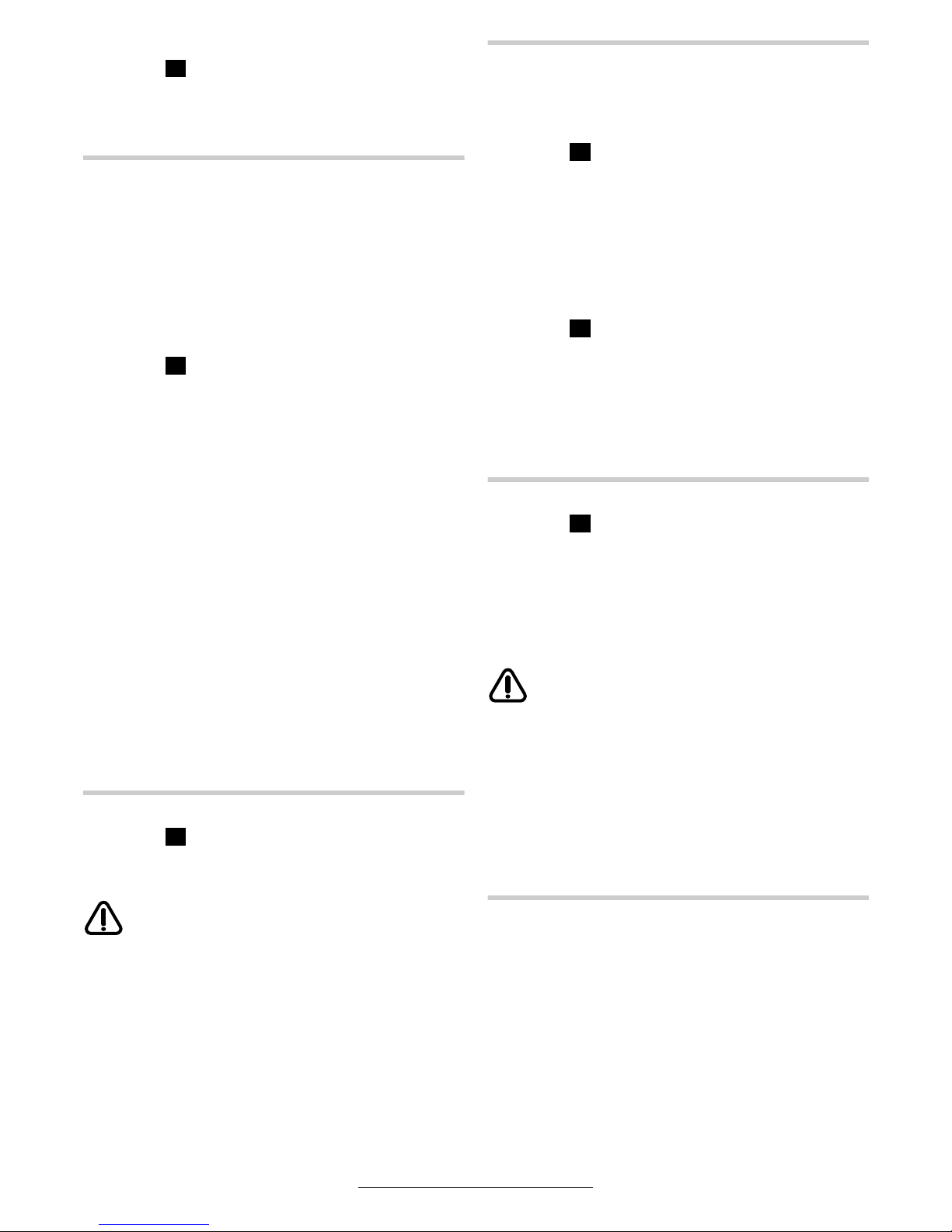

Product Specifications

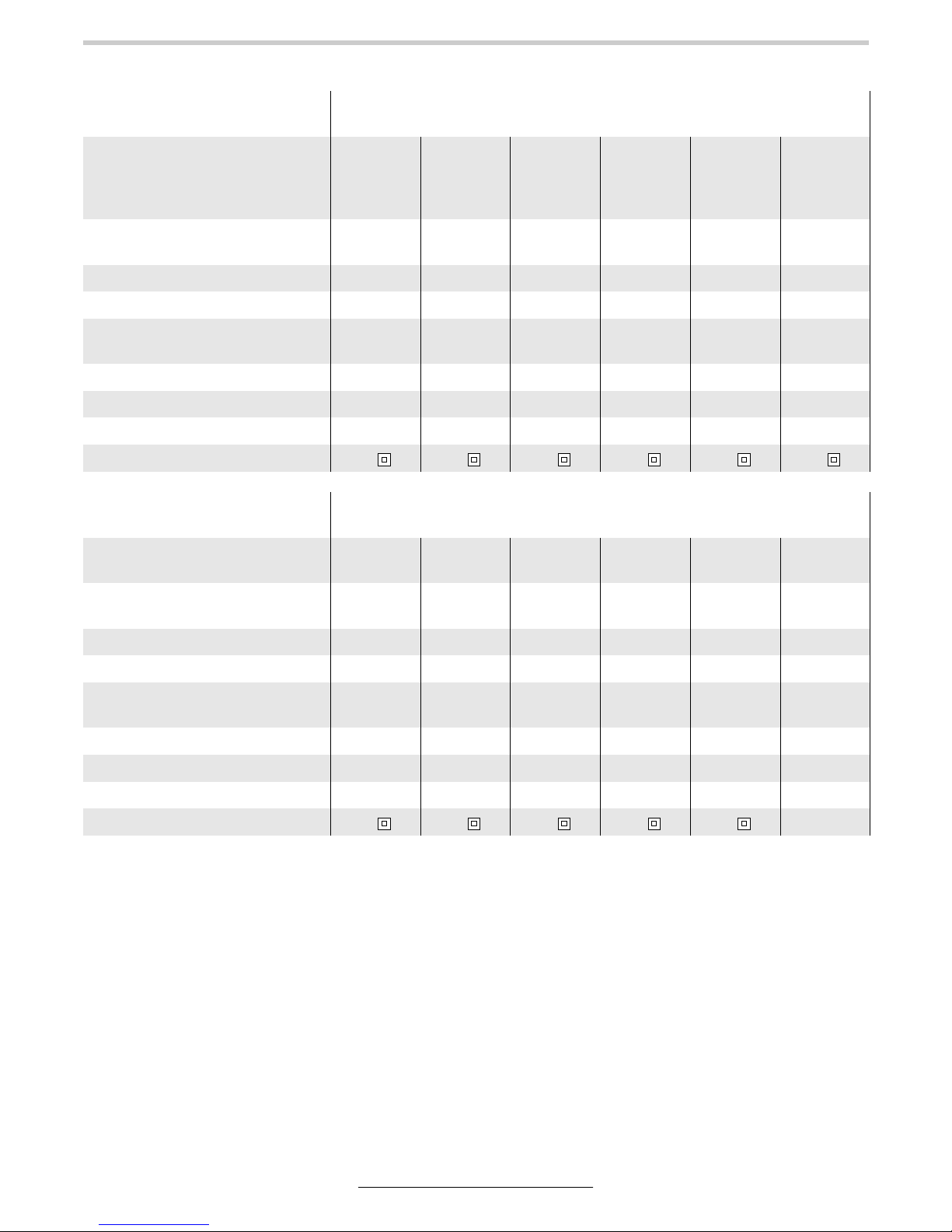

Compound Mitre Saw GCM 10

PROFESSIONAL

Order number

0 601 B20 …

Rated input power [W] 1 800 1 800 1 650 1 800 1 650 1 650

Voltage [V] 230 220/230 115 230/240 220 120

… 003

… 008

… 032

… 042

…004 … 005 … 006 …014 … 034

.

Frequency [Hz] 50 50/60 50/60 50/60 50/60 60

No load speed [min1] 4 500 4 500 4 500 4 500 4 900 4 500

Tool spindle [mm] 30 25.4 25.4 25.4 30 16

Weight without mains cable [kg] 16.0 16.0 16.0 16.0 16.0 16.0

Saw blade ∅ [Inch] 10 10 10 10 10 10

Protection class / II / II / II / II / II / II

Compound Mitre Saw GCM 10

PROFESSIONAL

Order number

0 601 B20 …

Rated input power [W] 1 800 1 800 1 650 1 800 1 800

Voltage [V] 240 220 110 220/230 220/230

Frequency [Hz] 50 60 50 50 50/60

No load speed [min1] 4 500 4 500 4 500 4 500 4 500

Tool spindle [mm] 25.4 25.4 30 25.4 25.4

Weight without mains cable [kg] 16.0 16.0 16.0 16.0 16.0

Saw blade ∅ [Inch] 10 10 10 10 10

… 037 …040 … 041 … 043 …050

Protection class / II / II / II / II / II

Values apply for the rated voltage [U] of 230/240 V. For

lower voltages and models for specific countries,

these values can vary.

Switchon actions cause brief drops in the mains volt

age. For unfavourable mains conditions, interference

with other equipment can occur.

For mains impedance of less than 0.15 Ω, no interfer

ence can be expected.

For maximum work piece dimensions,

see the Working Instructions Section

English–51 609 929 E91 • (04.10) PS

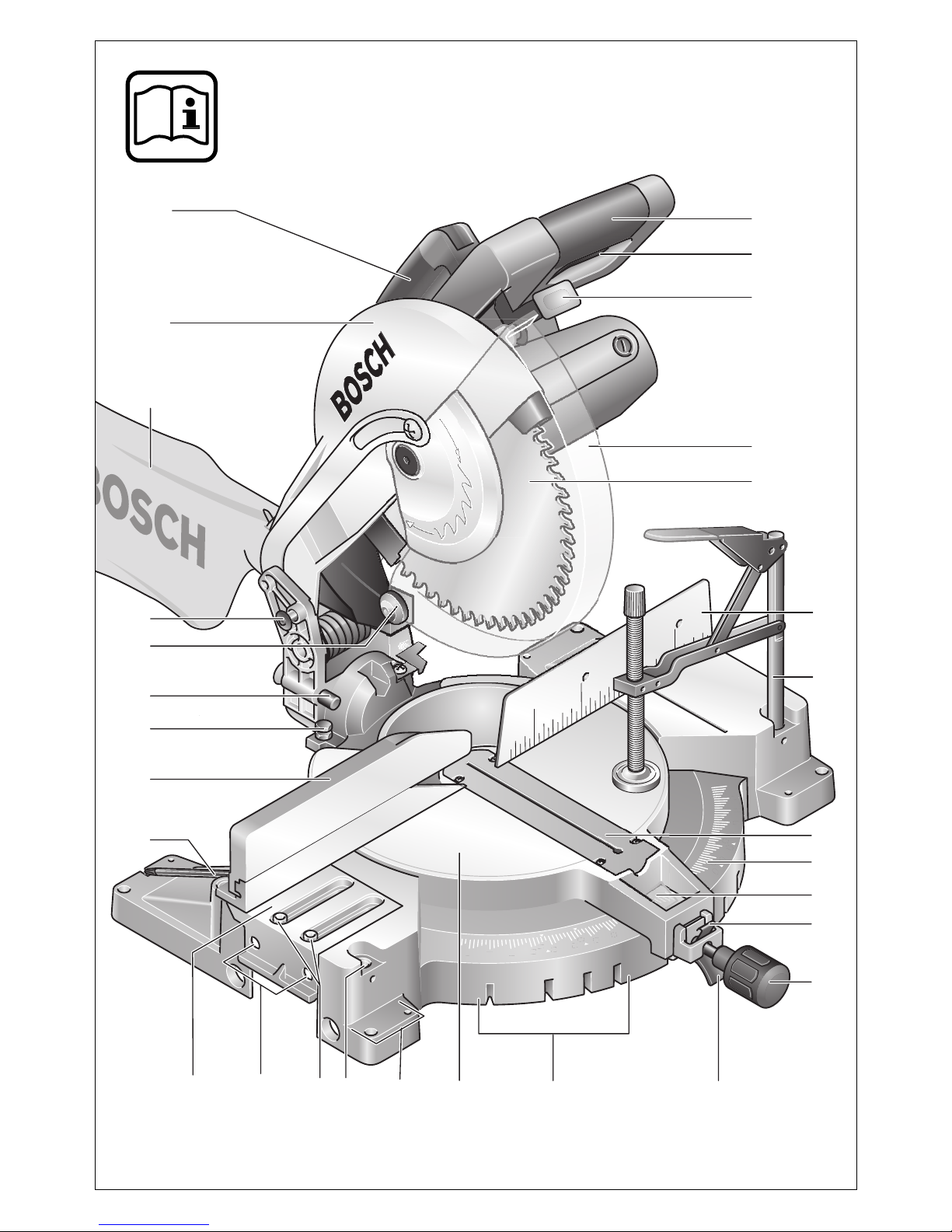

Product Elements

The numbering of the machine elements refers to the

illustrations of the electrotool on the front pages of the

operating instructions.

1 Handle

2 On/Off switch

3 Locking lever

4 Swinging guard

5 Saw blade

6 Fence

7 Quick action clamp

8 Table insert

9 Scale for miter angle (horizontal)

10 Fine scale

11 Locking clamp

12 Locking knob for variable miter angles (horizontal)

13 Lever for miter angle adjustment (horizontal)

14 Detents for standard miter angles

15 Saw table

16 Mounting holes

17 Holes for quick action clamp

18 Sockethead screws (6 mm) of the saw table ex

tension

19 Holes for extension hoop

20 Saw table extension

21 Allen key (6 mm) / Phillips screwdriver

22 Fence extension

23 Stop bolt for 33,9° bevel angle (vertical)

24 Pin of the setting knob for 33.9° bevel angle

(vertical)

25 Roller

*

26 Transport locking pin

27 Dust bag

28 Protective hood

29 Transport handle

30 Clamping lever for fence extension

31 Setting knob for 33.9° bevel angle (vertical)

32 Clamping handle for variable bevel angle (vertical)

33 Elongated hole

34 Sawdust ejector

35 Sockethead screws (6 mm) of the fence

36 Ring/openended wrench (ring: 13 mm; open

ended: 12 mm)

37 Phillips screw (attachment of the swinging guard)

38 Spindle lock

39 Hexhead bolt for attaching the saw blade

40 Clamping flange

41 Tool spindle

42 Length stop

43 Extension hoop

44 Clamping lever of the quick action clamp

45 Threaded rod of the quick action clamp

46 Screws of the table insert

47 Angle indicator (vertical)

Not all the accessories illustrated or described are in

cluded in standard delivery.

Not included for the tool executions:

*

0 601 B20 004, … 005, … 006, … 034, … 037,

… 040, … 043, … 050.

The swinging guard 4 cannot be locked. Perform the

operations described in the following accordingly with

out the locking lever 3.

English–61 609 929 E91 • (04.10) PS

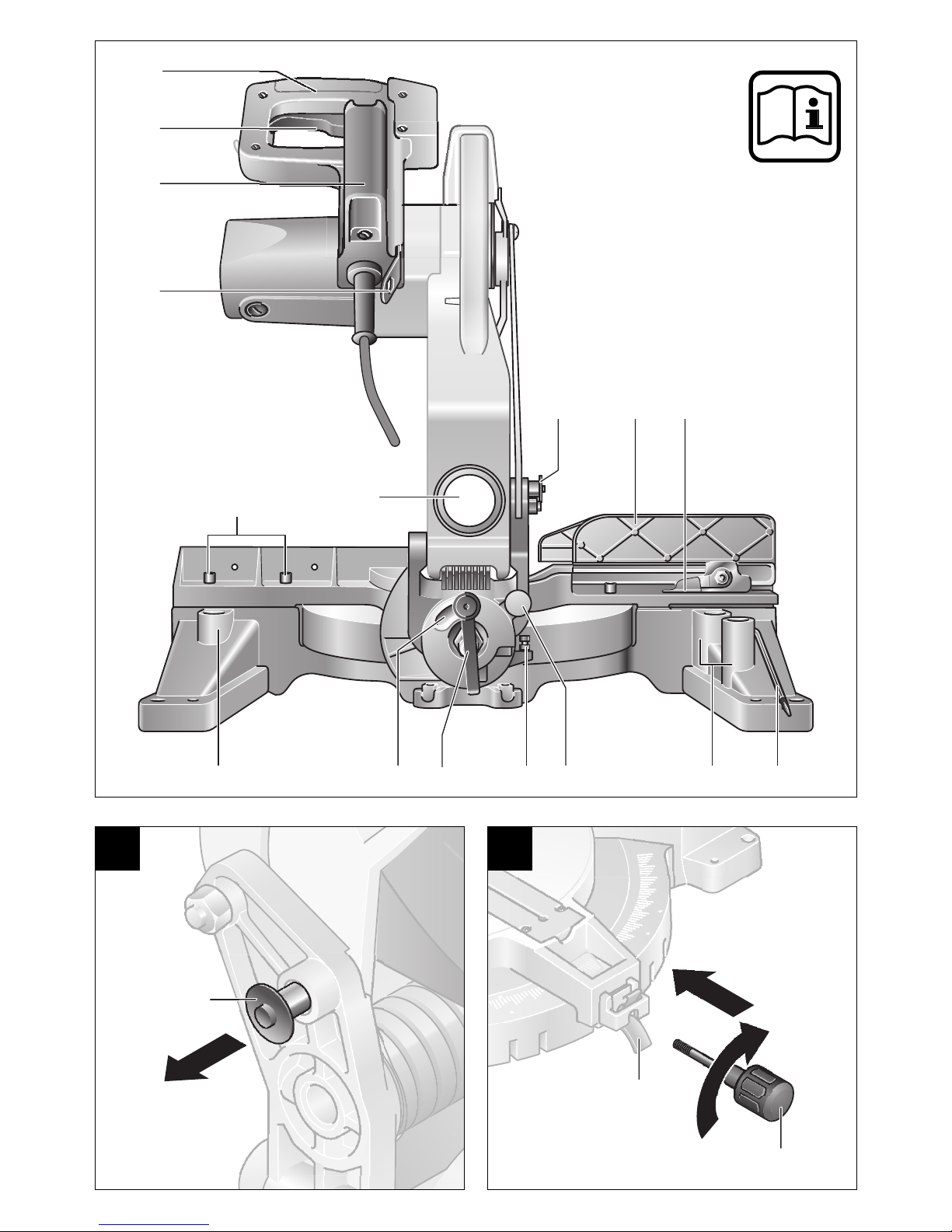

4 OPERATING INSTRUCTIONS

Transport Safety

(see Figure )

Before all work on the machine, pull the power

plug.

The transport locking pin 26 makes possible easy han

dling of the machine when transporting to the various

working locations.

Securing the Machine (Transport Position)

Press the locking lever 3 (also see the illustration )

and, at the same time, swing the tool arm down with

the handle 1 to the stop.

Press in the transport safety 26 and release the han

dle.

Releasing the Machine (Working Position)

Press the tool arm with the handle 1 downward some

what to relieve the load on the transport locking pin.

Pull the transport safety 26 completely outward.

Guide the tool arm slowly upward.

A

N

Mounting the Locking Knob

(see Figure )

Screw the locking knob 12 into the hole above the le

ver 13.

Do not tighten the knob too firmly.

B

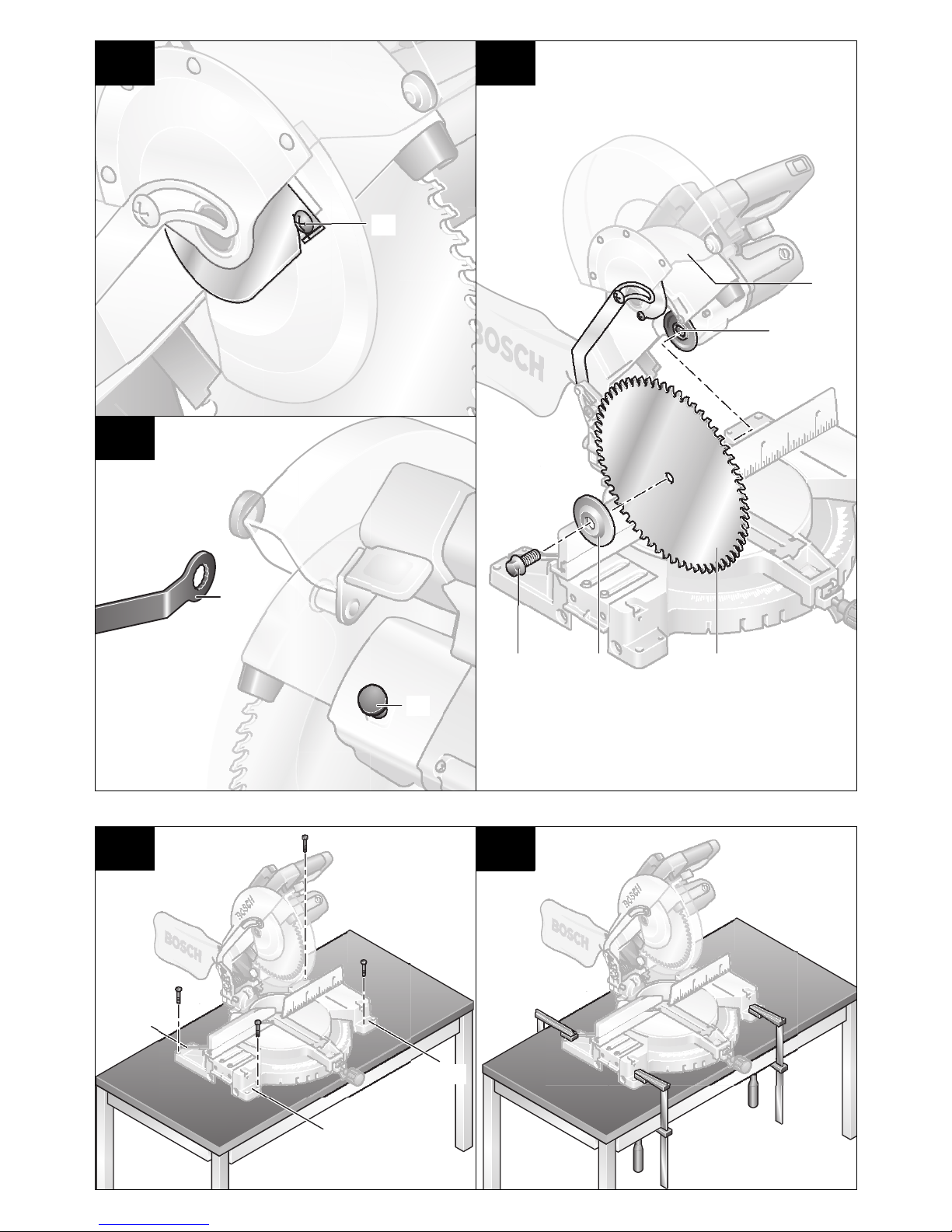

Changing the Tool

Before all work on the machine, pull the power

plug.

Use only sharp, flawless saw blades. Change

cracked, bent or dull saw blades without delay.

Use only saw blades that comply with the characteris

tic data given in these operating instructions and have

been tested according to EN 8471 and appropriately

marked.

Use only saw blades whose allowable rotational speed

is as least as high as the noload speed of the electro

tool.

Actuate the spindle lock only when the saw blade is at

a standstill.

The saw blade becomes very hot while working; do

not take hold of it until it has cooled.

Wear protective gloves to avoid injury from the sharp

cutting edges of the saw blade during changing the

saw blade.

Removing the Saw Blade

Place the machine in the working position.

Press the locking lever 3 (also see Figure ) and

swing the swinging guard 4 to the rear to the stop.

Hold the swinging guard in this position.

Loosen the screw 37 with a commercially available

Phillips screwdriver (Caution: Spring loaded!). Do

not unscrew the screw completely. (see Figure ).

Pull the swinging guard completely to the rear until it is

held with the pin of the locking lever 3.

Turn the hexhead bolt 39 with the ring wrench 36

(SW 13) provided while pressing the spindle lock 38 at

the same time until it engages. (see the illustration )

Hold the spindle lock depressed and screw out the

hexhead bolt 39 in the clockwise direction (lefthand

threads!). Take off the clamping flange 40. Remove

the saw blade 5. (see Figure )

Mounting the Saw Blade

If necessary, clean all parts to be mounted.

Place the new saw blade on the tool spindle 41.

(see Figure )

Place on the clamping flange 40 and insert the hex

head bolt 39. Press the spindle lock 38 until it engag

es and tighten the hexhead screw 39 in the counter

clockwise direction with a torque of approx. 15 23

Nm.

Press the swinging guard 4 down at the front until the

screw 37 engages in the cutout. It may be necessary

to hold the tool arm by the handle to achieve the spring

loading of the swinging guard.

Retighten the screw 37.

Guide the swinging guard slowly downward until the

pin of the locking lever 3 behind the swinging guard

audibly engages.

C3

Take care during the mounting that the

cutting direction of the teeth (direction of

the arrow on the saw blade) agrees with

the direction of the arrow on the swinging

guard!

C3

N

C1

C2

Stationary or Flexible Mounting

To ensure safe handling, the electrotool

must be mounted on a flat and stabile

working surface (e.g., workbench).

Stationary Mounting

(see Figure )

Attach the electrotool with suitable screw fasteners to

the working surface. The holes 16 serve for this pur

pose.

D1

English–71 609 929 E91 • (04.10) PS

Flexible Mounting

(see Figure )

Clamp the electrotool with commercially available

screw clamps by the feet to the working surface.

D2

Dust/Chip Extraction

Dust is generated while working that can be det

rimental to health, inflammable or explosive.

Suitable protective measure are required.

For example: Some types of dust are considered

to be carcinogenic. Use suitable dust vacuuming

and wear a dust protection mask.

Integrated Dust Extraction

(see Figure )

Press the clamp on the dust bag 27 together and slide

the dust bag over the sawdust ejector 34. The clamp

must engage in the groove on the sawdust ejector.

Release the clamp on the dust bag.

The dust bag must never come in contact with moving

parts of the machine while sawing.

Empty the dust bag in a timely manner.

External Dust Extraction

Use a suitable adapter from the Bosch accessory pro

gram to connect a vacuum cleaner to the sawdust

ejector 34. Firmly attach the adapter and vacuum

cleaner hose.

The vacuum cleaner must be suitable for the material

to be worked.

When vacuuming dry dust that is especially detrimen

tal to health or carcinogenic, use a special vacuum

cleaner.

E

Extending the Fence

(see Figure )

Before all work on the machine, pull the power

plug.

For vertical bevel angle sawing, the fence must be re

positioned.

Loosen the clamping lever 30 and pull the fence exten

sion 22 completely out.

Reclamp with the clamping lever.

F

Ensure when extending or enlarging the

fence that the functionality of the electro

tool (especially of the swinging guard) is

not restricted.

Extending the Saw Table

Before all work on the machine, pull the power

plug.

Saw Table Extension

(see Figure )

Long work pieces must be supported at the free end.

Loosen the two sockethead screws 18 with the Allen

key 21 (6 mm) provided.

Pull out the saw table extension 20 to the stop and

retighten the sockethead screws.

Extension Hoop

(see Figure )

Slide the extension hoop 43 on either side of the elec

trotool to the desired length into the holes 19 provid

ed for this purpose.

Use the stop 42 to saw off work pieces of equal

lengths.

G

H

Clamping the Work Piece

(see Figure )

Before all work on the machine, pull the power

plug.

To ensure optimum working safety, the work piece

must always be firmly clamped.

Do not work with work pieces that are too small to

clamp.

Press the work piece firmly against the fence 6 and the

fence extension 22.

Insert the quick action clamp 7 provided into one of the

holes 17 intended for it. Adapt the quick action clamp

to the work piece by twisting the threaded rod 45.

Press the clamping lever 44 and thereby firmly clamp

the work piece.

I

When clamping the work piece, do not

reach with the fingers under the clamping

lever of the quick action clamp.

Adjusting the Miter Angle

Before all work on the machine, pull the power

plug.

To ensure precise cuts, the basic adjustments of the

electrotool must be checked and adjusted as neces

sary after intensive use (see Section „Checking and

Adjusting Basic Adjustment“).

English–81 609 929 E91 • (04.10) PS

Standard Horizontal Miter Angles

(see Figure )

J

For quick and precise setting of often used miter an

gles, detents 14 are provided on the saw table:

Left

15° 22,5° 31,6° 45°

0°

Right 15° 22,5° 31,6° 45°

Place the machine in the working position.

Loosen the locking knob 12 in case it is tightened.

Pull the lever 13 and turn the saw table 15 to the de

sired miter angle to the right or the left. Release the le

ver. The lever must be felt to engage in the detent.

Variable Horizontal Miter Angle

The horizontal miter angle can be set in the range from

48° (left side) to 48° (right side).

Place the machine in the working position.

Loosen the locking knob 12 in case it is tightened.

Pull the lever 13 and press the locking clamp 11 at the

same time until it engages in the groove provide for this

purpose (see the illustration ). In this manner, the

K

saw table becomes freely moveable.

Rotate the saw table 15 to the left or right and set the

desired miter angle with the aid of the fine scale 10.

Retighten the locking knob 12.

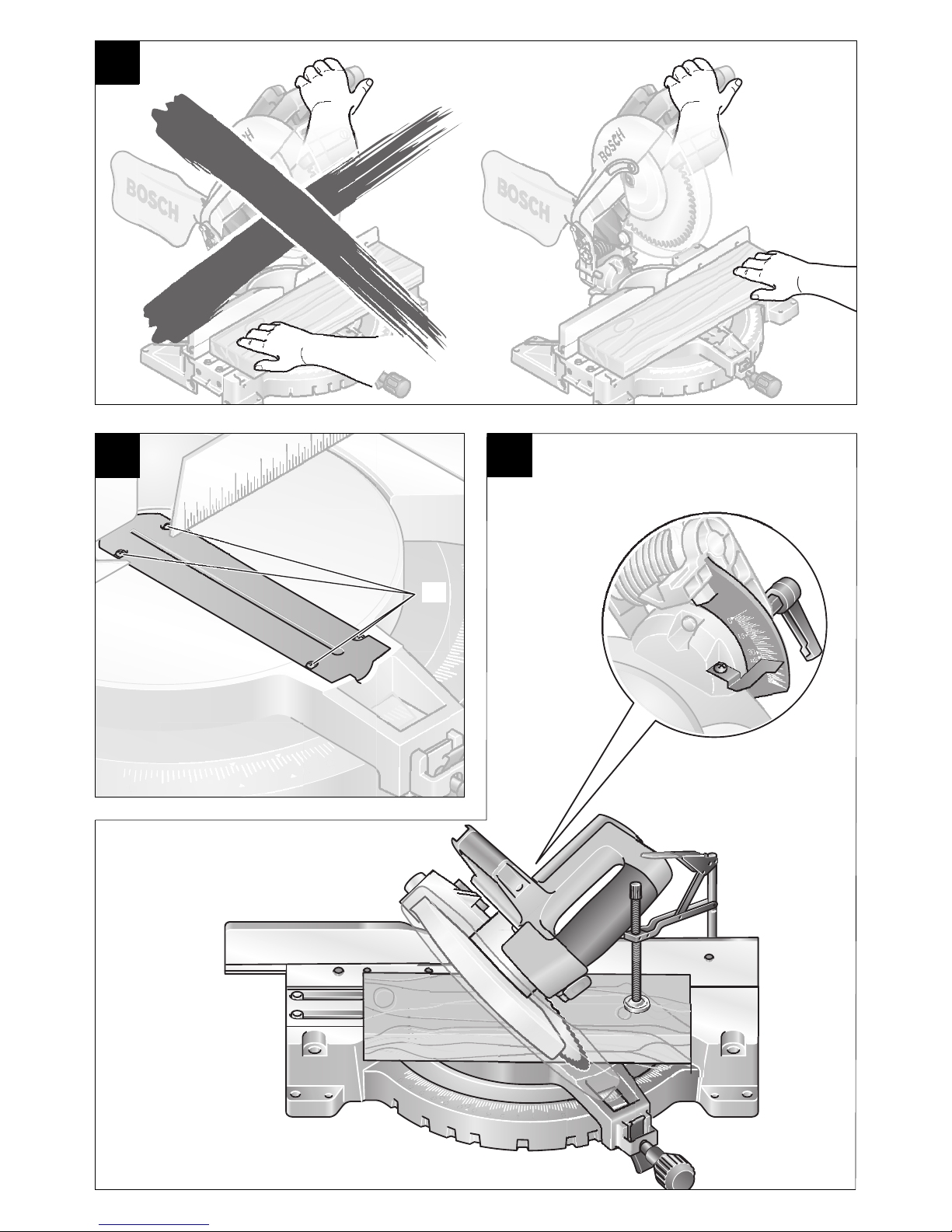

Standard Vertical Bevel Angles

(see Figure )

L

For quick and precise setting of often used bevel an

gles, stops are provided for the angles of 0°, 33.9° and

45°.

Place the machine in the working position.

Loosen the clamping handle 32.

For the standard angles of 0° or 45°, swing the tool

arm with the handle 1 to the stop at the upper or the

lower end of the elongated hole 33.

For the standard angle of 33.9°, press the setting knob

31 completely in. Then swing the tool arm with the

handle 1 until the pin 24 rests against the stop bolt 23.

Retighten the clamping handle 32.

Variable Vertical Bevel Angle

(see Figure )

M

The vertical bevel angle can be set in the range from

0° to 45°.

Loosen the clamping handle 32.

Swing the tool arm with the handle 1 until the angle in

dicator 47 points to the desired bevel angle.

Hold the tool arm in this position and retighten the

clamping handle 32.

Fine scale

With the fine scale 10, the horizontal miter angle can

be set with an accuracy of up to ¼°.

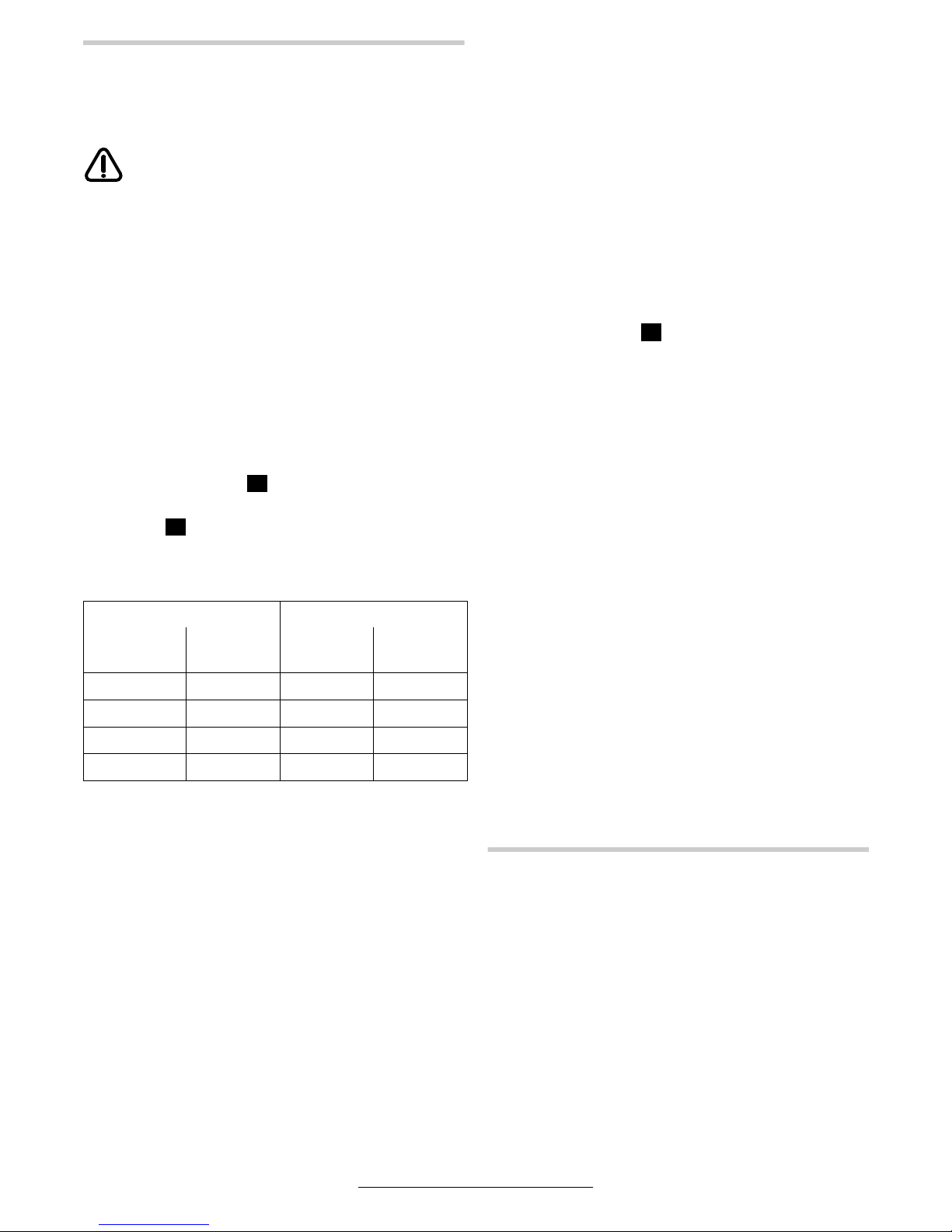

Desired Setting of

the Initial Angle x

Align the Fine

Scale Mark

... with the

Mark (Scale 9)

(Scale 10)

x,25 ° ¼° x + 1°

x,5 ° ½° x + 2°

x,75 ° ¾° x + 3°

Example:

To set to a miter angle of 40.5°, the ½° mark of the fine

scale 10 must be aligned with the 42° mark of the

scale 9.

Putting into Operation

Switching On and Off

To put into operation, pull the on/off switch 2 in the

direction of the handle 1.

For safety reasons, the on/off switch of the ma

chine cannot be locked on but must remain de

pressed during operation.

For sawing, press in addition the locking lever 3. (see

the Figure

Only by pressing the locking lever can the tool arm be

guided downward.

To switch off the machine, release the on/off switch

2.

0 601 B20 037 (Australia)

To put into operation, slide the switch lock in the di

rection of the tool arm. Then press the on/off switch 2

and hold it depressed.

For safety reasons, the on/off switch of the ma

chine cannot be locked on but must remain de

pressed during operation.

To switch off the machine, release the on/off switch

2.

N

)

English–91 609 929 E91 • (04.10) PS

Working Instructions

Before all work on the machine, pull the power

plug.

General Sawing Instruction

For all cuts, it must first be ensured that

the saw blade at no time can come in con

tact with the fence, screw clamp or other

machine parts. Remove possible interfer

ing auxiliary stops or adjust them accord

ingly.

Do not load the machine so heavily that it comes to a

standstill.

Advancing that is too fast reduces considerably the

performance capability of the electrotool and reduces

the service life of the saw blade.

Use only sharp saw blades that are suitab le for the ma

terial being worked.

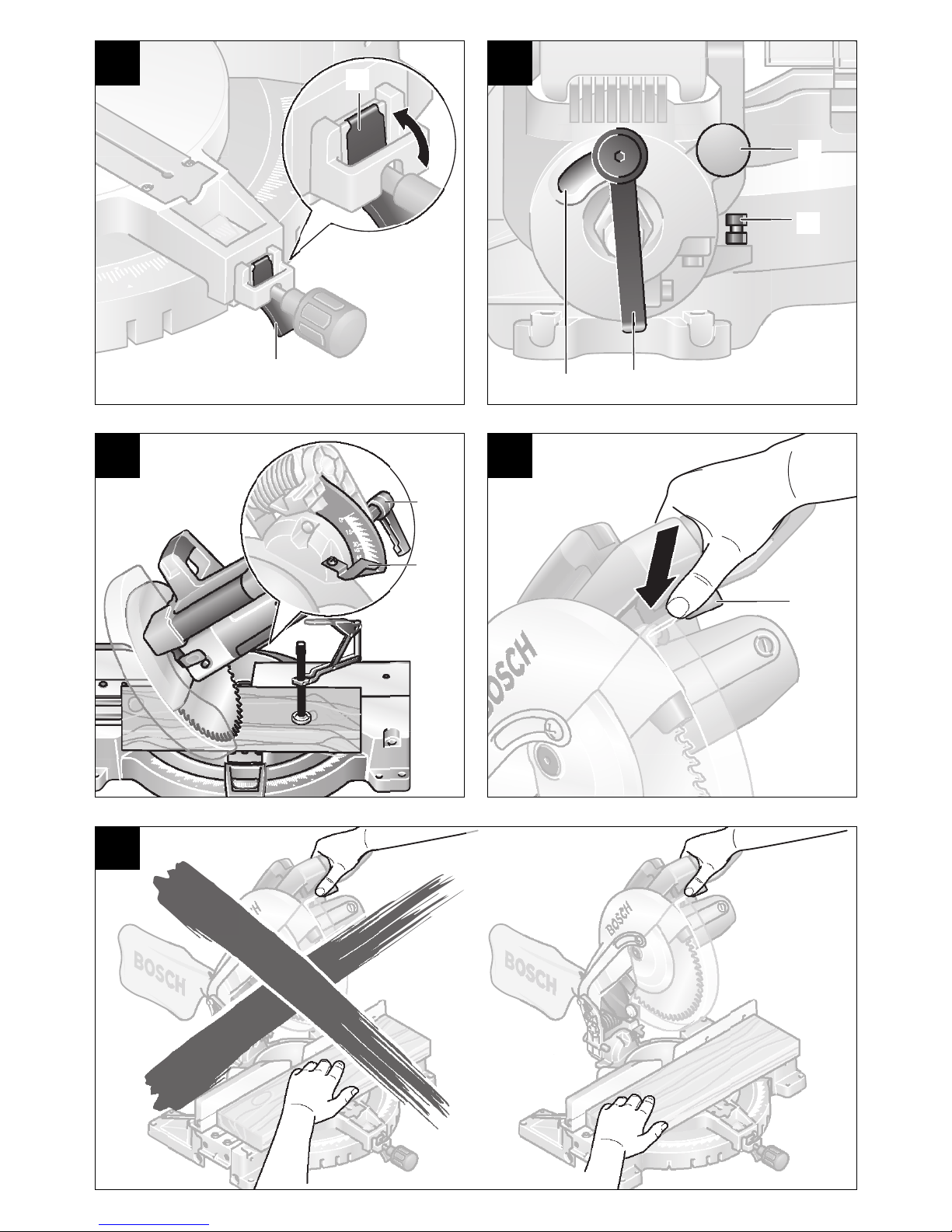

Hand Positioning

Keep fingers, hands and arms away from the rotating

saw blade. (see Figure )

Do not cross your arms when operating the tool arm.

(see Figure )

P

O

Special Work Pieces

When sawing curved or round work pieces, they must

be especially secured against slipping. At the cutting

line, no gap may exist between the work piece and the

fence or saw table.

In case necessary, a special fixture must be fabricated.

Table Insert

The red table insert 8 can become worn after long us

age of the electrotool.

Replace a defective table insert.

Place the electrotool in the working position.

Unscrew the screws 46 with the Phillips screwdriver

provided. (see Figure )

Insert the new table insert 8 and screw in all screws 46

again.

Set the vertical bevel angle to 0° and saw a slot in the

table insert.

Then set the vertical bevel angle to 45° and again saw

into the slot. With this procedure, it is ensured that the

table insert is as close as possible to the teeth of the

saw blade without coming in contact with them.

Q

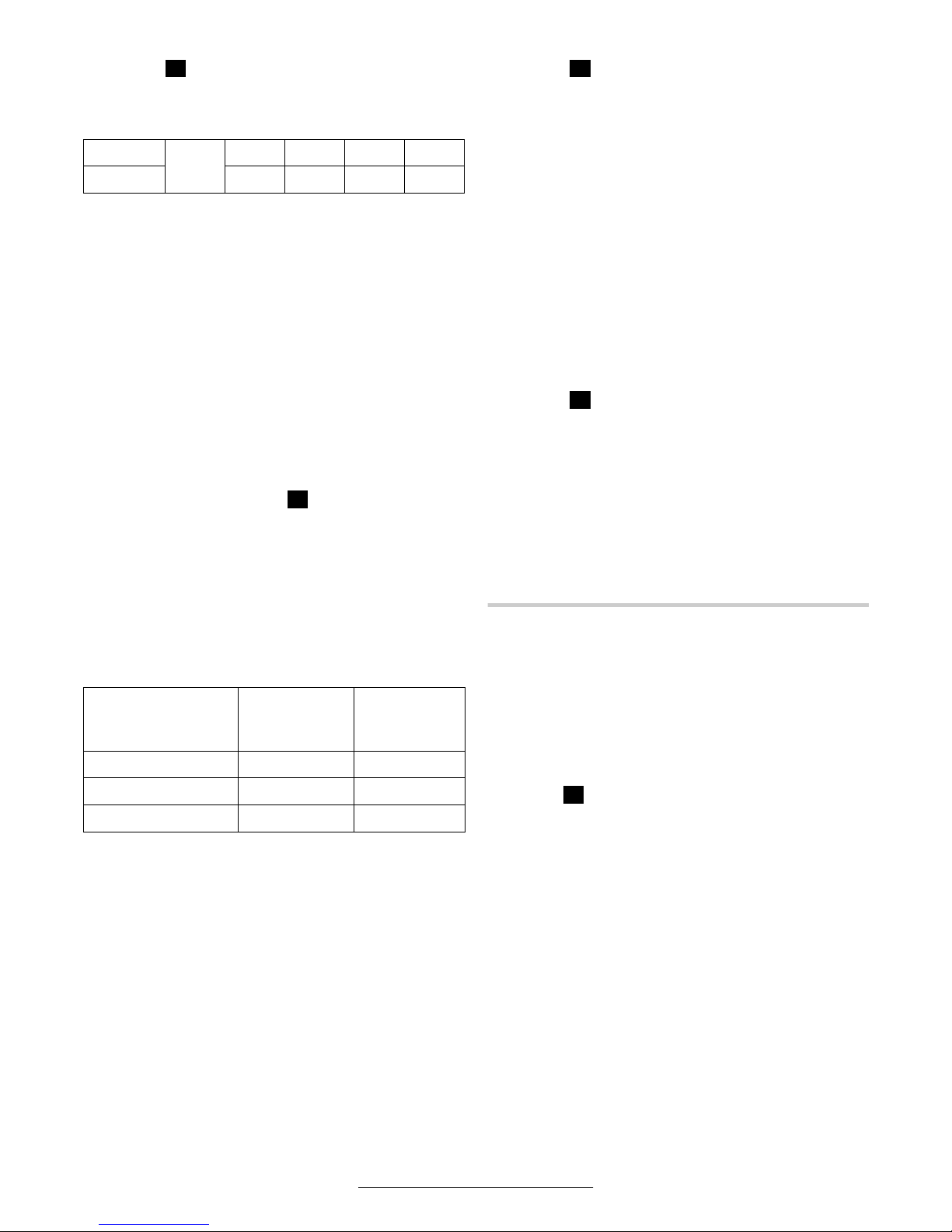

Maximum Work Piece Dimensions

Sawing Angle Height x Width [mm]

Miter

(Horizontal)

0° 0° 89 x 95 61 x 144

45° 0° 89 x 67 61 x 101

0° 45° 46 x 105 35 x 144

45° 45° 46 x 95 30 x 99

Cut-off Sawing

Clamp the work piece firmly according to its dimen

sions.

Set the desired miter angle.

Switch on the electrotool.

Press the locking lever 3 and guide the tool arm with

the handle 1 slowly downward.

Saw through the work piece with uniform advancing.

Switch off the electrotool and wait until the saw blade

has come to a complete standstill.

Guide the tool arm slowly upward.

Bevel

(Vertical)

At Max.

Height

At Max.

Width

Working with Profile Moldings

(Floor or Ceiling Moldings)

Profile moldings can be work with two different meth

ods:

– Placed against the fence,

– Lying flat on the saw table.

Always make trial cuts with the miter angle settings

first on scrap wood.

English–101 609 929 E91 • (04.10) PS

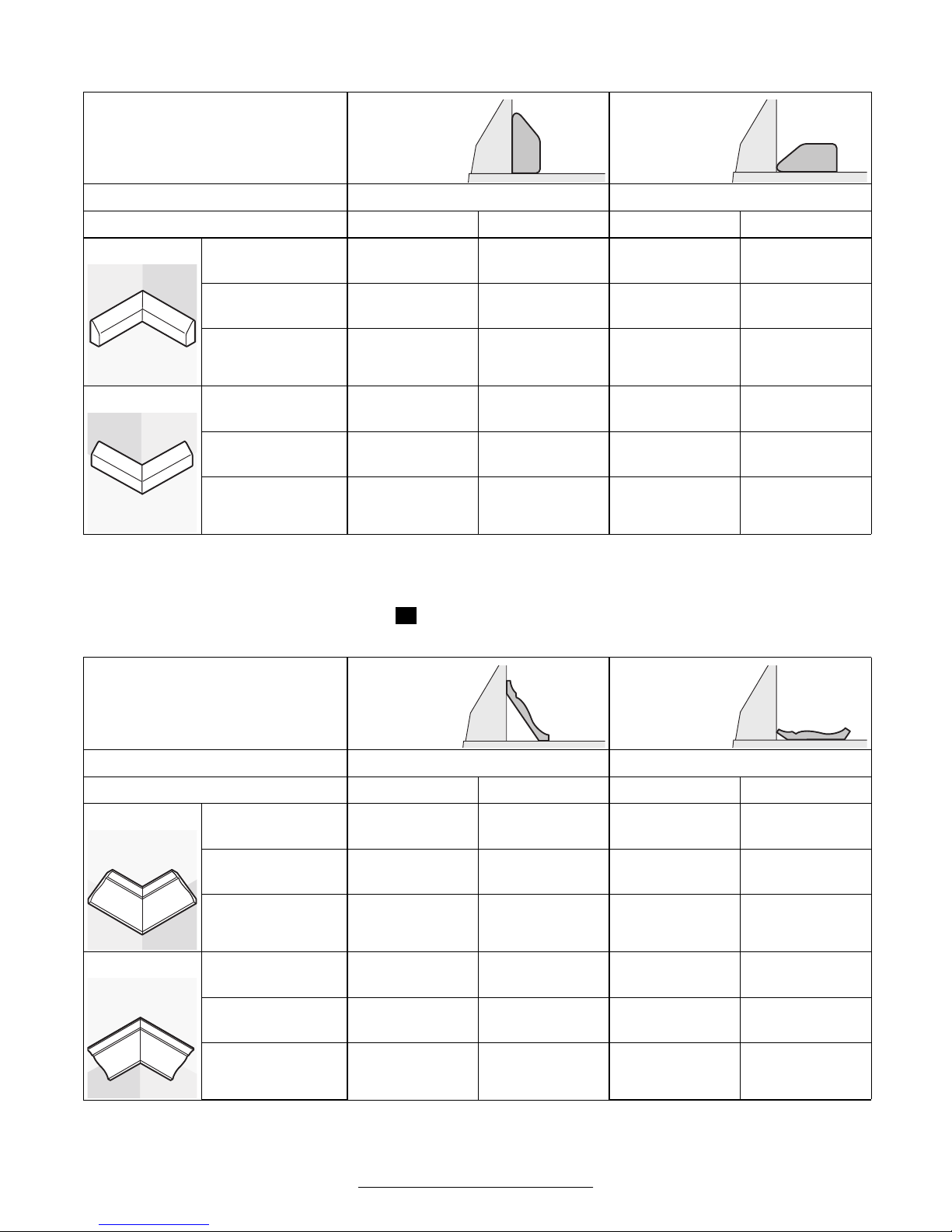

Floor Moldings

The following table contains instructions for the working of floor moldings.

Setting Placed

Against the

Fence

Lying Flat

on the Saw

Table

Vertical Bevel Angle 0° 45°

Floor Molding Left Side Right Side Left Side Right Side

Inner Corner Horizontal Miter

Angle

Positioning of the

Work Piece

The finished work

piece is located …

Outer Corner Horizontal Miter

Angle

Positioning of the

Work Piece

The finished work

piece is located …

45° Left 45° Right 0° 0°

Lower edge on

the saw table

…

to the left of

the cut

Lower edge on

the saw table

…

to the right of

the cut

Upper edge on

the fence

…

to the left of

the cut

45° Right 45° Left 0° 0°

Lower edge on

the saw table

…

to the right of

the cut

Lower edge on

the saw table

…

to the left of

the cut

Lower edge on

the fence

…

to the right of

the cut

…

Lower edge on

the fence

…

to the left of

the cut

Upper edge on

the fence

to the right of

the cut

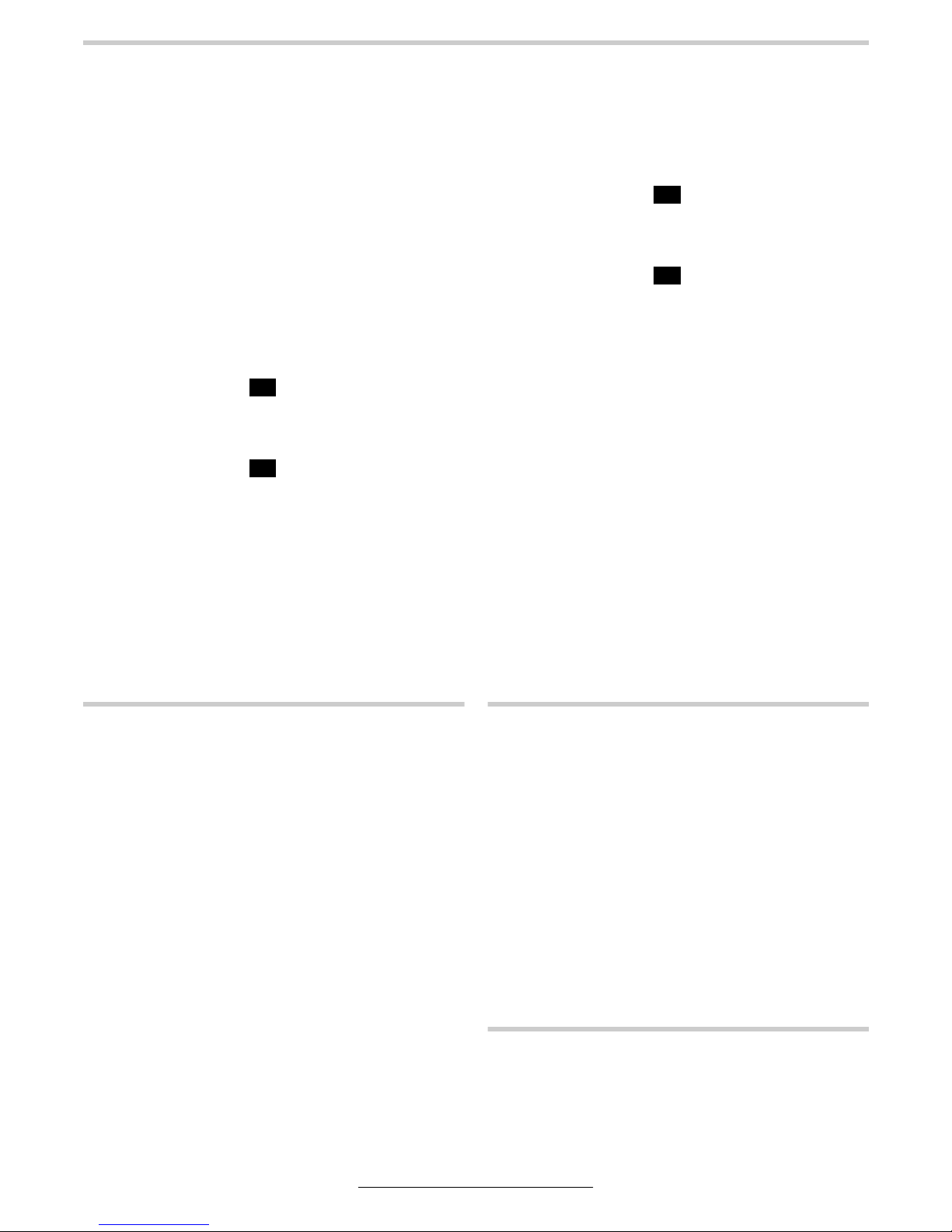

Ceiling Molding (According to US Standard)

When the ceiling molding is to be work lying flat on the saw table, the standard miter angle of 31.6° (horizontal)

and 33.9° (vertical) must be set. (see Figure )

R

The following table contains instructions for the working of ceiling moldings.

Setting Placed

Against the

Fence

Lying Flat

on the Saw

Table

Vertical Bevel Angle 0° 33,9°

Ceiling Molding Left Side Right Side Left Side Right Side

Inner Corner Horizontal Miter

Angle

Positioning of the

Work Piece

The finished work

piece is located …

Outer Corner Horizontal Miter

Angle

Positioning of the

Work Piece

45° Right 45° Left 31.6° Right 31.6° Left

Lower edge on

the fence

…

to the right of

the cut

Lower edge on

the fence

…

to the left of

the cut

Upper edge on

the fence

…

to the left of

the cut

Lower edge on

the fence

…

to the left of

45° Left 45° Right 31.6° Left 31.6° Right

Lower edge on

the fence

Lower edge on

the fence

Lower edge on

the fence

Upper edge on

the fence

the cut

The finished work

piece is located …

…

to the right of

the cut

…

to the left of

the cut

…

to the right of

the cut

…

to the right of

the cut

English–111 609 929 E91 • (04.10) PS

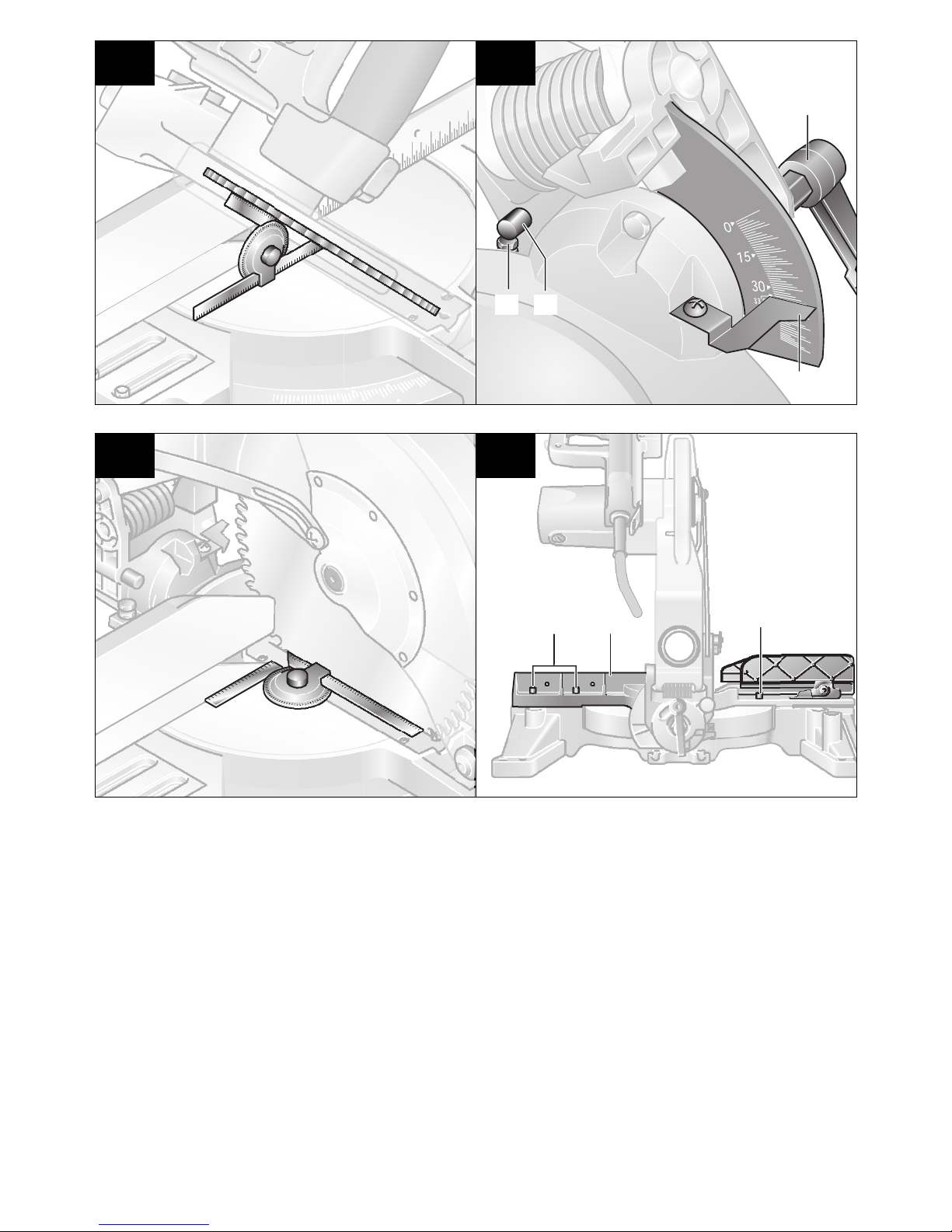

Checking and Adjusting Basic Adjustment

Before all work on the machine, pull the power

plug.

To ensure precise cuts, the basic adjustment must be

checked and adjusted as necessary after intensive us

age.

Bevel Angle 33,9° (Vertical)

Place the machine in the working position.

Rotate the saw table 15 to the detent 14 for 0°. Loos

en the clamping lever 30 and pull the fence extension

22 completely out.

Loosen the clamping handle 32 and press the setting

knob 31 completely in. Swing the tool arm with the

handle 1 until the pin 24 rests against the stop bolt 23.

Checking: (see Figure

Place a combination square set to 33,9° on the saw

table 15. The leg of the square must be flush with the

saw blade over its entire length.

Adjusting: (see Figure )

Loosen the locking nut of the stop bolt 23 with the

openended wrench 36 (12 mm) provided. Turn the

stop bolt either in or out until the leg of the square is

flush with the saw blade over its entire length.

Retighten the clamping handle 32. Then retighten the

locking nut of the stop screw 23.

S1

)

S2

Fence

Place the electrotool in the transport position.

Rotate the saw table 15 to the detent 14 for 0°. Loos

en the clamping lever 30 and pull the fence extension

22 completely out.

Checking: (see Figure

Set the combination square to 90° and place it on the

saw table 15. The square must be flush with the fence

6 over its entire length.

Adjusting: (see Figure

Loosen all three sockethead screws 35 with the Allen

key 21 (6 mm) provided. Rotate the fence 6 until the

square is flush with the fence over its entire length. Re

tighten the sockethead screws.

T1

)

T2

)

5 MAINTENANCE AND SERVICE

Maintenance

Before all work on the machine, pull the power

plug.

Always keep the machine and the ventilation slits clean

for efficient and safe working.

The swinging guard must always be able to move free

ly and close by itself. Therefore, always keep the area

around the swinging guard clean.

Remove dust and chips by blowing out with com

pressed air or with a brush.

Clean the roller 25 regularly.

Should the tool fail in spite of careful manufacturing

and testing procedures, have the repairs performed by

an authorized customer service location for Bosch

ElectroTools.

For inquiries and spare parts ordering, please include

the 10digit order number on the nameplate of the

tool.

Accessories

Saw blade 254 x 30 mm, 40 teeth. . . 2 608 640 438

Saw blade 254 x 25,4 mm, 40 teeth . 2 608 640 459

Saw blade 254 x 16 mm, 40 teeth. . . 2 608 640 466

Saw blade 254 x 25,4 mm, 120 teeth 2 608 640 465

Quick action clamp . . . . . . . . . . . . . . 2 608 040 205

Table insert . . . . . . . . . . . . . . . . . . . . 2 607 960 014

Dust bag . . . . . . . . . . . . . . . . . . . . . . 2 605 411 187

Extension hoop (356 mm) . . . . . . . . . 2 607 001 911

Angle adapter for dust bag . . . . . . . . 2 608 601 171

Vacuuming adapter for 35 mm hose . 2 605 702 022

Carrying bag . . . . . . . . . . . . . . . . . . . 2 605 435 019

Disposal

Tool, accessories and packaging should be sorted for

environmentfriendly recycling.

The plastic components are labeled for categorized re

cycling.

English–121 609 929 E91 • (04.10) PS

Service and Customer Advice

Exploded views and information on spare parts can be

found under: www.boschpt.com

In case of a claim, repair or purchase of replacement

parts or in case of queries or other problems please

contact your local dealer or Bosch representative.

People’s Republic of China

Website: www.boschpt.com.cn

Toll Free hotline:

Sole Agent:

Melchers (H.K.) Ltd.

Hong Kong Representative Office:

Room 1210, Shun Tak Centre, WestTower,

168 – 200 Connaught Road, Central Hong Kong

Customer Service Hotline:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +852 25 48 79 14

Fax

EMail: bosch@melchers.com.hk

Guangzhou Representative Office:

Room 1108, T. P. Plaza,

9/109 Liu Hua Road,

Guangzhou, P.R. China

. . . . . . . . . . . . . . . . . . . . . 800 8 20 84 84

. . . . . . . . +852 25 89 15 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 20 86 66 87 00

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 20 86 67 78 45

Fax

Postal code: 510010

EMail: bosch@gz.melchers.com.cn

Bosch After-sales Service Centre

Guangzhou:

1/F, East Wing, No. 4 Zeng Cha Road,

Guangzhou, P.R. China

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 20 81 75 84 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 20 81 75 88 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 20 81 75 71 69

Fax

Postal code: 510165

EMail: bsc@gz.melchers.com.cn

Shanghai Representative Office:

13 Floor, East Ocean Centre,

No. 588 Yanan Road (East),

Shanghai, P.R. China

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 21 63 52 88 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 21 63 51 31 38

Fax

Postal code: 200001

EMail: boschew@sh.melchers.com.cn

Beijing Representative Office:

Room 503 – 504, Beijing Tower,

No. 10 Changan Ave (East)

Beijing, P.R. China

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 10 65 25 77 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 10 65 12 35 05

Fax

Postal code: 100006

EMail: bosch@bj.melchers.com.cn

Bosch After-sales Service Centre Beijing:

Room 102 – 103, Beijing Liuliqiao Lanjinglijia,

No. 10 Xisanhuan South Road, Fengtai District,

Beijing, P.R. China

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 10 63 36 77 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 10 63 36 77 76

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 10 63 36 77 71

Fax

Postal code: 100073

EMail: boschservice@bj.melchers.com.cn

Chongqing Representative Office:

Room 1804,Metropolitan Tower,

68 Zourong Road, Yuzhong District,

Chongqing, P.R. China

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 23 63 82 80 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 23 63 82 80 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 23 63 82 80 43

Fax

Postal code: 400010

EMail: bosch@cq.melchers.com.cn

Bosch After-sales Service Centre

Chongqing:

16611 Yuzhou Road, Gaoxin District,

Chongqing, P.R. China

. . . . . . . . . . . . . . . . . . . . . . . +86 23 68 57 91 93

Fax . . . . . . . . . . . . . . . . . . . . . . +86 23 68 57 90 23

Postal code: 400041

EMail: bsc@cq.melchers.com.cn

Wuhan Representative Office:

Rm 202, Unit C, Apartment Bldg.

Yangtze Hotel,1131 Liberation Ave,

Wuhan, P.R. China

. . . . . . . . . . . . . . . . . . . . . . . +86 27 83 63 78 85

Fax . . . . . . . . . . . . . . . . . . . . . . +86 27 83 62 32 96

Postal code: 430030

EMail: bosch@wh.melchers.com.cn

Bosch After-sales Service Centre Shanghai:

East Four First Floor Building A,

No. 357 Zhaohua Road,

Shanghai, P.R. China

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 21 62 51 13 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +86 21 62 51 07 60

Fax

Postal code: 200050

EMail: boschservice@sh.melchers.com.cn

Wuhan After-sales Service Centre:

160 Aomen Road, Jiang’an District,

Hankou, Wuhan, P.R. China

. . . . . . . . . . . . . . . . . . . . . . . +86 27 82 44 81 57

Fax . . . . . . . . . . . . . . . . . . . . . . +86 27 82 44 81 60

Postal code: 430015

EMail: boschservice@wh.melchers.com.cn

English–131 609 929 E91 • (04.10) PS

Indonesia

P. T. Multi Tehaka

Karang Anyar Permai Block B24

Jl. Karang Anyar No. 55

Jakarta Pusat 10740

Indonesia

. . . . . . . . . . . . . . . . . . . . . . . +62 21 6 59 52 22 (5 lines)

. . . . . . . . . . . . . . . . . . . . . . . . . . . +62 21 6 59 52 52 3

Fax

sales@bosch.co.id

www.bosch.co.id

Phillippines

Robert Bosch, Inc.

Zuellig Building

Sen. Gil Puyat Avenue

Makati City 1200, Metro Manila

Philippines

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +63 2 8 17 32 31

www.bosch.com.ph

Singapore

Robert Bosch (SEA.) Pte. Ltd.

38 C Jalan Pemimpin

Singapore 915701

Republic of Singapore

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +65 3 50 54 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +65 3 50 53 27

Fax

www.bosch.com.sg

Vietnam

Ho Chi Minh City

Robert Bosch (SEA) Pte Ltd

Resident Representative Office HCMC

Tacasin Business Centre, 2nd Floor

243243B Hoang Van Thu P.1

Tan Binh District

Vietnam

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +84 8 8 47 87 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +84 8 8 47 83 28

Fax

Malaysia

Robert Bosch (SEA.) Pte. Ltd.

No. 8a, Jalan 13/6

Selangor Darul Ehsan

Petaling Jaya 46200

Malaysia

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +60 3 79 58 30 00

Fax (EW Dept.)

www.bosch.com.sg

Thailand

Robert Bosch Ltd.

Liberty Square Building

No. 287, 11 Floor

Silom Road, Bangrak

Bangkok 10500

. . . . . . . . . . . . . . . . . . . +60 3 79 58 38 38

. . . . . . . . . . . . . . . +66 2 6 31 18 79 18 88 (10 lines)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 2 38 47 83

Fax

Robert Bosch Ltd., P. O. Box 2054

Bangkok 10501, Thailand

Bosch Service Training Centre

28692869/1 Soi Ban Kluay

Rama IV Road (near old Paknam Railway)

Prakanong District

10110 Bangkok

Thailand

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 6 71 78 00 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 2 49 42 96

Fax

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 2 49 52 99

Fax

Australia

Robert Bosch Australia L.t.d.

RBAU/SPT2

1555 Centre Road

P.O. Box 66 Clayton

3168 Clayton/Victoria

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 8 00 80 47 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 8 00 81 95 20

Fax

CustomerSupportSPT@au.bosch.com

www.bosch.com.au

Specifications subject to change without notice.

Argentina

RBAR

. . . . . . . . . . . . . . . . . . . . . . . . . . . 0810 555 2020

Bolivia

HANSA

. . . . . . . . . . . . . . . . . . . . . . . . . . +59 12 314 445

Brasil

RBLA

. . . . . . . . . . . . . . . . . . . . . . . . . . 0800 70 45 446

Chile

EMASA

. . . . . . . . . . . . . . . . . . . . . . . . . . . 600 7378 4832

Colômbia

INNOVATEQ

. . . . . . . . . . . . . . . . . . . . . . . . . . .+571 629 4284

Costa Rica

MADISA

English–141 609 929 E91 • (04.10) PS

. . . . . . . . . . . . . . . . . . . . . . . . . . .+506 233 6255

Equador

ELECTRO DIESEL

. . . . . . . . . . . . . . . . . . . . . . . . . +593 4 220 2688

El Salvador

PROYESA

. . . . . . . . . . . . . . . . . . . . . . . . . . .+503 221 0666

Guatelmala

EDISA

. . . . . . . . . . . . . . . . . . . . . . . . . +502 2 331 7227

Honduras

CHIPS

. . . . . . . . . . . . . . . . . . . . . . . . . . .+504 556 9781

México

RBMX

. . . . . . . . . . . . . . . . . . . . . . . . . . .+55 5284 3000

Paraguai

CHISPA

. . . . . . . . . . . . . . . . . . . . . . . . . +595 21 553 315

Peru

AUTOREX

. . . . . . . . . . . . . . . . . . . . . . . . . . +51 1 475 5453

Venezuela

RBVE

. . . . . . . . . . . . . . . . . . . . . . . . +58 212 207 4511

Specifications subject to change without notice.

English–151 609 929 E91 • (04.10) PS

1 INSTRUCCIONES GENERALES DE SEGURIDAD

PARA HERRAMIENTAS ELÉCTRICAS

ADVERTENCIA

ciones de seguridad siguientes, ello puede dar lugar a

una descarga eléctrica, incendio o lesión seria.

¡Conserve estas instrucciones advertencia en un

lugar seguro!

Puesto de trabajo

Mantenga limpio y bien iluminado su puesto de

trabajo. El desorden y una iluminación deficiente en

las áreas de trabajo pueden provocar accidentes.

No utilice el aparato en un entorno con peligro de

explosión, p. ej. en el que se encuentren com

bustibles líquidos, gases o material en polvo. Las

herramientas eléctricas pueden producir chispas sus

ceptibles de inflamar materiales en polvo o vapores.

Mantenga alejados a los niños y otras personas

de su puesto de trabajo al emplear el aparato. En

caso de que otras personas le distraigan puede llegar

a perder el control sobre el aparato.

Nunca deje funcionar la herramienta eléctrica sin

estar presente, desconéctela en ese caso. Espere

a que el útil se haya detenido por completo antes de

dejar sola una herramienta eléctrica.

Seguridad eléctrica

Antes de conectar la herramienta eléctrica, cer

ciorarse de que la tensión de la fuente de energía

coincide con las indicaciones de la placa de ca

racterísticas del aparato y que la variación de

ésta no supere el 10 %. Si la tensión de la fuente de

energía no coincidiese con la tensión que requiere la

herramienta eléctrica, ello puede producir serios acci

dentes y deteriorar la herramienta eléctrica.

Evite que su cuerpo toque partes conectadas a

tierra como tuberías, radiadores, cocinas y refri

geradores. Existe un riesgo mayor a quedar expues

to a una sacudida eléctrica si su cuerpo tiene contacto

con tierra.

No exponga las herramientas eléctricas a la llu

via y evite que penetren líquidos en su interior.

Existe un riesgo mayor a quedar expuesto a una sacu

dida eléctrica si penetran ciertos líquidos en una herra

mienta eléctrica.

No utilice el cable de alimentación para transpor

tar o colgar el aparato, ni tire de él para sacar el

enchufe de la toma de corriente. Mantenga el ca

ble de alimentación alejado del calor, aceite, es

quinas cortantes o piezas móviles. Los cables de

alimentación dañados pueden provocar una sacudida

eléctrica.

Lea íntegramente y aténga

se a estas instrucciones. En

caso de no respetar las instruc

Seguridad personal

Esté atento a lo que hace y emplee la herramien

ta eléctrica con prudencia. No utilice la herra

mienta eléctrica si estuviese cansado, ni tampo

co después de haber consumido alcohol, drogas

o medicamentos. El no estar atento durante el uso

de una herramienta eléctrica puede provocarle serias

lesiones.

Utilice una vestimenta de trabajo adecuada. No

se ponga ropa holgada ni joyas. Emplee una re

decilla si lleva el pelo largo. Mantenga el pelo, la

ropa y los guantes alejados de las piezas móvi

les. La ropa holgada, las joyas, o el pelo largo, pueden

ser agarrados por las piezas en movimiento.

Evite una puesta en marcha fortuita del aparato.

Cerciorarse de que el aparato esté desconecta

do antes conectarlo a la toma de corriente. Si

transporta el aparato sujetándolo por el interruptor de

conexión/desconexión, o si introduce el enchufe en la

toma de corriente con el aparato conectado, ello pue

de dar lugar a un accidente.

Retire las herramientas de ajuste o llaves fijas

antes de conectar la herramienta eléctrica. Una

herramienta o llave colocada en una pieza rotante

puede producir lesiones al ponerse a funcionar.

Sea precavido. Trabaje sobre una base firme y

mantenga el equilibrio en todo momento. Ello le

permitirá controlar mejor la herramienta eléctrica en

caso de presentarse una situación inesperada.

Utilice un equipo de protección, y en todo caso

unas gafas de protección. Se recomienda colocar

se una mascarilla antipolvo, zapatos con suela anti

deslizante, un casco o protectores auditivos.

Trato y uso cuidadoso de herramientas eléctricas

Utilice un dispositivo de sujeción o un tornillo de

banco para fijar la pieza de trabajo. La sujeción de

la pieza de trabajo con la mano o presionándola contra

el cuerpo no le permite manejar el aparato de forma

segura.

No sobrecargue el aparato. Use la herramienta

prevista para el trabajo a realizar. Con la herra

mienta adecuada podrá trabajar mejor y más seguro

dentro del margen de potencia indicado.

No utilice herramientas con un interruptor defec

tuoso. Las herramientas que no se puedan conectar

o desconectar son peligrosas y deben hacerse repa

rar.

Saque el enchufe de alimentación antes de reali

zar un ajuste en el aparato, cambiar de accesorio

o al guardar el aparato. Esta medida preventiva re

duce el riesgo a conectar accidentalmente el aparato.

Español–11 609 929 E91 • (04.10) PS

Guarde las herramientas fuera del alcance de los

niños y de las personas que no estén familiariza

das con su uso. Las herramientas utilizadas por per

sonas inexpertas son peligrosas.

Cuide sus aparatos con esmero. Mantenga los

útiles bien afilados y limpios. Las herramientas cui

dadas convenientemente y empleadas con útiles afila

dos dejan guiarse y controlarse mejor.

Controle si funcionan correctamente, sin atas

carse, las partes móviles del aparato y si existen

partes rotas o deterioradas que pudieran afectar

al funcionamiento de la herramienta. Haga repa

rar las piezas defectuosas del aparato por un

servicio técnico oficial antes de volver a utilizar

la herramienta eléctrica. Muchos de los accidentes

se deben a aparatos con un mantenimiento deficiente.

La herramienta eléctrica no deberá modificarse

ni deberá utilizarse para fines diferentes de los

mencionados en el apartado „Utilización regla

mentaria“. Toda modificación, además de ser antirre

glamentaria, puede causar graves daños.

Solamente utilice los accesorios que recomien

da el fabricante del aparato. El uso de accesorios

concebidos para otros aparatos puede resultar peli

groso.

Servicio

Únicamente haga reparar su herramienta eléctri

ca por un profesional. La reparación o manteni

miento realizados por personal no cualificado puede

resultar peligroso.

Para la reparación o mantenimiento del aparato

emplee exclusivamente piezas de repuesto origi

nales. Siga las instrucciones indicadas en el

apartado „Mantenimiento“ de las presentes ins

trucciones. El uso de accesorios diferentes de los

previstos o el incumplimiento de las instrucciones

mencionadas en el apartado „Mantenimiento“ puede

suponer una sacudida eléctrica o provocar una lesión.

2 INSTRUCCIONES DE SEGURIDAD PARA

APARATOS ESPECÍFICOS

PARA INGLETADORA

Su puesto de trabajo, o el área en que éste trabajan

do, deberán estar suficientemente iluminados.

Es caso de dañar o cortar el cable de alimentación du

rante el trabajo, no toque el cable, y extraiga inmedia

tamente el enchufe de alimentación. Jamás emplee el

aparato con un cable dañado.

Colóquese unas gafas de protección y protectores au

ditivos.

El polvo producido al trabajar puede ser nocivo para la

salud, combustible, o explosivo. Ello requiere tomar

unas medidas de protección adecuadas.

Por ejemplo: ciertos materiales en polvo son cancerí

genos. Emplear unos equipos de aspiración de polvo

interna, y colocarse una mascarilla antipolvo.

Los aparatos utilizados en la intemperie deberán co

nectarse a través de un fusible diferencial ajustado a

una corriente de disparo máxima de 30 mA. Solamen

te utilice cables de prolongación homologados para su

uso en exteriores.

Siempre mantenga el cable de alimentación detrás del

aparato.

Antes de su uso montar la herramienta eléctrica sobre

una superficie plana y estable.

Nunca se coloque encima de la herramienta eléctrica.

Ello puede dar lugar a graves lesiones en caso de vol

carse la herramienta eléctrica, o al tocar accidental

mente la hoja de sierra.

Solamente aserrar los materiales que el fabricante de

la herramienta eléctrica indica.

Antes de trabajar con el aparato cerciorarse de que la

guarda protectora pendular funcione reglamentaria

mente. Ésta debe moverse libremente y cerrarse de

forma automática. No es permisible bloquearla para

mantenerla abierta.

Únicamente utilice la herramienta eléctrica después de

haber despejado de la superficie de trabajo las herra

mientas de ajuste, virutas, etc. Las piezas pequeñas

de madera u otros objetos pueden ser proyectados a

alta velocidad contra el usuario al ser atrapados por la

hoja de sierra en funcionamiento.

Siempre sujete firmemente con un dispositivo la pieza

de trabajo. En las piezas de trabajo largas deberá so

portarse convenientemente su extremo libre. No ase

rrar piezas que sean tan pequeñas que no dejen suje

tarse convenientemente.

Jamás permita que otra persona sujete o soporte la

pieza al trabajar. Siempre utilice una prolongación de

la mesa de aserrar o un dispositivo para sujeción de la

pieza adecuados.

No trabajar materiales que contengan amianto.

Solamente sujete la herramienta eléctrica por las em

puñaduras aisladas si existe el riesgo de que el disco,

pueda dañar un cable oculto, o el propio cable de ali

mentación del aparato. El contacto con un conductor

eléctrico puede someter bajo tensión las partes metá

licas del aparato y provocar una descarga eléctrica.

Español–21 609 929 E91 • (04.10) PS

Esperar a que la hoja de sierra haya alcanzado las re

voluciones máximas antes de comenzar a aserrar la

pieza.

Mantenga alejadas las manos, dedos y brazos de la

hoja de sierra en funcionamiento.

Proteja la hoja de sierra contra golpes y choques. No

ejerza una presión lateral contra la hoja de sierra.

Únicamente emplee hojas de sierra afiladas y en per

fecto estado. Sustituir inmediatamente aquellas hojas

de sierra que estén fisuradas, deformadas o sin filo.

No coloque los dedos detrás de la regleta tope en las

proximidades de la hoja de sierra para sujetar la pieza

de trabajo, retirar virutas, o por otros motivos, ya que

su mano quedaría demasiado cerca de la hoja de sie

rra en funcionamiento.

Siempre aserrar una pieza solamente. Las piezas de

trabajo superpuestas o colocadas una al lado de otra

no dejan sujetarse correctamente, pueden bloquear la

hoja de sierra, o pueden desplazarse al aserrar.

La línea de corte debe estar libre de obstáculos por la

cara superior e inferior de la pieza. No aserrar materia

les con clavos, tornillos, etc.

En caso de que la hoja de sierra se atasque, desco

necte inmediatamente la herramienta eléctrica y saque

el enchufe de alimentación. Solamente entonces trate

de liberar la pieza de trabajo.

No aplicar con brusquedad la hoja de sierra contra la

pieza de trabajo, ni ejercer una presión de aplicación

excesiva al trabajar con la herramienta eléctrica. Ante

todo evite que la hoja de sierra se atasque al trabajar

esquinas, bordes, etc.

Al serrar juntas, preste atención a que la hoja de sierra

no se enganche en la pieza de trabajo.

Tenga cuidado de no sobrecargar el motor, especial

mente al trabajar piezas grandes. Solamente aserrar

ejerciendo una presión leve sobre la empuñadura.

¡Precaución! La hoja de sierra sigue girando cierto

tiempo por inercia después de desconectar la herra

mienta eléctrica

Utilice hojas de sierra adecuadas al tipo de material a

procesar.

Únicamente emplee las hojas de sierra que el fabrican

te de la herramienta eléctrica recomienda.

Atenerse a las instrucciones de montaje y uso del fa

bricante de la hoja de sierra.

Solamente accionar el bloqueador del husillo con la

hoja de sierra detenida.

La hoja de sierra puede llegar a ponerse muy caliente

al trabajar. Por ello, dejarla enfriar antes de tocarla.

Ponerse unos guantes de protección al cambiar la

hoja de sierra para no lesionarse con sus filos.

Tenga en cuenta las dimensiones de la hoja de sierra.

El orificio debe ajustar sin holgura en el husillo porta

discos. No emplee piezas de reducción ni adaptado

res.

Considere la velocidad de máxima permisible de la

hoja de sierra.

No es admisible utilizar hojas de sierra de acero de

corte rápido altamente aleado (acero HSS).

Jamás utilizar la herramienta eléctrica sin la placa de

inserción. Sustituir una placa de inserción defectuosa.

Bosch solamente puede garantizar un funcionamiento

correcto del aparato, si éste se utiliza exclusivamente

con los accesorios originales previstos.

Nota importante: algunos de los símbolos siguientes pueden ser importantes en la aplicación de su aparato.

Por ello, intente retener en su memoria los símbolos y su significado. La interpretación correcta de los símbolos

facilita, y hace más seguro, el manejo del aparato.

Símbolo Denominación Significado

V Volt Tensión eléctrica

A Amperos Intensidad de corriente

Ah Amperioshora Capacidad, cantidad de energía acumulada

Hz Hertz Frecuencia

W Watts Potencia

SIMBOLOGÍA

Español–31 609 929 E91 • (04.10) PS

Símbolo Denominación Significado

Nm Newtonmetro Unidad de energía, par de giro

kg Kilogramo Masa, peso

mm Milímetro Longitud

min/s Minutos/segundos Tiempo, intervalo

°C/°F Grados centígrados/Fahrenheit Temperatura

dB Decibelios Unidad del nivel de sonido relativo

∅ Diámetro P.ej. tamaño de brocas, discos de amolar, etc.

1

/n0 Revoluciones Revoluciones en vacío

min

…/min Revoluciones por minuto Vueltas, impactos, órbitas, etc., por minuto

0 Posición de desconexión Velocidad cero, par de giro cero

SW Entrecaras (en mm) Separación entre dos o más caras paralelas que

llevan algunos elementos de sujeción, previstas

para aplicar a ellas una herramienta, ya sea direc

tamente (p. ej. en tuercas o cabezas de tornillo

hexagonales), exteriormente (p. ej. con una llave

anular), o interiormente (p. ej. un tornillo con hexá

gono interior)

Giro a izquierdas/derechas Sentido de giro

/ Hexágono interior/cuadradillo

externo

Flecha Efectuar la acción en sentido de la flecha

Corriente alterna Tipo de intensidad y tensión

Corriente continua Tipo de intensidad y tensión

Corriente alterna o continua Tipo y característica de intensidad y tensión

Clase de protección II Los aparatos de la clase de protección II están

Clase de protección I

según DIN: Tierra de protección

(conductor de protección)

Símbolo de advertencia Informa al usuario sobre el manejo correcto del

Señal de obligación Indicaciones para el manejo correcto, p. ej. leer las

Tipo de porta útiles

completamente aislados.

Los aparatos pertenecientes a la clase de protec

ción I deben conectarse a tierra.

aparato o le advierte sobre un posible peligro.

instrucciones de manejo.

Español–41 609 929 E91 • (04.10) PS

Simbología específica del aparato

Símbolo Significado

Señal de obligación ¡Área de peligro! Mantenga alejados de este área

Señal de obligación Ponerse unas gafas de protección.

Señal de obligación Colóquese un protector de oídos.

Señal informativa Tenga en cuenta las dimensiones de la hoja de sie

las manos, dedos o brazos.

rra. El orificio debe ajustar sin holgura en el husillo

portaútiles. No emplee piezas de reducción ni

adaptadores.

3 DESCRIPCIÓN DE FUNCIONAMIENTO

Observe las ilustraciones correspon

dientes de la herramienta eléctrica en

las primeras páginas, al leer estas ins

trucciones de manejo.

Utilización reglamentaria

La herramienta eléctrica ha sido proyectada para tra

bajar sobre una base estable y realizar cortes longitu

dinales y transversales rectos en madera, siendo posi

ble ajustar ángulos de corte horizontales entre 48° y

+48°, así como ángulos de corte verticales entre 0° y

+45°.

Información sobre ruido y

vibraciones

Determinación de los valores de medición según nor

ma EN 61 029.

El nivel de ruido típico del aparato, determinado con

un filtro A, corresponde a:

Nivel de presión de sonido 97 dB(A).

Nivel de potencia acústica 110 dB(A).

Inseguridad en la medición K = 3 dB.

¡Usar protectores auditivos!

El nivel de vibraciones típico en la mano/brazo es me

nor de 2,5 m/s

2

.

Español–51 609 929 E91 • (04.10) PS

Características técnicas

Ingletadora GCM 10

PROFESSIONAL

Nº de referencia

0 601 B20 …

Potencia absorbida

nominal

Tensión [V] 230 220/230 115 230/240 220 120

Frecuencia [Hz] 50 50/60 50/60 50/60 50/60 60

Revoluciones en va

cío

Husillo porta útiles [mm] 30 25,4 25,4 25,4 30 16

Peso sin cable de red [kg] 16,0 16,0 16,0 16,0 16,0 16,0

∅ de la hoja de sierra [pulgadas] 10 10 10 10 10 10

Clase de protección / II / II / II / II / II / II

Ingletadora GCM 10

Nº de referencia

0 601 B20 …

Potencia absorbida

nominal

[W] 1 800 1 800 1 650 1 800 1 650 1 650

[min1] 4 500 4 500 4 500 4 500 4 900 4 500

[W] 1 800 1 800 1 650 1 800 1 800

… 003

… 008

… 032

… 042

PROFESSIONAL

… 037 … 040 … 041 …043 … 050

… 004 … 005 …006 … 014 … 034

Tensión [V] 240 220 110 220 220/230

Frecuencia [Hz] 50 60 50 50 50/60

Revoluciones en va

cío

Husillo porta útiles [mm] 25,4 25,4 30 25,4 25,4

Peso sin cable de red [kg] 16,0 16,0 16,0 16,0 16,0

∅ de la hoja de sierra [pulgadas] 10 10 10 10 10

Clase de protección / II / II / II / II / II

Las indicaciones son válidas para tensiones nominales

[U] 230/240 V. Estos valores pueden variar para ten

siones menores y en las ejecuciones para ciertos paí

ses.

Los picos de intensidad durante la conmutación pro

ducen un descenso transitorio de la tensión. Bajo unas

condiciones de la red desfavorables, esto puede llegar

a afectar a otros aparatos.

En redes de una impedancia inferior a 0,15 Ω es muy

improbable que se produzcan perturbaciones.

Las dimensiones máximas de la pieza se indican en el

capítulo „Indicaciones de trabajo“

[min1] 4 500 4 500 4 500 4 500 4 500

Español–61 609 929 E91 • (04.10) PS

Elementos del aparato

La numeración de los elementos del aparato corres

ponde a la que se indica en las ilustraciones de la he

rramienta eléctrica en las primeras páginas de estas

instrucciones de manejo.

1 Empuñadura

2 Interruptor de conexión/desconexión

3 Palanca de bloqueo *

4 Guarda protectora pendular

5 Hoja de sierra

6 Regleta tope

7 Mordaza de cierre rápido

8 Placa

9 Escala para ángulo de corte (horizontal)

10 Escala de precisión

11 Clip de enclavamiento

12 Botón de enclavamiento para ángulos de corte

discrecionales (horizontal)

13 Palanca para ajuste de ángulos de corte estándar

(horizontal)

14 Muescas para ángulos de corte estándar

15 Mesa de aserrar

16 Taladros de sujeción

17 Taladros para mordaza de cierre rápido

18 Tornillos con hexágono interior (entrecaras 6) para

prolongación de mesa

19 Taladros para estribo de prolongación

20 Prolongación de mesa

21 Llave macho hexagonal (entrecaras 6) / destorni

llador de estrella

22 Prolongación de la regleta tope

23 Tornillo tope para ángulo de corte de 33,9° (verti

cal)

24 Perno del botón de ajuste para el ángulo de corte

33,9° (vertical)

25 Rodillo de deslizamiento

26 Seguro para transporte

27 Saco colector de polvo

28 Guarda protectora

29 Empuñadura de transporte

30 Palanca de fijación para prolongación de la regleta

tope

31 Botón de ajuste para ángulo de corte de 33,9°

(vertical)

32 Palanca de enclavamiento para ángulos de corte

discrecionales (vertical)

33 Muesca marcada

34 Expulsor de virutas

35 Tornillos con hexágono interior (entrecaras 6) de

regleta tope

36 Llave de anillo / llave fija

(anillo: entrecaras 13; fija: entrecaras 12)

37 Tornillo cabeza de estrella (sujeción de guarda

protectora pendular)

38 Bloqueador del husillo

39 Tornillo de cabeza hexagonal para sujeción de la

hoja de sierra

40 Brida de apriete

41 Husillo portadiscos

42 Tope longitudinal

43 Estribo de prolongación

44 Palanca de fijación de la mordaza de cierre rápido

45 Barra roscada de la mordaza de cierre rápido

46 Tornillos de la placa

47 Indicador de ángulos (vertical)

Los accesorios ilustrados o descritos pueden no

corresponder al material suministrado de serie con el

aparato.

* no se incluye en las ejecuciones:

0 601 B20 004, … 005, … 006, … 034, … 037,

… 040, … 043, … 050.

La caperuza protectora pendular 4 no puede enclavar

se. Efectúe las maniobras descritas a continuación en

la forma correspondiente sin la palanca de bloqueo 3.

Español–71 609 929 E91 • (04.10) PS

Loading...

Loading...