Page 1

RAID Subsystem DVA-08K

DVA-08K SCSI Premium Series

en Installation Manual

Page 2

Page 3

RAID Subsystem DVA-08K | Installation Manual Table of Contents | en 3

Table of Contents

1 Warnings and Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Enclosure Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Chassis Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.3 Front Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.4 Hard Drive Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.5 Rear Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.6 Backplane Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Subsystem Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.1 LCD Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.2 Drive Trays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.3 The RAID Controller Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.4 Battery Backup Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.5 Power Supply Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.6 Cooling Fan Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4 Subsystem Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.1 I

2.4.2 LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.3 Firmware and Bosch RAIDWatch GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.4 Audible Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5 Hot-Swappable Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5.1 Hot-Swap Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5.2 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5.3 Normalized Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2

C Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Installation Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 Precautions and Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.2 Static-Free Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.3 BBU Warnings and Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 General Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.1 Installation Procedure Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4 Unpacking the Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.5 Rackmounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.1 Considerations for Installation Site and Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.2 Mounting Holes Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.6 Drive Tray Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Subsystem Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1 Subsystem Monitoring Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Status-indicating LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.1 Brief Overview of the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.2 Drive Tray LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.3 Controller Module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.4 Ethernet Port LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.5 BBU Module LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.6 PSU LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.7 LCD Keypad Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.8 Cooling Fan Module LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Audible Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.1 Default Threshold Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.2 Failed Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4 I

2

C Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 4

4 en | Table of Contents RAID Subsystem DVA-08K | Installation Manual

5 Subsystem Connection and Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1 Basic Configuration Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.2 SCSI Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.1 SCSI Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.2 SCSI Port on the Controller Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.3 SCSI Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3 Host Connection Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.4 Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4.1 Power On Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4.2 Power On Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4.3 Power On Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4.4 Power On Status Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.4.5 LCD Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.5 Power Off Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6 Subsystem Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.1.1 General Notes on Component Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2 Replacing Controller Module Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2.2 Notes on Controller Module Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2.3 Removing the Controller Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2.4 Replacing the Controller Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.3 Replacing or Upgrading Memory Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.3.1 Memory Module Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.3.2 Selecting a Memory Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.3.3 DIMM Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4 Replacing a Faulty BBU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.5 Replacing a Failed PSU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.5.1 Notes on PSU Module Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.5.2 Replacing the PSU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.6 Replacing a Failed Cooling Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.1 Notes on Cooling Fan Module Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.2 Replacing a Cooling Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.7 Drive Tray Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.7.1 Notes on Hard Drive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.7.2 Replacing a Failed Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7 Appendix: Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.1 Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.1.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.1.2 Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.2 Drive Tray Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3 Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4 Cooling Module Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.5 RAID Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.6 Fault Tolerance Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8 Appendix: Spare Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.1 Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.1.1 Spare Parts Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.1.2 Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.1.3 Controller Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.2 Accessories and Optional Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9 Appendix: Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.1 SCSI Port: VHDCI Connector Pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.2 COM1 Cable: DB9 and Audio Jack Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.3 Null Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.4 Ethernet Port Pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.5 Main Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10 Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 5

RAID Subsystem DVA-08K | Installation Manual Warnings and Certifications | en 5

1 Warnings and Certifications

1.1 Warning

A shielded power cord is required in order to meet FCC emission limits and also to prevent

interference to nearby radio and television reception.

Use only shielded cables to connect I/O devices to this equipment. You are cautioned that

changes or modifications not expressly approved by the party responsible for compliance

could void your authority to operate the equipment.

1.2 Safety Precautions

Precautions and Instructions

• Prior to powering on the subsystem, ensure that the correct power range is being used.

• The RAID subsystems come with drive bays. Leaving any of these drive bays empty will

seriously affect the efficiency of the airflow within the enclosure, and will consequently

lead to the system overheating, which can cause irreparable damage.

• If a module fails, leave it in place until you have a replacement unit and you are ready to

replace it.

• Airflow Consideration: The subsystem requires an airflow clearance, especially at the

front and the rear side.

• Handle subsystem modules using the retention screws, extraction levers, and the metal

frames/faceplates. Avoid touching PCB boards and connector pins.

• To comply with safety, emission, or thermal requirements, none of the covers or replace-

able modules should be removed. Make sure that during operation, all enclosure modules

and covers are securely in place.

• Be sure that the rack cabinet into which the subsystem chassis will be installed provides

sufficient ventilation channels and airflow circulation around the subsystem.

• Provide a soft, clean surface to place your subsystem on before working on it. Servicing

on a rough surface may damage the exterior of the chassis.

• If it is necessary to transport the subsystem, repackage all disk drives separately. If using

the original package material, other replaceable modules can stay within the enclosure.

ESD Precautions

Observe all conventional anti-ESD methods while handling system modules. The use of a

grounded wrist strap and an anti-static work pad are recommended. Avoid dust or debris in

your work area.

1.3 Certification

FCC Class B Radio Frequency Interference Statement

FCC (applies in the U.S. and Canada)

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules (47 CFR, Part 2, Part 15 and CISPR PUB. 22

Class B). These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with

this user’s manual, may cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 6

6 en | Warnings and Certifications RAID Subsystem DVA-08K | Installation Manual

turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help

This device complies with Part 15 of FCC Rules. Operation is subjected to the following two

conditions: 1) this device may not cause harmful interference, and 2) this device must accept

any interference received, including interference that may cause undesired operation.

This device is in conformity with the EMC.

CB (Certified Worldwide)

This device meets the requirements of the CB standard for electrical equipment with regard to

establishing a satisfactory level of safety for persons using the device and for the area surrounding the apparatus. This standard covers only safety aspects of the above apparatus; it

does not cover other matters, such as style or performance.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 7

RAID Subsystem DVA-08K | Installation Manual Introduction | en 7

2 Introduction

This manual covers the DVA-08K series of RAID subsystems.

With its basic hardware redundancy and the capability of fast I/O transfer, the 2U RAID SATA

subsystem is an ideal solution to meet the ever increasing demands for addition of storage

capacity. Despite its ease of use, the subsystem does not compromise data protection for

convenience. The subsystem’s embedded firmware offers the same protection and maintenance functionalities as those designed for an enterprise-level RAID solution. The subsystems

provide unprecedented configuration flexibility and allow for the customization of storage

subsystems to meet specific demands. It is a rigorous and durable subsystem that can be easily configured and operated.

Fully featured RAID redundancy (which provides advanced data protection) ensures that the

complete range of RAID levels (RAID 0, 1(0+1), 3, 5, 10, 30 and 50) is supported by the controller head. A long list of sophisticated firmware functions (dedicated/global hot-spares, battery protected disk cache, configurable reaction schemes against drive errors, remote and

real-time array monitoring, and more) further guarantees the overall availability of valuable

data.

IT managers using the RAID subsystems will be able to rapidly develop a comprehensive storage array. And the modular nature of the subsystem minimizes the maintenance effort to use

the RAID appliance.

2.1 Product Overview

The subsystem comes with two (2) SCSI-320 host channels interfaced through four (4) VHDCI

68-pin SCSI ports. The subsystem comes in a 2U-profile rack-mountable chassis which houses

a RAID controller module featuring complete RAID configuration and data protection functionality. The subsystem’s operation is protected by redundant, hot-swappable power supplies

and cooling fan modules. Designed for a high level availability, all major components are hotreplaceable including its Li-ION battery and the RAID-protected disk drives.

The subsystem supports high-density array capacity by its eight drive bays for SATA-II interface disk drives. The subsystem facilitates large I/O transfer, over its dual PCI-X buses architecture, and transmission of block I/Os over flexible caching and a dedicated XOR engine. The

subsystem is ideal for direct-attached data storage, backup, and retrieval. It combines the

capabilities and block-level performance of RAID storage with the reliable SCSI transfer technologies.

Configured arrays are easily combined with multiple ID/LUNs that appear to the host ports,

turning massive capacity into manageable units for data-sharing in a heterogeneous environment.

The RAID 2U-profile, SCSI-to-SATA RAID storage comes in two different models. The only difference between the two models is the number of SATA-II drive bays.

SCSI Host Ports

Connectivity: The subsystem features a 320MB/s bandwidth from each of its SCSI host channels. The dual-stack VHDCI connectors on the rear panel facilitate the connection to multiple

host computers and combining the storage capacities of multiple RAID subsystems. Its backward compatibility with older SCSI protocols requires minimum investment for upgrading

equipment. Storage volumes are associated with SCSI ID/LUNs on the host channels. The

subsystem firmware provides flexible configurations of storage volumes which include, logical

drives in supported RAID 0, 1 (0+1), 3, and 5 levels, logical volumes that consist of one or

more logical drives, and the logical partitions of the previously mentioned configurations.

These volumes then appear as SCSI targets over the host links.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 8

8 en | Introduction RAID Subsystem DVA-08K | Installation Manual

i

Channels: The SCSI ID/LUN mapping method enables users to associate a storage volume

with multiple IDs or LUNs on the host channels. The mapping method can easily cope with

host-side configurations such as clustered servers or high availability path redundancy. On the

drive side, all of the eight (8) SATA-II drives are connected each through a dedicated SATA

channel. Each drive channel is routed to an enclosure drive tray that is equipped with a standard SATA connector with of hot-swap capability. The methods used for assembling physical

drives, fault management, and status monitoring are identical to that used with Bosch’s long

line of RAID storage enclosures.

Active Components

The subsystem comes with:

• A single RAID controller module

• Two redundant, hot-swappable cooling modules

• Dual redundant, hot-swappable, load-sharing power supplies

• A module slot for a Li-ION battery module.

• The front section of the enclosure houses eight (8) hot-swap drive bays for SATA-II or

backward compatible with SATA-I hard disk drives.

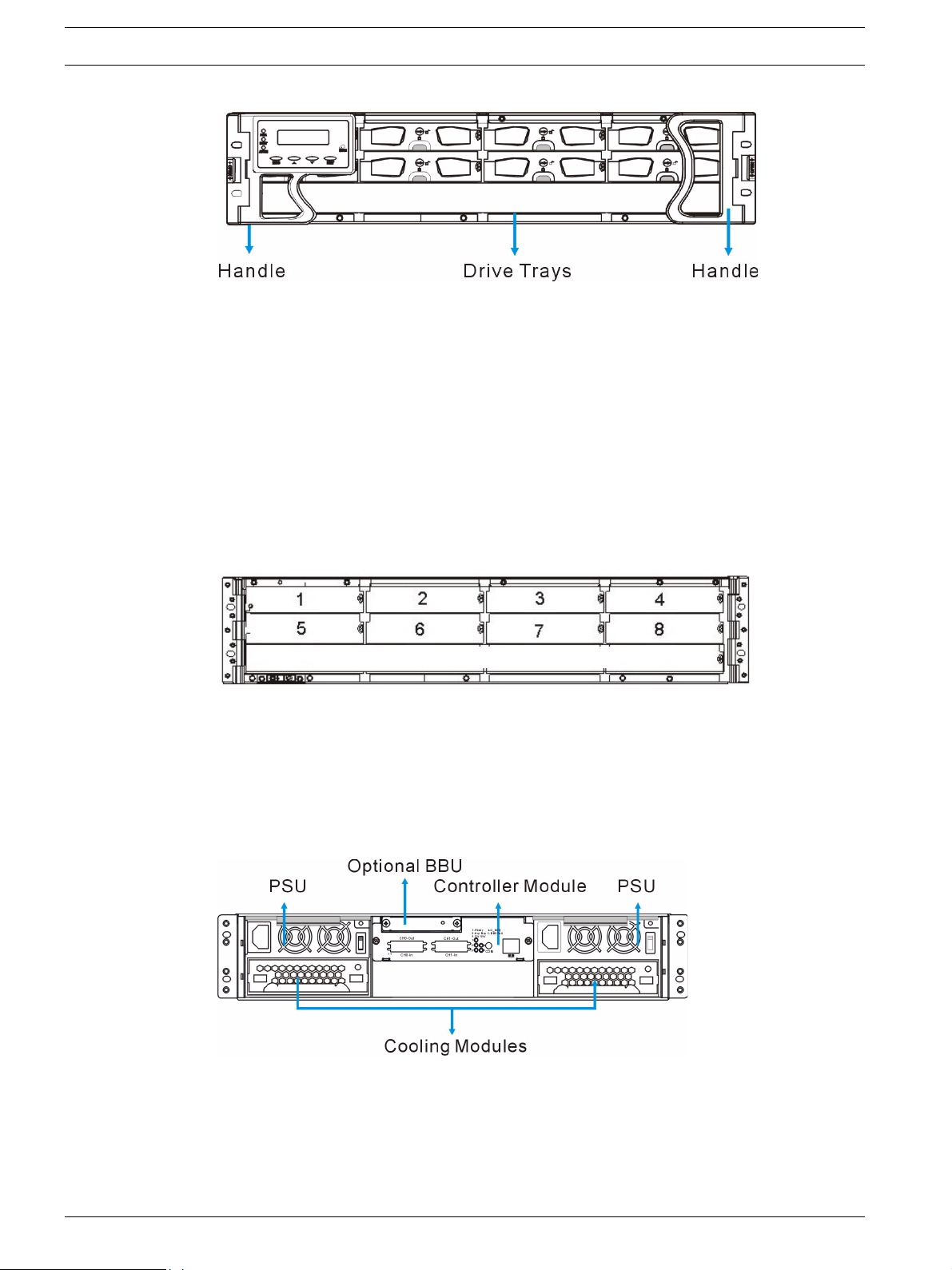

The subsystem is shown below:

Fig. 2.1 8-bay SATA RAID Subsystem

NOTICE!

On receiving and unpacking your subsystem, please check the package contents against the

included unpacking checklist. If any modules appear to be missing, please contact your subsystem vendor immediately.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 9

RAID Subsystem DVA-08K | Installation Manual Introduction | en 9

2.2 Enclosure Chassis

2.2.1 Chassis Overview

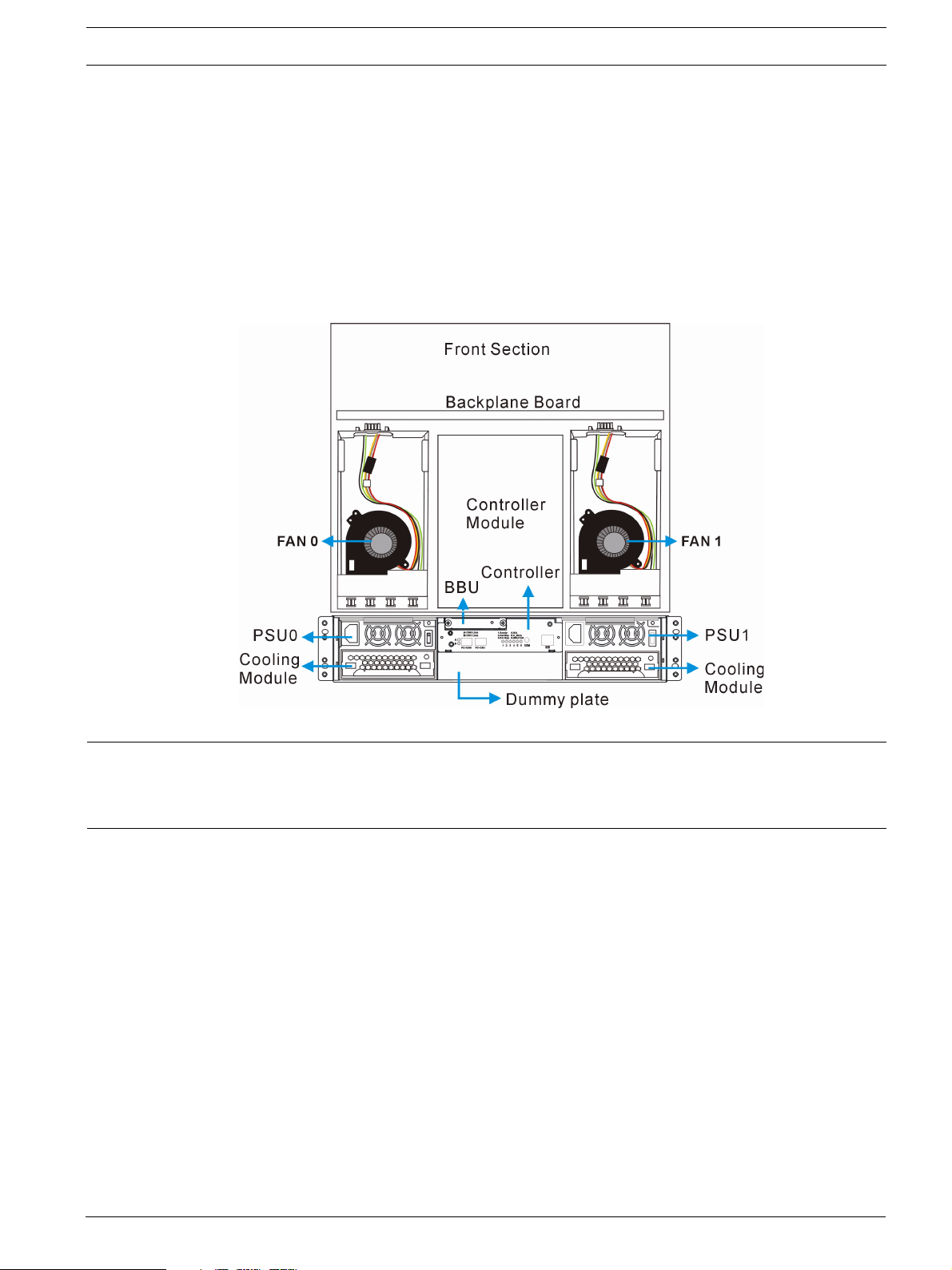

The RAID subsystem comes in a 2U metal chassis. A backplane board divides the enclosure

internally into front and rear sections. The front section accommodates eight (8) drive trays

(with their associated hard drives) and the rear section accommodates two (2) PSU modules,

two (2) single-fan cooling modules, and a single RAID controller module. The two (2) forearm

handles on the front of the subsystem enable you to easily insert/extract the chassis into/from

a rack or cabinet. Pre-drilled mounting holes on the sides of the chassis allow you to attach

separately purchased slide rails.

Fig. 2.2 Top View o f the R A I D subs y ste m

CAUTION!

When working with the subsystem, it is important to use tools with extreme care. Do not place

tools or other items on top of the enclosure to help avoid damaging the chassis finish.

2.2.2 Physical Dimensions

The subsystem comes in a standard 2U, 19” chassis with the following dimensions:

• Measured with forearm handles: 482mm x 88mm x 505mm (width x height x depth)

• Measured without forearm handles: 446mm x 88mm x 490mm (width x height x depth)

2.2.3 Front Panel Overview

The front section of the subsystem features a 4 x 2 layout for eight (8) 3.5-inch disk drives and

a foldable LCD keypad panel. The front panels of the RAID subsystems described in this manual are shown in Figure 2.3. A description of the front panel component is given below:

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 10

10 en | Introduction RAID Subsystem DVA-08K | Installation Manual

Fig. 2.3 Front View

The front panel is designed to accommodate the following components:

• Forearm handles with an LCD keypad panel: The LCD Panel mounted on the left handle

shows system information and provides local access to the firmware-embedded configuration and monitoring utility.

• Drive bays with drive tray canisters: The drive bays are used to house the subsystem hard

drives. The DVA-08K contains 8 drive bays with a blank plate covering the lower part of

the front panel.

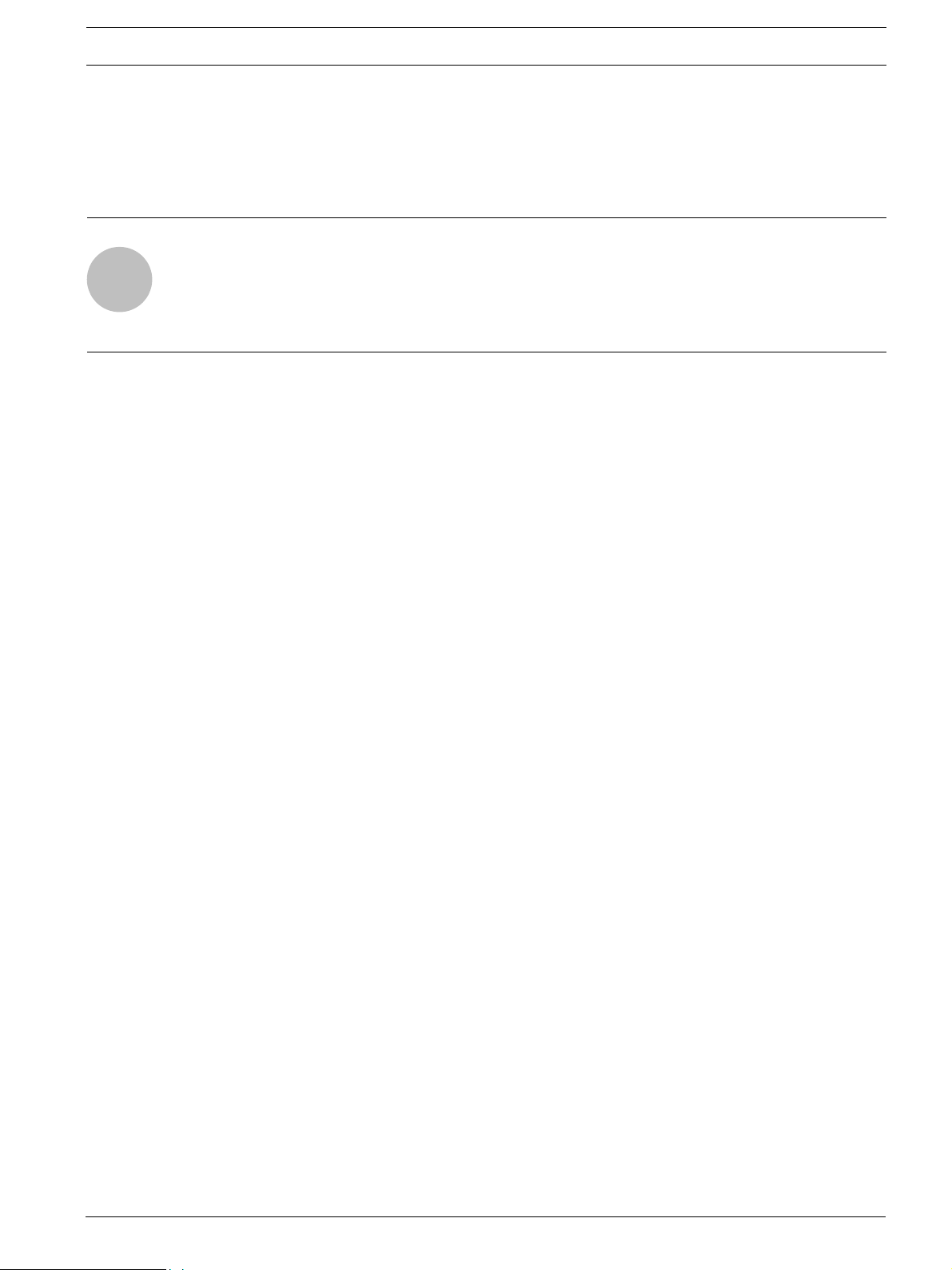

2.2.4 Hard Drive Numbering

The subsystem is housed in an enclosure that is 4 bays wide and 2 bays high. When viewed

from the front, drive bays (slots) are numbered 1 to 8, from the left to the right, and then from

the top to the bottom.

Fig. 2.4 Drive Bays Numbering Sequence

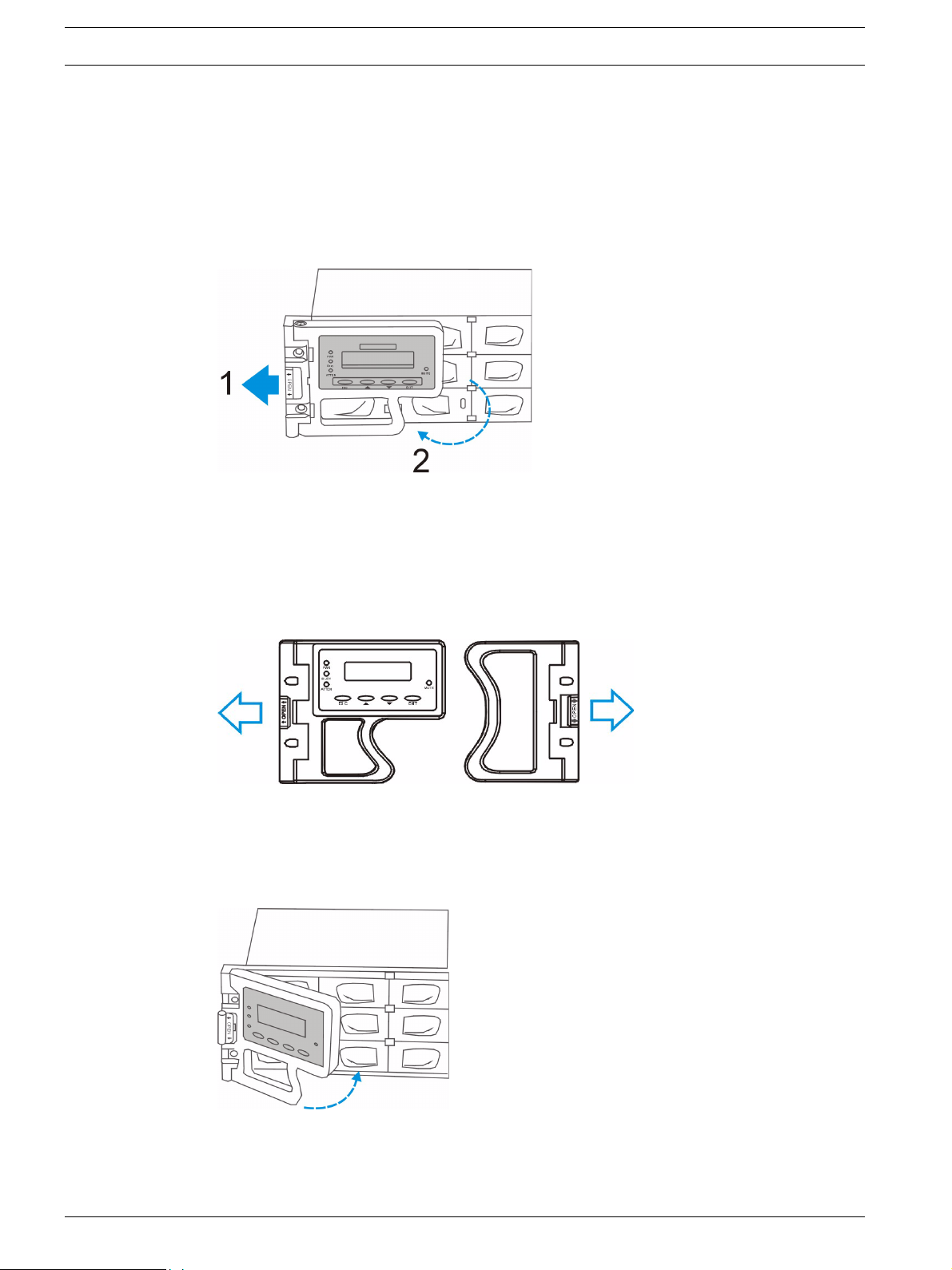

2.2.5 Rear Panel Overview

The rear section of the subsystems are accessed through the rear panel and is reserved for a

single RAID controller module, one (1) battery backup unit (BBU), two (2) power supply units

(PSUs), and two cooling fan modules.

The subsystem rear view is shown in Figure 2.5. A description of the rear panel component is

given in the proceeding discussions:

Fig. 2.5 Rear View

The rear panel shown above is designed to accommodate the following components:

• RAID controller module: The controller module contains a controller main board and a

pre-installed DDR DIMM module.

• Power Supply Unit (PSU): The PSU is used to provide power to the subsystem.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 11

RAID Subsystem DVA-08K | Installation Manual Introduction | en 11

i

• BBU module: A BBU provides the protective implementation to cached data; and, unless

deselected when purchasing the subsystems, is installed into the module slot located at

the upper left corner of the controller module.

• Cooling fan module: The redundant cooling fan module is used to ventilate the subsystem

and to reduce the temperature within the subsystem.

NOTICE!

Each of the power supplies on the sides of the enclosure houses one cooling fan module in a

removeable canister. When a power supply is removed, the cooling module is also removed.

Therefore, replace the power supply unit as soon as possible whenever it becomes necessary.

Cooling fan modules can be independently removed from the chassis without affecting PSU

operation.

2.2.6 Backplane Board

An integrated backplane board separates the front and rear sections of the subsystem. The

PCB board provides traces for logic level signal traces and low voltage power paths. It contains no user-serviceable components.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 12

12 en | Introduction RAID Subsystem DVA-08K | Installation Manual

2.3 Subsystem Components

All the active components on the subsystem can be accessed through either the front or rear

panel. The modular design of the active components facilitates their easy installation and

removal. Hot-swap mechanisms are incorporated to eliminate power surges and signal

glitches that might occur while removing or installing these modules.

2.3.1 LCD Panel

Fig. 2.6 Opening the Front Handle

The LCD panel shown in Figure 2.6 consists of a 16 characters x 2 rows LCD screen with push

buttons, a mute button, and LED status indicators. The LCD front panel provides full access to

all array configurations and monitoring. After powering up the subsystem, the initial screen

will show the subsystem model name. A different name can be manually assigned to the subsystem or different drive arrays. This will enable easier identification in a topology consisting

of numerous arrays.

Fig. 2.7 Front Panel Retention Latch

To access drive bays in the left- or right-hand side column, first flip the retention latches (see

Figure 2.7) on the enclosure front handles, and then swing the handles to the left- and righthand sides. To close the handles (see Figure 2.8), swing the handles toward the system; gently press the handles until a click is heard. The latches will keep the handles in place.

Fig. 2.8 Closing the Front Handles

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 13

RAID Subsystem DVA-08K | Installation Manual Introduction | en 13

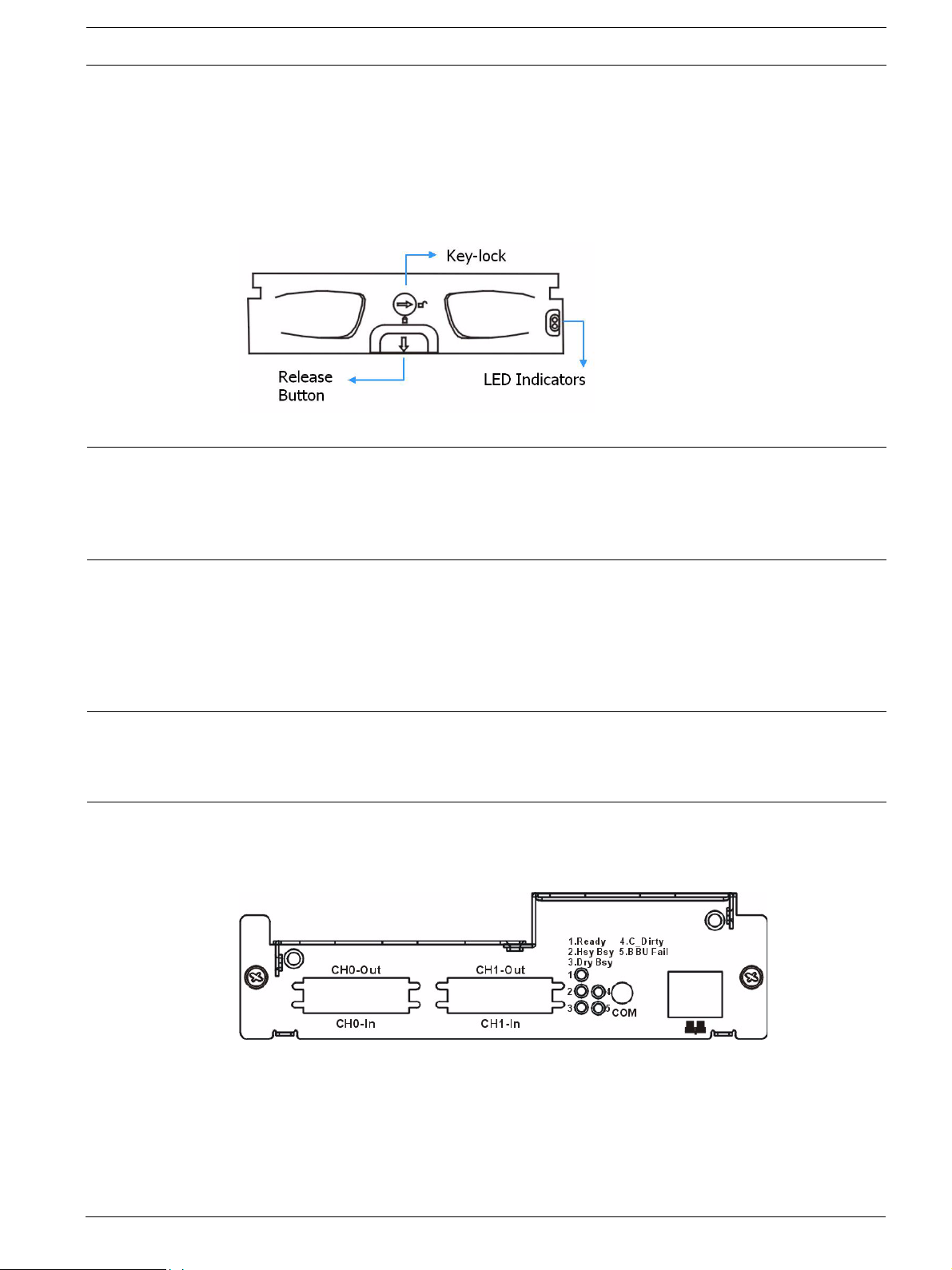

2.3.2 Drive Trays

The subsystem comes with 8 drive trays (see Figure 2.9) designed to accommodate separately

purchased standard 1-inch pitch, 3.5-inch disk drives. The drive bays are accessed from the

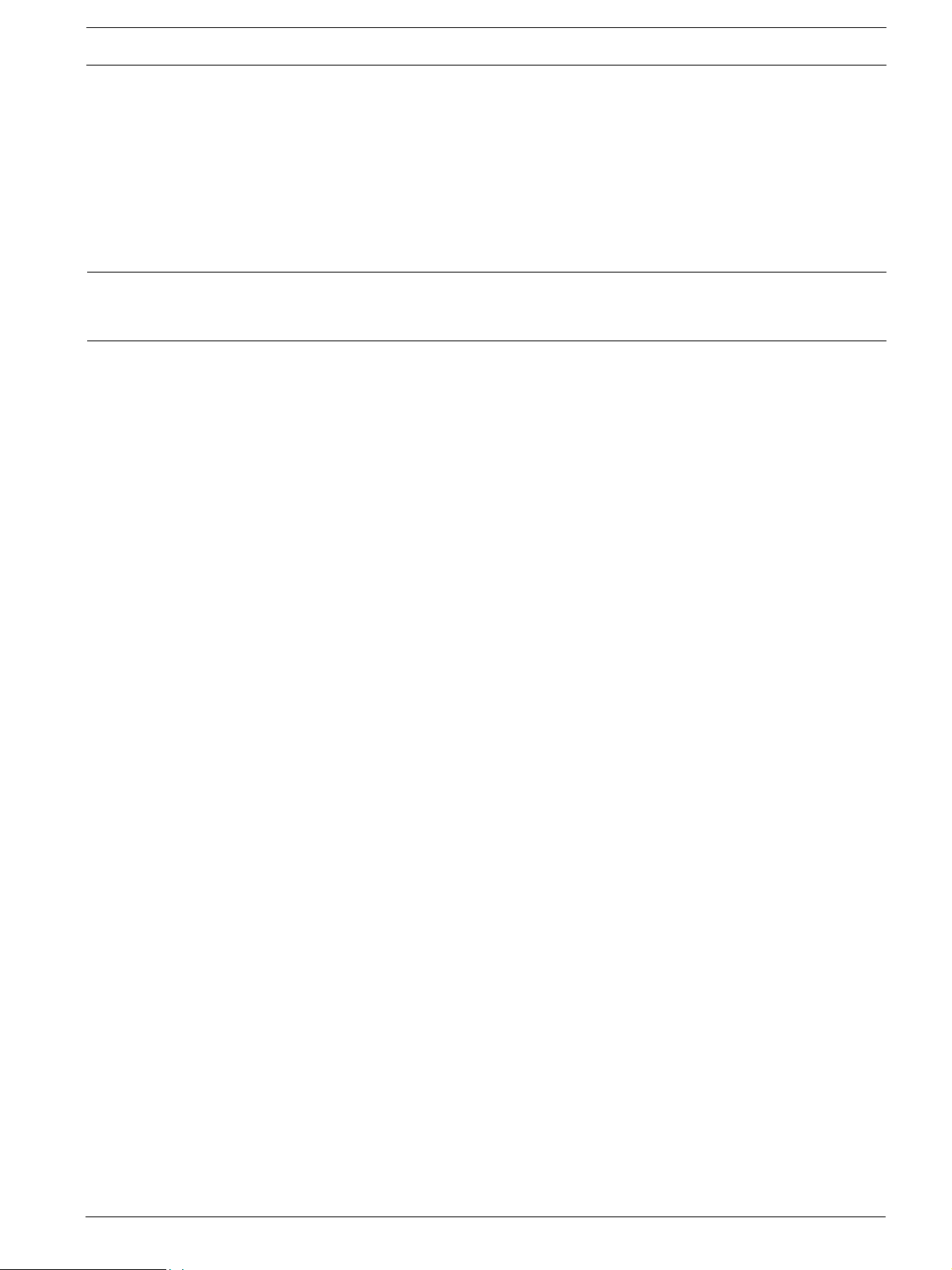

enclosure front. Two LED’s on the front of the tray are used to indicate the drive status. A keylock on each drive tray secures the hard drive in place, while an easily accessible release button ensures fast and efficient drive hot-swapping.

Fig. 2.9 Drive Tray Front View

CAUTION!

Be careful not to warp, twist, or contort the drive tray in any way (e.g., by dropping it or resting heavy objects on it). The drive tray has been customized to fit into the drive bays in the

subsystem. If the drive bay superstructure is deformed or altered, the drive trays may not fit

into the drive bay.

2.3.3 The RAID Controller Module

The RAID controller module contains a main circuit board, a preinstalled 256MB capacity or

above DDR RAM DIMM module, and the necessary support interfaces. The controller module

contains no user-serviceable components. Except when replacing a faulty unit or installing/

upgrading the cache memory inside, the controller module should never be removed or

opened.

CAUTION!

Although the RAID controller can be removed, the only time you should touch the controller

itself is to replace the memory module or to install the memory module. The RAID controller is

built of sensitive components and unnecessary tampering can damage the controller.

Controller Module Interfaces

The subsystems provide external interfaces to host computers and management station(s)

through the RAID controller’s rear-side faceplate as shown in Figure 2.10.

Fig. 2.10 Controller Module Faceplate

• Host Ports

SCSI-320 Host Ports: Two SCSI-320 host channels connect the subsystem to the host

computers equipped with SCSI-320 compatible adapters through the dual-stack VHDCI

connectors. The dual-stack connectors facilitate cascade connections for configurations

such as host clustering or cascading with another RAID subsystem.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 14

14 en | Introduction RAID Subsystem DVA-08K | Installation Manual

i

NOTICE!

This subsystems come with preset configurations for channel mode and channel ID settings,

and should be sufficient for most applications.

• Ethernet Port

All controller modules on the subsystems come with a single 10/100BasedT RJ-45 Ethernet port. The Ethernet port is used for local or remote management through the network

using the Bosch RAIDWatch GUI manager or Telnet protocol.

• COM Port

All controller modules come with one RS-232C (audio jack) serial port. The serial port is

used for local access to the system-embedded configuration utility over the included

serial port cable.

DIMM Module

The controller module comes with a preinstalled 256MB capacity or above DDR RAM DIMM

module and can support a larger capacity up to 2GB. The DIMM module is mounted in an easily accessible location on the controller board. However, when the DIMM module is being

changed, the controller module must be removed from the subsystem chassis.

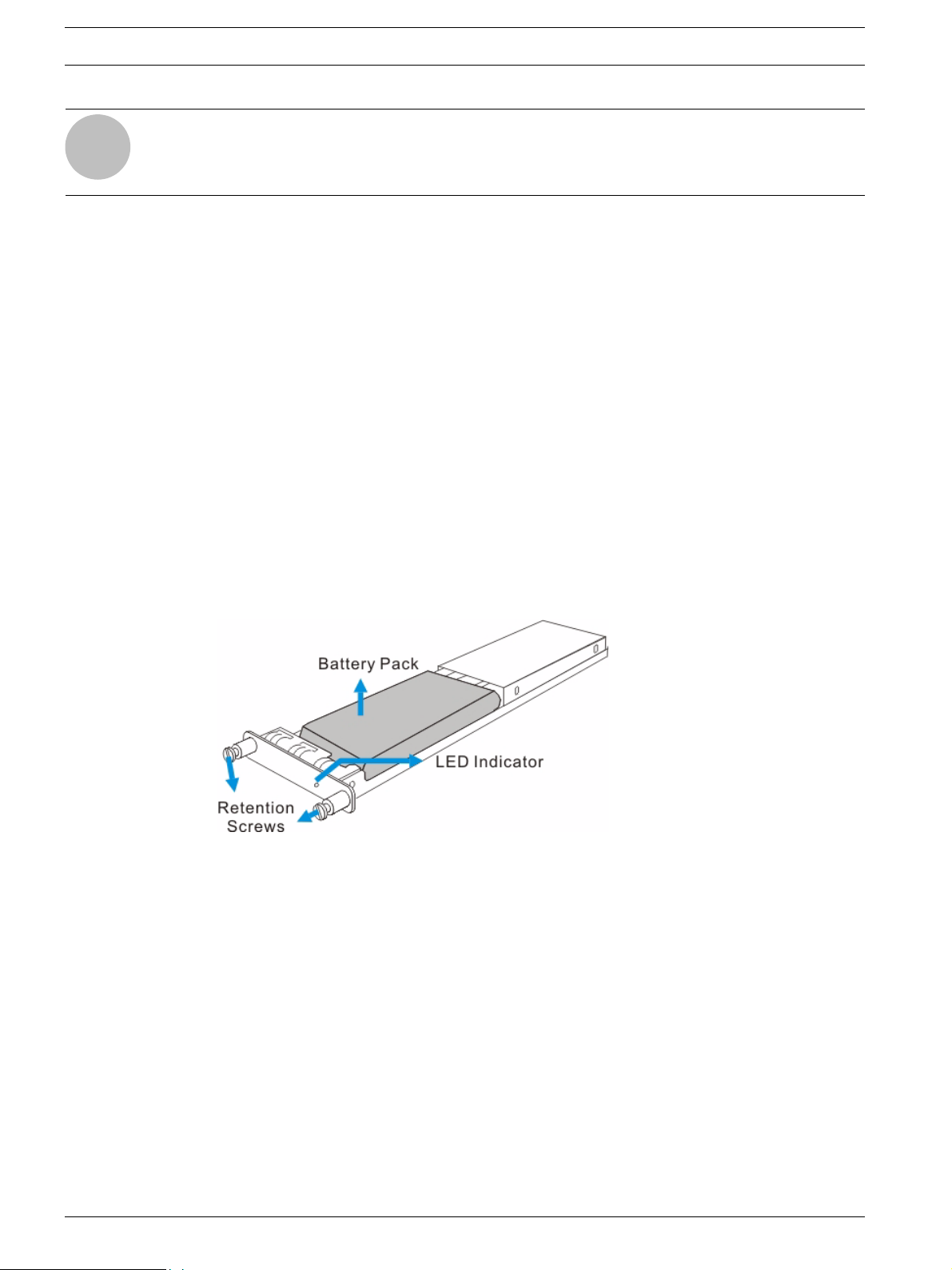

2.3.4 Battery Backup Unit

The Li-ION battery backup unit (BBU) module sustains cache memory for days after a power

failure. It is installed on the upper left corner of the controller module in the rear of subsystem

chassis. Please refer to Section 3 Hardware Installation for installation details.

Fig. 2.11 BBU Module

In accordance with international transportation regulations, the BBU module is only charged

to between 35% and 45% of its total capacity when shipped. Therefore, when powering on the

subsystem for the first time the BBU will begin to charge its batteries to their full capacity. It

normally requires approximately twelve (12) hours for the battery to be fully charged. If the

battery is not fully charged after twelve (12) hours (its LED is still flashing), there is a problem

with the BBU module and you should contact your subsystem vendor immediately. While the

battery is being charged, the LED on the BBU rear panel and the fifth LED on the controller

module will flash.

You can check the status of the battery’s charge via Bosch RAIDWatch Manager or the firmware utility screen.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 15

RAID Subsystem DVA-08K | Installation Manual Introduction | en 15

i

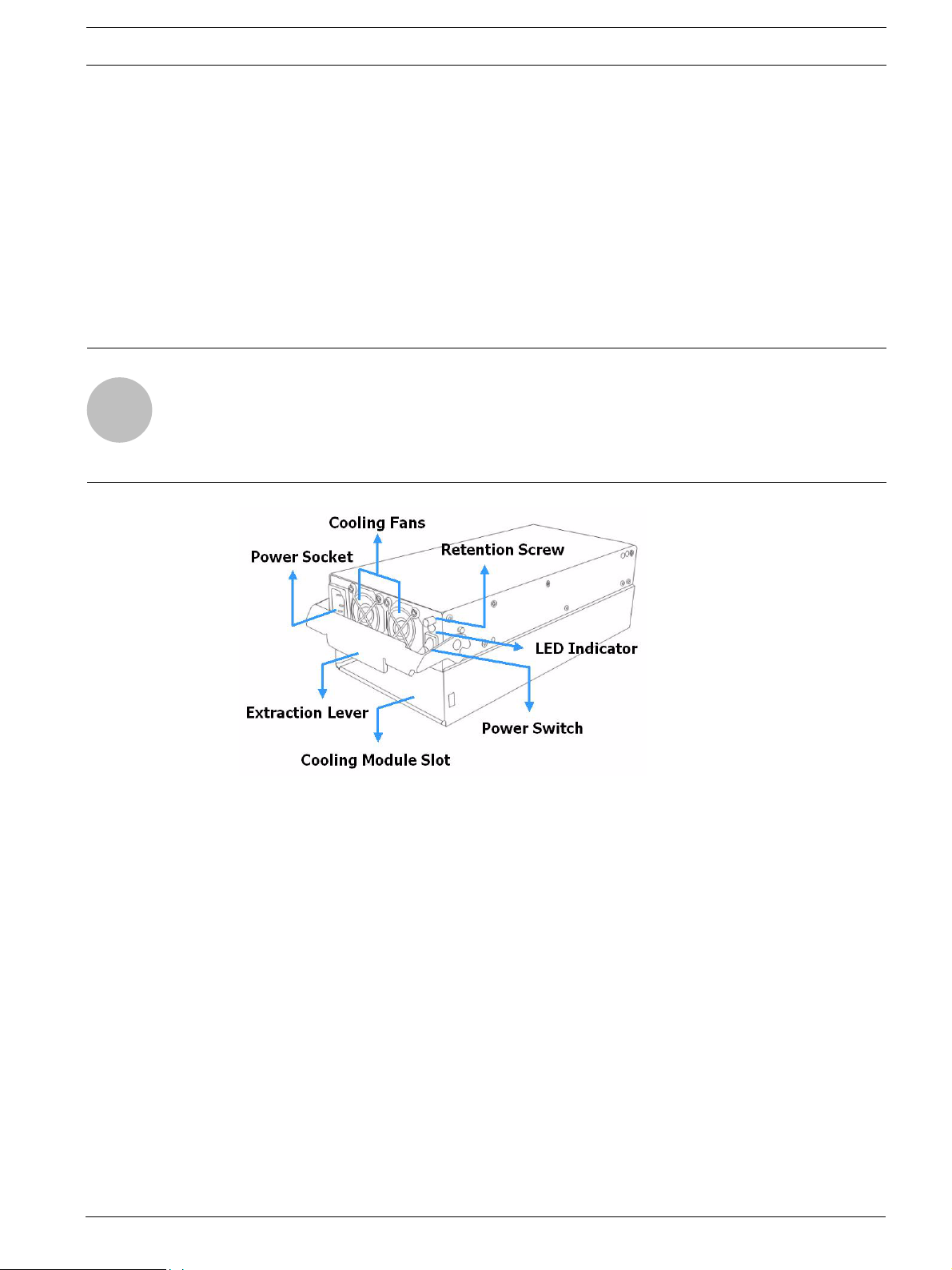

2.3.5 Power Supply Units

The SATA-based RAID subsystems are equipped with two (2) redundant, hot-swappable, 2U,

350W power supply unit (PSUs) modules. The PSU is permanently mounted into a 2U high

(dual-level) bracket especially designed to house both the PSU and a cooling module mounted

underneath. PSUs can be found on either side of the controller module.

Each PSU comes with a single power socket for power cord plug-in and a single power switch

for you to turn the PSU on and off. Each PSU also comes with two embedded cooling fans to

provide sufficient airflow to keep the PSU cool. A single LED is used to indicate the PSU status. A handle at the back of the PSU has been especially designed to enable you to remove the

PSU from the subsystem while the system is still online. This should only be done if the PSU

has failed and needs to be replaced.

NOTICE!

Hot-swapping the PSU also removes the cooling module at the lower slot.

A retention screw at the upper right corner of the PSU module is used to secure the PSU to

the enclosure. If the PSU needs to be removed, the retention screw must be removed first.

When installing a new PSU module, make sure that the retention screw has been firmly

secured.

Fig. 2.12 PSU Module

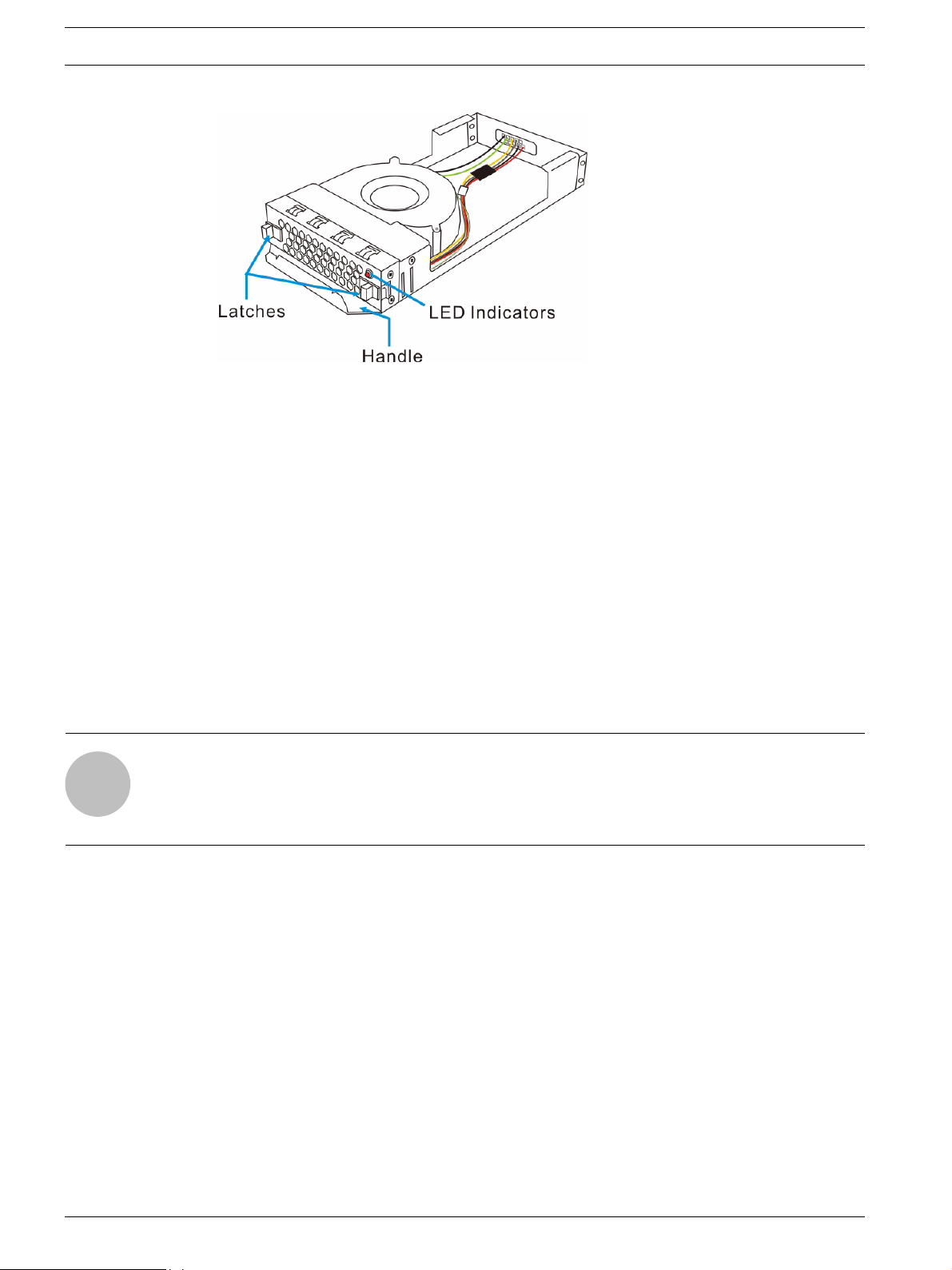

2.3.6 Cooling Fan Modules

The SATA-based RAID subsystem is equipped with two 1U single-fan, redundant, hot-swappable cooling modules shown in Figure 2.13. One 9.7cm fan is housed in each cooling module.

These modules have been designed to generate a cooling flow from the front to the rear of the

subsystem to extract the heat generated by the SATA hard drives. Two of the cooling fan modules are installed directly beneath the PSUs.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 16

16 en | Introduction RAID Subsystem DVA-08K | Installation Manual

i

Fig. 2.13 Top View of a Cooling Fan Module

Advanced Fault-Preventative Operation

The cooling fan modules support dual-speed operation modes that help to protect the subsystem in the event of component failure or extreme working condition.

Intelligent Dual Speed Operation

The cooling fans operate with two rotation speeds. Under normal operating conditions, the

cooling fans run at the low speed, which is sufficient for maintaining efficient airflow across

components. Under the following conditions, cooling fans raise their rotation speed to

increase the airflow:

1. Component Failure: if another cooling fan module, a PSU, or a temperature sensor fails,

the remaining cooling fan(s) automatically raises its rotation speed.

2. Elevated Temperature: if the temperature breaches the upper threshold set for any of the

interior temperature sensors, the cooling fans automatically raises its rotation speed.

3. During the subsystem initialization stage, the cooling fans operate at the high speed and

return to lower speed once the initialization process is completed and no erroneous condition is detected.

NOTICE!

There are two values set for the upper temperature thresholds. One is set for event notification and the other triggering higher fan rotation speed. The preset value for event notification

can be changed using the firmware-embedded configuration utility, while the fan speed trigger is not a user’s option.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 17

RAID Subsystem DVA-08K | Installation Manual Introduction | en 17

2.4 Subsystem Monitoring

The SATA-based RAID subsystem comes with a number of different monitoring methods that

provide you with continual updates on the status of the system and individual components.

The following monitoring features are included in the subsystem.

2.4.1 I2C Bus

The following subsystem elements are interfaced to the RAID controller over a non-user-ser-

viceable I2C bus:

• Cooling fan modules

• PSUs

• Temperature sensors

2.4.2 LED Indicators

The following active components come with LEDs to indicate the status of the individual components:

• RAID controller

• LCD panel

• Cooling fan module

• PSU module

• BBU module

• Drive trays

2.4.3 Firmware and Bosch RAIDWatch GUI

Firmware: The firmware is pre-installed software that is used to configure the subsystem. The

firmware can be accessed either through the LCD keypad panel or a terminal emulation program running on a management computer that is connected to the subsystem’s serial port.

Bosch RAIDWatch: Bosch RAIDWatch is a premier Web-based graphical user interface (GUI)

that can be installed on a remote computer and is used to access the array through LAN or the

Internet. The manager communicates with the array via the connection of the existing host

interface or Ethernet link to the RJ-45 LAN port.

2.4.4 Audible Alarms

The subsystems come with audible alarms that are triggered when certain active components

fail or when certain (controller or subsystem) thresholds are exceeded. If you hear hastily

repeated beep tones from the subsystems it is imperative that you immediately determine and

rectify the problem.

Event notification messages indicate the completion of or the condition when proceeding with

array configuration tasks and are always accompanied by two or three successive and prolonged beeps.

CAUTION!

Failing to respond when a critical alarm is heard can lead to permanent damage of the subsystem. When an audible alarm is heard, rectify the problem as soon as possible.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 18

18 en | Introduction RAID Subsystem DVA-08K | Installation Manual

2.5 Hot-Swappable Components

2.5.1 Hot-Swap Capabilities

The subsystem comes with a number of hot-swappable components. A hot-swap component

is one that can be exchanged while the subsystem is still online without affecting the operational integrity of the subsystem. These components should only be removed from the subsystem when they are being replaced. At no other time should these components be removed

from the subsystem.

2.5.2 Components

The following components are all hot-swappable:

• Power supply units (PSUs)

• Cooling fan modules

• Hard drives

• BBU module

2.5.3 Normalized Airflow

Proper subsystem cooling is referred to as “normalized” airflow. Normalized airflow ensures

the sufficient cooling of the subsystem and is only attained when all components are properly

installed. Therefore, a failed component should only be hot-swapped when a replacement is

available. If a failed component is removed but not replaced, permanent damage to the subsystem can result.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 19

RAID Subsystem DVA-08K | Installation Manual Hardware Installation | en 19

3 Hardware Installation

This chapter gives detailed instructions on how to install the subsystem. When installing the

subsystem, it is necessary to mount the chassis into a rack or cabinet and to install hard

drives and drive trays. Installation into a rack or cabinet should occur before the hard drives or

drive trays are installed into the subsystem. Please confirm that you received all of the components listed on the Unpacking List that came with the subsystem before proceeding with the

installation process.

CAUTION!

Please note that the installation instructions described in this chapter should be carefully followed to prevent any difficulties and damages to your system.

3.1 Installation Prerequisites

• Static free installation environment: The subsystems must be installed in a static-free

environment to minimize the possibility of electrostatic discharge (ESD) damage. (See

Section 1 Warnings and Certifications).

• Component check: Before installing the subsystems, you should first check to see that

you have received all the required components. If any items appear damaged, contact

your vendor for a replacement.

• Hard drives: Hard drives must be purchased separately prior to the subsystem installa-

tion.

• Cabling:

– The subsystems requires an external VHDCI-to-VHDCI SCSI round cable to connect

the subsystem to a host computer.

– One (1) audio-jack-to-DB9 cable is provided to facilitate the connection of the COM1

port for local terminal emulation access to the array.

– Two (2) power cords are provided for the power connections to the power sources.

– The RJ-45 Ethernet cable for network management connection is a user-supplied

item.

• Memory module: If you wish to change the pre-installed memory module, a separately

purchased module must be installed. Please contact your vendor for a different memory

module or consult the list of compatible modules.

• Rack installation: The enclosure chassis can be installed into a rack cabinet using self-

purchased mounting rails. A printed copy of installation guide is provided with the slide

rails package.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 20

20 en | Hardware Installation RAID Subsystem DVA-08K | Installation Manual

3.2 Safety Precautions

3.2.1 Precautions and Instructions

• Be sure the correct power range (100-120 or 220-240VAC) is supplied by your rack cabi-

net, UPS device, or power outlet.

• Thermal notice: All drive trays (even if they do not contain a hard drive) must be installed

into the enclosure. Leaving a drive bay or module slot open will severely affect the airflow

efficiency within the enclosure, and will consequently lead to system overheating. Keep a

faulty module in place until you have a replacement unit and you are ready to replace it.

• An enclosure without disk drives can weigh over 25 kilograms. Two (2) people are

required to install or relocate the subsystem. To avoid damage to disk drives, drives

should be removed from the enclosure before moving the subsystem.

• Handle the system modules by the retention screws, extraction levers, or the modules

metal frames/faceplates only. Avoid touching the PCB boards, connector pins, and soldered surfaces.

• Airflow considerations: The subsystem requires an airflow clearance especially on the

front and rear. For proper ventilation, a minimum of 2.5cm is required between the front

of the enclosure and rack cover; a minimum of 5cm is required between the enclosure

and end of the rack.

• None of the covers or replaceable modules should be removed in order to maintain com-

pliance with safety, emission, or thermal requirements.

• Always secure every enclosure module by its retaining screws or make sure it is held in

place by its latches.

• Always make sure the subsystem has a safe electrical earth connection via power cords

or chassis ground by the rack cabinet.

• Be sure that the rack cabinet in which the subsystem chassis is to be installed provides

sufficient ventilation channels and airflow circulation around the subsystem.

• Provide a soft, clean surface to place your enclosure on before working on it. Servicing

the enclosure on a rough surface may damage the finish of the chassis.

• If it is necessary to transport the subsystem, repackage all disk drives separately. If using

the original package material, all other modules can stay within the enclosure.

3.2.2 Static-Free Installation

The subsystem contains static-sensitive electronic components that can be damaged by

improper handling and electrostatic discharge (ESD). To prevent ESD damage to any of the

components, follow these precautions before touching or handling them:

• Discharge the static electricity from your body by wearing an anti-static wristband or by

touching a grounded metal surface.

• Avoid carpets, plastic, vinyl, and styrofoam in your work area.

• Handle all components by holding their edges or metal frame. Avoid touching PCB boards

and connector pins.

3.2.3 BBU Warnings and Precautions

The BBU module sustains cache memory in the event of a power failure or in the unlikely event

if both PSUs have failed. Having the protection to cached data by a BBU is highly recommended. The BBU provides additional data security and helps minimize the chance of data

loss during power outage.

• Replace the BBU once it shows symptoms failing to hold the charge. Although the life

expectancy of a BBU is determined by the times it has been charged or discharged, a BBU

can approximately last for one year. If the battery recharge time is obviously longer than

the suggested 12 hours, or if the fault LED is lit, replace the battery.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 21

RAID Subsystem DVA-08K | Installation Manual Hardware Installation | en 21

• Install or replace the BBU module only with a BBU module supplied by your subsystem

vendor. Use of battery cells provided by another source will void our warranty.

• Always dispose of discharged or used batteries in an ecologically responsible manner.

Dispose used BBUs at authorized battery disposal sites only.

• Do not use nor leave the BBU near a heat source or direct sunlight. Heat can melt the

insulation and damage other safety features of battery cells, possibly leading it to acid

leak and result in flames or explosion.

• Do not immerse the BBU in water nor allow it to get wet. Its protective features can be

damaged. Abnormal chemical reactions may occur, possibly causing functional defects,

acid leak, and other hazardous results.

• Do not disassemble or modify the BBU. If disassembled, the BBU could leak acid, over-

heat, emit smoke, burst and/or ignite.

• Do not pierce the BBU with a sharp object, strike it with a hammer, step on it, or throw it.

These actions could damage or deform it, internal short-circuiting can occur, possibly

causing functional defects, acid leaks, and other hazardous results.

• If the BBU leaks, gives off a bad odor, generates heat, becomes discolored or deformed,

or in any way appears abnormal during use, recharging or storage, immediately remove it

from the subsystem and stop using it. If this is discovered when you first use the BBU,

return it to Bosch or your system vendor.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 22

22 en | Hardware Installation RAID Subsystem DVA-08K | Installation Manual

i

3.3 General Installation Procedure

The following instructions can save installation time. Detailed, illustrated instructions for each

component are given in the following sections.

CAUTION!

To ensure that your system is correctly installed, please follow the steps outlined below. If you

follow these steps, installation will be fast and efficient. If you do not follow these steps, you

may have incorrectly installed the hardware.

1. Unpack: Unpack the subsystem and confirm that all the components on the Unpacking

Checklist have been included.

2. Rack/Cabinet installation: If the subsystem is going to be installed in a rack or cabinet, it

should be installed prior to installing the hard drives. Installing the subsystem into a rack

or cabinet requires at least two (2) people.

3. Install drive trays: After the hard drives have been installed into the drive trays, the drive

trays must be installed into the enclosure itself. (See Section 3.6 Drive Tray Installation)

4. Cable connection: Use the power cords that came with the subsystem to connect the

subsystem to the main power source. Use self-purchased SCSI cable to connect host

ports to servers.

5. Power up: Once the components have been properly installed and all cables are properly

connected, you can power up the subsystem and configure the RAID array. (See

Section 5.4 Power On)

3.3.1 Installation Procedure Flowchart

Table 3.1 shows a flowchart of the installation procedure. As you complete each step, check

off the “Done” box on the right. Please use this flowchart in conjunction with the instructions

that follow.

Step Installation Procedure Done

1Unpack See Section 3.4 Unpacking the Subsystem

3 Rack/Cabinet Installation See Section 3.5 Rackmounting

5 Drive Tray Installation See Section 3.6 Drive Tray Installation

6 Cable Connection

7Power On See Section 5.4 Power On

Tab le 3 .1 Installation Procedure Flowchart

3.4 Unpacking the Subsystem

Use the unpacking checklist in your package to check packing contents. Carefully check the

items contained in each box before proceeding with installation.

NOTICE!

A detailed packing list can be found in your product shipping package or product CD.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 23

RAID Subsystem DVA-08K | Installation Manual Hardware Installation | en 23

3.5 Rackmounting

The subsystem is easily installed into a standard 19-inch rack cabinet using the mounting

holes on the sides of chassis.

The enclosure chassis can be installed using self-purchased mounting rails.

3.5.1 Considerations for Installation Site and Chassis

• Make sure you have an appropriate site location and cables prepared with adequate

lengths to connect to main power and other devices.

• At least two people will be required to install the chassis. Disk drives should only be

installed after the chassis is properly mounted. The chassis can weigh about 24Kgs without disk drives.

• The following tools are necessary for mounting the chassis:

– #4 Phillips-head screwdriver

– Wrenches may be necessary, depending on the rack type

• Use the included M5 or M6 screws for securing the chassis through its front mounting

ears.

• More details about the use of optional slide rails are given in the Installation Guide that

came with the slide rail package.

3.5.2 Mounting Holes Positions

• Integrators may design their own brackets or slide rails using the twenty-two (22) mount-

ing holes on the sides of chassis.

• There are six (6) mounting holes with six (6) M4 nuts near the end of the chassis on each

side. Shown below are the locations of these mounting holes. (See the arrow marks in

Figure 3.2). See the next diagram for another group of mounting holes on a horizontal

line.

Fig. 3.1 Enclosure Side Mounting Holes (1)

• Figure 3.2 shows holes that are designed for slide rail options. There are five (5) mount-

ing holes for #6-32 screws on the sides of the enclosure for use with slide rails purchased

separately from Bosch or other vendors.

• For information on installing the chassis using the slide rails, please refer to the Installa-

tion Manual that came with the kit.

Fig. 3.2 Enclosure Side Mounting Holes (2)

• Use M5 or M6 pan-head screws to secure the chassis to the front cabinet posts.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 24

24 en | Hardware Installation RAID Subsystem DVA-08K | Installation Manual

3.6 Drive Tray Installation

Once the hard drives have been installed in the drive trays, the drive trays can be installed into

the subsystem.

WARNING!

All drive trays must be installed into the enclosure even if they do not contain a hard drive. If

the trays are not installed into the enclosure, the ventilation required for cooling will be disturbed and the subsystem will overheat.

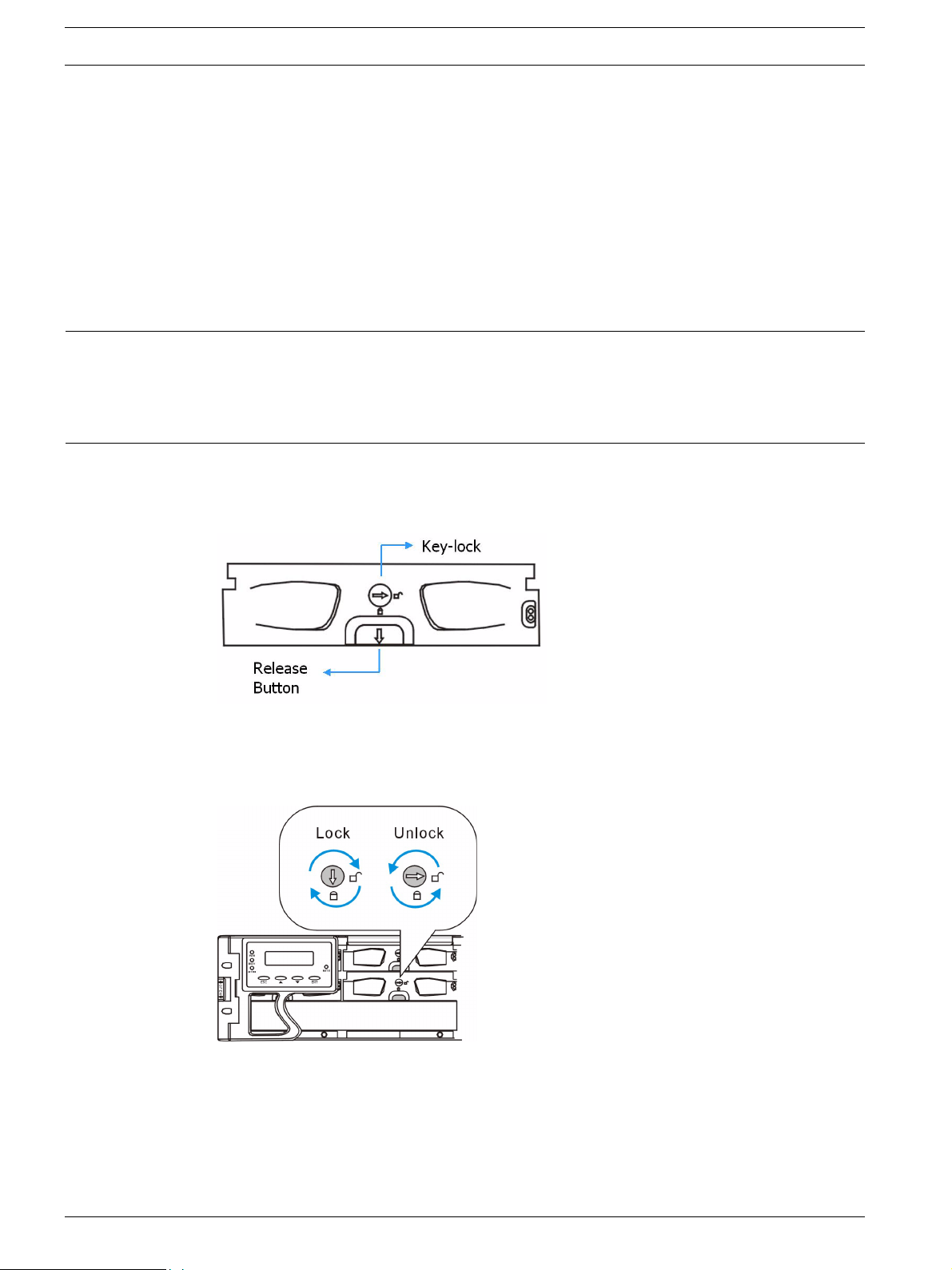

1. Make sure that the hard drive is secured to the drive tray. Make sure the key-lock is in the

unlocked position. The key-lock is unlocked if the groove on its face is in a horizontal orientation. If the groove is in a vertical position, as shown in Figure 3.3, then the key-lock is

locked and the front flap on the drive tray cannot be opened.

Fig. 3.3 Front View of an Individual Drive Tray

2. Open the front flap on the drive tray. (See Figure 3.4). To open the flap, push the release

button on the front bezel. The front flap will open in an upward direction.

Fig. 3.4 Opening Drive Tray Front Flap

3. Align the drive tray with the slot in which you wish to insert it. Make sure that it is resting

on the rails inside the module slot. Once the drive tray is lined up with the slot, gently

slide it in. This should be done smoothly and gently.

4. Close the front flap on the drive tray. Make sure the front flap is closed properly. Closing

the front flap ensures that the drive tray is firmly connected to the corresponding connector on the backplane board. If the front flap is not closed properly, the connection

between the HDD and the subsystem will not be secure. DO NOT slam the drive tray into

place! The connector pins might be damaged. If the front flap is not closed properly, the

connection between the hard drive and the subsystem will not be secure.

5. Lock the flap into place by turning the key-lock until the groove on its face is pointing

down (vertical orientation). (See Figure 3.5)

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 25

RAID Subsystem DVA-08K | Installation Manual Hardware Installation | en 25

Fig. 3.5 Drive Tray Key-lock Rotation

6. Once all drive trays are installed, the RAID subsystem will poll the drive channels and recognize the drives and scan them in automatically.

7. When powered up, you should check the LEDs on drive bezels to ensure all drives are

receiving power and are functional. All drive LEDs should be solid green after the initialization stage.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 26

26 en | Subsystem Monitoring RAID Subsystem DVA-08K | Installation Manual

4 Subsystem Monitoring

This chapter provides information on how to monitor the subsystem.

4.1 Subsystem Monitoring Overview

The subsystem is equipped with a variety of self-monitoring features that help to keep subsystem managers informed of the subsystem operational status. These monitoring features provide vital feedback to help you maintain the operational integrity of the subsystem. Prompt

response to warnings and subsystem component failure notifications will ensure safe operation of the subsystem and help ensure the longevity of the subsystems.

Self-monitoring features include:

• Firmware (FW): The RAID controllers in the subsystems come with pre-installed FW. The

FW can be accessed using either the LCD keypad panel or a PC running terminal software

through the RS-232C (audio jack) serial port. Device status information can be obtained

from the FW.

• Bosch RAIDWatch: Bosch RAIDWatch is a fully integrated Java based Graphical User

Interface (GUI) that came with the subsystem and can be used to monitor and maintain

the subsystem using web browsers. Connection to a Bosch RAIDWatch station is made

using the existing Ethernet ports.

• The Bosch RAIDWatch Panel View can be customized to show a direct, graphical repre-

sentation of the subsystem in the content panel of the Bosch RAIDWatch screen. Panel

View allows you to quickly determine the operational status of critical components.

• Configuration Client: The powerful Configuration Client sub-module can be used to keep

you informed of system events via a variety of communication methods like email, LAN

broadcast, fax, pager, MSN messenger, ICQ, and SMS. The sub-module runs as an independent program from Bosch RAIDWatch main program. The Configuration Client helps

prevent blind time and keeps you constantly informed as to the status of the storage

management subsystem.

• LEDs: Device-status-indicating LEDs are placed on all of the subsystems’ active compo-

nents. These LEDs inform you of the integrity of a given component or a given link. You

should become familiar with the different LEDs on the subsystem and be aware of their

functions. (See Figure 4.2)

• Audible Alarm: An audible alarm is present on the subsystem controller board and will be

triggered if any of a number of threatening events occurred. These events usually jeopardize the functional and operational integrity of the controller board and must be heeded

at all times. Events such as a breaching of the temperature threshold will trigger the

alarm and if an onsite subsystem manager is present, the manager should, using either

the LCD panel or the PC hyper-terminal, determine the cause of the alarm and take the

appropriate corrective measures. (See Figure 4.3)

• Inter-Integrated Circuit (I

ing modules, sensors for RAID controller board/backplane temperature and voltage read-

ings.

Subsystem monitoring is a necessary part of subsystem management. If failure events or other

disruptive events are detected and reported, the subsystem managers must take the appropriate action to rectify the problem. Failure to act in a properly specified manner to a system

event (like overheating) can cause severe and permanent damage to the subsystem.

2

C): The I2C bus monitors the operational integrity of the cool-

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 27

RAID Subsystem DVA-08K | Installation Manual Subsystem Monitoring | en 27

4.2 Status-indicating LEDs

4.2.1 Brief Overview of the LEDs

The following devices come with LEDs that inform subsystem managers about the operational

status of the component on which they are mounted. The RAID subsystem features statusindicating LEDs distributed over the active components in the following ways:

Component LED(s) per Unit Total LEDs Definition

Drive Trays 216See Section 4.2.2 Drive Tray

LEDs

Controller Module 55See Section 4.2.3 Controller

Module LEDs

Ethernet Ports 22See Section 4.2.4 Ethernet

Port LEDs

BBU Module 11See Section 4.2.5 BBU Module

LED

PSU Module 12See Section 4.2.6 PSU LED

LCD Keypad Panel 33See Section 4.2.7 LCD Keypad

Panel

Cooling Fan Module 12See Section 4.2.8 Cooling Fan

Module LED

Table 4.1 LED Distribution

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 28

28 en | Subsystem Monitoring RAID Subsystem DVA-08K | Installation Manual

4.2.2 Drive Tray LEDs

Two LED indicators are located on the right side of each drive tray. (See Figure 4.1) Refer to

Table 4.2 for LED definitions. When notified by a drive failure message, you should check the

drive tray indicators to find the correct location of the failed drive. Replacing the wrong drive

can cause fatal failure of a logical array.

Fig. 4.1 Drive Tray LEDs

LED Name Color Status

Drive Busy Blue ON indicates read/write activity on the drive.

Power Status Red/

Green

Table 4.2 Drive Tray LED Definitions

4.2.3 Controller Module LEDs

The rear-facing faceplate of the RAID controller module is shown in Figure 4.2. The rear-facing

faceplates on the two models look identical. The LEDs are numbered from 1 to 5. There are

two more LEDs on the Ethernet port. The definitions are shown in Table 4.3 below.

Fig. 4.2 Controller Faceplate

OFF indicates there is no read/write activity on the drive.

GREEN indicates that power is being supplied to the drive.

OFF indicates no power is being supplied to the drive or the

drive tray is not properly installed. .

RED indicates drive failure or faults have occurred.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 29

RAID Subsystem DVA-08K | Installation Manual Subsystem Monitoring | en 29

LED Name Color Status

1 Controller Ready Green ON: Indicates controller is active and

operating normally.

FLASHING: Indicates controller initialization is taking place.

OFF: Controller is not ready for operation.

2 Hst_Bsy

(Host Ports Busy)

3 Drv_Bsy

(Drive Busy)

4 C_Dirty

(Cache Dirty)

5 BBU_Fail Amber ON: Indicates the BBU has failed and

Table 4.3 Controller Module LED Definitions

4.2.4 Ethernet Port LEDs

The subsystem comes with a RS-232C audio jack serial port that can be used to assign a permanent IP to the subsystems. After a permanent IP address has been assigned, an Ethernet

cable can be used to connect the RJ-45 Ethernet port to a network hub or router. This enables

you to manage your subsystem locally or remotely over TCP/IP. See Figure 4.3 for the loca-

tions of the two LED indicators on Ethernet port. Refer to Table 4.4 for the LED definitions.

Green FLASHING: Activities on the host ports.

OFF: No activities on the host ports.

Green FLASHING: Activities on the drive side.

OFF: No activities on the drive side.

Amber ON: Indicates that data is currently

being cached in memory or is being

held up by the BBU during a system

power loss.

cannot sustain cached data.

OFF: Indicates the BBU can sustain

cached data in memory.

FLASHING: The BBU is charging.

Fig. 4.3 Ethernet Port Indicators

Name Color Color

Link Status Green ON: Indicates a valid connection to network

LAN Activity Green BLINKING: Indicates active transmissions

Table 4.4 Ethernet Port LED Definitions

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 30

30 en | Subsystem Monitoring RAID Subsystem DVA-08K | Installation Manual

4.2.5 BBU Module LED

The BBU module has an LED on its faceplate. (See Figure 4.4) The function is the same as the

fifth LED on the controller module. The LED is off when the BBU is functioning normally and is

able to sustain the cache memory. The LED flashes to indicate the BBU is currently charging

its battery cells. If the LED is illuminating amber, the unit may have failed. Please contact your

system vendor to verify the problem.

Fig. 4.4 BBU Module LED

4.2.6 PSU LED

Fig. 4.5 PSU LED

Each PSU comes with a single LED located just above the power switch and just below the

retention screw (see Figure 4.5). The LED is used to indicate the operational status of the PSU

module. Please refer to the PSU LED definitions shown in Table 4.5.

Color Status

Flashing Green The power supply has not been turned on. The PSU module LED will

blink when the subsystem is connected to a power source but has not

been turned on.

Static Green The PSU is operating normally and experiencing no problems

Static Red The PSU has failed and is unable to continue providing power to the

subsystem.

OFF The power cord is unplugged or the power cord is plugged but no

power is being supplied from the power source.

Tab le 4 .5 PSU Module LED Definitions

4.2.7 LCD Keypad Panel

The LCD panel located on the front aluminum foldable handle comes with three status LEDs.

The LEDs are marked from top to bottom “PWR,” “BUSY” and “ATTEN” and are clearly seen in

Figure 4.6 below. The definitions of these LEDs are shown in Table 4.6. The mute button can

be used to stop the alarm until the next controller event occurs.

Fig. 4.6 LCD Keypad Pa nel

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 31

RAID Subsystem DVA-08K | Installation Manual Subsystem Monitoring | en 31

i

Name Color Status

POWER Blue ON indicates that power is being supplied to the subsys-

tem.

OFF indicates that no power is being supplied to the subsystem.

BUSY White Flashing indicates that there is activity on the host/drive

channels.

OFF indicates that there is no activity on the host/drive

channels.

ATTENTION Red ON indicates that one or more component failure/critical

events have occurred.

OFF indicates that the subsystem and all its components

are operating normally.

Tab le 4.6 LCD Panel LED Definitions

NOTICE!

The LCD panel ATTEN LED will be turned on during the power up process. The ATTEN LED will

be turned off after the boot up procedure is completed correctly.

4.2.8 Cooling Fan Module LED

The cooling fan module comes with a single status-indicating red LED shown in Figure 4.7.

LED definitions are given in Figure 4.7.

Fig. 4.7 Cooling Fan Module LED

RED Status

OFF The cooling fan module is operating normally.

ON The cooling fan module has failed and must be replaced.

Table 4.7 Cooling Fan Module LED Definitions

The subsystem has a novel approach to stabilizing the temperature within the subsystem:

When the sensors within the enclosure detect critical working conditions, such as high ambient temperature or the failure of any cooling or PSU module, the system will turn the cooling

fans to high speed to extract more heat. Once the ambient temperature cools down to normal

or the faulty module has been replaced, the cooling fans return to normal speed.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 32

32 en | Subsystem Monitoring RAID Subsystem DVA-08K | Installation Manual

i

4.3 Audible Alarm

Different subsystem environmental and operational parameters (i.e., temperature, etc.) have

been assigned a range of values between which they can fluctuate. If either the upper or lower

thresholds are exceeded, an audible alarm will automatically be triggered. The alarm will also

be triggered when an active component of the subsystem fails. If the subsystem manager is

onsite and hears the alarm, the manager will have to read the error message on the LCD

screen or the PC terminal in order to determine what has triggered the alarm. After determining what has occurred, the subsystem manager must take appropriate actions to rectify the

problem.

CAUTION!

When an alarm is triggered, it is necessary for you to determine the problem. If the audible

alarm is ignored and the problem is not rectified, unexpected damages may occur.

4.3.1 Default Threshold Values

NOTICE!

The threshold values listed below are used to trigger a warning event and sound the alarm. A

different value set is reserved for triggering the cooling fans to operate at a high rotation

speed. The fan speed value set is not user-configurable.

Table 4.8 shows the default threshold values for the subsystem. If any of these values are surpassed, the alarm will sound.

Upper Threshold Lower Threshold

+3.3V +3.6V +2.9V

+5V +5.5V +4.5V

+12V +13.2V +10.8V

CPU Temperature 90ºC 5ºC

Board Temperature 80ºC 5ºC

Enclosure Ambient

Temperature

Tab le 4 .8 Default Threshold Values

The controller self-monitoring thresholds in Table 4.8 are the default threshold values. The values set for the subsystem’s ambient temperature are pre-configured before shipping and cannot be changed.

40ºC 0ºC

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 33

RAID Subsystem DVA-08K | Installation Manual Subsystem Monitoring | en 33

i

4.3.2 Failed Devices

The audible alarm will be triggered if any of the following devices fail:

• Cooling fan modules

• PSU modules

• BBU modules

• Hard drives

• Components on the RAID controller

NOTICE!

If the temperature exceeds a preset threshold, the BBU charger circuits will stop charging.

You will then receive a message that says “Thermal Shutdown/Enter Sleep Mode.” When the

temperature falls back within normal range, the battery will resume charging.

4.4 I2C Monitoring

Module presence detection and the general working status of cooling fan and other modules

are monitored through an I2C serial bus. If any of these modules fails, the failure will be

detected and you will be notified via the various methods described above.

Bosch Security Systems F.01U.027.797 | V2 | 2008.08

Page 34

34 en | Subsystem Connection and Operation RAID Subsystem DVA-08K | Installation Manual

5 Subsystem Connection and Operation

This chapter introduces sample topologies, configuration options and server connections for

the RAID subsystems and discusses both the power on and power off procedures.

5.1 Basic Configuration Rules

When you are configuring your storage subsystem, follow these basic rules:

• Using a mix of LVD and legacy devices, such as devices using single-ended signaling, is

not recommended. Use LVD terminators if all your devices support LVD signaling. Please

refer to the documentation provided with your SCSI devices to avoid possible conflicts.

• When selecting the number of hard drives to be included in a logical configuration that

should be presented through the host channels, the transfer rates and the mechanical

performance of the hard disks should be considered. The combined bandwidth of the

two SCSI host channels is 640MB/s, sufficient for most applications. If properly config-

ured, combining subsystems or drive enclosures may increase the number of drives and

help to bring out the most of IOPs performance.

• If you consider cascading multiple enclosures, considerations may include the character-

istics of your I/O load. Select the correct combination of optimization mode and a spe-

cific RAID level.

• An optimal configuration is always a compromise among different factors. For instance, a

large array with many drive members may be more efficient, but the chance of failing a

member is also increased.

• The drives in the same logical array should have the same capacity; it is preferred that all

the drives in the enclosure have the same capacity.

• A spare drive should have a minimum capacity equivalent to the largest drive that is to be

replaced. If the capacity of the spare is less than the capacity of the drive to be replaced,

then the controller will not proceed with the failed drive rebuild.

F.01U.027.797 | V2 | 2008.08 Bosch Security Systems

Page 35

RAID Subsystem DVA-08K | Installation Manual Subsystem Connection and Operation | en 35

5.2 SCSI Connection Overview

The SCSI host ports connect to SCSI-320 host adapters (HBA) that comply with 320MB/s

transfer rate and SCSI-3 protocol, best capable of 64-bit/133MHz PCI operation. Connection

of the subsystem’s SCSI ports is flexible. For example, you may use the two VHDCI ports of a

dual-stacked connector to connect a host channel to two separate, clustered servers. If high

availability or path redundancy software is applied, a total of 4 VHDCI ports are available for