Page 1

Ceiling Mount

PIR Detector with Self-Test

DS938Z

en Installation Guide

Reading Bosch Security Systems, Inc. Product Date Codes

For Product Date Code information, refer to the Bosch Security Systems, Inc.

Web site at: http://www.boschsecurity.com/datecodes/.

© 2012 Bosch Security Systems, Inc. 130 Perinton Parkway Fairport, NY 14450

Page 2

-29°C to +50°C

(-20°F to +120°F )

UL Listed

installations,

the temperature

range is 0°C to +50°C

(+32°F to +120°F)

0 - 95% Relative Humidity

(0 - 85% UL/C-UL Installations)

Changes or modifi cations not expressly approved

by Bosch Security Systems, Inc. can void the user’s

authority to operate the equipment.

UL/C-UL

Perform Walk Test at least once a year.

Use only a Listed limited-power source.

The Listed control unit or a Listed burglary power

supply must provide 4 hours (20 mAh) of standby

power.

Install the unit in accordance with National

Electrical Code NFPA 70 and Part 1 of the Canadian

Electrical code CSA C22.1.

Adjust the microwave range control, if necessary, to

achieve maximum range.

SELV

Connect all wiring to a safety extra-low voltage (SELV) circuit only.

Ligue todas as cablagens apenas a um circuito de segurança de tensão extra baixa (SELV).

Conecte el cableado únicamente a un circuito de seguridad para voltajes muy bajos (SELV).

Alle Drähte sind ohne Ausnahme an Niederspannung anzuschließen.

Sluit alle bedrading uitsluitend aan op een circuit met een extra lage veiligheidsspanning.

Prenez soin de connecter tous les câbles à un circuit à très basse tension de sécurité (TBTS).

Collegare tutti i cavi esclusivamente a un circuito SELV (circuito di sicurezza a bassissima tensione).

EN 50131-2-2 Grade 2

EN 50130-5 Environmental Class II

IP30 IK04 (EN 60529, EN 62262)

7.2 Selecting the Optical Module

1. For ceilings between 8 and 13 ft. (2.4 and 4.0 m) from the fl oor, use

the optical module marked AR8-13. This marking can be found next to

the two optical module tabs.

2. For ceilings between 13 and 18 ft. (4.0 and 5.5 m) high, use the optical

module marked AR13-18.

3. To replace an optical module, push the optical module tabs towards

the center until the module snaps free of the circuit board. Holding the

new module by the tabs, snap the new module into place.

NOTICE!

When replacing the mirror, make sure it is facing the same

direction as before it was removed.

4. Replace the enclosure onto the base.

5. Close cover and turn clockwise to secure.

NOTICE!

Avoid fi ngerprints on the mirrored surfaces. Should the mirrored sur-

faces become soiled or otherwise marked, they can be cleaned using a

soft, clean cloth and any commonly available, mild window cleaner.

AR8-13

Region Certifi cation

Europe CE EN50131-2-2, Grade 2

EN50130-5 Environmental Class II

Poland TECHOM 98/07 Klasy "C"

USA UL ANSR: Intrusion Detection Units

(UL639)

Sweden INTYG 04-683

Trademark names are used throughout this document. In most cases, these designations are claimed as

trademarks or registered trademarks in one or more countries by their respective owners. Rather than

placing a trademark symbol in every occurrence of a trademark name, Bosch Security Systems, Inc.

(hereinafter referred to as Bosch) uses the names only in an editorial fashion and to the benefi t of the

trademark owner with no intention of infringing the trademark.

2 © 2012 Bosch Security Systems, Inc.

432154321

BASEBOARD HEAT

WINDOW

321 123

BASEBOARD HEAT

WINDOW

5

1123

5

4

MASK 3

SECTORS

4

MASK 15

SECTORS

AR8-13

AR8-13

4321 5 432 1

AR8-13

Figure 7.2: Masking

8 Coverage

• 360° by 60 ft. (18.3 m) diameter coverage when mounted on 8 to 18 ft

(2.4 to 5.5 m) high ceilings.

• The coverage pattern consists of 64 zones grouped into 16 barriers,

with one additional zone looking straight down from the unit (sabotage). Each barrier is 30 ft (9.2 m) long and 4.4 ft. (1.3 m) wide at 30

ft (9.2 m).

• The DS9382 comes with a choice of two optical modules. Refer to Section 5.1 to determine the best module for on ceiling height.

F.01U.263.663 | 01 | 05.2012 | 11

Page 3

If the time period selected has elapsed from the last alarm, the LED will

432143125

D

E

F

I

TOP VIEW

fl ash two times and the Trouble Output will activate.

Setting the Motion Monitor timer to shorter periods can be used to force a

protection walk test of remotely located zones.

It is recommended that the 30 day timer be selected. This verifi es that the

unit is operational and avoids nuisance trouble conditions caused by holidays, vacations, etc.

7 Optical Module

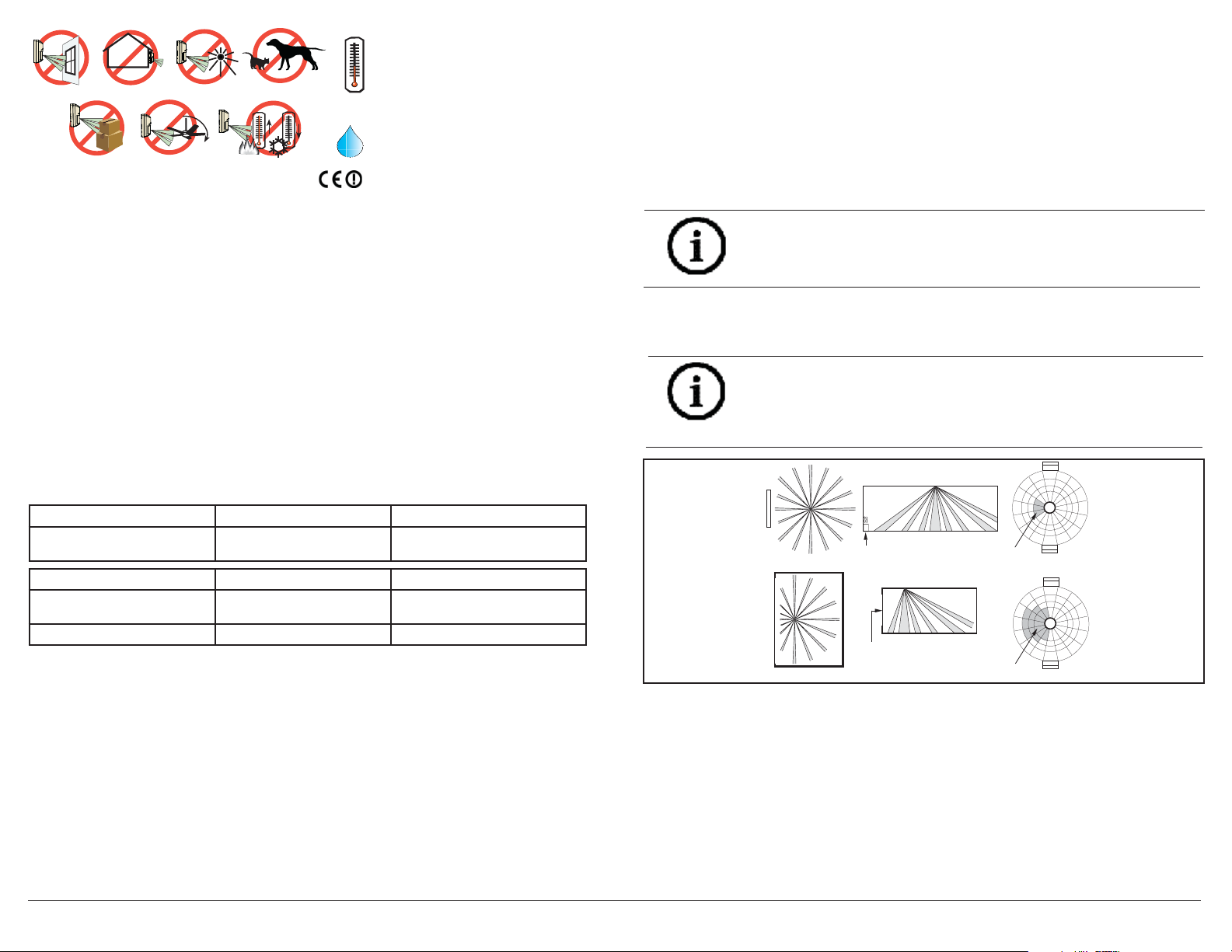

7.1 Optical Module Masking

Peel-off masks are provided with the unit for each segment of the optical module to allow for customized coverage, or to block out areas of

objects that may cause thermal disturbances. The mask is self-adhesive

and pre-cut in the shape of the optical module.

The location of the zone to be masked depends on the position of the

detector. Therefore, determine the mirror surface to be masked before

removing the mirror from the detector.

To block out a particular zone or group of zones, peel off a section of

the mask that corresponds to the appropriate zone, and stick it on the

mirror segment. Before attempting any masking, be sure the chosen

mirror surface is the correct one. Refer to Figure 7.1 to identify mirror

segments and zones.

NOTICE!

When disabling the look-down segment, do not mask segment 5 directly as this will disable the entire detector. Instead, mask the segment on

the dome directly below segment 5.

SIDE VIEW

4

M-3 M-2 M-1 E-1 E-2 E-3

5

E-4

AR8-13

A

P

B

O

N

M

L

K

J

C

D

E

F

G

H

I

AR8-13

O

N

M

L

K

A

P

J

B

C

G

H

1 Overview

The DS938Z is a high performance passive infrared intrusion detector. It is

equipped with advanced PIR detection and supervision circuits and is designed to provide an alarm condition upon detection of an intruder passing

through its area of coverage.

Employing balanced dual-opposed sensing elements, the DS938Z passive

infrared (PIR) detector makes use of the fact that all objects give off (emit)

infrared energy, and that the warmer an object is, the greater the amount

of infrared energy given off. The DS938Z uses PIR receiver technology

designed to detect the change in infrared energy caused when a target of a

different temperature from a stable background passes through its fi eld of

coverage.

The coverage pattern consists of sensor zones arranged to form a circular

coverage pattern.

Using Motion Analyzer II circuitry, the detector must fi rst see a change in

infrared energy in one zone followed by a change of energy in the remaining zone. Therefore, disturbances that occur in only one fi nger do not

constitute motion and are ignored. This “catch sensitivity” may be changed

in the fi eld by the installer to provide the degree of sensitivity required by

the installation.

Self-test and supervision circuits provide reliable operation in a variety of

installation environments. The result is a highly advanced detector offering

superior performance with freedom from false alarms.

Specifi cations

Dimensions

(HxDia)

Input

Power

Alarm Relay Silent-operating Form “C” relay. Contacts rated <100 mA, 25 VDC, 2.5W maximum, <20

Tamper Contacts rated at 28 VDC, 125 mA maximum, <1 Ohm. Connect tamper circuit to a 24-

Trouble

Output

Optional

Accessory

3.5 in. x 5.25 in. (8.9 cm x 13.3 cm)

6.0 to 15.0 VDC; 5 mA standby, 20 mA in alarm with LEDs enabled. Use only an Approved

Limited Power Source.

Ohm closed for DC resistive loads.

hour protection circuit.

Maximum current load is 25 mA.

TC6000 test cord.

Figure 7.1: Mirror module to pattern reference

NOTICE!

When attempting to remove any masking, many adhesives will either

destroy the mirror surface or leave enough residue behind to reduce

coverage performance.

10 © 2012 Bosch Security Systems, Inc.

F.01U.263.663 | 01 | 05.2012 | 3

Page 4

2 Mounting

Select a location likely to intercept an intruder moving beneath and across

the coverage pattern. Refer to Figure 2.1. Recommended mounting height

range is 8 to 18 feet (2.4 to 5.5 m).

The surface should be solid and vibration-free. (i.e. Drop tiles should be

secured if the area above the tiles is used as an air return for HVAC systems).

30 ft

26 ft 20 ft 13 ft 7 ft 0 ft 7 ft 13 ft 20 ft 26 ft

9 m

8 m

6 m

4 m

2 m

0 m

2 m

4 m

6 m

8 m

9 m 30 ft

Figure 2.1: Coverage Pattern

1. Remove the base from the enclosure by pressing the two enclosure release tabs inward while lifting the enclosure away from the base. Refer

to Figure 2.2.

Enclosure release openings (2)

Anti-vandal

locking screw

holes (2)

Figure 2.2: Opening cover

NOTICE!

Slightly rock the enclosure side-to-side during removal to overcome the

friction caused by the base-to-enclosure terminal pins.

2. Open the cover by turning counterclockwise.

3. Route wiring as necessary to the rear of the base and through the center hole. Refer to Figure 2.3.

30 ft

30 ft

26 ft

20 ft

13 ft

7 ft

0 ft

7 ft

13 ft

20 ft

26 ft

Test lead

cutout

Interface

pins

≤5.5 m

4.6 m

≥4.0 m

0 m

≤4.0 m

3.0 m

≥2.4 m

0 m

8 m6 m4 m2 m0 m2 m4 m6 m8 m

9 m

Enclosure release tabs

Optical module

Cover twist tabs (4)

AR13-18

AR8-13

Interface connector

≤18 ft

15 ft

≥13 ft

0 ft

≤13 ft

10 ft

≥8 ft

0 ft

9 m

6.2 False Alarm Prevention

Turn on all heating and cooling sources that would normally be in operation during times of protection. Stand away from the unit and outside the

coverage pattern, then monitor the background noise for at least three

minutes.

Readings should not deviate from the reference level more than ±0.15

VDC. For readings outside these limits; eliminate the cause, rotate the unit

slightly, or mask out the mirror segment(s) looking down at the thermal

disturbance.

6.3 Coverage Margin

Again walk across the farthest edge of required coverage.

A minimum voltage change of 1.0 VDC from the reference level is required

in the wintertime when the background temperature is cool. This will make

up for summertime, when the background is warmer. If testing the unit in

the summertime, the minimum recommended voltage change is 0.75 VDC.

When testing is completed, remove the TC6000 Test Cord, and twist-lock

the cover into place.

6.4 Supervision Feature

The DS938Z performs several supervision features that, combined with

the advanced motion detection capabilities of the detector, provide an extremely high level of security. A supervision trouble condition is indicated

at the detector by the Alarm/Test LED (see the Supervision Display Chart).

• The LED indicates the cause of the supervision trouble using coded

pulses. The supervision trouble signal activates the Trouble Output

available at terminal 8, which should be connected to a 24-hour zone.

The supervision features function as follows:

LED CAUSE

ON Unit alarm

2 Flashes Motion monitor time out

4 Flashes PIR self-test failure

PIR: The operation of the PIR is electronically checked approximately every 12 hours. If the PIR fails, the Alarm/Test LED will fl ash four times and

the Trouble Output will activate.

Motion Monitor Supervision: This feature verifi es that the detector has a

clear view of the detection area and has not been blocked. When selected

using switches S4 and S5, a supervision timer is activated. A trouble condition will be indicated if the detector has not alarmed at least once during

the selected time period (this feature can be disabled by placing both

switches in the Off position). The time period selected should be long

enough to allow adequate time for holiday weekends.

Refer to Section 4.0 Feature Selection for proper switch settings.

4 © 2012 Bosch Security Systems, Inc.

F.01U.263.663 | 01 | 05.2012 | 9

Page 5

NOTICE!

ED

)

ANTI-T AMPER SCREW HOLE

The use of a Sonalert type device (sounder) will provide an audible

tone during the time the unit is in alarm. Of the three available connector pins, the center pin is positive (+) with respect to either outside pin

(outside pins are common (-)).

Use of the sounder is intended only as an aid for walk testing during

installation.

3. Place the cover on the unit, and twist-lock it clockwise into place.

CAUTION!

Be sure all wiring is unpowered (de-energized) before routing.

REQUIRED FOR EN50131

INST ALLATIONS

ALARM/TEST L

INDICATOR (3

REAR WIRE

ENTRANCE

TERMINAL

STRIP

18

TEST LEAD

CUTOUT

NOISE

VOLTAGE

SOUNDER

NOTICE!

Be sure the TC6000 and Sonalert leads are dressed through the cutout.

4. Apply power to the unit.

5. Wait at least two minutes, after applying power, to start walk tests.

NOTICE!

Walk testing should be done across the coverage pattern as shown.

6. The edge of the coverage pattern is determined when the Alarm/Test

LED indicator (and optional Sonalert®, if installed) fi rst turns on.

7. Walk test the unit from all directions to determine the boundaries.

8. After completion of the walk tests, remove the Sonalert® (if installed).

6 Final Tests

6.1 Noise Measurement

NOTICE!

Meter readings are very important in determining background disturbance levels and catch margin sensitivity.

1. Connect a 20,000 ohm/volt (or greater) DC VOM to the Noise Voltage

connector using the TC6000 as shown. Set meter scale for about 3.0

VDC.

2. The base reference level for reading background noise or target voltages is approximately 2.0 VDC. Installations in quiet environments,

therefore, will result in a steady meter reading between 1.9 and 2.1

VDC. Look for areas and sources of thermal disturbances if the meter

fl uctuates greatly.

LO

WIRE

TIE-DOWNS (2)

MOUNTING

SLOTS (4)

Mounting Base

INTERFACE

PINS

GAIN SELECT

JUMPER

LO

HI

CONFIGURATION

SWITCHES

with Cover and Optical Module Removed

HI

ON

OFF

ANTI-TAMPER SCREW HOLE

REQUIRED FOR EN50131

INSTALLATIONS

Top View of Enclosure

COVER

TAMPER

Figure 2.3: Overview

4. Firmly mount the base. Depending on local regulations, the base may

be directly surface mounted using anchors, mollies, or wing-nuts, or

may be mounted to standard 4-inch octagonal or square electrical

boxes.

NOTICE!

The DS938Z base will not completely cover a 4-inch square box. Where

aesthetics are important, a 4-inch octagonal box is recommended.

NOTICE!

Mounting to removable ceiling tiles is not recommended unless a

sandwich is made of the base, ceiling tile, and a back plate behind the

tile. Covers used for 4-inch octagonal and square boxes make a suitable

back plate (when used with bolts and wing nuts, as an example).

3 Wiring

CAUTION!

Only apply power after all connections have been made and inspected.

Do not coil excess wiring inside detector.

AWG (0.8 mm) wire in the terminal strip.

Use no smaller than #22

8 © 2012 Bosch Security Systems, Inc.

F.01U.263.663 | 01 | 05.2012 | 5

Page 6

RELAY

KEY GUI

DE

INTERFACE

12345678

– +

6to15

VDC

Figure 3.1: Wiring to terminals

Alarm

TROUBLE

TAMPER

PINS

Terminals 1 (-) & 2 (+): Power contacts.

Terminals 3 (NO), 4 (C), & 5 (NC): Alarm relay contacts. Use terminals 4

& 5 for Normally Closed circuits. Do not use with capacitive or inductive

loads.

Terminals 6 (T) & 7 (T): Normally Closed tamper contacts.

Terminal 8 (TR): Solid state Trouble output. Shorts to ground (-) when the

detector is in a Trouble condition.

4 Feature Selection

The DS938Z has several features that are controlled using the confi guration

switches.

Motion

Monitor

Sensitivity

4 ON and 5 OFF = 4 Day

4 OFF and 5 ON = 30 Day

4 OFF and 5 OFF = Disabled

2 ON and 3 OFF = High

2 OFF and 3 ON = Intermediate

2 ON and 3 ON = Standard

1 ON = ON

LED

1 OFF = OFF

}

}

• Standard Sensitivity: Tolerates environment extremes on this setting,

but requires the largest amount of intruder motion to achieve an alarm.

• Intermediate Sensitivity: The recommended setting for most installations. Use in locations where an intruder is expected to cover only a

small portion of the protected area. Tolerates normal environments on

this setting. The detector is shipped in Intermediate Sensitivity mode.

• High Sensitivity: The setting for fast response to intruder signals. For

use only in extremely quiet environments where ceiling drafts, and

thermal and illumination transients are not anticipated.

If both switches are in the OFF position, the unit will default to the intermediate setting.

NOTICE!

Although the sensitivity modes provide different degrees of tolerance

to environmentally caused alarms, the installer should assure peak

background noise voltage readings do not exceed ±0.15 VDC. (See

Section 8.0 Final Tests).

4.3 Signal Gain

The DS938Z permits selection of the signal gain depending upon the

environment to be protected. The gain select jumper is located under the

optical module. Refer to Figure 2.3.

• High Gain: Recommended for large coverage applications up to 60

ft. (18.3 m) in diameter. The DS938Z is shipped in this setting. If

the gain select jumper is missing, the unit will default to High Gain.

• Low Gain: Recommended for applications where the area to be covered is 40 ft. (12.2 m) or less in diameter and for applications where

High Gain may be too sensitive for environmental extremes.

NOTICE!

Setting the DS938Z for Low Gain reduces the coverage area to 40 ft.

(12.2 m) in diameter.

OPEN

Figure 4.1: Selecting features

4.1 LED Operation

ON: Allows the Alarm/Test LED to operate when activated by

motion.

OFF: The LED will not operate on alarm activation, but will

indicate a supervision trouble condition.

4.2 Sensitivity Selection

Sensitivity modes depend on the type of coverage desired and the installation environment.

6 © 2012 Bosch Security Systems, Inc.

5 Setup and Walk Testing

1. Attach a TC6000 Test Cord to the Noise Voltage terminals. Since the

outside terminals are common, polarity is not important and the black

lead may be toward or away from the optical module.

2. Attach a Sonalert to the sounder pins at this time if one will be used

during walk testing.

F.01U.263.663 | 01 | 05.2012 | 7

Loading...

Loading...