Page 1

TriTech Ceiling Mount

PIR/Microwave Detector

DS9360

en Installation Guide

Page 2

-40°C to +49°C

(-40°F to +120°F )

UL Listed

installations,

the temperature

range is 0°C to +49°C

(+32°F to +120°F)

0 - 95% Relative Humidity

(0 - 85% UL Installations)

Pour les

installations

certifi ées NFA2P,

Température de

fonctionnement

-10°C à +55°C

Changes or modifi cations not expressly approved

by Bosch Security Systems, Inc. can void the user’s

authority to operate the equipment.

UL

Perform Walk Test at least once a year.

Use only a Listed limited-power source.

The Listed control unit or a Listed burglary power

supply must provide 4 hours (32 mAh) of standby

power.

Install the unit in accordance with National

Electrical Code NFPA 70.

Adjust the microwave range control, if necessary, to

achieve maximum range.

SELV

Connect all wiring to a safety extra-low voltage (SELV) circuit only.

Ligue todas as cablagens apenas a um circuito de segurança de tensão extra baixa.

Conecte el cableado únicamente a un circuito de seguridad para voltajes muy bajos.

Alle Drähte sind ohne Ausnahme an Niederspannung anzuschließen.

Sluit alle bedrading uitsluitend aan op een circuit met een extra lage veiligheidsspanning.

Prenez soin de connecter tous les câbles à un circuit à très basse tension de sécurité (TBTS).

Collegare tutti i cavi esclusivamente a un circuito di sicurezza a bassissima tensione.

This product is intended for use in the following countries within the European Union and in other countries

outside of the European Union:

Austria, Belgium, Denmark, Finland, Greece, Luxembourg, Netherlands, Norway, Spain, Sweden, Italy

EN 50131-2-4 Grade 2

EN 50130-5 Environmental Class II

IP30 IK04 (EN 60529, EN 62262)

Certifi cat NF A2P 2820200006A0

2 boucliers NF324 - H58

Autosurveillance à l’ouverture

Immunité champ magnétique

Test sans masque de vision verticale

et sans immunité aux animaux

www.afnor.org

www.cnpp.com

Specifi cations

Dimensions

(HxDia)

Input

Power

Standby

Power

Alarm Relay Silent-operating Form “C” relay. Contacts rated <100 mA, 25 VDC, 2.5W <20 Ohm closed

Tamper Contacts rated at 28 VDC, 125 mA maximum, <1 Ohm. To be connected to a SELV (Safety

Compliance This device complies with Part 15 of the FCC Rules. Operation is subject to the following

För svensk installationsanvisning se www.boschsecurity.se.

3.5 in. x 5.25 in. (8.9 cm x 13.3 cm)

6.0 to 15.0 VDC; 8 mA standby, 60 mA in alarm with LEDs enabled. Use only an Approved

Limited Power Source.

There is no internal standby battery. Standby power must be provided by an Approved

Limited Power Source. Eight mAh required for each hour of standby time needed. For UL

Listed Requirements, 32 mAh standby current is required.

maximum for DC resistive loads.

Extra-Low Voltage) circuit only. Connect tamper circuit to a 24-hour protection circuit.

two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesirable operation.

2 © 2015 Bosch Security Systems, Inc.

Page 3

1 Installation Considerations

re

Cover

Never install the detector in an environment that causes an alarm

condition in one technology. Good installations start with the LED off

when there is no target motion. It should never be left to operate with the

tri-color LED in a constant or intermittent green, yellow, or red condition.

NOTICE!

Microwave energy will pass through glass and most common

non-metallic construction walls.

Eliminate interference from nearby outside sources.

Point the unit away from outside traffi c (roads/alleys).

2 Mounting

Select a location likely to intercept an intruder moving beneath and across

the coverage pattern. Recommended mounting height range is 8 to 18 feet

(2.4 to 5.5 m).

The surface should be solid and vibration-free. (i.e. Drop tiles should be

secured if the area above the tiles is used as an air return for HVAC systems).

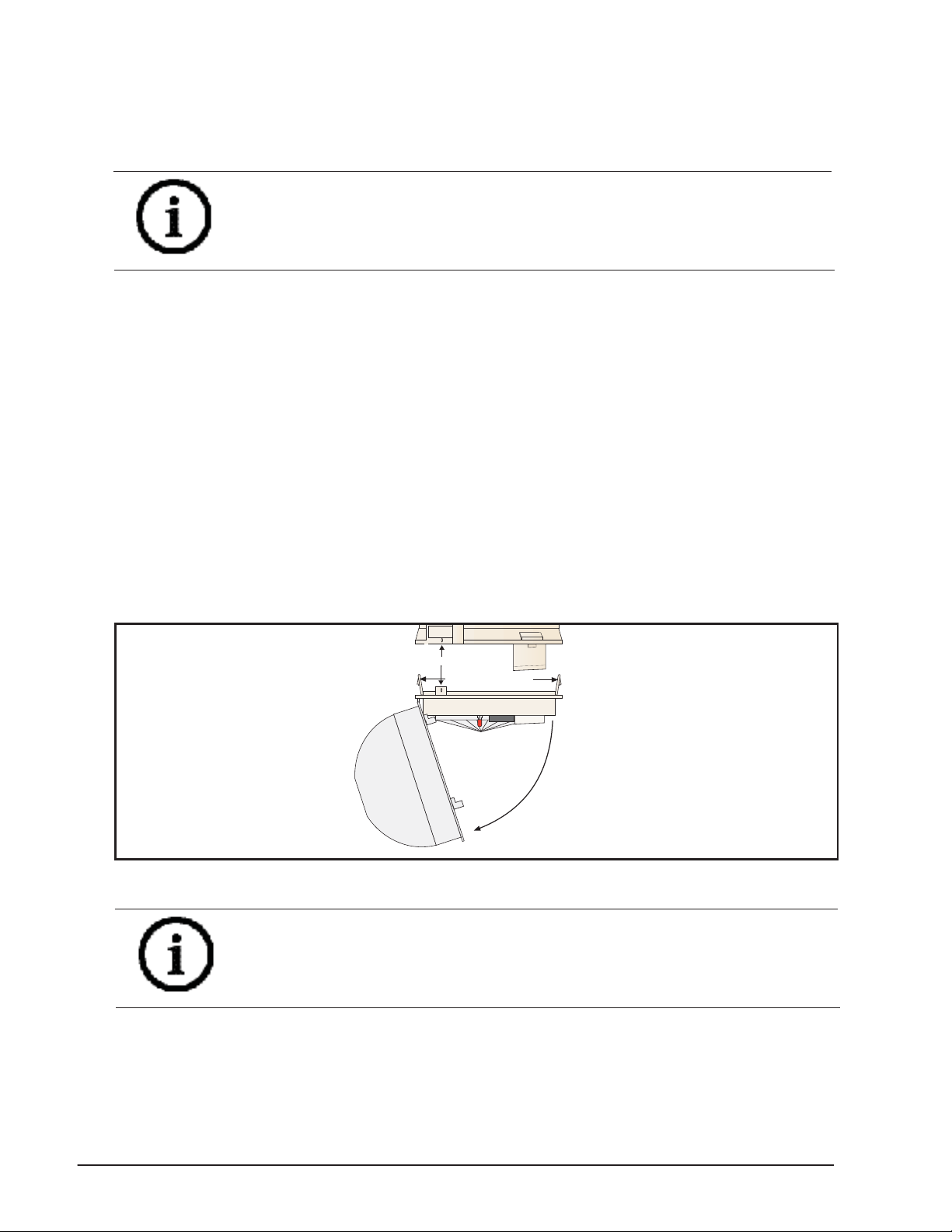

1. Remove the base from the enclosure by pressing the two enclosure

release tabs inward while lifting the enclosure away from the base.

Refer to Figure 2.1.

Base

Anti-vandal locking screw holes

Enclosure Release Tabs

Enclosu

The Cover remains

attached to the

Enclosure

Figure 2.1: Opening cover

NOTICE!

Slightly rock the enclosure side-to-side during removal to overcome the

friction caused by the base-to-enclosure terminal pins.

2. Open the cover by turning counterclockwise. One side of the cover will

remain attached to the base of the detector. Do not attempt to entirely

remove the cover. Refer to Figue 2.1.

3. Route wiring as necessary to the rear of the base and through the

center hole. Refer to Figure 2.2.

F.01U.263.664 | 05 | 2015.10 | 3

Page 4

NOTICE!

T

Be sure all wiring is de-energized before routing.

4. Firmly mount the base. Depending on local regulations, the base may

be directly surface mounted using anchors, mollies, or wing-nuts, or

may be mounted to standard 4-inch octagonal or square electrical

boxes.

NOTICE!

The DS9360 base will not completely cover a 4-inch square box. Where

aesthetics are important, a 4-inch octagonal box is recommended.

NOTICE!

Mounting to removable ceiling tiles is not recommended unless a

sandwich is made of the base, ceiling tile, and a back plate behind the

tile. Covers used for 4-inch octagonal and square boxes make a suitable

back plate (when used with bolts and wing nuts, as an example).

WIRE

TIE-DOWNS (2)

MOUNTING

SLOTS (4)

Figure 2.2: Mounting

3 Wiring

CAUTION!

Only apply power after all connections have been made and inspected.

Do not coil excess wiring inside detector.

AWG (0.8 mm) wire in the terminal strip.

REAR WIRE

ENTRANCE

Mounting Base

TERMINAL

INTERFACE

POWER

STRIP

18

PINS

Anti-vandal Screw Hole

Required for

EN50131

Installations

Wires

To

Cover

ALARM

LED

Top View of

TAMPER

LED and

LED Jumper

Sensitivity

Jumper

LED

OFF ON

I H

MIN

Microwave

Adjustment

Anti-vandal Screw Hole

Required for

EN50131

Installations

Use no smaller than #22

ROUBLE

-

+

+

-

Figure 3.1: Wiring to terminals

4 © 2015 Bosch Security Systems, Inc.

NO

C

NC

T

TR

T

Page 5

Terminals 1 (-) & 2 (+): Power contacts.

Terminals 3 (NO), 4 (C), & 5 (NC): Alarm relay contacts. Use terminals 4

& 5 for Normally Closed circuits. Do not use with capacitive or inductive

loads.

Terminals 6 (T) & 7 (T): Normally Closed tamper contacts.

Terminal 8 (TR): Solid state Trouble output. Shorts to ground (-) when the

detector is in a Trouble condition.

4 Coverage

• 360° by 60 ft. (18.3 m) diameter coverage when mounted on 8 to 18 ft

(2.4 to 5.5 m) high ceilings.

• The coverage pattern consists of 64 zones grouped into 16 barriers,

with one additional zone looking straight down from the unit

(sabotage). Each barrier is 30 ft (9.2 m) long and 4.4 ft. (1.3 m) wide

at 30 ft (9.2 m).

• The DS9360 comes with a choice of two optical modules. Refer to

Section 5.1 to determine the best module for on ceiling height.

30 ft

26 ft 20 ft 13 ft 7 ft 0 ft 7 ft 13 ft 20 ft 26 ft

9 m

8 m

6 m

4 m

2 m

0 m

2 m

4 m

6 m

8 m

9 m 30 ft

8 m6 m4 m2 m0 m2 m4 m6 m8 m

9 m

30 ft

30 ft

26 ft

≤5.5 m

20 ft

4.6 m

≥4.0 m

13 ft

7 ft

0 m

0 ft

7 ft

≤4.0 m

3.0 m

≥2.4 m

13 ft

20 ft

0 m

8 m6 m4 m2 m0 m2 m4 m6 m8 m

26 ft

9 m

9 m

AR13-18

AR8-13

≤18 ft

15 ft

≥13 ft

0 ft

≤13 ft

10 ft

≥8 ft

0 ft

9 m

5 Optical Module

5.1 Selecting the Optical Module

1. For ceilings between 8 and 13 ft. (2.4 and 4.0 m) from the fl oor, use

the optical module marked AR8-13. This marking can be found next to

the two optical module tabs.

2. For ceilings between 13 and 18 ft. (4.0 and 5.5 m) high, use the optical

module marked AR13-18.

3. To replace an optical module, push the optical module tabs towards

the center until the module snaps free of the circuit board. Holding the

new module by the tabs, snap the new module into place.

4. Replace the enclosure onto the base.

5. Close cover and turn clockwise to secure.

NOTICE!

Avoid fi ngerprints on the mirrored surfaces. Should the mirrored surfaces become soiled or otherwise marked, they can be cleaned using a

soft, clean cloth and any commonly available, mild window cleaner.

F.01U.263.664 | 05 | 2015.10 | 5

Page 6

432143125

D

E

F

I

TOP VIEW

M

5.2 Optical Module Masking

Peel-off masks are provided with the unit for each segment of the

optical module to allow for customized coverage, or to block out areas

of objects that may cause thermal disturbances. The mask is selfadhesive and pre-cut in the shape of the optical module.

The location of the zone to be masked depends on the position of the

detector. Therefore, determine the mirror surface to be masked before

removing the mirror from the detector.

To block out a particular zone or group of zones, peel off a section of

the mask that corresponds to the appropriate zone, and stick it on the

mirror segment. Before attempting any masking, be sure the chosen

mirror surface is the correct one.

NOTICE!

When attempting to remove any masking, many adhesives will either

destroy the mirror surface or leave enough residue behind to reduce

coverage performance.

SIDE VIEW

-4

M-3 M-2 M-1 E-1 E-2 E-3

5

N

E-4

M

L

AR8-13

A

P

O

K

J

B

C

D

E

F

G

H

I

AR8-13

O

N

M

L

K

A

P

J

B

H

Figure 8.1: Masking

When replacing the mirror, make sure it is facing the same direction as

before it was removed.

6 LED Operation

The detector uses a tri-color LED to indicate the various alarm and

supervision trouble conditions that may exist. See chart below.

LED CAUSE

C

G

Steady red Unit alarm

Tri-color Microwave activation

Steady green PIR activation

Flashing red Warm-up period after power-up (2 min)

Flashing red (4 pulse sequence) Replace unit

If the detector experiences a Microwave or PIR self-test failure, it is in

need of replacement.

6 © 2015 Bosch Security Systems, Inc.

Page 7

NOTICE!

During walk testing, the LED will light for the fi rst technology

(microwave or PIR) and then light red to indicate a detector alarm. The

LED will not indicate activation of the second technology by lighting its

color.

7 Feature Selection

7.1 LED On/Off Pins

The ON position allows operation of the tri-color LED. If LED indication

is not desired after setup and walk tests are completed, place in the OFF

position. The OFF position does not prevent the LED from indicating

supervision trouble conditions.

Sensitivity

Jumper

Figure 6.1: Selecting features

LED

Jumper

OFF

ON

LED

OFF ON

I H

I

H

7.2 PIR Sensitivity Selection Pins

For selection, place the plug across the pins marked I for Intermediate

mode or H for High mode.

• Intermediate Sensitivity (I): Tolerates environment extremes on this

setting, but requires the largest amount of intruder motion to achieve

an alarm.

• High Sensitivity (H): The recommended setting for most installations.

Use in locations where an intruder is expected to cover only a small

portion of the protected area. Tolerates normal environments on this

setting. The detector is shipped in High Sensitivity mode.

7.3 Microwave Adjustment

NOTICE!

It is important to wait 1 minute after removing/replacing the cover so

the microwave portion of the detector can settle, and to wait at least 5

seconds between the following walk testing procedures.

1. The tri-color LED should be off before walk testing.

2. Walk test across the pattern at the intended coverage’s farthest end.

Start walking from outside the intended protection area and observe

the tri-color LED. The edge of the microwave pattern is determined

by the fi rst tri-color, microwave activation of the LED (or the fi rst red

activation if the green PIR LED activates fi rst).

F.01U.263.664 | 05 | 2015.10 | 7

Page 8

3. If adequate range can not be reached, increase the Microwave Range

Adjust slightly. Continue walk testing (waiting 1 minute after removing/

replacing the cover) and adjusting the range until the farthest edge of

desired coverage has been accurately placed.

4. Walk test the unit from all directions to determine all the detection

pattern boundaries.

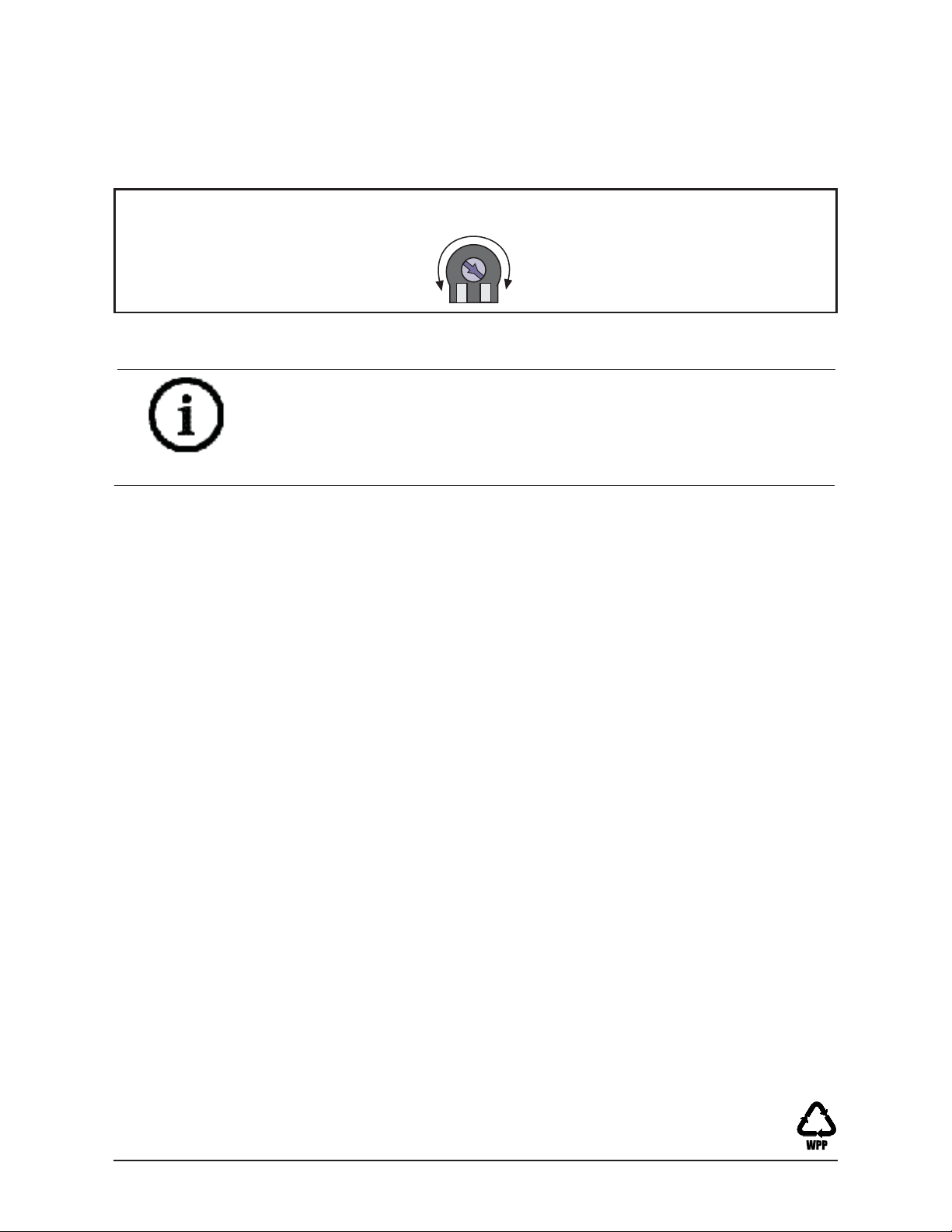

Microwave

Adjustment

MIN

Figure 6.2: Adjusting microwave range

NOTICE!

Do not adjust the microwave range higher than required. Doing so

may cause the detector to catch movement outside of the intended

coverage pattern.

MAX

8 Supervision Features

The supervision features function as follows:

• PIR/Microwave: The complete circuit operation of these subsystems

is checked approximately every 6 hours. If the PIR or microwave

subsystem fails, the red LED will fl ash 4 times per cycle and the unit

should be replaced.

• Default: The detector will default to PIR technology protection if the

microwave subsystem fails.

9 Other Information

9.1 Anti-Vandal Screws for EN50131 Applications

After the cover has been installed and twisted into place, the entire

assembly can be secured together using the supplied anti-vandal screws.

The anit-vandal screws are required for EN50131 applications. Refer to the

Top View of Enclosure in Figure 2.2 for the location of the screw holes.

9.2 Maintenance

At least once a year, the range and coverage should be verifi ed. To ensure continual daily operation, the end user should be instructed to walk

through the far end of the coverage pattern. This ensures an alarm output

prior to arming the system.

Bosch Security Systems, Inc. product manufacturing dates

Use the serial number located on the product label and refer to the Bosch

Security Systems, Inc web site at: http://www.boschsecurity.com/datecodes/.

© 2015 Bosch Security Systems, Inc. 130 Perinton Parkway Fairport, NY 14450

Loading...

Loading...