Bosch D6412, D4412 Operation And Installation Manual

Operation and Installation Guide

Control Panels D6412/D4412

D6412/D4412

Contents

Contents

1.0 Introduction ............................................................................................................................................................................................. 7

1.1 Organization ........................................................................................................................................................................... 7

1.2 Other Literature Referenced ............................................................................................................................................. 8

1.3 Documentation Conventions ............................................................................................................................................. 8

1.3.1 Type Styles Used in this Guide ......................................................................................................................................... 8

1.3.2 Tips, Important Notes, Cautions, and Warnings ........................................................................................................... 8

1.4 FCC Notice ............................................................................................................................................................................ 9

1.4.1 Part 15 ..................................................................................................................................................................................... 9

1.4.2 Part 68 ..................................................................................................................................................................................... 9

2.0 Overview................................................................................................................................................................................................. 10

2.1 Specifications ......................................................................................................................................................................10

2.2 SIA Control Panel Standard ............................................................................................................................................12

2.3 Standard Features .............................................................................................................................................................. 12

2.3.1 Points ..................................................................................................................................................................................... 12

2.3.2 Areas and Accounts ........................................................................................................................................................... 12

2.3.3 Communicator ..................................................................................................................................................................... 12

2.3.4 Command Centers ............................................................................................................................................................. 13

2.3.5 Keyswitch .............................................................................................................................................................................. 13

2.3.6 Alarm Event Memory .......................................................................................................................................................... 13

2.3.7 Event Log .............................................................................................................................................................................. 13

2.3.8 EMI/Lightning Transient Protection ............................................................................................................................... 13

2.3.9 Programming ........................................................................................................................................................................ 13

2.3.10 Other Features .................................................................................................................................................................... 13

2.3.11 Control Panel Assembly .................................................................................................................................................... 14

2.3.12 Listings and Approvals ....................................................................................................................................................... 14

3.0 Installation ............................................................................................................................................................................................. 15

3.1 Before You Begin ................................................................................................................................................................ 15

3.2 Enclosure Options .............................................................................................................................................................. 15

3.3 Premises Wiring ..................................................................................................................................................................15

3.4 Installing the Assembly ...................................................................................................................................................... 16

3.4.1 Connecting Earth Ground ................................................................................................................................................ 16

3.4.2 Closing the Installer Switch ............................................................................................................................................. 16

3.5 Finishing the Installation ................................................................................................................................................... 17

3.5.1 Earth Ground and Installer Switch ................................................................................................................................. 17

3.5.2 Charge the Battery as You Finish ................................................................................................................................... 17

3.5.3 Install and Wire Detection Devices ............................................................................................................................... 17

3.5.4 Install Modules ..................................................................................................................................................................... 17

3.5.5 Make the Telephone Connections .................................................................................................................................. 17

3.5.6 Connect the On-Board Points and Command Centers ........................................................................................... 17

3.5.7 Power Up ............................................................................................................................................................................... 18

3.6 Programming the Panel .....................................................................................................................................................18

3.7 Check for Fire Alarm Verification....................................................................................................................................18

3.8 Testing the System .............................................................................................................................................................18

4.0 Power Supply ...................................................................................................................................................................................... 19

4.1 Primary Power ...................................................................................................................................................................... 19

4.1.1 Primary (AC) Power Circuit .............................................................................................................................................. 19

4.1.2 Installing the Transformer .................................................................................................................................................. 19

4.2 Secondary Power ................................................................................................................................................................ 19

4.2.2 Installing the Battery .......................................................................................................................................................... 19

4.2.3 Replacement ........................................................................................................................................................................ 19

D6412/D4412 Operation and Installation Guide

Page 2 © 2003 Bosch Security Systems45349E

D6412/D4412

Contents

4.2.4 Battery Supervision ............................................................................................................................................................ 19

4.2.5 Battery Charging Circuit - Float Charge ...................................................................................................................... 20

4.2.6 Battery Discharge/Recharge Schedule ........................................................................................................................ 20

4.2.7 System Status LED............................................................................................................................................................ 20

4.3 External Power Supply ...................................................................................................................................................... 20

5.0 Power Outputs ................................................................................................................................................................................... 21

5.1 Circuit Protection ................................................................................................................................................................ 21

5.2 Available Power ................................................................................................................................................................... 21

5.2.1 Auxiliary Power ..................................................................................................................................................................... 21

5.2.2 Installer’s Keypad Connector ........................................................................................................................................... 21

5.2.3 Alarm Power ......................................................................................................................................................................... 21

5.3 Continuous Power Output ................................................................................................................................................ 21

5.3.1 Continuous Current Draw ................................................................................................................................................. 21

5.4 Alarm Power .........................................................................................................................................................................21

5.4.1 Available Power ................................................................................................................................................................... 21

5.5 Output Programming ......................................................................................................................................................... 22

6.0 Telephone Connections .................................................................................................................................................................. 23

6.1 Registration ......................................................................................................................................................................... 23

6.2 Notification .......................................................................................................................................................................... 23

6.3 Location................................................................................................................................................................................ 23

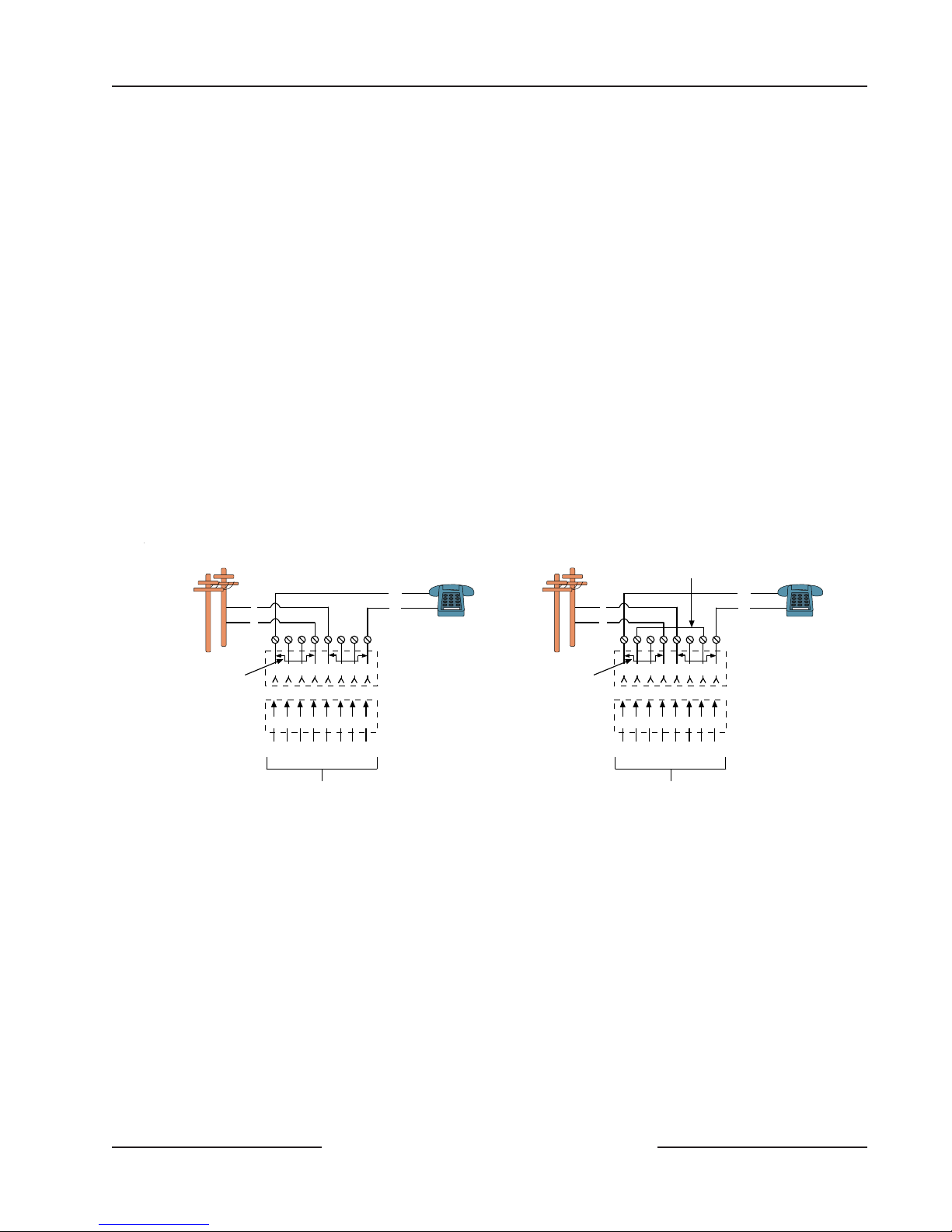

6.4 Phone Cord Connection .................................................................................................................................................. 23

6.5 System Status LED (Red) ............................................................................................................................................... 23

6.6 Dialing Format ..................................................................................................................................................................... 23

6.7 Phone Line Fault ................................................................................................................................................................ 24

6.8 Called Party Disconnect .................................................................................................................................................. 24

6.9 Communication Failure .................................................................................................................................................... 24

6.10 Ground Start ....................................................................................................................................................................... 24

6.10.1 Program PO1 for Ground Start ...................................................................................................................................... 24

7.0 On-Board Sensor Loops .............................................................................................................................................................. 27

7.1 Description ........................................................................................................................................................................... 27

7.2 Two-wire Smoke Detector Configuration ..................................................................................................................... 27

7.3 Four-wire Smoke Detector Configuration .................................................................................................................... 27

7.4 Sensor Loop 1 Configuration ......................................................................................................................................... 28

7.5 Single Point Configuration (Points 2 to 8) ................................................................................................................. 28

7.6 Doubled Point Configuration .......................................................................................................................................... 29

7.7 Sensor Loop Response Time .......................................................................................................................................... 29

8.0 Off-Board Sensor Loops .............................................................................................................................................................. 31

8.1 SDI Point Expanders .......................................................................................................................................................... 31

8.2 DX2010 Point Expander Module ................................................................................................................................... 33

8.2.1 DX2010 Overview .............................................................................................................................................................. 33

8.2.2 DX2010 Installation ............................................................................................................................................................ 33

8.2.3 DX2010 to Panel SDI Bus Connections ......................................................................................................................34

8.2.4 DX2010 Auxiliary Output Connections ......................................................................................................................... 36

8.2.5 DX2010 Tamper Input Connections .............................................................................................................................. 36

8.2.6 DX2010 Sensor Loop (Point) Connections .................................................................................................................36

8.2.7 DX2010 Address Programming ....................................................................................................................................... 37

8.2.8 DX2010 Status LED .......................................................................................................................................................... 38

9.0 On-Board Outputs ........................................................................................................................................................................... 39

10.0 Off-Board Outputs ........................................................................................................................................................................... 41

10.1 Overview ............................................................................................................................................................................... 41

10.2 DX3010 Octo-Output Module ........................................................................................................................................41

10.2.1 Overview ............................................................................................................................................................................... 41

D6412/D4412 Operation and Installation Guide

Page 3© 2003 Bosch Security Systems 45349E

D6412/D4412

Contents

10.2.2 Configuring the DX3010 Octo-Output Module .......................................................................................................... 41

10.2.3 Relay Outputs ...................................................................................................................................................................... 41

10.2.4 Installation ............................................................................................................................................................................. 42

10.2.5 DX3010 to D6412/D4412 SDI Bus Wiring Connections ....................................................................................... 42

10.2.6 Address Programming ........................................................................................................................................................ 44

11.0 Arming Devices................................................................................................................................................................................... 45

11.1 Description ........................................................................................................................................................................... 45

11.2 Command Centers ............................................................................................................................................................ 45

11.2.1 Assigning the Command Center an Address .............................................................................................................. 45

11.2.2 Command Center Installation .......................................................................................................................................... 46

11.3 D268/D269, D279 Independent Zone Control ......................................................................................................... 47

11.4 Keyswitch ..............................................................................................................................................................................47

11.4.1 Keyswitch Description ....................................................................................................................................................... 47

11.4.2 Keyswitch Programming .................................................................................................................................................... 47

11.4.3 Keyswitch Installation ........................................................................................................................................................ 48

11.4.4 Keyswitch Operation .......................................................................................................................................................... 48

12.0 SDI Devices .......................................................................................................................................................................................... 49

12.1 Description ........................................................................................................................................................................... 49

12.2 Installation ............................................................................................................................................................................ 49

12.3 DX4010 RS-232 Serial Interface Module .................................................................................................................. 50

12.3.1 DX4010 Installation ............................................................................................................................................................ 50

12.3.2 DX4010 to D6412/D4412 SDI Bus Wiring Connections ....................................................................................... 51

12.3.3 RAM IV Direct Connection ............................................................................................................................................... 51

12.3.4 Configuration Jumpers ....................................................................................................................................................... 52

12.3.5 Supervision ...........................................................................................................................................................................52

12.3.6 DX4010 Module’s DB9 Connector ................................................................................................................................ 52

13.0 Installer’s Keypad and Installer Mode .................................................................................................................................... 53

13.1 Installer’s Keypad Connector .......................................................................................................................................... 53

13.2 Entering the Installer Mode ............................................................................................................................................. 53

13.2.1 Installer’s Passcode ............................................................................................................................................................ 53

13.2.2 Service Start/Service End Reports ................................................................................................................................ 54

13.3 Installer’s Menu .................................................................................................................................................................. 54

13.3.1 Press [1] for Bell Test ......................................................................................................................................................... 54

13.3.2 Press [2] for Strobe Test ................................................................................................................................................... 54

13.3.3 Press [3] for Battery Test .................................................................................................................................................. 54

13.3.4 Press [4] for Test Report ...................................................................................................................................................54

13.3.5 Press [5] for Point Status ................................................................................................................................................. 54

13.3.6 Press [6] for Output Test .................................................................................................................................................. 55

13.3.7 Press [7] for RF Menu ....................................................................................................................................................... 55

13.3.8 Press [8] for Keypad Program ......................................................................................................................................... 56

13.3.9 Press [9] Program Key ....................................................................................................................................................... 57

13.3.10 Exiting the Installer’s Menu ..............................................................................................................................................58

13.3.11 Press [0] Call for Service Details ................................................................................................................................... 58

14.0 Installation Label ................................................................................................................................................................................ 59

15.0 Terminal Quick Reference ............................................................................................................................................................. 61

16.0 Troubleshooting ................................................................................................................................................................................. 63

16.1 Introduction .......................................................................................................................................................................... 63

16.1.1 Arming Issues ....................................................................................................................................................................... 63

16.1.2 Point Issues .......................................................................................................................................................................... 63

16.1.3 Command Center Issues .................................................................................................................................................. 64

16.1.4 Programming Issues ........................................................................................................................................................... 64

16.1.5 Miscellaneous Issues ......................................................................................................................................................... 64

D6412/D4412 Operation and Installation Guide

Page 4 © 2003 Bosch Security Systems45349E

D6412/D4412

Contents

Appendix A: Approved Applications Compliance Guide ............................................................................................................... 65

A-1 Listings and Approvals ...................................................................................................................................................... 65

A-2 System Chart ...................................................................................................................................................................... 66

A-3 System Wiring Diagrams, Issue A ................................................................................................................................. 67

A-4 Current Rating Chart for Standby Battery Calculations ......................................................................................... 68

A-5 Standby Battery Requirements ...................................................................................................................................... 68

A-6 Standby Battery Calculation for NFPA 72 Fire Alarm Applications ..................................................................... 68

Appendix B: SDI Address Chart ................................................................................................................................................................. 69

Tables

Table 1: D6412/D4412 Installation Guide Organization........................................................................................................... 7

Table 2: Other Literature Referenced ............................................................................................................................................. 8

Table 3: Compatible Command Centers ...................................................................................................................................... 13

Table 4: System Status LED Description ....................................................................................................................................20

Table 5: On-Board Sensor Loops .................................................................................................................................................. 28

Table 6: Point Scan Time/Pulse Count Time Selections ........................................................................................................29

Table 7: Point Expansion Mapping ................................................................................................................................................. 31

Table 8: DX2010 Wire Lengths ...................................................................................................................................................... 34

Table 9: DX2010 Address 106 ....................................................................................................................................................... 37

Table 10: DX2010 Address 107 (for D6412 only) ..................................................................................................................... 37

Table 11: DX2010 Address Settings ............................................................................................................................................. 38

Table 12: DX2010 Address Jumper Settings .............................................................................................................................. 38

Table 13: DX3010 Wire Lengths .................................................................................................................................................... 42

Table 14: DX3010 Address Settings ............................................................................................................................................. 44

Table 15: DX3010 Address Jumper Settings .............................................................................................................................. 44

Table 16: Command Center Address Assignments DIP Switch Settings ........................................................................... 45

Table 17: Command Center Wire Lengths .................................................................................................................................. 46

Table 18: DX4010 Address Settings ............................................................................................................................................. 52

D6412/D4412 Operation and Installation Guide

Page 5© 2003 Bosch Security Systems 45349E

D6412/D4412

Figures

Figures

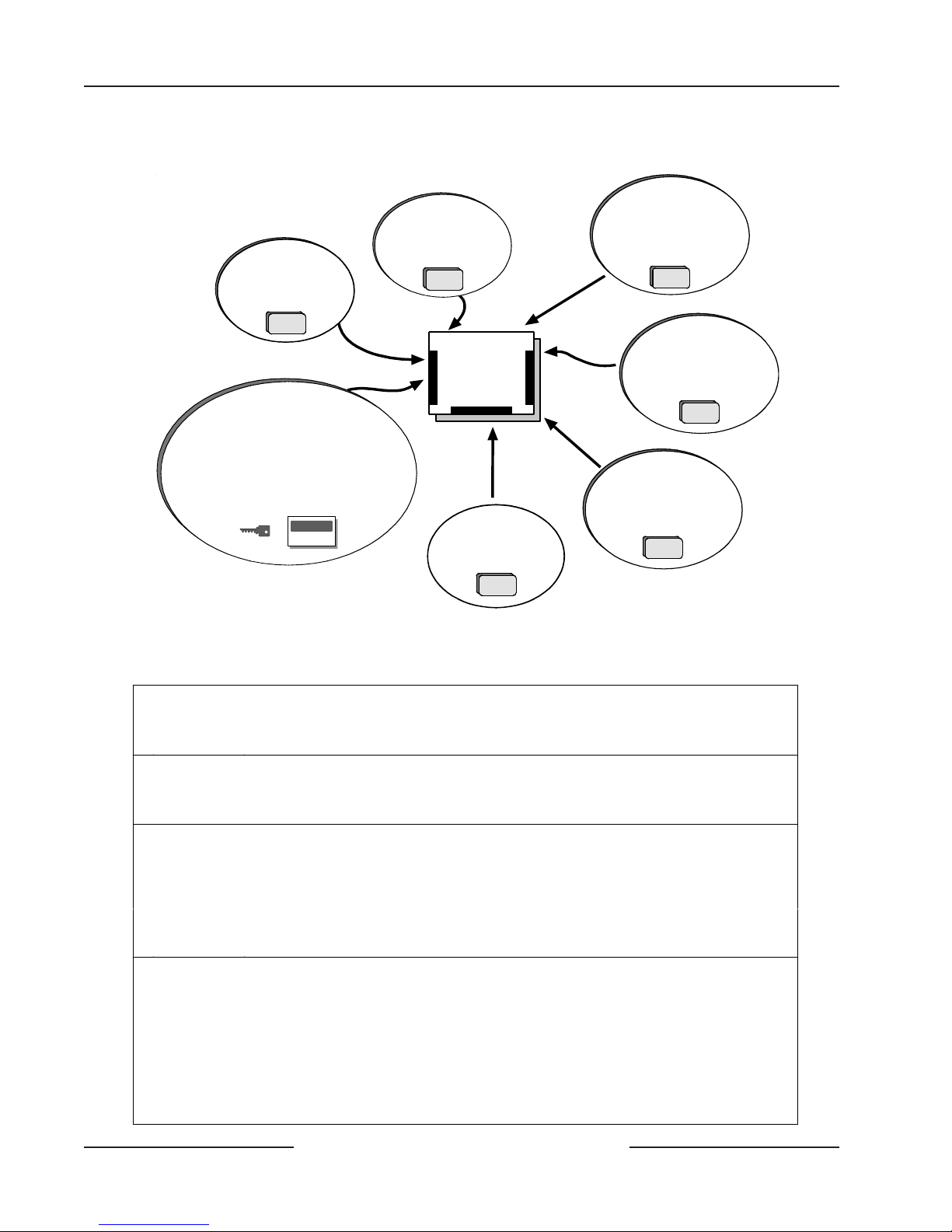

Figure 1: System Configuration ...................................................................................................................................................... 10

Figure 2: Enclosure Mounting ......................................................................................................................................................... 16

Figure 3: Installer Switch .................................................................................................................................................................. 16

Figure 4: System Status LED ......................................................................................................................................................... 20

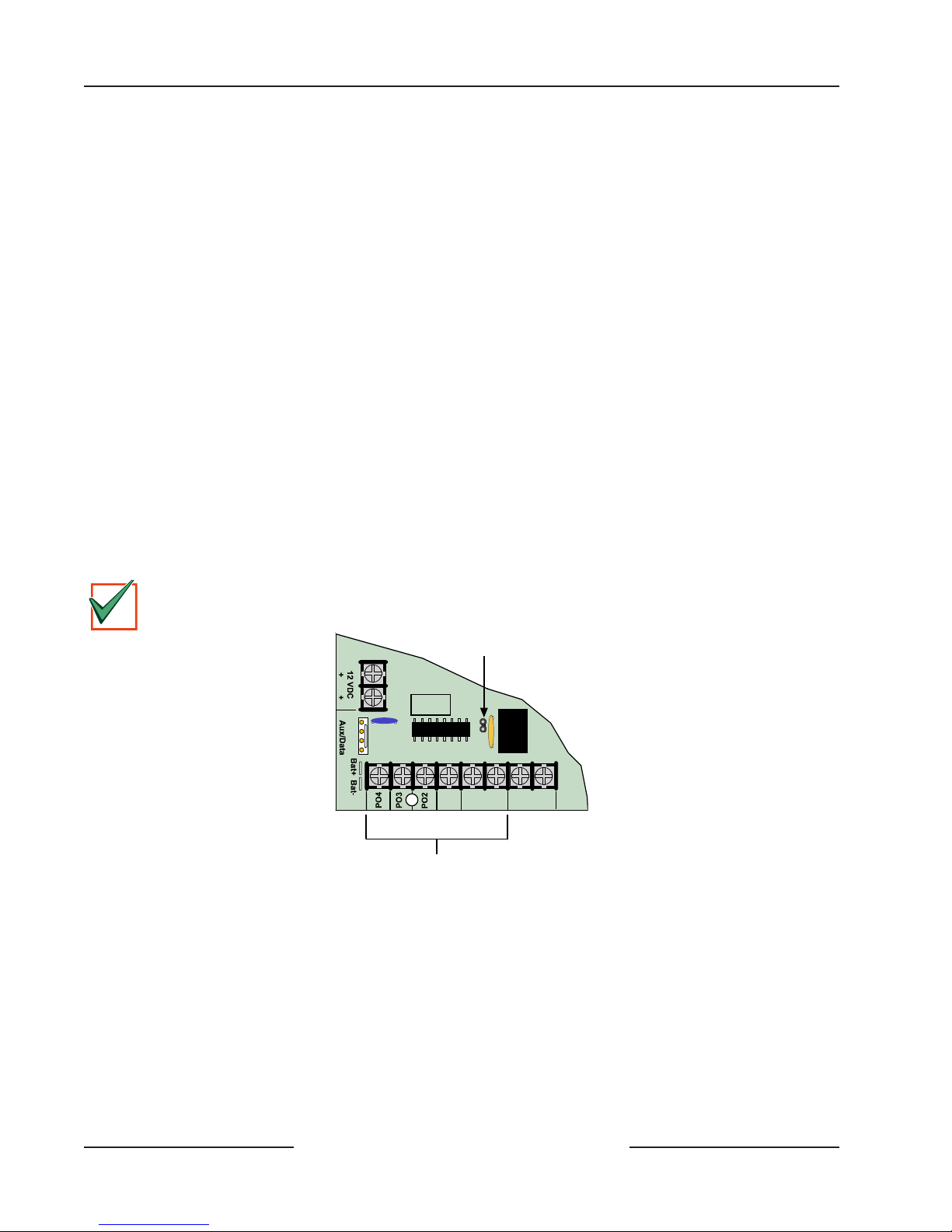

Figure 5: On-Board Outputs ........................................................................................................................................................... 22

Figure 6: RJ31X/RJ38X Wiring ...................................................................................................................................................... 23

Figure 7: Ground Start ...................................................................................................................................................................... 25

Figure 8: Typical Two-Wire Smoke Detector Wiring .................................................................................................................27

Figure 9: Typical Four-Wire Smoke Detector Wiring ................................................................................................................ 27

Figure 10: Sensor Loop 1 Wiring ................................................................................................................................................... 28

Figure 11: Single Point Sensor Loop Wiring .............................................................................................................................. 28

Figure 12: On-Board Doubled Point Sensor Loop Wiring....................................................................................................... 29

Figure 13: Installing the DX2010 in D203 Enclosure .............................................................................................................. 33

Figure 14: Installing the DX2010 in the Panel Enclosure .......................................................................................................33

Figure 15: Optional Enclosure Mounting Locations for the DX2010 ................................................................................... 34

Figure 16: Wiring the DX2010 to the D6412/D4412 .............................................................................................................. 35

Figure 17: Wiring the DX2010 for External Power Supply ...................................................................................................... 35

Figure 18: Auxiliary Output Connections ..................................................................................................................................... 36

Figure 19: DX2010 Tamper Input Wiring ..................................................................................................................................... 36

Figure 20: DX2010 Sensor Loop Wiring, Single Loop Configuration ................................................................................. 37

Figure 21: DX2010 Sensor Loop Wiring, Doubled Loop Configuration .............................................................................. 37

Figure 22: DX2010 DIP Switch Configuration ........................................................................................................................... 38

Figure 23: DX2010 Status LED .....................................................................................................................................................38

Figure 24: PO1 Wiring ..................................................................................................................................................................... 39

Figure 25: PO2-PO4 Wiring ...........................................................................................................................................................39

Figure 26: DX3010 - Control Panel Enclosure Side Mounting ............................................................................................. 42

Figure 27: Installing the DX3010 in a Remote Enclosure ....................................................................................................... 42

Figure 28: Wiring the DX3010 to the D6412/D4412 .............................................................................................................. 43

Figure 29: Wiring for External Power Supply .............................................................................................................................. 43

Figure 30: DX3010 Address DIP Switches .................................................................................................................................44

Figure 31: Command Center DIP Switch Orientation ............................................................................................................. 45

Figure 32: Wiring Command Centers to the D6412/D4412 ................................................................................................. 46

Figure 33: External Power for Command Centers ..................................................................................................................... 47

Figure 34: Keyswitches ..................................................................................................................................................................... 48

Figure 35: SDI Device Wiring ......................................................................................................................................................... 49

Figure 36: External Power for SDI Devices ................................................................................................................................. 50

Figure 37: DX4010 RS-232 Serial Interface Module .............................................................................................................. 50

Figure 38: DX4010 Power Connections ...................................................................................................................................... 51

Figure 39: Creating a RAM IV Direct Connection .................................................................................................................... 51

Figure 40: DX4010 P2/P3 Jumper Pin Settings ........................................................................................................................ 52

Figure 41: DX4010 DIP Switch Orientation ...............................................................................................................................52

Figure 42: DX4010 D89 Connector Layout ............................................................................................................................... 52

Figure 43: Installer’s Keypad ........................................................................................................................................................... 53

Figure 44: Installer Switch ............................................................................................................................................................... 54

Figure 45: Adding RF ID Codes Menu Display .......................................................................................................................... 55

Figure 46: RF ID Code Display ...................................................................................................................................................... 55

Figure 47: Test RF Devices Display ............................................................................................................................................... 55

Figure 48: RF Device Test Status Display ................................................................................................................................... 55

Figure 49: RF ID Code Display ...................................................................................................................................................... 56

Figure 50: PK32 to D6412/D4412 Connections ...................................................................................................................... 57

D6412/D4412 Operation and Installation Guide

Page 6 © 2003 Bosch Security Systems45349E

D6412/D4412

Introduction

1.0 Introduction

This guide addresses the installation of the D6412 and D4412 Control Panel only, and should not be used for any other

panel.

1.1 Organization

This guide is divided into 16 sections with seven appendices. Table 1 contains a summary of each section.

Section

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0

15.0

16.0

Appendices A: Approved Applications and Compliance Guide

Introduction

Overview

specifications, standard and new features.

Installation

the panel and ready for programming.

Power Supply

instructions for correcting problems with them.

Power Outputs

output and built-in siren driver.

Telephone Connections

On-Board Sensor Loops

on the D6412/D4412.

Off-Board Sensor Loops

including detailed instructions for connecting the DX2010 Point Expansion Module.

On-Board Outputs

Off-Board Outputs

including detailed instructions for connecting the DX3010 OctoOutput Module.

Arming Devices

zone controls.

SDI Devices

that connect to the D6412/D4412’s data terminals (SDI bus).

Installer’s Keypad and Installer Mode

the Installer’s Mode.

Installation Label

terminal.

Terminal Quick Reference

terminal.

Troubleshooting

B: SDI Address Chart

- This section.

- Overview of the D6412/D4412 Control Panel, including operational

- Basic installation instructions, including everything needed to power up

- Information about the primary and secondary power sources and

- Information about the available powered outputs, including the alarm

- Information about connecting the phone line.

- Information about the eight on-board sensor loops available

- Information about available off-board sensor loops,

- Information about the four on-board programmable outputs.

- Information about available off-board programmable outputs,

- Information about command centers, keyswitches, and independent

- Descriptions and installation instructions for various optional modules

- Copy of the installation label found inside the D6412/D4412

- Chart providing a short description of each D6412/D4412

- Potential solutions to a variety of commonly encountered problems.

Description

- Information for using an Installer’s Keypad and

T able 1: D6412/D4412 I nstallation Guide Organization

D6412/D4412 Operation and Installation Guide

Page 7© 2003 Bosch Security Systems 45349E

D6412/D4412

Introduction

1.2 Other Literature Referenced

Throughout this guide, references are made to other documentation. Review the documents in the table below for a complete

description of the panel. Part numbers are included for ordering purposes.

Document Name Part Number

D6412/D4412 Program Entry Guide 45351

D6412 Program Record Sheet 45350

D4412 Program Record Sheet 50485

D6412/D4412 TSN: Smoke Detector Compatibility 46928

User's Guide for LED Command Centers 46840

User's Guide for Text Command Centers 46841

D6412 Firmware Release Notes 46929

D4412 Firmware Release Notes 50482

DX2010 Installation Guide 49533

DX3010 Installation Guide 49529

DX4010 Installation Guide 49539

Table 2: Other Literature Referenced

1.3 Documentation Conventions

These conventions are intended to call out important features, items, notes, cautions, and warnings that the reader should be

aware of in reading this document.

1.3.1 Type Styles Used in this Guide

T o help iden tify important items in the text, the following type styles are used:

Bold text Usually indicates selections that you may use while programming your

panel. It may also indicate an important fact that should be noted.

Bold italicized Used to denote notes, cautions, and/or warnings.

Italicized text Refers the user to another part of the guide or to another document entirely.

Courier text Indicates what may appear on the command center/keypad or in a report

received at the central station receiver .

[Text in bracket s] Indicates to the user that a specific key should be pressed. Example: Press

[Cmd] to exit this feature.

1.3.2 Tips, Important Notes, Cautions, and Warnings

Throughout this document, helpful tips, important notes, cautions and warnings are presented for the reader to keep in

mind. These appear different from the rest of the text as follows;

Important Notes - should be heeded for successful operation and programming. Also, tips and shortcuts may be

included here.

Caution - These caution the operator that physical damage to the panel and/or optional equipment may occur.

W arning - These warn of the possibility of physical damage to the operator and/or equipment.

D6412/D4412 Operation and Installation Guide

Page 8 © 2003 Bosch Security Systems45349E

D6412/D4412

Introduction

1.4 FCC Notice

1.4.1 Part 15

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with this

instruction guide, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user is required to

correct the interference at his own expense.

1.4.2 Part 68

This equipment complies with Part 68 of FCC rules. A label contains, among other information, the FCC registration

number and ringer equivalence number (REN). If requested, this information must be provided to the telephone company.

The Bosch Security Systems D6412/D4412 Control Panel is registered for connection to the public telephone network using

an RJ38X or RJ31X jack.

The ringer equivalence number (REN) is used to determine the number of devices that may be connected to the telephone

line. Excessive RENs on the telephone line may result in the devices not ringing in response to an incoming call. In most, but

not all areas, the sum of the RENs should not exceed five (5). To ascertain of the number of devices that may be connected to

the line, as determined by the RENs, contact the telephone company to determine the maximum REN for the calling area.

If the D6412/D4412 Control Panel causes harm to the telephone network, the telephone company notifies you in advance. If

advance notice isn’ t practical, the telephone compan y notifies the customer as soon as possible. Also, you are advised of your

right to file a complaint with the FCC if you believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations, or procedures that could affect the

operation of the equipment. If this happens, the telephone company provides advance notice so you can make the necessary

modifications for maintaining uninterrupted service.

If trouble is experienced with the D6412/D4412 Control Panel, please contact Bosch Security Systems Customer Service for

repair and/or warranty information. If the trouble is causing harm to the telephone network, the telephone company may

request that you remove the equipment from the network until the problem is resolved. User repairs must not be made, and

doing so voids the user’ s warranty .

This equipment cannot be used on public coin service provided by the telephone company . Connection to Party Line service

is subject to state tariffs. (Contact your state public utilities commission for information.)

FCC Registration Number: ESVMUL-46531-AL-E

Ringer Equivalence: 0.1B

Service Center in USA: National Repair Center

130 Perinton Parkway

Fairport, NY 14450-9199 USA

(800) 289-0096 ext. 4220

D6412/D4412 Operation and Installation Guide

Page 9© 2003 Bosch Security Systems 45349E

D6412/D4412

Overview

2.0 Overview

DX2010

Point Expansion Module

DX3010

Octo-Output Module

RF3224 Premises

RF Receiver

(up to 4 RF keypads

and 32 keyfobs)

Use command c enters and/or key switches to

arm the panel by area. Each area can have its

own account number or areas can be grouped

together with a common account number.

Points of protection are assigned to areas.

2.1 Specifications

Voltage Input

Primary:

Secondary:

Current Requirements

Panel:

Power Outputs

Continuous:

Note: Up to 400 mA at 11. 5 VD C to 12.4 VDC for UL Listed burglary applications, 120 mA for Fire and

Battery Discharge/Recharge Schedule

Combined Burglary/Fire (continuous supply) total for all device s and outputs.

Alarm

Power:

Discharge

Cycle:

Recharge

Cycle:

Control Panel

8 On-Board

Sensor Loops

4 On-Board

Outputs

DX3020 Module

Provides control for

X-10 modules.

(for connection of serial printer

D8132 Modules provide

additional power for command

centers and o ther powered

DX4010

Serial Interface Module

or other RS-232 devic e) .

devices.

Figure 1: System Configuration

18 VAC 22 VA class 2 plug-in transformer CX4010 (D1825)

12 VDC, 7 Ah sealed lead acid rechargeable battery or 12 VDC, 18 Ah sealed lead acid

rechargeable battery.

100 mA

See Appendix : Approved Applications Compliance Guide for the current requirements of other

system components.

Up to 600 mA maximum at 11.5 VDC to 12.4 VDC (continuous supply) total for all devices

and outputs for non UL a pplications.

400 mA for Fire and combined Fire/Burglary; 1500 mA for UL Burglary; 1850 mA for other

(not investigated by UL ). Applies to all four outputs combined. See the Outputs section of the

D6412/D4412 Program Entry Guide (P/N: 45351).

AC Off: Command centers indicate trouble. AC Fail Report sent as programmed.

•

13.8 VDC: Charging Float Level.

•

12.1 VDC: Low Battery trouble at command centers.Low Battery Report as prog rammed.

•

10.2 VDC: Panel shuts down as voltage falls below 10.2 VDC.

•

AC On: Panel restarts, battery charging begins, AC Restoral Report sent as programmed, AC

•

trouble clears from command centers.

13.0 VDC: Battery Restoral Reports sent, battery trouble clears from command centers.

•

3.8 VDC: Battery float charged.

•

D6412/D4412 Operation and Installation Guide

Page 10 © 2003 Bosch Security Systems45349E

D6412/D4412

Overview

Minimum

Operating

Voltage

SDI Bus (Data)

Telephone

Connections

Environmental

Arming Stati o ns

Compatible

Enclosures

Compatible

Accessories

Control Panel

Configurations

10.2 VDC

12 VDC nominal. 305 m (1000 ft.) of 22 AWG (0.8 mm) cable.

RJ31X or RJ38X jack can be interfaced with panel

Temperature: 0°C to +50°C (+32° to +122°F)

Relative Humidity: 5% to 8 5% at +30°C (+86°F ) non-condensing

D625 VF Text Command Center

•

D623 LCD Text Command Center

•

D621 LED Command Center

•

Keyswitch

•

D2203 Universal Enclosure (included with panel), D8103 Universal Enclosure, D8109 Fire

Enclosure, D8108A Attack Resistant Enclosure.

Note: When ordering a compatible enclosure, order the D6412M (includes the mounting skirt

and the D6412LC) or the D4412M (includes the mounting skirt and the D4412LC). In addition,

order the CX4010 transformer.

D621 LED Command Center

•

D623 Text Command Center, LC D Display

•

D625 Text Command Center, Vacuum Fluorescent Display

•

DX2010 (D9528) Point Expansion Module

•

DX3010 (D9529) Octo-Output Module

•

DX3020 (X7410I) Module (not investigated by UL)

•

DX4010 (D9533) Serial Output Module (not investigated by UL)

•

DX8010 Telephone Command Module (not investigated by UL)

•

DS RF3224 Premises RF Receiver

•

DS RF3332/3334 Keyfob (not investigated by UL)

•

DS RF3341 Keypad (not investigated by UL)

•

Programming Key (PK32)

•

D6412 - Complete control panel assembly in the D2203 Universal Enclosure. A CX4010

•

Transformer is su pplied.

D6412LT - Complete control panel assembly in the D2203 Universal Enclosure. A CX4010

•

Transformer must be ordered separately.

D6412LC - Complete control panel assembly without an enclosure or transformer. A

•

CX4010 Transformer must be ordered separately.

D6412M - Complete control panel assembly with a mounting skirt for the compatible

•

enclosure. A CX4010 Transformer must be ordered separately. See Compatible Enclosures

in this table for compatibl e enclosure alternatives.

D4412 - Complete control panel assembly in the D2203 Universal Enclosure. A CX4010

•

Transformer is su pplied.

D4412LT - Complete control panel assembly in the D2203 Universal Enclosure. A CX4010

•

Transformer must be ordered separately.

D4412LC - Complete control panel assembly without an enclosure or transformer. A

•

CX4010 Transformer must be ordered separately.

D4412M - Complete control panel assembly with a mounting skirt for the compatible

•

enclosure. A CX4010 Transformer must be ordered separately. See Compatible Enclosures

in this table for compatibl e enclosure alternatives.

D6412/D4412 Operation and Installation Guide

Page 11© 2003 Bosch Security Systems 45349E

D6412/D4412

I

T

I

T

Overview

2.2 SIA Control Panel Standard

The D6412/D4412 utilizes features within the SIA Control Panel Standard, Features for False Alarm Reduction,

SIA CP-01-1994.02 (R2000.01). SIA features are noted in the D6412/D4412 Program Entry Guide (P/N: 45351). The standard

is available through:

Security Industry Association (SIA)

635 Slaters Lane, Suite 110

Alexandria, Virginia 22314

You can e-mail requests for standards to: Standards@SIAOnline.org.

2.3 Standard Features

2.3.1 Points

The Bosch Security Systems D6412 Control Panel provides up to 40 separate points of protection (24 for the D4412 panel).

Point programming parameters determine the panel’ s response to open and shorted co nditions on the point’ s sensor loop.

Points are programmed individually with several options to customize the protection to your installation. There are eight

sensor loops available on the panel (for on-board points). Off-board point locations can be standard wired sensor loops

(DX2010 Point Expander) or premises RF transmitters (premises RF receiv er is required). The 40 points of protection for the

D6412 (24 points for the D4412) can be located on any combination of wired and RF locations.

2.3.2 Areas and Accounts

The system supports up to four separate areas for the D6412 and up to two separate areas for the D4412. You can assign all

points to a single area or spread them out over a maximum of two or four areas, model dependent.

You arm and disarm the panel by are. You can arm and disarm several areas with one function. You can also assign a

passcode an authority level that allows a user to arm an area from a remote command center in another area. Assigning each

area its own account number creates four (D6412) or two (D4412) separate accounts in one panel. Assigning the same

account number to different areas groups them together in a single account.

Area options include: exit tone and delay , separate fire and burglary outputs, and auto opening and closing skeds. A rea 1 can

be programmed as a common area. A “First to Open, Last to Close” arming feature is available.

2.3.3 Communicator

The panel uses a built-in digital communicator to send reports to the receiver. It transmits reports in either Modem IIIa²,

Contact ID, or Pager format.

Only the following central station receivers support the panel’s Modem IIIa² fo rmat:

• D6600 with CPU v01.01.03 (or higher)

• D6500 with D6511 MPU v1.05 (or higher)

The D6500 with D6510 MPU does not support the panel’s M odem IIIa2 Format.

MPORTAN

The panel connects to an RJ31X jack for phone line seizure. Connection to the RJ31X complies with FCC regulations for

using the public telephone network. You can pr ogram the panel to route reports to one of two routing destinations.

The system has routing capabilities that allow you to direct groups of system event reports and individual point reports to

two different routing destinations. The reports can be routed to either destination, both destinations, or to Destination 2

only on failure of Destination 1.

Each routing destination can be programmed with two phone numbers.

Check panel communications at least once annually (from panel to central station) to verify the panel is

communicating properly in the selected reporting format.

MPORTAN

D6412/D4412 Operation and Installation Guide

Page 12 © 2003 Bosch Security Systems45349E

D6412/D4412

Overview

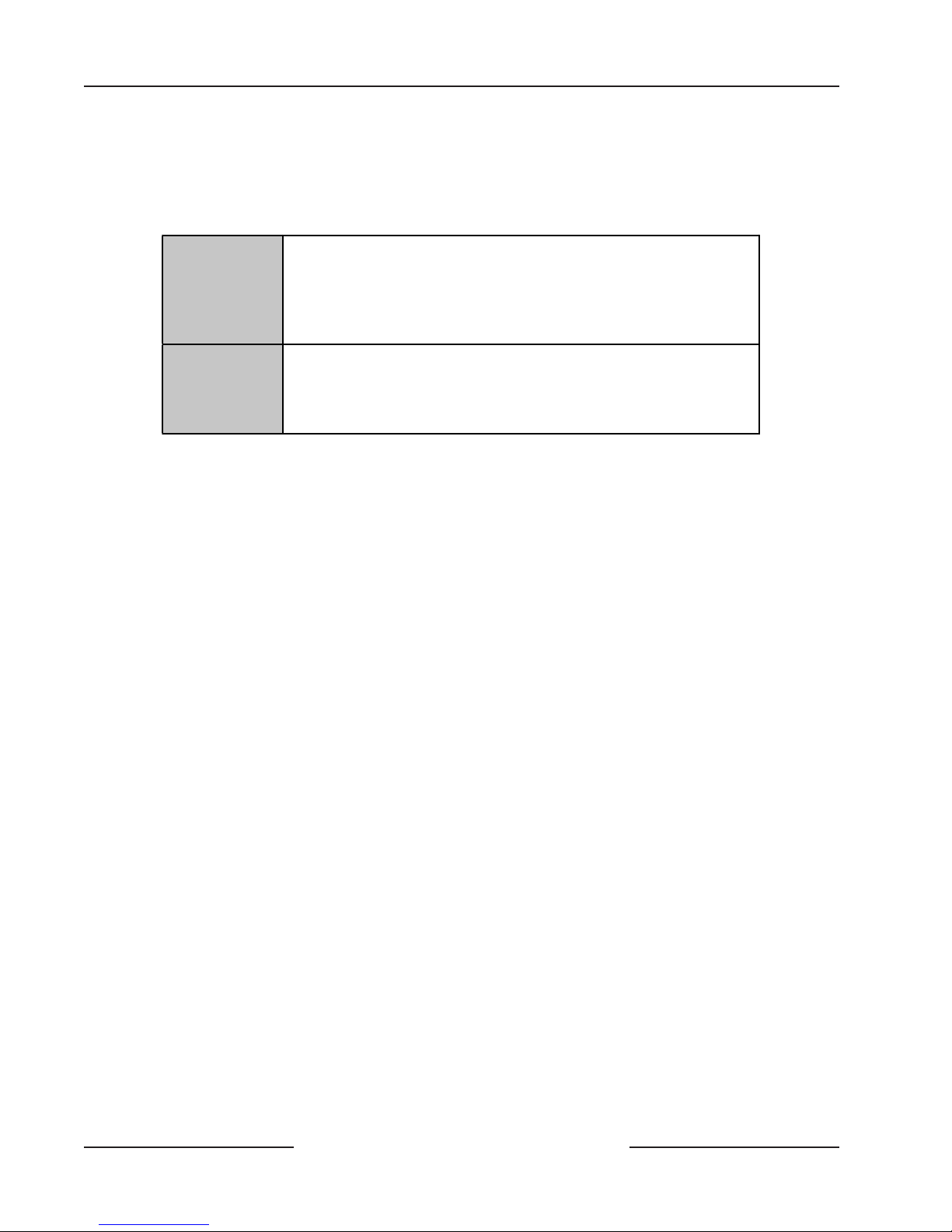

2.3.4 Command Centers

You can connect a maximum of eight, fully-supervised command centers to the system. The available power affects the total

number of command centers you can connect without providing an auxiliary power supply.

The panel transmits a Serial Device Trouble R eport, SDI MISSING in the Mode m IIIa² fo rmat or Sys Peripheral

Trouble in the Contact ID format, if it loses communication with a command center . Table 3 shows the command centers

compatible with the panel. Refer to Command Center in the D6412/D4412 Program Entry Guide (P/N: 45351) for complete

details on programming command center options.

Model Display

D621 16-Point LED

D623 Two lines of 16 charact er s, LC D

D625 Two lines of 16 charac t er s, v acuum fluorescent

Table 3: Compatible Command Centers

2.3.5 Keyswitch

You can arm and disarm any of the available areas with maintained or momentary closure devices such as keyswitches. P oint

programming determines loop responses and which area a keyswitch controls. Sub-control units (D279) can arm and

disarm individual points.

2.3.6 Alarm Event Memory

The system uses alarm event memory to store alarm events for each area. You can view the area alarm events at a command

center assigned to the area. The panel clears the area’s alarm event memory and starts storing new alarm events when you

turn the area on.

2.3.7 Event Log

The system stores 254 events from all areas in its event log. All events can be stored even if the panel does not send a report

for them. You can view the log at a text co mmand center (the D623 for example), print it locally using the DX4010 Serial

Interface Module and a serial printer , or upload it to the Remot e A ccount M anager (RAM IV).

See Appendix B in the D6412/D4412 Program Entry Guide (P/N: 45351) for a listing of log events and how to view them.

2.3.8 EMI/Lightning Transient Protection

The panel maintains Bosch Security Systems high level of quality and field dependability . Its design significantly reduces

electromagnetic interference and malfunction generally caused by lightning.

2.3.9 Programming

Use either a text keypad or the Remote Account Manager (RAM IV) to program the panel. Refer to the D6412/D4412

Program Entry Guide (P/N: 45351) for programming options.

2.3.10 Other Features

The panel has many programmable features. A short list of some of the features follows.

• Supervision of AC (primary power), battery (secondary power), SDI bus devices (keypads, point expanders,

programmable output modules, alternate communication modules, etc.), central processing unit (CPU), and the

telephone line (voltage only).

• Aut omatic syste m test reports

• Remote access for programming, diagnostics, and log uploads using the Remote Account Manager (RAM IV)

• Fire Alarm Verification

• Up to twenty (D6412) or twelve (D4412) Programmable Outputs, including a supervised siren driver

• Skeds (scheduled events)

Complete details on all the features can be found in the D6412/D4412 Program Entry Guide (P/N: 45351).

D6412/D4412 Operation and Installation Guide

Page 13© 2003 Bosch Security Systems 45349E

D6412/D4412

Overview

2.3.11 Control Panel Assembly

The Bosch Security Systems control panel is shipped from the factory pre-assembled. You should receiv e the following parts

with your panel.

Literature Package

D6412

Control Panel

D6412/D4412 Installat ion Guide (P/N: 45349)*

D6412 Program Record Sheet (P/N: 45350)*

D6412/D4412 Program Entry Guide (P/N: 45351)*

D6412 Release Notes (P/N: 46929)

D6412/D4412 TSN: Smoke Detector Compatibility (P/N: 46928)*

D6412 Specifications Sheet (P /N: 48392)*

D4412

Control Panel

D6412/D4412 Installat ion Guide (P/N: 45349)*

D4412 Program Record Sheet (P/N: 50485)*

D6412/D4412 Program Entry Guide (P/N: 45351)*

D4412 Release Notes (P/N: 50482)

D6412/D4412 TSN: Smoke Detector Compatibility (P/N: 46928)*

* This literature is available in a separate literature package for dealers.

Assembly

• Printed Circuit Board (PCB)

• CX4010 transformer (order separately when ordering the D6412LC, D4412LC, D6412LT, D4412L T, D6412M,

or D4412M)

• T w o mounting clips

• Two #6 x 3/4 in. screws

• Eight 2.2 kΩ EOL resistors (eight-pack [P/N: 47819], single resistor [P/N: 25944B])

• Eight 3.65 kΩ point-doubling EOL resistors (eight-pack [P/N: 47821], single resistor [P/N: 38130B])

• One 2.21 kΩ fire EOL resistor (P/N: 25899)

• Two 14 in., 18 AW G (1.2 mm), c olor-c oded battery leads

• Three PCB support standoffs (P/N: 30503B)

Ordered Separately

Order the following to complete a basic eight-point installation.

• Command center (or keyswitch)

• D118 Speaker (for PO2 in supervised configuration) D118 not investigated by UL.

• D126 Battery

• D164 Phone Cord

Configured packages are also available. Please consult your Bosch Security Systems Product Catalog.

2.3.12 Listings and Approvals

Fire

CSFM

Burglary

U n d erwriters L ab o ra to ries

H o u seh o ld F ire Wa rn in g UL9 85

App roved by the Califo rn ia State Fire Marshal for Co n trol Un its (Hou sehold)

U n d erwriters L ab o ra to ries

- UL1023 H ousehold

- UL365 Police Connect

- UL609 Local

- UL1076 Proprietary

- UL609 Central Station

- UL609 D igital Alarm

D6412/D4412 Operation and Installation Guide

Page 14 © 2003 Bosch Security Systems45349E

D6412/D4412

I

T

Installation

3.0 Installation

3.1 Before You Begin

This section contains a general installation procedure. It refers to other sections of the guide for detailed instructions.

Bosch Security Systems recommends you review this guide and the D6412/D4412 Program Entry Guide (P/N: 45351) before

you begin installation to determine the hardware and wiring requirements for the features you want to use.

As you read through this guide, have the following documents at hand:

• D6412 Program Record Sheet (P/N: 45350) or D4412 Program Record Sheet (P/N: 50485)

• User’ s Guide (Text Command Center [P/N: 46841]; LED Command Center - 46840). A co ndensed version of the

User’s Guide is found in the D6412/D4412 Program Entry Guide (P/N: 45351).

• Installation guide for each command center model you intend to install.

Before you begin installing the panel, you should be familiar with keypad programming or the Remote Account Manager

(RAM IV).

3.2 Enclosure Options

The D2203 Enclosure is supplied with the standard D6412/D4412 Control Panel. To mount the D6412 in one of the Bosch

Security Systems enclosures listed below, ord er the D6412M version (order the D4412M version for the D4412).

• D8103 Universal Enclosure (gray)

• D8109 Fire Enclosure (red)

• D8108A Attack Resistant Enclosure (gray)

The “M” version substitutes a D2202 M ounting Skirt for the D2203 enclosure allowing installation in the other enclosures.

“M” does not include a transformer . Order a CX4010 separately . R efer to A ppendix A: Approved A pplications Compliance

Guide to determine if your application requires a specific enclosure.

Mount the enclosure in the desired location.

3.3 Premises Wiring

Run the necessary wiring throughout the premises and route the wires into the enclosure.

Electro Magnetic Interference (EMI) may cause problems. EMI may occur if you install the system or run system

wires near the following:

MPORTAN

If you think that EMI may be a problem, use shielded cable. The drain wire for the shielded cable must have continuity from

the earth ground terminal on the panel to the end of the wire run. If continuity is not maintained, the shielded cable may

aggravate potential noise problems rather than eliminate them.

Connecting the drain wire to ground at any place other than the earth ground terminal may also produce problems. If you

cut the drain wire to install devices, be certain to splice it together. Carefully solder and tape all splices.

• Computer network system

• Electrical lines, fluorescent fixtures or telephone cabling

• Ham radio transmitter site

• Heavy machinery and motors

• High voltage electrical equipment or transformers

• PBX telephone system

• Public service (police, fire departments, etc.) using radio communications

• Radio station transmitter site or other broadcast station equipment

• Welding shop

D6412/D4412 Operation and Installation Guide

Page 15© 2003 Bosch Security Systems 45349E

D6412/D4412

Installation

3.4 Installing the Assembly

1. Place the panel mounting clips on the appropriate standoff in the enclosure (see Figure 2).

2. Slide the panel into the slots at the top of the enclosure and then secure it with the two screws provided

(see Figure 2).

3. Connect earth ground to the panel before making any other connections (see Section 3.4.1 Connecting

Earth Ground).

Mounting Slots

D6412/D4412 PCB Location

D6412/D4412 BOARD

TERMINALS

Install the PCB support standoffs here (P/N: 30503B)

Corner of

D6412/D4412

Mounting

PCB

Clip

Mounting Clip Assembly

Enclosure

Standoff

=

Figure 2: Enclosure Mounting

3.4.1 Connecting Earth Ground

T o help pr event damage from electrostatic charges or other transient electrical surges, connect the system to earth ground

before making any other connections. A grounding rod or cold water pipe are recommended earth ground references.

Do not use telephone or electrical ground for the earth ground connection. Use 14 to 16 AW G (1.8 mm to 1.5 mm) wire

when making the connection. Use only the earth ground terminal. Do not connect any other panel terminals to earth

ground.

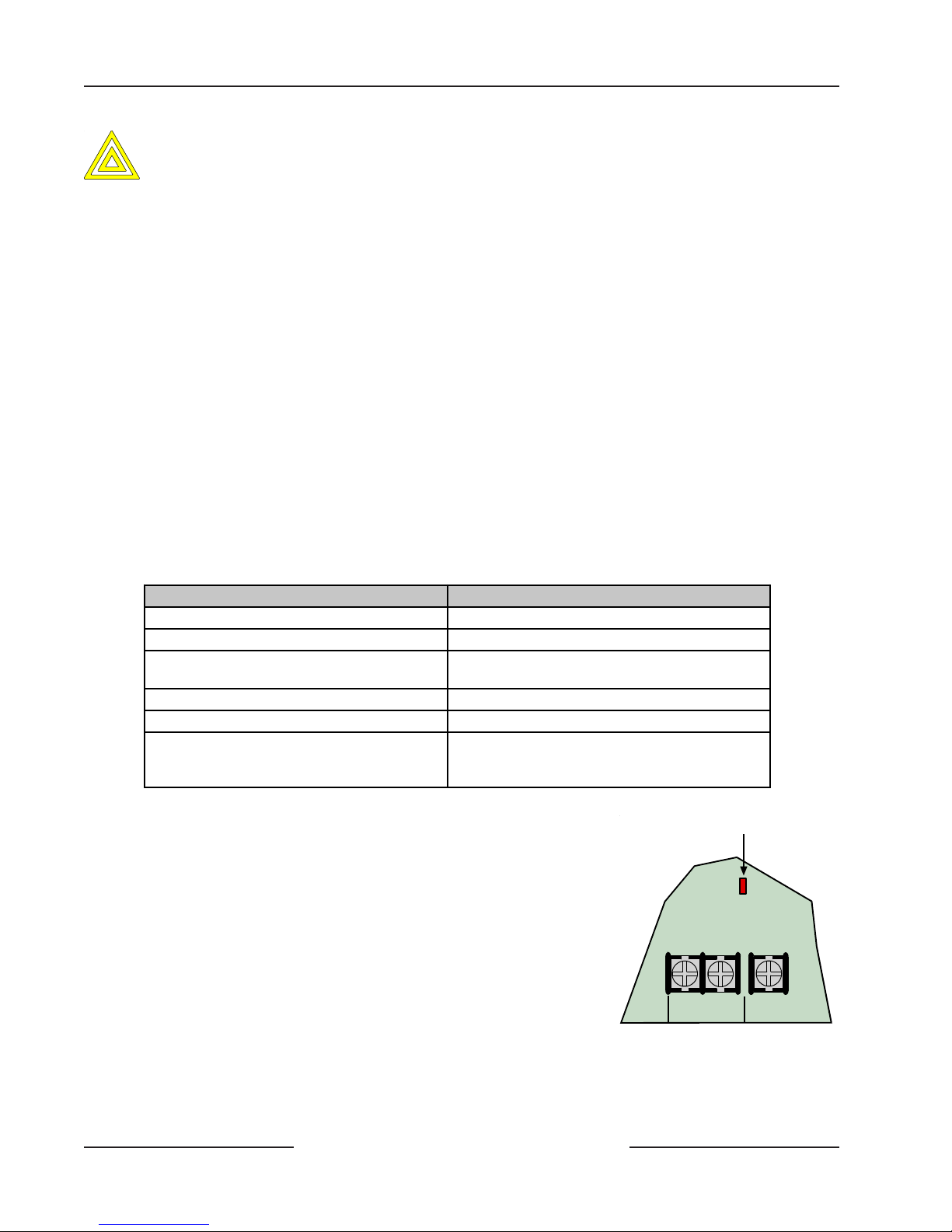

3.4.2 Closing the Installer Switch

Closing the Installer Switch disables the panel (see Figure 3). System reporting is disabled and the system cannot be armed. A

system trouble shows at all keypads.

D6412/D4412 Operation and Installation Guide

JP1

AUXILIARY

Installer

Figure 3: Installer Switch

Page 16 © 2003 Bosch Security Systems45349E

INSTALLER SWITCH

NORMAL (OPEN)

INSTALLER SWITCH

LOCKED (CLOSED)

D6412/D4412

Installation

Opening the Installer Switch from the closed position resets the panel. The panel resets all its timers, counters, indexes, and

buffers. Any points that restore after a reset is performed do not generate Restoral Reports.

Leaving the Installer Switch in the closed position lets you power up the panel and charge the battery as you install the

detection devices and command centers.

3.5 Finishing the Installation

3.5.1 Earth Ground and Installer Switch

First, make the earth ground connection and close the Installer Switch if you have not already done so.

T o reduce the occurrence of false alarms upon toggling of the Installer Switch, the panel ignores all point faults while the

devices stabilize during the setup process. The panel’s start-up process tak es appro ximately 60 sec. to co mplete. It occurs at

power-up and when the panel resets (Installer Switch OPEN). See Section 3.5.7 Power Up and Section 13.3.10 Exiting the

Installer’s M enu for more information. During this period, a screen showing the panel model number (D6412 or D4412),

firmware revision number , and a “Please W ait...” message appears for appro ximately 10 sec onds.

D6412 Rev

Please Wait...

3.5.2 Charge the Battery as You Finish

Connect the battery and then the transformer so that the panel can charge the battery as you finish the installation. See

Section 4.0 Power Supply for instructions.

Self-Diagnostics at Power U p and R e set: The system performs a series of self-diagnostic tests of its hardware, software, and

program at power up and at reset. They take about 60 sec. to co mplete. Command centers may display “ S yst em Fault ” and

sound during the power up and reset interval.

If the panel fails any of the tests, a system trouble message appears at the command centers.

T ouch the Earth Ground Terminal First: To discharge any static charge you may be carrying, alwa ys touch the panel’s earth

ground terminal before beginning work on the panel.

3.5.3 Install and Wire Detection Devices

Install and wire detection devices and command centers at their locations throughout the premises. Do not make the

connections at the panel end of the wiring yet.

Section 7.0 On-Board Sensor Loops contains instructions for wiring the on-board point locations to detection devices. Section

11.0 Arming Devices contains instructions for wiring the command centers.

Instructions for wiring the off-board point locations are found in the instructions packaged with the point expansion

devices.

3.5.4 Install Modules

1. P ower Down First: P ower do wn the unit by unplugging the transformer and disconnecting the battery.

Bosch Security Systems recommends powering down the unit when installing modules or when making

wiring connections to the panel.

2. Install and wire any modules required for your installation as described in the module’s installation

instructions.

Instructions for the DX2010 Point Expansion Module and the DX3010 Output Expansion Module are included in this guide.

See Section 8.0 Off-Board Sensor Loops for DX2010 instructions and Section 10.0 Off-Board Outputs for DX3010 instructions.

3.5.5 Make the Telephone Connections

If you are connecting the panel to a ground start phone system, you need to install a D133/D134 Relay . See Section 6.0

T elephone Connections for complete instructions.

3.5.6 Connect the On-Board Points and Command Centers

Connect the on-board points and command center wiring to the system. See Section 7.0 On-Board Sensor Loops and Section

11.0 Arming Devices for instructions.

X.XX

D6412/D4412 Operation and Installation Guide

Page 17© 2003 Bosch Security Systems 45349E

D6412/D4412

Installation

3.5.7 Power Up

Reconnect the battery and then plug in the transformer.

Leave the Installer Switch in the CLOSED position for now . (See Figure 3). The following sequence of events occurs:

1. “System Fault” appears on the text command center(s) and all command centers emit a single tone for

approximately 10 seconds.

2. A screen showing the panel model number (D6412 or D4412), firmware revision number and a “Please

Wait... ” message appears for approximately 10 seconds.

3. “Trouble! Press Cmd 4 to View” appears. Press the [CMD] and [4] keys. A new message appears:

Date/Time lost! Press 5 to set.” Press the [5] key to enter the Dat e/Time window and set accordingly .

To reduce the occurrence of false alarms upon panel power -up (or restoration of power after a complete

loss of primary and secondary power), the panel ignores all point faults for approximately 60 sec. while

the devices stabilize. This process is part of the panel’s start-up process, and it occurs at pow er -up. This

60-sec. period begins when the “Please Wait... ” screen appears.

The “Trouble! Press Cmd 4 to V iew” message reappears, indicating that the Installer Switch is closed. To

return the system to normal (disarmed, no fault/trouble conditions), open the Installer Switch (unless

you are ready to program the panel).

D6412 Rev

Please Wait...

3.6 Programming the Panel

If you have not created a program for the panel, review the D6412/D4412 Program Entry Guide (P/N: 45351). Make certain

you have all the required accessory modules installed for the features you want to use.

Note: The Installer Switch must be in the closed position to program the panel from a keypad.

You can enter your custom program at a text keypad, or send it to the panel from the R emo te A cc ount Manager (RAM IV).

There is a connector provided on the panel for quick connection of an installer’s k eypad to the system for programming. See

Section 13.0 Installer’s K eypad and Installer Mode for complete instructions for the installer keypad.

After you finish programming, move the Installer Switch to the open position. If the unit is programmed for reporting, the

panel transmits a Reboot Report to the receiver .

X.XX

3.7 Check for Fire Alarm Verification

You must check the Alarm Verification Box in the lower left corner of the label if you programmed Point 1 for Fire with

V erification. See Point Index in the D6412/D4412 Program Entry Guide (P/N: 45351). R efer to Section 14.0 Installation Label

for the location of the Alarm Verification Box on each installation label.

3.8 Testing the System

After finishing the installation and programming of the panel, make a complete functional test of the system. T est the panel

and all devices for proper operation. Test after you first program the panel and after any subsequent programming session.

W alk Test: U se the Walk Test (Cmd 44) or the point test available in the Installer Mode to perform a complete test of the

panel. See Section 13.0 Installer’s K eypad and Installer Mode.

If you test a device and the panel does not respond, there may be a problem with the device, wiring, a module setting, or

programming for the point.

Clear After T est: To clear the event memory and report buffer , mom entarily close the Installer Switch. E vents sto red in the

panel’s event log are not clear ed.

D6412/D4412 Operation and Installation Guide