Bosch BVA 2.0 Installation Instructions Manual

Bosch BVA 2.0 Series Air Handler

2-3-4-5 Ton Capacity

R410A

Installation Instructions

|

2

Bosch IDS BVA 2.0 Installation Instructions

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BVA 2.0 | 3

Table of Contents

1 Key to Symbols and Safety Instructions 4

1.1 Key to Symbols 4

1.2 Safety 4

2 General 6

2.1 Installations in High Humidity Environments 6

2.2 Unit Dimensions 9

3 Applications 10

3.1 Vertical Upfl ow 10

3.2 Vertical Downfl ow 10

3.3 Horizontal 10

3.4 Installation in an Unconditioned Space 12

4 Electrical wiring 13

4.1 Power Wiring 13

4.2 Control Wiring 13

4.3 Grounding 13

4.4 Electrical Data 13

4.5 Electric Heat Kit MCA/MOP Data 14

5 Airfl ow Performance 15

5.1 Indoor Fan Motor Function 16

6 Ductwork 17

7 Refrigerant Connections 18

7.1 Condensate Drain Connection 18

8 Air Filter (Not Factory-Installed) 19

9 Filter Installation Dimensions 20

10 Maintenance 21

10.1 Cleaning Precautions 21

10.2 Regular Maintenance 21

11 Wiring Diagrams 22

Bosch Thermotechnology Corp. | 02.2019

Data subject to change

|

4

Bosch IDS BVA 2.0 Installation Instructions

1 Key to Symbols and Safety Instructions

1.1 Key to Symbols

Warnings

Warnings in this document are identifi ed by a warning triangle

printed against a grey background.

Keywords at the start of a warning indicate the type and seriousness

of the ensuing risk if measures to prevent the risk are not taken.

The following keywords are defi ned and can be used in this document:

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor to moderate injury.

NOTICE is used to address practices not related to personal injury.

Important information

1.2 Safety

Please read before proceeding

WARNING:

These instructions are intended as an aid to qualified,

licensed service personnel for proper installation,

adjustment and operation of this unit. Read these

instructions thoroughly before attempting installation or

operation. Failure to follow these instruction may lead to

improper installation, adjustment, service or maintenance

possibly resulting in fire, electrical shock, property damage,

personal injury or death.

This document is customer property and is to remain with this unit.

These instructions do not cover all the diff erent variations of systems nor

does it provide for every possible contingency to be met in connection

with installation.

WARNING: FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH

All phases of this installation must comply with NATIONAL,

STATE AND LOCAL CODES. If additional information is

required please contact your local distributor.

This symbol indicates important information where there is no risk to

people or property.

WARNING: ELECTRICAL SHOCK

Disconnect all power to unit before installing or servicing.

More than one disconnect switch may be required to

deenergize the equipment. Hazardous voltage can cause

severe personal injury or death.

WARNING: ELECTRICAL SHOCK

If removal of the blower assembly is required, all disconnect

switches supplying power to the equipment must be

deenergized and locked (if not in sight of unit) so the

field power wires can be safely removed from the blower

assembly. Failure to do so can cause electrical shock

resulting in personal injury or death.

WARNING: FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH

Because of possible damage to equipment or personal

injury, installation, service, and maintenance should

be performed by trained, qualified service personnel.

Consumer service is recommended only for filter cleaning /

replacement. Never operate the unit with the access panels

removed.

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BVA 2.0 | 5

WARNING:

This product can expose you to chemicals including Lead

and Lead components, which are known to the State

of California to cause cancer and birth defects or other

reproductive harm. For more information go to

P65Warnings.ca.gov

WARNING: ELECTRICAL SHOCK

The unit must be permanently grounded. Failure to do so can

result in electrical shock causing personal injury or death.

CAUTION: FIRE HAZARD

The material of plenum and ductwork must meet the latest

edition of the NFPA 90B standard.

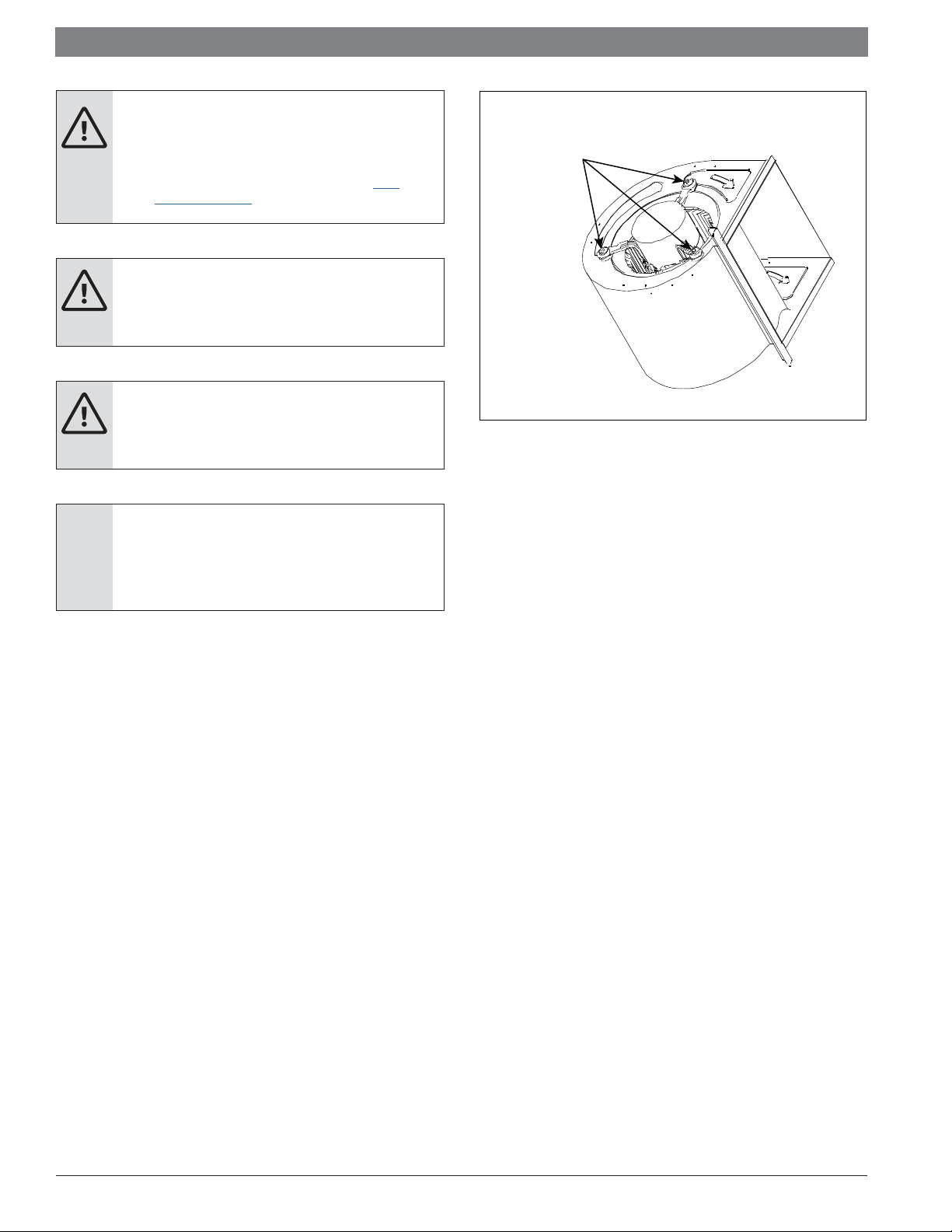

NOTICE:

Make sure the blower motor support is tight (3-motor

mounting bolts - Fig. 1). Then check if wheel is tightly

secured to motor shaft before operating unit.

.

www.

Blower Motor

Mounting Bolt

Figure 1

Bosch Thermotechnology Corp. | 02.2019

Data subject to change

|

6

Bosch IDS BVA 2.0 Installation Instructions

2 General

The unit can be positioned for bottom air return in the upfl ow position, left and right

air return in the horizontal position and top air return in downfl ow position.

This air handler provides the fl exibility for installation in any upfl ow, downfl ow or

horizontal application. Adjust the motor speed tap through the DIP switch (located

on the Air Handler's control board) to select correct air fl ow according to airfl ow

performance table in Section 5. Please refer to wiring diagram for Dip Switch

settings.

Please refer to Figure 8 for high and low voltage wiring connections.

To ensure the proper installation, select a solid and level site. Ensure enough

2.1 Installations in High Humidity Environments

When the unit is installed in a hot and humid place, if the humidity inside the

installation space exceeds 86℉ and RH 80%, it is recommended to insulate the

cabinet exterior. Use glass wool or polyethylene foam as insulation; the thickness

should be more than 2 in. and it must fi t inside the installation space opening.

Condensation may come from the surface of the insulation. Be sure to use

insulation that is designed for use with HVAC Systems. Condensation may be

produced on surface during cooling operation. It is also recommended to use

auxiliary drain pan and secure the unit fi rmly to prevent it from falling. See Figures

3, 4, 5, & 6.

Refer to local code requirements for usage of auxiliary drain pans.

clearance is maintained for installation and maintenance.

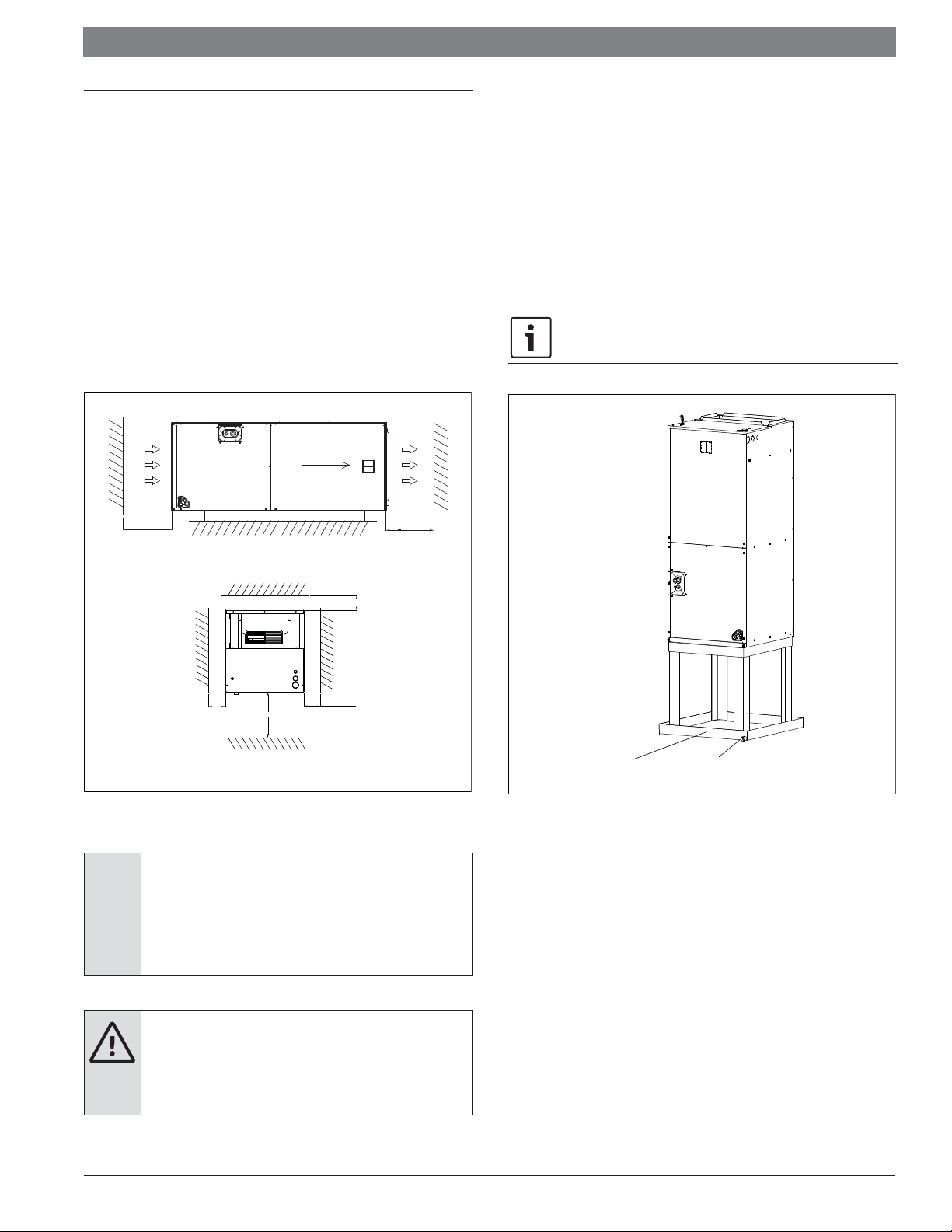

AIRFLOW

≥ "04≥40"

Clearances in the Horizontal Position

!

Clearances in the Vertical Position

Figure 2 Required Clearances

NOTICE:

The installed unit must have the required clearances as

shown in Figure 2. Failure to follow these instructions may

result in equipment damage and/or premature equipment

failure.

WARNING: FIRE HAZARD

Keep flammable material and vapors, such as gasoline, away

from the air handler. Failure to follow these instructions can

result in death, explosion, or fire.

Front of unit

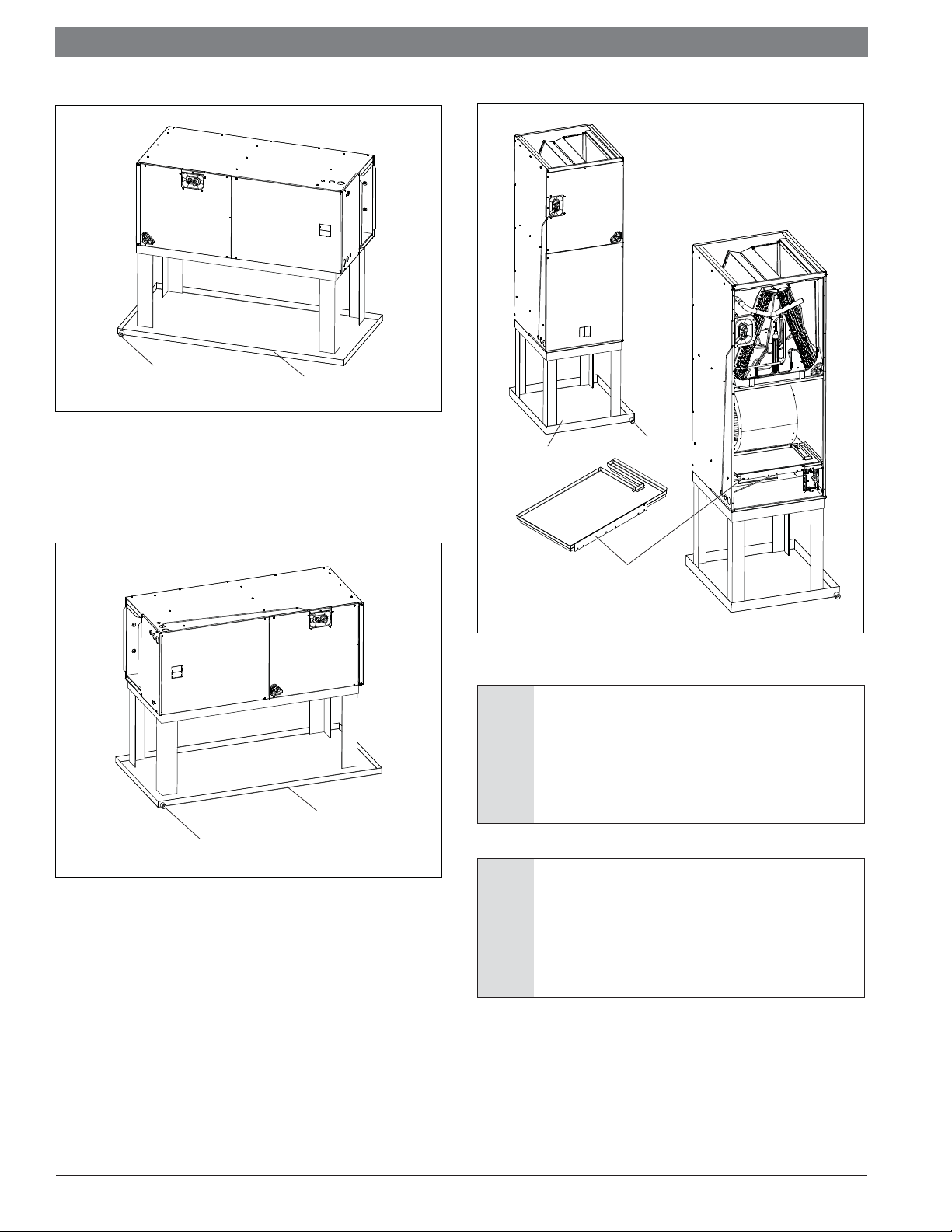

ı

25’’

!

!

Auxiliary drain pan

Figure 3

Installed Vertical Upfl ow

Drain piping

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BVA 2.0 | 7

Drain piping

Figure 4 Installed Horizontal Right

Drain piping

Auxiliary drain pan

Auxiliary drain pan

Auxiliary drain pan

Inner extra drain pan

Figure 6

Installed Vertical Downfl ow

NOTICE:

Inner extra drain pan is recommended to be installed for 4

Drain piping

and 5 ton vertical downflow applications installed in high

humidity environments. This inner extra drain pan can be

ordered from the manufacturer as a spare part. Refer to

Figure 6.

Figure 5

Installed Horizontal Left

Bosch Thermotechnology Corp. | 02.2019

NOTICE:

For high humidity installations which include electric

heat strips, it is recommended to install spacing brackets

(available as a spare part from the manufacturer) between

the heater and the heater collar to prevent condensation

from forming on the collar.

Data subject to change

|

8

Bosch IDS BVA 2.0 Installation Instructions

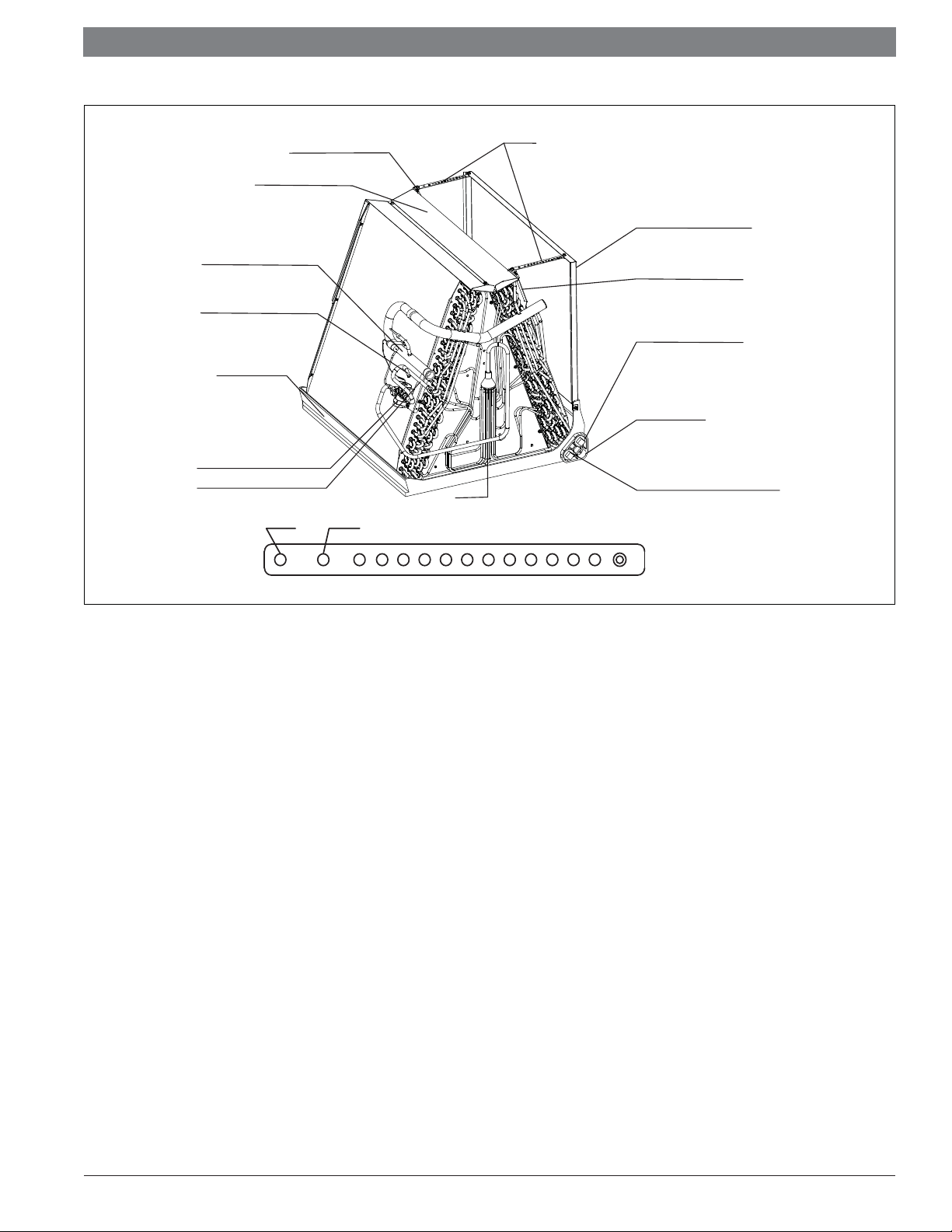

REAR WATER CATCHER

TOP AIR STOP

VAPOR LINE CONNECTION

SENSOR T2 LOCATION

VERTICAL DRAIN PAN

NON-ADJUSTABLE TXV

LIQUID LINE CONNECTION

THIS SYSTEM IS CHARGED WITH NITROGEN BEFORE SHIPMENT

60/48K 36/24K

STRAPS

STRAPS

HORIZONTAL DRAIN KIT

FRONT WATER CATCHER

AUXILIARY HORIZONTAL

DRAIN CONNECTION

PRIMARY DRAIN

CONNECTION

AUXILIARY UPFLOW/DOWNFLOW

DRAIN CONNECTION

Figure 7

Indoor Coil and Drain Pan Set-Up

Data subject to change

02.2019 | Bosch Thermotechnology Corp.

Installation Instructions Bosch IDS BVA 2.0 | 9

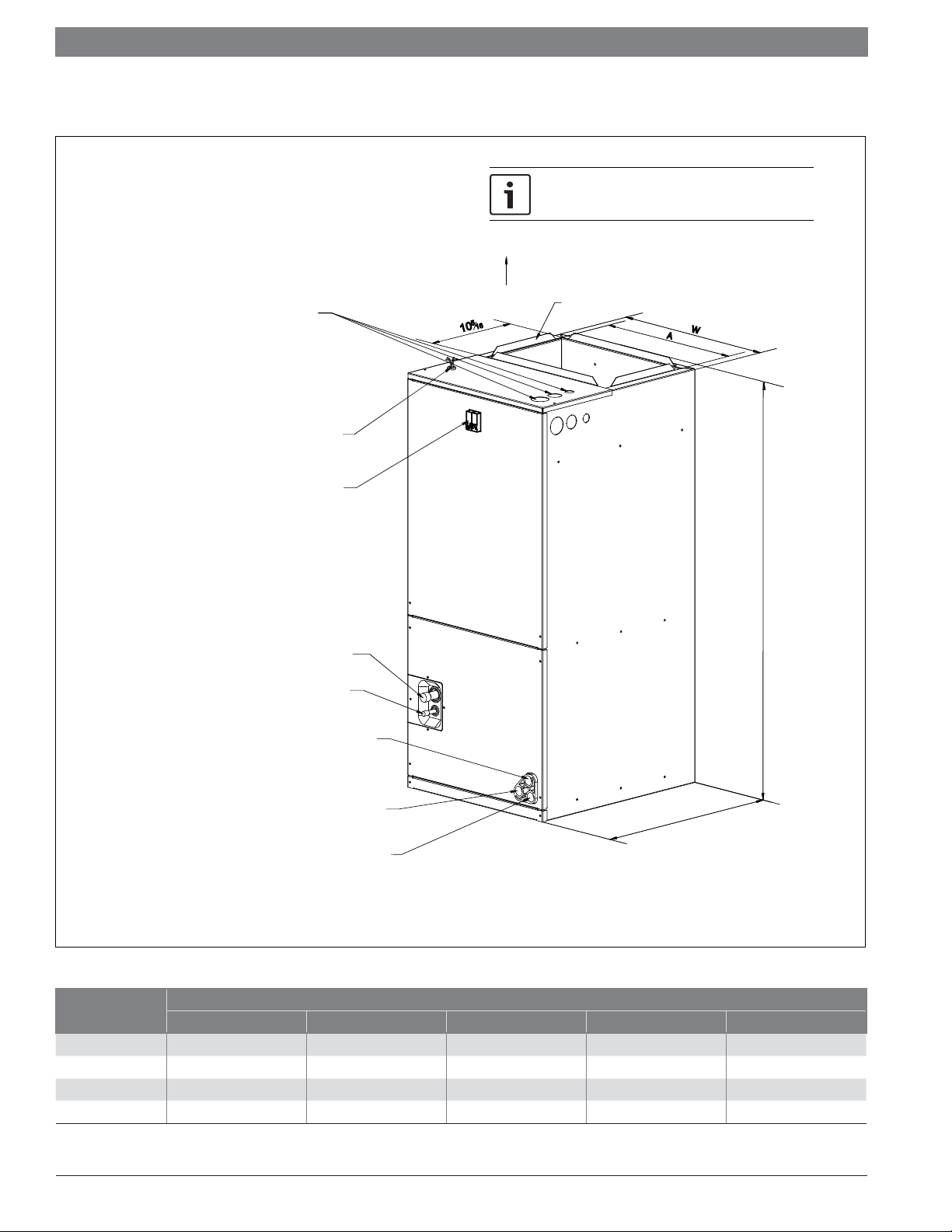

2.2 Unit Dimensions

25” CLEARANCE IS REQUIRED IN THE FRONT OF

THE UNIT FOR FILTER AND COIL MAINTENANCE.

ELECTRICAL CONNECTIONS

THROUGH TOP OR EITHER SIDE

SUPPLY AIR

HIGH VOLTAGE CONNECTION 1-

7

3

/

1-

/

8

"

8

",

DIA. KNOCK OUTS

LOW VOLTAGE CON

CIRCUIT BREAK

NECTION

ER SWITCH

(FOR ELECTRIC HEATER ONLY)

VA

POR LINE CONNECTION COPPER TUBE (SWEAT)

LIQUID LINE CON

NECTION COPPER TUBE (SWEAT)

AUXILIARY DRAIN CONNECTION 3/4"

FEMALE PIPE THREAD (NPT)

3

/

4

",

FLANGES ARE PROVIDED

FOR FIELD INSTALLATION

5

6

1

0

1

W

A

H

AUXILIARY DRAIN CONNECTION 3/4"

FEMALE PIPE THREAD (NPT)

PRIMARY D

FEMALE PIPE THREAD (NPT)

Figure 8

Model Size

Unit Height "H" Unit Width "W" Unit Length "D" Supply Duct "A" Liquid Line / Vapor Line

24 46-1/2 [1180] 19-5/8 [500] 21-5/8 [550] 18 [456] 3/8 / 3/4 [9.5]/[19]

36 46-1/2 [1180] 19-5/8 [500] 21-5/8 [550] 18 [456] 3/8 / 3/4 [9.5]/[19]

48 54-1/2 [1385] 22 [560] 24 [610] 19-1/2 [496] 3/8 / 7/8 [9.5]/[22]

60 54-1/2 [1385] 22 [560] 24 [610] 19-1/2 [496] 3/8 / 7/8 [9.5]/[22]

Table 1

Bosch Thermotechnology Corp. | 02.2019

D

RAIN CONNECTION 3/4"

UPFLOW UNIT SHOWN:

THE UNIT CAN BE POSITIONED FOR BOTTOM AIR RETURN IN THE UPFLOW POSITION, LEFT AND

RIGHT AIR RETURN IN THE HORIZONTAL POSITION, OR TOP AIR RETURN IN DOWNFLOW POSITION.

Dimensions Inch [mm]

Data subject to change

Loading...

Loading...