Page 1

Installation Instructions

Installation Manual

Bosch Eco26

External Model

BC2600RA

To be installed and serviced only

by an authorised person

This appliance is not suitable for

use as a pool heater

The "authorised installing person" is

responsible for:

1. Correct commissioning of this

appliance.

2. Ensure unit performs to the

specifications stated on the

rating label.

3. Demonstrate operation of unit to

customer before leaving.

Hand these instructions to

4.

customer

+

.

Service Department: 1300 30 70 37

www.bosch.com.au

SAR8854

Rev. 07/08

This appliance must be installed in accordance with the manufacturer's

installation instructions, AS5601, AS/NZS3500.4, AS3000 wiring regulations

and all Local Building, Water and Gas fitting regulations.

Failure to install this appliance in accordance with these installation

instructions may void warranty

In the interest of continued product improvement, Bosch reserves the

right to alter these specifications

without notice.

*SAR8854C*

Page 2

Installation Instructions

Robert Bosch

Installation Manual

(Australia) Pty. Ltd.

CONDENSING GAS WATER HEATER

Bosch Eco26+ <BC2600RA> (Outdoor Installation)

Potential dangers from accidents during installation and use are divided into the following three

categories. Closely observe these warnings, they are critical to your safety.

DANGER indicates an imminently hazardous situation which,

DANGER

if not avoided, will result in death or serious injury.

WARNING

CAUTION

WARNING: If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

Prohibited

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

Disconnect

Power

Earth

Be sure to do

CAUTION

Requests to Installers

• In order to use the water heater safely, read this installation manual carefully, and follow the

installation instructions.

• Failures and damage caused by erroneous work or work not as instructed in this manual are not

covered by the warranty.

• Check that the installation was done properly in accordance with this Installation Manual upon

completion.

•

After completing installation, please either place this Installation Manual in a plastic pouch and

attach it to the side of the water heater,

or hand it to the customer to retain for future reference.

2

Page 3

Installation Instructions

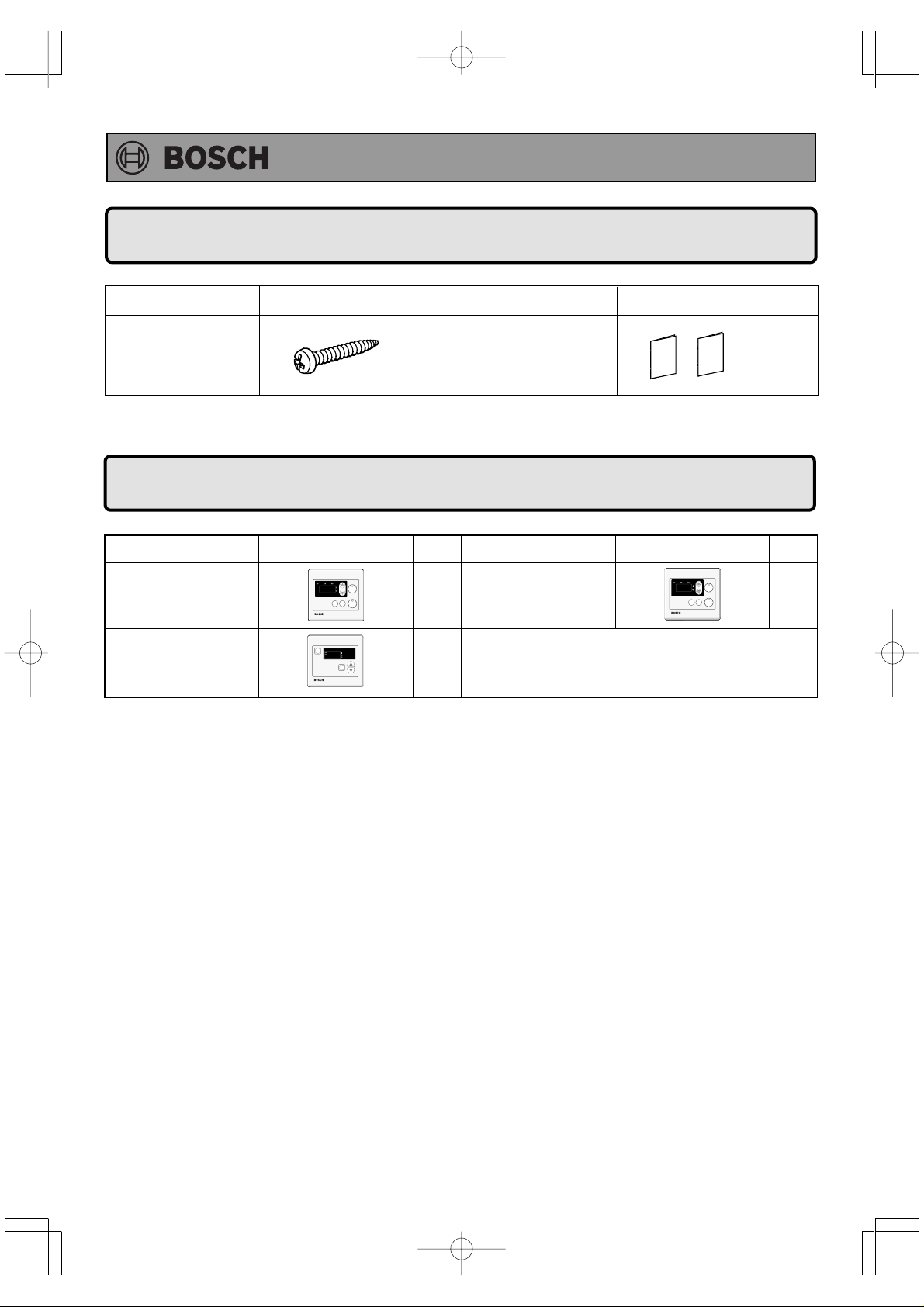

1.

Included Accessories

The following accessories are included with the unit.

Check for any missing items before starting installation.

Part Shape Q’ty

Owner's Guide,

Tapping Screw

Installation Manual

5

(this document)

The accessories listed below are not

included with the units, but may be necessary

2.

Optional Accessories

Main Controller

Bath Fill

Priority

Burner on

Temp.

YPRM67XB

Sub Controller

ON/OFF

YPRP62XB

Hot Water Temp

Priority

Burner on

ON/OFF

Volume

Set Time

Bath Fill

setting

Press 2sec.

to set time

Call

Hot Water Temp.

1

1

Main Controller

(YPRM67XB)

Sub Controller

(YPRP62XB)

for installation.

Bathroom Controller

(YPRS67XB)

• Maximum two Sub controllers can be used. See P.14 for details.

Bathroom Controller

Priority

YPRS67XB

Q’tyShapePart

1

each

Q’tyShapePartPart Shape Q’ty

Bath Fill

Burner on

Temp.

ON/OFF

Priority

Call

Bath Fill

1

3

Page 4

Installation Instructions

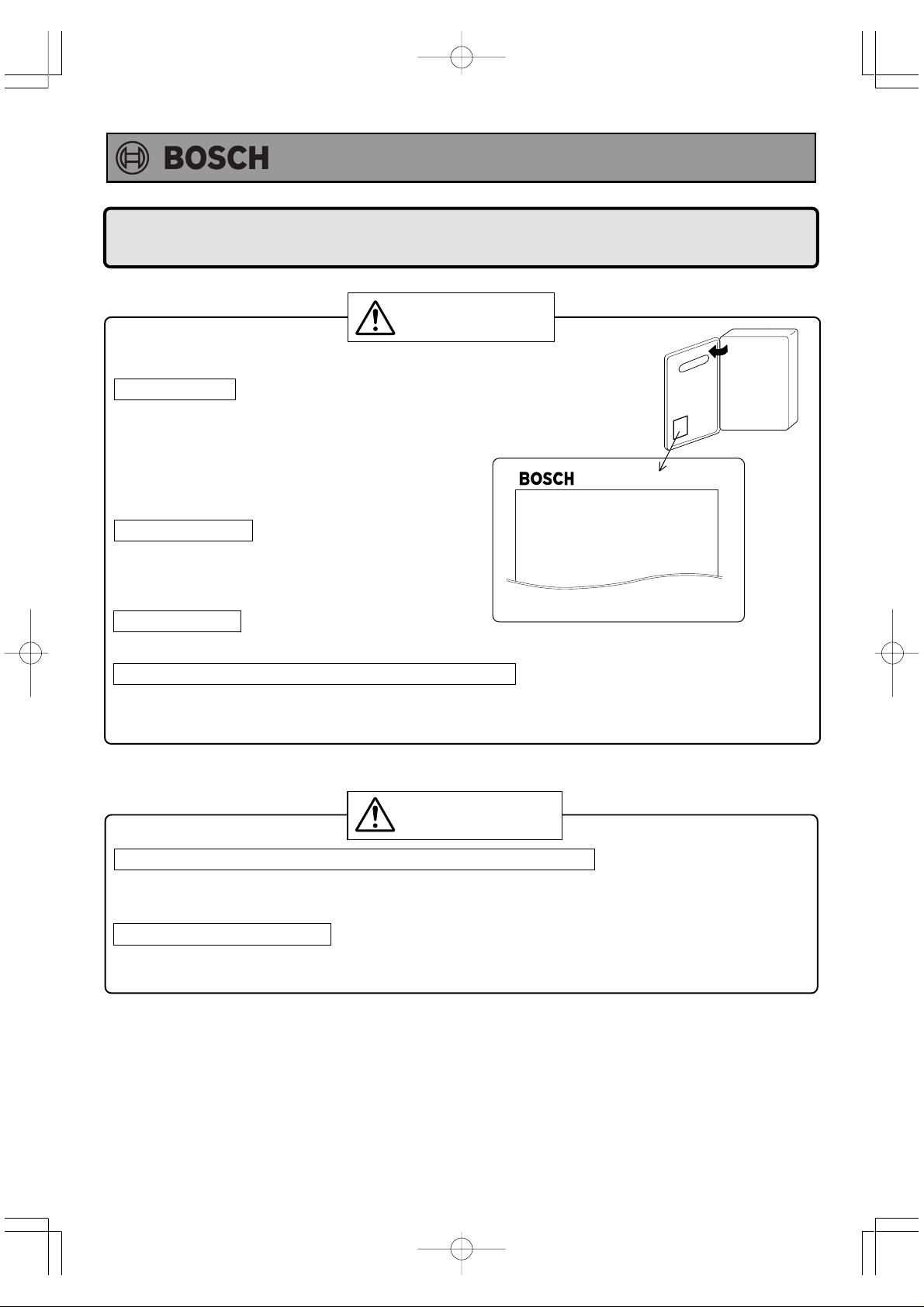

Before Installation

3.

WARNING

Check the Gas

• Check that the data plate (located inside of front cover) or

a temporary label (located on the front cover)

indicates the correct type of gas.

• Check that the gas supply line is sized for

178 MJ/hr for this unit.

•

DO NOT OPERATE WITH ANY OTHER GAS TYPE.

Check the Power

• The power supply required is 240/230VAC, at 50Hz.

Using the incorrect voltage may result in fire or

electric shock.

For NG Gas

MODEL BC2600RA

GAS TYPE

GAS CONSUMPTION

HEAT OUTPUT

ELECTRICAL RATING

RATED POWER

HOT WATER SUPPLY CAPACITY

GAS PRESSURE TEST POINT

: NG

: 178MJ/hr

: 45.7kW

: AC240/230V 50Hz

: 56.0W

: 26L/min RAISED 25°C

: MAX : 0.73kPa

: MIN : 0.18kPa

Warning labels

• Located on the right side of the casing -PLEASE READ THESE LABELS CAREFULLY!

Use Extreme Caution if Using With a Solar Pre-Heater

• A solar transfer valve must be installed with all solar applications when using Bosch Eco 26+.

• Solar systems installed without a solar transfer valve will void all Bosch warranty.

CAUTION

Do Not Use Equipment for Purposes Other Than Those Specified

• Do not use for other than increasing the temperature of the water supply, as unexpected accidents

may occur as a result.

Check Water Supply Quality

• If the water supply is hard, acidic or otherwise impure, treat the water with approved methods in

order to ensure full warranty coverage.

4

Page 5

Installation Instructions

Choosing Installation Site

4.

* Locate the appliance in an area where water leakage from the unit or connections will not result in

damage to the area adjacent to the appliance or to the lower floors of the structure. When such

locations cannot be avoided, it is recommended that a suitable drain pan, adequately drained, be

installed under the appliance. The pan must not restrict combustion air flow.

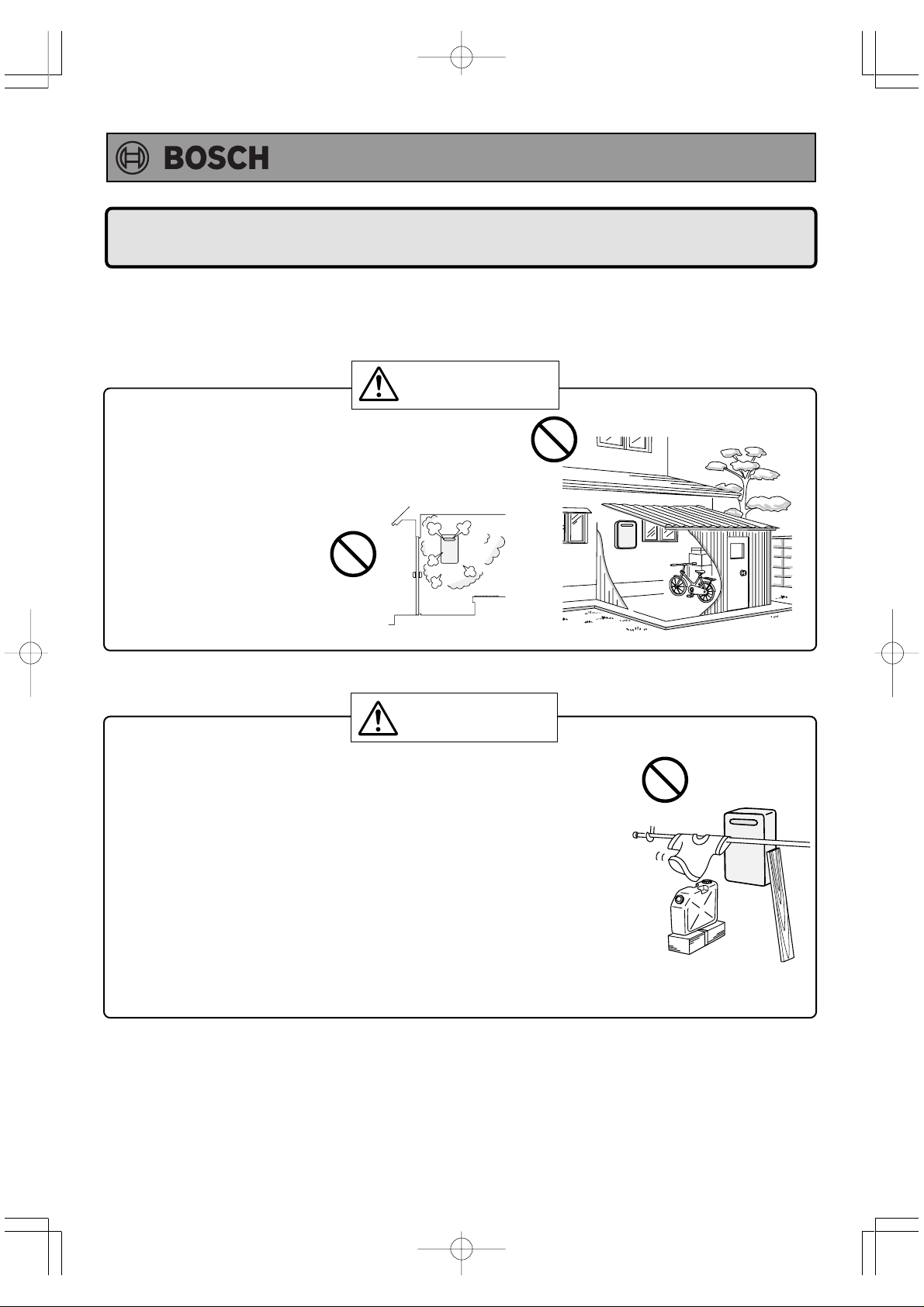

DANGER

• This water heater is for outdoor installation only.

Never install it indoors.

Do not enclose the termination with corrugated

metal or other materials.

This will cause carbon monoxide

poisoning and a potential fire

hazard.

Indoor

WARNING

• Avoid places where fires are common, such as those where petrol,

benzene and adhesives are handled, or places in which corrosive gases

(ammonia, chlorine, sulfur, ethylene compounds, acids) are present.

May result in fire.

• Avoid installation in places where dust or debris will accumulate.

Dust may block the air-supply opening, causing the performance of the

device fan to drop and incomplete combustion to occur as a result.

• Avoid installation in places where special chemical agents

(e.g., hair spray or spray detergent) are used.

Ignition failures and malfunction may occur as a result.

Prohibited

• Carbon Monoxide Poisoning Hazard. Do not install this water heater in a

mobile home, recreation vehicle or on a boat.

5

Page 6

Installation Instructions

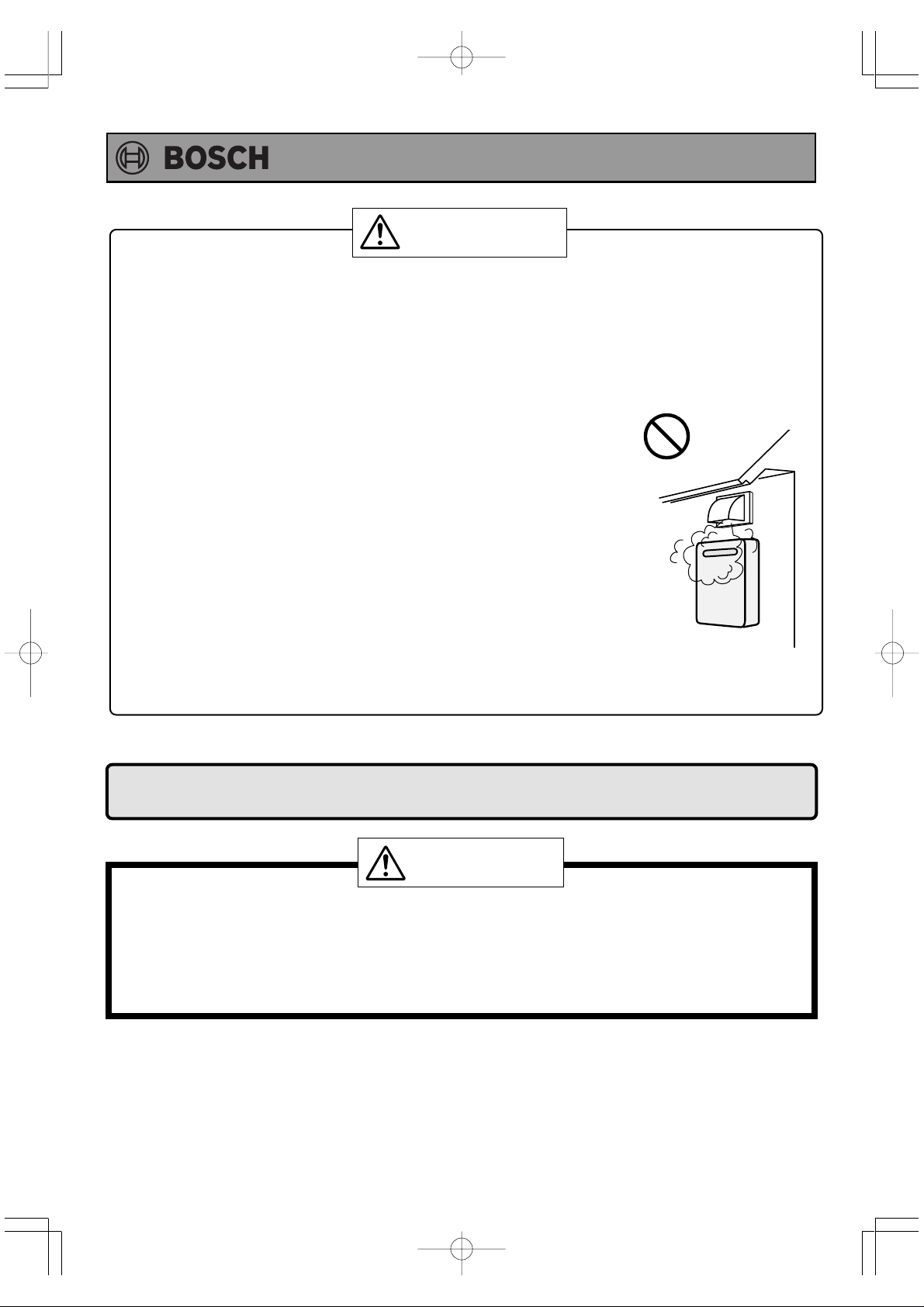

CAUTION

• Install the water heater in a location where it is free from obstacles and

stagnant air.

• Consult with the customer concerning the location of installation.

• Do not install the water heater near staircases or emergency exits.

• Do not install the water heater where the exhaust will blow on outer

walls or material not resistant to heat. Also consider the surrounding

trees and animals.

The heat and moisture from the water heater may cause discoloration of

walls and resinous materials, or corrosion of aluminium materials.

• Do not locate the vent termination directed towards a window or any

other structure which has glass or wired glass facing the termination.

• Install in a location where the exhaust gas flow will not be affected by

fans or range hoods.

• Take care that noise and exhaust gas will not affect neighbours.

• Avoid installation where the unit will be exposed to excessive winds.

Prohibited

• Before installing, make sure that the vent termination will have the proper

clearances according to AS5601, or your local authority.

• On combustible surfaces e.g. weatherboards etc. it is not required to

install a fire proof back board.

5. Installation Clearances

WARNING

Before installing, check for the following:

The location of the flue terminal must comply with the clearances shown on this page. If you are

unsure about clearances not indicated here, in general refer to AS5601, or your local authority. In

Western Australia refer to the WA Office of Energy rules and regulations.

Flue outlet must be free from any combustible material.

6

Page 7

Installation Instructions

CLEARANCES FOR FLUE TERMINAL (front of heater)

The location of the flue terminal must comply with the clearances shown on this page. If you are unsure

about clearances not indicated here, in general refer to AS5601, or your local authority. In Western

Australia refer to the WA Office of Energy rules and regulations.

a

j

W

f

n

jj

door

h

k

I

c

k

T

h

h

T

e

e

P

d

d

M

g

c

g

b

T

Use as a guide only. Refer to AS5601 or local gas fitting rules for specific locations

T=Flue terminal

I=Mechanical air inlet

Ref Item Minimum Clearance

a Below eaves, balconies and other projections

Appliances up to 50MJ/h input 300 200

Appliances over 50 MJ/h input 500 300

b From the ground, above a balcony or other surface 300 300

c From a return wall or external corner 500 300

d From a gas meter 1000 1000

e From an electricity meter or fuse box (P) 500 500

f From a drain pipe or soil pipe 150 75

g Horizontally from any building structure or obstruction facing a flue

terminal

h From any other flue terminal, cowl, or combustion air intake 500 300

j Horizontally from an opening window, door, non-mechanical air inlet. Or other opening

into a building with the exception of sub floor ventilation

Appliances up to 150 MJ/h 500 300

Appliances over 150MJ/h input up to 200 MJ/h input 1500 300

Appliances over 200 MJ/h input up to 250 MJ/h input 1500 500

Appliances over 250 MJ/h input 1500 1500

All fan assisted flue appliances in the direction of discharge 1500

k From a mechanical air inlet, including spa blower 1500 1000

n Vertically below an openable window, non-mechanical air inlet, or any other opening into a

building with the exception of sub-floor ventilation:

Space heaters up to 50 MJ/h 150 150

Other appliances up to 50 MJ/h 500 500

Appliances over 50 MJ/h and up to 150 MJ/h input 1000 1000

Appliances over 150 MJ/h input 1500 1500

M=Gas meter

P=Electricity meter

or fuse box

Shaded area indicates

prohibited area

W=Window

Natural

draft

500 500

mm

Fan

assisted

7

Page 8

Installation Instructions

6. Installation

Securing to the wall

• Installation must conform with all local building, water or Gas Regulations or AS5601.

• The weight of the device will be applied to the wall. If the strength of the wall is not suffi-

cient, reinforcement must be done to prevent the transfer of vibration.

Be sure to do

• Do not drop or apply unnecessary force to the device when installing. Internal parts may

be damaged and may become highly dangerous.

• Install the unit on a vertical wall and ensure that it is level.

Item

Check

CAUTION

• When installing with bare hands, take caution to

not inflict injury.

• Be careful not to hit electrical wiring, gas, or water

piping while drilling holes.

1. Drill a single screw hole, making sure to hit a stud.

2. Insert and tighten the screw and hang the unit by

the upper wall mounting bracket.

Locating Screw Holes

3. Determine the positions for the remaining four screws

(two for the top bracket and two for the bottom), and

remove the unit.

4. Drill holes for the remaining four screws.

5. Hang the unit again by the first screw, and then

insert and tighten the remaining four screws.

6. Take waterproofing measures so that water does

not enter the building from screws mounting the

Mounting

device.

Illustration

Location of Screw Hole

Mounting Bracket

(upper)

Locating Screw Holes

Tapping Screw

8

• Make sure the unit is installed securely so that it will

not fall or move due to vibrations or earthquakes.

Structure

Page 9

Installation Instructions

Gas Piping

7.

The appliance must be disconnected from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 3.5 kPa.

The appliance and its gas connections must be leak tested before placing the appliance in operation.

The inlet gas pressure must be within the range specified. This is for the purposes of input adjustment.

In order to choose the proper size for the gas line, consult local codes and / or the AS5601.

Gas Pressure

Size the gas line according to total MJ/h

demand of the building and length from

the meter or regulator so that the following supply pressures are available even

at maximum demand refer AS5601:

Natural Gas Supply Pressure

Min. 1.13 kPa

Max. 3.00 kPa

LP Gas Supply Pressure

Min. 2.75 kPa

Max. 3.50 kPa

Gas Meter

Select a gas meter capable of supplying

the entire MJ/h demand of all gas appliances in the building.

Gas Connection

1) Fit a union to the water heater gas inlet for easy connec-

2) Fit an AGA / NZGA approved isolating gas cock in the

3) Ensure that the supply pipe and the gas pressure regula-

4) For LPG appliances ensure that gas cylinders are of suf-

5) Before connecting the appliance to the gas service,

6) Check all joints for leaks with an approved leak tester

Follow the instructions from the gas supplier.

tion and removal. The thread diameter is 20 mm.

THIS DOES NOT INDICATE THE SIZE OF THE GAS

SUPPLY.

supply line adjacent to the water heater gas connection.

tor (LPG or Natural Gas) has sufficient flow capacity for

this and other appliances connected to the fitting line.

ficient size. The water heater alone will require 2 x 45 Kg

capacity cylinders.

purge any debris or air from the gas service.

after connection.

Measuring Gas Pressure

In order to check the gas supply pressure to the unit, a tap is

provided on the gas inlet. Remove the hex head philips screw from

the tap, and connect a manometer using a silicon tube.

In order to check the gas manifold pressure on the gas valve inside

the unit. The pressure can be checked by removing the hex head

philips screw and connecting a manometer with a silicon tube.

Refer to AS 5601 Installation Code or NZS 5261 : 2003 installation code for pipe sizing and details.

Ensure that the gas pipe size is correct. If undersized the appliance will not operate correctly

SERVICE CALLS ARE CHARGEABLE FOR UNITS WITH INCORRECT PIPE SIZES OR BLOCKED GAS OR

WATER FILTERS.

9

Page 10

Installation Instructions

Installation and service must be performed

8. Water Piping

This appliance is suitable for potable water applications. Do not use this appliance if any part has been underwater.

Immediately call a qualified service technician to inspect the appliance and replace any part of the control system and

gas control which has been under water.

Piping and components connected to the water heater shall be suitable for use with potable water.

Toxic chemicals, such as those used for boiler treatment, shall not be introduced into the potable water.

A water heater used to supply potable water may not be connected to any heating system or components previously

used with a nonpotable water heating appliance.

When water is required in one part of the system at a higher temperature than in the rest of the system, means such

as a mixing valve shall be installed to temper the water to reduce the scald hazard.

• Flush water through the pipe to clean out metal powder, sand and dirt before connecting it.

• Perform the following insulation measures for prevention of freezing.

• Take appropriate heat insulation measures (e.g., wrapping with heat

insulation materials, using electric heaters) according to the climate of

the region to prevent the pipe from freezing.

• Make sure that there are no water leaks from the cold and hot water

supply pipes, then insulate the pipes completely.

• Be sure to also completely insulate the water supply valve and the

cold and hot water connections on the water heater (refer to the figure

on the right).

• Do not cover the water drain plug with insulation so that water in the

pipe can be drained. (Refer to the figure in the right.)

•

Use a union coupling for connecting the pipes to reduce the force applied to the piping.

• When feed water pressure is too high, insert a depressurizing valve, or take water hammer prevention measure.

• Avoid using joints as much as possible to keep the piping simple.

• Avoid piping in which an air lock can occur.

•

Use approved piping materials.

• If installing the unit on a roof (Above lower-level hot water supply):

If the unit is installed on a roof to supply water to the levels below, make sure that the water pressure supplied to

the unit does not drop below 199 kPa. It may be necessary to install a pump system to ensure that the water

pressure is maintained at this level.

Check the pressure before putting the unit into operation.

Failure to supply the proper pressure to the unit may result in noisy operation, shorter lifetime of the unit, and may

cause the unit to shut down frequently.

by a qualified plumber.

Observe all applicable codes.

Completelyinsulate

thewaterinletand

outletfittings.

Donotcoverthewater

drainplugwithinsulation

sothatwaterinthepipe

canbedrained.

Insulatethewater

supplyvalvecompletely.

10

Page 11

Installation Instructions

Supply water piping

• Do not use PVC, iron, or any piping which has

been treated with chromates, boiler seal or other

chemicals.

•

Pipe sizing from the cold water supply should be

sized according to local BY LAWS for water supply.

• If sludge or foreign matter is present in the water

supply it is recommended that a separate filter/

strainer be fitted to the cold water supply line.

• A solar transfer valve must be fitted with all

solar applications using this appliance. Solar systems fitted without a solar transfer

valve will void all Bosch Warranty.

• A GATE VALVE OR BALL VALVE must be used

on the cold water inlet to the water heater. THIS

REQUIREMENT IS AN AUSTRALIA WIDE REQUIREMENT UNDER THE NATIONAL

PLUMBING CODE.

STOP TAPS OR COMBINATION STOP TAPS

AND NON-RETURN VALVES ARE NOT TO

BE USED.

• In order for the client to use the water heater

comfortably, 200 to 1000 kPa of pressure is

needed from the water supply.

Be sure to check the water pressure. If the water

pressure is low, the water heater cannot perform

to its full capability, and may become a source of

trouble for the client.

Drain processing

• Expansion water may drop from the pressure

relief valve and wet the floor.

Hot water piping

• Do not use lead, PVC, iron or any piping which

has been treated with chromates, boiler seal or

other chemicals.

• Keep the pipe lengths to a minimum, and make

sure that the pipework is well insulated as correct

performance of the appliance is dependent on

properly insulated pipework.

• DO NOT FIT ANY VALVES OR RESTRICTORS

TO THE OUTLET OF THE WATER HEATER.

• DO NOT FIT ANY OBSTRUCTION TO THE

PRESSURE RELIEF LOCATED ON THE HOT

WATER OUTLET CONNECTION.

• Use mixing valves with low water resistance. Use

shower heads with low pressure loss.

• If necessary, use a pump or other means to ensure that the supply water pressure to the inlet of

the heater does not fall below 199kPa when the

maximum amount of water is being demanded.

Also install a pressure meter on the inlet. If this is

not done, local boiling will occur inside the water

heater causing abnormal sounds and decreasing

the durability of the heat exchanger.

After purging the air from the system using the hot water supply taps, remove the water inlet strainer

located on the cold water supply inlet connection. Remove any debris from the filter and replace.

When replacing the filter, do not over-tighten the “O” ring seal.

It is recommended that for sanitary fixtures use primarily for the purpose of personal hygiene,

that a temperature control device be fitted (such as a tempering valve) as per AS3498.

No pressure reduction valve is required unless the water pressure exceeds 1000 kPa.

11

Page 12

Installation Instructions

9. Condensate Piping

PLEASE FOLLOW LOCAL CODES ABOUT CONDENSATE PIPING.

• This water heater is a high efficiency, fully condensing appliance which produces condensate during

operation. Therefore, it is necessary to install condensate piping. The water heater incorporates a collection, neutralization, and removal system which must be properly drained in order to ensure proper

operation of this appliance.

• The water heater is supplied with a pre-installed condensate neutralization system. No additional neutralizer is required unless local code dictates otherwise.

• In order to drain the condensate, a 15mm (1/2" BSP) male thread fitting is provided at the base of the

water heater.

DO NOT FIT ANY VALVES OR REDUCE THE SIZE OF THIS FITTING OR THE CONDENSATE PIPING

TO LESS THAN 15mm (1/2" BSP).

• Use plastic pipe, such as PVC, for the drain line. Do not use steel, black iron, or any other material which

can corrode when placed into contact with water.

• Keep the length of the drain pipe as short as possible.

• Horizontal runs must be sloped 1/50 downwards the drain.

• The end of the drain pipe must not be submerged in water or blocked in any way.

• Be sure to check that condensate is freely flowing from the drain piping after the system has been

installed. Condensate will begin flowing out of the water heater within 15 minutes after operation has

started.

• Take measures to prevent the condensate drain lines from freezing (insulation, heat tape, electric heaters, etc.).

Condensate piping to floor drain

DO NOT FIT

ANY VALVES

1/2" PVC pipe

Slope pipe

downwards 1/50.

Floor drain

The end of the drain pipe

must have an air gap.

KEEP CLEARANCE

12

Page 13

Installation Instructions

Consult a qualified electrician

10.

Disconnect Power

This appliance must be electrically earthed in accordance with Electrical Authority Regulations.

Caution: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation.

Verify proper operation after servicing.

Field wiring to be performed at time of appliance installation.

Electrical Wiring

Do not connect electrical power to the unit until all electrical wiring has been completed.

for the electrical work.

WARNING

Electrical Shock Hazard

Do not turn power on until electrical wiring is finished. Disconnect power before servicing.

Failure to do so may result in death or serious injury from electrical shock.

• The appliance is equipped with a 1.5m cable with a three pinned earthed plug to be connected to

240/230VAC at 50 Hz.

The power consumption may be up to 185W.

Use an appropriate circuit.

• The appliance requires a 240V in Australia and 230V in New Zealand, 50Hz weatherproof plug

installed in a protected position adjacent to the appliance.

• If the power cord is damaged and requires replacement, use only an original spare part available

from the manufacturer.

• Do not disconnect the power supply when not in use. When the power is off, the freeze prevention

in the water heater will not activate, resulting in possible freezing damage.

• Do not let the power cord contact the gas piping.

Tie the redundant power cord outside the water heater. Putting the redundant length of cord

inside the water heater may cause electrical interference and faulty operation.

Earth

• To prevent electrical shock, always plug power lead into an earthed point.

CAUTION

Electrostatic discharge can affect electronic components. Take precautions to prevent electrostatic discharges from

personnel or hand tools during the water heater installation and servicing to protect product’s electronic control.

13

Page 14

Installation Instructions

Remote Controller

The remote controller will indicate when the neutralizer unit is in need of replacement by displaying an error code.

Therefore, the remote controller should always be installed with this water heater in order to prevent an unexpected

disruption of hot water service.

Applicable Model

Bathstop

Main controller

Bathroom controller

Sub controller

*

Maximum temperature is controlled by the maximum default temperature set in the water heater.

The following combination of remote controls will operate the water heater.

Only Main Controller Works

Only Bathroom Controller Won't work

Only Sub Controller Won't work

Main & Bathroom Controller Works

Main, Bathroom & 1 or 2 Sub Controllers Works

Main & Sub Controller Won't work

Bathroom & Sub Controller Won't work

The bathroom and sub controllers have a maximum temperature setting of 50°C for safety. To ensure compliance with

Australian Standard AS/NZS3500.4, for sanitary areas, which may be achieved by using a Bosch appliance with a

delivery temperature greater than 50°C and installed with a tempering valve. In New Zealand, please refer to the New

Zealand Building Code and all other applicable electrical, gas fitting and plumbing codes.

YPRM67XB

YPRS67XB

YPRP62XB

Max temperature 75°C *

Max temperature 50°C

Max temperature 50°C

Install the remote controller according to the installation guide.

* The Bosch water heater has been factory set to allow a maximum temperature setting of 55°C.

To change the maximum temperature setting, connect the temperature selection wire as shown in the

below diagram. The default temperature is 55°C when the temperature selection wire is not connected.

<The changing procedure of the maximum temperature setting.>

1.

Turn the water heater off by pressing the ON/OFF button on the remote controller.

60°C

2.Disconnect electrical power to the water heater.

3. Remove the front cover of the water heater (4 screws).

4. Connect "WATER TEMPERATURE ADJUSTMENT CONNECTOR" tag

75 °C

WATER TEMPERATURE

connector to temperature that wants to switch "75°C (red wire)" or "60°C

(yellow wire)" tag connector as shown on the right.

5. Replace the front cover of the water heater (4 screws).

6. Reconnect electrical power to the water heater.

Remote controller

YPRM67XB

YPRS67XB

YPRP62XB

Factory Setting

37 - 55°C

37 - 50°C

37 - 50°C

Connect "75°C"

37 - 75°C

37 - 50°C

37 - 50°C

Connect "60°C"

"60°C" tag "75 °C" tag

37 - 60°C

37 - 50°C

37 - 50°C

WATER TEMPERATURE

ADJUSTMENT CONNECTOR

* Bath Fill temperature setting is 37 - 48°C.

WARNING

• When changing the temperature, make sure to confirm with the customer that the temperature of

the hot water will be very high and that there is a risk of scalding.

ADJUSTMENT CONNECTOR

14

It is recommended that for sanitary fixtures use primarily for the purpose of personal hygiene,

that a temperature control device be fitted (such as a tempering valve) as per AS3498.

Page 15

Installation Instructions

Connecting Remote Controller Cord to Unit

• Tie the redundant cord outside the water heater. Do not put the extra length inside the water heater.

• The remote controller cord can be extended up to 20m.

• Be sure to hand tighten when screwing to the terminal block. Power tools may cause damage to the

terminal block.

Remote controller cord

• Use remote controller cord for any extensions.

• Install according to the National Electrical Code and all applicable local codes.

1. Check to make sure that the remote controller cord

has plenty of slack in order to reach the external

connection terminal block.

2.Disconnect electrical power to the

water heater.

3. Remove the single screw securing the terminal

block cover and then remove the cover.

4. Pass the remote controller cord through the wiring

throughway and connect the Y terminals at the end

of the remote controller cord to the terminal block.

5. Replace the terminal block cover and install the

screw previously removed in step 3.

6. Reconnect electrical power to the water heater.

External connection

terminal block

Wiring throughway

Remote controller cord

Power cord

15

Page 16

Installation Instructions

Periodically check the following to ensure proper

11.

• The venting system must be examined periodically by a qualified service technician to check for

any leaks or corrosion.

• The burner flame must be checked periodically for a proper blue colour and consistency.

• If the flame does not appear normal, the burner may need to be cleaned.

• If the burner needs to be cleaned, it must be performed by a qualified service technician.

• Do not obstruct the flow of combustion and ventilation air.

• See Owner's Guide for further maintenance.

Warning:

12.

Maintenance

There is a scald potential if the output temperature is set too high.

Should overheating occur, or the gas supply fail to shut off, turn off the manual gas control valve to the appliance.

Do not use this appliance if any part has been under water. Immediately call a qualified service

technician to inspect the appliance and to replace any part of the control system and any gas control

which has been under water.

Periodically check and clean the filter inside the cold water inlet of the unit.

Trial Operation

operation of the water heater.

The installer should test operate the unit, explain to

the customer how to use the unit, and give the owner

this manual before leaving the installation.

• Preparation ........... (1) Open a hot water fixture to confirm that water is available, and then close

the fixture.

(2) Open the gas supply valve.

(3) Turn on the power supply. Using the remote controller, turn on the Power

On/Off button (the Operation lamp will turn on).

(1) Open a hot water fixture and confirm that the Burner On lamp comes on, and that hot water is

being produced. (If necessary, repeat until the air in the gas piping is bled out).

* White smoke may be noticed from the exhaust vent during cold weather. However, this is not a

malfunction of the unit.

* If an “11” error code appears on the remote controller, turn the unit off and then back on again,

and then open a hot water fixture again.

(2) Change the temperature setting on the remote controller and check that the water temperature changes.

• If the water heater does not operate normally, refer to “Troubleshooting” in the Owner's Guide.

* After the trial operation, clean the filter in the cold water inlet.

CAUTION

Handling after trial operation

• If the unit will not be used immediately, close off all gas and water shutoff valves, drain all of

the water out of the unit and the plumbing system to prevent the unit and system from freezing,

and bleed the gas out of the gas line.

Freezing is not covered by the warranty.

16

Page 17

Installation Instructions

WARNING

A fire or explosion may result if these instructions are not followed, which may cause lose of

life, personal injury or property damage.

Lighting Instructions

This water heater does not have a pilot. It is equipped with an ignition device that automatically lights

the burner.

Do not try to light the burner by hand.

1. Read the safety information in the installation manual or on the right side of the water heater.

2. Turn off all electrical power to the unit.

3. Do not attempt to light the burner by hand.

4. Turn the gas control manual valve (external to the unit) clockwise to the off position.

5. Wait five minutes to clear out any gas. If the smell of gas remains, stop, and follow the instructions

on page 3 of Owner's Guide.

6. Turn the gas control manual valve counterclockwise to the on position.

7. Turn on electric power to the unit.

8. The unit will now operate whenever hot water is called for. If the unit will not operate, follow the

shutdown instructions and call a service technician.

Shutdown Instructions

1. Stop any water demand.

2. Turn off electric power.

3. Turn the gas control manual valve clockwise to the off position.

Should overheating occur, or the gas supply fail to shut off, turn off the manual control valve to the appliance.

17

Page 18

Installation Instructions

13.

2-6.5 x 13

OBLONG HOLE

Dimensions

4- 13

4- 13

13

120

85

50

120

60

1010

622

31

10

567

260

20

28

600

566

338

350

334

267

19

4653

FLUE COLLAR

AIR INLET

2- 6.5

3-6.5 x 16.5

OBLONG HOLE

HOT WATER

OUTLET (R3/4)

177

48

DRAIN OUTLET (R1/2)

COLD WATER INLET (R3/4)

4242

135

(VIEW FROM TOP)

136

100

60

279

243

10

DRAIN OUTLET

WATER DRAIN VALVE

HOT WATER OUTLET

PRESSURE RELIEF VALVE

(WATER DRAIN VALVE)

GAS INLET (R3/4)

141

179

58

WIRING THROUGHWAYS

AIR INLET

HEIGHT OF EACH FITTING

FROM BOTTOM OF CASE

HOT WATER OUTLET

COLD WATER INLET

GAS INLET

DRAIN OUTLET

AIR INLET

COLD WATER INLET

WATER DRAIN VALVE

(WATER FILTER)

WIRING THROUGHWAYS

GAS INLET

44

57

49

28

18

Loading...

Loading...