Bosch AGS10-2, AGS20-2, AGS10E-2, AGS50-2 Installation And Servicing Instructions

Solar pump station for solar thermal systems

AGS10-2, AGS10E-2, AGS20-2, AGS50-2

Installation and servicing instructions

6 720 811 270 (2015/04) UK

2 | Table of contents

Table of contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 2

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Information on the solar pump station . . . . . . . . . . . . . . . . . . . . 3

2.1 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Determined use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Components and technical documentation . . . . . . . . . . . 5

2.4 EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 Other equipment required . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7 Air vent valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Installing pipework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 General information regarding pipework . . . . . . . . . . . . . 7

4.2 Laying pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be used in this document:

• NOTICE indicates a situation that could result in damage to property

or equipment.

• CAUTION indicates a situation that could result in minor to medium

injury.

• WARNING indicates a situation that could result in severe injury or

death.

• DANGER indicates a situation that will result in severe injury or death.

Important information

This symbol indicates important information where

there is no risk to people or property.

5 Installing the solar pump station . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Layout of the installation space . . . . . . . . . . . . . . . . . . . . 9

5.2 Mounting the solar pump station . . . . . . . . . . . . . . . . . . . 9

5.3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.4 Installing the safety assembly . . . . . . . . . . . . . . . . . . . . 10

5.5 Connecting the expansion vessel and pre-cooling

vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.6 Connecting pipework and pressure relief valve

discharge pipe to the solar pump station . . . . . . . . . . . 11

5.7 Installing temperature sensors . . . . . . . . . . . . . . . . . . . 12

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1 Use of heat transfer fluid . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2 Purging and filling with a hand pump (air vent on roof) 12

6.3 Setting the flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4 Completion of work . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 Commissioning, inspection and maintenance reports . . . . 18

9 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Additional symbols

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

1.2 General safety instructions

Mounting

Installation and maintenance must only be carried out by an approved

contractor.

▶ Please read these instructions carefully.

▶ Never modify components.

▶ Replace faulty parts immediately. Use only original spare parts.

▶ To limit the temperature at the tap to a maximum of 60 °C, install a

DHW mixer.

▶ Only use materials which are glycol resistant and which can withstand

temperatures of up to 150 °C.

Electrical work

▶ Ensure that electrical work is only carried out by authorised

electricians.

▶ Ensure that an isolator compliant with EN 60335-1 for disconnecting

all poles from the power supply is fitted.

If you wish to open the solar pump station:

▶ Disconnect the solar pump station from the power supply.

AGS10-2, AGS10E-2, AGS20-2, AGS50-26 720 811 270 (2015/04)

Instructing the user

6720801165.05-2.ST

11

2

10

1

2

3

4

5

6

8

2

1

2

13

12

3

4

5

6

9

6

2

1

2

11

6720801165.06-2.ST

12

7

6

7

8

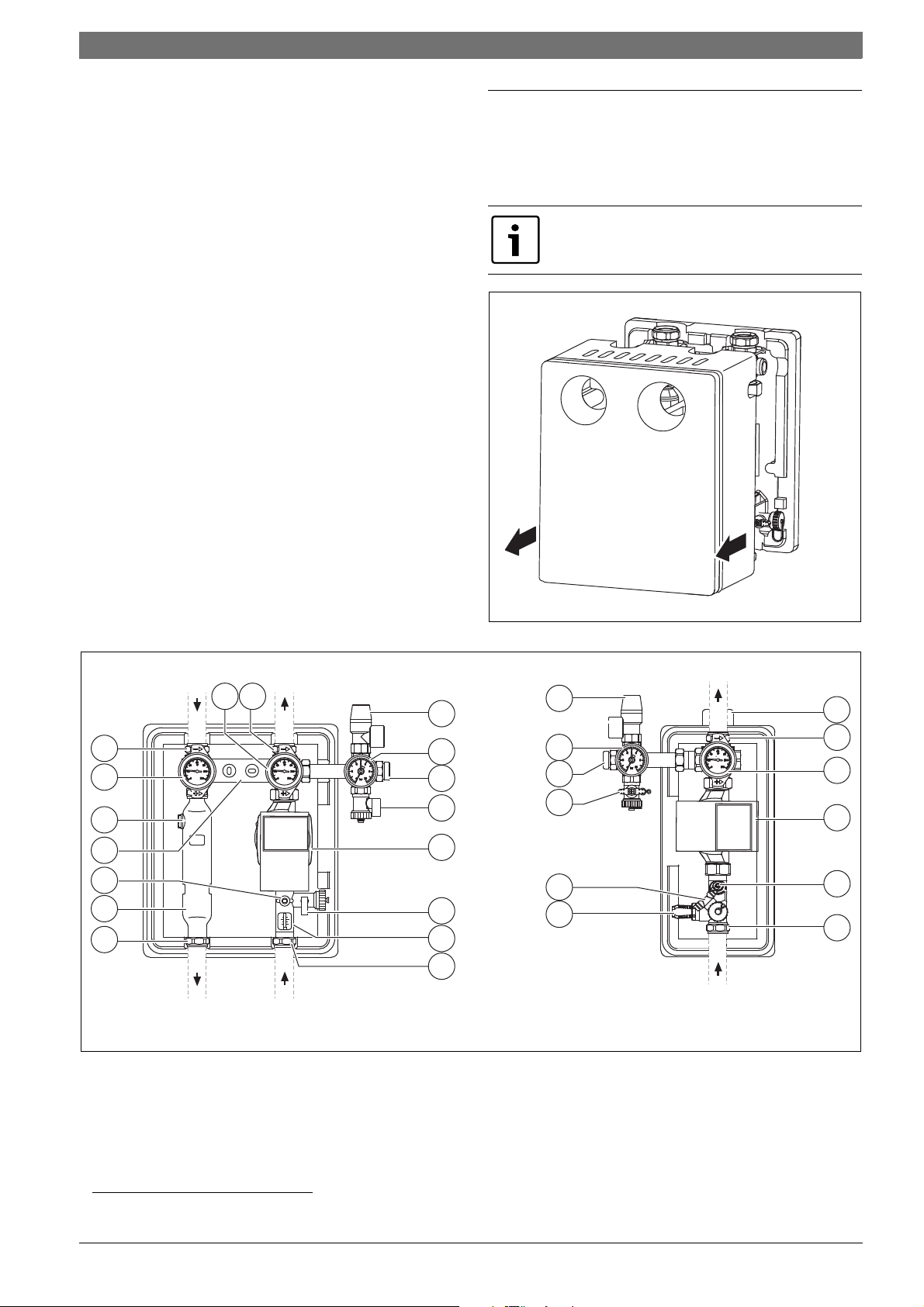

AGS10-2, AGS20-2, AGS50-2 AGS10E-2

▶ Instruct users as to how the appliance functions, as well as how to

operate the system as a whole.

▶ Explain that conversions and maintenance must only be carrie d out by

an authorised contractor.

▶ Point out the need for inspections and maintenance for safe and

environmentally friendly operation.

▶ Hand these installation and maintenance instructions to the user.

Point out that these instructions must be kept and passed on to the

next owner/user.

Information on the solar pump station | 3

2 Information on the solar pump station

2.1 Product description

If you wish to open the solar pump station:

▶ Pull the cover (insulation part) forwards.

The illustrations in this manual show the twin-line solar

pump station with external solar controller.

Fig. 1

Fig. 2 Single and twin-line solar pump stations without front insulation parts and without integral controllers and modules

[1] Ball valve with thermometer (red = flow1), blue = return) and

integrated check valve

(position 0° = normal running, 45 ° = check valve bypassed)

[2] Compression fitting

[3] Pressure relief valve

[4] Pressure gauge

1) Not for single-line solar pump stations

[5] Connection for expansion vessel

[6] Drain & fill valve (DFV)

[7] High-efficiency pump (with power cable and sensor cable)

[8] Flow limiter, type A

[9] Flow limiter, type B

[10] Air separator

[11] Control/shut-off valve

[12] Holder for wall mounting

[13] Ventilation

1)

1)

6 720 811 270 (2015/04)AGS10-2, AGS10E-2, AGS20-2, AGS50-2

4 | Information on the solar pump station

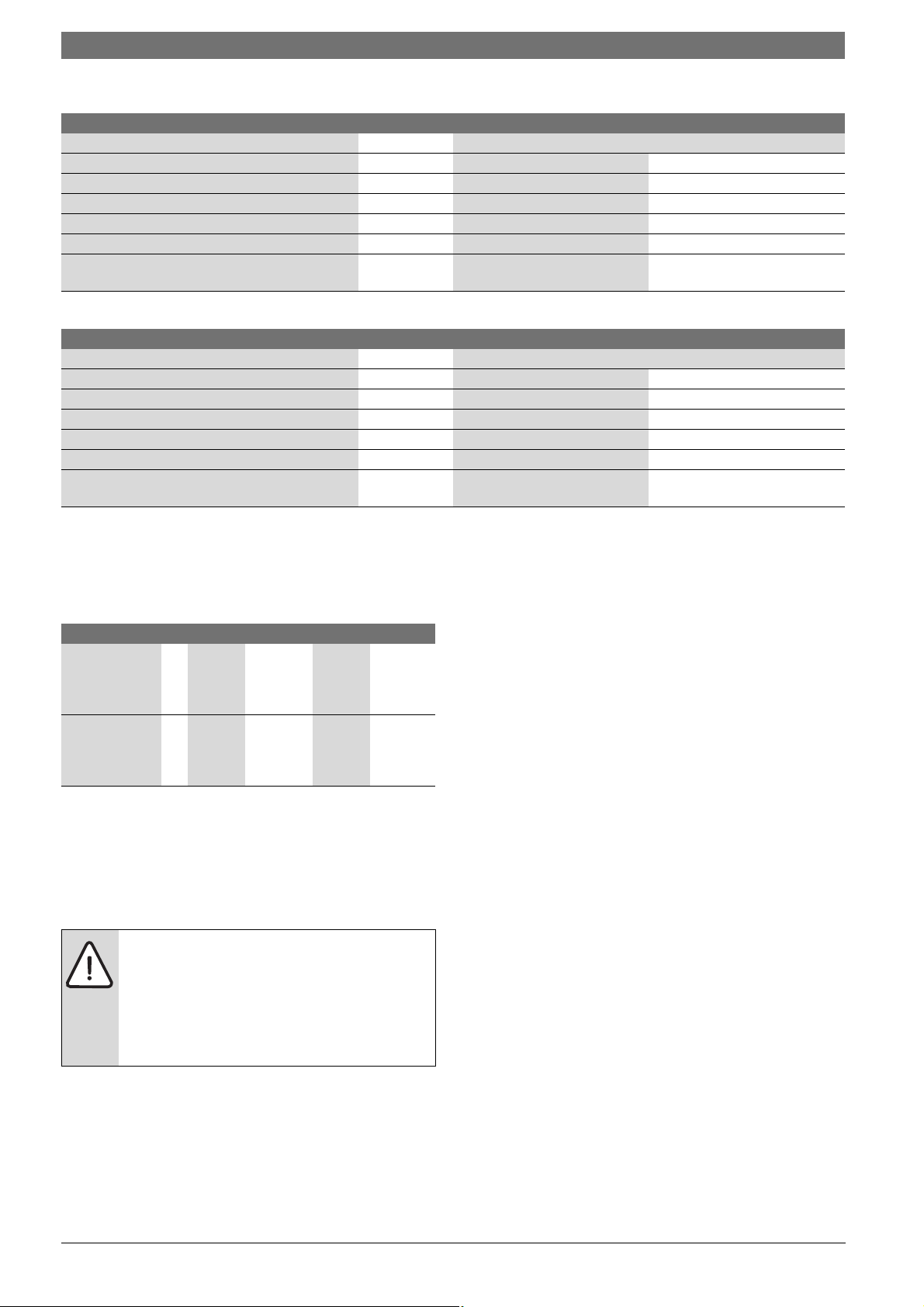

2.1.1 Specifications and variants

AGS10-2 AGS10E-2

Maximum possible temperature °C Flow: 130 / return: 110 (pump)

Safety valve response pressure bar 66

Pressure relief valve – DN 15, ¾ " connection DN 15, ¾ " connection

Mains voltage – 230V AC, 50 - 60 Hz 230V AC, 50 - 60 Hz

Maximum current consumption per pump A 0,4 A / EEI ≤ 0,2 0,4 A / EEI ≤ 0,2

Measurements (height x width x depth) mm 353x284x248 355x185x180

Flow and return connections

mm 15 / 22 15 / 22

(compression fittings)

Table 2 Specifications of AGS10-2 and AGS10E-2

AGS20-2 AGS50-2

Maximum possible temperature °C Flow: 130 / return: 110 (pump)

Safety valve response pressure bar 66

Pressure relief valve – DN 15, ¾ " connection DN 20, 1" connection

Mains voltage – 230V AC, 50 - 60 Hz 230V AC, 50 - 60 Hz

Maximum current consumption per pump A 0,7 A / EEI ≤ 0,2 1,0 A / EEI ≤ 0,23

Measurements (height x width x depth) mm 353x284x248 403x284x248

Flow and return connections

mm 22 28

(compression fittings)

Table 3 Specifications of AGS20-2 and AGS50-2

2.1.2 Energy efficiency

The following product data complies with the requirements of

EU Regulations 811/2013, 812/2013, 813/2013 and 814/2013 as

supplement to the Directive 2010/30/EU.

AGS10-2 AGS10E-2 AGS20 AGS50

Power

W 2.00 2.00 2.00 2.50

consumption

standby (W)

solstandby

Power

W 15 15 22.5 50

consumption full

load (W)

solpump

1)

Table 4

1) 50 % of nominal power input in operation at 72 mbar a nd 50 l/h.

2.1.3 Solar system and additional heat sources

It is often possible to attach multiple heat sources to combi and buffer

cylinders. These heat sources can completely heat the contents of the

cylinder to over 80 °C.

WARNING: Risk of injury from hot fluid leaks.

▶ To avoid blocking the path to the safety equipment,

leave the ball valves of the solar pump station open

during operation.

▶ If required, install an additional item of safety

equipment between the cylinder and the solar pump

station.

AGS10-2, AGS10E-2, AGS20-2, AGS50-26 720 811 270 (2015/04)

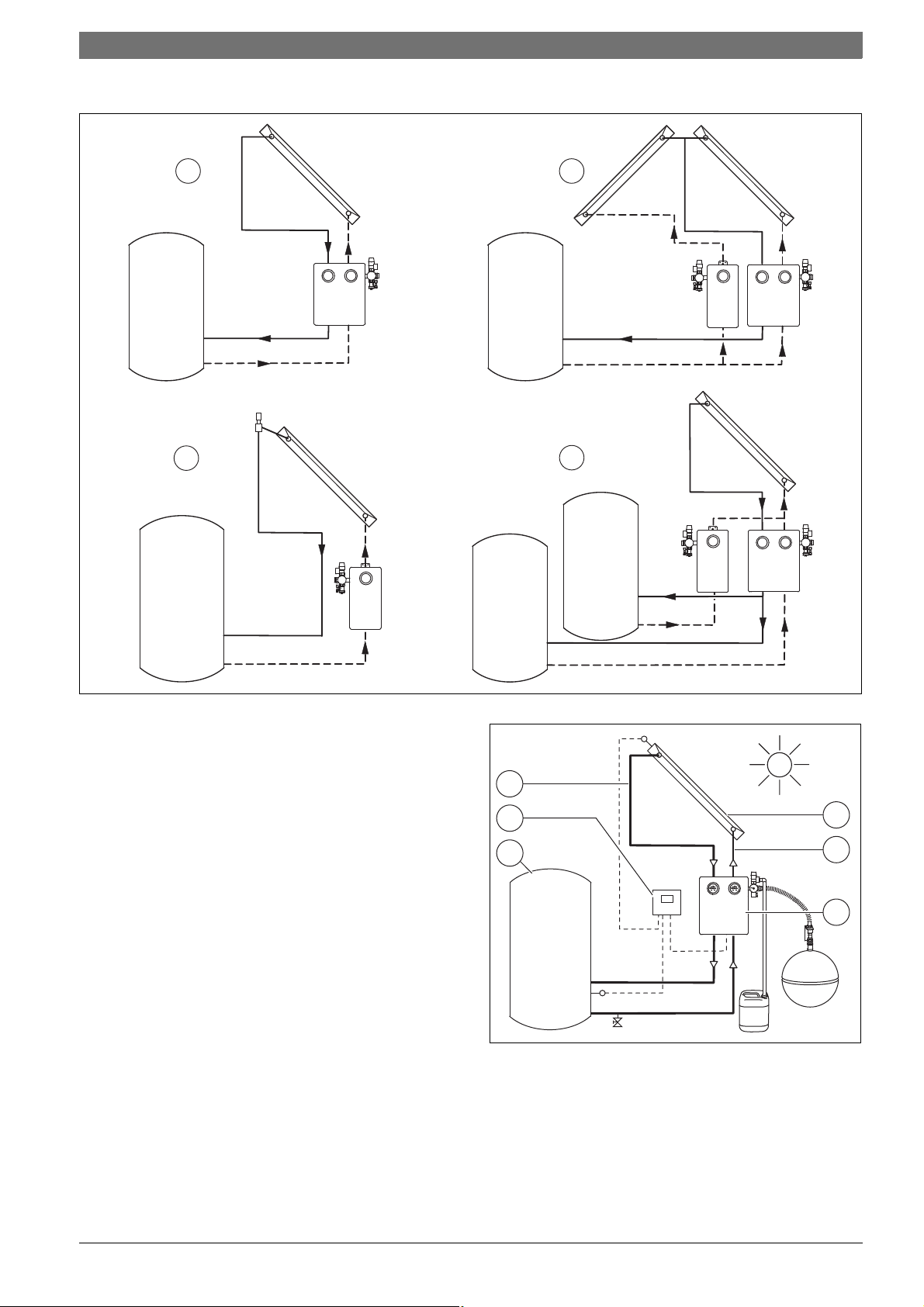

2.1.4 Application examples

1

2

4

7747006489.03-3.ST

3

6720640298-22.2ST

1

4

5

6

2

3

Information on the solar pump station | 5

Fig. 3 Different hydraulic applications

[1] Standard system with dual-circuit solar pump station

[2] Two collector arrays (e.g. east/west) with single and twin-line

solar pump stations

[3] 2-consumer system with single and twin-line solar pump station

[4] Standard system with 1-line solar pumping station and air vent on

roof

2.2 Determined use

▶ Solar pump stations may only be used for the operation of solar

systems in conjunction with suitable controllers.

▶ Solar pump stations may only be installed vertically ( Fig. 3) and

indoors.

The AGS solar pump stations must only be operated with propylene

glycol/water mixtures (heat transfer medium L or LS). The use of any

other heat transfer medium is not permitted.

2.3 Components and technical documentation

A solar thermal system is designed to heat domestic hot water (DHW)

and can also provide central heating backup where required. It is made

up of various components.

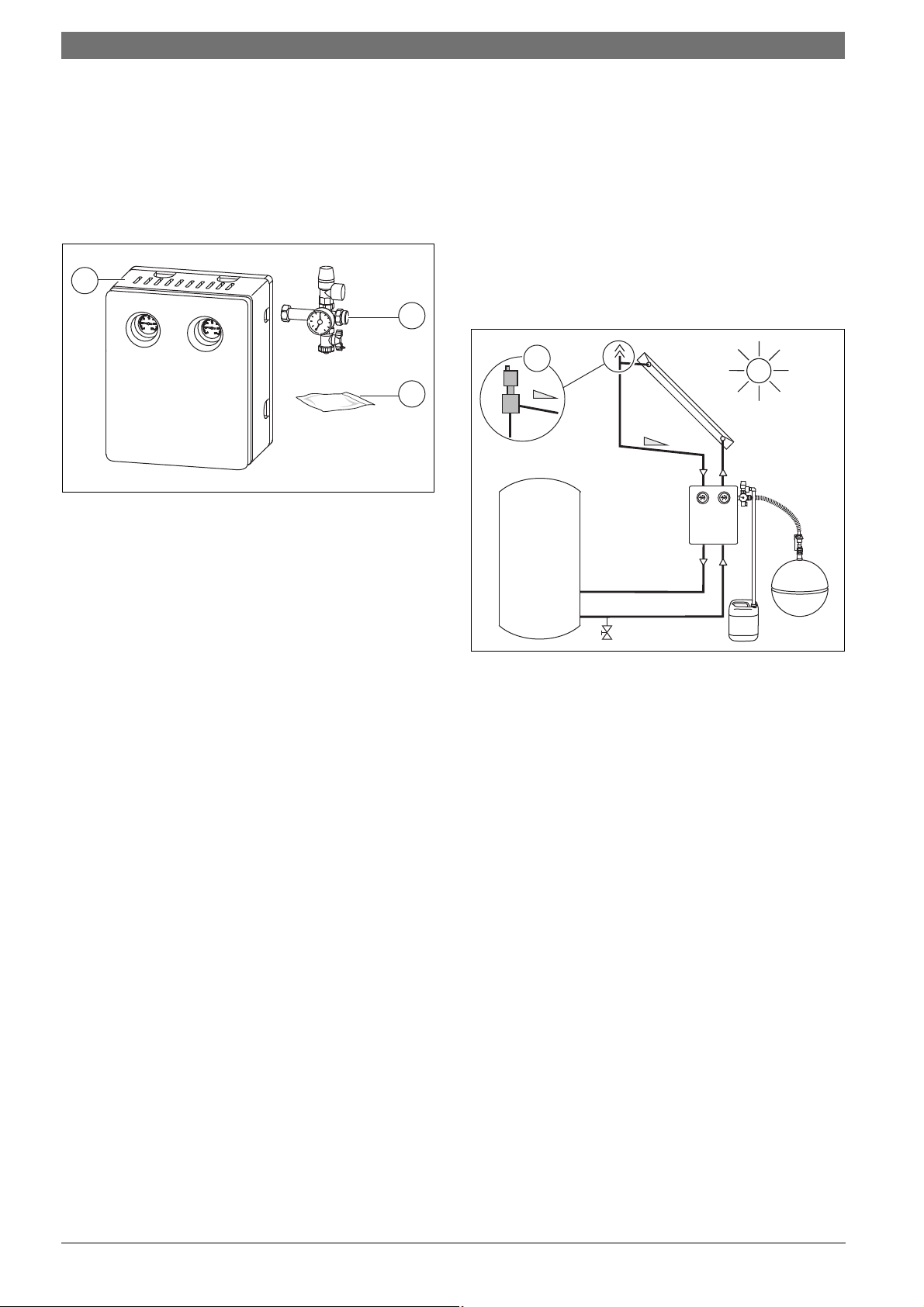

Fig. 4 Solar system components

[1] Collector with temperature sensor at the top

[2] Pipework (return)

[3] Solar pump station with expansion vessel, temperature and

safety equipment

[4] Solar cylinder

[5] Solar controller

[6] Pipework (flow)

6 720 811 270 (2015/04)AGS10-2, AGS10E-2, AGS20-2, AGS50-2

6 | Information on the solar pump station

6720811275.02-2.ST

1

2

3

6720801165.09-2.ST

1

2.4 EC Declaration of Conformity

Design and operation of this product conform to European Directives

and the supplementary national requirements. Its conformity is

demonstrated by the CE marking. The Declaration of Conformity can be

requested from the manufacturer (see the back cover for the address).

2.5 Scope of Delivery

▶ Check that the delivery is complete and undamaged.

Fig. 5 Solar pump station

[1] Solar pump station (single or twin-line solar pump station with or

without controller)

[2] Safety assembly (pressure relief valve, pressure gauge, fill and

drain valve)

[3] Bag with rawl plugs and screws

2.7 Air vent valve

Always provide an automatic air vent valve on each row of collectors for

the following systems connected in parallel:

1. System with more than two collector rows.

2. System with AGS50 solar pump station.

Solar-Lifestyle/Solar-Lito flat-plate collectors

The solar system is ventilated through one of the following processes:

1. Pressure filling with solar filling pump ( Chapter 6.2, page 12).

Install additional air vents if necessary, see point 1.– 2. above.

-or-

2. Automatic air vent valve [1] at the highest point of the system

( Chapter 6.2, page 12).

2.6 Other equipment required

In addition to the usual tools, a 13 mm socket with a 150 mm extension

is required for the installation work.

Fig. 6 Position of the automatic air vent valve

Solar-Lux vacuum tube collectors

Only pressure filling and heat transfer medium LS may be used for

ventilation ( Chapter 6.2, page 12). Install additional air vents if

necessary, see point 1.-2. above.

AGS10-2, AGS10E-2, AGS20-2, AGS50-26 720 811 270 (2015/04)

Regulations | 7

3 Regulations

Practical work is subject to currently applicable technical rules.

▶ Observe all standards, guidelines and requirements applicable to the

installation and operation of the system in your country and region.

Modified regulations or supplements are also valid at the time of

installation and must be observed.

Technical regulations applicable in the U.K. for the installation of thermal solar heating systems

• Electrical connection:

– Current IEE wiring regulations

• Connection of solar thermal systems:

– EN 12976: Thermal solar systems and components (factory made

systems)

– BS5918: Latest version: Solar heating systems for domestic hot

water.

• Installation and fittings of hot water heaters:

– BS5546:2006 Specification for installation of hot water supplies

for domestic purposes, using gasfired appliances of rated input not

exceeding 70kW.

– BS6700:2006 Specifications for design, installation testing and

maintenance of services supplying water for domestic use within

buildings and their curtilages.

• Installations should be made in accordance to the relevant MCS Solar

standards if the homeowner is applying for RHI

4 Installing pipework

4.1 General information regarding pipework

NOTICE: System damage through faulty parts.

▶ Only use materials which are resistant to glycol,

pressure and heat (at least up to 150 °C).

▶ Do not use plastic pipes (e.g. polyethylene pipes) or

galvanised pipework.

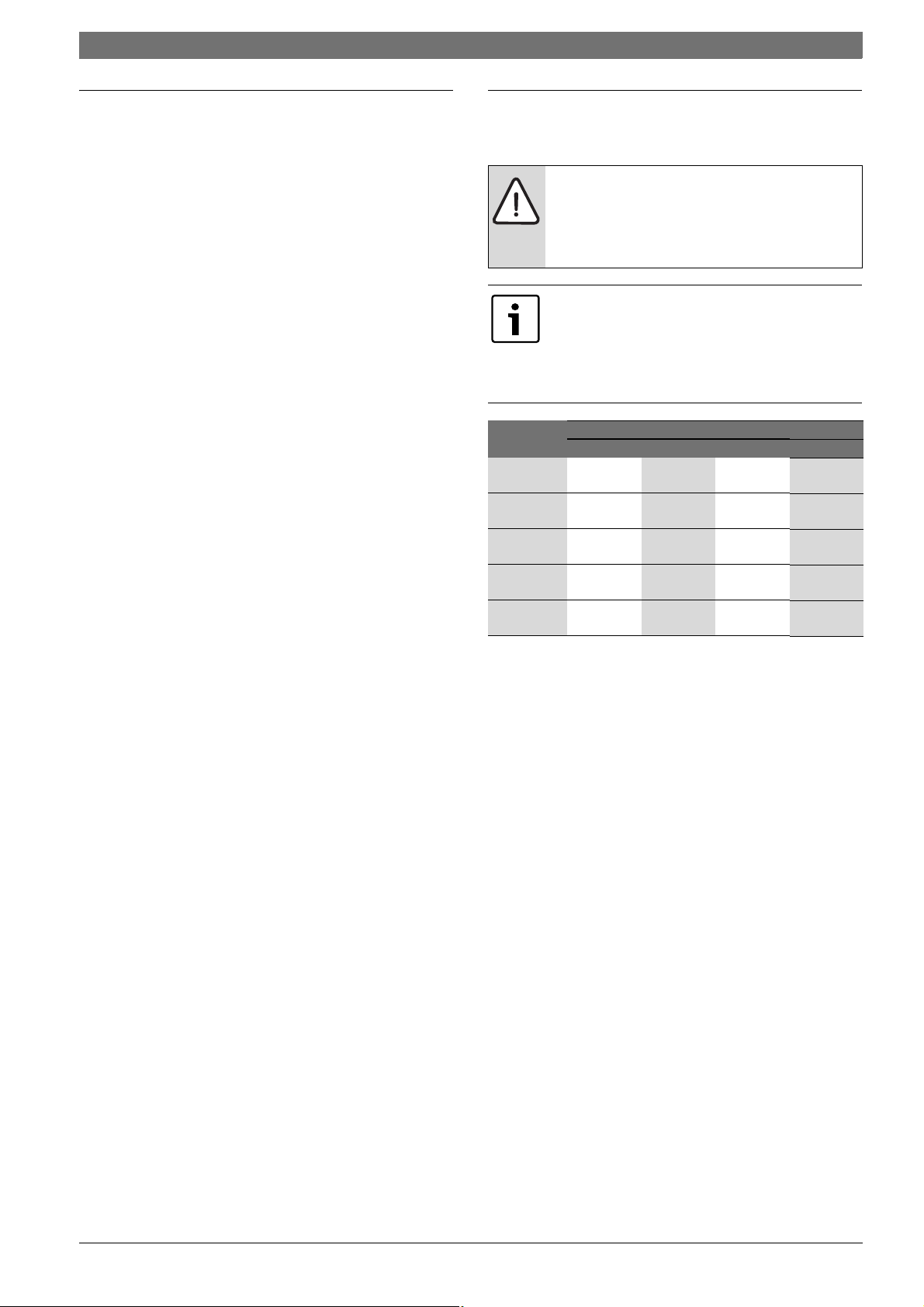

We recommend carrying out a pipe network analysis to

determine pipework sizing requirements. Basic design

estimates can be made using Tab. 5.

▶ If there are many additional points of resistance

(bends, valves, etc.), you may need to select a pipe

with a larger diameter.

Straight pipe

length

0 to 6 m Ø 15 mm

7 to 10 m Ø 15 mm

11 to 15 m Ø 15 mm

16 to 20 m Ø 22 mm

21 to 25 m Ø 22 mm

Table 5 Pipework sizing

1) For example, solar twin tube 15 (copper)

2) Or solar twin tube DN20 (stainless steel)

Number of collectors

2 to 5 6 to 10 11 to 15 16 to 20

(DN12)

(DN12)

(DN12)

(DN20)

(DN20)

Ø 22mm

1)

(DN20)

Ø 22mm

1)

(DN20)

Ø 22mm

1)

(DN20)

Ø 22mm

2)

(DN20)

Ø 28mm

2)

(DN25)

Ø 22mm

2)

(DN20)

Ø 22mm

(DN20)

Ø 28mm

(DN25)

Ø 28mm

(DN25)

Ø 28mm

(DN25)

Ø 22mm

(DN20)

Ø 28mm

(DN25)

Ø 28mm

(DN25)

Ø 28mm

(DN25)

Ø 35mm

(DN32)

6 720 811 270 (2015/04)AGS10-2, AGS10E-2, AGS20-2, AGS50-2

8 | Installing pipework

1

6720801165.08-2.ST

> 2 m

> 1,5 m

< 2 m

0,2-0,3 m0,2-0,3 m

6720811272.01-1.ST6720811272.01-1.ST

0.2-0.3 m

1.5 m

6720801165.09-2.ST

1

6720640298-61.2ST

2

1

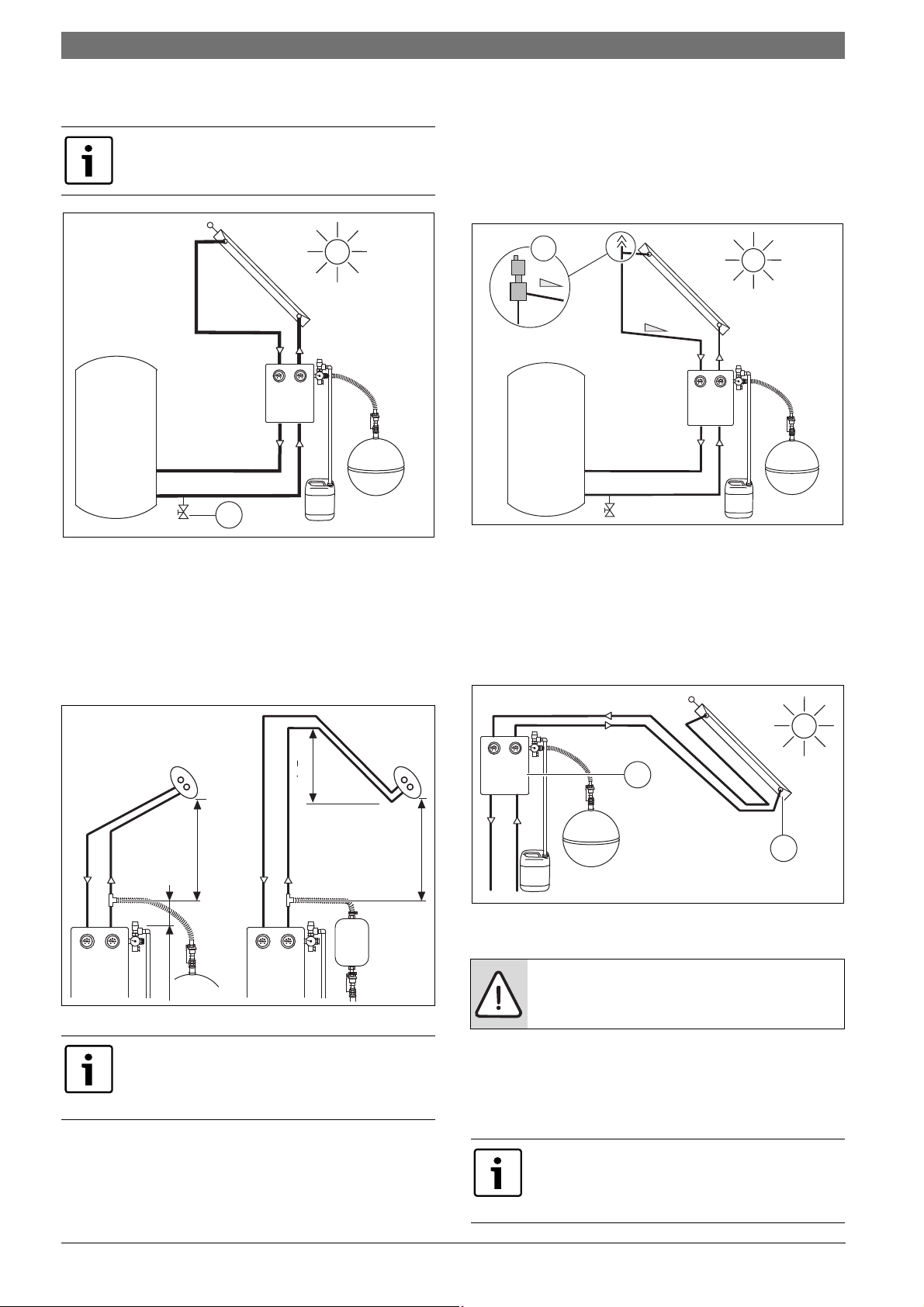

▶ Install a device into the return at the lowest point in the solar system

for draining the solar system (tee with fill and drain valve [1]).

If necessary, allow for the flow of a fill and drain valve as

well ( Chapter 6.2.1, page 13).

Fig. 7

4.2 Laying pipes

Evacuated tube collectors

The minimum pipe length from the solar pump station to the collector

array must be at least 10 m (single length).

The minimum height clearance for the connection of the expansion

vessel to the collector array is 2 m.

Solar-Lifestyle/Solar-Lito flat-plate collectors

To prevent air pockets when using an automatic air vent valve on the

collector array:

▶ Route the pipes from the pump station to the collector/air ve nt [1] on

a rising incline.

▶ If a change of direction downwards is unavoidable, install additional

heat-resistant (150 °C) air vents.

Fig. 9 Position of the automatic air vent valve

In some cases, the solar pump station [1] cannot be installed

underneath the collectors (e.g. in the case of attic installations).

Form a "pipe trough" with the flow in order to prevent overheating in

such systems:

▶ Firstly, route the flow to the height of collector return connection [2].

Then route it to the solar pump station.

Fig. 8 Distance to the collector array (Solar-Lux)

If the minimum pipe length or the minimum height

distance cannot be maintained:

▶ Form a "pipe trough" at least 1.5 m high with the flow

and return lines on the collector array ( Fig. 8).

Fig. 10

Connecting pipework

NOTICE: Risk of damage to the collector through heat

created by brazing.

▶ Do not solder close to evacuated tube collectors.

▶ Copper pipes must only be soldered with brazing solder i.e. no low

temperature soldering.

-or-

▶ Use glycol and heat-resistant (150 °C) compression fittings or push-

fit fittings.

If threaded pipe connections are caulked with hemp:

▶ Use a thread sealing compound resistant to

temperatures up to 150 °C (e.g. NeoFermit

universal).

AGS10-2, AGS10E-2, AGS20-2, AGS50-26 720 811 270 (2015/04)

Installing the solar pump station | 9

UV

> 150 °C

> 150 °C

6720801165.10-1.ST

7747006489.07.3 ST7747006489.07.3 ST

4

1

10

13

150 mm

2

60 mm

3

6720801165.11-2.ST

Earthing pipes

Arrange for work to be performed by a competent person.

▶ One earthing clamp must be fitted to both the flow pipe and the return

pipe (at any position).

▶ Connect the earthing clamps to the building's equipotential bonding

strip by means of a standard PVC-sheathed bonding cable (cable to be

sized in accordance with BS7671).

Insulating pipework

▶ Thermally insulate the pipework in the entire solar circuit in

accordance with regulations and best practice.

▶ Insulate outdoor piping with material which is both resistant to UV

light and high temperatures (up to 150 °C).

▶ Insulate indoor piping with material which is resistant to high

temperatures (up to 150 °C).

▶ Protect the insulation against damage from animals if required.

Observe minimum clearances from the solar pump

station to the collector array of the vacuum tube

collectors ( Chapter 4.2, page 8)

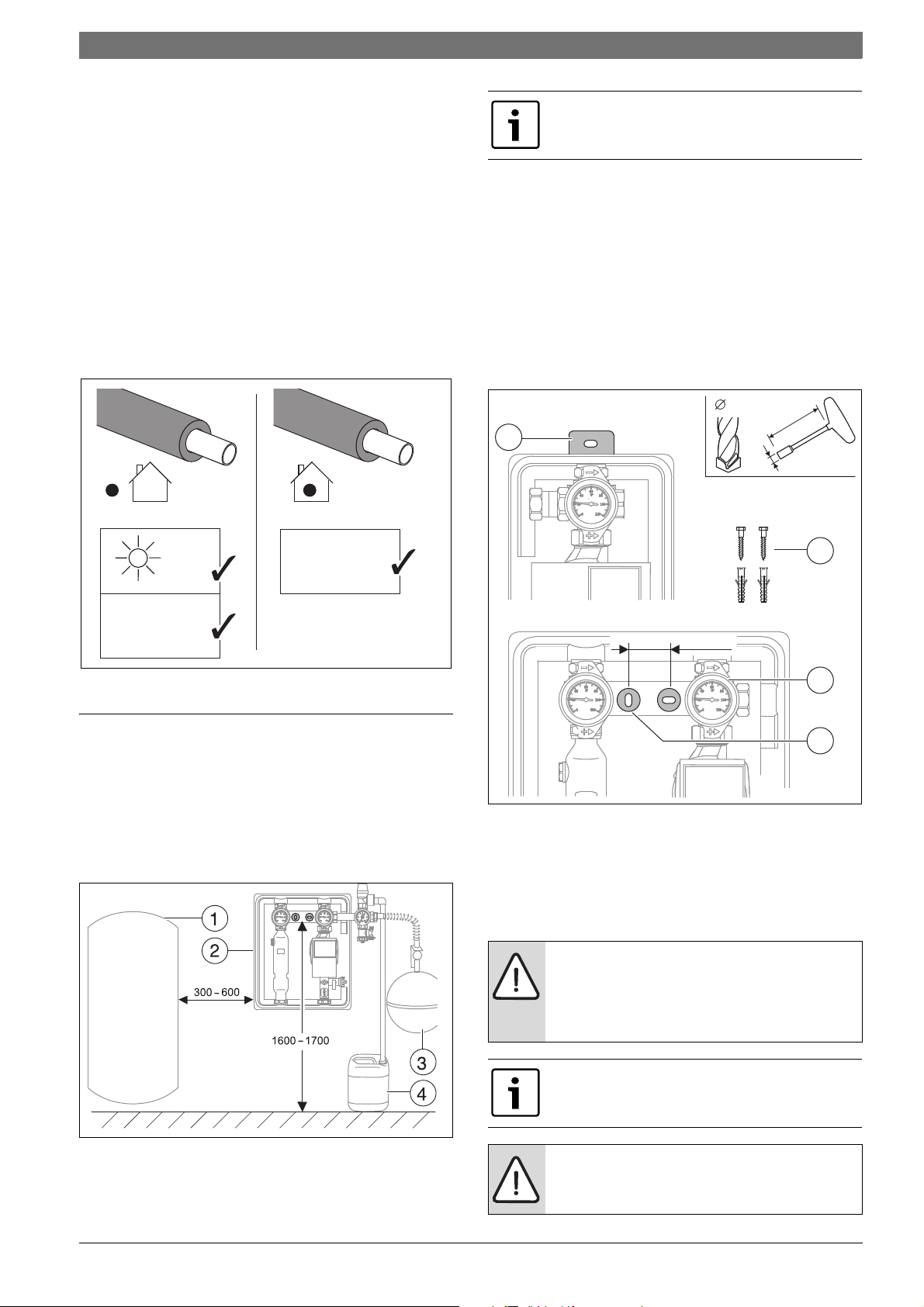

5.2 Mounting the solar pump station

Use a socket (13 mm) with a 150 mm extension to screw in the screws.

With shorter extensions, the handles and temperature gauges [3] can be

pulled forwards and removed for easier access to the screws.

Single-line solar pump station

▶ Drill hole and fix solar pump station using rawl plug and screw

supplied [1, 2].

Twin-line solar pump station

▶ Drill holes spaced 60 mm apart and fix solar pump station using rawl

plugs and screws supplied [4, 2].

Fig. 11 Minimum requirements of the insulation

5 Installing the solar pump station

5.1 Layout of the installation space

To make it easier to connect the temperature sensors:

▶ Install the solar pump station [2] as close as possible to the solar

cylinder [1].

▶ Allow enough room for a solar expansion vessel [3] and holding

container [4].

Fig. 13 Mounting the station

[1] Mounting for single-line solar pumping station

[2] Rawl plugs and screws supplied

[3] Thermometer

[4] Mounting for twin-line solar pump station

5.3 Electrical connection

DANGER: Danger to life through electric shock!

▶ Before carrying out work on electrical components,

isolate them from the power supply (230 V AC) (fuse,

circuit breaker) and secure against unintentional

reconnection.

Electrical connections must only be completed by

appropriately qualified engineers subject to local and

national regulations.

Fig. 12 Recommended positioning (measurements in mm)

[1] Solar cylinder

[2] Solar station

[3] Expansion vessel

[4] Drip pan

NOTICE: Damage through pump running dry!

▶ Do not run the pump until the pipework system has

been filled.

6 720 811 270 (2015/04)AGS10-2, AGS10E-2, AGS20-2, AGS50-2

Loading...

Loading...