Page 1

INSTALLATION

& OPERATION

MANUAL

4000 SERIES SIRENS

SIRENS

WARNING

Sirens produce loud sounds that may damage hearing

• Wear hearing protection when testing

• Use siren only for emergency response

• Roll up windows when siren is operating

• Avoid exposure to the siren sound outside of vehicle

Read all instructions and warnings before installing and using.

IMPORTANT:

INSTALLER This manual must be delivered to the end user

of this equipment.

Page 2

Introduction

The 4000 series of electronic sirens have been designed to meet the needs of all emergency vehicles. This

series of sirens incorporates many popular features of the Code 3® siren line with microprocessor based

circuitry and MOSFET technology.

Sirens are an integral part of an effective audio/visual emergency warning system.

However, sirens are only short range secondary warning devices. The use of a siren

does not insure that all drivers can or will observe or react to an emergency warning

signal, particularly at long distances or when either vehicle is traveling at a high rate of

speed. Sirens should only be used in a combination with effective warning lights and

never relied upon as a sole warning signal. Never take the right of way for granted. It

is your responsibility to be sure you can proceed safely before entering an intersec

tion, driving against traffic, or responding at a high rate of speed.

!

WARNING!

SIREN PRODUCTS:

The effectiveness of this warning device is highly dependent upon correct mounting

and wiring. Read and follow the manufacturer’s instructions before installing ng

this device. The vehicle operator should check the equipment daily to insure that all

features of the device operate correctly.

To be effective, sirens must produce high sound levels that potentially can inflict

hearing damage. Installers should be warned to wear hearing protection, clear

bystanders from the area and not to operate the siren indoors during testing. Vehicle

operators and occupants should assess their exposure to siren noise and determine

what steps, such as consultation with professionals or use of hearing protection

should be implemented to protect their hearing.

This equipment is intended for use by authorized personnel only. It is the user’s

responsibility to understand and obey all laws regarding emergency warning devices.

The user should check all applicable city, state and federal laws and regulations.

Code 3, Inc., assumes no liability for any loss resulting from the use of this warning

device.

Proper installation is vital to the performance of the siren and the safe operation of the

emergency vehicle. It is important to recognize that the operator of the emergency

vehicle is under psychological and physiological stress caused by the emergency

situation. The siren system should be installed in such a manner as to: A) Not reduce

the acoustical performance of the system, B) Limit as much as practical the noise

level in the passenger compartment of the vehicle, C) Place the controls within

convenient reach of the operator so that he can operate the system without losing eye

contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents.

Properly protect and use caution around live electrical connections. Grounding or

shorting of electrical connections can cause high current arcing, which can cause

personal injury and/or severe vehicle damage, including fire.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE

PROPER USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE

THE SAFETY OF EMERGENCY PERSONNEL AND THE PUBLIC.

Standard Features

The 4000 series of E-CON sirens consist of remotely mounted siren amplifier is operated by a user supplied

controls. The models are as follows:

4012 - 12V, No Public Address

4013 - 12V, With Public Address

4024 - 24V, No Public Address

4025 - 24V, With Public Address

2

2

Page 3

Instant-On- Applying Ground to the ACTIVEZ terminal will cause the siren to operate in Day power mode. When

either the Police or Emergency Medical Siren Tones are selected (SW1 set to 0 or 2), applying Ground to both

the ACTIVEZ and the NUIT terminal will switch to Night power mode. Pressing the microphone Push-to-Talk

(PTT) button on models 4013 and 4025 will activate the Public Address function.

Instant Public Address - The Public Address function will override the siren function when the microphone

Push-to-Talk button is pressed (Models 4013 and 4025 only).

Automatic Short Circuit Protection- The siren will sense a short circuit on the speaker terminals and

automatically go to standby until the fault is removed. Once the fault is removed the siren will return to normal

operation.

Noise Canceling Microphone - A Plug-in noise canceling microphone (Models 4013 and 4025 only) is provided

for easy service or replacement.

Unpacking & Pre-installation

After unpacking your 4000 Series Siren, carefully inspect the unit and associated parts for any damage that may

have occurred in transit. Report any damage to the carrier immediately.

Installation & Mounting

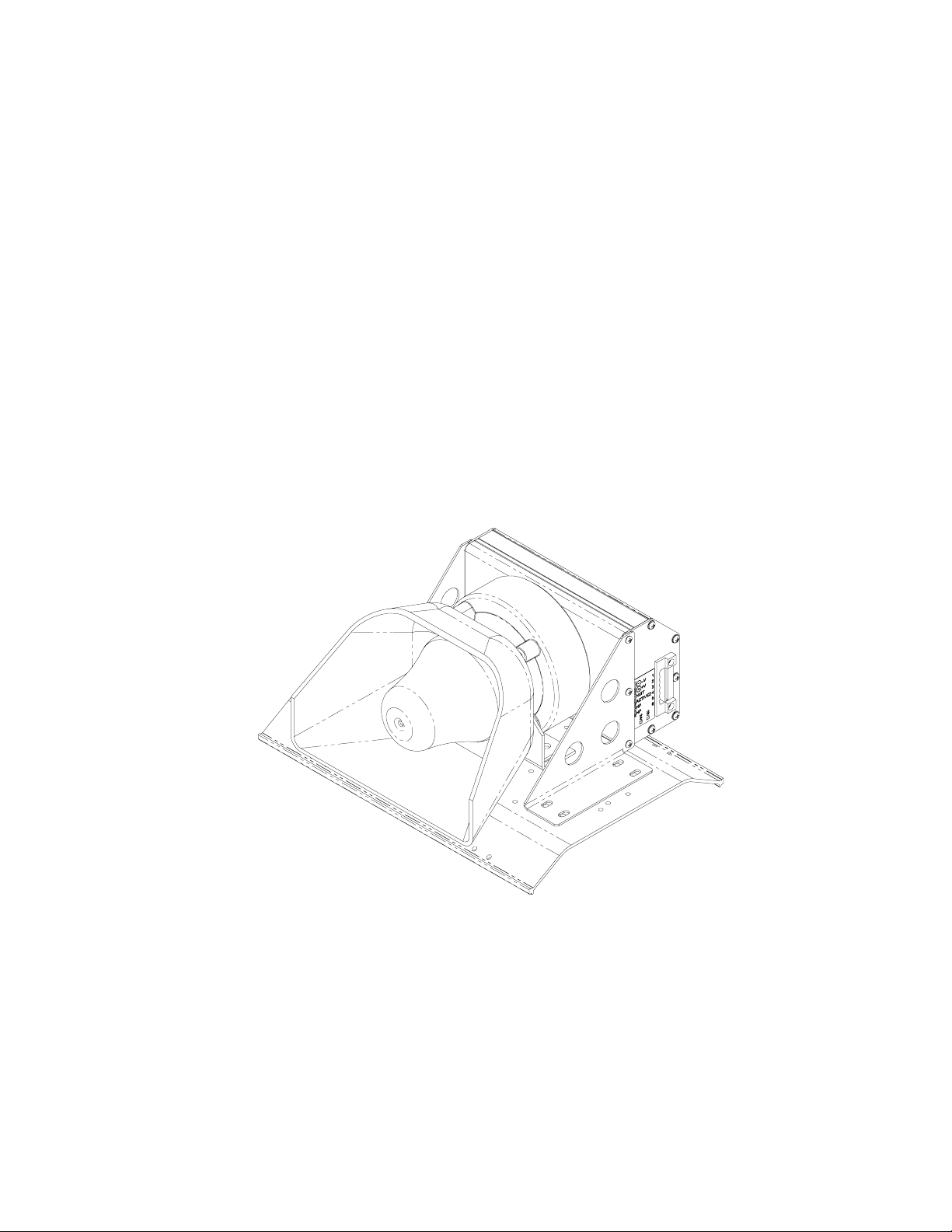

Figure 1, Light Bar Mounting

The 4000 Series of Sirens is designed to be mounted inside a light bar or inside the vehicle. Do not mount the

siren inside the engine compartment. Mounting hardware is supplied (see Fig. 2) for mounting the amplifier

inside the light bar.

NOTE: Setups and adjustments will be made in subsequent steps that may require access to the siren. Plan

the installation and wiring accordingly.

3

Page 4

Amplifier Connections

Siren Amplifier Connector - Refer to the Wiring Diagram in Figure 5 (page 10) for detailed

information about the amplifier connections. As a standard feature, the 4000 Series of Siren are

equipped with a combination plug-in terminal block/connector. To terminate the wires, strip

approximately 1/4" of insulation from the end of each wire and insert it in the appropriate hole in the

terminal block. Tighten the setscrew and proceed to the next connection.

Should you ever have to remove the unit, loosen the security screws and pull the terminal block

straight out. It will unplug from the siren, leaving the wiring in place.

Terminal Block Connections

-V - Connect to the negative terminal of the battery. This supplies ground (earth) to the siren. Use #14

gauge wire.

+V - Connect to a positive +12 volt DC source (+24 volts for Models 4024 and 4025). It is

recommended that the user protect this wire with a 10 Amp fuse or circuit breaker located at the

power source (5 Amp fuse for Models 4024 and 4025). Use #14 gauge wire.

NUIT - Connect to a switch which will supply ground (earth) when ON. Use #14-16 gauge wire.

ACTIVEZ - Connect to a switch will supply ground (earth) when ON. Use #14-16 gauge wire.

HP1 - Speaker - Connect to the wire from 100W ( 11 ohm ) speaker terminal 1.

HP2 - Connect to the wire from one 100W ( 11 ohm ) speaker terminal 2.

SETUP AND ADJUSTMENT

P.A. Volume Adjustment - Public Address volume is set by the sliding volume control located on

the front of the microphone. Set this control to give the desired PA Volume level. The user may

adjust this control at any time during use.

Tone Selection - Referring to Figure 2 and Figure 3 and the Siren Tone Chart, Figure 4, set the 16

position rotary switch SW1 (located inside the siren) to the number which corresponds to the desired

tone. Unless otherwise specified at the time of order, the default setting is 0 (Police).

All devices should be mounted in accordance with the manufacturer’s instructions and

!

WARNING!

securely fastened to vehicle elements of sufficient strength to withstand the forces applied

to the device. Ease of operation and convenience to the operator should be the prime

consideration when mounting the siren and controls. Adjust the mounting angle to allow

maximum operator visibility. Do not mount the Control Head Module in a location that will

obstruct the drivers view. Mount the microphone clip in a convenient location to allow the

operator easy access. Devices should be mounted only in locations that conform to their

SAE identification code as described in SAE Standard J1849. For example, electronics

designed for interior mounting should not be placed underhood, etc.

Controls should be placed within convenient reach* of the driver or if intended for two

person operation the driver and/or passenger. In some vehicles, multiple control switches

and/or using methods such as “horn ring transfer” which utilizes the vehicle horn switch to

toggle between siren tones may be necessary for convenient operation from two positions.

4

Page 5

Specifications

Siren Section

Input Voltage - 10 to 16 VDC, negative ground (earth) - Models 4012 and 4013

20 to 30 VDC, negative ground (earth) - Models 4024 and 4025

Operating Current (Day) - 9.2 Amps @ 13.8V with 11-ohm load (100W Spkr) - Models 4012 and 4013

4.6 Amps @ 27.6V with 11-ohm load (100W Spkr) - Models 4024 and 4025

Operating Current (Night) - 0.8 Amps @ 13.8V with 11-ohm load (100W Spkr) - Models 4012 and 4013

0.4 Amps @ 27.6V with 11-ohm load (100W Spkr) - Models 4024 and 4025

Operating Temperature - -35°C to +85°C

Standby Current: 25 ma If direct to battery, 0 ma w/Ignition OFF if through vehicle ignition switch

(recommended)

Voltage Output ( approx. ) 70V peak-to-peak (Day)

4.2V peak to peak (Night)

Weight - 1.08 Kg (with mounting brackets)

Audio Section

Audio Response - 3 dB down points - 500 to 3000 Hz.

1000 Hz. 0 dB Reference

Audio Distortion - 10% or less below clipping.

MAINTENANCE

Your Code 3® 4000 series siren has been designed to provide trouble free service. In case of difficulty, see

Troubleshooting. Also check for shorted or open wires. The primary cause of short circuits has

been found to be wires passing through firewalls, roofs, etc. If further difficulty persists, contact the factory for

troubleshooting advice or return instructions. Code 3® maintains a complete parts inventory and service facility

at the factory and will repair or replace (at the factorys option) any unit found to be defective under normal use

and in warranty. Any attempt to service a unit in warranty by anyone other than a factory authorized technician

without express written consent by the factory, will void the warranty. Units out of warranty can be repaired at

the factory for a nominal charge on either a flat rate or parts and labor basis. Contact the factory for details and

return instructions. Code 3® is not liable for any incidental charges related to the repair or replacement of a unit

unless otherwise expressly agreed to in writing.

5

Page 6

SW1

Figure 2, Disassembly

Figure 3, 16-Position Rotary Switch

Tone Select Chart

SW1 Discription

0 Police

1 Gendarmerie

2 Pompiers

3UMH

4 Ambulance

5

6

7

8

9

A

B

C

D

E

F

Figure 4, Tone Select Chart

6

Page 7

TROUBLESHOOTING

(Refer to wiring diagram on page 10)

PROBLEM

NO SIREN OUTPUT

FUSE BLOWS

NO OUTPUT FROM

SPEAKER, TONES

HEARD INSIDE

AMPLIFIER MODULE

SIREN TONES VOLUME

TOO LOW/GARBLED

PROBABLE CAUSE

A. NO +V OR GROUND

B. SHORTED SPEAKER OR

SPEAKER WIRES. sIREN IN OVER

CURRENT PROTECTION MODE

A. AMPLIFIER POWER WIRES

REVERSED POLARITY

A. SPEAKER NOT CONNECTED/

OPEN CIRCUIT IN SPEAKER WIRING

B. DEFECTIVE SPEAKER

A. LOW VOLTAGE TO SIREN

AMPLIFIER

B. HIGH RESISTANCE IN WIRING/

DEFFECTIVE SPEAKER

REMEDY

A. CHECK POWER

WIRES.

B. CHECK SPEAKER

CONNECTIONS

A. CHECK POLARITY

A. CHECK SPEAKER

WIRING

B. REPLACE SPEAKER

A. CHECK WIRING FOR

BAD CONNECTIONS/

CHECK VEHICLE

CHARGING SYSTEM

B. CHECK SPEAKER

WIRING/REPLACE

SPEAKER

HIGH RATE OF

SPEAKER FAILURE

PA VOLUME LOW OR

NO PA WITH VOLUME

CONTROL SET TO MAX

SIREN RUNS

PROPERLY BUT SHUTS

DOWN WHILE

RUNNING, THEN

STARTS RUNNING

AGAIN AFTER A FEW

MINUTES

A. HIGH VOLTAGE TO SIREN

B. 58 WATT SPEAKER CONNECTED,

58 WATT SPEAKER NOT ALLOWED

A. DEFECTIVE MICROPHONE

B. MICROPHONE NOT COMPLETELY

PLUGGED IN.

C. INCORRECT MICROPHONE

A. VEHICLE CIRCUIT BREAKERS

NOT RATED PROPERLY, AND ARE

OVERHEATING, OR ARE NOT

FUNCTIONING PROPERLY

A. CHECK VEHICLE

CHARGING SYSTEM

B. USE CORRECT

SPEAKER

A. REPLACE

MICROPHONE

B. PLUG MICROPHONE

IN SECURELY

C. USE ONLY CODE 3

MICROPHONE.

A. REFER TO

SPECIFICATIONS

SECTION. USE A

BREAKER RATED AT

1.25x THE AMPERAGE

OF THE EXPECTED

LOAD CURRENT.

7

Page 8

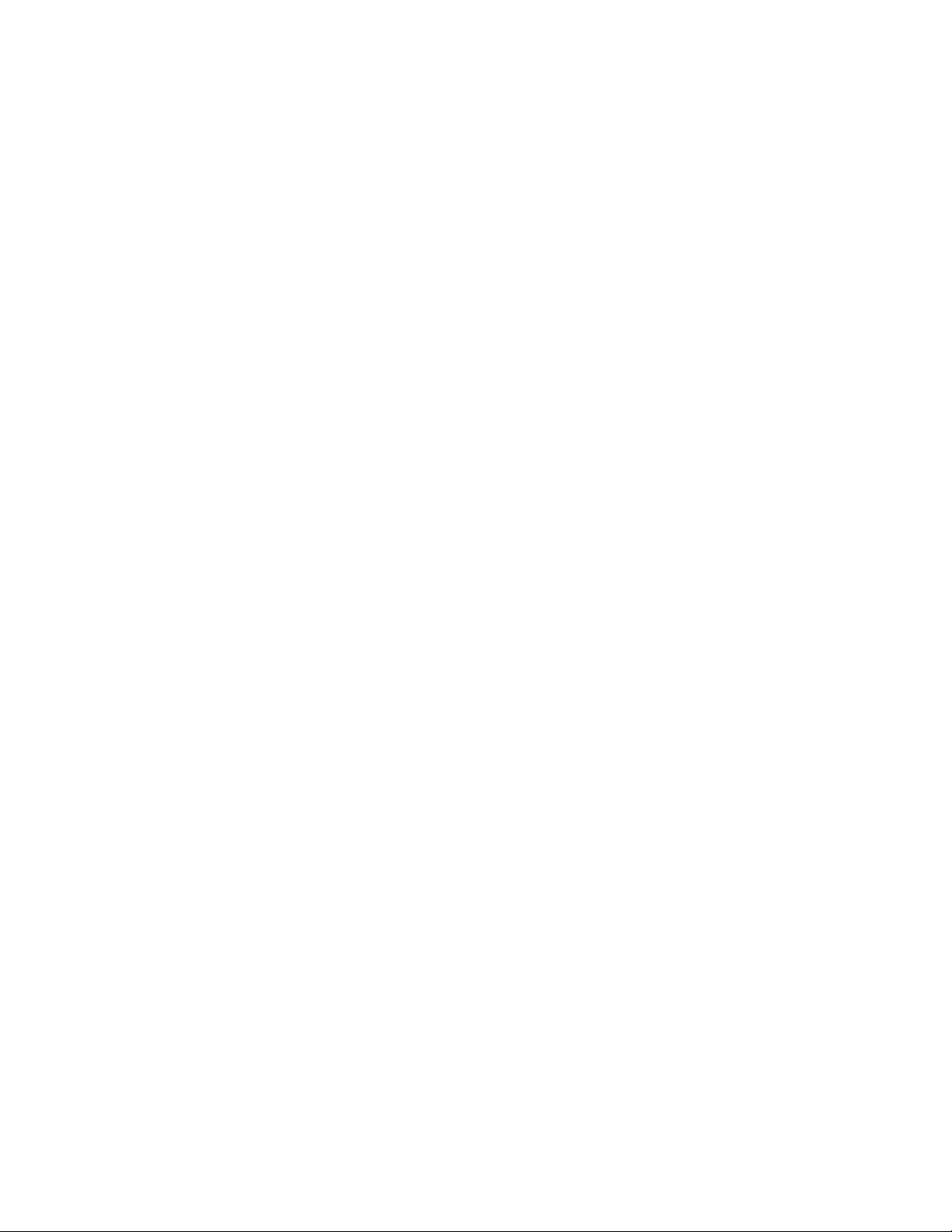

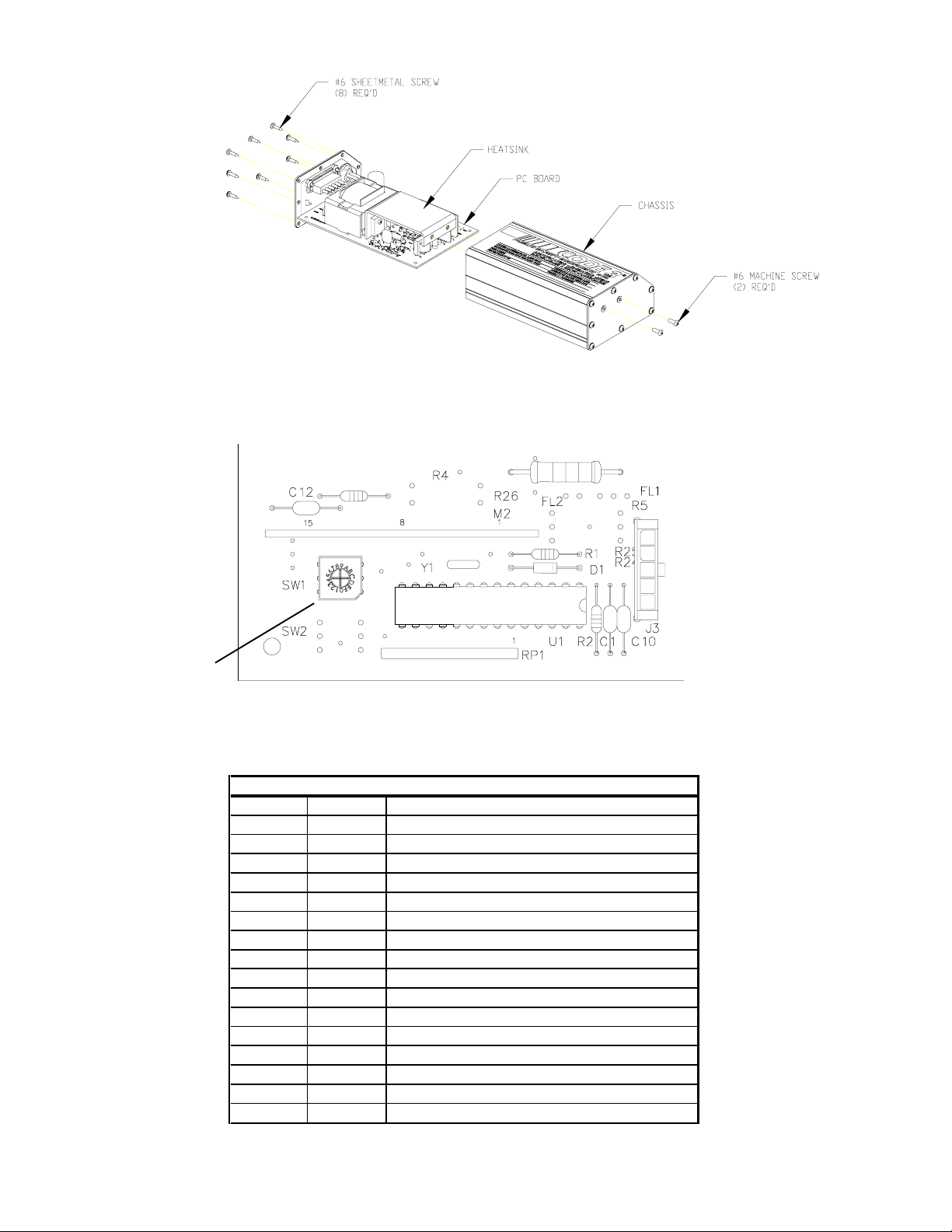

Siren Amplifier, Exploded View

8

Page 9

Ref No. Description Part No. Qty.

1 Fuse, 10A, Mini-ATO T03066 1

2 #6 x .5" SMS, Pan Hd Phil T06313 18

3 4-40 x .375" Machine Screw, Pan Hd. Phil T06937 2

4 #6 Flat washer, Nylon, Black T10151 20

5 Enclosure, Extruded Aluminum T11145 1

6 Gasket T11148 1

7 Wire harness, microphone T11191 1

8 End Plate T11150 1

9 PCB Assy 1

Model 4012, 12V, No PA T11186

Model 4013, 12V, with PA T11187

Model 4024, 24V, No PA T11188

Model 4025, 24V, with PA T11187

1 0 End Plate w/ Connector Assembly 1

No PA T11201

With PA T11202

MICROPHONE

Models 4013 & 4025 only

Figure 5, Wiring Diagram

NUIT

ACTIVEZ

100W

SPEAKER

9

External

FUSE

Ignition

Switch

Page 10

WARRANTY

Code 3, Inc.'s emergency devices are tested and found to be operational at the time of

manufacture. Provided they are installed and operated in accordance with manufacturer's

recommendations, Code 3, Inc. guarantees all parts and components except the lamps to a period

of 1 year (unless otherwise expressed) from the date of purchase or delivery, whichever is later.

Units demonstrated to be defective within the warranty period will be repaired or replaced at the

factory service center at no cost.

Use of lamp or other electrical load of a wattage higher than installed or recommended by the

factory, or use of inappropriate or inadequate wiring or circuit protection causes this warranty to

become void. Failure or destruction of the product resulting from abuse or unusual use and/or

accidents is not covered by this warranty. Code 3, Inc. shall in no way be liable for other damages

including consequential, indirect or special damages whether loss is due to negligence or breach of

warranty.

CODE 3, INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING,

WITHOUT LIMITATION, WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to obtain

a Return Goods Authorization Number (RGA number) before you ship the product to Code 3, Inc.

Write the RGA number clearly on the package near the mailing label. Be sure you use sufficient

packing materials to avoid damage to the product being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses incurred for the

removal and /or reinstallation of products requiring service and/or repair.; nor for the packaging, handling, and shipping: nor for the handling of products return to

sender after the service has been rendered.

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

10986 N. Warson Road

CODE 3, Inc.Ò

Code 3 is a registered trademark

of Public Safety Equipment, Inc.

10

Revision 0, 07/04 - Instruction Book Part No. 11195

©2004, CODE 3, Inc. Printed in USA

Page 11

INSTALLATION

et OPÉRATION

MANUEL

SIRÈNES DE SÉRIES 4000

SIRÈNES

AVERTISSEMENT

Les sirènes produisent les bruits forts qui peuvent

endommager l’audition

• Protection d’audition d’usage en examinant

• Utiliser la sirène seulement pour la réponse de secours

• Enrouler les fenêtres quand la sirène fonctionne

• Éviter l’exposition au bruit de sirène en dehors de du véhicule

Lire tous les instructions et avertissements avant dinstaller et employer.

IMPORTANT:

LINSTALLATEUR ce manuel doit être livré à lutilisateur de cet équipement.

11

Page 12

Introduction

Sirènes électroniques de séries 4000 ont été conçues pour satisfaire les besoins de tous les véhicules de

secours. Cette série de sirènes incorpore beaucoup de dispositifs populaires de la ligne de sirène

avec les circuits basés sur microprocesseur et la technologie de transistor MOSFET.

Les sirènes sont une partie intégrale dun système davertissement de secours efficace daudio/

visual. Cependant, les sirènes sont que des dispositifs davertissement secondaires de gamme

courte. Lutilisation dune sirène nassure pas que tous les conducteurs peuvent ou

observeront ou réagiront à un signal dalarme de secours, en particulier à de longues

distances ou quand lun ou lautre véhicule voyage à un rapport de vitesse élevé. On devrait

seulement être utilisé dans une combinaison avec les voyants dalarme efficaces et ne

jamais compter au moment des sirènes comme signal dalarme unique. Ne jamais prendre la

droite de la manière pour accordé. Il est de votre responsabilité dêtre sûr que tu peus

!

AVERTISSEMENT!

PRODUITS DE

SIRÈNE:

procéder sans risque avant dentrer dans une intersection, conduire contre le trafic, ou

répondre à un rapport de vitesse élevé.

Lefficacité de ce dispositif davertissement dépend fortement du support et du câblage

corrects. Lire et suivre les instructions du fabricant avant dinstaller ou à laide de ce

dispositif. Lopérateur de véhicule devrait vérifier le journal déquipement pour sassurer que

tous les dispositifs du dispositif fonctionnent correctement.

Pour être efficaces, les sirènes doivent produire les niveaux sonores élevés qui

potentiellement peuvent infliger des dommages daudition. Des installateurs devraient être

avertis de porter la protection daudition, spectateurs clairs du secteur et de ne pas actionner

la sirène à lintérieur pendant lessai. Les opérateurs et les occupants de véhicule devraient

évaluer leur exposition au bruit de sirène et déterminer quelles étapes, telles que la consultation avec des professionnels ou lutilisation de la protection daudition devraient être mises en

application pour protéger leur audition.

Cet équipement est prévu à lusage du personnel autorisé seulement. Il est de la

responsabilité de lutilisateur de comprendre et obéir toutes les lois concernant les dispositifs

davertissement de secours. Lutilisateur devrait vérifier tous les ville applicable, état et lois et

règlements fédéraux.

Le code 3, inc., nassume aucune responsabilité pour nimporte quelle perte résultant de

lutilisation de ce dispositif davertissement.

Linstallation appropriée est essentielle à lexécution de la sirène et de lexploitation sûre du

véhicule de secours. Il est important didentifier que lopérateur du véhicule de secours est

sous la contrainte psychologique et physiologique provoquée par la situation de secours. Le

système de sirène devrait être installé dune telle façon quant à: A) Ne pas réduire

lexécution acoustique du système, B) limite autant que pratique le niveau de bruit dans la

cabine passagers du véhicule, C) endroit les commandes dans lextension commode de

lopérateur de sorte quil puisse actionner le système sans contact doeil perdant avec la

chaussée.

Les dispositifs davertissement de secours exigent souvent des tensions et/ou des courants

électriques élevés. Correctement protéger et faire attention autour des raccordements

électriques de phase. Fondre ou court-circuiter des raccordements électriques peut causer

des courant élevé, ce qui peut des blessures graves et/ou endommage le véhicule, y compris

le mettre en feu.

LINSTALLATION APPROPRIÉE COMBINÉE AVEC LA FORMATION DOPÉRATEUR DANS LUTILISATION APPROPRIÉE DES

DISPOSITIFS DAVERTISSEMENT DE SECOURS EST ESSENTIELLE POUR ASSURER LA SÛRETÉ DU PERSONNEL DE

SECOURS ET DU PUBLIC.

de ®

du code 3

Dispositifs Standard

Les 4000 séries de E-escroquent des sirènes se composent de l’amplificateur à distance monté de sirène sont

fonctionnées par des régulations des marchés d’un utilisateur. Les modèles sont comme suit :

4012 - 12V, Aucune Adresse Publique

4013 - 12V, Avec L’Adresse Publique

12

Page 13

4024 - 24V, Aucune Adresse Publique

4025 - 24V, Avec L’Adresse Publique

Instantané-Sur - appliquer la terre à la borne d’ACTIVEZ fera fonctionner la sirène en mode de puissance de

jour. Quand la police ou des tonalités médicales de sirène de secours est choisie (SW1 placer à 0 ou à 2),

appliquant la terre à l’ACTIVEZ et la borne de NUIT commuteront au mode de puissance de nuit. En serrant le

microphone Pousser-à-Parler le bouton (PTTS) sur les models 4013 et 4025 activeront la fonction d’adresse

publique.

Adresse publique instantanée - la fonction d’adresse publique dépassera la fonction de sirène quand le

microphone Pousser-à-Parlent le bouton est serré (models 4013 et 4025 seulement).

Protection automatique de court circuit - la sirène sentira un court circuit sur les bornes de haut-parleur et ira

automatiquement à la ressource jusqu’à ce que le défaut soit enlevé. Une fois que le défaut est enlevé la sirène

reviendra à l’opération normale.

Microphone d’annulation de bruit - un microphone d’annulation de bruit embrochable (models 4013 et 4025

seulement) est donné pour le service ou le remplacement facile.

Déballage Et Préinstallation

Après déballage de votre sirène de 4000 séries, inspecter soigneusement l’unité et les pièces associées pour

déceler n’importe quels dommages qui ont pu être produits en transit. Rapporter n’importe quels dommages au

porteur immédiatement.

Installation Et Montage

Les 4000 séries de sirènes sont conçues pour être montées à l’intérieur d’un guide optique ou à l’ intérieur d'un

véhicule. Ne pas monter la sirène à l’intérieur du compartiment réacteur. Le matériel de support est fourni (voir

la fig. 2) pour monter l’amplificateur à l’intérieur du guide optique.

NOTE : Les installations et les ajustements seront faits dans les étapes suivantes, dépendant du modèle et

des options achetés, qui peuvent exiger l’accès au secteur arrière de l’unité. Projeter l’installation et le câblage

en conséquence.

Tous les dispositifs devraient être montés selon les instructions du fabricant et être

solidement attachés aux éléments de véhicule de la force suffisante pour résister aux

!

WARNING!

forces appliquées au dispositif. La facilité d’emploi et la convenance à l’opérateur devrait

être la considération principale en montant la sirène et les commandes. Ajuster l’angle

de support pour permettre la visibilité maximum d’opérateur. Ne pas monter la module de

commande dans un endroit qui obstruera la vue de conducteurs. Monter l’agrafe de

microphone dans un endroit commode pour permettre à l’opérateur l’accès facile. Des

dispositifs devraient être montés seulement dans les endroits qui se conforment à leur

code d’identification de SAE comme décrit dans SAE J1849 standard. Par exemple,

l’électronique conçue pour le support intérieur ne devrait pas être underhood, etc..

placés.

Des commandes devraient être placées dans l’extension commode * du conducteur ou

si prévu pour l’opération de deux personnes le conducteur et/ou le passager. Dans des

quelques véhicules, commutateurs de commande multiples et/ou méthodes en utilisant

telles que “le transfert d’anneau de klaxon” qui utilise le commutateur de klaxon de

véhicule pour basculer entre les tonalités de sirène peut être nécessaire pour l’opération

commode de deux positions.

13

Page 14

Raccordements D’Amplificateur

Connecteur d’amplificateur de sirène - se référer au diagramme de câblage sur le schéma 5 (page

10) pour des informations détaillées sur les raccordements d’amplificateur. Comme dispositif

standard, les sirènes de série 4000 sont équipées d’une borne embrochable block/connector de

combinaison. Pour terminer les fils, dépouiller approximativement 1/4"de l’isolation de l’extrémité de

chaque fil et l’insérer dans le trou approprié dans le TB. Serrer la vis de réglage et procéder au

prochain raccordement.

Si tu doit jamais enlever l’unité, desserrer les vis de sécurité et tirer le TB directement dehors. Il

débranchera de la sirène, laissant le câblage en place.

Raccordements De TB

- V - Relier à la borne négative de la batterie. Ceci fournit la terre (la terre) à la sirène. Fil de mesure

de l’utilisation #14.

+V - relier à un positif la source de C.C de +12 volts (+24 volts pour models 4024 et 4025). On

recommande que l’utilisateur protègent ce fil avec un fusible un le disjoncteur de 10 ampères situé à

la source d’énergie (fusible de 5 ampères pour models 4024 et 4025). Fil de mesure de l’utilisation

#14.

NUIT - relier à un commutateur qui assurera la terre (la terre) quand DESSUS. Fil de mesure de

l’utilisation #14-16.

ACTIVEZ - relier à un commutateur qui assurera la terre (la terre) quand DESSUS. Fil de mesure de

l’utilisation #14-16.

HP1 - haut-parleur - se relient au fil (11 ohms) de la borne 1 du haut-parleur 100W.

HP2 - relier au fil d’une (11 ohms) borne 2 du haut-parleur 100W.

INSTALLATION ET AJUSTEMENT

P.A. Ajustement de volume - le volume d’adresse publique est placé par la commande de volume

coulissante située sur l’avant du microphone. Placer cette commande pour donner le niveau désiré de

volume de PA. L’utilisateur peut ajuster cette commande à tout moment pendant l’utilisation.

Choix de tonalité - se rapportant au schéma 2 et le schéma 3 et le diagramme de tonalité de

sirène, le schéma 4, a placé le commutateur rotatoire SW1 de 16 positions (situé à l’intérieur de la

sirène) au nombre qui correspond à la tonalité désirée. Sauf indication contraire à l’heure d’ordre,

l’arrangement de défaut est 0 (police).

Caractéristiques

Section De Sirène

Tension dentrée - 10 à 16 volts continu, la terre négative (la terre) - models 4012 et 4013

20 à 30 volts continu, la terre négative (la terre) - models 4024 et 4025

Courant dopération (jour) -9.2 ampères @ de 13.8V avec la charge d11ohm (100W Spkr) - 4012 et 4013

4.6 ampères @ de 27.6V avec la charge d11ohm (100W Spkr) - 4024 et 4025

Courant dopération (nuit) - 0.8 ampère @ de 13.8V avec la charge d11ohm (100W Spkr) - 4012 et 4013

0.4 ampère @ de 27.6V avec la charge d11ohm (100W Spkr) - 4024 et 4025

Température de fonctionnement - °C -35 au °C +85

14

Page 15

Courant De secours: 25 mA si directement à la batterie, 0 mA w/Ignition AU LOIN si par le

commutateur dallumage de véhicule (recommandé)

Tension produite (approximativement) 70V de crête à crête (jour)

crête 4.2V à la crête (nuit)

Poids - 1.08 kilogramme (avec des supports)

Section Audio (Models 4013 Et 4025)

Réponse sonore - le DB 3 se dirige vers le bas - 500 à 3000 hertz.

1000 hertz. 0 références de DB

Déformation audio - 10% ou moins au-dessous de la coupure.

ENTRETIEN

Votre Code 3® sirène de 4000 séries a été conçu pour fournir le service sans ennuis. En cas de difficulté, voir

le dépannage. En outre vérifier court-circuité ou ouvrir les fils. La cause primaire des courts-circuits s’est

avérée des fils passer par des murs à l’épreuve du feu, des toits, etc… Si plus loin la difficulté persiste, entrer

en contact avec l’usine pour le conseil de dépannage ou les instructions de retour. Le Code 3® maintient des

pièces complètes inventorient et service le service à l’usine et répareront ou remplaceront (à l’option de l’usine)

n’importe quelle unité avérée défectueux sous l’utilisation normale et dans la garantie. N’importe quelle tentative

d’entretenir une unité dans la garantie par n’importe qui autre qu’un technicien autorisé par usine sans

consentement écrit exprès par l’usine, annulera la garantie. Des unités hors de la garantie peuvent être

réparées à l’usine pour une somme nominale sur un taux forfaitaire ou des pièces et base de travail. Entrer en

contact avec l’usine pour des détails et des instructions de retour. Le du code 3

d’aucun frais fortuit lié à la réparation ou au remplacement d’une unité à moins qu’ait autrement expressément

été d’accord sur dans l’écriture.

®

n’est pas responsable

15

Page 16

16

Amplificateur De Sirène, Vue Éclatée

Page 17

No.

De Référence Description Numéro de la pièce. Quantité.

1 Fusible, 10A, Mini-ATO T03066 1

2 5"SMS, casserole Hd Phil de 6 x T06313 18

3 vis de machine de 375"de 4-40 x, casserole Hd Phil T06937 2

4 #6 rondelle plate, nylon, noir T10151 20

5 Clôture, Aluminium Expulsé T11145 1

6 Garniture T11148 1

7 Harnais de fil, microphone T11191 1

8 Plaque d’extrémité T11150 1

9 Assy de Carte

(model 4012) T11186 1

(model 4013) T11187 1

(model 4024) T11188 1

(model 4025) T11189 1

1 0 Plaque d’extrémité avec l’Assemblée de connecteur 1

Aucune PA T11201

Avec la PA T11202

MICROPHONE

Models 4013 & 4025 only

Le Schéma 5, Diagramme De câblage

17

NUIT

ACTIVEZ

HAUTPARLEUR

100W

Externe

FUSIBLE

Moteur

Commutateur

Page 18

DÉPANNAGE

PROBLÈME

AUCUN RENDEMENT

DE SIRÈNE.

COUPS DE FUSIBLE.

AUCUN RENDEMENT

DE ORATEUR,

TONALITÉS ENTENDU

À L’INTÉRIEUR

AMPÈRE MODULE.

TONALITÉS DE SIRÈNE

VOLUME AUSSI

LOW/GARBLED.

CAUSE PROBABLE

A. AUCUN +V OU TERRE

B. HAUT-PARLEUR COURT-CIRCUITÉ

OU FILS De HAUT-PARLEUR.

SIRÈNE DANS MODE COURANT DE

PROTECTION D’EXCÉDENT.

A. Les FILS De PUISSANCE

D’AMPLIFICATEUR ONT RENVERSÉ

La POLARITÉ

A. CIRCUIT NON RELIÉ/OUVERT

D’ORATEUR DANS Le CÂBLAGE De

HAUT-PARLEUR

B. HAUT-PARLEURS DÉFECTUEUX

A. BASSE TENSION À

l’AMPLIFICATEUR De SIRÈNE

B. RÉSISTANCE ÉLEVÉE DANS Le

HAUT-PARLEUR De WIRING/

DEFECTIVE

REMÈDE

A. VÉRIFIER Les FILS

De PUISSANCE.

B. VÉRIFIER Les

RACCORDEMENTS De

HAUT-PARLEUR

A. VÉRIFIER La

POLARITÉ

A. VÉRIFIER Le

CÂBLAGE De HAUTPARLEUR

B. REMPLACER

SPEAKER(S)

A. EXAMINER Le CÂBLAGE

POUR DÉCELER Les

CONNEXIONS

MAUVAISES/Le SYSTÈME

De REMPLISSAGE

VÉHICULE De CONTRÔLE

B. VÉRIFIER SPEAKER(S)

WIRING/REPLACE

SPEAKER(S)

TAUX ÉLEVÉ DE

ÉCHEC D’ORATEUR.

P.A. VOLUME BAS OU

AUCUN P.A. LA

COMMANDE DE

VOLUME ÉTANT PLACÉ

AU MAXIMUM.

La SIRÈNE

FONCTIONNE

CORRECTEMENT MAIS

S’ARRÊTE TOUT EN

COURANT, DÉMARRE

ALORS COURIR

ENCORE APRÈS

QUELQUES MINUTES

A. HAUTE TENSION À la SIRÈNE

B. HAUT-PARLEUR De 58 WATTS

RELIÉ. 58 WATTS NON LAISSÉS.

A. MICROPHONE DÉFECTUEUX

B. MICROPHONE PAS

COMPLÈTEMENT BRANCHÉ.

C. MICROPHONE INCORRECT.

A. Les DISJONCTEURS De

VÉHICULE NON ÉVALUÉS

CORRECTEMENT, ET

SURCHAUFFENT, OU NE

FONCTIONNENT PAS

CORRECTEMENT

A. VÉRIFIER Le

SYSTÈME De

REMPLISSAGE De

VÉHICULE

B. EMPLOYER Le HAUTPARLEUR CORRECT

A. REMPLACER Le

MICROPHONE

B. BRANCHER Le

MICROPHONE

SOLIDEMENT

C. UTILISER

SEULEMENT Le

MICROPHONE Du CODE

3.

A. SE RÉFÉRER À la

SECTION De

CARACTÉRISTIQUES.

EMPLOYER Un BRISEUR

ÉVALUÉ À 1.25x

LAMPÉRAGE Du

COURANT PRÉVU De

CHARGE.

18

Page 19

NOTES

19

Page 20

GARANTIE

Les dispositifs du secours de Code 3, sont examinés et ont trouvé pour être opérationnels à

l’heure de la fabrication. S’ils sont installés et actionnés selon les recommandations du fabricant,

les garanties du code 3, de l’inc. toutes les pièces et les composants excepté les lampes à une

période de 1 an (à moins qu’autrement exprimé) à partir de la date de l’achat ou de la livraison, celui

qui est plus tardif. Des unités démontrées pour être défectueuses au cours de la période de garantie

seront réparées ou remplacées au centre commercial d’usine à aucun coût.

L’utilisation de la lampe ou de toute autre charge électrique d’une puissance en watts plus haut

qu’installé ou recommandé par l’usine, ou l’utilisation de la protection inadéquate ou insatisfaisante

de câblage ou de circuit fait devenir cette garantie vide. L’échec ou la destruction du produit résultant

de l’abus ou de l’utilisation et/ou des accidents peu communs n’est pas couvert par cette garantie.

Le code 3, inc. sera nullement responsable d’autres dommages comprenant des dommages

consécutifs, indirects ou spéciaux si la perte est due à la négligence ou à l’infraction de la garantie.

CODER 3, MARQUES D’INC. AUCUNE AUTRE GARANTIE EXPRÈS OU IMPLICITE

COMPRENANT, SANS LIMITATION, DES GARANTIES DE FORME PHYSIQUE OU VALEUR

MARCHANDE, EN CE QUI CONCERNE CE PRODUIT.

RETOURS DE PRODUIT

Si un produit doit être retourné pour la réparation ou le remplacement *, svp entrer en contact

avec notre usine pour obtenir un nombre de retour d’autorisation de marchandises (nombre de

RGA) avant toi bateau le produit pour coder 3, inc.. Écrire le nombre de RGA clairement sur le

paquet près de l’étiquette d’envoi.Être sûr tu les matériaux d’emballage suffisants d’utilisation

pour éviter d’endommager le produit étant retourné tandis qu’en transit.

* Coder 3, réservations d’inc. la droite de réparer ou remplacer à sa discrétion. Le code 3, inc. n’assume aucune responsabilité ou responsabilité pour des

dépenses encourues pour le déplacement et/ou la réinstallation des produits exigeant le service et/ou la réparation ; ni pour l’empaquetage, manipuler, et

embarquer : ni pour la manutention des produits revenir à l’expéditeur après que le service ait été rendu.

.

St. Louis, Missouri 63114-2029—USA

10986 N. Warson Road

Ph. (314) 426-2700 Fax (314) 426-1337

CODE 3, Inc.Ò

CODE 3 est une marque déposée

d’ Public Safety Equipment, inc.

20

Révision 0, 07/04 - Numéro de la pièce 11195 De Livre D’Instruction

©2004, Public Safety Equipment, Inc. imprimé aux Etats-Unis

Loading...

Loading...