Table of Contents

N74 Engine

Subject Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

N74 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

N74 Engine Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Horse Power and Torque Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Engine Components/Systems Overview . . . . . . . . . . . . . . . . . . . . . . .11

Engine Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Engine designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Engine identification and number . . . . . . . . . . . . . . . . . . . . . . . . . .13

Engine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Engine Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Cylinder Head Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Oil Sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Crankcase Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Register Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Oil Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Crankshaft Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Connecting Rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Pistons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Chain Tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Valve Train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

VANOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Roller Cam Followers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Belt Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Oil Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Pressure Limiting Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Initial Print Date: 12/09

Revision Date: 08/10

Subject Page

Oil Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Oil Spray Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Oil spray nozzles for piston crown cooling . . . . . . . . . . . . . . . . . . .29

Oil spray nozzles for timing chain lubrication . . . . . . . . . . . . . . . .29

Oil Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Engine Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Coolant Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Main coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Auxiliary water pump for exhaust turbochargers . . . . . . . . . . . . . .32

Expansion Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Charge Air Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Auxiliary Coolant Pump for Charge Air Cooling . . . . . . . . . . . . . . . . .35

Charge-air Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Engine Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Intake Air Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Turbocharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Exhaust Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Charging Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Blow-off control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Charge Air Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Intake Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Exhaust Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Secondary Air System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Secondary air pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Secondary air valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

On-board diagnosis of secondary air system . . . . . . . . . . . . . . . .43

Vacuum System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Fuel Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

High Pressure Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Hydraulic Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Outward-opening Piezo Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Subject Page

BLANK

PAGE

N74 Engine

Model: F01/F02

Production: From Start of Production

After completion of this module you will be able to:

• Describe the features of the N74B60U0 engine

• Describe the specifications of the N74 engine

• Identify the internal and external components of the N74 engine

4

N74 Engine

Introduction

N74 Engine

The N74 engine is the successor to the N73 engine, but shares many technical features

with the N63 engine. Thus the N74 engine also has high precision injection featuring

outward-opening piezo injectors located centrally in the combustion chamber and twin

turbochargers with indirect charge air cooling. On the N74 engine, however, the exhaust

turbochargers are located on the outside of the engine.

N74B60U0 engine

N74 Engine

5

Models with the N74 engine were launched to the US market in the September 2009.

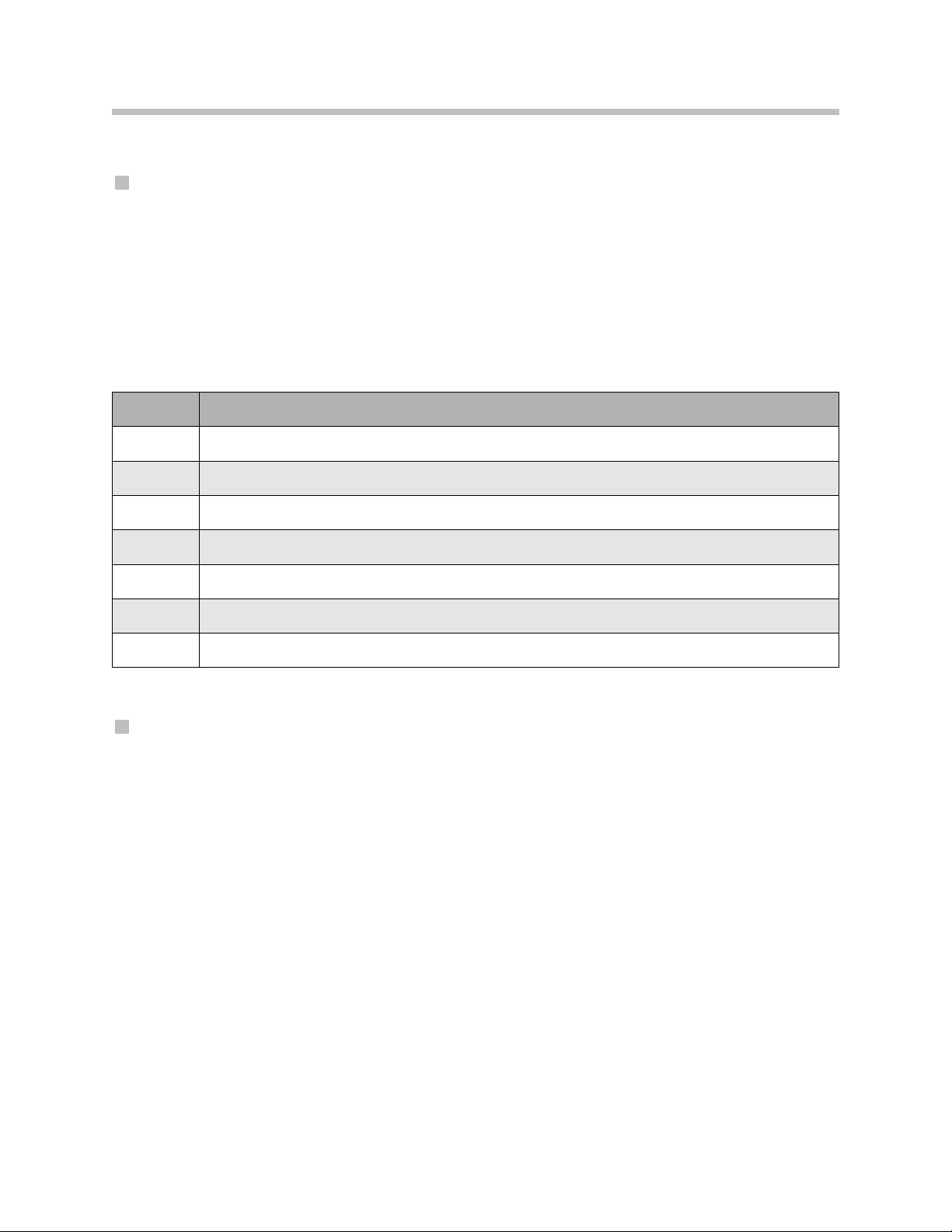

Model Modelseries Engine Poweroutputinkw/bhp TorqueinNm

760i F01 N74B60U0 400/535 750

760Li F02 N74B60U0 400/535 750

History

The following chart list all previous BMW Twelve-cylinder gasoline engines.

Engine Model

M70B50

M70B50

M70B50

S70B56

M73B54

M73B54

N73B60

750i E32 4988 220/300 450 ME1.2 5/87-9/90

850i E31 4988 220/300 450 ME1.7 4/90-11/94

750i E32 4988 220/300 450 ME1.7 9/90-11/94

850Csi E31 5576 208/381 550 ME1.7.1 10/92-9/97

750i E32 5379 240/326 490 ME5.2 9/94-9/01

850Ci E31 5379 240/326 490 ME5.2 9/94-9/99

760i E65 5972 327/445 600 MED9.2.1 + HPFI 9/02-9/08

Model

series

Displacement

incm³

Poweroutput

inkW/bhp

Torque

inNm

Enginecontrol

system

Introduced-

discontinued

N73B60

6

N74 Engine

760Li E66 5972 327/445 600 ED9.2.1 + HPFI 9/02-9/08

N74 Engine Features

The N74 engine also shares many other common features with the N63 engine, such as

a volumetric-flow-controlled oil pump and a camshaft drive with tooth-roller type chains.

By using the latest technology, it has been possible to increase power output substantially,

while at the same time reducing fuel consumption – Efficient Dynamics in fact.

Index Explanation

1

2

3

4

5

6

7

Camshaft drive with toot-roller type chain

High pressure pump for high precision injection

Charge air cooling for indirect charge air cooling

Outward-opening piezo injector

Volumetric-flow-controlled oil pump

Exhaust turbocharger

Charging pressure control by means of wastegate valves

7

N74 Engine

Technical Data

N73B60O1 N74B60U0

Type

Firing order

Displacement

Bore / stroke

Power output at

engine speed

Torque at engine speed

Power output per liter

Cutoff speed

Compression ratio

Maximum Boost

V12 60° V12 60°

1-7-5-11-3-9-

6-12-2-8-4-10

[cm³] 5972 5972

[mm] 89/80 89/80

[kW/bhp]

[rpm]

[Nm/lb-ft]

[rpm]

[kw/l] 53.58 66.98

[rpm] 6500 6500

bar NA (Naturally Aspirated) 0.7

320/435

6000

600/400

3950

11.5 10.0

1-7-5-11-3-9-

6-12-2-8-4-10

400/535

5250-6000

750/550

1500-5000

Distance between

cylinders

Valves per cylinder

Diameter of intake valve

Diameter of

exhaust valve

Diameter of main

bearing journals of the

crankshaft

[mm] 98 98

44

[mm] 35.0 33.2

[mm] 29 29

[mm] 70 65

8

N74 Engine

Diameter of connecting

rod bearing journals

of the crankshaft

N73B60O1 N74B60U0

[mm] 54 54

Fuel specification

Fuel

Engine control system

Exhaust emission

standard US

[RON] 98 95

[RON] 91-98 91-98

2 x MED 9.2.1

1 x VALVETRONIC control unit

2 high-pressure fuel injection valve control units

(HPFI)

LEVII ULEV II

2 x MSD87-12

N74 Engine

9

Horse Power and Torque Diagram

Full load diagram for the N74B60 engine, compared with the N73B60 and N63B44 engines

10

N74 Engine

Engine Components/Systems Overview

The following provides an overview of the features of the N74 engine:

• Engine block

The main components of the engine block have been re-designed, although most

features are already used on other BMW engines.

• Crankshaft

Although the Pistons and connecting rods have been borrowed from the N63

engine, the crankshaft is a new design.

• Valve train

The VANOS units from the N63 engine are used and the camshafts are

manufactured in the same way. The N74 does not use a VALVETRONIC system.

• Camshaft

The tooth-roller type chain of the N63 engine is used. Only the chain length and the

layout of the timing gears have been adapted to suit the twelve-cylinder engine.

• Belt drive

The structure of the belt drive includes a “revolver” tensioning system and is identical to that on the N63 engine.

• Oil supply

Though the oil supply system has been designed for the N74 engine, in principle,

it's the same as that on the N63 engine. Consequently a volumetric-flow-controlled

oil pump is also used here.

• Crankcase ventilation

The engine uses the same crankcase ventilation principle as N63 engine with a new

feature called register ventilation. With this feature, the oil separators now have four

cyclones per cylinder bank and in naturally-aspirated operation, ventilation only

occurs via cylinder bank 2.

• Cooling system

Two separate cooling circuits are used as on N63, one to cool the engine and

turbocharger bearings and one for charge air cooling, this latter circuit also provides

cooling for the two engine control units.

11

N74 Engine

• Air intake and exhaust system

The air intake and exhaust systems are the same as that on the N63 engine.

This means there are two conventional exhaust turbochargers with wastegate and

blow-off valves. In contrast to the N63 engine, however, the exhaust turbochargers

are located on the outside.

• Secondary air system

As with N73 engine, the N74 is equipped with a secondary air system.

One new feature, however, are the two pressure sensors that monitor system

operation.

• Vacuum system

The N74 engine has a two-stage vacuum pump as on the N63. The vacuum

system only differs in that it has two vacuum reservoirs.

• Fuel system

The N74 engine uses “injection guided” (HPI) high precision injection in homogeneous operation at all times, as on the N54 and N63 engines. The structure of the

system is the same as that on the N63 engine. Consequently, the same injectors are

used and the high pressure pumps are also very similar.

• Engine electrical system

A total of five control units were used on the N73 for engine control purposes.

The N74 now has two engine control units, one of which has the role of the master

(primary), the other the secondary. The two MSD87-12 control units are located to

the left and right of the engine compartment and are cooled by the low temperature

cooling circuit of the engine intercoolers.

The N74 engine uses the most current BMW systems. Although the N74 engine has

been designed from scratch, from a technology point of view it is, the same as the N63

engine and has also borrowed many individual components from this engine.

12

N74 Engine

Engine Identification

Engine designation

In the technical documentation, the engine designation is used to ensure the clear

identification of engines.

The N74 engine is available in the following version: N74B60U0

In the technical documentation, you will also find the short form of the engine designation

N74 which only permits identification of the engine type.

The following chart explains the meaning of each component of the engine designation.

Index Explanation

N

7

4

B

60

U

0

Engine with high precision injection and turbocharging

BMW Group "New generation"

12-cylinder engine

Gasoline engine

6.0 liters displacement

Lower power stage

New development

Engine identification and number

To ensure clear identification and classification, the engines have an identification mark

on the crankcase. This engine identification is also necessary for approval by the

authorities.

Decisive here are the first seven positions. The N74 engine has an engine identification

that complies with the new standard, in which the first six positions are the same as the

engine designation. The seventh position is a consecutive letter that can be used for

various distinctions, e.g. power stage or exhaust emission standard. A general assignment

is not possible, but an "A" usually means the basic model.

The engine number is a consecutive number that permits unmistakable identification of

each individual engine. The engine designation and number are on the crankcase behind

the bracket for the air conditioning compressor.

13

N74 Engine

Engine Components

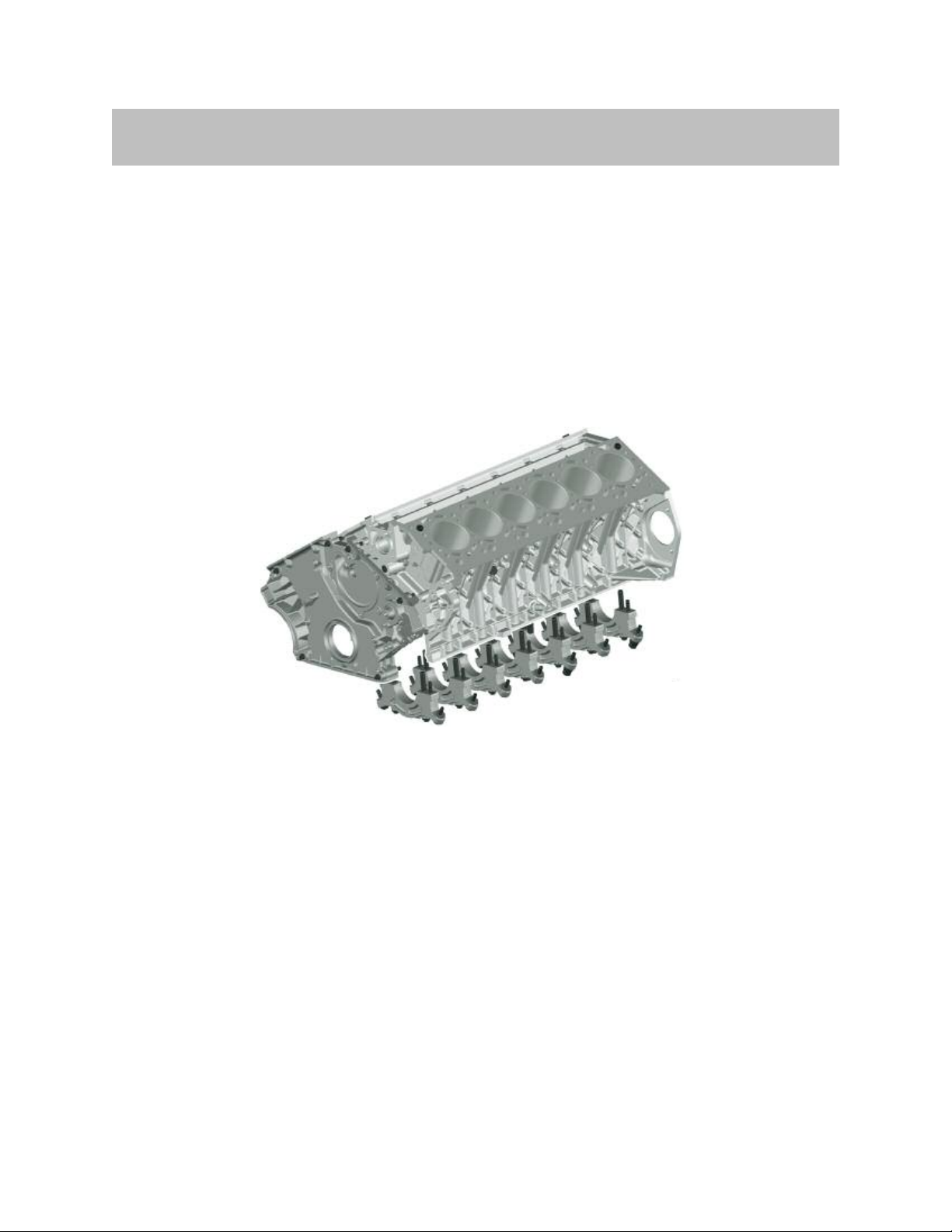

Engine Block

The engine block of the N74 engine is a new design. It is similar to the N63 engine

concept, but with a cylinder bank angle of 60° and the following features:

• Block made of an aluminum alloy (Alusil)

• Closed deck crankcase design

• Honed cylinder liners

• Lowered side walls (deep skirt) with main bearing caps

• Double main bearing bolting with additional side wall connection.

The closed-deck design and the bolt connections of the cylinder heads in the bottom of

the cylinder housing ensure high rigidity and low deformation of the exposure-honed

cylinder liners.

The crankcase with lowered side walls (deep skirt) has double main bearing bolting

with additional side wall connections by means of threaded support sleeves and bolts

designed to absorb the lateral forces from the crankshaft common on the V-engine configuration.

There are coolant passages to cool the (hot zone) area between the cylinders. In order

to keep the pumping losses in the crankcase to a minimum, there are one to six ventilation holes below each of the main bearing seats.

The use of separate channels for the oil return from the cylinder heads and for crankcase

ventilation reduces the amount of oil in the blow-by gases.

As on the N63 engine, the torque converter is bolted onto the flywheel through an

opening in the converter housing with six bolts positioned at an angle of 30°. This

makes it easier to replace the transmission.

14

N74 Engine

Cylinder Head

The cylinder head features the injector and spark plugs arranged in the center of the

combustion chamber. The layout of the high pressure fuel pumps is similar to that on the

N63 engine; however because of the conventional cylinder head arrangement (intake side

on the inside, exhaust side on the outside) they are located above the intake camshafts

(respectively between cylinders 1 and 2 and 7 and 8).

As on the N63 engine, the intake port features a trailing edge (around the valve seats) for

creating more intensive charge movement.

Coolant flows diagonally across the cylinder head (from the outer side of the engine

towards the V chamber), whereby the inlet is at the outside rear and the outlet at the

inside front. This is referred to as diagonal cooling.

As on the N63 engine, only one non-return valve for the oil circuit is incorporated into

the cylinder head. The N74 uses two VANOS non-return valves, they are now integrated

into the VANOS solenoid valves.

Cylinder Head Cover

The cylinder head covers are made of die-cast aluminum. They accommodate the oil

separation of the crankcase ventilation. The oil separators are made of plastic and are

very similar to those in the N63 engine.

Oil Sump

The engine oil sump is structured in two parts. The upper and lower sections of the diecast aluminum oil sump have been optimized with regard to strength and acoustics.

A two-part oil deflector also ensures particularly low oil foaming in extreme driving situations. A surge plate ensures that an adequate oil level is achieved in the case of high

longitudinal and lateral dynamic forces.

The thermostat for the engine oil cooler as well as the oil filter with an oil filter insert made

of synthetic fleece are integrated in the engine oil sump. The lower section of the oil

sump contains the oil level sensor that enables electronic oil level measurement. There is

no oil dipstick.

15

N74 Engine

Crankcase Ventilation

Crankcase ventilation works to a large extent in the same way as on the N63 engine.

However, the N74 has register ventilation, which is also used on the S63 engine.

16

N74 Engine

Loading...

Loading...