BMW N73B60 Workbook

Subject Page

N73B60 Engine

Objectives of the Module........................................................................2

Purpose of the System............................................................................3

Technical Data........................................................................................ 4

Disassembly - Components

Intake Manifold....................................................................................... 6

Cylinder Head Cover...............................................................................8

Ancillary Components and Drive Belts.................................................... 9

Cylinder Heads......................................................................................10

Valvetronic.............................................................................................11

Fuel Injectors.........................................................................................14

Lubrication Components.......................................................................15

Crankshaft and Bearings.......................................................................17

Pistons and Connecting Rods...............................................................17

Crankcase.............................................................................................19

Lubrication System................................................................................19

Cooling System.....................................................................................21

Table of Contents

N73B60 Engine - Workbook

2

N73B60 Engine - Diagnosis

N73B60 Engine

Model: E66 - 760Li

Production: MY 2003

This intent of this workbook is to assist you with key components for disassembly/reassembly in addition to the detailed information found in the Repair Instructions, Technical Data

and Tightening Torques from the latest TIS information.

This section will be instructor led for a brief review of the N73 engine. You are encouraged

to use this workbook with the latest TIS information to make notes during disassembly/

reassembly of the engine. This will be valuable to you as supplementary information or a

memory refresher when performing repairs in the future.

NNoottee::

For more in depth and detailed information about the N73 engine, refer to the ST047

2003 Systems Diagnosis training manual.

For additional and updated information, always refer to:

www.bmwcenternet.com

- TIS information/updates

- Service Information Bulletins

- DCS messages

Objectives:

After completion of this module you will be able to:

• Disassemble the N73 engine.

• Perform critical measurements and observations to determine engine condition.

• Correctly reassemble (including valve gear timing) the N73 engine.

3

N73B60 Engine - Diagnosis

N73B60 Engine

Purpose of the System

The N73 engine is a complete new BMW development from the NG Series (New

Generation) as a B60 (6 liter). The N73B60 will be used in the E66 as a 760Li (USA).

The BMW 760Li will set new standards in terms of performance and driving dynamics in

the 12-cylinder market segment as well as significantly reduce fuel consumption.

For the first time at BMW, Valvetronic technology (combination of Bi-VANOS and variable

intake valve lift) is supplemented by direct injection (DI).

In addition, the N73 cylinder heads use 4 valve technology.

The combination of these cutting edge technologies provides low fuel consumption and

maximum power output and torque, making the N73 the best engine in its class.

KT-9765

4

N73B60 Engine - Diagnosis

Technical Data

Technical Data Comparison N73B60 M73B54

V-angle configuration 12 cyl. V / 60º 12 cyl. V / 60º

Displacement (cm 3) 5972 5379

Bore / Stroke (mm) 89 / 80 79 / 85

Cylinder spacing (mm) 98 91

Crankshaft main bearing diam. (mm) 70 75

Conrod big end diam. (mm) 54 48

Power output (kW/HP)

at engine speed (rpm)

320 / 438

6000

240 / 326

5000

Torque (Nm)

at engine speed (rpm)

600

3950

490

3900

Idle speed (rpm)

Maximum engine speed (rpm)

550

6500

600

6500

Compression ratio 11.3 : 1 10 : 1

Valves per cylinder 4 2

Intake valve diam. (mm) 35 42

Exhaust valve diam. (mm) 29 36

Intake valve lift (mm) 0.3 - 9.85 10.3

Exhaust valve lift (mm) 9.7 10.3

Engine weight (kg) 280 -

Fuel requirement Premium unleaded Premium unleaded

Knock control Ye s Ye s

Injection pressure (bar) 50 - 120 3.5

Digital Motor Electronics (ECM) 2x MED 9.2.1 & Valvetronic ECU

with 2x HDEV ECU

2x ME 5.2 & EML IIIs

Emission compliance level LEV LEV

Firing order 1-7-5-11-3-9-6-12-2-8-4-10 1-7-5-11-3-9-6-12-2-8-4-10

Fuel consumption savings compared

with M73

12 % -

Maxmimum regulated vehicle speed

(km/h / mph)

250 / 155 250 / 155

5

N73B60 Engine - Diagnosis

Power and Torque Output - N73B60 / M73B54

N73B60

M73B54

Engine RPM

6

N73B60 Engine - Diagnosis

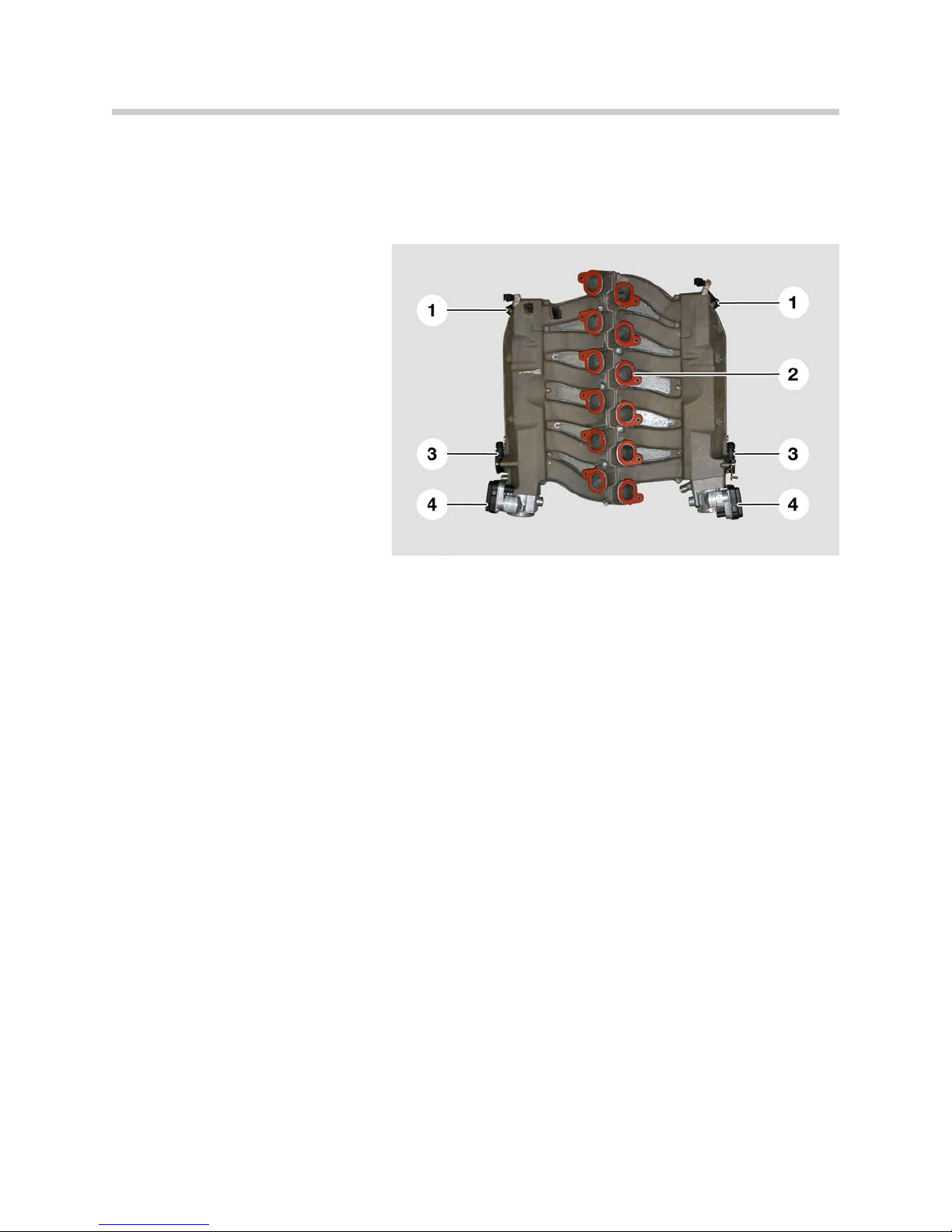

Intake Manifold

The intake system is a complete component constructed of magnesium in a shell type

design and has separate manifold chambers for each cylinder bank.

1. Intake manifold pressure sensors

2. Captured gaskets

3. Pressure control valves for crankcase

ventilation

4. Throttle valves

The individual parts of the intake system are bonded and bolted to each other, providing

considerable weight reduction (separating the shell halves is not permitted).

The entire intake system is protected against corrosion by a dip coating procedure. The

fastening bolts of the add on parts are also coated and must be replaced in the event of

damage, to prevent corrosion and pitting.

All of the gaskets (2) are secured by retainers (captured) to provide ease of installation. The

intake system is isolated from the engine by rubber elements on the fastening bolts.

An intake manifold pressure sensor (1) is used for each cylinder bank. Recording the manifold differential pressure is necessary for the correct throttle position (synchronization) so

that a manifold differential pressure of 50 mbar can be balanced on each bank.

Both sides of the induction system are fitted with a pressure control valve (3) for crankcase

ventilation which is distributed to both banks.

NNoottee::

When replacing the spark plugs, it is necessary to remove the entire intake system to

avoid damaging the spark plugs during installation. The spark plugs must be replaced

every 100,000 miles in US vehicles.

KT-9589

7

N73B60 Engine - Diagnosis

Intake Manifold - Removal

Top Diagram

• Remove plug connections on the throttle

assemblies (1).

• Detach engine vent hoses from pressure control valves (2).

• Detach oustide braces for intake manifold

(3 L/R).

Lower Diagram

• Remove plug connections on the intake manifold pressure sensors (1 L/R).

• Remove bolts (2) along sections (3).

• Lift intake manifold up to remove.

Questions

HHooww mmaannyy aattttaacchhiinngg bboollttss aarree tthheerree??

WWhhaatt iiss tthhee ttiigghhtteenniinngg ttoorrqquuee?? NNmm

HHooww aarree tthhee iinnttaakkee mmaanniiffoolldd ggaasskkeettss hheelldd iinn ppllaaccee??

CCaann tthhee ggaasskkeettss bbee rreeuusseedd??

NNootteess::

001

Loading...

Loading...