Technical�training.

Product�information.

N63TU2�Engine

BMW�Service

General�information

Symbols�used

The�following�symbol�is�used�in�this�document�to�facilitate�better�comprehension�or�to�draw�attention

to�very�important�information:

Contains�important�safety�information�and�information�that�needs�to�be�observed�strictly�in�order�to

guarantee�the�smooth�operation�of�the�system.

Information�status�and�national-market�versions

BMW�Group�vehicles�meet�the�requirements�of�the�highest�safety�and�quality�standards.�Changes

in�requirements�for�environmental�protection,�customer�benefits�and�design�render�necessary

continuous�development�of�systems�and�components.�Consequently,�there�may�be�discrepancies

between�the�contents�of�this�document�and�the�vehicles�available�in�the�training�course.

This�document�basically�relates�to�the�European�version�of�left-hand�drive�vehicles.�Some�operating

elements�or�components�are�arranged�differently�in�right-hand�drive�vehicles�than�shown�in�the

graphics�in�this�document.�Further�differences�may�arise�as�the�result�of�the�equipment�specification�in

specific�markets�or�countries.

Additional�sources�of�information

Further�information�on�the�individual�topics�can�be�found�in�the�following:

• Owner's�Handbook

• Integrated�Service�Technical�Application.

Contact:�conceptinfo@bmw.de

©2015�BMW�AG,�Munich

Reprints�of�this�publication�or�its�parts�require�the�written�approval�of�BMW�AG,�Munich.

The�information�contained�in�this�document�forms�an�integral�part�of�the�technical�training�of�the

BMW�Group�and�is�intended�for�the�trainer�and�participants�in�the�seminar.�Refer�to�the�latest�relevant

information�systems�of�the�BMW�Group�for�any�changes/additions�to�the�technical�data.

Contact:

Achim�Gloede

Tel.:�+49�(0)�89�382�50398

E-mail:�achim.gloede@bmw.de

Information�status:�May�2015

BV-72/Technical�Training

N63TU2�Engine

Contents

1. Introduction.............................................................................................................................................................................................................................................1

1.1. Models.....................................................................................................................................................................................................................................1

1.2. Technical�data............................................................................................................................................................................................................. 1

1.2.1. Full�load� diagram�................................................................................................................................................................ 3

1.3. New�features�on�the�N63TU2�engine...................................................................................................................................4

1.3.1. Overview............................................................................................................................................................................................. 4

1.3.2. N63TU2�engine�components........................................................................................................................... 5

1.4. Engine�identification..................................................................................................................................................................................... 11

1.4.1. Engine�designation....................................................................................................................................................... 11

1.4.2. Engine�identification....................................................................................................................................................11

2. Engine�Mechanical................................................................................................................................................................................................................ 13

2.1. Engine�housing..................................................................................................................................................................................................... 13

2.1.1. Crankcase.....................................................................................................................................................................................13

2.1.2. Cylinder�head�gasket................................................................................................................................................. 15

2.1.3. Cylinder�head......................................................................................................................................................................... 16

2.1.4. Cylinder�head�cover.....................................................................................................................................................18

2.1.5. Oil�sump......................................................................................................................................................................................... 25

2.2. Crankshaft�drive...................................................................................................................................................................................................27

2.2.1. Crankshaft�with�bearings.....................................................................................................................................28

2.2.2. Flywheel.......................................................................................................................................................................................... 29

2.2.3. Connecting�rod�with�bearing.........................................................................................................................30

2.2.4. Piston�with�piston�rings......................................................................................................................................... 32

2.3. Camshaft�drive/chain�drive................................................................................................................................................................. 34

2.4. Valve�gear.......................................................................................................................................................................................................................35

2.4.1. Design................................................................................................................................................................................................ 35

2.4.2. Valvetronic................................................................................................................................................................................... 39

2.5. Belt�drive......................................................................................................................................................................................................................... 50

2.6. SynTAK�(synergy�thermo-acoustic�capsule)......................................................................................................... 51

3. Oil�Supply...............................................................................................................................................................................................................................................52

3.1. Overview.......................................................................................................................................................................................................................... 52

3.1.1. Hydraulic�circuit�diagram..................................................................................................................................... 52

3.2. Oil�pump�and�pressure�control.................................................................................................................................................... 54

3.2.1. Intake�neck................................................................................................................................................................................. 54

3.2.2. Oil�pump.........................................................................................................................................................................................55

3.2.3. Map�control�valve.............................................................................................................................................................57

3.2.4. Normal�operation..............................................................................................................................................................59

3.2.5. Emergency�operation................................................................................................................................................60

3.3. Oil�cooling�and�filtering............................................................................................................................................................................ 62

3.3.1. Oil�cooling....................................................................................................................................................................................63

N63TU2�Engine

Contents

3.3.2. Oil�filtering................................................................................................................................................................................... 65

3.4. Oil�monitoring..........................................................................................................................................................................................................65

3.4.1. Oil�level.............................................................................................................................................................................................65

3.4.2. Oil�pressure�sensor...................................................................................................................................................... 65

3.4.3. Oil�temperature�sensor........................................................................................................................................... 66

3.5. Oil�spray�nozzles................................................................................................................................................................................................. 66

3.5.1. Piston�crown�cooling..................................................................................................................................................66

3.5.2. Chain�drive..................................................................................................................................................................................67

3.5.3. Camshaft........................................................................................................................................................................................68

3.5.4. Valvetronic�servomotor........................................................................................................................................... 68

4. Cooling.........................................................................................................................................................................................................................................................69

4.1. System�overview.................................................................................................................................................................................................70

4.1.1. Cooling�circuit,�engine�...........................................................................................................................................71

4.1.2. Cooling�circuit�of�charge�air�cooler�and�DME..................................................................... 83

4.2. Heat�management........................................................................................................................................................................................... 86

4.2.1. Auxiliary�water�pump.................................................................................................................................................. 86

4.2.2. Data-map�thermostat................................................................................................................................................ 87

4.2.3. Coolant�temperature�sensor.......................................................................................................................... 96

5. Intake�Air�and�Emission�System................................................................................................................................................................. 97

5.1. Overview.......................................................................................................................................................................................................................... 97

5.2. Intake�air�system.................................................................................................................................................................................................99

5.2.1. Hot�film�air�mass�meter..................................................................................................................................... 100

5.2.2. Intake�silencer...................................................................................................................................................................101

5.2.3. Intake�manifold................................................................................................................................................................ 101

5.3. Exhaust�turbocharger............................................................................................................................................................................. 102

5.3.1. Charging�pressure�control.............................................................................................................................103

5.3.2. Function......................................................................................................................................................................................104

5.4. Exhaust�emission�system................................................................................................................................................................ 105

5.4.1. Exhaust�manifold..........................................................................................................................................................105

5.4.2. Catalytic�converter.....................................................................................................................................................106

5.4.3. Exhaust�system...............................................................................................................................................................108

5.4.4. Electrically�controlled�exhaust�flaps...............................................................................................110

6. Vacuum�System......................................................................................................................................................................................................................112

7. Fuel�Preparation.................................................................................................................................................................................................................... 113

7.1. Overview......................................................................................................................................................................................................................113

7.2. Fuel�pump� control........................................................................................................................................................................................114

7.3. High�pressure�pump.................................................................................................................................................................................114

N63TU2�Engine

Contents

7.4. Injectors........................................................................................................................................................................................................................ 115

8. Fuel�Supply.....................................................................................................................................................................................................................................116

9. Engine�Electrical�System..................................................................................................................................................................................... 117

9.1. Overview......................................................................................................................................................................................................................117

9.2. Engine�control�unit..................................................................................................................................................................................... 124

9.2.1. Overall�function............................................................................................................................................................... 126

9.3. Alternator....................................................................................................................................................................................................................127

N63TU2�Engine

1.�Introduction

The�N63TU2�engine�replaces�the�predecessor�N63TU.�The�key�enhancements�of�the�N63TU2�over

the�N63TU�are�the�improved�exhaust-gas�characteristics,�the�availability�of�the�engine�torque�over�a

wider�speed�range�together�with�optimized�consumption,�and�a�more�efficient�production�process�in

the�plant�for�the�new�N63TU2�engine.

The�unique�selling�points�of�the�new�N63TU2�engine�for�the�market�include�innovative�detailed

solutions�such�as�the�internal�engine�thermal�management�system�during�warm-up�(called�SCC,

"Split�Cooling�Combined",�the�engine�oil/coolant�heat�exchanger�integrated�into�the�engine�V,

the�half-shell�intake�system�and�the�engine�charging�using�the�twin-scroll�exhaust�turbocharger

technology.

The�new�N63TU2�engine�will�be�introduced�into�series�production�for�the�first�time�with�the�new�G12.

In�this�documentation�the�differences�to�the�N63TU�predecessor�engine�are�described.

1.1.�Models

Development�series N63B44O2�engine Series�introduction

G12 BMW�750i

BMW�750i�xDrive

07/2015

1.2.�Technical�data

Engine Unit N63B44O1 N63B44O2

Development�series F02�LCI G12

Model�designation BMW�750i BMW�750i

Design V8 V8

Displacement [cm³] 4395 4395

Firing�order 1-5-4-8-6-3-7-2 1-5-4-8-6-3-7-2

Bore/stroke [mm] 89/88.3 89/88.3

Power�output

at�engine�speed

Cutoff�speed [rpm] 6,500 6,500

Power�output�per�liter [kW/l] 75/1 75/1

Torque

at�engine�speed

[kW�(HP)]

[rpm]

[Nm�(lb-ft)]

[rpm]

330�(445)

5,500�-�6,000

650�(480)

2,000�-�4,500

330�(445)

5,500�-�6,000

650�(480)

1,800�-�4,500

Compression�ratio [ε] 10.0 10.5

Valves�per�cylinder 4 4

Fuel [RON] 91�-�98 91�-�98

Fuel�consumption�complying�with�EU [l/100km] 8.6 -

CO2�emissions [grams�per

kilometer]

199 -

1

N63TU2�Engine

1.�Introduction

Engine Unit N63B44O1 N63B44O2

Digital�Motor�Electronics MEVD�17.2.8 DME�8.8

Exhaust�emissions�legislation ULEV�II ULEV�II

Maximum�speed [km/h] 250 250

Acceleration�0–100�(0–62)km/h�(mph) [s] 4.8 -

The�data�on�consumption/acceleration�and�CO2�emissions�for�this�model�was�unavailable�at�the�time

this�document�was�created.

2

N63TU2�Engine

1.�Introduction

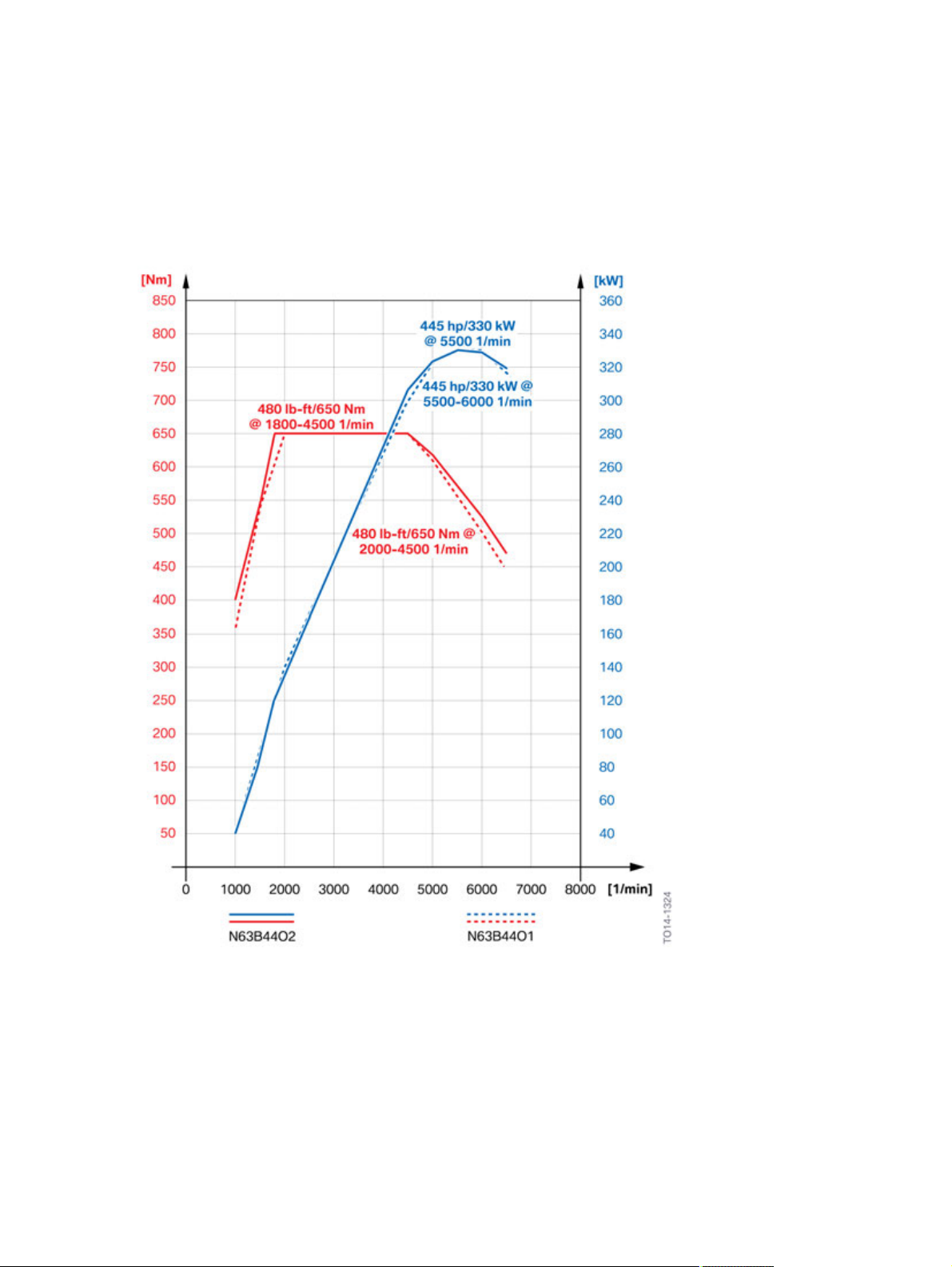

1.2.1.�Full�load�diagram

N63TU�engine�in�the�F01�LCI/N63TU2�engine�in�the�G12

Full�load�diagram,�N63B44O2�engine�compared�to�the�N63B44O1�engine

3

N63TU2�Engine

1.�Introduction

1.3.�New�features�on�the�N63TU2�engine

1.3.1.�Overview

N63TU2�engine,�exploded�diagram

4

N63TU2�Engine

1.�Introduction

Index Explanation

1 Cylinder�head�cover

2 Cylinder�head�cover�gasket

3 Cylinder�head

4 Cylinder�head�gasket

5 Crankcase

6 Crankshaft�drive

7 Oil�sump�gasket,�top

8 Oil�sump,�top

9 Oil�sump�gasket,�bottom

10 Oil�sump,�bottom

11 Timing�case�cover�gasket

12 Timing�case�cover

1.3.2.�N63TU2�engine�components

Engine�mechanics

Component New

feature

Cylinder�head

cover

Cylinder�head

Cylinder�head

gasket

Identical

concept

Carry-over

part

Comment

Modified�to�accommodate�VANOS

solenoid�valves.

Partial�integration�of�the�intake

neck�into�the�cylinder�head.

Optimized�weight�–�weight

saving�of�1.5�kg�per�cylinder�head

compared�to�the�N63TU�engine.

Mountings�for�VANOS�solenoid

valves�removed

Ducts�for�directing�the�engine�oil

simplified.

Internal�engine�thermal

management�system�integrated.

Revised�cylinder�head�gasket�at

water�passages�for�the�thermal

management�system.

Changeover�to�partial�screen

printing�coating.

Crankcase

Internal�engine�thermal

management�system�integrated.

Modified�to�accommodate�the

engine�oil/coolant�heat�exchanger.

Ducts�for�directing�the�engine�oil

simplified.

5

N63TU2�Engine

1.�Introduction

Component New

feature

Crankshaft

with�main

bearing

Connecting

rod

Gudgeon�pin Taken�over�from�N63TU�engine.

Connecting

rod�bearing

shells

Piston

Piston�rings

Flywheel

SynTAK

Identical

concept

Carry-over

part

Comment

Taken�over�from�N63TU�engine.

Taken�over�from�N63TU�engine.

Material�changed�over�to�steel/

aluminium�anti-friction�coating

(IROX).

Oil�scraper�ring�groove�modified

from�4�to�8�oil�drains.

Modified�to�accommodate�a

higher�compression�ratio.

Taken�over�from�N63TU�engine.

Width�of�oil�scraper�ring.

reduced�from�2�mm�to�1.8�mm.

Three-part�flywheel�(four-part�on

the�N63TU).

0.52�kg�weight�reduction�.

Synergy�thermoacoustic�capsule.

Provides�acoustic�and�thermal

insulation.

Valve�gear

Component New

feature

Chain�drive

with�timing

chain

VANOS

Fully�variable

valve�lift

adjustment

Identical

concept

Carry-over

part

Comment

Taken�over�from�N63TU�engine.

Taken�over�from�modular�engines.

Increased�adjustment�speed�and

reduced�susceptibility�to�dirt.

Taken�over�from�N63TU�engine.

Gate�only�screwed�using�one

screw,�as�on�modular�engines.

6

N63TU2�Engine

1.�Introduction

Component New

feature

Intake�valves

and�exhaust

valves

Valve�guides

Camshafts

Belt�drive�and�ancillary�components

Component New

feature

Vibration

damper

Belt�drive

Identical

concept

Identical

concept

Carry-over

part

Carry-over

part

Comment

Chrome-plated�valve�stems.

Material�changed�over�to�hightemperature-resistant�brass.

Modified�mountings�to

accommodate�VANOS�units�from

modular�engines.

Exhaust�camshaft�with�modified

timing.

Comment

Optimized�weight�(500�g�lighter

than�on�the�N63TU).

Concept�taken�over�from�the

N63TU�engine.

Belt�pulley�for�crankshaft�is�new

and�made�from�high-strength

plastic.

Belt�level�moved�forwards

by�20�mm.

Air�conditioning�compressor

arranged�on�the�right�of�the

engine.

7

N63TU2�Engine

1.�Introduction

Oil�supply

Component New

feature

Oil�pump

Oil�sump

Oil�filter

module

Oil�spray

nozzles

Air�intake�and�exhaust�emission�systems

Component New

Intake�manifold Half-shell�intake�system�used.

feature

Identical

concept

Identical

concept

Carry-over

part

Carry-over

part

Comment

Characteristic�map-controlled

pendulum�slide�pump.

Two�versions�for�rear-wheel�drive

and�four-wheel�drive.

Four-wheel�drive�with�aperture�for

front-wheel�drive.

Rear-wheel�drive�with�sealed

side�boxes�for�optimal�use�of�the

available�space.

Oil�pressure�sensor�and

characteristic�map�control�valve

integrated.

Modified�opening�pressure�and

closing�pressure.

Comment

Exhaust

manifold

Exhaust

turbocharger

Exhaust

system

Heat

shields

Upstream

catalytic

converter

Vacuum�system

Component New

Vacuum

pump

feature

Identical

concept

Carry-over

part

Adapted�to�the�twin-scroll

turbocharger�concept.

Twin-scroll�concept.

Electrical�wastegate�valves.

Optimized�for�minimal�exhaust�gas

pressure.

Electrical�exhaust�flaps.

Active�Sound�Design�(ASD)�in�the

passenger�compartment.

Taken�over�from�N63TU�engine.

Top�heat�shield�adapted�to�twinscroll�concept.

Comment

Taken�over�from�N63TU�engine.

Auxiliary�consumers�removed.

8

N63TU2�Engine

1.�Introduction

Fuel�preparation

Component New

feature

High�pressure

pump

Injectors Taken�over�from�N63TU�engine.

Cooling

Component New

feature

Engine�oil-tocoolant�heat

exchanger

Hightemperature

circuit

Engine�cooling

Mechanical

coolant

pump

Characteristic

map

thermostat

Identical

concept

Identical

concept

Carry-over

part

Carry-over

part

Comment

Bank-specific�with�modified�inlet

connector.

Comment

Engine�oil/air�heat�exchanger

removed�from�front�of�vehicle,

replaced�by�engine�oil/coolant

heat�exchanger�in�engine�V.

Additional�electric�coolant�pump

for�exhaust�turbocharger.

Further�developed�into�a

characteristic�map-dependent

coolant�pump.

With�opening�detection�and�return

passages�barrier.

Lowtemperature

circuit

Charge�air

cooling

Engine�electrical�system

Component New

feature

Digital�Motor

Electronics

DME

VANOS

solenoid�valves

Valvetronic

servomotor

Hot�film�air

mass�meter

Indirect�charge�air�cooling�with�2

heat�exchangers.

Identical

concept

Carry-over

part

Own�coolant�circuit.

Electric�coolant�pump.

Comment

DME�8.8.0

Hardware�from�modular�engines.

Coolant�cooling.

Taken�over�from�modular�engines.

Taken�over�from�modular�engines.

Hot�film�air�mass�meter�8�taken

over�from�modular�engines.

9

N63TU2�Engine

1.�Introduction

Component New

feature

Oxygen

sensors

Ignition�coils

Spark�plugs Taken�over�from�N63TU�engine.

Knock�sensors Taken�over�from�N63TU�engine.

Oil

temperature

sensor

Intake�pipe

pressure/

temperature

sensor

Camshaft/

crankshaft

sensor

Coolant

temperature

sensor

Identical

concept

Carry-over

part

Comment

Control�sensor�taken�over�from

the�N63TU�engine�(LSU�ADV).

Monitoring�sensor�taken�over�from

modular�engines�(LSF�Xfour).

Extended�ignition�coils�based�on

the�N55�engine.

Taken�over�from�N63TU�engine.

Taken�over�from�N63TU�engine.

Taken�over�from�modular�engines.

Can�be�recorded�as�a�camshaft

sensor�or�crankshaft�sensor.

Taken�over�from�the�N55�engine.

Oil�pressure

sensor

Oil�level�sensor

Rail�pressure

sensor

Electrical

wastegate

valve�actuator

Starter�motor Adapted�to�MSA�2.3.

Alternator Taken�over�from�modular�engines.

Electromotive

throttle

controller

Oil�pressure�sensor�instead�of�oil

pressure�switch�in�the�N63TU.

Oil-level�sensor�based�on�oil-level

sensor�in�the�N63TU.

Taken�over�from�the�N63TU

engine.

Taken�over�from�the�N55�engine.

Taken�over�from�modular�engines.

10

N63TU2�Engine

1.�Introduction

1.4.�Engine�identification

1.4.1.�Engine�designation

The�N63TU2�engine�in�version�N63B44O2�is�described�in�this�documentation.�The�N63B40O2

engine�in�a�different�capacity�class�is�also�available�for�the�Chinese�market;�however,�this�engine�is�not

considered�in�this�documentation.�The�basic�design�of�the�N63B40O2�engine�is�identical�to�that�of�the

N63B44O2�engine.�The�reduced�capacity�is�the�result�of�a�reduced�piston�stroke�caused�by�a�longer

connecting�rod�and�the�reduced�compression�ratio.

In�the�technical�documentation,�the�engine�designation�is�used�to�ensure�unambiguous�identification

of�the�engine.

The�technical�documentation�also�contains�the�short�form�of�the�engine�designation�N63TU2,�which

only�indicates�the�engine�type.

Itemization

Index Explanation

N BMW�Group�"New�Generation"

6 V8�engine

3 Engine�with�exhaust�turbocharger,�Valvetronic

and�direct�fuel�injection�(TVDI)

B Gasoline�engine�installed�longitudinally

44 4.4�liters�displacement

O Upper�performance�class

2 Second�revision

1.4.2.�Engine�identification

The�engines�have�an�identification�mark�on�the�crankcase�to�ensure�unambiguous�identification�and

classification.�This�engine�identification�is�necessary�for�approval�by�government�authorities.�The�first

six�positions�of�the�engine�identification�correspond�to�the�engine�designation.

The�engine�number�can�be�found�on�the�engine�above�the�engine�identification.�This�consecutive

number,�in�conjunction�with�the�engine�identification,�permits�unambiguous�identification�of�each

individual�engine.

11

N63TU2�Engine

1.�Introduction

Example�of�an�N63TU�engine,�engine�identification�and�engine�number

Index Explanation

22620097 Individual,�consecutive�engine�number

N BMW�Group�"New�Generation"

6 V8�engine

3 Engine�with�exhaust�turbocharger,�Valvetronic�and�direct�fuel�injection�(TVDI)

B Gasoline�engine�installed�longitudinally

44 4.4�liters�displacement

B Type�test�concerns,�standard

12

N63TU2�Engine

2.�Engine�Mechanical

2.1.�Engine�housing

The�engine�housing�comprises�of�the�engine�block,�cylinder�heads,�cylinder�head�covers,�oil�sump�and

the�gaskets.

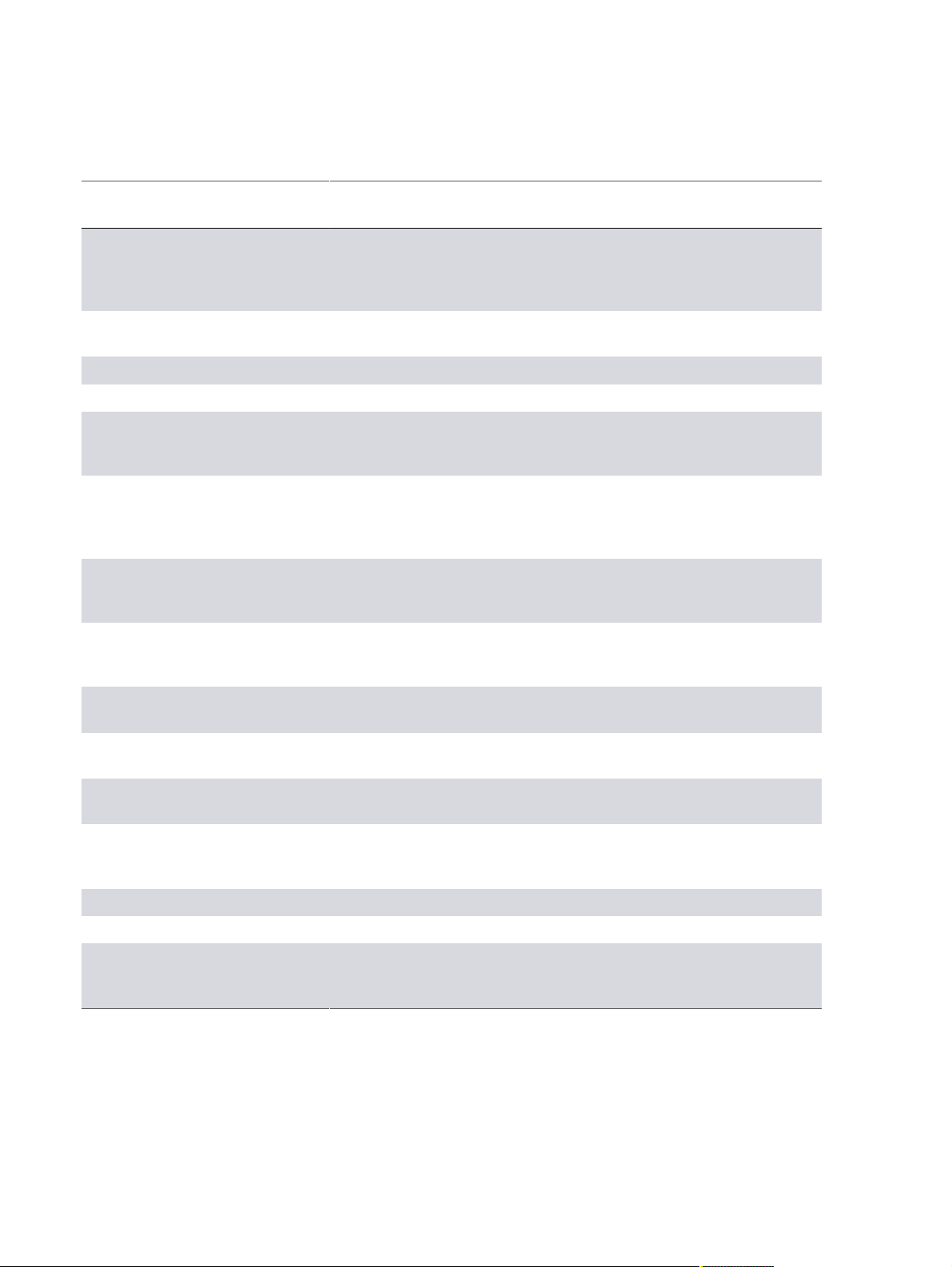

2.1.1.�Crankcase

The�crankcase�on�the�N63TU2�engine�has�been�completely�redesigned�and�is�manufactured�from

low-pressure�die�cast�AlSi17Cu4Mg,�as�on�the�N63TU�engine.�The�cylinder�barrels�are�made�from

Alusil.�Like�its�predecessor�in�the�N63TU�engine,�the�closed-deck�crankcase�in�the�N63TU2�engine�is

characterized�by�a�double�main�bearing�screw�connection�with�side�wall�connection.

The�crankcase�cast�part�consists�of�the�cylinder�bores�with�Alusil�coating,�the�bearing�ways�with�the

bore�holes�for�the�crankshaft�and�associated�bearings�and�the�water�jackets�of�the�cylinders.�The

water�jackets�of�the�crankcase�and�the�water�ducts�in�the�cylinder�head�form�the�basis�for�the�revised

coolant�passages�inside�the�engine�and�the�thermal�management�system�of�the�N63TU2�engine.�This

design�has�also�deleted�the�need�for�the�coolant�chamber�sealing�cap�at�the�rear�on�the�crankcase.

N63TU2�engine,�crankcase�with�screw�connections

Index Explanation

1 Crankcase

2 Double�main�bearing�screw�connection�with�side�wall�connection

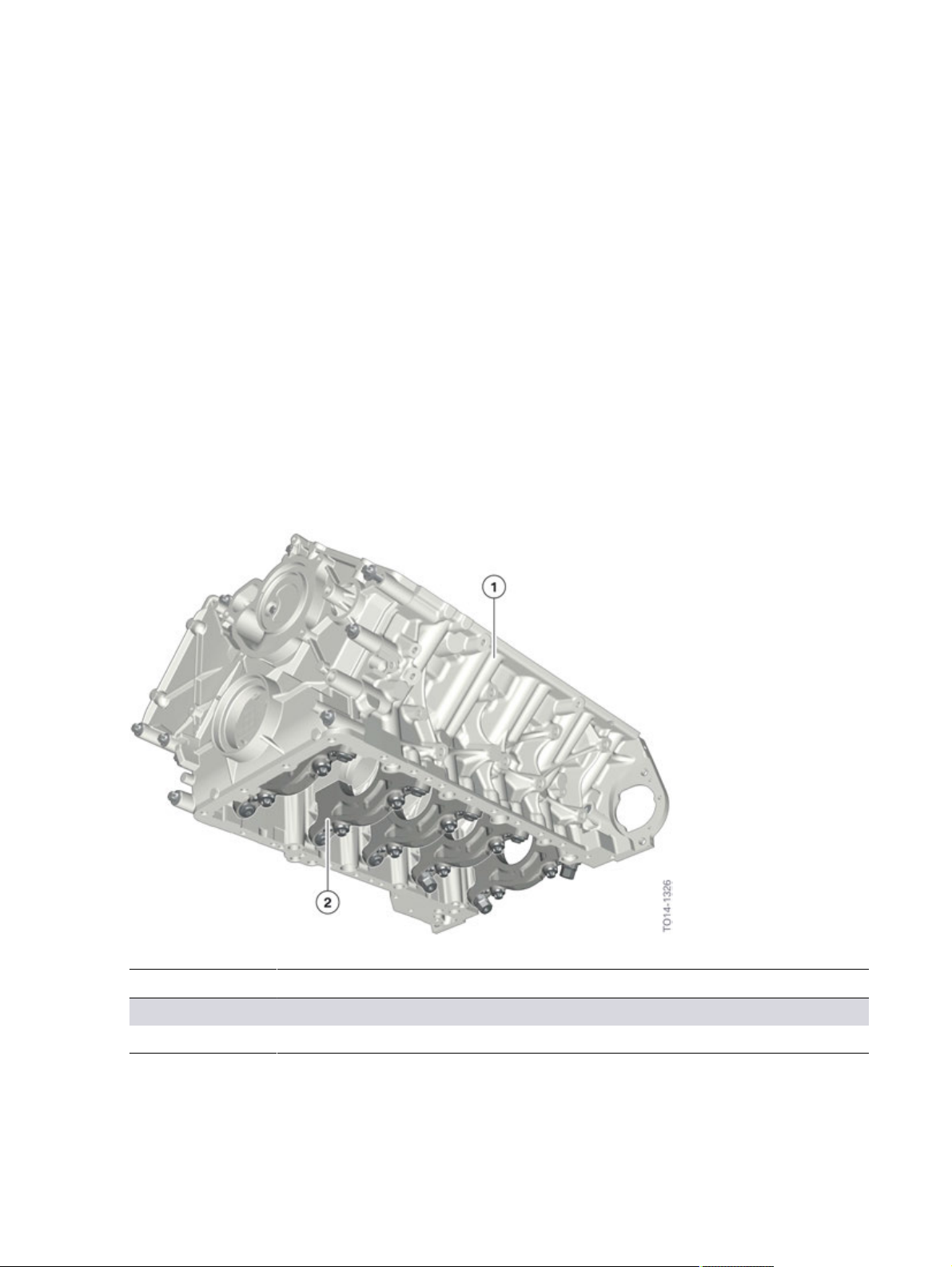

The�V�area�of�the�N63TU2�has�been�adapted�to�the�crankcase�with�regard�to�the�attachment�of�the

engine�oil/coolant�heat�exchanger.�The�oil�holes�as�well�as�the�water�ducts�in�the�crankcase�have�been

adapted�to�the�connection�required�for�the�engine�oil/coolant�heat�exchanger.

13

N63TU2�Engine

2.�Engine�Mechanical

N63TU2�engine,�crankcase

Index Explanation

A Crankcase�with�engine�oil/coolant�heat�exchanger

B Crankcase�without�engine�oil/coolant�heat�exchanger

1 Coolant�return�from�engine�oil/coolant�heat�exchanger

2 Engine�oil-to-coolant�heat�exchanger

3 Crankcase

4 6x�screw�connection�for�the�engine�oil/coolant�heat�exchanger

5 Oil�return�from�engine�oil/coolant�heat�exchanger

6 Oil�supply�to�engine�oil/coolant�heat�exchanger

7 Coolant�supply�to�engine�oil/coolant�heat�exchanger

8 Oil�supply�for�exhaust�turbocharger

14

N63TU2�Engine

2.�Engine�Mechanical

2.1.2.�Cylinder�head�gasket

As�on�the�N63TU�engine,�a�three-layer�spring�steel�gasket�is�used�for�the�cylinder�head�gasket.�There

is�a�stopper�plate�(2)�in�the�area�of�the�cylinder�bores�in�order�to�achieve�sufficient�contact�pressure�for

sealing.

N63TU2�engine,�cylinder�head�gasket

Index Explanation

1 Top�spring�steel�layer�with�anti-stick�coating

2 Stopper�layer

3 Bottom�spring�steel�layer�with�anti-stick�coating

In�contrast�to�the�N63TU�engine,�on�the�N63TU2�the�contact�surfaces�with�the�cylinder�head�and

engine�block�are�no�longer�fully�coated,�but�instead�have�partial�screen�printing�coating.�By�omitting

the�coating�in�the�coolant�duct�areas,�the�risk�of�the�coating�coming�loose�and�contaminating�the

coolant�circuit�is�minimized.

N63TU2�engine,�cylinder�head�gasket�coating

Index Explanation

1 Partial�screen�printing�coating

2 Cylinder�head�gasket

15

N63TU2�Engine

2.�Engine�Mechanical

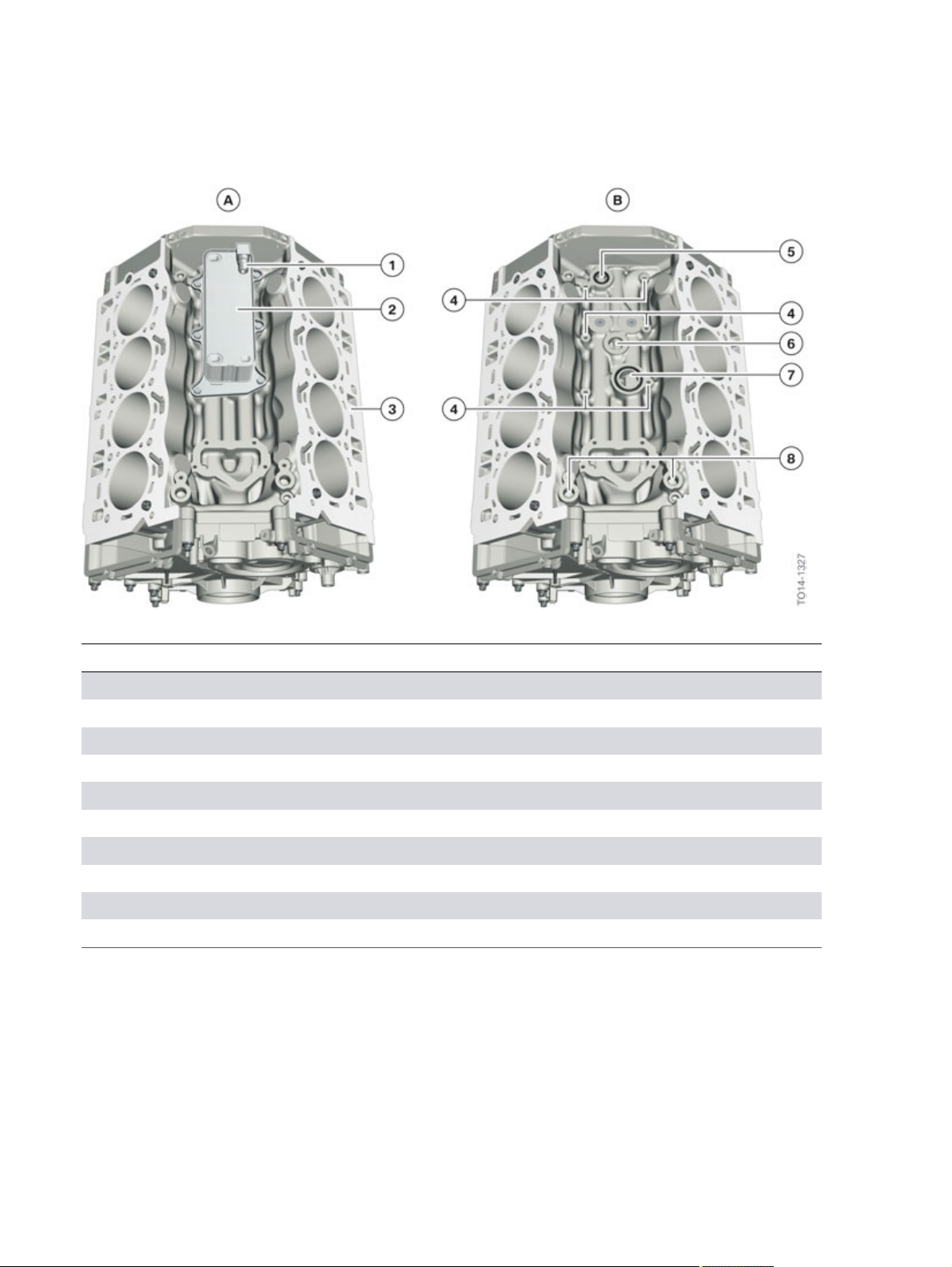

2.1.3.�Cylinder�head

The�cylinder�head�of�the�N63TU2�engine�is�a�new�feature�with�partially�integrated�intake�system.

Thanks�to�this�partially�integrated�intake�system�in�the�cylinder�head,�the�passages�characteristics

of�the�incoming�air�has�been�optimized�and�the�space�required�to�install�the�intake�pipe�has�been

significantly�reduced.�It�has�also�allowed�the�weight�of�the�cylinder�head�to�be�reduced�by�1.5�kg�/�3.3

lbs.

N63TU2�engine,�cylinder�head

Index Explanation

1 Sealing�flange�for�intake�system

2 Partially�integrated�intake�pipe

3 Flange�for�Valvetronic�servomotor

4 Cylinder�head�bank�1

With�the�exception�of�the�combustion�chamber�dome�and�the�valve�gear�(which�have�been�taken

over�from�the�N63TU),�the�cylinder�head�is�a�completely�new�component�in�the�N63TU2�engine.�The

coolant�passages�in�the�cylinder�head�are�separate�from�the�coolant�passages�around�the�cylinder

bores.�By�taking�over�the�VANOS�solenoid�valves�into�the�cylinder�head�cover�and�the�VANOS

adjusters�(as�is�already�the�case�for�the�N20�engine�and�the�modular�engines),�the�bore�holes�for�the

VANOS�solenoid�valves�in�the�cylinder�head�could�be�removed,�meaning�the�associated�engine�oil

ducts�in�the�cylinder�head�can�also�be�simplified.

3rd-generation�Valvetronic�technology�is�also�used�in�the�N63TU2�engine,�as�is�already�the�case�in�the

N55�and�N63TU�engines.�The�Valvetronic�servomotor�is�connected�on�the�outer�side�at�the�cylinder

head.

The�combination�of�exhaust�turbocharger,�Valvetronic�and�direct�fuel�injection�is�known�as�Turbo

Valvetronic�Direct�Injection�(TVDI).

16

N63TU2�Engine

2.�Engine�Mechanical

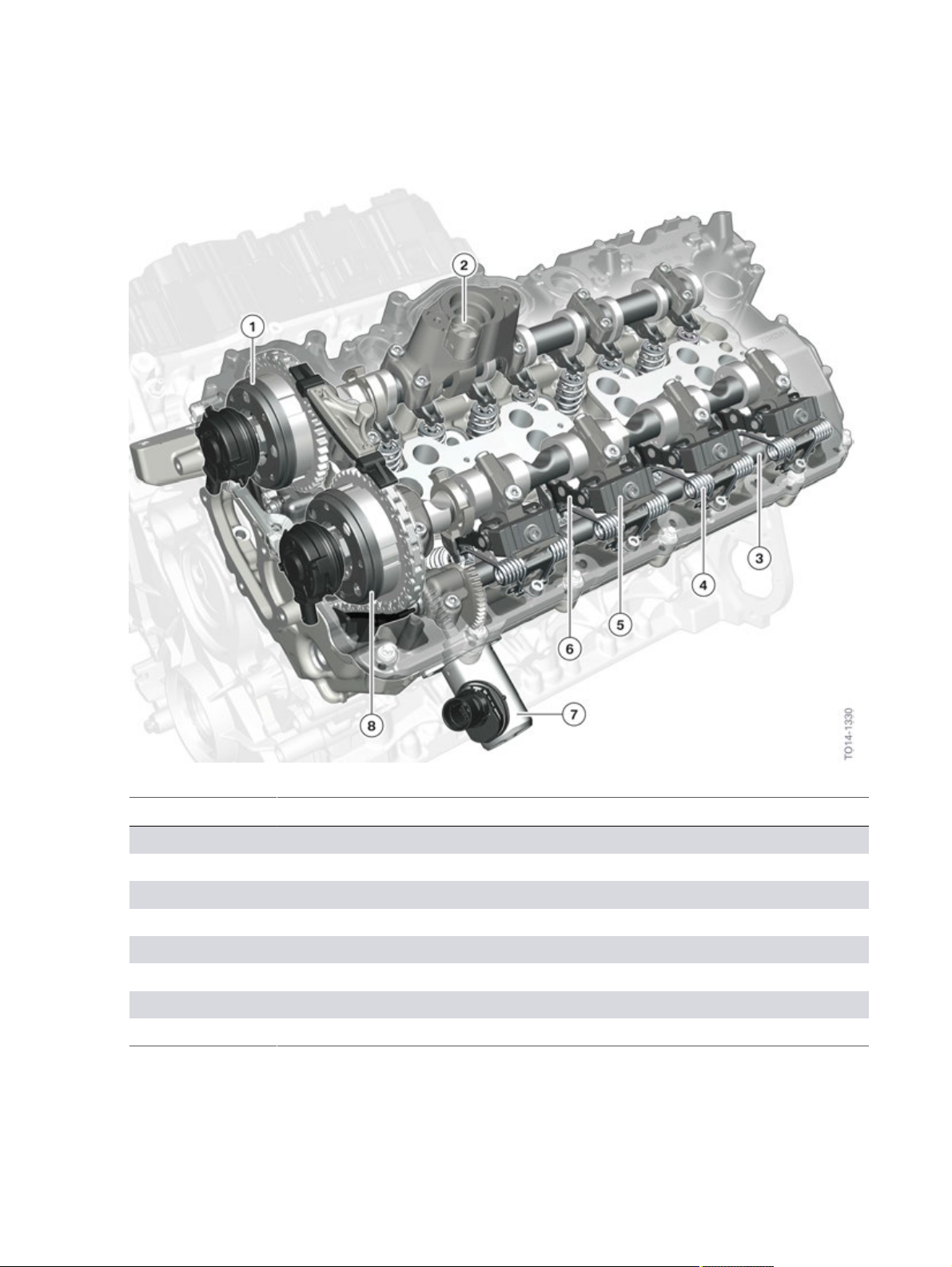

N63TU2�engine,�cylinder�head�with�Valvetronic

Index Explanation

1 VANOS,�exhaust�side

2 Roller�tappet,�high-pressure�pump

3 Eccentric�shaft

4 Torsion�spring

5 Gate/guide�block

6 Intermediate�lever

7 Valvetronic�servomotor

8 VANOS,�intake�side

17

N63TU2�Engine

2.�Engine�Mechanical

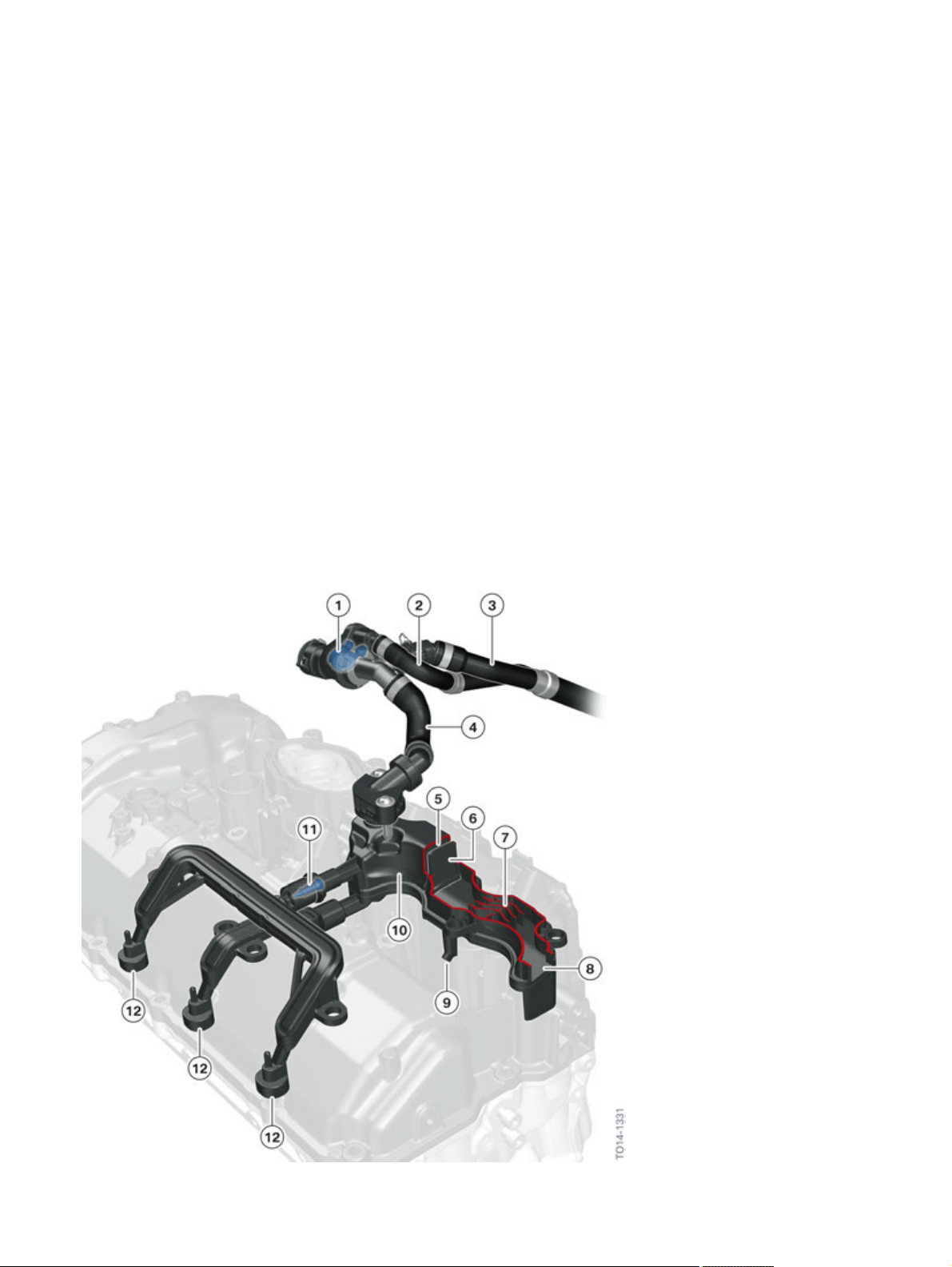

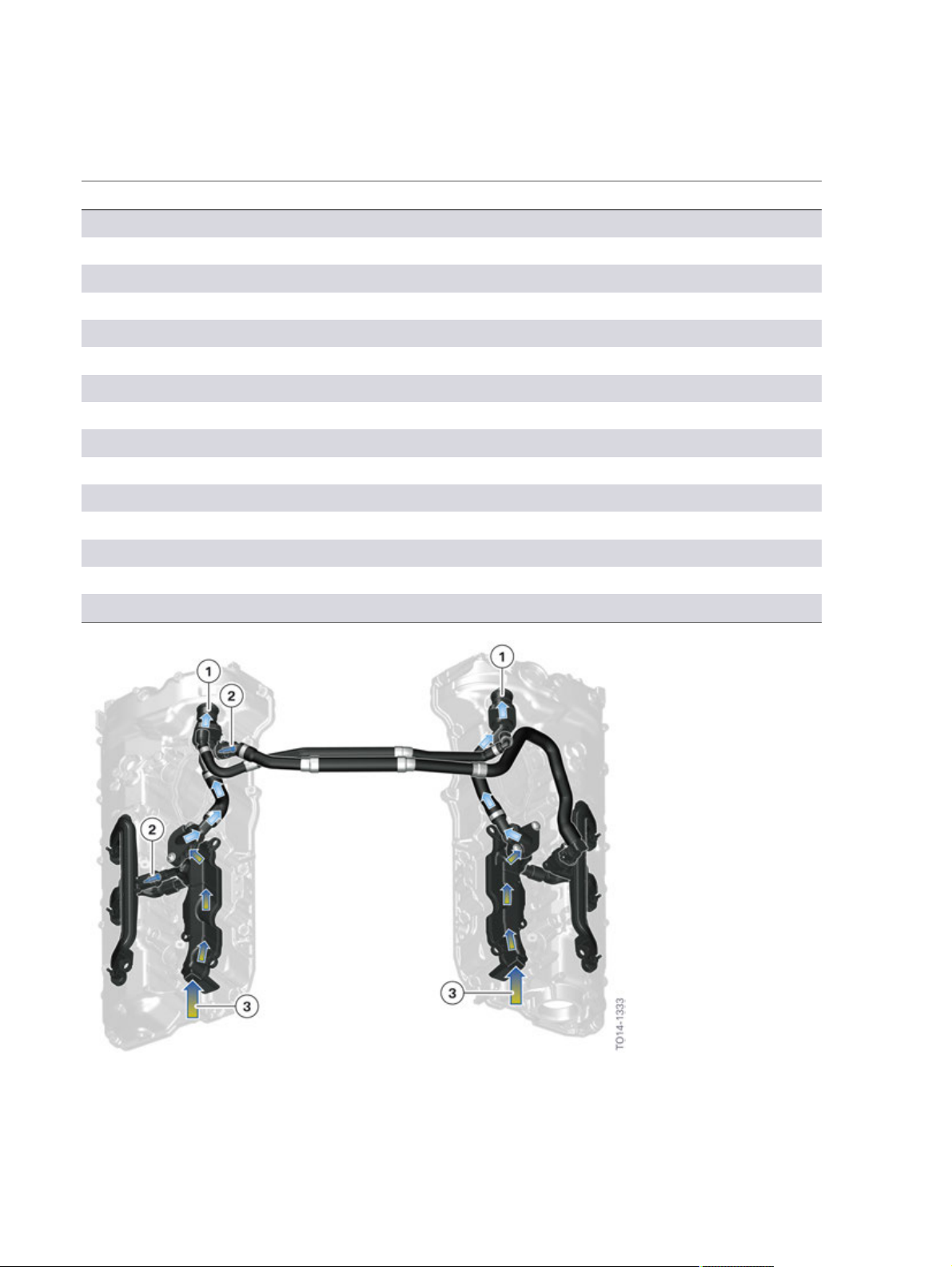

2.1.4.�Cylinder�head�cover

Design

The�design�of�the�cylinder�head�cover�in�the�N63TU2�engine�is�the�same�as�for�the�N63TU�engine,

but�with�minor�modifications�to�the�crankcase�ventilation�and�the�mountings�for�the�VANOS�solenoid

valves.�As�in�the�N63TU,�a�ventilation�register�with�an�additional�ventilation�line�is�used.�Each�bank�has

its�own�oil�separator.�An�additional�line�from�the�crankcase�ventilation�to�the�air�intake�system�is�not

used�as�corresponding�bore�holes�for�the�individual�intake�ports�are�integrated�in�the�cylinder�head.

The�camshaft�sensors�are�positioned�on�the�front�of�the�cylinder�head�cover.

To�separate�the�oil�contained�in�the�blow-by�gas,�a�labyrinth�oil�separator�is�used.�A�pre-separator

(7)�and�a�fine�deflection�plate�with�small�air�vents�(6)�are�in�the�passages�direction.�The�oil�drops�are

separated�at�these�barriers�and�return�to�the�cylinder�head�via�the�return�line�(9�and�10).�An�impact

surface�(5)�with�an�upstream�mesh�that�ensures�further�separation�of�oil�particles.�The�oil�return

(10)�is�equipped�with�a�non-return�valve�in�order�to�prevent�direct�intake�of�blow-by�gasses�without

separation.�If�the�oil�level�increases�in�this�pipe,�the�non-return�valve�opens�and�the�oil�drops�into�the

cylinder�head.�Finally,�depending�on�the�operating�condition�of�the�engine,�the�cleaned�blow-by�gases

are�fed�back�into�the�intake�system�either�via�the�non-return�valve�(1)�or�via�the�volume�control�valve

(12�and�3).

N63TU2�engine,�cylinder�head�cover�with�crankcase�ventilation

18

N63TU2�Engine

2.�Engine�Mechanical

Index Explanation

1 Non-return�valve�for�the�clean�air�pipe�with�leak�hole

2 Purge�air�line

3 Intake�pipe�with�volume�control�valve

4 Line�to�clean�air�pipe

5 Impact�surface�with�upstream�mesh�that

6 Fine�deflector�plate�with�small�air�vents

7 Pre-separator

8 Inlet�for�blow-by�gases

9 Oil�return

10 Oil�separator

11 Volume�control�valve�for�the�air�intake�system�with�throttle�function

12 Connecting�line�via�blow-by-gas�channel�for�the�intake�port

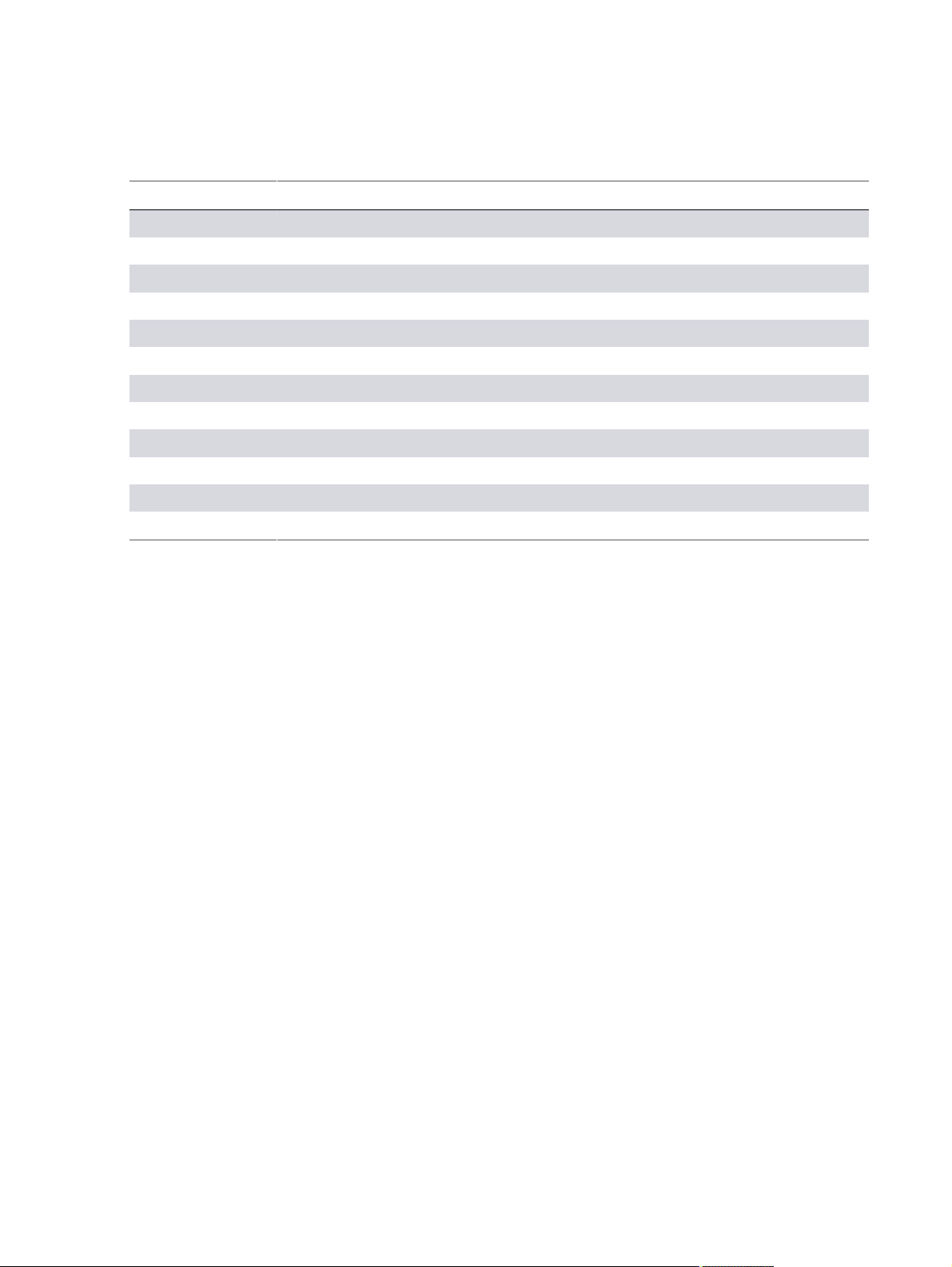

Crankcase�ventilation�in�naturally�aspirated�engine�operation

In�the�naturally�aspirated�engine�operation�there�is�a�vacuum�in�the�air�intake�system�(12).�The�two

volume�control�valves�(3)�are�opened.�The�cleaned�blow-by�gases�reach�the�inlet�areas�of�both�banks

and�thus�the�air�intake�system�through�the�left�oil�separator�via�the�intake�pipe�(5)�and�ducts�in�the

cylinder�head�(19).�As�there�is�a�risk�that�oil�may�be�drawn�in�via�the�crankcase�ventilation�in�the�case�of

large�vacuums,�the�volume�control�valve�has�a�throttle�function�and�limits�the�passages�and�thus�also

the�pressure�level�in�the�crankcase.

The�vacuum�in�the�crankcase�ventilation�keeps�the�non-return�valves�(2�and�6)�closed.�Fresh�air

flows�from�the�two�clean�air�pipes�through�the�right�oil�separator�into�the�inside�of�the�engine�via�the

overlying�leakage�holes.�The�vacuum�in�the�crankcase�ventilation�is�thus�restricted.�At�the�same�time

the�chemical�ageing�of�the�lubricating�oil�and�also�the�water�content�in�the�blow-by�gases�are�reduced

by�flushing�the�crankcase�with�fresh�air.

19

N63TU2�Engine

2.�Engine�Mechanical

N63TU2�engine,�overview�of�crankcase�ventilation�in�the�naturally�aspirated�engine�operation

Index Explanation

B Ambient�pressure

C Vacuum

D Exhaust�gas

E Oil

F Blow-by�gases

1 Leakage�hole�in�the�housing�of�the�non-return�valve

2 Non-return�valve�for�the�clean�air�pipe

3 Volume�control�valve�for�the�air�intake�system�with�throttle�function

4 Purge�air�line

5 Intake�system�from�bank�2�to�bank�1

20

N63TU2�Engine

2.�Engine�Mechanical

Index Explanation

6 Line�to�the�clean�air�pipe�with�non-return�valve�and�leakage�hole

7 Clean�air�pipe

8 Oil�separator

9 Charge�air�cooler

10 Intake�silencer�with�hot�film�air�mass�meter�8

11 Throttle�valve

12 Intake�manifold

13 Oil�return

14 Ventilation�duct

15 Crank�chamber

16 Oil�sump

17 Exhaust�turbocharger

18 Oil�return�duct

19 Duct�in�the�cylinder�head

20 Non-return�valve

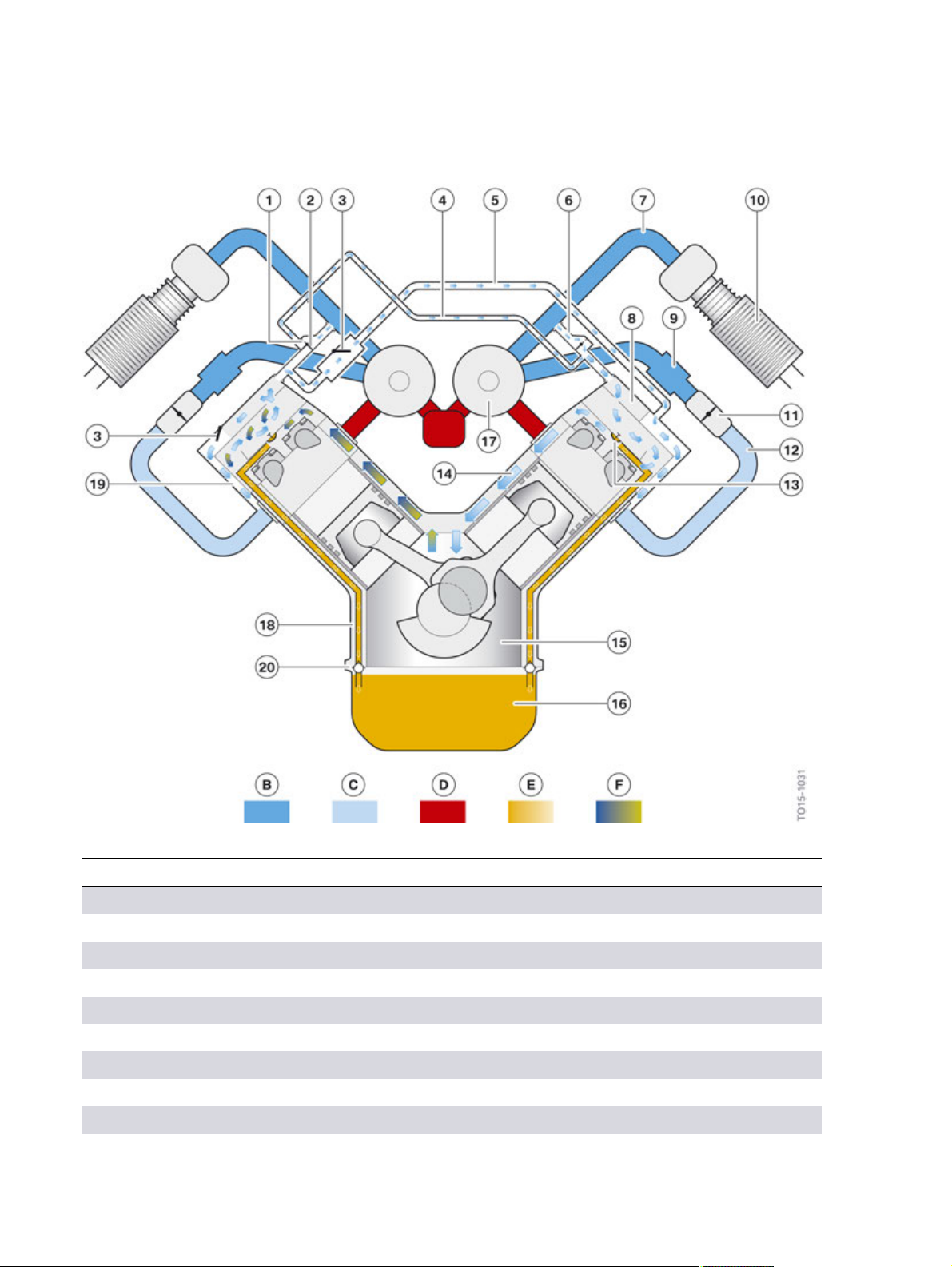

N63TU2�engine,�components�of�the�crankcase�ventilation�in�the�naturally�aspirated�engine�operation

21

N63TU2�Engine

2.�Engine�Mechanical

Index Explanation

1 Fresh�air�supply�via�leakage�holes�when�non-return�valves�are�closed

2 Volume�control�valves�open

3 Purge�air�line

4 Inlet�of�the�blow-by�gases�to�the�inlet�area�of�the�cylinder�head

5 Supply�of�scavenging�air�via�the�oil�separator�to�the�crankcase

6 Intake�of�blow-by�gases�to�the�oil�separator

7 Intake�of�the�cleaned�blow-by�gases�into�the�inlet�area�of�the�cylinder

head�via�ducts

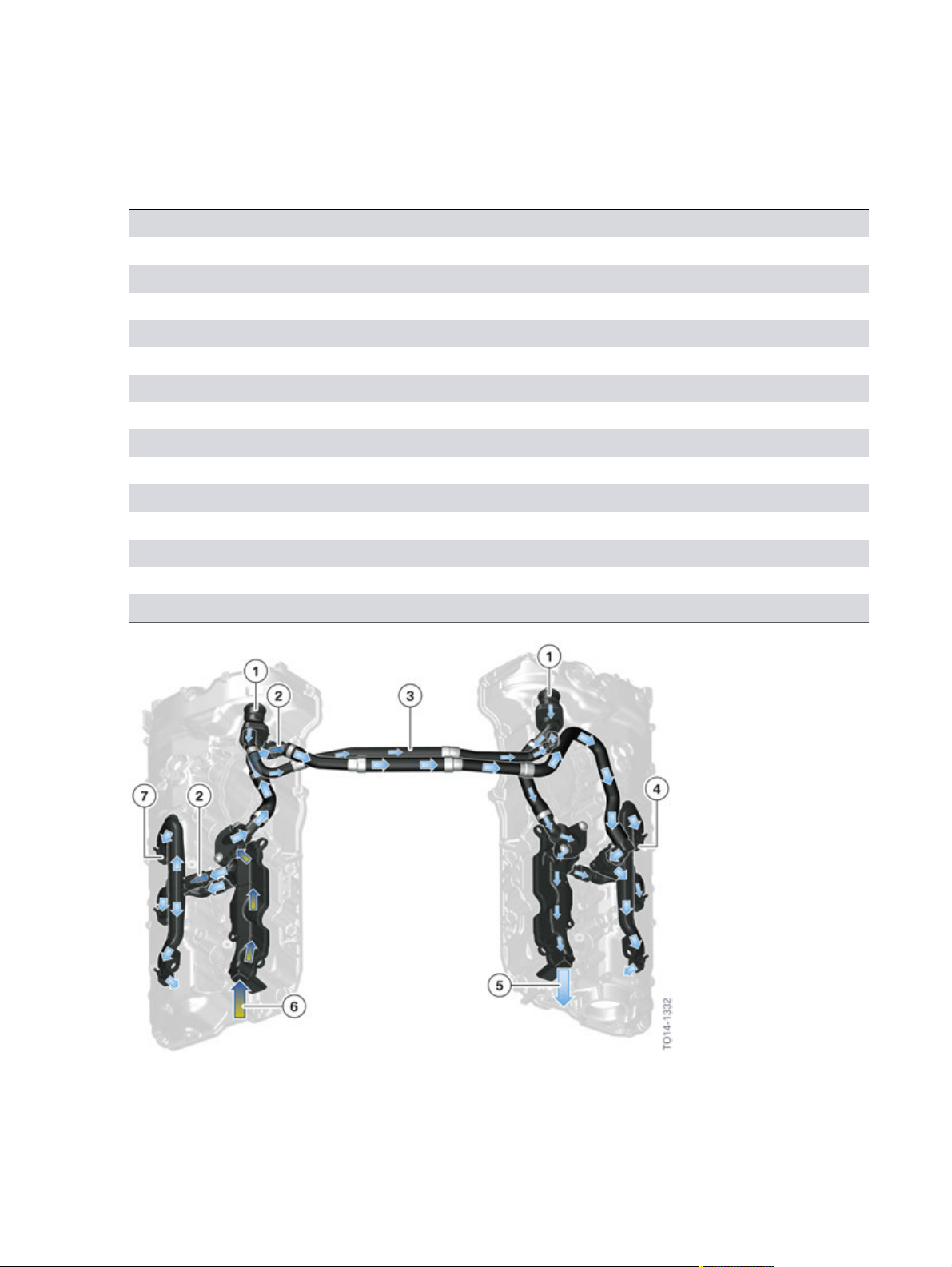

Crankcase�ventilation�in�charged�operation

In�charged�operation�the�pressure�in�the�intake�system�(12)�increases�and�thus�closes�the�volume

control�valves�(3).�As�there�is�a�vacuum�in�this�operating�condition�in�the�clean�air�pipe�(7),�the�nonreturn�valves�(2�and�6)�for�the�clean�air�pipe�thus�open�and�the�cleaned�blow-by�gases�are�conveyed�via

the�compressor�of�the�exhaust�turbocharger�and�the�charge�air�cooler�(9)�into�the�air�intake�system.

22

N63TU2�Engine

2.�Engine�Mechanical

N63TU2�engine,�overview�of�ventilation�in�charged�operation

Index Explanation

A

C Vacuum

D Exhaust�gas

E Oil

F Blow-by�gases

1 Leakage�hole�in�the�housing�of�the�non-return�valve

2 Non-return�valve�for�the�clean�air�pipe�open

3 Volume�control�valves�for�the�intake�system�with�throttle�function,�closed

4 Purge�air�line

5 Intake�pipe�from�bank�2�to�bank�1

Charging�pressure�2.5

+0.3

�bar�absolute

23

N63TU2�Engine

2.�Engine�Mechanical

Index Explanation

6 Line�to�the�clean�air�pipe�with�open�non-return�valve

7 Clean�air�pipe

8 Oil�separator

9 Charge�air�cooler

10 Intake�silencer�with�hot�film�air�mass�meter�8

11 Throttle�valve

12 Intake�manifold

13 Oil�return

14 Ventilation�duct

15 Crank�chamber

16 Oil�sump

17 Exhaust�turbocharger

18 Oil�return�duct

19 Duct�in�the�cylinder�head

20 Non-return�valve

N63TU2�engine,�components�of�the�crankcase�ventilation�in�charged�operation

24

Loading...

Loading...