Page 1

SBF-3E and SBF-5E

BLODGETT OVEN COMPANY

ELECTRIC BOILER FREE CONVECTION STEAMER

INSTALLATION – OPERATION – MAINTENANCE

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 864-0183

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

www.blodgett.com

S00106 Rev B (2/08)

1

Page 2

symbol to avoid possible injury or death.

service or maintenance can cause property damage, injury or death.

thoroughly before installing, operating or servicing this equipment.

NOTICE: Unit must be level to assure proper performance.

Intended for commercial use only. Not for household use.

This manual should be retained for future reference.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

WARNING: Improper installation, operation, adjustment, alteration,

Read the installation, operating and maintenance instructions

WARNING: Never spray water in electrical components.

2

Page 3

TABLE OF CONTENTS

DESCRIPTION PAGE

1.0 Service Connection ................................................................................................... 4

2.0 Introduction ............................................................................................................... 5

3.0 Installation .................................................................................................................. 6

4.0 Performance Check ................................................................................................... 8

5.0 Operating Instructions ............................................................................................... 9

6.0 Cooking Guidelines .................................................................................................. 13

7.0 Preventative Maintenance ......................................................................................... 15

8.0 Troubleshooting ........................................................................................................ 17

9.0 Wire Diagrams .......................................................................................................... 22

3

Page 4

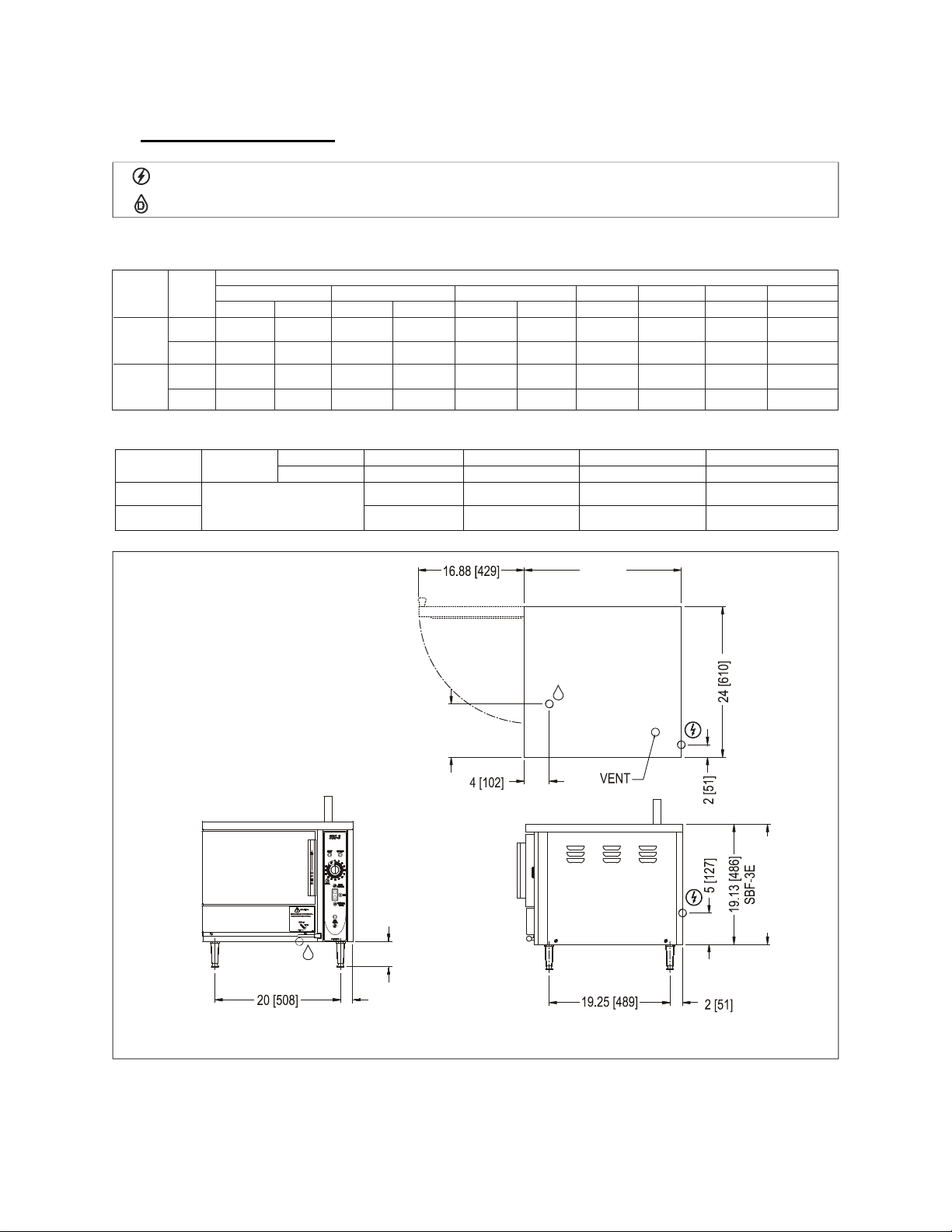

25.5 [648] SBF-5E

D

2 [51]

4 [102]

8.5 [216]

D

25 [635]

DIMENSIONS ARE IN INCHES (MM)

ELECTRICAL CONNECTION: Ø1 1/8" hole for electrical connection. Rating to be as specified on data plate.

DRAIN: ½”NPT

ELECTRICAL CHARACTERISTICS

SBF-3E

MODEL

3 phase

25.0

kW

9

1 phase

AMPS PER LINE

SBF-5E

15

3 phase 1 phase 3 phase 3 phase

41.6

N/A

N/A

6

10

40.9

68.2

27.3

45.5

23.6

39.4

N/A

N/A

37.5

62.5

25.0

41.7

21.7

36.0

N/A

N/A

13.7

22.8

N/A

N/A

1 phase

43.3

72.1

28.9

48.1

208V 220V 240V 380V

3 phase

12.5

20.9

N/A

N/A

415V

3 phase

10.8

18.0

N/A

N/A

480V

3 phase

8.7

14.4

N/A

N/A

600V

PAN CAPACITIES

SBF-3E

MODEL

SBF-5E

PAN

DEPTH

Inches

mm

Total Quantity of Pan

1

25

6

10

2.5

64

3

5

4

102

2

3

6

152

1

2

1.0 SERVICE CONNECTION

4

Page 5

2.0 INTRODUCTION

DESCRIPTION

The model SBF-3E steamer comes equipped with a standard 9.0 kW heating block that can be

reduced to 6 kW on single phase supplies. Model SBF-5E steamer comes equipped with a

standard 15.0 kW heating block that can be reduced to 10 kW on single phase supplies.

Your new steamer has been designed and manufactured to meet the toughest industry

standards. The best possible workmanship and materials along with laboratory tests have been

utilized in its design.

Proper installation, care and maintenance will give you years of reliable, trouble free operation.

The SBF-3E and SBF-5E are electric fired pressureless steam cookers. The cooking

compartments are equipped with a three-piece door with inner gasket plate isolated from the

exterior surface. Door latch operates by slam action for positive sealing of the door. Operating

controls are displayed on a front-mounted panel and include indicator lights for ready and

cooking modes, a timer to set cook times and an illuminated rocker mode selection switch for

TIMED COOKING, OFF and CONSTANT STEAM.

BASIC FUNCTIONING

The cooker is ready for operation when the READY light comes on.

At the end of the set interval, timer contacts switch to shut off the cooking operation and sounds

a signal buzzer and will maintain a safe food holding temperature at or above 150ΕF. The

buzzer is silenced by returning the timer dial to the OFF position. The READY light will be

illuminated.

5

Page 6

commercial cooking app li anc es.

the right side panel as you face the unit.

3.0 INSTALLATION

UNPACKING

Immediately after unpacking the steamer, check for possible shipping damage. If the steamer is

found to be damaged after unpacking, save the packaging materials and contact the carrier

within 15 days of delivery. File a claim regardless of extent of damage.

We cannot assume responsibility for damage or loss incurred in transit.

Prior to installation, verify that the electrical service agrees with the specifications on the

machine data plate which is located on the left side panel.

LOCATING

Allow space for vent and electrical connection. Minimum clearances for proper air circulation is

2" on the sides and 6" on the back. Allow adequate access for servicing.

LEVELING

Using a spirit level, adjust the feet to level the unit, front to back and side to side. The unit must

be level for proper operation. Warranty will be void for improper installation.

ELECTRICAL CONNECTIONS

WARNING: The unit must be electrically grounded and comply with

local codes, or in the absence of local codes with the national

electrical code ANSI/NFPA to latest edition. Canadian installation

must comply with CSA Standard (C22.2 No. 109-M1981 General

Requirements Canadian Electrical Code, Part II 109-M1981) for

WARNING: Disconnect electrical power supply and place a tag at

the disconnect switch to indicate that you are working on circuit.

Use copper wire suitable for at least 200Ε Fahrenheit (90Ε Celsius).

The steamer must be grounded. The wiring diagram is located on

Make electrical connection through the 1-1/8" (29 mm) diameter hole provided using 3/4" (19

mm) trade size conduit. Refer to the wiring diagram located inside the right side panel. Use

90ΕC minimum insulated wire.

6

Page 7

of the stand, below power supply connection.

3.0 INSTALLATION (Continued)

PLUMBING CONNECTIONS

No plumbing connections are required as steamer is filled manually.

DRAIN CONNECTIONS

No drain connection is required.

WATER CONDITION

For best results, Blodgett recommends that the water supply meet the following specification:

Hardness: Less than 2 grains or 35 ppm.

Total Dissolved Solids (TDS): Less than 60 ppm.

PH Factor: 7.0 to 7.5

This degree of hardness can easily be obtained with the use of a properly maintained water

softener.

VENT HOOD

Some local codes may require the steamer to be located under an exhaust hood. It is

recommended that this steamer be located under an exhaust hood to remove excess steam

during cooking operations.

Information on the construction and installation of ventilating hood may be obtained from the

standard for “Vapor Removal for Cooking Equipment”, NFPA No. 96 (Latest Edition).

WARNING: For an appliance equipped with casters, the installation

shall be made with an adequate flexible electrical conduit; adequate

means must be provided to limit the movement of the appliance

without depending on or transmitting stress to the electrical conduit.

The location where restraining means may be attached is to the rear

7

Page 8

opening the door.

compartment contains live steam. Stay clear when opening door.

4.0 PERFORMANCE CHECK

WARNING: The steamer and its parts are hot. Use care when

operating, cleaning or servicing the steamer. The cooking

compartment contains live steam and hot water. Stay clear while

Once the steamer has been installed, thoroughly test the steamer before operation.

1. Check that door opens and closes for proper operation.

2. Inspect the door gasket to ensure there is no damage.

3. Check without water in the steamer and with “CONTINUOUS” cooking mode selected, that

the “LOW WATER” indicator and alarm comes on within 10 minutes of a cold start.

4. Open compartment door and pour in water up to the “Water Level” mark located at back of

compartment.

5. Select TIMED COOKING mode with the power switch and set the timer to the OFF position.

6. Close door and wait approximately 10 minutes for the READY indicator to illuminate which

will indicate the unit is up to proper operating temperature.

7. Open the door to verify the cavity has reached cooking temperature. Water in the bottom of

the cooking cavity should be between 200 to 210°F.

8. Set the timer to 5 minutes and close the door to initiate the cooking cycle. The COOKING

indicator should illuminate. Allow the timed cooking cycle to complete, verifying that the end

of cycle buzzer sounds and the COOKING indicator is out. The ‘READY’ light will illuminate.

BEFORE FIRST USE

Clean the protective oils from all surfaces of the steamer. Use a non-corrosive, grease

dissolving commercial cleaner, following manufacturer’s directions. Rinse thoroughly and wipe

dry with a soft clean cloth.

WARNING: The steamer and its parts are hot. Use care when

operating, cleaning or servicing the steamer. The cooking

8

Page 9

RE

AD

Y

CO

OK

I

NG

CO

OK

I

NG

C

ON

S

TA

NT

OFF

STEAM

TI

ME D

ADD

W A

TER

5.0 OPERATING INSTRUCTIONS CONTROLS

1. Door Handle - Move handle up to open door to

cooking cavity.

2. Ready Pilot Light - When lit, indicates the

steamer cavity is above 150° F (65° C) and is ready

for the cooking cycle.

3. Cooking Pilot Light - When lit, indicates that a

cooking cycle is in progress.

4. Timer Dial- Set the cooking time (0 to 60 minutes)

- steam cooking will begin after the door is closed.

The cooking cycle will be interrupted if the door is

opened during the cooking cycle; resume cooking by

closing the door. Holding temperature in the cavity

will keep cooked foods warm after cooking cycle, at

or above 150° F (65° C).

5. Mai n Power Swi tch

TIMED COOKING - The steamer will begin heating

to the pre-set temperature for standby. Red light will

illuminate on the main power switch. Cooking cycle

is determined by timer dial.

OFF - The steamer is powered off.

CONTINUOUS STEAM - Steamer will heat to enter

into a continuous cooking cycle. Both indicator lights

will remain off during continuous steam cooking

cycles

6. Add Water Pilot Light - Illuminates to indicate a

low water condition or that the temperature of the

heater element is above normal. A buzzer will also

sound an audible alarm.

7. Drain Handle - Use to drain the steamer at end of

day.

9

Page 10

5.0 OPERATING INSTRUCTIONS (Continued)

COOKING

CAUTION: Live steam and accumulated hot water in the

compartment may be released when the door is opened.

1. Close drain valve.

2. Remove the deflector plate to expose the bottom of the cavity.

3. Pour water through the door up to the “WATER LEVEL” mark on the back wall of the cavity

and then replace the deflector plate.

4. Close the door, select “TIMED COOKING” mode with the power switch and set the timer to

one minute position. The unit will be ready for operation in approximately ten minutes when

the “READY” indicator lamp is illuminated and the buzzer sounds.

5. Turn the timer to “OFF” position to silence the buzzer, slide pans of food into cooking

compartment pan supports and close cooking compartment door.

6. Select “CONSTANT STEAM” or “TIMED COOKING” mode.

7. In “CONSTANT STEAM” mode the unit will begin the cooking cycle and continue

indefinitely until user intervention or unit runs out of water. There are no indicator lights

illuminated in this mode.

8. In “TIMED COOK ING” mode the unit will run through the cooking cycle determined by

number of minutes selected with the timer. The end of the cooking cycle is indicated by the

buzzer and the illuminated “READY” lamp. The unit will hold the cooked foods in a warm

state and will maintain the cooking cavity at or above 150ΕF (65ΕC) with the timer set to the

“OFF” position.

9. The cooking cycle may be interrupted at any time by opening the compartment door. To

resume operation, close the door.

10. Open door slightly at first letting most of the steam out of the compartment and then fully

open the door.

11. Unload by sliding pans of food from pan supports.

12. Close the door to ensure the unit is ready for the next cook cycle.

10

Page 11

Use a non-abrasive cleaner to remove discolorations.

5.0 OPERATING INSTRUCTIONS (Continued)

SHUTDOWN

CAUTION: When the unit is not in use, leave the cooking

compartment doors ajar to prolong the life of the door gasket.

1. Drain the steamer after each day’s use.

2. Set the power switch to “OFF”

CAUTION: Drain water is very hot and can cause severe personal

injury.

3. Drain the steamer into a suitable receptacle capable of holding 3 gallons of boiling water.

4. Thoroughly clean the unit.

CLEANING

WARNING: Never use chlorine or bleach solution for cleaning door

gasket.

Never use steel wool or other metallic pads to clean the steamer.

Weekly, or more often if necessary, clean the exterior with damp

cloth and polish with soft dry cloth.

1. After each period of daily operation (more frequently as required to maintain cleanliness),

the cooker should be thoroughly cleaned by completing the following steps:

2. Perform SHUTDOWN procedure.

3. Remove the deflector plate and pan supports by lifting up and off mounting studs and wash

with a mild detergent. Rinse and set aside for reassembly.

4. When the unit has cooled, use hot soapy water to clean the interior of the steamer and

thoroughly rinse and dry all surfaces with a clean dry cloth.

11

Page 12

originally installed position.

5. Inspect the drain opening to assure there are no obstructions.

6. Replace the pan supports and deflector in compartment and leave door ajar.

WARNING: When this appliance is installed with casters and is

connected to the supply service with flexible electrical conduit, a

restraint to prevent damage to the electrical conduit should have

been installed. If disconnection of the restraint is necessary,

reconnect this restraint after the appliance has been returned to its

12

Page 13

6.0 COOKING GUIDELINES

1. Frozen vegetables should always be cooked in perforated 12" x 20" x 2 ½ “ (1/1 65 mm)

pans, 7 ½ lbs. (3.4 kg) maximum per pan.

2. Frozen entrees should be underlined with a perforated pan for best results. If they are

defrosted first, the heating time will be decreased.

3. Fresh foods may also be cooked in this unit. Vegetables and other foods where the stock is

not to be retained should be cooked in perforated 12" x 20" x 2 ½" (1/1 65 mm) pans for the

most nutritious results.

4. Total cooking time will vary depending on the load, even though the timer setting is the

same.

5. All foods, except cakes and pastry, can be cooked in a steam cooking unit.

6. Steam cooked meals have greater nutritional value since they retain most of their vitamins

and minerals.

7. Because foods are cooked faster by the higher temperatures of steam cooking, they can be

prepared closer to serving time, insuring maximum freshness.

8. Steam cooked foods have a higher percent yield more portions per dollar spent.

9. Food may be served from the same pan in which it is steam cooked, thus reducing food

breakage since there is no extra handling or transferring of food from cooking pans to

serving pans. It also reduces pot washing tasks.

10. Some important advantages of steam cooking are labour saving, reduced operating costs,

space saving, and the lifting of heavy stock pots is eliminated.

11. Rice and pasta products, if thoroughly wet at the start of the cooking process, are very

easily prepared.

12. Food such as potatoes, poultry, seafood, and some meats may be blanched in the steam

cooker, thus reducing the total cooking time and grease absorption.

13. The steam cooker will loosen foods burned on pans making washing easier.

14. Solid pans are recommended when liquid is to be retained and perforated pans when the

liquid is not to be retained.

15. Eggs may be cooked out of the shell if they are to be chopped which eliminates peeling

after steaming .

16. The steam cooker can be opened during the cooking period to add or remove items.

13

Page 14

SBF-3E

SBF-5E

4"

2

3

STEAM COOKING

Your steamer efficiently cooks vegetables or other foods for immediate serving. Steam cooking

should be carefully time controlled. Keep hot food holding time to a minimum to produce the

most appetizing results. Prepare small batches, cook only enough to start serving, then cook

additional amounts to meet demand. Separate frozen foods into smaller pieces to allow more

efficient cooking.

Use a pan cover for pre-cooked frozen dishes that cannot be cooked in the covered containers

in which they are packed if they require more than 15 minutes of cooking time. When cover is

used, approximately one-third additional cooking time is necessary.

Cooking time for frozen foods depends on amount of defrosting required. If time permits, allow

frozen foods to partially thaw overnight in a refrigerator. This will reduce their cooking time.

PREPARATION

Prepare vegetables, fruits, meats, seafood and poultry normally by cleaning, separating, cutting,

removing stems, etc. Cook root vegetables in a perforated pan unless juices are being saved.

Liquids can be collected in a solid 12" x 20" pan placed under a perforated pan. Perforated

pans are used for frankfurters, wieners and similar items when juices do not need to be

preserved. Solid pans are good for cooking puddings, rice and hot breakfast cereals.

Vegetables and fruits are cooked in solid pans in their own juices. Meats and poultry are

cooked in solid pans to preserve their own juices or to retain broth. Canned foods can be

heated in their opened cans (cans placed in 12" x 20" solid pans) or the contents may be

poured into solid pans.

The steamer compartment is designed to accept combinations of the pan of 12" x 20" (either

solid or perforated) as shown on the following table.

DEPTH OF PAN NUMBER OF PANS

1" 6 10

2 ½" 3 5

6" 1 2

14

Page 15

hardware may damage the equipment and will void any warranty.

compartment contains live steam. Stay clear when opening door.

appliance malfunction. Refer to warranty terms.

7.0 PREVENTIVE MAINTENANCE

A good preventive maintenance program begins with the daily cleaning procedure. Additional

preventive maintenance operations are presented in this section. In establishments that employ

full-time maintenance personnel, the tasks described can be assigned to them. For other

installations, tasks requiring mechanical or electrical experience should be performed by an

authorized service agency.

The following paragraphs are set for minimum preventive maintenance procedures that must be

completed periodically to assure continued trouble-free operation of the cooker.

CAUTION: Under no circumstances should hardware (or parts) be

replaced with a different length, size, or type other than as specified

in the parts list. The hardware used in the cooker has been selected

or designed specifically for its application, and the use of other

WARNING: Disconnect the power supply to the appliance before

cleaning or servicing.

WARNING: The steamer and its parts are hot. Use care when

operating, cleaning or servicing the steamer. The cooking

CLEANING

At the end of each day, or between cooking cycles if necessary:

CAUTION: Do not use cleaning agents that are corrosive.

NOTICE: Contact the factory, the factory representative or a local

service company to perform maintenance and repairs should the

15

Page 16

contact with skin, rinse with cl e an water .

7.0 PREVENTIVE MAINTENANCE (Continued)

CLEANING

Weekly, or more often if necessary:

1. Clean exterior with a damp cloth and polish with a soft dry cloth.

2. Use a non-abrasive cleaner to remove discolorations.

It is NOT RECOMMENDED to use cleaning agents that are corrosive.

Use of cleaning agents that contain chloride, acids or salts which are corrosive may cause

pitting and corrosion when used over a period of time; this will reduce the life of the appliance.

Should pitting or corrosion occur, this is not covered by warranty.

Follow the recommended cleaning instructions. Use a mild detergent, warm water and rinse

thoroughly.

NEVER SPRAY WATER INTO ELECTRIC CONTROL S OR LOUV RES.

MONTHLY

REMOVAL OF SCALE DEPOSITS

It is recommended that your steamer be descaled once a month, or more often if necessary.

Should your steamer develop a heavy build-up of lime scale deposits, use the CLR®

TREATMENT KIT available from your authorized service agent.

DESCALING PROCEDURE

WARNING: Read and follow instructions on the CLR® bottle. Use

plastic or rubber gloves to avoid skin contact. If CLR® comes in

1. Set power switch to “OFF”.

2. Remove diffuser plate and pan support racks.

3. Pour one quart of solution into the cavity.

4. Fill the remainder with water up to the “WATER LEVEL” line.

5. Set the power switch to “TIMED COOKING” and set the timer to 30 minutes.

16

Page 17

Cooking indicator light

Timer dial not turning

6. At the end of the 30 minute cook cycle, turn power switch “OFF” and drain the contents of

the cavity.

7. Thoroughly flush the cavity with clean water and dry with a soft cloth. LEAVE

COMPARTMENT DOOR OPEN WHEN NOT IN USE. Th e steamer is now ready for use.

Turn off for overnight shutdown.

8.0 TROUBLESHOOTING

GENERAL

PROBLEM PROBABLE CAUSE REMEDY

fails to light with

Timer set.

Steam fails to

generate with cooking

indicator light on.

Steams continuously

without the cooking or

ready light on .

a. Main power circuit breaker

tripped.

b. Door interlock switch contacts

not closed.

c. Door interlock switch faulty. Replace switch.

d. Indicator light burned out. Replace light.

e. Faulty timer contacts. Replace timer.

f. Faulty wiring.

g. Fuse blown. Replace with same rated fuse.

a. Faulty wiring.

a. Faulty thermostatic switch. Replace thermostat.

b. Power switch - continuous

steam setting is selected.

a. Faulty timer motor. Replace timer.

b. Faulty wiring.

Locate external circuit breaker for

incoming power and place in ON

position.

Shut cooker door to close switch

contacts. Check alignment of door with

switch.

Inspect condition of wire and tightness of

all connections. Correct as needed.

Inspect condition of wire and tightness of

all connections. Correct as needed.

This is normal operation when

“continuous steam” is selected.

Inspect condition of wire and tightness of

all connections. Correct as needed.

Buzzer fails to sound

at end of timer

setting.

a. Timer contacts faulty. Replace timer.

b. Buzzer faulty. Replace buzzer.

c. Faulty wiring.

17

Inspect condition of wire and tightness of

all connections. Correct as needed.

Page 18

8.0 TROUBLESHOOTING (Continued)

COMPONENT TESTING

60-MINUTE TIMER

Timer Contacts

Defective timer contacts will result in failure of cooker compartment to operate. When this

occurs, remove the side panel and proceed as follows:

1. Turn off power to the cooker at external circuit breaker.

2. Disconnect all three wires from timer terminals.

3. Connect an ohmmeter between terminals 1 and 3.

4. Rotate timer dial beyond the “0 - Minute” point (any setting) to obtain a reading of zero ohms

on the ohmmeter. If zero ohm reading cannot be obtained, timer contacts are defective and

the timer must be replaced.

5. Move ohmmeter leads to terminals 1 and 4.

6. Rotate timer dial to “0 - Minute” position. (An audible click indicates correct position). If zero

ohm reading cannot be obtained, the timer is defective and must be replaced.

7. Remove ohmmeter and replace all three leads on timer terminals.

Timer Motor

A defective timer motor will cause continuous operation in the TIME mode, with the timer dial

failing to return to the “0 - Minute” position.

To confirm timer motor condition, proceed as follows:

1. Carefully check motor wire leads and tighten loose connections.

WARNING: Use care while working with control panel. Terminals

carry 240 Volts.

2. Turn on power to the steamer.

18

Page 19

8.0 TROUBLESHOOTING (Continued)

3. Set timer dial (any setting beyond “0 - Minute”). If operation is correct, the motor will turn the

dial toward “0 - Minute”. If the motor fails to operate, it is defective and the entire timer must

be replaced.

4. Shut off power to the cooker.

Door Interlock Switch

Malfunction of the cooker door interlock switch prevents timer indicator lights from turning on

and steam generator from operating when the timer dial is set. If steam does not enter the

compartment and the cooking indicator light fails to turn on with the door latch securely

engaged, the fault may be in the door interlock switch. Proceed as follows:

1. Turn off power to the cooker.

2. Disconnect wires to the door switch terminals.

3. Connect an ohmmeter between the terminals of the switch. The switch is marked “C” for

common, “NC” for normally closed and “NO” for normally open.

4. Actuate the switch by closing the cooking compartment door. If a zero reading cannot be

obtained between the C and NO terminals, the switch is defective and must be replaced.

5. Remove the ohmmeter and replace the leads on switch terminals.

Indicator Lights

If the cooker compartment functions correctly, with the single exception that the indicator light

fails to light during operation, the fault is a defective indicator light. A “burned out” or defective

light is verified by using an AC voltmeter at the leads, with input power on the selector switch in

the correct position for that timer, the timer set, and the door latches closed. If 240 volts is

present, the fault is in the indicator light and requires replacement. If 240 volts is not present,

the fault is in the wiring or control components (selector switch, timer or door switch).

Buzzer

If the buzzer does not sound at the termination of the operator-selected timer setting (timer dial

returned to “0 - Minute” position), the fault may be a defective buzzer. Buzzer operation is

verified using an AC voltmeter at buzzer coil connections with input power on and selector

switch and coinciding timer dial set at the “0 - Minute” position. If voltage is 240 volts, the fault

is in the buzzer, which must be replaced. If 240 volts is not present, the fault is in the wiring or

control components (timer or selector switch).

19

Page 20

before removing side panels.

8.0 TROUBLESHOOTING (Continued)

Wiring

WARNING: Disconnect the power supply to the appliance before

cleaning or servicing.

Using an ohmmeter, wiring continuity between the connections shown on the wiring diagram is

readily verified. This is best done in stages, removing only those wires required for each

continuity check. As each lead is replaced, it should be checked for evidence of corrosion, and

cleaned if necessary. All leads must be tightly attached so as to provide a good electrical

connection.

Door Gasket

Check gasket for cuts and replace if necessary.

Door Gasket Replacement

The cooking compartment door gaskets are made of a silicone-type rubber material that is very

durable but subject to wear during normal operation. Should the gasket leak replace it.

1. Open the cooking compartment door.

2. Remove the six or eight screws from the gasket plate in the door panel assembly.

3. Remove the gasket plate and the door gasket from door panel.

4. Install the new door gasket to the door panel. Replace the gasket plate and six or eight

screws.

5. Gasket replacement is now complete.

Door may be difficult to close until gasket has compressed to conform to opening. Leaving door

closed overnight will compress gasket.

Exterior Panel Removal

WARNING: To prevent hazard in servicing the cooker, be certain

that the electrical disconnect circuit breaker for the steamer is OFF

Access to all internal plumbing and electrical assemblies is from the right side. The right-side

panel is removed by removing the bottom screws from panel.

20

Page 21

8.0 TROUBLESHOOTING (Continued)

STAINLESS STEEL

To remove normal dirt, grease or product residue from stainless steel, use ordinary soap and

water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean

cloth. Never use vinegar or any corrosive cleaner.

To remove grease and food splatters or condensed vapours that have baked on the equipment,

apply cleanser to a damp cloth or sponge and rub cleanser on the metal in the direction of the

polishing lines on the metal. Rubbing cleanser as gently as possible in the direction of the

polished lines will not mar the finish of the stainless steel. NEVER RUB WITH A CIRCULAR

MOTION.

Soil and burnt deposits which do not respond to the above procedure can usually be removed

by rubbing the surface with SCOTCH-BRITE scouring pads or STAINLESS scouring pads. DO

NOT USE ORDINARY STEEL WOOL as any particles left on the surface will rust and further

spoil the appearance of the finish. NEVER USE A WIRE BRUSH, STEEL SCOURING PADS

(EXCEPT STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS. Surfaces which are

marred collect dirt more rapidly and become more difficult to clean. Marring also increases the

possibility of corrosive attack. Refinishing may then be required.

TO REMOVE HEAT TINT

Darkened areas sometimes appear on the stainless steel surface where the area has been

subjected to excessive heat. These darkened areas are caused by thickening of the protective

surface of the stainless steel and are not harmful. Heat tint can normally be removed by the

foregoing, but tint which does not respond to this procedure calls for a vigorous scouring in the

direction of the polish lines using SCOTCH-BRITE scouring pads or a STAINLESS scouring

pad in combination with a powdered cleanser. Heat tint action may be lessened by not applying

or by reducing heat to equipment during slack periods.

21

Page 22

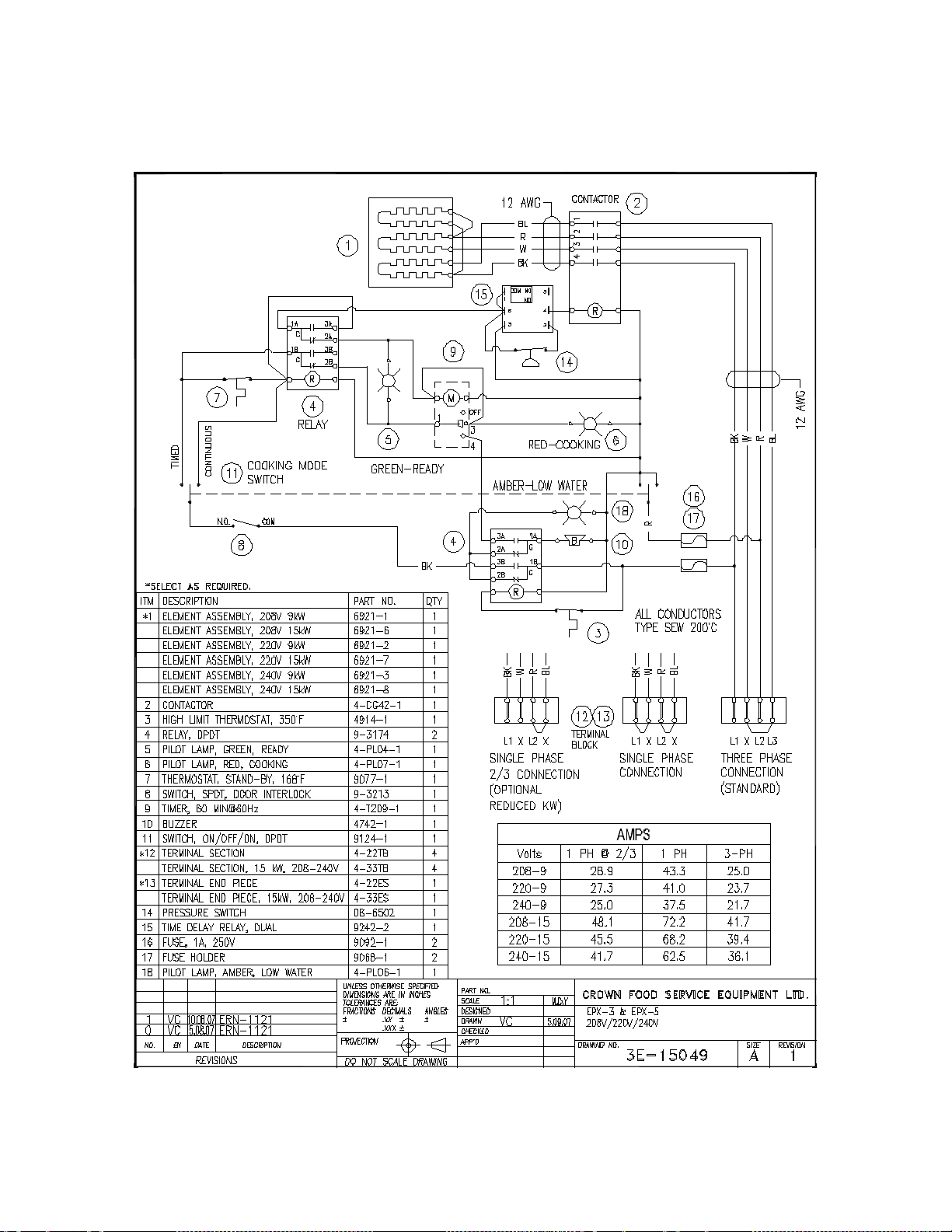

9.0 WIRE DIAG RAMS

22

Page 23

23

Page 24

24

Loading...

Loading...