Page 1

Fitting instructions

8 622 400 046 7 612 001 120

TravelPilot RGS 05

Page 2

GB

Safety instructions

Installation and connection regulations

While installing and mounting this equipment, you must

disconnect the negative terminal of the battery. Important: You

must also comply with all safety instructions given by the auto

manufacturer (alarm system, vehicle immobilizer, airbag)!

Before drilling holes for mounting the equipment or laying the wiring,

make sure that no existing wiring or auto parts (such as the petrol

tank, fuel line) will be damaged.

Use wire bushings on sharp-edged holes.

In order to avoid any interference, lay all wiring far enough away

from the wire harnesses.

Equipment fuses:

Basic unit: 5 A wire fuse

5 A miniature fuse

GPS receiver: 5 A wire fuse

Magnetic field sensor (electronic compass)

Note: You must determine the optimum mounting location for

the magnetic field sensor in each vehicle individually. Before

permanently installing the magnetic field sensor, attach it

temporarily and then test the chosen location with the installation

and calibration CD-ROM to make sure everything operates

correctly.

The magnetic field sensor must be installed in the passenger room. It

determines the driving direction by measuring the horizontal earth

magnetic field component. Since the earth magnet field is relatively

small, you must ensure that there is no magnetic or electromagnetic

interference affecting the magnet field sensor at the chosen mounting

location.

Use the enclosed mounts to attach the magnet field sensor to a window

which cannot be opened or, especially where estate wagons or liftback

cars are concerned, mount it without fasteners underneath the inside roof

lining using double-sided sticky tape.

Note: If the magnetic field sensor is mounted in the direct vicinity

of an AM radio antenna integrated into the rear window, it may

cause occasional interference in the radio reception in the long

wave range.

Notes on the operation of the system

In order to ensure the trouble-free operation of the navigation system, a

calibration must be performed after the equipment has been installed. A

special installation and calibration CD-ROM, including operating

instructions, is required. Software available for the Berlin RCM 303 A

operating panel from version 04.11.94 is capable of controlling the

navigation componentry. Older software must be replaced by the most

recent update, whereby an update for the tuner software is also required

(at least version 08.09.94).

Note: An error message list, a service checklist and diagnostic aids have

been included at the end of these installation instructions.

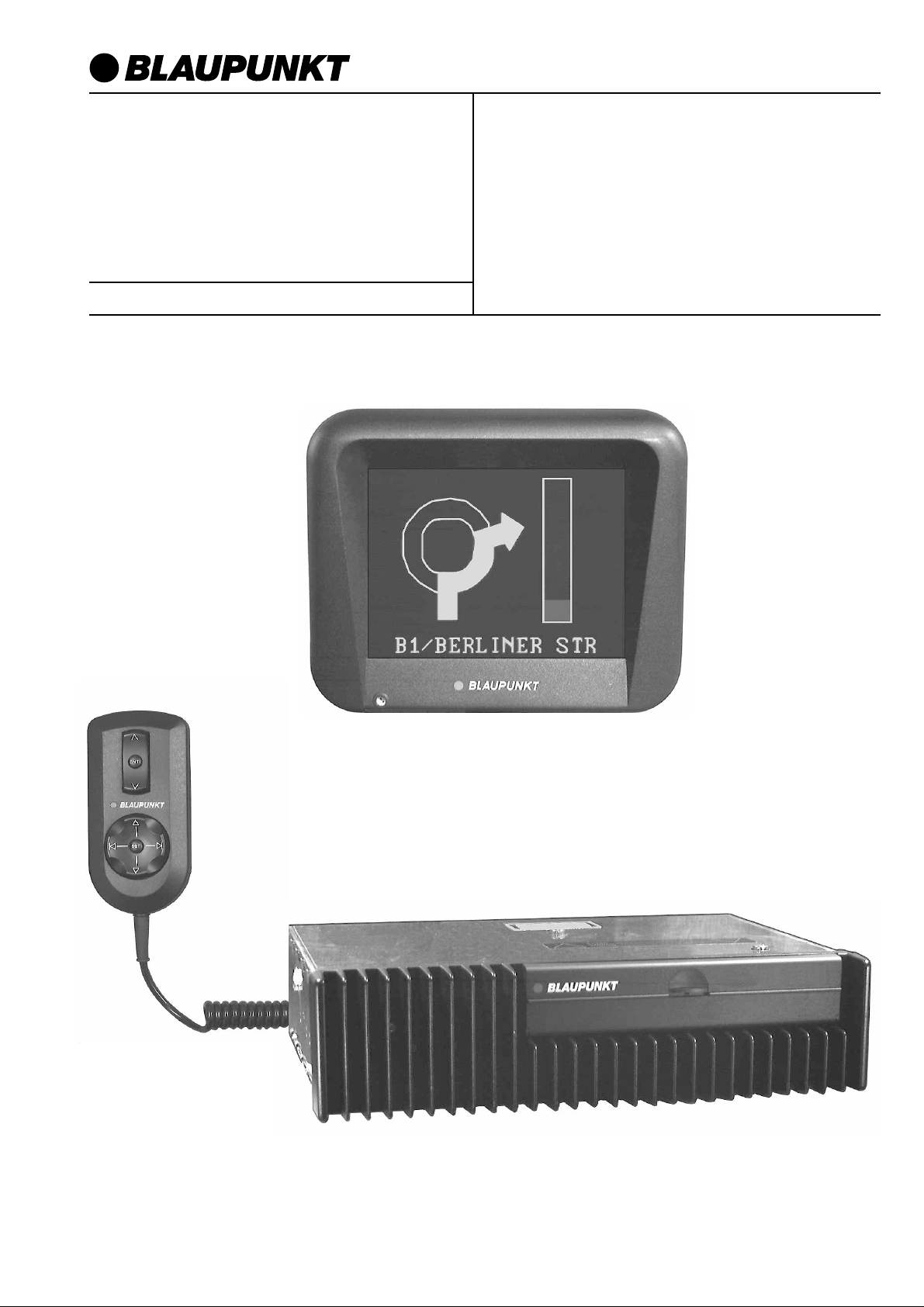

Componentry Fig. 1

The navigation componentry consists of a navigation computer with an

integrated CD-ROM drive (navigation unit), a NAVI interface, a GPS

receiver with an antenna, a precision resistor for the rear window

defogger, a magnetic field sensor, wheel sensors, a loudspeaker and

mounting material.

Mounting location for the navigation unit

Remove the transport block (two brass screws in the upper plate)

before beginning the installation work. Keep these screws in a safe

place in case the unit must be set in for servicing. After removing

the screws, insert the enclosed plugs into the holes in the upper

plate.

The navigation unit need not be installed at any particular position.

When choosing the mounting location for the navigation unit, you must

make sure that the unit is installed lying in a horizontal position (you must

be able to read the writing on the flap).

Make sure that there is enough room to insert the navigation CD into the

CD drive. Use the enclosed installation material in order to mount the

navigation unit.Positive connection Fig. 2

Positive connection Fig. 2

The navigation unit must be connected to permanent plus 12 V and

positive via the ignition.

Lay the permanent plus 12 V wire (red) to the battery (do not lay the wiring

directly by the wire harnesses). Attach the fuse carrier to protect the

positive wire and connect it to the positive terminal on the battery (if

necessary, drill a hole through the splashboard and use wire bushings

accordingly).

Connect the switching plus wire (black) with the fuse carrier at terminal

15 (switched to plus via the ignition) behind the fuse. In cars in which it

is not possible to connect the wire in the fuse box, use the enclosed fuse

carrier to connect the wire directly to terminal 15 at the ignition. Remove

the steering wheel panelling first.

Negative connection Fig. 2

Screw the negative wire (brown) directly onto the chassis. Scratch the

contact point for the ground down to the bare metal and grease it with

antiseize graphite petroleum (important for good grounding).

Testing the mounting location of the magnetic field

sensor

Two different tests are required.

1. Test for permanent magnetic interference

Load the installation disk.

Select „find compass location“, and then „compass ellipse“ and drive the

vehicle in a circle. A circle should appear on the display inside the

squares (ideally the circle should be in the centre). If this circle is partially

or entirely outside of the squares, then you must mount the magnetic field

sensor in a different place.

2. Testing for interference caused by other electrical equipment

Load the installation disk, select „find compass location“ and then

„compass error“.

Press „reset“, switch on the consumers (e.g. sliding sun roof, rear

window wiper).

The value indicated for „Loc. error“ must be less than 3.5.

Press reset each time you switch on a different piece of electrical

equipment.

After having tested each piece of electrical consumer individually,

check logical combinations as well. The sum of the values for the

consumers must not exceed a „Loc. error“ of 3.5.

If the value registered exceeds 3.5, then you must mount the

magnetic field sensor in a different location.

Note: Do not switch on the rear window defogger while testing for

interference from the electrical equipment. Any interference caused

by the rear window defogger is registered separately during

calibration and then compensated.

Precision resistor for the rear window defogger

(shunt)

The precision resistor has 2 connection wires and 1 measuring wire:

1. Connection to the ground contact of the rear window defogger

(length: 250 cm),

2. Connection to the vehicle chassis (length: 75 cm),

3. Measuring wire to the navigation unit (length: 50 cm), Fig. 3

The mounting location of the precision resistor depends on the length of

the wiring.

Do not lengthen the connection wires for the ground contact and the

vehicle chassis. Do not attach the connection for the vehicle chassis to

the liftback in estate wagons or liftback cars. Select the mounting location

for the precision resistor so that any heat build-up will be eliminated

(chassis metal).

Lay the measuring wire to the navigation unit and connect it to the

corresponding jack of the compact plug, Fig. 3

Note: No other electrical equipment (e.g. rear window wiper) may be

connected to the ground contact for the rear window defogger, except for

the rear window defogger.

- 19 -

Page 3

Wheel sensors and magnetic strips Fig. 4

Safety instructions

Never screw the wheel sensor clamp onto any stress-bearing

parts.

Never drill holes in any stress-bearing parts.

Do not attach the sensor wiring to the brake lines or to any

moving parts.

The wheels must be tightened using the torque recommended

by the factory (approx. 100 Nm).

Mount the wheel sensors and the magnetic strips on the free-rolling

wheels, for four-wheel drive cars, on the rear wheels.

In order to mount both the wheel sensors and the magnetic strips, the

vehicle must be jacked up.

Screw the wheel sensors onto the sensor mounts and look for a suitable

mounting location. The sensors must not swing mechanically and they

should be placed in a sheltered location.

While mounting the wheel sensors, it is essential to comply with the

installation tolerances, Fig. 5

Mounting the magnetic strips

After you have found a suitable location for the wheel sensors, you must

determine the position of the magnetic strips on the inside of the wheel

rims. Mark the location selected for the magnetic strip and remove the

wheel.

Before unscrewing the wheel nuts, mark the position of the wheel on the

wheel hub.

Because the magnetic strips are glued into position, the rim must be free

of rust, dirt, grease and water. Clean the inside of the wheel rim

thoroughly (brake cleaning fluid, brake and clutch cleaner).

To ensure that the glue adheres properly, the rims must be at room

temperature.

After thoroughly cleaning and perhaps allowing the rims to warm up, glue

the magnetic strips onto the marked spots over the entire area parallel to

the outer edge of the rim, Fig. 4

Notes

Do not glue the magnetic strips directly onto the edge of the rim, as here

they can be damaged very easily.

Do not piece the magnetic strip together and cut it only at the

marked points (maximum gap between the beginning and end

point, one field = 25 mm).

Mount the wheels and tighten the nuts. Align the wheel sensors in

keeping with the installation tolerances, Fig. 5, and screw them on.

Lay the sensor wires into the interior of the vehicle (use any existing

bushings or drill new holes) and lay them to the navigation unit.

GPS receiver

Mounting the antenna

Important information:

- Mount the antenna on a metal roof only. It is not permissible to

mount the antenna on synthetic roofs or aluminium.

- When mounted on a roof (held only by a magnet), the antenna

must not be exposed to temperatures lying outside a range of -20°

C to +80° C.

- It is not permissible to mount the antenna on roofs covered with

leather or synthetic material.

- Use protective sheathing to protect the antenna wire from being

pinched.

- The adhering surface of the antenna must be free of dirt, snow, ice,

etc.

- You must not lengthen, shorten or bend the antenna wire. Do not

remove the plug during the installation.

- If the antenna is painted with the same colour as the vehicle,

especially paints containing a high percentage of metal, this may

adversely affect the reception. There is no guarantee that the

antenna will operate properly after it has been painted.

Seen from the driving direction, the antenna is to be mounted on the righthand side in the rear of the vehicle (passenger’s side, in Great Britain,

driver’s side). On notchback vehicles, mount the antenna on the lid of the

boot using the corner clamps, Fig. 6.

On estate wagons and liftback cars, set the antenna on the roof with its

magnetic foot, Fig. 7.

For a roof mount, remove the corner clamps, Fig. 8.

For estate wagons and liftback cars, lay the antenna wire along the rain

gutter downwards and into the interior of the vehicle, Fig. 9.

Any obstacles near the antenna, such as roof or bicycle carriers, may

adversely affect or even prevent satellite reception.

Lay the antenna wire into the interior of the vehicle and connect the BNC

plug on the antenna wire with the antenna jack on the GPS receiver.

It is advisable to remove the antenna from the roof when driving through

a carwash.

Installation of the GPS receiver

The mounting location of the GPS receiver depends on the length of the

antenna cable (2.5 m) and the connection line to the navigation unit (1.5

m).

Screw the GPS receiver into a dry position in the boot . Do not use screws

longer than 7 mm, otherwise you may destroy the GPS receiver, Fig. 10.

Loudspeaker

Install the loudspeaker for the voice directions in the foot area of the

vehicle so that it is possible to understand the voice instructions clearly.

Connecting the sensors for the navigation unit

Lay the connecting wires for the precision resistor, the wheel sensors, the

loudspeaker and the magnetic field sensor to the navigation unit and

connect them to the compact plugs, Fig. 11.

Display

The display is mounted on a swivel base.

If it is not possible to mount the display on a swivel base, you may

alternately use a gooseneck. You can order the gooseneck as an

accessory under the order number 7 607 039 100.

The hook-up wire can be laid into the base either from the side or from

underneath. In order to lay the wire into the base from underneath, drill

a 15 mm hole where the display is to be installed and pull the plug from

the display.

Warning: Make sure not to damage any other wires, the airbag, etc.

while drilling the hole.

In order to pull the plug in the display, screw it apart as follows:

1. Loosen the four screws on the back of the display and remove the

rear plate (Fig. 12).

2. Loosen the two screws on the strain relief inside and remove it

(Fig. 13).

3. Remove the plug carefully and push it through the base. Push the

wire through the hole where the display is to be installed, push it from

underneath into the base and plug it in. Screw the display back

together (Fig. 14).

The base can also be mounted on the back of the display. Proceed as

follows:

1. Loosen the four screws on the back plate of the display and remove

the rear plate (Fig. 12).

2. Loosen the two screws on the strain relief inside and remove it

(Fig. 13).

3. Remove the plug carefully and push it through the base.

4. Remove the cover from the back plate of the display and remove the

retaining spring (Fig. 15).

5. Pull the base off the back plate and insert it where the cover was

located (Fig. 16).

Push the retaining spring into the notch in the base, insert the cover

where the base was located, lay the wire through the base and reassemble the display (Fig. 17).

In order to mount the base, unscrew it and use four screws to fix it to the

installation location (Fig 18).

Modifications reserved!

- 20 -

Page 4

Componentry Fig. 1

Navigation unit

Operating Panel

- 21 -

Page 5

Componentry Fig. 1

GPS receiver GPS antenna

Precision resistor Magnetic field sensor

- 22 -

Page 6

Componentry Fig. 1

Wheel sensors (2x) Wheel sensor extension cord (2x)

Display

Loudspeaker

- 23 -

Page 7

Mounting material

Positive-negative connection Fig. 2

UBatt

terminal 30

red

Ignition

terminal 15

black

ground

brown

- 24 -

Page 8

Rear window

Heckscheibe

Chassis

Chassis

75 cm

Heckscheibe

rear window

250 cm

Precision resistor connection Fig. 3

Connection block for the navigation unit

+

measuring wire 50 cm

precision resistor

Mounting the wheel sensor and magnetic strip Fig. 4

max. 25 mm

cut edge

- 25 -

12.7 mm

rim edge

12.7 mm

magnetic strips

Page 9

Installation tolerances for the wheel sensors Fig. 5

Clearance Z: Z = 6.5 mm ± 1.5 mm

Offset Y: The centre of the sensor must be located over the

entire circumference of the wheel over the magnetic

strip.

Z

centre of the

sensor

YY

Set angle: The edges of the wheel sensor must be set at a

distance conforming to Z.

Turning angle: The turning angle must not exceed 10°.

Length of the

metal holder: The free-standing length must be kept as short as

possible (max. 90 mm).

If the free-standing length is greater than 90 mm,

then the metal holder must be reinforced.

≤ 10˚

Z ≥ 5 mm

Z ≤ 8 mm

≤ 90 mm

Rotation angle T: The rotation angle must not exceed 20°.

Special case: T = 90°, do not mount the metal

holder facing in the direction of the magnetic strip.

- 26 -

T

Special case

90˚

metal holder will affect

the magnetic field

Page 10

loop

Fig. 7Fig. 6

Fig. 8

loop

Fig. 9 Fig.10

- 27 -

Page 11

- 28 -

Kl. 15

1

2

V

Kl.30

+12V

+

5A

Connecting the sensors for the navigation unit, Fig. 11

Rear window

Chassis

75 cm

Rear window

250 cm

Precision resistor Wheel sensor Loudspeaker Wheel sensor

Operating Panel Magnetic field sensor

Page 12

Mounting the Display

Fig. 12

Fig. 13

Fig. 15

Fig. 16

Fig. 14

Fig. 17

Fig. 18

- 29 -

Page 13

Error message list

The following error messages can appear in the top line on the

screen in any menu regardless of what function is currently being

performed.

„Check r. wheel sensor“, „Check l. wheel sensor“:

No signals are being received from the wheel sensor indicated, or the

signals are being interrupted sporadically. This error can only be registered

while the car is in motion.

„Check the compass“:

The compass is not connected or the voltage level of the compass is

outside of the valid value range. This error can only be registered while

the car is in motion.

„Check the GPS antenna“:

The GPS antenna wire is faulty. This message will appear only if the GPS

receiver is connected.

„CD reading error“:

Either no data is being read from the CD or the CD player is making

repeated transmission errors. This may be caused by damp or dirty CDs,

CDs slipping in the cartridge or errors on the CD in the map data.

„Please insert disk“:

The CD has been removed while the system was in operation. If the

navigation programme continues to try and retrieve data from the CD in

order to load the map data or calculate a route, for example, then the error

message „CD reading error“ may appear.

Service Checklist

Check the following points during servicing!

1) Is the operating power supply all right?

2) Is the basic navigation unit mounted so that it is free of vibration?

3) Has the navigation CD-ROM been loaded correctly into the CDROM player?

4) Has the mounting location for the magnetic field sensor been

selected correctly?

5) Does the customer transport metal parts frequently and are

these parts in the vicinity of the magnetic field sensor?

6) Have the wheel sensors been installed on the free-rolling wheels

at a distance of 5 to 8 mm from the magnetic strips?

7) Have the wheel sensors been mounted on the corner clamps so

that they are free of vibration?

8) Have the magnetic strips been mounted correctly and not

damaged?

9) Have the magnetic strips been glued in straight with a gap of not

more than 2.5 cm?

„No voice output“:

Voice output is not possible because the vocabulary data is being loaded.

This message will only then appear, when the user allows the acoustic

driving recommendation to repeat.

„No GPS receiver connected“:

will appear in the DSC MENU / GPS STATUS if no data is received from

the GPS receiver via the serial interface. Possible causes: The wire

connecting the GPS receiver and the navigation unit is not hooked up or

is damaged, the power supply to the GPS receiver is faulty.

„No position“:

This message will appear in the DSC MENU / GPS STATUS without

including the number of satellites, if there is no information to be

evaluated from the telegram from the GPS receiver directly after the

system has been started. If the number of satellites appears on the

screen, then the current location cannot be determined because there

are not enough satellites available for locating.

„Language is being loaded“:

will appear in the DSC MENU / AUDIO MENU, when the current

vocabulary data is being loaded into the speech processor. This process

takes approximately 15 minutes and is done automatically when the data

in the speech processor storage has been lost, for example, after an

interruption in the power supply or when a different language has been

selected.

10) Has the precision resistor been mounted correctly and its

operation tested?

11) Is the GPS antenna all right, is the reception obstructed in any

way?

„No crossing exists“:

In order to enter a location into the DSC MENU / LOCATION ENTRY, you

must also enter a crossing. If a location is entered for which no street

names are known or if a street in the city is entered, but no crossing is

known, then this error message will appear.

„The streets cross repeatedly“:

When entering the location, streets have been selected which cross each

other more than once, for example, because they are crescent-shaped.

- 30 -

Page 14

Error: Frequent loss of locating with message faulty „left“

or „right wheel sensor“

Load the installation disk

Select „wheel sensor test“ and drive straight on.

Are the impulses for wheel 1 and 2 the same?

Is the difference between the counters practically „zero“?

yes

Run „sensor - emulator test“ for

basic navigation unit. O.K.?

Have the wheel sensors been

mounted properly and at the correct

distance to the magnetic strips?

yes

no

Are the magnetic strips damaged?

Have the magnetic strips been mounted at

the correct distance (6.5 mm) to the wheel

sensor?

Are the magnetic strips in position properly?

no

Replace magnetic strips.

No calibration required.

no

Mount the wheel sensors properly at

the correct distance (6.5 mm) to the

magnetic strips.

yes

„Sensor - emulator test“

Plug the wheel sensor into the emulator.

O.K.?

no

Replace the basic navigation unit and

do a complete calibration.

no

Replace wheel sensor.

No calibration required.

- 31 -

Page 15

Error: Locating loss when the rear window defogger is switched on

and the magnetic field sensor has been mounted on the rear window

Load the installation disk.

Select the hardware test „wiring test“.

Switch on the rear window defogger.

The indication for „precision resistor“ must change

by > 30 points, for example from 435 to 390

no

Test the basic navigation unit with the

„sensor - emulator test“. Test passed?

yes

Check the mechanical wiring to the precision resistor.

(Chassis and rear window wiring, signal wire to the

basic navigation unit) O.K.?

yes

Test the signal wire to the basic

unit with an ohmmeter on transition.

(Resistance measures 3.3 mΩ)

no

Replace the basic navigation unit and

do a complete calibration.

no

Repair wiring.

no

Replace precision resistor and do a

complete calibration on the basic

navigation unit.

- 32 -

Page 16

Error: Regular locating loss even after a short drive

Load the installation disk.

Select „find compass location“, then select

„compass ellipse“.

Drive the vehicle in a circle.

Is there an ellipse visible on the screen inside

the squares?

yes

Run the „sensor - emulator test“ on

the basic navigation unit.

Install the magnetic field sensor, lay

the wiring.

Do a complete calibration on the basic

no

Replace the basic navigation unit and

do a complete calibration.

navigation unit.

yes

no

Replace the magnetic field sensor.

Repeat the „compass ellipse“ test.

Is there an ellipse visible on the screen inside

the squares?

no

Replace the basic navigation unit and

do a complete calibration.

- 33 -

Page 17

Error: Regular locating loss due to wheel magnetism

Jack up the vehicle.

Load the installation disk.

Select „find compass location“, then select „compass error“.

Press „reset“.

Turn each wheel.

The value indicated for „Loc. error“ must be less than „3.5“.

no

Demagnetise the wheel and repeat the test.

Error: Regular locating loss due to constant magnetic changes in the vehicle

Load the installation disk.

Select „find compass location“, then select

„compass ellipse“.

Drive the vehicle in a circle.

Is there an ellipse visible on the screen inside

the squares?

no

Metal parts affect the magnetic field sensor

e. g.- subsequently installed loudspeaker system

- loading large metal parts into the boot

- magnetic field sensor too close to vehicle chassis parts

- strong magnetism surrounding the vehicle

- sliding sun roof

Find a new location for mounting the magnetic

field sensor and do a complete calibration on

the basic navigation unit.

- 34 -

Page 18

Error: Occasional locating loss due to electrical equipment in the vehicle

Load the installation disk.

Select „find compass location“ and then select „compass error“.

Press „reset“.

Switch on each piece of electrical equipment individually.

The value indicated for „Loc. error“ must be less than „3.5“.

Check logical equipment combinations as well. The sum of the values for

the equipment must not exceed a „Loc. error“ of 3.5.

no

Eliminate interference (if possible)

e.g. relay the wiring for the car phone.

Error: „CD reading error“ appears in the display

Remove the navigation CD from the CD-ROM player.

Is the NAV-CD lying correctly in the cartridge?

Is the cartridge closed properly?

Find a new location for the magnetic field

sensor and do a complete calibration on the

basic navigation unit.

yes

no

Are there any scratches clearly visible

on the data side of the NAV-CD?

yes

Replace the NAV-CD and the basic

navigation unit and do a complete

calibration.

Insert the NAV-CD correctly into its

cartridge and close it properly.

Do a test drive.

no

In the winter, moisture may sometimes condense on

the laser system when it warms up after starting.

After a few minutes the condensation will evaporate.

The navigation system will operate properly again.

- 35 -

Page 19

Error: No GPS satellite reception for several days

Load the installation disk.

Select „GPS status display“.

„No GPS communication available“ will appear

on the display.

Connect a test GPS antenna.

Find a clear area and switch the navigation

system on. After approximately 1 minute GPS

communication should be possible.

yes

Install the GPS antenna properly and

lay the wiring.

Do not calibrate the basic navigation

unit.

yes

Replace defective wiring or fuses.

Do not calibrate the basic

navigation unit.

no

Check the connection wire from the

GPS receiver to the navigation and

the power supply.

no

Replace the GPS receiver.

Wait approximately 1 minute.

yes

Install the GPS receiver properly.

Do not calibrate the basic navigation

unit.

no

Replace the basic navigation unit and

do a complete calibration.

- 36 -

Loading...

Loading...