Page 1

Model 9120, 9121 & 9122

Instruction Manual

SINGLE OUTPUT PROGRAMMABLE DC POWER SUPPLY

Page 2

Table of contents

General Information ……………………………………………. 3

Features …………………………………………………..……… 5

Local Mode Operation ………………….……………………….. 7

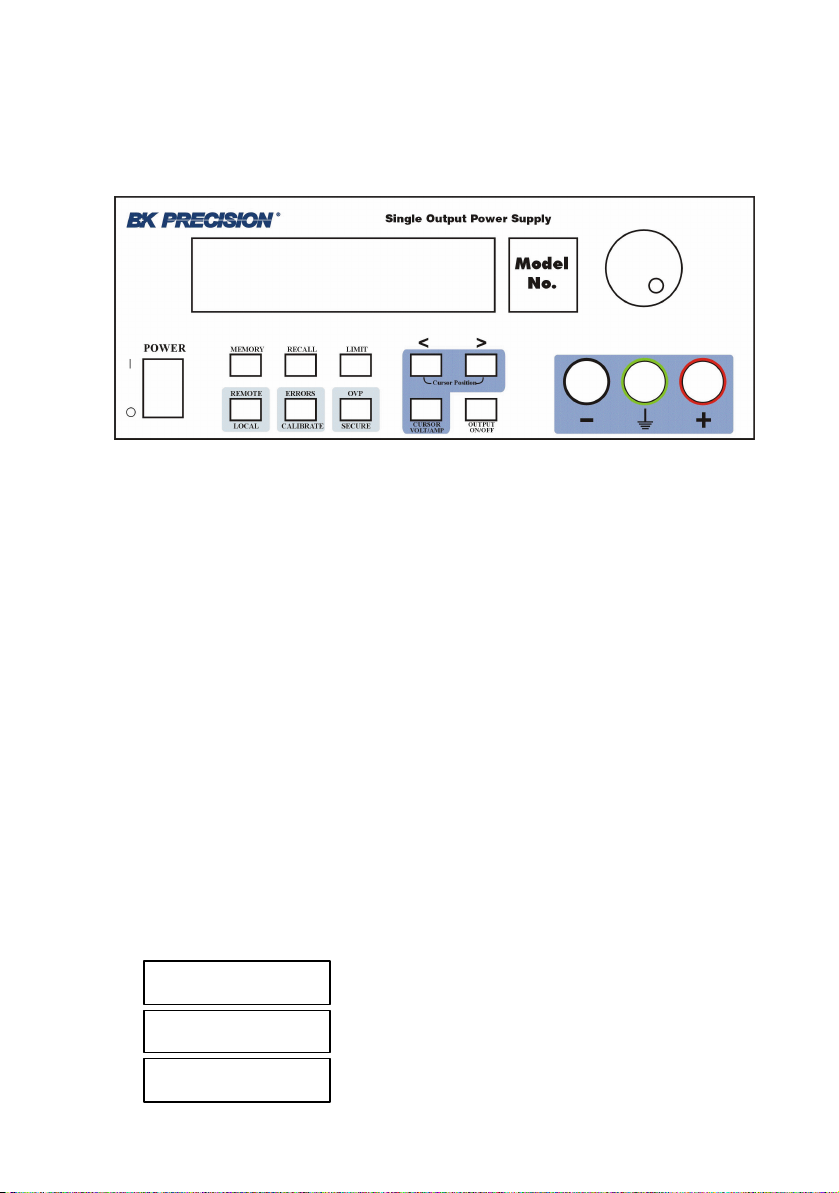

Front panel description ……………………………………………. 7

Memory key ………………… ……………………………………. 7

Storing states in front panel mode ………………………………… 10

Recall key …………………………………………………………. 12

Recalling states in front panel mode ……………………………… 14

Limit key ………………………………………………………….. 15

Modes of operation ……………………………………………….. 16

Constant current operation ………………………………………... 18

Constant voltage operation ………………………………………. .. 20

On / Off key ……………………………………………………….. 22

Remote / Local key ………………………………………………... 23

Errors / Calibrate key …………………………………………… … 25

Calibration Overview ……………………………………………. 28

Calibration security code ……………………………………... ... 28

Unsecure procedure for calibration …………………………….… 29

Hardware unsecure procedure for calibration ……………………. 32

Calibration Procedure …………………………………………… 34

Voltage Calibr ation Procedure ……………………………………. 35

Volt Zero Scale Calibration ……………………………………….. 35

Volt Full Gain Calibration ………………………………………... 36

OVP Calibration …………………………………………………… 37

Current Calibration Procedure …………………………………….. 38

Current Zero Scale Calibration ……………………………………. 38

Current Full Gain Calibration …………………………………….. 39

OVP / Secure key ………………………………………………….. 41

Programming OVP in front panel mode …………………………. 44

Clearing OVP condition …………………………………………… 46

Rear panel description ………………………………………… …… 50

Remote Interface ……………………………………..………….. 51

SCPI Commands …………………………………………………. 52

SCPI Commands Overview ………………………………………. 54

DISPlay Subsystem ……………………………………………….. 54

1

Page 3

Table of contents

OUTPut Subsystem ………………………………………………… 55

SYSTem Subsystem ……………………………………………….. 55

SOURce Subsystem ……………………………………………….. 56

MEASure Subsystem ………………………………………………. 62

TRIGger Subsystem ………………………………………………… 63

Non_SCPI commands ………………………………………………. 67

IEEE 488.2 commands ……………………………………………... 68

SCPI Status Registers ……………………………………………….. 70

Error Messages …………………………………………………… 74

Command Errors …………………………………………………… 74

Execution Errors …………………………………………………… 76

Device-specific Errors ……………………………………………... 76

Self-test Errors …………………………………………………….. 77

Calibration Errors …………………………………………………. 79

Technical Specifications ……………………………………….… 82

Supplemental Characteristics ……………………………………… 86

Programming Ranges ………………………………………………. 88

Reset Values ………………………………………………………... 89

Interface Cable ……………………………………………………… 90

Warranty Information ……………………………………….… 91

Service Information ………………………………………….… 93

2

Page 4

General Information

Single output programmable DC power suppl ies.

Output voltage is: 0 to 30.0 V for Model 912 0

0 to 20.0 V for Model 912 1

0 to 60.0 V for Model 9122

Output current is: 0 to 3.00 A for Model 9120

0 to 5.00 A for Model 9121

0 to 2.50 A for Model 9122

The power supply can be locally or remote controlled.

Interfaces: RS232 (Standard)

The commands available in remote interface mode are

• SCPI (Standard Commands for Programmable Instruments) commands

(SCPI 99 standard)

Page 5

4

Page 6

Features

• Constant Voltage / Constant C urrent modes of operation

This power supply can operate in either constant voltage or constant current

modes. The passing from one mode of operation to another is automatic.

The active mode of operation is indicated using two indicators:

CV – constant voltage mode of operation

CC – constant current mode of operation

• Overvoltage protection

Overvoltage protection circuit can be locally or remote activated.

When it is active, ovp indicator is displayed.

• Output on / off

When output off, output voltage is 0 V.

This permits a zero output voltage without switching off the power supply.

• 100 operating states storage

States are identified by location number and name.

Stored parameters are: voltage limit, voltage step, overvoltage protection level,

state of overvoltage protection circuit, current limit, current step, voltage trigger

value, current trigger value, trigger delay value, trigger source, stored state

name, state of display, output state.

After power on, state 0, named power_up will become the current operating

state.

• error messages

Errors are stored in a 20 locations FIFO (first in first out) queue.

They can be read in local mode (error number returned) or in remote operation

mode (error number and definition returned).

Every error is announced by a beep and the err indicator.

5

Page 7

6

Page 8

Local mode operation

Front panel keys description

Memory key

Note: Memory location 00 is the “Power-up” state. When the unit is powered

up, the power supply will set itself to the settings stored in location 00.

Note: If you press the Recall button while turning the power on, the power

supply will power up using memory location 01 parameters.

This button is used to store power supply’s current operating state in nonvolatile memory. Using this function all operating parameters are saved so they

can be recalled. You can store 100 differe nt operating states in the non-volatile

memory.

Stored parameters are: voltage limit, voltage step, overvoltage protection level,

state of overvoltage protection circuit, current limit, current step, voltage trigger

value, current trigger value, trigger delay value, trigger source, stored state

name, state of display, output state.

By pressing Memory key, you enter in Memory menu.

By turning the knob following options will be displayed:

Store State

Name State

Exit

7

Page 9

Options are selected by pressing Memory key when the desired option is

displayed.

Memory menu overview

Store State

Store State option will store the current operating state without setting a

name for this state. The state will be identified using location number in

non-volatile memory and the default name.

By pressing Memory key, state number and state name are displayed in

ascending order by turning the knob.

In this menu, Exit option is available, too. In this case, you leave the store

operation mode, without changing anything. No Change message will be

displayed and the power supply returns to the previous state (the state

before entering Memory menu).

The states are scrolled using the knob.

A location is selected by pressing Memory key. If the location you choose

is already written, it is overwritten (without an y warning) with the current

state parameters, but the name (the set one or the default one remains

unchanged). Done message will be displayed.

Name State

Name State option allows you to set a name for the current state (you can

also change a name set before).

The state name can have up to 10 charatcters. The default name is 10 blank

characters.

By pressing Memory key, state number of non-volatile memory locations is

displayed in ascending order by turning the knob.

In this menu Exit option is available, too. In this case, you leave the store

operation mode, without changing anything. No Change message will be

displayed and the power supply returns to the previous state (the state

before entering Memory menu).

The states are scrolled using the knob.

8

Page 10

By pressing Memory key again, state name can be set.

Important note!

A state name must be set here, or the state will not be saved.

When setting the name, selected digit has the cursor underneath it.

Characters of the name are selected by rotating the knob. When desired

ASCII character is displayed, you can pass to another digit selection using >

< cursor position keys. When the name is set, you press Memory again and

the current state is stored in the selected location of the non-volatile

memory. Done message wil l be displayed.

Important note!

Store State option will store the parameters of current operation state and will

not set a name for the stored state.

NameState option will set a name for the the state to be saved.

Exit

Exit option allows you to leave th e store operation mode, without changing

anything. No Change message will be displayed and the power supply

returns to the previous state (the state before entering Memory menu).

Important note!

If you enter in the Memory menu and no action takes place for approx. 20

seconds, the power supply leaves the Memory menu. No Change message is

displayed and the power supply returns to the previous state (the state before

entering Memory menu).

9

Page 11

Storing states in front panel mode

To store an operating state in front panel mode you must follow the steps

described bellow:

1. Set the power supply in the desired operating state

Stored parameters are: voltage limit, voltage step, overvoltage protection level,

state of overvoltage protection circuit, current limit, current step, voltage trigger

value, current trigger value, trigger delay value, trigger source, stored state

name, state of display, output state.

Voltage step, current step, voltage trigger value, current trigger value, trigger

delay value, trigger source and state of display parameters can be set only over

the remote interface, using SCPI commands (for more details, see SCPI

Commands section)

The rest of the parameters can be set both from the front panel or over the

remote interface.

2. Enter the Memory menu

By pressing Memory key, you enter Memory menu.

By turning the knob, following options are displayed:

Store State

Name State

Exit

Options are selected by pressing Memory key again.

3. Select StoreState option

When Store State or Name State options are selected, state number and state

name (if available) of non-volatile memory locations are displayed in ascending

order, by turning the knob.

If Store State option is selected, the stored operating state has the default

name, if none set before.

Store State option will store the parameters of current operation state and will

not set a name for the stored state.

The saving action is realized by pressing Memory key. After that, Done

message will be displayed.

10

Page 12

and the power supply returns to normal mode.

4. Select Name State option

In order to select this option , Memory key must be pressed again.

NameState option will set a name for the the state to be saved.

The saving action is realized by pressing Memory key. After that, Done

message will be displayed.

Important note!

The power supply allows 100 states to be stored. When shipped, the power

supply has power_up state stored and all the other locations are empty.

The stored states are kept in a non -volatile memory, so they won’t be lost when

the power supply is turned off.

A state location can be overwritten without any notification from the power

supply.

Done

11

Page 13

Recall key

This key is used to recall an operating state from the storage locations in nonvolatile memory. You can recall any operating state from 100 different

operating states stored in the non-volatile memory. The recalled state becomes

the current operating state.

By pressing Recall key, you enter in Recall menu.

By turning the knob, following options will be displayed:

00: power_up

01:

02: Test_mode

etc. (all 100 operating states are displayed)

Exit

Reset

Options are selected by pressing Recall key when the desired option is

displayed.

Recalling action is terminated by pressing Recall key. After that, Done

message will be displayed.

Recall menu overview

01: State 1

When a state option is selected, the stored state recalled becomes the current

operating state of the power supply.

Recalled parameters are: voltage limit, voltage step, overvoltage protection

level, state of overvoltage protection circuit, current limit, current step,

voltage trigger value, current trigger value, trigger delay value, trigger

source, stored state name, state of display, output state.

12

Page 14

Exit

Exit option allows you to leave the Recall menu, without changing

anything. No Change message will be displayed and the power supply

returns to the previous state (the state before entering Recall menu).

Reset

Reset option allows you to reset the power supply without switching off

(for more details see Reset Values section) .

00: power_up

After power up, the power supply recalls state 0.

When delivered, power_up state has the following parameters:

U

I

= 1 V

lim

= maximum available current value (see Programing ranges

lim

table, in the Techincal Specifications section)

OVP trip level = maximum programmable value (see Programing

ranges table, in the Techincal Specifications section)

Output state on

The rest of the parameters have the default value after reset. (see Reset

values table, in the Techincal Specifications section)

For this operating state, Name State option is not available (so the state

name cannot be changed ), but Store State option is available (so the user

can save the desired state for power up) .

Important note!

If you enter Recall menu and no action takes place for approx. 20 seconds, the

power supply leaves the Recall menu. No Change message is displayed and

the power supply returns to the previous state (the state before entering Recall

menu).

13

Page 15

Recalling states in front panel mode

To recall an operating state in front panel mode, you must follow the steps

described bellow:

1. Enter the Recall menu

By pressing Recall key, you enter the Recall menu.

By turning the knob, following options are displayed:

01: State 1

02: Test_mode

etc. (all 100 operating states are displayed)

Exit

Reset

2. Select the operating state

By using < > keys and turning the knob all operating states stored in nonvolatile memory are displayed. An operating state is selected by pressing

Recall key when desired state is displayed.

3. Recall the operating state

When Recall key is pressed, the selected operating state becomes the current

operating state of the power supply, after Done message is displayed.

14

Page 16

Limit key

The power supply works in 2 modes:

ØØ Limit mode

ØØ Normal mode

In limit mode limit values of voltage and current are displayed. These are the

programmed values (from the front panel or over the remote interface).

Limit key is used to get the power supply to limit mode. In this mode, lmt

indicator and limit values for voltage and current will be displayed.

In limit mode, limit values can be adjusted by turning the knob. To adjust

values in limit mode, > < keys must be used to select the digit you want to

adjust. The selected digit has the cursor underneath it. To increase / decrease

value of digit, knob must be turned.

After setting the limit values, by pressing Limit key, the power supply returns

to normal mode. It also returns to normal mode after several seconds (display

time-out) with no action.

In normal mode, voltage and current values measure d at the output terminals of

the power supply are displayed.

When you turn on the power supply, the cursor is placed underneath the voltage

value (units digit). To pass from voltage value to current value Volt/Amp key

must be used. This key toggles between voltage value and current value.

15

Page 17

Modes of operation

Depending on the application, the power supply can be used as a constant

current source or as a constant voltage source.

In order to understand constant current and constant voltage operation, a

numeric example will be used.

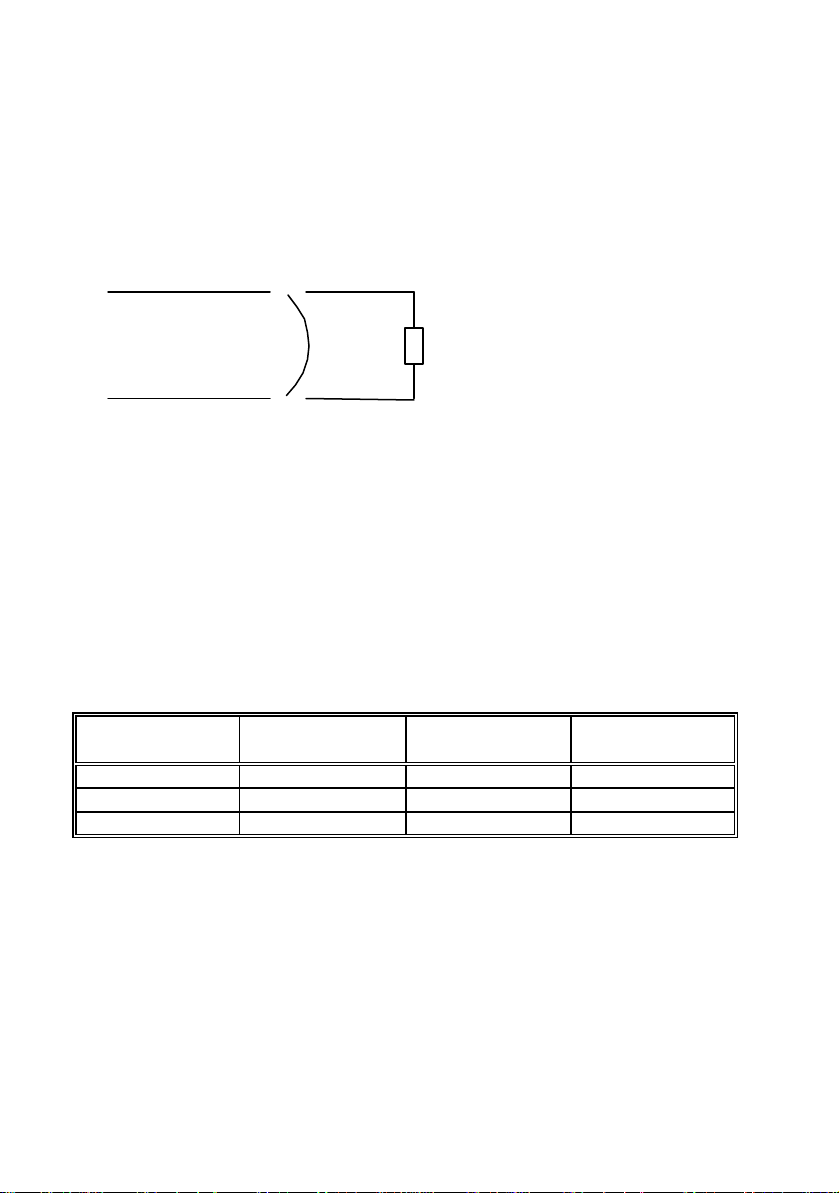

U

out

R

Let’s consider a resistor connected to the output terminals of the power supply

(R resistor).

Limit (programmed) values are:

U

=5V

lim

I

=2A

lim

U

and I

out

are the voltage and current values measured at the output

out

terminals of the power supply.

Depending on the resistor value, the power supply will pass from one mode of

operation to another

R (Ù) U

(V) I

out

(A) Mode of

out

operation

10 5 0.5 CV

5 5 1 CV

1 2 2 CC

In constant voltage mode, programmed voltage value is equal with the voltage

value measured at the output terminals of the power supply. (U

out

= U

lim

).

Using Ohm’s law, depending on the resistor’s value, output current value can

be calculated and it is smaller than current limit value (see first and second

rows of the table).

The power supply will remain in CV operation as long as the limit current

value is greater than output current value.

16

Page 18

When the resistor’s value decreases so the output current value becomes equal

to the current limit value, power supply will go to constant current operation

(see third row of the table) .

If the resistor value is R = 1 Ù, for U

= 5V, using Ohm’s law the output

out

current is 5A. But this value is greater than current limit value, so the power

supply limits the output current to the limit programmed value. That is why in

the third row of the table I

= 2 A. In this case, U

out

is changed, too. Using

out

Ohm’s law again, the output voltage is calculated using output current value

and the resistor value, so it is 2 V.

So the power supply will go to constant current operation when the output

current value becomes equal or greater than the limit value.

When the output current value becomes smaller than the limit value (by

changing resistor’s value), the power supply will go back to constant voltage

operation.

In conclusion:

CV: U

out

= U

lim

and I

out

< I

lim

CC: U

out

< U

lim

and I

out

= I

lim

The following section will explain how to get the power supply in constant

current operation mode and in constant voltage operation mode.

17

Page 19

Constant current operation

In constant current operation, current values in limit mode and normal mode are

the same, but voltage values are not.

To set the power supply in constant current operation, you must follow the

steps described bellow:

1. Select the limit values for voltage and current parameters (U

I

), depending on the application

lim

2. Calculate resistor’s value R

load

.

Using Ohm’s law, calculate the resistor’s value that allows the power supply to

go in constant current mode of operation.

3. Turn on the power supply and set limit mode operation

Press Limit key to set limit mode.

Now the power supply displays limit values for voltage and current. lmt

indicator is displayed, too. (it will be displayed until you go to normal mode).

4. Set voltage and current limit values

Limit values must be chosen so the following conditions are respected:

U

I

lim

> I

lim

· R

,so U

load

lim

lim

< U

< I

out

out

Voltage and current limit values are set using:

Volt / Amp key to select current value,

> < keys to select the digit to adjust (selected digit has cursor underneath it)

knob to set the digit to desired value

5. Set normal mode operation

You can set normal mode operation by pressing Limit key or let the display

time-out (after several seconds with no action, power supply returns to normal

mode operation).

6. Disable the output of the power supply

By pressing On / Off key, the output of the power supply can be disabled.

7. Connect R

R

resistor is connected between (-) and (+) terminals of the power supply.

load

resist or to the output terminals

load

lim

and

18

Page 20

8. Enable the output of the power supply

By pressing On / Off key, you enable the output.

Power supply goes to normal mode operation and CC indicator will be

displayed. In this case constant current operation is active.

If CV indicator will be displayed, you must set a higher value for voltage limit.

Important note!

By turning the knob, voltage and current limit values can be adjusted.

The adjustion of the voltage limit value can be seen only in limit mode.

The adjustion of the current limit value can be seen in both limit mode and

normal mode.

Important note!

Constant current operation can be used depending on the application.

It is very useful to protect the circuitry connected to the power supply from

accidently increases of current value.

19

Page 21

Constant voltage operation

In constant voltage operation, voltage values in limit mode and normal mode

are the same, but current val ues are not

To set the power supply in constant voltage operation, you must follow the

steps described bellow:

1. Select the limit values for voltage and current parameters (U

I

), depending on the application

lim

2. Calculate resistor’s value R

load

.

Using Ohm’s law, calculate the resistor’s value that allows the power supply to

go in constant current mode of operation.

3. Turn on the power supply and set limit mode operation

Press Limit key to set limit mode.

Now the power supply displays limit values for voltage and current. lmt

indicator is displayed, too. (it will be displayed until you go to normal mode).

4. Set voltage and current limit values

Limit values must be chosen so the following conditions are respected:

U

I

lim

< I

lim

· R

load

,so

U

lim

lim

< U

< I

out

out

lim

and

Voltage and current limit values are set using:

Volt / Amp key to select current value,

> < keys to select the digit to adjust (selected digit has cursor underneath it)

knob to set the digit to desired value

5. Set normal mode operation

You can set normal mode operation by pressing Limit key or let the display

time-out (after several seconds with no action, power supply returns to normal

mode operation).

6. Disable the output of the power supply

By pressing On / Off key, the output of the power supply can be disabled.

7. Connect R

R

resistor is connected between (-) and (+) terminals of the power supply.

load

resistor to the output terminals

load

20

Page 22

8. Enable the output of the power supply

By pressing On / Off key, you enable the output.

Power supply goes to normal mode operation and CV indicator will be

displayed. In this case constant voltage operation is active.

If CC indicator will be displayed, you must set a higher value for current limit.

Important note!

By turning the knob, voltage and current limit values can be adjusted.

The adjustion of the current limit value can be seen only in limit mode.

The adjustion of the voltage limit value can be seen in both limit mode and

normal mode.

21

Page 23

On / Off key

On / Of f key is used to enable / disable the output of the power supply from the

front panel. By pressing On / Off key, you alternate these two states: output on

/ output off.

When the output is off, power supply displays:

Output off

The indicators according to power supply’s state will also be displayed (e.g.:

ovp, err indicators).

When output off, output voltage is 0 V. So this command permits a zero output

voltage without switching off the power supply.

When output off, knob is disabled, to prevent the unwanted ch anges in voltage

and current values. The keys from the front panel are not disabled. You can

also go to limit mode and set limit values for voltage and current. In this case

both lmt and off indicators will be displayed.

When output off, by press ing On / Off key,the output is enabled. The power

supply will go to normal mode of operation (voltage and current measured

values are displayed) or to limit mode of operation (voltage and current limit

values are displayed), depending on the state the power supply was before

disabling the output.

The output state of the power supply is one of the parameters stored in nonvolatile memory for each state .

22

Page 24

Remote / Local key

This key has a double function, depending on the state of the power supply

(remote mode or local mode).

Local Mode function

While in local mode of operation, Remote / Local key has a double function,

depending on the state of the power supply.

If the power supply is in calibrating mode, Remote / Local key is used to leave

the calibrating mode and return to normal mode of operation (for more details,

see Calibration Overview section)

When in local mode of operation, by pressing Remote / Local key, RS 232

interface parameters are displayed:

Available settings for RS232 interface:

♦ Baud rate: 1200, 2400, 4800, 9600 (factory setting: 9600)

♦ Parity and data bits: None – 8 data bits (factory setting)

Odd – 7 data bits

Even – 7 data bits

♦ Number of start bits: 1 bit (cannot be changed)

♦ Number of stop bits: 1 bits (cannot be changed)

Set RS – 232 remote interface parameters

1. Select RS – 232 interface

Press Remote / Local key. Following message will be displayed:

RS - 232

Press Remote / Local key again. Baud rate settings will be displayed.

2. Select baud rate

By turning the knob, you will view available baud rate.

When desired baud rate is displayed, press Remote / Local key. Parity settings

will be displayed.

23

Page 25

Select parity

By turning the knob, you will view available parities.

When desired parity is displayed, press Remote / Local key.

These settings are saved in non-volatile memory, so they don’t change when

you turn of the power supply.

If you didn’t change anything of the previous set parameters, the power supply

will display No Change message.

If you did change a single parameter from the previous set parameters, Saved

message will be displayed.

After one of these messages is displayed for several seconds, you return to the

previous state.

Important note!

If you enter in the Remote / Local submenu and no action takes place for

approx. 20 seconds, the power supply will leave this submenu. No Change

message is displayed and the power supply returns to the previous state (the

state before entering this submenu).

Important note!

While in local mode, if by pressing Remote / Local key

message will be displayed, it means that the RS-232 remote interface

parameters cannot be read from the non-volatile memory. The power supply

must be turned off and then turned on.

If this message is displayed again while pres sing Remote / Local key in local

mode, the power supply must be delivered to B&K Precision for service.

Remote interface function

When in remote interface mode of operation, rmt indicator will be displayed.

In this case, all front panel keys are disabled, except Remote / Local key,

which is active. This allows you to put the power supply in local mode of

operation, so all front panel keys become active.

I / O Error

24

Page 26

Errors / Calibrate key

This key has a double function: errors related in normal mode (see this section)

and calibration related in calibration mode (see calibration section).

There are 2 types of errors: user defined errors and errors defined by SCPI 1999

standard.

Every time an error is generated, a beep will be generated by the power supply

and err indicator will be displayed.

Generated errors are saved in an error queue, in FIFO (first in – first out) order.

If more than 20 errors are generated, the last error is overwritten with –350

error (queue overflow error) and no more errors are saved.

While in remote mode (rmt indicator is displayed), errors are erased from the

queue as you read them.

By pressing Errors / Calibrate key, you enter Errors / Calibrate menu. By

turning the knob, following options are displayed:

Errors

Cal String

Exit

Options are selected by pressing Errors / Calibrate key when the desired

option is displayed.

Errors

Errors option allows you to view the generated errors.

If you press Errors / Calibrate key again, by turning the knob you can see

all generated errors. Error’s code will be displayed. When all errors were

viewed, if continue to turn the knob, they will be displayed again.

After you viewed all errors, you press Errors / Calibrate key again. The

power supply will erase all the errors from the error queue and Errors

Erased message will be displayed.

25

Page 27

After several seconds the power supply will go back to normal mode. The

err indicator will not be displayed anymore.

If there are no errors in the queue and you select Errors option in order to

view the errors, the power supply will display:

No Errors

And then it will return to normal mode.

There are 3 ways of erasing the error queue:

♦ By turning off and then turning on the power supply

♦ By pressing Errors / Calibrate key after errors are displayed, in local

mode

♦ By reading errors, in remote operation.

Important note!

If you let the display time out, the power supply will go back to normal

mode, without erasing the error queue.

Cal String

The power supply allows you to store a calibration message. It may contain

last calibration date, the date when the next calibration must be done or the

name and the phone number of the person to contact for a new calibration.

This message can have up to 40 characters. It can be set only remote

interface and it is saved in non-volatile memory.

When delivered, the power supply has the following calibration string set:

“CALIBRATION DATE: MMM/DD/YYYY” (for example:

CALIBRATION DATE: Feb/11/2005)

Cal String option allows you to view the calibration string.

If you press Errors / Calibrate key when Cal String option is displayed,

the calibration message will be displayed. To scroll through the calibration

message, you must press < key. To increase the scrolling speed, you must

press > key. To decrease scrolling speed, you must press < key.

26

Page 28

Exit

Exit option allows you to leave this menu, without changing anything.

Exiting message will be displayed and the power supply returns to the

previous state (the state before entering this menu).

Important note!

If you enter in the Errors / Calibrate menu and no action takes place for

approx. 20 seconds, the power supply leaves this menu. Exiting message is

displayed and the power supply returns to the previous state (the state before

entering Errors / Calibrate menu).

27

Page 29

Calibration overview

Calibration is a procedure that ensures that the power supply will work

properly, with parameters specified within Technical Specification section.

Before initiating the calibration procedure, the following conditions must be

assured:

§

disconnect any loads connected to the power supply and turn it on

§

§

let the power supply turned on for 1 hour, with no loads connected before

§

you start the calibration procedure

§

calibration ambient temperature must be 25 0C

§

§

ambient relative humidity must be less then 80%.

§

Recommended calibration interval is 1 year.

Important note!

In order to perform the calibration procedure, a digital multimeter is needed. It

must have the following characteristics:

Voltage resolution: 0.1 mV

Current resolution: 0.01 mA

Acurracy: 0.01 %

Calibration security code

To prevent accidental or unauthorized calibration procedures, the power supply

has a calibration security code. This security code is optional, so you may have

it or not. The power supply will work properly in both cases.

Security code may contain numbers (0..9), small letters (a..z) and spaces (“ “).

Any of these characters may be used as the first character in security code.

Security code may contain up to 11 characters. But it is not necessary for you to

use all 11 char acters for the security code.

The security code is saved in non-volatile memory and it doesn’t change when

you turn on or turn off the power supply.

When delivered, power supply has the following security code: 0000

In order to initiate the calibration procedure, first you must unsecure the power

supply (if a security code is set).

28

Page 30

Unsecure procedure for calibration

To unsecure the power supply, the next steps bust be followed:

1. Turn on the power supply in calibrating mode

To enter calibrating mode, you must turn on the power supply while pressing

Errors / Calibrate key. You release the key after the long beep. After that, the

power supply will display:

Calibrating Mode

Secured

if the power supply is secured (if the power supply has a security code set). If

this message is displayed, go to step 2.

or :

Calibrating Mode

Unsecured

if the power supply is not secured (if the power supply has been turned off after

the unsecure procedure).

If the power supply is already unsecured, you can proceed with calibration (see

Calibration procedure section)

2. Enter security code

Press OVP / Secure key. The power supply will display:

Security code:

_ _ _ _ _ _ _ _ _ _ _

Here you must enter the security code, using > < keys and knob. The selected

digit has the cursor underneath it. If you set the digit to the desired value, you

must press > key and go to the next digit, if you want.

After you entered the security code, press OVP / Secure key and if the security

code is correct, the power supply will display:

Calibrating Mode

Unsecured

29

Page 31

From this moment you can proceed with calibration (see Calibration

p rocedure section) or you can go back to normal mode operation.

From now on, the power supply remains unsecured until you set a new secure

code.

If the security code you entered is not correct, power supply will display:

Security code:

invalid

for 1 second. 703 error (Invalid secure code) and a short beep will be

generated. You can see the error in normal mode operation (by pressing Local

key).

After that power supply will display again:

Security code:

_ _ _ _ _ _ _ _ _ _ _

and you must enter security code again , using < > keys and knob. If you don’t

remember the correct security code, you may follow the hardware unsecure

procedure (see Hardware unsecure procedure ).

Important Note!

While in calibrating mode, before you unsecure the power supply, only Local,

< > and Secure keys are active (all the rest are locked). The knob is also active.

Local key can be used at any moment of unsecure procedure to leave

calibrating mode and go back to normal mode operation. Secure key is used in

unsecure procedure of the power supply (allows you to enter and validate the

secure code).

While in calibrating mode, after you unsecure the power supply, only Local,

Secure, < > and Calibrate keys are active. The knob is also active.

Local key is used to leave calibrating mode and go back to normal mode

operation.

Secure key is used to set a new security code (you may introduce a new

security code and secure again the power supply).

Calibrate key is used to proceed with calibration.

Attention!

Local key is active all the time while in calibrating mode and by pressing it the

power supply returns to normal mode. Leaving the unsecure procedure does not

30

Page 32

change anything concerning the secure state of the power supply (secured or

unsecured).

After you changed the security code or unsecured the power supply, you can go

back to normal mode by pressing Local key. (You can come back to

calibrating mode only by turning off the power supply and starting it in

calibrating mode).

But once you started the calibration procedure, it is recommended to finish it

and to go back to normal mode by turning off and on the power supply.

31

Page 33

Hardware unsecure procedure for calibration

This procedure may be used to unsecure the power supply if you forgot the

security code.

To unsecure the power supply without using the security code, follow the next

steps:

1. Turn off the power supply. Disconnect the power cord and all loads

connected to the power supply.

2. Remove power supply’s cover. Set J6 jumper for hardware unsecuring

mode.

J5 J6

J5 J6

Normal

unsecuring

3. Connect the power cord to the power supply. Turn on th e power supply in

calibrating mode.

4. Unsecure the power supply.

To unsecure the power supply you must press Secure key. Power supply will

display:

Calibrating Mode

Secured

Press again Secure key the power supply will display:

Security code:

_ _ _ _ _ _ _ _ _ _

Here any security code may be introduced, since it is not verified by the power

supply.

Press again Secure key and you will unsecure the power supply. It will display:

Calibrating Mode

Unsecured

Hardware

unsecuring

32

Page 34

The power supply remains unsecured until you enter a new security code.

Important note!

Even if you are in calibrating mode, you cannot set a security code as long as

the J6 jumper is in hardware unsecuring position.

5. Set J6 jumper for normal unsecuring mode.

Important note!

If you turn on the power supply in either normal mode or calibrating mode and

J6 jumper is in hardware unsecuring position, error 701 (Calibration security

disabled by jumper) will be generated.

6. Turn off the power supply and reassemble it.

33

Page 35

Calibration procedure

Before initiating the calibration procedure, the following conditions must be

assured:

§

disconnect any loads connected to the power supply and turn it on

§

§

let the power supply turned on for 1 hour, with no loads connected before

§

you start the calibration procedure

§

calibration ambient temperature must be 25 0C

§

§

ambient relative humidity must be less then 80%.

§

On calibration procedure there are three parameters that must be calibrated:

voltage, OVP and current.

You can leave the calibration procedure at any time by turning off the power

supply or by pressing Local key.

But once you started the calibration procedure, it is recommended to finish it

and to go back to normal mode by turning off and then turning on the power

supply.

In order to be sure that the power supply will work properly in normal mode

after you leave the calibration procedure, you must turn off the power supply.

Recommended calibration interval is 1 year.

Before calibrating the power supply you must unsecure it, if secured (see

Calibration Overview section).

After you unsecured the power supply and you pressed Calibrate key, you go

to Calibrate menu. By turning the knob next options are available:

1. Volt Zero Scale

2. Volt Full Gain

3. OVP

4. Curr Zero Scale

5. Curr Full Gain

Options are selected by pressing Calibrate key.

Important note!

In order to perform a correct calibration the calibration procedures from the

Calibrate menu must be followed in the order they are displayed by the power

supply.

34

Page 36

Voltage Calibration Procedure

After you unsecured the power supply and you pressed Calibrate key, you

entered calibrate mode.

Volt Zero Scale Calibration

1. Select Volt Zero Scale calibration procedure

In order to start voltage calibration procedure, you must select Volt Zero Scale

option.

The power supply will display:

You select this option by pressing Calibrate key.

The power supply will display:

2. Initiate DAC calibration procedure

Connect a digital voltmeter to the output terminals of the power supply. After

that, you must adjust DAC value displayed by the power supply until the

voltmeter indicates the closest possible to 0.000 V value.

For this, you use > < keys and the knob.

It is not necessary to disconnect the digital voltmeter, since you will need it

later on calibration procedure!

3. Initiate ADC calibration procedure

Press Calibrate key. This will initiate ADC calibration procedure. The power

supply will display:

After ADC calibration, power supply will return to Calibrate menu Volt Full

Gain calibration procedure.

Calibrating Mode

Volt Zero Scale

Volt Zero Scale

DAC:1999

Volt Zero Scale

ADC Calibrating

35

Page 37

Volt Full Gain Calibration

1. Select Volt Full Gain calibration proce dure

In order to finish voltage calibration procedure, you must select Volt Full Gain

option.

The power supply will display:

You select this option by pressing Calibrate key.

The power supply will display:

2. Initiate DAC calibration procedure

Connect a digital voltmeter to the output terminals of the power supply. After

that, you must adjust DAC value displayed by the power supply until the

voltmeter indicates the correct voltage value, depending on the model of the

power supply (see the tabl e bellow).

For this, you use > < keys and the knob

3. Initiate ADC calibration procedure

Press Calibrate key. This will initiate ADC calibration procedure. The power

supply will display:

After ADC calibration, power supply will return to Calibrate menu, OVP

calibration procedure.

Calibrating Mode

Volt Full Gain

Volt Full Gain

DAC:31470

Power supply model Voltage value for

Volt Full Gain calibration

9120 16.3840 V

9121 16.3840 V

9122 32.7680 V

Volt Full Gain

ADC Calibrating

36

Page 38

OVP Calibration

While performing this calibration procedure, the power supply must have no

loads connected to the output terminals.

1. Select OVP calibration procedure

In order to initiate OVP calibration procedure, you must select OVP option.

The power supply will display:

You select this option by pressing Calibrate key.

The power supply will displ ay:

Important note!

This calibration procedure will take several minutes.

After OVP calibration, power supply will return to Calibrate menu, Current

calibration procedure.

Calibrating Mode

OVP

Calibrating OVP

Please wait…

37

Page 39

Current Calibration Procedure

Current calibration procedure must be permormed after Voltage calibration

procedure.

Current Zero Scale Calibration

While performing this calibration procedure, the power supply must have no

loads connected to the output terminals.

1. Select Curr Zero Scale calibration procedure

In order to start current calibration procedure, you must select Curr Zero Scale

option.

The power supply will display:

2. Initiate DAC calibration procedure

You select this option by pressing Calibrate key. So Current Zero Scale

calibration procedure will be initiated.

The power supply will display:

After a while, the power supply will display:

Important note!

This calibration procedure will take several minutes.

Calibrating Mode

Curr Zero Scale

Curr Zero Scale

ADC:Calibrating

Curr Zero Scale

DAC:Calibrating

After Current Zero Scale calibration procedure, power supply will return to

Calibrate menu, Curr Full Gain calibration procedure.

38

Page 40

Curr Full Gain Calibration

1. Select Curr Full Gain calibration procedure

In order to finish current calibration procedure, you must select Curr Full

Gain option.

The power supply will displ ay:

You select this option by pressing Calibrate key.

The power supply will display:

2. Initiate DAC calibration procedure

In order to initiate Curr Full Gain calibration procedure, you must connect a

digital ammeter to the output terminals of the power supply.

If don’t connect a digital ammeter within 30 seconds, the power supply will

display:

and it will return to Calibrate menu.

After you connected the digital ammeter, you must adjust DAC value displayed

by the power supply until the ammeter indicates indicates the correct current

value, depending on the model of the power supply (see the table bellow).

For this, you use > < keys and the knob

3. Initiate ADC calibration procedure

Press Calibrate key. This will initiate ADC calibration procedure. The power

supply will display:

Calibrating Mode

Curr Full Gain

Curr Full Gain

Connect Ammeter

Calibrating Mode

CC Not Set

Power supply model Current value for

Curr Full Gain calibration

9120 2.62144 A

9121 2.62144 A

9122 1.31072 A

39

Page 41

Curr Full Gain

ADC Calibrating

After ADC calibration, power supply will return to Calibrate menu.

In this moment, the calibration procedure is finished. By presing Local key, the

power supply will return to local mode.

Important note!

In order to be sure that the power supply will work properly in normal mode

after you leave the calibration procedure, you must turn off the power supply.

40

Page 42

OVP / Secure key

This key has a double function: OVP settings in normal mode operation and

secure key in calibration mode operation (for the latter see Calibration

section).

In this section OVP functions will be described.

OVP circuit prevents the output voltage from rising above a programmed

voltage value. So the load connected to the output terminals is protected to

overvoltage situations.

Overvoltage protection circuit is activated when output voltage value becomes

equal or greater than the programmed trip level for overvoltage protection

circuit.

OVP menu overview

By pressing OVP / Secure key, you enter OVP menu.

Here, programmed OVP trip level will be displayed.

When you turn on the power supply, OVP trip level is OVP trip level value

saved at power_up state (state 0). This value can be changed by the user (and

saved in power_up state if wanted).

Here you can set desired OVP trip level, by using > < keys to select the digit

you want to adjust (sel ected digit has the cursor underneath) and knob to set the

digit to desired value.

The programming range for OVP trip level depends on the model of the power

supply (see the table bellow):

Power supply

model

9120 1 V 33 V

9121 1 V 22 V

9122 1 V 63 V

The OVP trip level you set is programmed by pressing OVP / Secure key.

After that, you enter the OVP menu.

By turning the knob, following options are displayed:

OVP min value OVP max value

41

Page 43

OVP On

OVP Clear

OVP Off

Options are selected by pressing OVP / Secure key when the desired option is

displayed.

OVP On

OVP On option enables overvoltage protection circuit. OVP trip level is the

level value you programmed on Level option (after you first pressed OVP /

Secure key).

If you want to keep the previously programmed trip level, you simply press

OVP / Secure key, without changing anything.

If you enable the overvoltage protection circuit, when you return to normal

mode, ovp indicator will be displayed.

OVP Off

OVP Off option makes OVP trip level equal to maximum availabale OVP

value , no matter what what value is set in OVP menu (but the value from

OVP menu does not change).

For maximum available OVP value see the table above.

If you select OVP Off option, when you return to normal mode, ovp

indicator will not be displayed anymore.

Important note!

When OVP On option is selected, OVP trip level is equal to the

programmed level, shown in OVP menu.

When OVP Off option is selected, OVP trip level is equal to the maximum

available value for this parameter, depending on the model of the power

supply (see the table above). In this case, the programmed OVP trip level,

shown in OVP menu does not change!

42

Page 44

Output Off

OVP Clear

OVP Clear option is used to clear to OVP condition (for more details about

how you get back to normal mode after OVP level was tripped, see next

section).

After you select the desired option, a message will be displayed.

If you didn’t change anything of the previous set parameters, the power

supply will display No Change message.

If you did change a single parameter from the previous set parameters Done

message will be displayed.

After one of these messages is displayed for several seconds, you return to

normal mode.

Important note!

If you enter in the OVP menu and no action takes place for approx. 20 seconds,

the power supp ly will leave the OVP menu. No Change message is displayed

and the power supply returns to the previous state (the state before entering

OVP menu).

If the output voltage value becomes equal or greater than OVP programmed

level and the overvoltage protection circuit is enabled, the power supply will

display:

Over Voltage

And the output voltage value will be 0 V (output is disabled).

There are three ways of clearing the OVP condition:

Ø By increasing OVP trip level and clearing the OVP condition

Ø By decreasing the output voltage and clearing the OVP condition

Ø By disabling OVP circuit and by clearing the OVP condition

Important note!

When you turn on the power supply, the overvoltage protection circuit is

enabled and the OVP trip level is equal to the one saved in power_up state

(factory setting: maximum available value ).

43

Page 45

Programming overvoltage protection circuit in front panel mode

If you want to program an OVP trip level and to enable the overvoltage

protection circuit using front panel keys, follow the next st eps:

1. Turn on the power supply

When you turn on the power supply, the overvoltage protection circuit is

enabled and OVP trip level is set to maximum available value for OVP

parameter, depending on the model of the power supply (see table in the

prevous sec tion).

2. Enter the OVP menu and set OVP trip level

By pressing OVP / Secure key, you enter the OVP menu. The power supply

will display the programmed OVP trip level.

For changing this value, you can use > < to select the digit you want to adjust

(selected digit has the cursor underneath) and then turn the knob to set the

desired value.

After you set the desired value for OVP trip level, you press OVP / Secure key.

Important note!

You cannot set an OVP trip level lower than 1 Volt.

The maximum OVP trip le vel value depends on the model of the power supply

(see table in the previous section )

3. Enable the OVP circuit

After you set the desired OVP trip level and you pressed OVP / Secure key,

OVP On, OVP Off and OVP Clear options are available.

To enable the OVP circuit, you select OVP On option by turning the knob

OVP On

4. Exit the OVP submenu

To exit the OVP submenu and to validate all the settings you have done, then

you press OVP / Secure key.

After that, Changed message will be displayed and the power supply return to

previous state (the state before you entered the OVP submenu), in normal mode

operation.

44

Page 46

ovp indicator will be displayed. If you didn’t change anything, the power

supply will display No Change message.

45

Page 47

Clearing the overvoltage condition

Output Off

There are three ways of clearing the OVP condition:

Ø By increasing OVP trip level and clearing the OVP condition

Ø By decreasing the output voltage and clearing the OVP condition

Ø By disabling OVP circuit and by clearing the OVP condition

Attention!

The latter solution disables the OVP circuit, but the first and the second don’t!

In this section we will describe the steps you must follow to clear the OVP

condition in all three cases.

If the output voltage value becomes equal or greater than OVP programmed

level and the overvoltage protection circuit is enabled, the power supply will

display:

Over Voltage

And the output voltage value will be 0 V (output is disabled).

46

Page 48

Clearing OVP condition

Clearing the OVP condit ion by increasing OVP trip level

1. Enter the OVP menu

By pressing OVP / Secure key, you enter the OVP menu.

2. Adjust OVP trip level

When you enter OVP menu, OVP trip level is displayed.

Here, you set OVP trip level to a level higher than the programmed voltage

value (U

lim

).

3. Clear OVP condition

After you set the OVP trip level, you press OVP / Secure key.

Here, OVP On, OVP Off, OVP Clear options are available. Select OVP

Clear option by turning the knob.

OVP Clear

After that, press OVP / Secure key. The power supply will display:

Clear OVP:Done

and after several seconds it will return to normal mode. ovp indicator will be

displayed (the OVP circuit is still enabled).

Important note!

If you enter in the OVP menu and no action takes place for approx. 20 seconds,

the power supply will leave the OVP menu. No Change message is displayed

and the power supply returns to the previous state (the state before entering

OVP menu).

47

Page 49

Clearing the OVP condition by decreasing the output voltage

1. Decrease the output voltage level bellow OVP trip level

Press Limit key and enter limit mode. Limit values of voltage and current will

be displayed. ovp and lmt indicators will also be displayed.

Adjust for output voltage limit to a lower value than the OVP trip level.

Press Limit key to exit limit mode.

2. Enter OVP menu and clear OVP condition

Here you check that the OVP trip level is greater than the output voltage limit

you set. If it isn’t, go to step 1.

Don’t adjust OVP trip level!

Clear OVP condition by turning the knob and selecting OVP Clear option:

OVP Clear

After that, press OVP / Secure key. The power supply will display:

Clear OVP:Done

and after several seconds it will return to normal mode. ovp indicator will be

displayed (the OVP circuit is still enabled).

Important note!

If you enter in the OVP menu and no action takes place for approx. 20 seconds,

the power supply will leave the OVP menu. No Change message is displayed

and the power supply returns to the previous state (the state before entering

OVP menu).

48

Page 50

Clearing the OVP condition by disabling OVP circuit

Output Off

1. Disable OVP circuit

By pressing OVP / Secure key, you enter OVP menu.

Here you disable OVP circuit by turning the knob and selecting OVP Off

option.

OVP Off

It doesn’t matter if you change or not OVP trip level as long as you disable the

OVP circuit. But you must be careful to set it to the right value before you

enable OVP circuit next time.

After you selected OVP Off option and you pressed OVP / Secure key, the

power supply will display

Over Voltage

because you didn’t clear the OVP condition yet

2. Enter OVP menu and clear OVP condition

You enter OVP menu again by pressing OVP / Secure key. Now you clear

OVP condition by turning the knob and selecting OVP Clear option:

OVP Clear

After that, press OVP / Secure key. The power supply will di splay:

Clear OVP:Done

and after several seconds it will return to normal mode. ovp indicator will be

displayed (the OVP circuit is still enabled).

Important note!

If you enter in the OVP menu and no action takes place for approx. 23 seconds,

the power supply will le ave the OVP menu. No Change message is displayed

and the power supply returns to the previous state (the state before entering

OVP menu).

49

Page 51

Rear panel description

+s

-s

+

-

On the rear panel of the power supply there are:

§

RS-232 interface connector

§

§

AC inlet

§

§

Power-line fuse -holder assembly

§

§

Rear output terminals.

§

The sensing terminals (+s and -s) are connected to the outp ut terminals of the

power supply by jumpers.

For the power supply to work properly, the jumpers must be kept in that

position.

50

Page 52

Remote interface

RS – 232 interface is used for remote communication.

For this, you must connect your power supply to a computer terminal (see

Technical Specification section, Interface Cable paragraph).

For remote control of the power supply, SCPI (Standard Commands for

Programmable Instruments) commands are used.

In this section SCPI commands will be described to you.

Here are some conventions used in SCPI standard:

♦ A command consists of a command keyword (command name) and a

parameter (it may be optional or not)

♦ Lower case and upper case letters are considered equivalent

♦ Letter case is used to differentiate between the accepted short form (the

uppercase characters) and the long form (the whole keyword)

♦ Square brackets ( [ ] ) are used to enclose:

♦ a keyword that is optional when programming the command

♦ one or more parameters that are optional when controlling the

instruments.

If no parameter is specified, default parameter is considered.

The braces are not sent with the command string.

♦ Braces or curly brackets ( {} ) are used to enclose one or more parameters

that may be included zero or more times.

The braces are not sent with the command string.

♦ The angle brackets (<>) are used to enclose the type name.

A value of the specified type must be added to the command.

The angle brackets are not sent with the command string.

♦ The vertical bar ( | ) can be read as “or” and it is used to separate

alternative parameter options.

Only one parameter can be sent with the command.

♦ The query form of a command is generated by appending a question mark

to the last keyword. Not all commands have a query form and some

commands exist only in query form.

51

Page 53

SCPI Command Terminators

A command string sent to the power supply must terminate with a new line

character (ASCII decimal code of 10) or a a carriage return character (ASCII

decimal code of 13 )

Important note!

The power supply will go to remote mode of operation (it can accept

commands over RS232 interface) if SYSTem:REMote command is sent.

If other remote interface commands are sent before sending SYSTem:REMote

command, the power supply will respond with Power supply in local mode

message.

52

Page 54

SCPI commands

DISPLAY Subsystem

:DISPlay

[:WINDow][:STATe ] {OFF|ON}

[:WINDow][:STATe ]?

[:WINDow]:TEXT[:Data] <quoted string>

[:WINDow]:TEXT[:DATA]?

[:WINDow]:TEXT:CLEar

MEASure Subsystem

:MEASure

:CURRent[:DC]?

[:VOLTage][:DC]?

OUTPut Subsystem

:OUTPut

[:STATe] {OFF|ON}

[:STATe]?

SOURCE Subsystem

[:SOURce]

:CURRent[:LEVel][:IMMediate][:AMPLitude] {<current>|MIN|MAX|UP|DOWN}

:CURRent[:LEVel][:IMMediate][:AMPLitude]? [MIN|MAX]

:CURRent[:LEVel][:IMMediate]:STEP[:INCrement] {<numeric value>|DEFault}

:CURRent[:LEVel][:IMMediate]:STEP[:INCrement]? [DEFault]

:CURRent[:LEVel][:IMMediate]:TRIGgered[:AMPLitude] {<current>|MIN|MAX}

:CURRent[:LEVel][:IMMediate]:TRIGgered[:AMPLitude]? [MIN|MAX]

:VOLTage[:LEVel][:IMMediate][:AMPLitude] {<current>|MIN|MAX|UP|DOWN}

:VOLTage[:LEVel][:IMMediate][:AMPLitude]? [MIN|MAX]

:VOLTage[:LEVel][:IMMediate]:STEP[:INCrement] {<numeric value>|DEFault}

:VOLTage[:LEVel][:IMMediate]:STEP[:INCrement]? [DEFault]

:VOLTage[:LEVel][:IMMediate]:TRIGgered[:AMPLitude] {<voltage>|MIN|MAX}

:VOLTage[:LEVel][:IMMediate]:TRIGgered[:AMPLitude]? [MIN|MAX]

:VOLTage:PROTection[:LEVel] {<voltage>|MIN|MAX}

:VOLTage:PROTection:STATe {0|1|OFF|ON}

:VOLTage:PROTection:STATe?

:VOLTage:PROTection:TRIPped?

:VOLTage:PROTection:CLEar

SYSTem Subsystem

:SYStem

:BEEPer[:IMMediate]

:ERRor?

53

Page 55

:VERSion?

TRIGger Subsystem

INITiate[:IMMediate]

TRIGger[:SEQuence]:DELay {<seconds>|MIN|MAX}

TRIGger[:SEQuence]:DELay? [MIN|MAX]

TRIGger[:SEQuence]:SOURce {BUS|IMM}

TRIGger[:SEQuence]:SOURce?

*TRG

Non-SCPI commands

SET {<voltage>|DEF|MIN|MAX}[,<current>|DEF|MIN|MAX]

SET?

CALibration:MESSAGE <quoted string>

CALibration:MESSAGE?

SYSTem:REMote

IEEE 488.2 commands

*CLS

*ESE <enable value>

*ESE?

*ESR?

*IDN?

*OPC

*OPC?

*RST

*SAV {0 | 1 | 2 | … | 99}

*RCL {0 | 1 | 2 | … | 99}

*SRE <enable value>

*SRE?

*STB?

*TRG

54

Page 56

SCPI commands overview

System – Related Commands

DISPlay Subsystem

This subsystem controls the presentation of textual information and

measurement data.

:DISPlay[:WINDow][:STATe] {0|1|OFF|ON}

This command turns power supply’s display off and on. When the display is

off, only annunciators are displayed.

You can replace off|on parameters with 0|1 numeric values.

:DISPlay[:WINDow][:STATe]?

This command queries front panel display status. It returns only numeric

values: 0 (off) or 1 (on).

:DISPlay[:WINDow]:TEXT[:Data] <quoted string>

This command displays a message on the front panel. The power supply will

display up to 16 characters and all the rest will be truncated. The string will be

sent between simple or double quotes.

:DISPlay[:WINDow]:TEXT[:DATA]?

This command queries the last sent message. It returns a quoted string.

DISPlay[:WINDow]:TEXT:CLEar

This command clears the message displayed on the front pannel. Power supply

will return to the previous state.

55

Page 57

OUTPut Subsystem

This subsystem controls the output of the power supply.

:OUTPut[:STATe] {0|1|OFF|ON}

This command enables and disables the output of the power supply. You can

replace off | on parameters with 0 | 1 numeric values.

When output is enabled, the power supply will display voltage and current

value measured on the output terminals of the power supply.

When output is disabled, the power supply will display Output Off message

and the annunciators according to power supply’s state.

When output is disabled, output voltage is 0 V and the current is 0.002 A.

After power on reset, output will be disabled.

OUTPut[:STATe]?

This command queries the output state of the power supply. It returns only

numeric values: 0 (for off state) or 1 (for on state)

SYSTem Subsystem

This subsystem contains functions that are not directly related to power supply

performance.

:SYStem:BEEPer[:IMMediate]

This command determines the power supply to generate a beeper right after she

received this command.

:SYSTem:ERRor?

This command queries the power supply’s error queue. Errors are retrieved in a

firs-in-first-out order, so the first generated error is the first read error. When all

the errors were read, err annunciator will not be displayed anymore and error

queue is empty.

The error queue can store up to 20 errors. If more errors will be generated, on

the last position will be written – 350 error (queue overflow) and no more

errors will be stored until the queue is cleared.

:SYSTem :VERSion?

This command queries the SCPI version number for which the instrument

complies. The response is a strin g in the form YYYY.V, where YYYY represents

the year version and V represents the approved revision number for that year

(for example, 1990.0).

56

Page 58

Output Setting Commands

SOURce Subsystem

According to SCPI standard, SOURce node is optional, so the devices which

are primarily sources accept shorter commands.

This subsystem contains commands that program power supply parameters or

commands that query programmed power supply parameters (for example:

programmed values for current and voltage, programmed values for step

current and step voltage, lowest or highest value possible to program for current

and voltage )

:CURRent[:LEVel][:IMMediate][:AMPLitude] {<current>|MIN|MAX|UP|DOWN}

This command allows you to set the current value to the output of the power

supply.

Instead of a numeric value, you can use “MINimum” os “MAXimum”, “Up” or

“DOWN” parameters.

MIN allows you to set the lowest current value, which is 0 A.

MAX allows you to set the highest possible current value for model you have.

With UP or DOWN parameters, this command allows you to increase /

decrease the output value of the current with a preset value (the step you set

with :CURRent:STEP {< numeric value>|DEFault} command, or the default

step of the power supply). When you exceed the minimum or the maximum

possible value by increasing / decreasing the output value, error – 222 (Data out

of range) error will be generated.

:CURRent[:LEVel][:IMMediate][:AMPLitude]? [MIN|MAX]

This command queries the programmed current level. When using MIN or

MAX parameters, the power supply returns the lowest and the highest value

that are possible to program for current.

:CURRent[:LEVel][:IMMediate]:STEP[:INCrement]{<numeric value>|DEFault}

This command allows you to set the current step for CURR UP or CURR

DOWN command. The minimum value for step is 1 mA.

:CURRent[:LEVel][:IMMediate]:STEP[:INCrement]? [DEFault]

This command queries the programmed step value (if no parameter specified),

or the default step value (if DEFault parameter is specified within the

command). The returned value is specified in Amps.

Example: Here is an example of how you program current step value and

how you increase / decrease current output value using step.

57

Page 59

CURR:STEP 0.2 ;program current step value

CURR UP ;increase output current

CURR:STEP 0.5 ;program current step value

CURR DOWN ;decrease output current

Note: If no step value was programmed before CURR UP or CURR

DOWN commands, default step value (0.001 A) will be used.

CURRent[:LEVel][:IMMediate]:TRIGgered[:AMPLitude] {<current>|MIN|MAX}

This command allows you to program the current trigger value, which is

transfered to the output terminals when a trigger signal occurs.

By programming this value, you don’t change the current programmed value.

Instead of a numeric value, you can use “MINimum” or “MAXimum

parameters.

MIN allows you to set the lowest current value, which is 0 V.

MAX allows you to set the highest possible current value for model you have.

:CURRent[:LEVel][:IMMediate]:TRIGgered[:AMPLitude]? [MIN|MAX]

This command queries the programmed current trigger level. When using MIN

or MAX parameters, the power supply returns the lowest or the highest value

allowed for current trigger parameter.

:VOLTage[:LEVel][:IMMediate][:AMPLitude] {<voltage>|MIN|MAX|UP|DOWN}

This command allows you to set the voltage value to the output of the power

supply.

Instead of a numeric value, you can use “MINimum” or “MAXimum”, “Up” or

“DOWN” parameters.

MIN allows you to set the lowest voltage value, which is 0 V.

MAX allows you to set the highest possible current value for model you have.

With UP or DOWN parameters, this command allows you to increase /

decrease the output value of the voltage with a preset value (the step you set

with :VOLTage:STEP {<numeric value>|DEFault} command, or the default

step of the power supply). When you exceed the minimum or the maximum

possible value by increasing / decreasing the output value, error – 222 (Data out

of range) error will be generated.

:VOLTage[:LEVel][:IMMediate][:AMPLitude]? [MIN|MAX]

This command queries the programmed voltage level. When using MIN or

MAX parameters, the power supply returns the lowest or the highest value that

is possible to program for voltage parameter.

:VOLTage[:LEVel][:IMMediate]:STEP[:INCrement] {<numeric value>|DEFault}

58

Page 60

This command allows you to set the voltage step for VOLT UP or VOLT

DOWN command. The minimum value for step is 10 mV.

:VOLTage[:LEVel][:IMMediate]:STEP[:INCrement]? [DEFault]

This command queries the programmed step value (if no parameter specified),

or the default step value (if DEFault parameter is specified within the

command) for voltage. The returned value is specified in Volt.

Example: Here is an example of how you program voltage step value and

how you increase / decrease voltage output value using step.

VOLT:STEP 0.2 ;program voltage step value

VOLT UP ;increase output voltage

VOLT:STEP 0.5 ;program voltage step value

VOLT DOWN ;decrease output voltage

Note: If no step value was programmed before VOLT UP or VOLT

DOWN commands, default step value (0.011 V) will be used.

:VOLTage[:LEVel][:IMMediate]:TRIGgered[:AMPLitude] <current>|MIN|MAX}

This command allows you to program the voltage trigger value, which is

transfered to the output terminals when a trigger signal occurs.

By programming this value, you don’t change the voltage programmed value.

Instead of a numeric value, you can use “MINimum” or “MAXimum

parameters.

MIN allows you to set the lowest voltage value, which is 0 V.

MAX allows you to set the highest possible voltage value for model you have.

:VOLTage[:LEVel][:IMMediate]:TRIGgered[:AMPLitude]? [MIN|MAX]

This command queries the programmed voltage trigger level. When using MIN

or MAX parameters, the power supply returns the lowest or the highest value

allowed for vol tage trigger parameter.

:VOLTage:PROTection[:LEVel] {<voltage>|MIN|MAX}

This command allows you to set the voltage level at which the the overvoltage

protection circuit will be activated. If the output voltage will get equal or

greater than the programmed OVP level, then the power supply will have

output voltage value 0 V (output is disabled).

:VOLTage:PROTection:STATe {0|1|OFF|ON}

This command allows you to disable / enable the overvoltage protection circuit.

After power on reset, the overvoltage protection circuit is enabled and the

programmed OVP value is 33 Volt.

59

Page 61

:VOLTage:PROTection:STATe?

This command queries the overvoltage protection circuit state. The returned

parameter is always a numeric parameter: 0 (for OFF state) or 1 (for ON state).

:VOLTage:PROTection:TRIPped?

This command queries if the protection circuit is tripped or not. The returned

parameter is always a numeric parameter:. 0 for OVP circuit not tripped or 1 for

OVP circuit tripped.

:VOLTage:PROTection:CLEar

This command allows you to clear the overvoltage protection circuit. This

command does not affect the programmed voltage trip level.

After this command the power supply returns to the previous state (output

voltage will have the same value as before OVP was enabled). In this case,

before you clear the protection circuit, you must lower the output voltage below

OVP trip level or increase the OVP trip level above the output voltage value.

Here are some examples of how you work with overvoltage protection circuit

using remote interface commands:

Example 1: Here is an example of how you program the overvoltage

protection circuit using remote interface commands:

VOLT:PROT 5 ;set OVP trip level at 5V

VOLT:PROT? ;responds with programmed OVP trip level (5V)

VOLT:PROT:STAT ON ;enable OVP circuit

VOLT:PROT:STAT? ;responds with OVP circuit state (1 or 0n)

VOLT:PROT:TRIP? ;responds if OVP circuit is enabled

;(0 if output voltage lower than OVP trip

;level and 1 otherwise)

Attention: OVP circuit is enabled if output voltage becomes equal or

greater than the programmed trip level for OVP circuit.

It is not necessary to check every setting with the interogative command!

Here is an example of how you use this commands.

Example 2: Here is an example of how you clear the overvoltage

condition by increasing OVP trip level, using remote interface

commands:

60

Page 62

Let’s say that the output voltage is lower than 5V. No load connected.

VOLT:PROT 5 ;program OVP trip level

VOLT:PROT:STAT ON ;enable OVP circuit

If OVP circuit is already enabled, you don’t have to enable it again!

VOLT 6 ;OVP circuit enabled

When output voltage becomes equal or greater than OVP trip level (here

is 5V), OVP circuit is enabled. Output is disabled and Over Voltage

message will be displayed.

VOLT:PROT 5.5 ;increase OVP trip level

Still output is disabled and Over Voltage message is displayed (because

you didn’t clear OVP condition yet)

VOLT:PROT:CLEAR ;clear OVP condition

Power supply returns to previous state before enabling OVP circuit. It

will display 6V and 0A. Since you didn’t disable OVP circuit, ovp

annunciator will be displayed.

Example 3: Here is an example of how you clear the overvoltage

condition by decreasing output voltage level, using remote interface

commands:

Let’s say that the output voltage is lower than 10V. No load connected.

VOLT:PROT 10 ;program OVP trip level

VOLT:PROT:STAT ON ;enable OVP circuit

If OVP circuit is already enabled, you don’t have to enable it again!

VOLT 10 ;OVP circuit enabled

When output voltage becomes equal or greater than OVP trip level (here

is 10V), OVP circuit is enabled. Output is disabled and Over Voltage

message will be displayed.

VOLT 5.5 ;decrease output voltage level

61

Page 63

VOLT? ;returns programmed output voltage (5.5V)

Still output is disabled and Over Voltage message is displayed (because

you didn’t clear OVP condition yet)

VOLT:PROT:CLEAR ;clear OVP condition