Page 1

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIÓNES

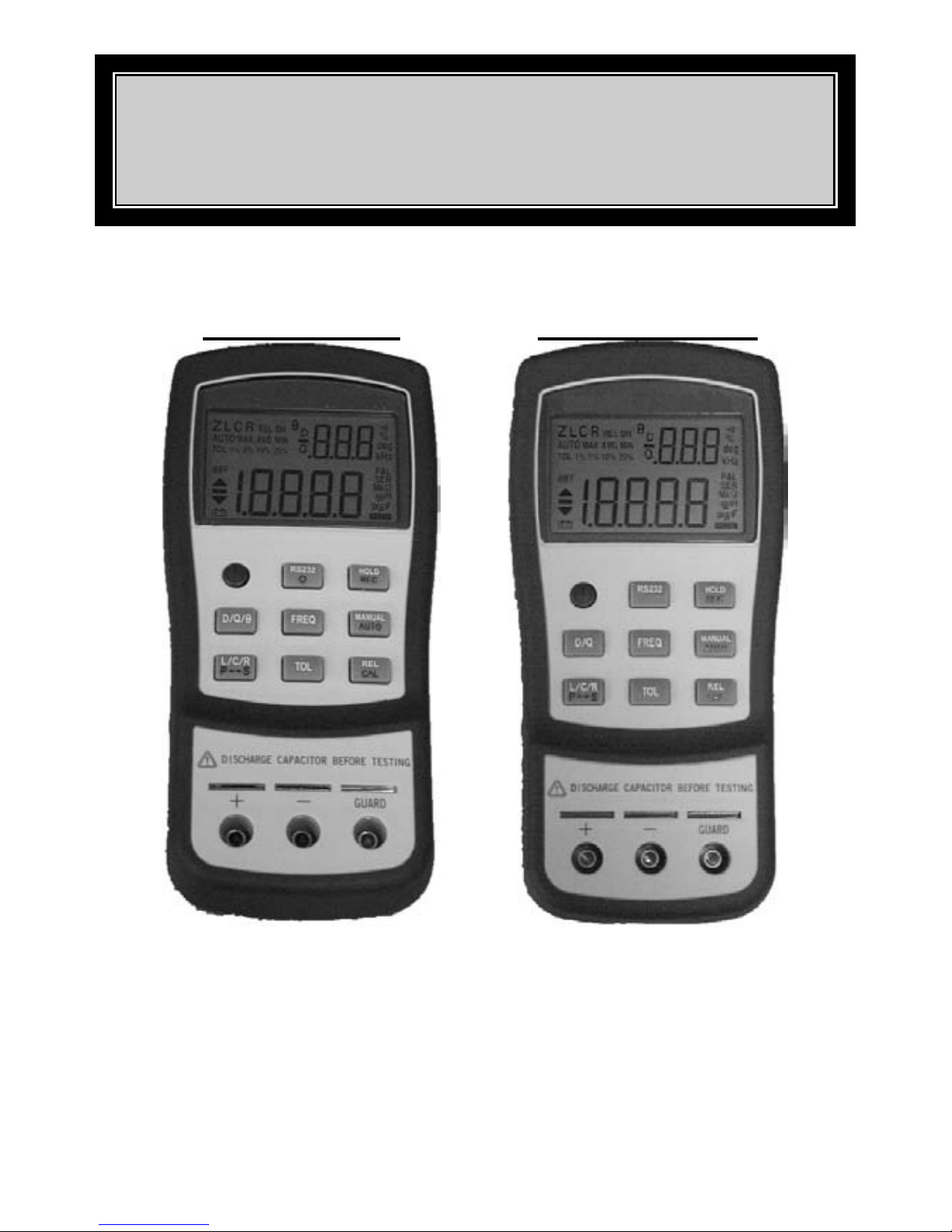

Dual Display LCR Meter

Model 878A / 879

Medidor LCR de Doble Exhibicion

Visual

Modelos 878A/ 879

Page 2

1

DUAL DISPLAY L/C/R METER

INSTRUCTION MANUAL

Model-A = 879

Model-B = 878A

Page 3

2

TABLE OF CONTENTS

PAGE

Safety

3

Introduction

5

Front Panel Illustration

6

LCD Display Ill ustration

7

How to Operate

9

Operati ng Instruct ions

13

Data Hold

13 Static Recording

13 Dissipation Factor / Quality Factor/ Phase Angle

13 Test F requency

14 L/C/R function selector

14 Relative

14 Tolerance

14 Auto/manual ranging

15 Automatic Fuse Detection

15

Parallel / Series Mode 15

Calibration

16 Auto Power Off/ Disable Auto Power Off

17 Low Battery Indicat ion

17 Backlit Display

17 Communication

18

General Specification

19

Electrical Specification

20

Maintenance

28

Spanis h M anual

33

Page 4

3

SAFTEY

Read "SAFETY INFORMATION" before using this meter.

NOTE

The meter is a hand-held, battery-operated instrum e nt fo r testing

inductance, capacitance and resistance. If this device is damaged or

something i s missing, cont act the place of purchase immediately.

This manual contains information and warnings must be followed to

ensure safe operation as well as to maintain the meter in a safe

condition. Some common international electrical symbols used in this

manual are shown below Table:

DC - Direct Current

See Explanation In The Manual

Table 1-1. International Electrical Symbols

Before using the meter, read the following safety information carefully.

In this manual, "WARNING", is reserved for conditions and actions

that pose hazard(s) to the user; "CAUTION", is reserved for conditions

and actions that may damage your meter.

Page 5

4

SAFETY INFORMATION

To ensure that you use this device safely, follow the safety guidelines

listed below:

•

This meter is for indoor use, altitude up to 2,000 m.

•

The warnings and precautions should be read and well

understood before the instrument is used.

•

Use this device only as specified in this manual; otherwise,

the protection provided by the meter may be impaired.

•

When measuring in-circuit components, first de-energize th e

circuits befo r e connecting to the test lead s.

•

Disc h arge capacitor b efore testing.

•

The meter is safety-certified in compliance with EN61010

(IEC 1010-1) Installation Category II (CAT. II) 50 V,

Pollution Degree 2 envi ronment.

•

Use the meter only as specified in this manual. Otherwise,

the protection provided by the meter may be impaired.

•

The power for the meter is supplied with a single standard

9V battery. But also a line operation is possible using a 12V

AC to DC ad aptor. If a power adaptor is selected, plea se be

sure t o u s e fu lfi lled t h e s af et y req u i rem en t s of a r ele van t IEC

standard.

Page 6

5

INTRODUCTION

This 19,999-count L/C/R hand-held meter is a special microprocessorcont rolled meter for mea su rin g func tion s of in duct anc e, cap acit anc e and

resistance. Extremely simple to operate, the instrument not only takes

absolute parallel mode measurements, but also capable of series mode

measu rement . The meter provi des di rect a nd accu rate m easuremen ts of

inductors, capacitors and resistors with different testing frequencies. It is

selecta ble for auto and manual ranging.

Front panel pushbuttons maximize the convenience of function and

feature selection such as data hold; maximum, minimum and average

record mode; relative mode; tolerance sorting mode; frequency and

L/C/R selection.

The test data can be transferred to PC through an optiona l full isolat ed

optical RS232C interface.

Backlight display for easy reading in dark places (Model-A only).

A tilt stand provides position flexibility for viewing and operating the

meter. The over-molding rubber case protects the meter to be stronger.

With single 9V battery operation is standard for the meter, a DC 12V

pow er ada ptor can also be used as an optio na l power input.

Page 7

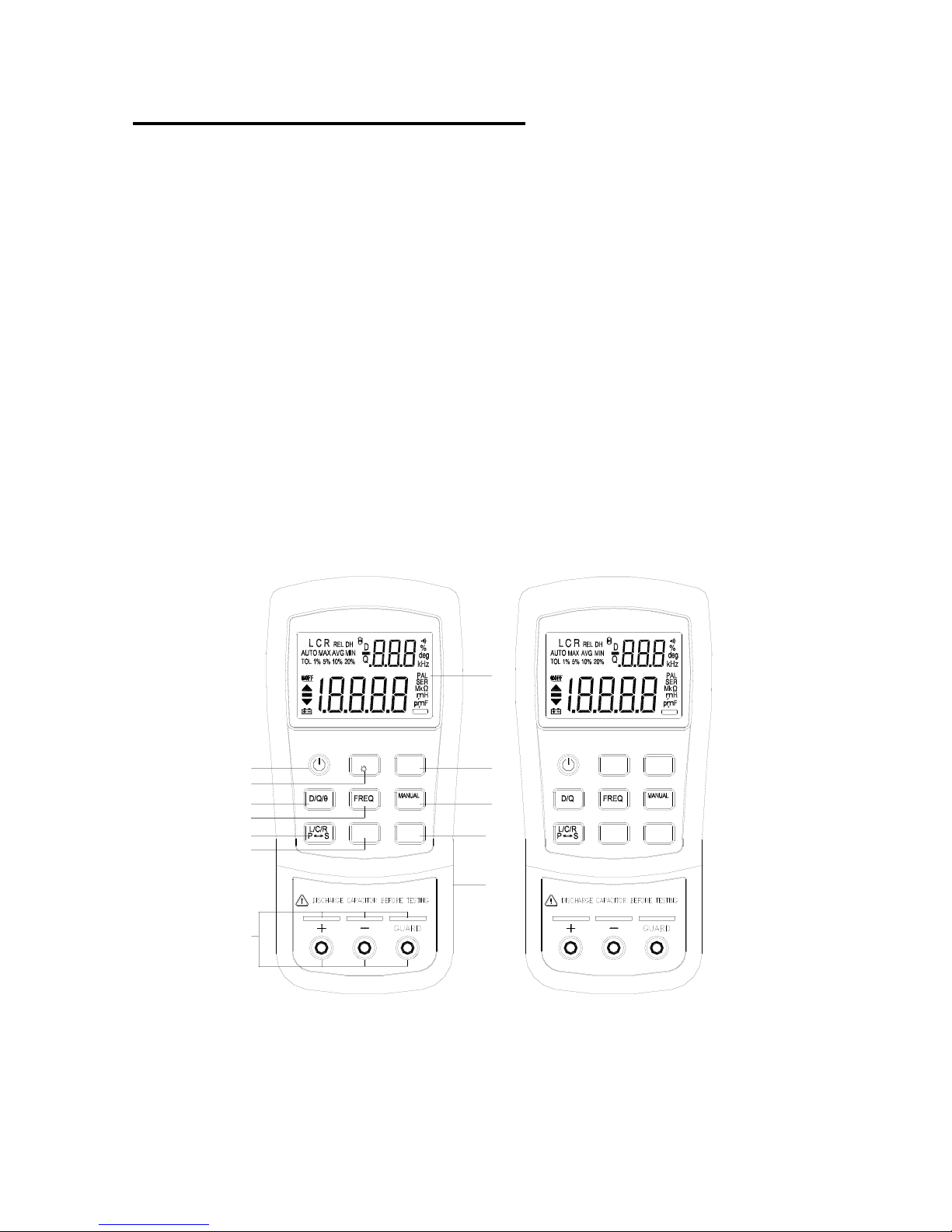

6

FRONT PANEL ILLUSTRATION

1.

LCD display

2.

Power ON/OFF button

3.

RS232 and Ba cklit button

4.

Dissipation factor, Quality factor and Phase an gl e selection

button

5.

Test frequency selection button

6.

Inductance, Capacitance and Resistance function selection

button. Parallel and series mode selection button

7.

Tolerance mode s electio n button

8.

Data h old, Maxi mum, Minim um and Averag e readi ng select ion

button

9.

Range selection button

10.

Relative mode and Calib ration selection button

11.

DC 12V adaptor inp ut

12.

Input sockets and Terminals

REL

CAL

AUTO

TOL

AUTO

TOL

REL

CAL

RS232

HOLD

REC

HOLD

REC

RS232

1

8

9

10

11

2

3

4

5

6

7

12

u

u

RS232 RS232

u

u

Figure-1. Front panel for Model-A and Model-B.

Page 8

7

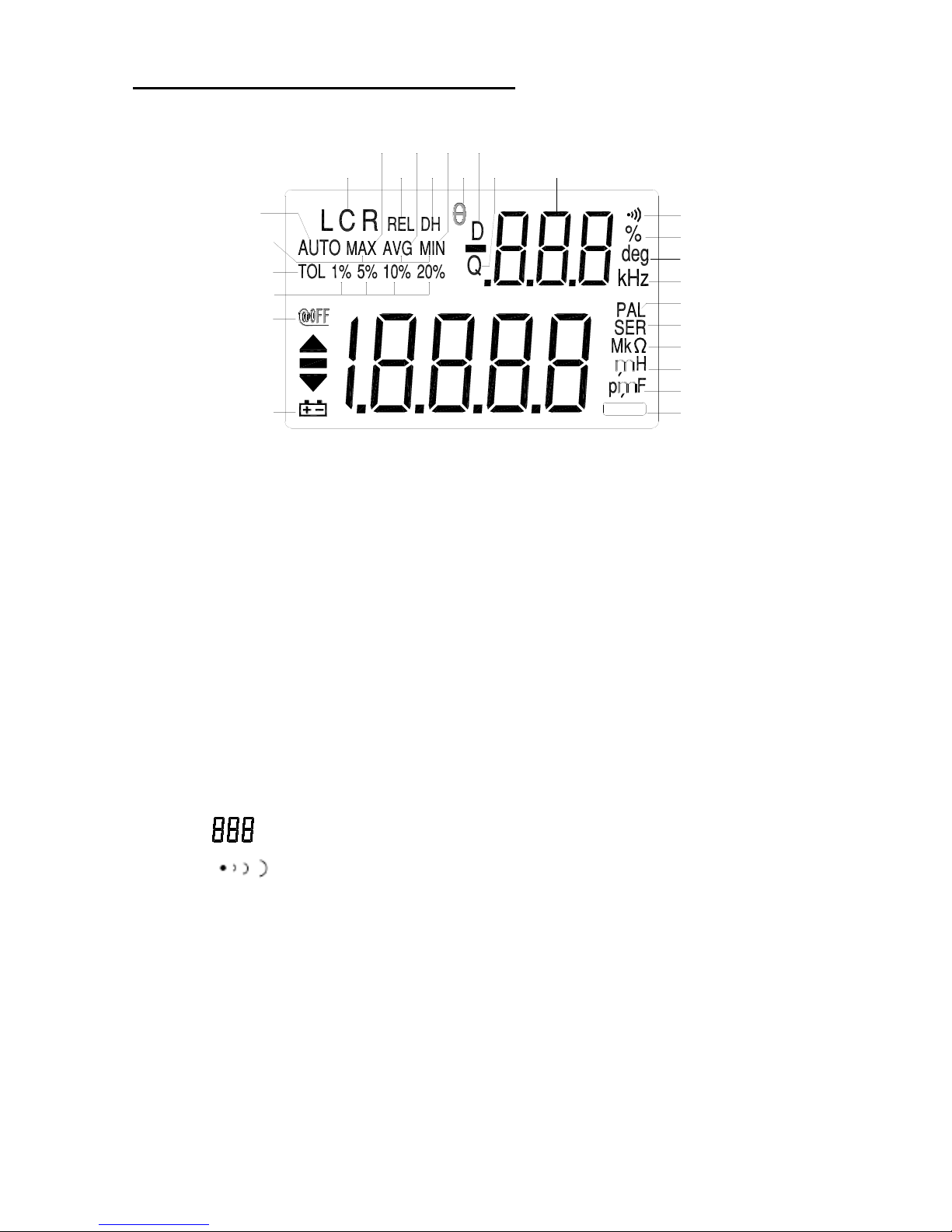

LCD DISPLAY ILLUSTRATION

12

13

14

15

22

24

23

21

25

26

1

16

17

18

19

20

2

3 4 6 10

119875

RS232

u

u

Figure 2. LCD Display.

1.

AUTO:

Auto-ranging indicator

2.

LCR:

L, C or R function indicator

3.

MAX:

Maximum reading indicator

4.

AVG:

Average reading indicator

5.

REL:

Relative mode indicator

6.

MIN:

Minimum reading indica t or

7.

DH:

Data hold indicator

8.

Θ:

Phase angle indicator (Model-A only )

9.

Q:

Quality factor ind icator

10.

D:

Dissipation factor indicator

11.

:

Secondary display

12.

:

Beeper tone indicator for tolerance mode

13.

%:

Tolerance (percentage) indicator

14.

deg:

Phase Angle degree indicator (Model-A only )

15.

kHz:

Fr eque nc y i nd icator

16.

MAX AVG MIN:

Recording mode indicators

17.

TOL:

Tolerance mode indicator

18.

1%5%10%20%:

Tolerance sorting (percent) indicator

Page 9

8

19.

:

Auto power- off indicator

20.

:

Low battery indicator

21.

PAL:

Para l lel mode indicator

22.

SER:

Series mode indicato r

23.

MkΩ:

Resi stance (Ohm) indicator

24.

:

Inductance (Henry) indicator

25.

:

Capacitan ce (Farad) indicator

26.

:

RS232 ind icator

Special Indication Charac ters

: Indicates short connectors

: Indicat es open connectors

: Indicates calibration mode

: Indicat es damaged or open fuse

Page 10

9

HOW TO OPERATE

Caution

•

When measuring within a circuit, the circuit must be deenergiz ed before conn ectin g the test leads.

•

The instrument that used in dusty environment should be

wiped and cleaned regularly.

•

Do not leave the instrument exposed to direct heat from the

sun or beat s ource for long periods.

•

Before removing the cover, ensure that the instrument is

disconnected from any circuit and in power "OFF" position.

Note:

For achieving optimum precision for all L, C and R

measurements at either the highest or lowest ranges, it is

recommended to calibrate the meter b efore testing.

Page 11

10

I

nductance Measurement

1.

Press the "

POWER

" button to tu rn on the meter.

2.

Press “

L/C/R

” button to sel ect inductance measurement.

3.

Insert a n induc tor int o componen t recept acle s ocket or co nnect th e

test clip to the component leads as required.

4.

Press “

FREQ

” button to select testing frequency.

5.

Press “

D/Q

” button to select Q factor for secondary display.

6.

Read the display readings for inductance value and quality factor.

AUTO

TOL

REL

CAL

HOLD

REC

RS232

u

Figure-3. Induct an c e M easurement.

Page 12

11

Capacitance Measurement

1.

Press "

POWER

" button to turn on the meter.

2.

Press “

L/C/R

” button to select cap acitan ce measurement .

3.

Insert a capacit or into th e component recepta cle socket or connect

the test clip to the component leads as required.

4.

Press “

FREQ

” button to select testing frequency.

5.

Press “

D/Q

” button to select D factor for secondary display.

6.

Read the display readings for capacitance value and dissipation

factor.

Warning

To avoid electrical hazards, discharge the capacitor to be tested before

measuring.

AUTO

TOL

REL

CAL

HOLD

REC

RS232

Figure-4. Capacitance Measurement.

Page 13

12

Resistance Measurement

1.

Press "

POWER

" button to turn on the meter.

2.

Press “

L/C/R

” button to sel ect Resistance measurement.

3.

Insert a resistor into the component receptacle socket or connect

the test clip to the component leads as required.

4.

Press “

FREQ

” button to select testing frequency (this meter will

not give you the DC resi stance of a comp o nent).

5.

Read the display readings for resistance value.

AUTO

TOL

REL

CAL

HOLD

REC

RS232

Figure-5. Resistance Measurement.

Page 14

13

OPERATING INSTRUCTIONS

Data Hold

This data hold function allows the operat or to freeze the di s play. To

enter this mode, press the “HOLD” pushbutton; press again to release.

Static Recording

Press the “

REC

” pushbutton for more than one second to enter the static

recording mode. The maximum and minimum readings are then stored

in memory, whil e a beepi ng to ne i s produced when a new tested value

has been recorded. Push the same button to cycle through the

maximum, minimum and average of the present readings. The

MAX

,

MIN

or

AVG

indicators will display on LCD will turn on to indicate

what value is being displayed. When ever the “

MAX AVG MIN

”

indicators appear on the LCD simultaneously, the display reading is

always a present value.

To exit this mode, press and hold the pushbutton for more than one

second.

Notes:

1. Static rec ording cap tures on ly stable val ues and upd ates the m emory;

it will not record any “

OL

” (overload) value for any of the

L/C/R

functions. In addition, the meter will not record which values are

below 50 counts in Capacitance measurement.

2. Static recording is only available in manual ranging; however,

activation while in auto-ranging will automatically set meter to

manual ran ging and cause ca libration p rompts to be displayed in the

recommended ranges.

Dissipation Factor / Quality Factor/ Phase Angle

The “

D/Q/Θ

” value can be displayed interchangeably by pressing the

“

D/Q/Θ

” button when the meter is set to Inductance or Capacitance

mode. It does not apply to resistance measurement. The ph ase angle i s

available on Model-A only.

Page 15

14

Test Frequency

Default testing frequency is 1KHz. Push “

FREQ

” key to se l ect the

desi r ed test f r equency.

L/C/R Function Selector

Simply press the “

L/C/R

” pushbutton to select the desired L, C or R

function.

Relative

Press the “REL” key t o enter the relat ive mode and sto r es the display

reading as a reference value. It will then display all subsequent readings

in relative t o referen ce valu e. Press the button again to exit the relative

mode.

Notes:

1.

The rela tive mode can ’t be activated if the display value i s either

“

OL

” or “

0000

”.

2.

Relative mode is only available in manual ranging; however,

activation while in auto-ranging will automatically set the meter to

manual ranging and cause calibration prompts to be displayed in

the recommen ded ranges.

3.

The relative mode cannot be activated if the meter is set at autoranging with data hold activated.

Tolerance

There are 1%, 5%, 10% an d 2 0% tolerance range. To enter th is

tolerance mode, insert the appropriate component as a standard value

into the socket or connect the component to the test probes, then pre s s

the “TOL” pushbutton to set this va lue, as the standard reference

tolerance. Similarly, any value which appears on the LCD display, such

as DH or MAX/MIN/AVG, can be u sed as a standard value to sort

components. Press this button again to cycle through 1%, 5%, 10% and

20% tolerance as desire.

This funct i on is des ign ed for con ven ient comp onent sorting. An audible

tone will sound whenever the component under test exceeds the setting

Page 16

15

toleran ce. Con versely, a single ton e of “Be” indica tes the component is

within the setting tolerance.

Notes:

1.

The tole ra n c e mod e c an ’t be act i vat ed if th e t est ed di sp la y is ei t h er

“

OL

” or “

0000

”; nor can it be activated the tested capacitance

value is below 10 counts.

2.

Tolerance mode is only available in manual ranging; however,

activati on while in aut o-ranging will automatically set the meter to

manual ranging and cause calibration prompts to be displayed in

the recommen ded ranges.

3.

The tolerance mode can’t be activated if the meter is set at autoranging with data hold mod e ac tivated.

4.

For 20% selection is available on Model-A only.

Auto / Manual Range

The auto-ranging mode is default status when the meter is powered on.

For sp ecifi c measu r ement, pr ess “AUTO” button to select man ual

ranging. To return to the auto -ranging mode, press and hold the

“AUTO” button for more than one second.

Automatic Fuse Detection

When t he meter detects that the protective fuse is open, the “FUSE”

character will appear and an internal beep will sound continuously. In

this situation, none of the function keys can be operated and all other

meter functions will be discontin ued. Fuse replacem ent i s requi red.

Figure-6. Fuse Det ection

Parallel / Series Mod e

The meter is capable of displaying Parallel and Series mode data fo r all

ranges. The parallel mode is default for Capacitance and Resistance

Page 17

16

measurements, and the series mode is default for Inductance

measurement. Press “L/C/R” button for more than 1 second to toggle

“SER” and “PAL” mode.

Calibration

Calibration is available to all ranges. Simply press and hold “

CAL

”

button for more than one second to enter the calibration mode and

calibration prompts will be displayed. Follow the prompts for open

connector (

) or short connector ( ) connection and press the

“

CAL

” button. After calibration is completed, the meter will be

restored to normal display and ready for n ormal usage.

Figure-7. Open/ Short Calibration

The function calibrates the meter’s internal parameters as well as

external connector residues for further measuring. It is highly

recommen ded t o calibra te extremel y high or low ranges for L, C an d R

before making precision measurements. Calibration prompts will be

displayed automatically every time those ranges are manually or

functionally selected, (e.g.

REL, TOL, REC

etc.), and calibration is

recommended. Simply follow the open connector (

) or short

connector (

) instruction and then press the “

CAL

” button. You

may skip the calibration by pressing the “

D/Q

” button.

Notes:

1.

Changing measurement frequencies is handled the same as

selecting a different hardware range, and so automatic calibration

prompts will be displayed in the recomm ended ranges.

Page 18

17

2.

Be sure to use same testing position after short calibration.

Auto Power Off/ Disable Auto Power Off

When the meter has not been used for five minutes after the last

operat io n was made, a long “beep” tone will sound. The meter will then

automatically enter a “sleep” mode and there will be no display on the

LCD. To reactivate the meter, simply press any pushbutton. After reactivating.

When th e meter i s to be used for long peri od, the aut o power-off c an b e

disabled by pressing and holding “

L/C/R

” button while turning meter

ON. Release the button, and press any button again. The

symbol

will be disappeared to confirm that the auto power off has been disabled.

By using a 12V AC adaptor as an optional power source, auto power off

is disabl e d au tomatically.

Note: It i s recommended that the meter should always be switched off

when not in use.

Low Batt ery Indication

When the “ “ symbol flashes on the display, the battery voltage is

below normal working voltage and is weakening . Repl ace battery with a

new one t o maintain accurac y of the meter.

Backlit Display

(Model-A only)

Press and hold “ “ key for more than one second to toggle backlit

ON/OFF.

Page 19

18

Communication

This meter has communication capability. By using the optional RS23 2

package (AK 87X), with full optical isolated cable and software. This

function will assist user to record data easily.

Referring the following procedures to set up the communication

between your meter and personal computer.

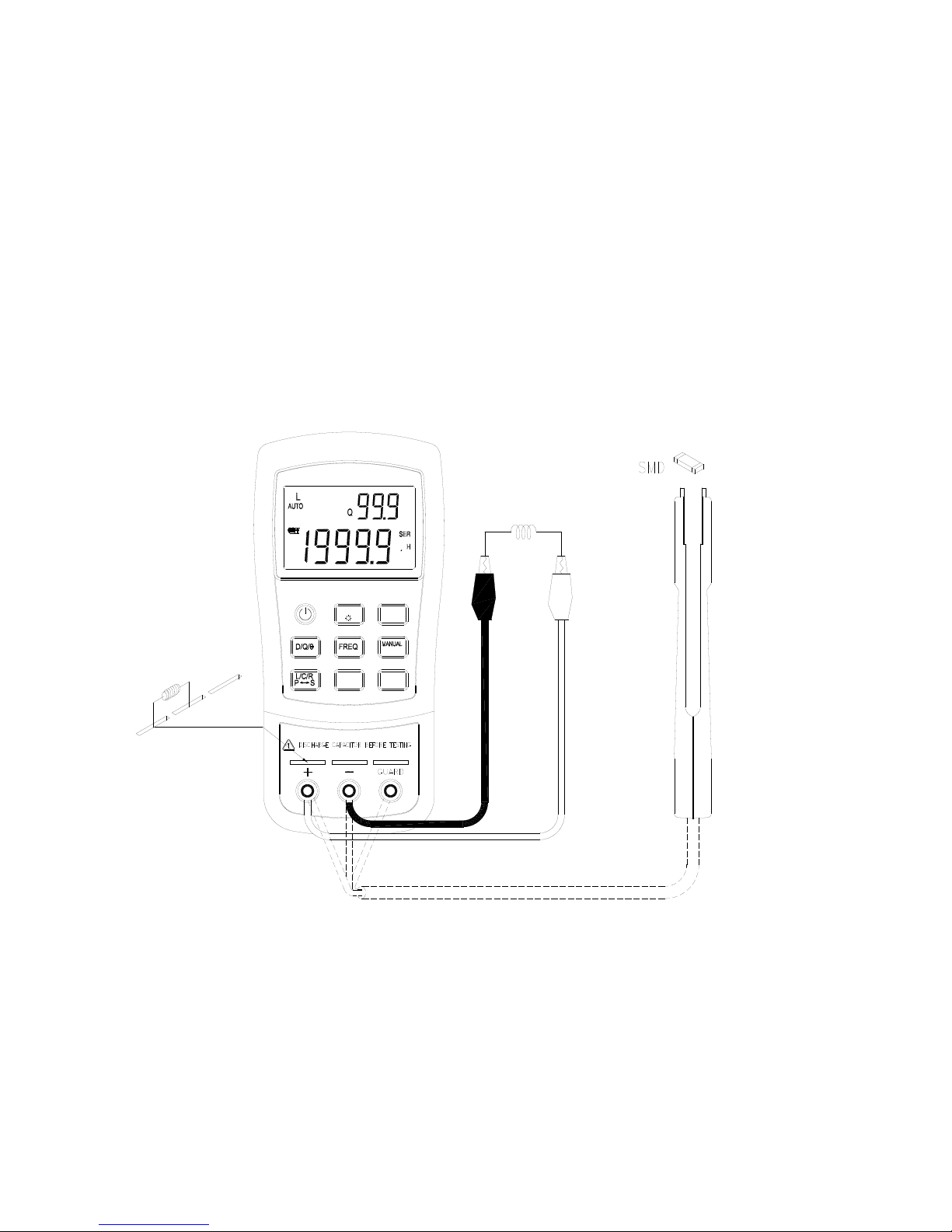

1.

Fixes one side of cable to the meter, and the text side shall be

facing up. To connect the 9-pin’s terminal of cable to

communica tion port 1 or 2 of personal comput er. See the

Figure-

8

.

2.

Press “RS232” button to enable this interface. You will find that

the symbol of “

” is lit on the display.

3.

Execute the software to take the data for your applications.

4.

Be sure to push the snap ends on the cable of meter side for

removing th e cable.

Figure-8. Cable Connection Of Communication

The text

side shall

be facing

Page 20

19

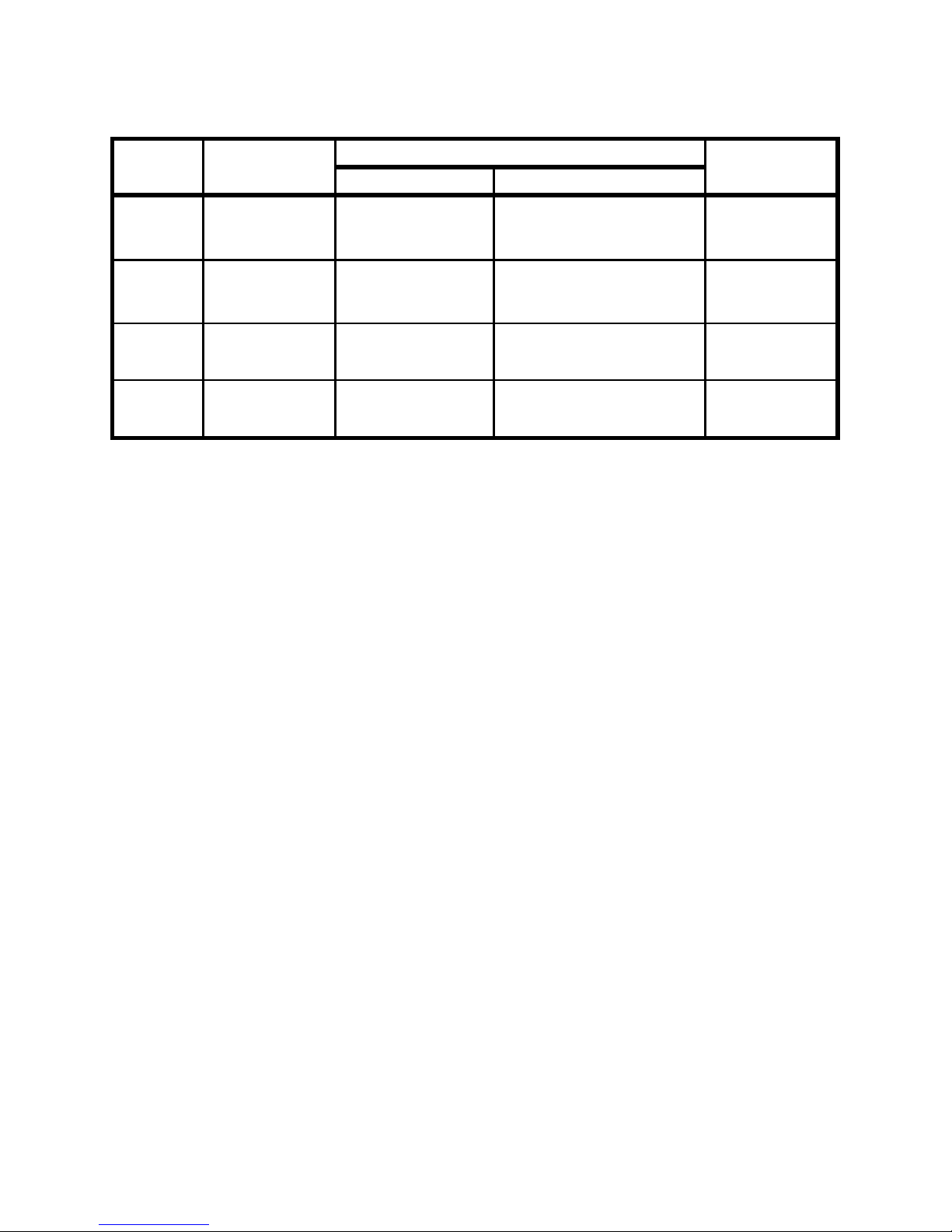

GENERAL SPECIFICATION

Items

879

878A

Parameters Measured

L/C/R/D/Q/Θ

L/C/R/D/Q

Measuring C ircuit Mo de

Inductance (L)

–Defaults to series mode

Capacitance/ Resistance (C/R)

-De faults to pa r allel mode

Displays

L/C/R: Maximum display 19999

D/Q: Maximum display 999 (Auto Range ).

Ranging Mode

Auto & Manual

Measuring Terminals

3 terminals with sockets

Test Frequency

Accuracy:

±0.1 %

100Hz=100 Hz

120Hz= 120 Hz

1KHz =1010 Hz

10KHz= 9.6 KHz

120Hz= 120 Hz

1KHz =1010 Hz

Backlit display

Included

Excluded

Tolerance mode

1%, 5%, 10%, 20%

1%, 5%, 10%

Test Signal Le ve l

0.6Vrms approx.

Measuring Rate

1 time/second, nominal

Response time

Approx. 1 second/ DUT (device under test)(@

manual range)

Auto Power-Off

5 minutes approx. without operation

Temperature Coefficient

0.15 x (Specified Accuracy) / °C(0-18° or 28-40°)

Operation Temperature

0°C to 40°C; 0-70% R.H.

Storage Temperature

-20°C to +50°C; 0-80% R.H.

Low Battery Indication

Approx. 6.8V

Power Consumption

Approx. 40mA for operation/ 0.08 mA after Auto

Power-off.

Power Requirements

1) DC 9V Battery

2) E xt. DC Adaptor: DC 12Vmin –15Vmax.

(Load 50mA Min.)

Protective Fuse

0.1A/250V Fuse (input protective)

S tandard Accessories

Test a lliga tor clips (pair)

DC 9V Battery.

User manual

Dimensi ons (L/W/ H)

7.2 x 3.4 x 1.6” (184 x 87 x 41 mm)

We ight

11.6oz (330 grams)

Page 21

20

ELECTRICAL SPECIFICATI ONS

Accuracy is expressed as: ± (% of reading + n o. of least signif icant

digits) at 23℃±5℃and <75% R.H.

Mode l 8 79:

Resistance (Parallel mode)

Test Frequency: 100 / 120 Hz

Range

Maximum

Display

Accuracy

Specified Note

@100 Hz

@120Hz

10MΩ 9.999MΩ

2.0%+8 *3 2.0%+8 *3 After open ca l.

2000KΩ 1999.9KΩ

0.5%+5 0.5%+5 After ope n cal.

200KΩ

199.99KΩ

0.5%+3 0.5%+3 -

20KΩ 19.999KΩ

0.5%+3 0.5%+3 -

2000Ω 1999.9Ω

0.5%+3 0.5%+3 -

200Ω

199.99Ω

0.8%+5 0.8%+5 After short cal.

20Ω

19.999Ω

1.2%+40 1.2%+40 After short cal.

Test Frequency: 1K / 10K Hz

Range

Maximum

Display

Accuracy

Specified Note

@1K Hz

@10KHz

10 MΩ

9.999MΩ

2.0%+8 * 3 3.5%+10 * 3 After ope n cal.

2000 KΩ 1999.9KΩ

0.5%+5 2.0%+10 After open cal.

200 KΩ 199.99KΩ

0.5%+3 1.5%+5 -

20 KΩ

19.999KΩ

0.5%+3 1.5%+5 -

2000 Ω

1999.9 Ω

0.5%+3 1.5%+5 -

200 Ω 199.99 Ω

0.8%+5 2.0%+10 Aft e r short cal.

20 Ω 19.999 Ω

1.2%+40 2.5%+200 After short c al.

Notes:

1.

This specification is based on the measurement performed at the test socket.

2.

DUT (Device Under Test) & Test leads be properly s hie lded to GUARD if

necessary.

3.

This specification is based on battery operation.

Page 22

21

Capacitance (Parallel mode)

Test Frequency: 100 / 120 Hz

Range Maximum

Display

Accuracy

Spec. Note

Capacitance

DF

10mF

19.99mF *5

3.0%+5

(DF<0.1)

10%+100/Cx+5

(DF<0.1)

After short c al.

1000μF

1999.9μF*6

1.0%+5

(DF<0.1)

2%+100/Cx+5

(DF<0.1)

After short c al.

200μF

199.99μF

0.7%+3

DF<0.5

0.7%+100/Cx+5

(DF<0.5)

-

20μF 19.999μF 0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

2000nF

1999.9nF

0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

200nF

199.99nF

0.7%+5

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

After ope n cal.

20nF

19.999nF

1.0%+5

(DF<0.1)

2%+100/Cx+5

(DF<0.1)

After ope n cal.

Test Frequency: 1 KHz

Range

Maximum

Display

Accuracy

Spec. Note

Capacitance

DF

1mF

1.999mF *5

3.0%+5

(DF<0.1)

10%+100/Cx+5

(DF<0.1)

After short c al.

200μF

199.99μF

1.0%+5

(DF<0.1)

2.0%+100/Cx+5

(DF<0.1)

After short c al.

20μF

19.999μF

0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

2000nF

1999.9nF

0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

200nF 199.99nF 0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

20nF 19.999nF 0.7%+5

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

After ope n cal.

2000pF 1999.9pF 1.0%+5

(DF<0.1)

2.0%+100/Cx+5

(DF<0.1)

After ope n cal.

Page 23

22

Test Frequency: 10 KHz

Range

Maximum

Display

Accuracy

Spec. Note

Capacitance

DF

50μF 50.0μF 3.0%+8

(DF<0.1)

12%+100/Cx+10

(DF<0.1)

After short c al.

20μF 19.999μF 3.0%+6

(DF<0.2)

5.0%+100/Cx+8

(DF<0.2)

After short c al.

2000nF 1999.9nF 1.5%+5

(DF<0.5)

1.5%+100/Cx+6

(DF<0.5)

-

200nF 199.99nF 1.5%+5

(DF<0.5)

1.5%+100/Cx+6

(DF<0.5)

-

20nF 19.999nF 1.5%+5

(DF<0.5)

1.5%+100/Cx+6

(DF<0.5)

-

2000pF 1999.9pF 2.0%+6

(DF<0.5)

3.0%+100/Cx+6

(DF<0.5)

After ope n cal.

200pF 199.99pF 3.0%+8

(DF<0.1)

5.0%+100/Cx+8

(DF<0.1)

After ope n cal.

Notes:

1.

Q Value is the reciprocal of DF.

2.

This specification is based on the measurement performed at the test socket.

3.

DUT & Tes t leads should be properly shielded to GUARD if necessar y.

4.

Cx=Counts of displayed C value, e.g. C=88. 88μF then Cx=8888.

5.

This reading can be extended to 1999 MAX display with accuracy not

specified.

6.

This reading can be extended to 19999 MAX display with accuracy not

specified.

Page 24

23

Inductance (Series mode)

Test Frequency: 100 / 120Hz

Range

Maximum

Display

Accuracy (DF<0.5)

Spec. Note

Inductance

DF

1000H 999.9H 1.0%+(Lx

/10000) %+5

2%+100/Lx+5 After open cal.

200H 199.99H 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5 -

20H 19.999H 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5 -

2000m 1999.9mH 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5 -

200mH 199.99mH 1.0%+(Lx

/10000)%+5

3%+100/Lx+5 After short ca l.

20mH 19.999mH 2.0%+(Lx

/10000)%+5

10%+100/Lx+5 After short c al.

Test Frequency: 1 KHz

Range

Maximum

Display

Accuracy (DF<0.5)

Spec. Note

Inductance

DF

100H 99.99H 1.0%+(Lx

/10000) %+5

2.0%+100/Lx+5 After open cal.

20H 19.999H 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5 -

2000mH 1999.9mH 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5 -

200mH 199.99mH 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5 -

20mH 19.999mH 1.0%+(Lx

/10000)%+5

3.0%+100/Lx+5 After short cal.

2000µH 1999.9µH

2.0%+

(Lx/10000)%+5

10%+100/Lx+5 After short c al.

Page 25

24

Test Frequency: 10 KHz

Range

Maximum

Display

Accuracy (DF<0.5)

Spec. Note

Inductance

DF

1000mH 999.9mH 2.0%+(Lx

/10000)%+ 8

2.0%+100/Lx+10 -

200mH 199.99mH 1.5%+(Lx

/10000)%+8

2.0%+100/Lx+10 -

20mH 19.999mH 1.5%+(Lx

/10000)%+10

3.0 %+100/Lx+15 -

2000µH 1999.9µH

2.0%+(Lx

/10000)%+10

8.0 %+100/Lx+20

After short c al.

Notes:

1.

1.Q Value is the reciprocal of DF.

2.

This specification is based on the measurement performed at the

test socket.

3.

DUT & Test leads shall be properly shielded to GUARD if

necessary.

4. Lx=counts of displayed L value, e.g. L=88.88H, then Lx=8888.

Page 26

25

Model 878A:

Resistance (parallel mode)

Test Frequency: 120Hz / 1KHz

Range Maximum

Display

Accuracy

Specified Note

@120 Hz

@1KHz

10MΩ 9.999MΩ

2.0%+8 *3 2.0%+8 *3 After open cal.

2000KΩ

1999.9KΩ

0.5%+5

0.5%+5

After ope n cal.

200KΩ 199.99KΩ

0.5%+3

0.5%+3

-

20KΩ 19.999KΩ

0.5%+3 0.5%+3 -

2000Ω

1999.9Ω

0.5%+3

0.5%+3

-

200Ω 199.99Ω

0.8%+5

0.8%+5

After short c al.

20Ω 19.999Ω

1.2%+40 1.2%+40 After short ca l.

Notes:

1.

This specification is based on the measurement performed at the test socket.

2.

DUT (Device Under Test) & Test leads be properly shielded to GUARD i f

necessary.

3.

This specification is based on battery operation.

Capacitance (parallel mode)

Test Frequency: 120 Hz

Range Maximum

Display

Accuracy Spec. Note

Capacitance

DF

10mF

19.99mF *5

3.0%+5

(DF<0.1)

10%+100/Cx+5

(DF<0.1)

After short c al.

1000μF 1999.9μF*6

1.0%+5

(DF<0.1)

2%+100/Cx+5

(DF<0.1)

After short c al.

200μF 199.99μF 0.7%+3

DF<0.5

0.7%+100/Cx+5

(DF<0.5)

-

20μF

19.999μF

0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

2000nF

1999.9nF

0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

200nF

199.99nF

0.7%+5

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

After open cal.

20nF

19.999nF

1.0%+5

(DF<0.1)

2%+100/Cx+5

(DF<0.1)

After ope n cal.

Page 27

26

Test Frequency: 1 KHz

Range

Maximum

Display

Accuracy

Spec. Note

Capacitance

DF

1mF

1.999mF *5

3.0%+5

(DF<0.1)

10%+100/Cx+5

(DF<0.1)

After short c al.

200μF 199.99μF 1.0%+5

(DF<0.1)

2.0%+100/Cx+5

(DF<0.1)

After short c al.

20μF 19.999μF 0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

2000nF

1999.9nF

0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

200nF

199.99nF

0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

20nF

19.999nF

0.7%+5

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

After ope n cal.

2000pF

1999.9pF

1.0%+5

(DF<0.1)

2.0%+100/Cx+5

(DF<0.1)

After ope n cal.

Notes:

1.

Q Value is the reciprocal of DF.

2.

This specification is based on the measurement performed at the test socket.

3.

DUT & Tes t leads should be properly shielded to GUARD if necessary.

4.

Cx=Counts of displayed C value, e.g. C=88. 88μF then Cx=8888.

5.

This reading can be extended to 1999 MAX display with accuracy not

specified.

6.

This reading can be extended to 19999 MAX display with accuracy not

specified.

NOTE: Specifications and inf o r m ation are s ubject t o change withou t

notice. Please visit

www.bkprecision.com for the most current product

information.

Page 28

27

Inductance (Series mode)

Test Frequency: 120Hz

Range Maximum

Display

Accuracy (DF<0.5) Spec. Note

Inductance

DF

1000H

999.9H

1.0%+(Lx

/10000) %+5

2%+100/Lx+5

After ope n cal.

200H 199.99H 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5 -

20H 19.999H 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5 -

2000m

1999.9mH

0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

200mH

199.99mH

1.0%+(Lx

/10000)%+5

3%+100/Lx+5

After short cal.

20mH

19.999mH

2.0%+(Lx

/10000)%+5

10%+100/Lx+5

After short c al.

Test Frequency: 1 KHz

Range

Maximum

Display

Accuracy (DF<0.5)

Spec. Note

Inductance

DF

100H

99.99H

1.0%+(Lx

/10000) %+5

2.0%+100/Lx+5

After ope n cal.

20H

19.999H

0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

2000mH

1999.9mH

0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

200mH

199.99mH

0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

20mH 19.999mH 1.0%+(Lx

/10000)%+5

3.0%+100/Lx+5 After s hort cal.

2000µH 1999.9µH

2.0%+

(Lx/10000)%+5

10%+100/Lx+5 After short ca l.

Notes:

1.

Q Va lue is the reciprocal of DF.

2.

This specification is based on the measurement performed at the

test socket.

3.

DUT & Test leads shall be properly shielded to GUARD if

necessary.

4. Lx=counts of displayed L value, e.g. L=88.88H, then Lx=8888.

Page 29

28

MAINTENANCE

WARNING

To avoid electrical shock, do not perform any service unless you are

qualified to do so.

SERVICE

If the instrument fails to operate, to check battery and test leads, and

replaces them if necessary. If the instrument still can’t work, double

check ope rating procedure as desc r i bed in thi s instructio n ma nual. When

servicing, use sp ecified replacement par ts only. The meter mu st be

comp letely turned o ff wh ile replacing either the fuse or battery.

Battery Replacement

The meter is powe red a single 9V battery, with NEDA1604, JIS006P,

IEC6F22 carbon-zinc or alka l ine battery. Replace bat tery if the low

battery sign (

) is displayed and flashing. Use the following

procedures to replace the battery:

1.

Loosen screws with suitable screwdriver and remove

battery cover as

Figure-9

.

2.

Replace the degraded battery with a new battery.

Figure-9. Battery Replacement.

Page 30

29

Fuse Replacement

The meter can sel f-detect if its input protective fuse is either open or

damaged. In this case, the LCD will display the symbol "FUSE" and an

audible beep will sounds continuously, warning the user to replace the

damaged fuse to maintain the accuracy of measurement. While

replacing t he fuse, the power of the meter must be completely shut off.

1.

Loos en screws with suitable screwdriver and remove battery cover

as

Figure-9

.

2.

Loosen screws with sui table sc re wdriver a n d remove b ot tom cover

as

Figure-10

.

3.

Replace the damaged fuse wit h specified one.

Figure-10. Fuse Replacement

Page 31

30

Cleaning the Meter

WARNING

To avoid electrical shock or damaging the meter, never get water inside

the case.

Before c lean ing this meter, make sure the power is switched in

OFF position and remove external DC adaptor. To clean the

meter, wipe t he di rty pa rts with ga uze or soft c loth soaked with

diluted neutral detergent. Do not get too wet to prevent the

detergent from penetrating into inside parts and causing

damages. After cleaning, make sure the instrument is dried

completely before using.

Page 32

31

Limited One-Year Warranty

B&K Precision Corp. warrants to the original purchaser that its products

and the component pa rts thereof , will be free from def ects in

workmanship and materials for a period of one year from date of

purchase.

B&K Precision Corp. will, without charge, repair or replace, at its

option, defective product or component parts. Returned product must be

acc o mpanied by proof of the purchase date in the form of a sales receipt.

To obtain warranty coverag e in the U.S.A., this product m us t be

registered by completing a warranty registration form on

www.bkprecision.com within fifteen (15) days of purchase.

Exclusions: This warranty does not apply in the event of misuse or

abuse of the product or as a resul t of unautho rize d al terations or

repairs. The warra nty is void if the seria l number is altered, defaced

or remo ved.

B&K Precision Corp. shall not be liable for any consequential damages,

including without limitation damages resulting from loss of use. S om e

states do not allow limita tions of incidental or cons equential damages .

So the above lim itation or exc lusion may not ap ply to you.

This warranty gives you specific rights and you may have other rights,

which vary from state-to-state.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Page 33

32

Service Information

Warranty Service: Please return the product in the original packaging

with proof of purchase to the address below. Clearly state in writing the

performance problem and return any leads, probes, connectors and

acc essories that you are usi ng with th e devic e.

Non-Warranty Service: Return the product in the origi nal packaging to

the address below. Clear ly state in writing the performance problem and

return any leads, probes, connectors and accessories that you are using

with the device. Customers not on open account must include payment

in the form of a money order or credit card. For the most current rep ai r

charges please visit

www.bkprecision.com and click on “service/repair”.

Return all merchandise to B&K Precision Corp. with pre-paid shipping.

The flat-rate repair charge for Non-Warranty Service does not include

return shipping. Return shipping to locations in North American is

included for Warranty Service. For overnight shipments and non-North

American shipping fees plea se contact B&K Precisi o n Corp.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Include with the returned instrument your complete return

shipping address, contact name, phone number and description of

problem.

Page 34

33

22820 Savi Ranch Parkway

Yorba Linda, California 92887

www.bkprecision.com

©2006 B&K Precision Corporation

Printed in 481-524-9-001

Loading...

Loading...