Page 1

Model 2110

Fraction

Collector

Instruction

Manual

Catalog Numbers

731-8120

731-8122

Page 2

Warranty

Model _________________________________________

Serial No. ______________________________________

Date of Delivery_________________________________

Warranty Period _________________________________

Unless otherwise specified, instruments sold by Bio-Rad Laboratories

are under warranty for 1 year against defects in materials and workmanship.

If any defects should occur during this warranty period, Bio-Rad will

replace the defective parts without charge. However, the following

defects are specifically excluded:

1. Defects caused by improper operation

2. Repair or modification done by anyone other than Bio-Rad

Laboratories or their authorized agent.

3. Use of fittings or other spare parts supplied by anyone other than Bio-

Rad Laboratories.

4. Damage caused by deliberate or accidental misuse.

5. Damage caused by disaster.

6. Damage due to use of improper solvent or sample.

This warranty does not apply to tubing and fuses.

For inquiry or request for repair service, contact Bio-Rad

Laboratories after confirming the model and serial number of your instrument.

For Technical Service Call Your Local Bio-Rad Office or in the U.S.

call 1-800-4BIORAD(1-800-424-6723)

Page 3

Table of Contents

Section 1 Safety .............................................................................. 1

Section 2 Introduction ................................................................... 2

Section 3 Unpacking and Voltage Conversion ............................ 3

3.1 Unpacking Instructions ............................................................ 3

3.2 Voltage Conversion ..................................................................

3

Section 4 Physical Description and Control Features................ 5

4.1 Physical Description.................................................................

5

4.2 Front Panel Functions ..............................................................

7

4.3 Rear Panel Connections ...........................................................

8

Section 5 Instrument Set-Up......................................................... 9

5.1 Tubing Installation ...................................................................

9

5.2 Carousel Installation.................................................................

11

5.3 Collection Tube Installation.....................................................

11

5.4 Waste Collection Port...............................................................

12

Section 6 Stand Alone Operation ................................................. 12

6.1 Stop (Standby) and Run ...........................................................

12

6.2 Collection Modes .....................................................................

12

6.3 Operation without Direct Connection to a System..................

14

6.4 Manual Advance.......................................................................

15

6.5 Reset/End of Run ..................................................................... 15

Section 7 Remote Operation of the Model 2110

Fraction Collector ......................................................... 15

7.1 Remote Operation with Model EP-1 Econo Pump.................. 15

7.2 Remote Operation with BioLogic LP ...................................... 16

7.3 Remote Operation with BioLogic system................................ 16

7.4 Remote Operation with other Instruments............................... 16

Section 8 Accessories ..................................................................... 18

8.1 Instrument Dust Cover ............................................................. 18

8.2 Micro Tube Adaptor ................................................................. 18

Section 9 Cleaning and Maintenance........................................... 19

9.1 Drop Sensor.............................................................................. 19

9.2 Instrument Case, Carousel, and Drainage Tube....................... 19

Section 10 Troubleshooting ............................................................. 19

Appendix A Technical Specifications ................................................ 21

Page 4

Appendix B Model 2110 Fraction Collector Procedure

for Adjusting Drop Detector Signal Level .................. 22

Appendix C Ordering Information................................................... 24

Page 5

Section 1

Safety

Disconnect supply before servicing. No user serviceable parts inside,

refer servicing to Bio-Rad service personnel.

High leakage current, ensure proper grounding.

This instrument is intended for laboratory use only.

This product conforms to the “Class A” standards for electromagnetic emmissions intended for laboratory equipment applications.

It is possible that emissions from this product may interfere with some

sensitive appliances when placed nearby or in the same circuit as

those appliances. The user should be aware of this potential and take

appropriate measures to avoid interference.

1

!

!

Page 6

Section 2

Introduction

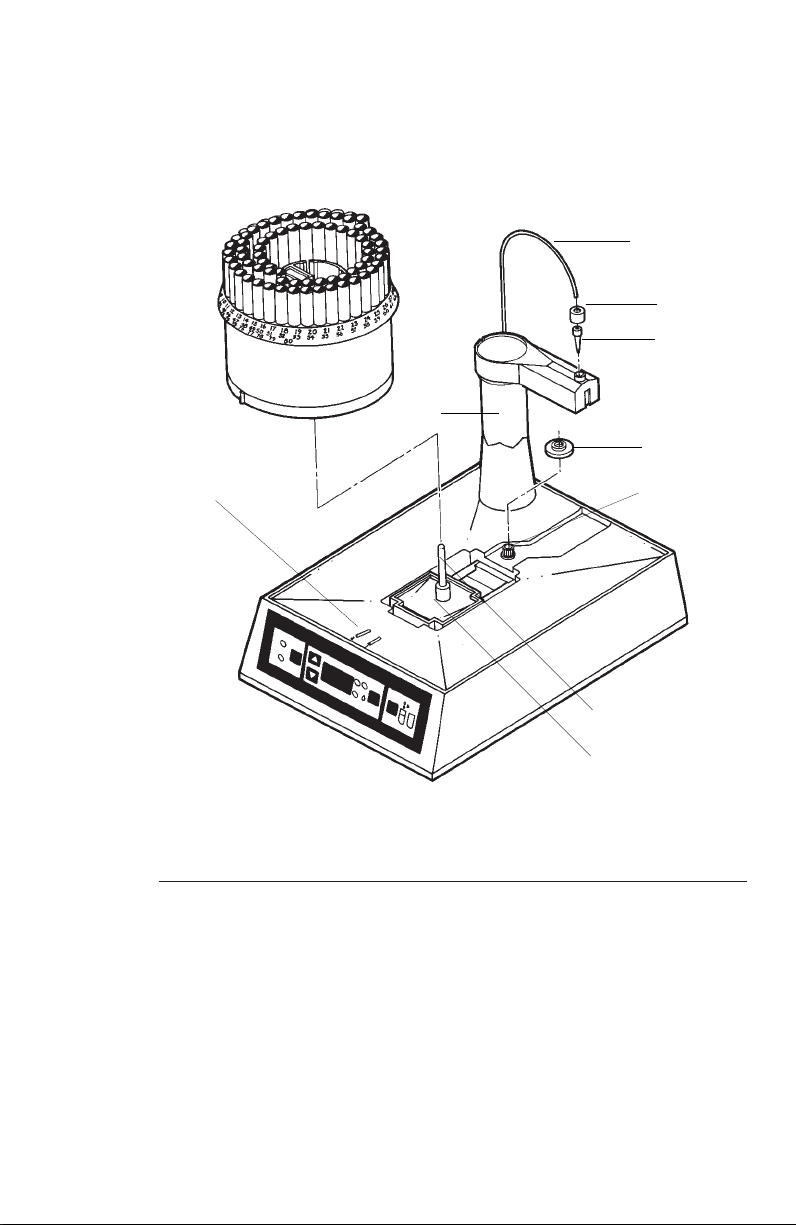

Fig. 2.1. Model 2110 Fraction Collector.

The Model 2110 Fraction Collector (Figure 2.1), shown with the

optional instrument dust cover, is designed to be used with gravity feed

columns, preparative electrophoresis and liquid chromatography systems.

The Model 2110 Fraction Collector will accurately collect up to 80

fractions, at a flow rate of up to 40 ml/min. The Model 2110 Fraction

Collector accepts standard 13 x 100 mm test tubes or, with an optional

adaptor, 1.5 ml micro test tubes. Tubes are advanced by a motor-driven

22

Page 7

carousel where tube changes are initiated upon reaching a predetermined

drop count (1-999 drops) or time interval (0.05-99.9 minutes), or upon

command from an external source.

The silicone drop former insures uniform drop size for accurate drop

count measurement. The drop former will accommodate either 1¼

1

¼16-inch inlet tubing, without the need for additional fittings.

The Model 2110 Fraction Collector is spill-proof and solvent resistant.

A drain tube at the rear of the case channels all spills to waste. The membrane front panel is sealed to the case and the carousel drive is positioned

in such a way that it will not be affected by spills.

Section 3

Unpacking and Voltage Conversion

3.1 Unpacking Instructions

Lift the instrument out of its packing by grasping the instrument case.

Do not lift by the drop arm. Remove the power cord and bag of accessories. Remove the fraction collector from its protective bag. Check off all

parts against the supplied packing list. You may want to retain the original packaging material in the event the instrument needs to be returned for

service. If repackaging is necessary, be careful to position the carousel so

that it is not resting against the motor drive gear.

8-inch or

Warning: The Model 2110 Fraction Collector is shipped in its 120 V

version. For 220 V operation, refer to the procedure below.

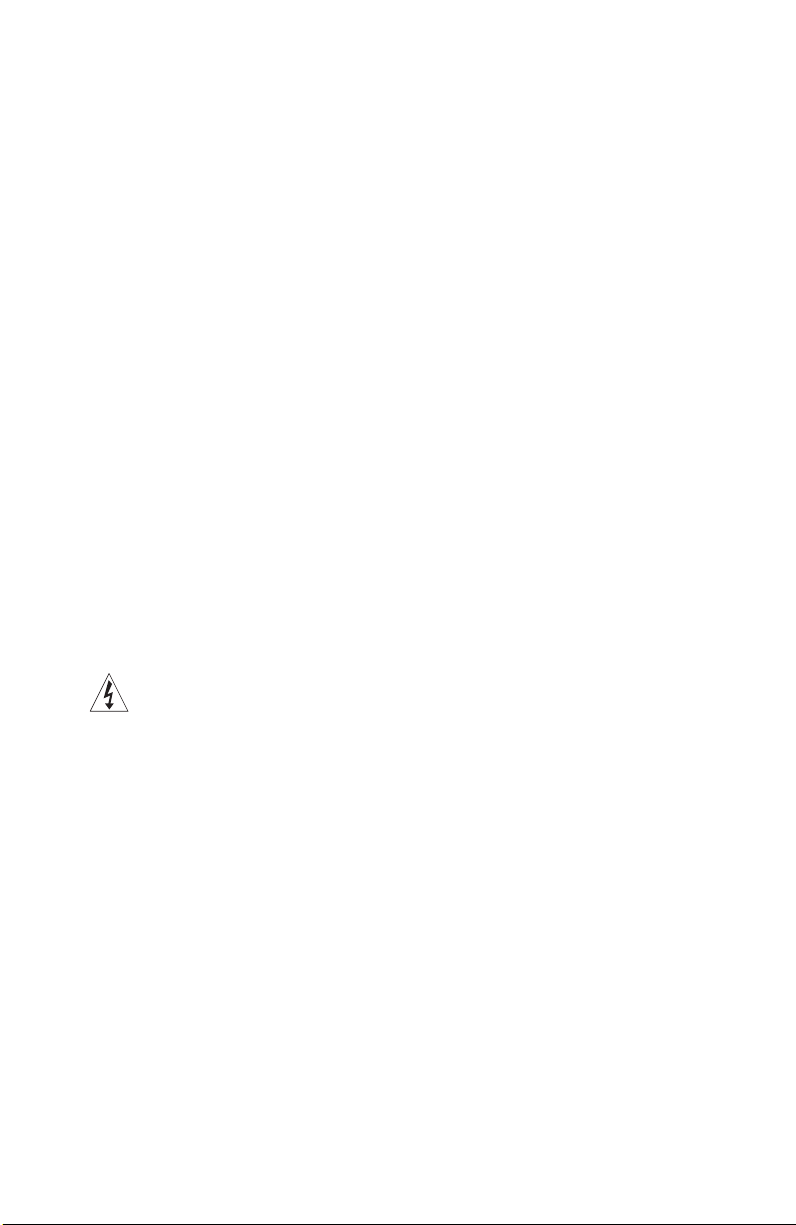

3.2 Voltage Conversion

Prior to connecting the power cord to the power entry module and

power mains, make sure the voltage indicated on the fraction collector

power entry module matches your line voltage. If it does not, use the

following procedure to make the conversion. (See Figure 3.1.)

1. Insure that the unit is disconnected from the wall socket.

2. Remove the fuse drawer with a small-blade screwdriver or similar tool.

3. Pull the fuse holder out of the fuse drawer and ensure that the voltage

shown in the window corresponds to the voltage you are using (100, 120,

220, 240 V ). To change the voltage, grasp the fuse drawer and withdraw

it (see Figure 3.1). Rotate the fuse drawer so that the voltage shown is cor-

rect, and reinsert it. The fuse holder is keyed and cannot be installed

improperly. The Model 2110 Fraction Collector uses 0.20 A fuses for

100/120 V operation, and 0.10 A fuses for 220/240 V operation.

3

Page 8

4. Reinsert the fuse drawer in the power entry module, with the locking

tab to the left. The voltage indicator will read right-side-up if the

drawer is oriented correctly. Push the fuse drawer in gently until it

snaps into place.

5. Connect the power cord to the power entry module and power mains.

6. There is no power switch on the fraction collector. When connected

to an AC power source, the Model 2110 Fraction Collector will come

on in the Stop or Set mode.

Fig. 3.1. Voltage conversion.

Fuse drawer (110 V configuration)

Fuse drawer (220 V configuration)

4

Page 9

Section 4

Physical Description and Control Features

4.1 Physical Description

Fig 4.1. Model 2110 Fraction Collector features.

Feature Function

Drop arm Directs flow to the collection tubes.

• Collection position, rotated forward, the drop

arm is directly above each collection tube.

• Standby position, rotated rearward, the drop

arm allows installation of the carousel or allows

flow to drip onto the case and to waste. To

change positions, gently lift and rotate the drop

arm.

5

Inlet tubing

Arm cap

Drop former

Drive seal

Drop arm

Drive gear

Pivot shaft

Slider

Carousel

positioning

guides

Page 10

Feature Function

Carousel Holds the collection tubes. The tube positions are

numbered 1-80 on the flange of the carousel, and

line up with the center of each tube. The carousel

is designed so that any liquid spilled in it will

flow to the center and out the rear of the base. The

carousel may also be used for storage of test

tubes.

Drop former Seals against the inlet tubing (1¼16

" or

1

¼8

" OD) to

form uniform size drops.

Arm cap Holds the drop former in place.

Drive gear Engages the carousel and advances it.

Drive seal Protects the electric drive from direct spills.

Waste line Collects drainage or spills and directs it to waste.

See Section 5.5 for connection.

Inlet tubing Inlet tubing (not included) can be any rigid or

flexible tubing with

1

¼16" or 1¼8" OD, usually

coming directly from a detector.

6

Page 11

4.2 Front Panel Functions

MODEL 2110 FRACTION COLLECTOR

Fig. 4.2. Front panel controls.

Feature Function

Run/Stop key The Run/Stop key is used to select

Time/Drop key The Time/Drop key is used to select

standby or active mode. In the active

mode, the collector will collect by

time or drops, or accept an external

signal. When the collector is controlled by a system, both the standby

and active mode lights will be lit,

and the LED display will read “---”.

collection by time or by drops.

Arrow keys The Arrow keys are used for

increasing or decreasing the length

of time for collection in each tube,

or changing the number of drops to

be collected in each tube.

ml

LED multi This three-digit display will show

min

ml/min

%

display decimal minutes or drop count that

has progressed for the tube currently

collecting. When the collector is controlled by a system, both the standby

and active mode lights will be lit, and

the LED display will read “---”.

Advance key Pressing the advance key will

advance the carousel one position.

7

Page 12

Fig. 4.3 Rear Panel connections.

4.3 Rear Panel Functions

Connection Function

Power entry Grounded 3-pin receptacle for the

module power cord. Also contained within is

9-pin “D” For remote operation of the collector.

connector The Model 2110 can be controlled by

a four-position 100 V/120 V/ 220 V/

240 V line voltage selector. The

collector is shipped in its 120 V or

220 V version. For operation at other

voltages, refer to Section 3.2.

Bio-Rad’s Model EP-1 Econo Pump,

the BioLogic LP low pressure

chromatography system, or the

BioLogic System, a high resolution

liquid chromatography system. The

Model 2110 can also be controlled by

other non-Bio-Rad equipment. See

Section 7 for additional information.

8

Page 13

Section 5

Instrument Set-Up

5.1 Tubing Installation

1. Insert the drop former, narrow end downward, into the drop arm,

pressing it firmly in the hole (see Figure 4.1).

2. Using a twisting motion, press the arm cap onto the drop arm to hold

the drop former in place.

3. Insure that the end of the inlet tubing is cleanly cut and not flattened

or deformed.

Insert tubing into the drop former, pushing down on the tubing until

the drop former starts to stretch. Do not use excessive force. Then,

gently pull out on the tubing until the drop former returns to its

original shape.

4. The inlet tubing may be routed through the tubing holder fitting at the

rear of the movable portion of the drop arm.

9

Page 14

ab

21

c

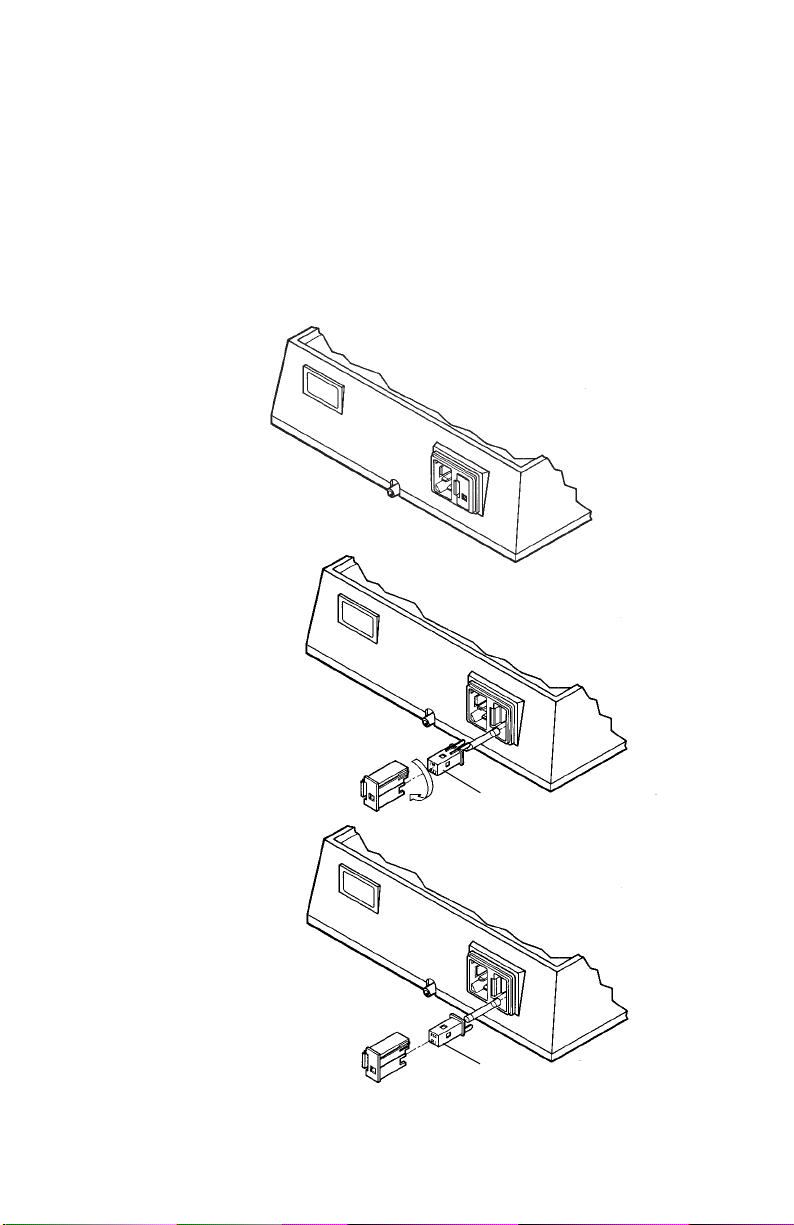

Fig. 5.1. Carousel installation.

10

Page 15

5.2 Carousel Installation

The Model 2110 Fraction Collector fills tubes from the outside of the

carousel inward. Load as many tubes as desired into the carousel, starting

at the outside end of the spiral and moving inward. The carousel need not

be fully loaded, since any eluant flowing after the last tube will drain

through the carousel into the well in the case and out the central drain tube

located at the rear of the instrument.

1. Swing the drop arm to the waste (rear) position by gently lifting and

rotating (Figure 5.1a).

2. Hold the carousel so that the notch in its outline is toward the rear of

the instrument.

3. Place the carousel on the pivot shaft, holding it about 1¼2" above its

seated position.

4. Push the carousel and the pivot shaft toward the rear of the

instrument, settling it down over the drive gear so that the gear is

trapped near the start of the spiral.

5. Holding the gear teeth free from engagement, turn the carousel counterclockwise until it stops against the gear (Figure 5.1b). Release the

carousel and it will spring into engagement on the drive gear.

Engagement may be confirmed by trying to move the carousel gently

(Figure 5.1c).

6. Check the alignment with the two positioning guides located on the

top front of the instrument case. The number corresponds to the first

tube that will be filled.

Swing the drop arm into the collect (front) position. Make sure the

drive gear is fully seated into the grooved underside of the carousel. This

automatically aligns the drop former over the first tube.

5.3 Collection Tube Installation

Load the carousel with up to eighty 13 x 100 mm test tubes. You may

find a tube which fits too tightly into the carousel. It is best to discard

these rather than risk breaking the tube upon installation. Tubes 39

through 53 are raised above tubes 1-38 to make tube removal easier.

To locate an individual tube in a carousel, find its number on the

angled flange. The tube is in line with the number and the center of the

carousel. The top row of numbers corresponds to the outermost row of

tubes, the middle row corresponds to the next row of tubes, and the bottom row to the innermost row of tubes. To divert a large amount of eluant

to waste at the beginning of a run, you can simply remove the first

11

Page 16

collection tube, and the eluant will flow through the carousel to waste out

the rear of the collector.

5.4 Waste Collection Port

All spills on the top of the case and carousel, as well as waste eluant

within the carousel, drain to a central waste-collection port at the rear of

the instrument case. From this port, a drain tube passes out through the

rear of the case. This tube may be directed into a waste-collection vessel,

or an extension tube may be attached to the provided barbed union fitting.

Note: To provide proper drainage, the waste-collection vessel must be

positioned so that the exit of the drain tube is no higher than the bot-

tom of the fraction collector case.

Section 6

Stand Alone Operation

This section describes the stand-alone operation of the Model 2110

Fraction Collector. Refer to Section 7 for information about connecting

the Model 2110 to the Model EP-1 Econo Pump, the BioLogic LP, the

BioLogic System, or Bio-Rad’s preparative electrophoresis systems..

6.1 Stop (Standby) and Run

The Model 2110 Fraction Collector powers up automatically in the

Stop or Standby mode, with the LED lit. When in the Stop mode, the

collection mode, either Time or Drops can be selected, and the time interval or number of drops to be collected per tube can be set. When in the

Run mode, the Arrow keys are inactivated.

6.2 Collection Modes

The Model 2110 Fraction Collector will collect fractions by counting

the number of drops or by a specified time interval per tube. The collection mode is selected using the key on the front panel. In either mode,

time and drop count are continuously monitored, so that you can switch

between the two collection modes, monitoring time and drop count since

the last tube advance.

12

Page 17

Drop Collection Mode

The fraction collector counts drops at flow rates up to ~5 ml/min. Drop

counting is performed by the sensor in the drop arm. If the flow rate exceeds

5 ml/ min., counting will not be accurate, and use of the Time mode is

recommended.

1. Plug the Model 2110 Fraction Collector into a

grounded wall outlet. The collector will power

up in the Stop, or Standby mode, with the

LED lit.

2. Press the Time/Drop key until the LED is

lit.

3. Select the number of drops to be collected per

collection tube by pressing the keys.

The LED display will display the number of

drops to be collected.

4. Insure that the carousel is in the desired position, and press the Run/Stop key to begin collection. The LED will be lit.

5. The fraction collector will reset the display to

‘0’ and begin counting drops up to the drop

limit set, and then advance. The display reads

‘A’ during each carousel advance.

13

Page 18

Time Mode

The fraction collector collects fractions at intervals of .01 minutes, for

times per tube in the range of .05 to 9.99 minutes, and at.10 minute intervals for times per tube in the range of 10.0 to 99.9 minutes.

1. Press the Run/Stop key until the LED is lit.

2. Press the Time/Drop key until the LED is lit.

3. Select the time interval per tube by pressing the

keys. The LED multi-display will display

the time interval selected.

4. Insure that the carousel is in the desired position.

Press the key to begin the program. The

LED will be lit.

5. The fraction collector will reset the display to ‘0’,

and begin counting time up to the set time interval, and then advance.

Note: When the Model 2110 Fraction Collector reaches the preset

time interval in a time mode collection scheme, it will collect one

extra drop prior to advancing. This minimizes the chance of a drop

falling between tubes during carousel advance. If the delay between

drops is greater than 5% of the preset time interval, the collector will

advance to the next fraction instead of waiting for one extra drop.

6.3 Operation without Direct Connection

to a System

The Model 2110 can be used in stand-alone mode with any system.

Simply set up the collector in time mode or drop mode and press “start”

at the initiation of the method.

Alternatively, a light-weight gravity feed column (such as 2 ml

Poly-Prep

®

columns, Econo-Pac®columns, and small Econo-Column

®

chromatography columns) can be connected directly to the Model 2110

Fraction Collector, avoiding the need for interconnecting tubing. A

two-way stopcock is used to make the connection and control eluant flow.

14

ml

min

ml/min

%

Page 19

1. Attach the stopcock into the hole in the top of the drop arm. Position

the stopcock so that its handle overhangs the end of the arm and is free

to turn.

2. Attach the column to the stopcock, making sure both stopcock and

column are firmly connected.

6.4 Manual Advance

The Model 2110 Fraction Collector may be manually advanced to the

next tube by pressing the key. This key is functional in both

Stop/Standby and Run modes. When pressed during a run, the drop and

time counts will automatically reset to 0, and restart the time or drop

count.

6.5 Reset/End of Run

If the Model 2110 Fraction Collector is allowed to complete 80

advances, the display will read END. To reset, push twice. (Note:

Manual advances are not counted.) Reposition the carousel to begin

collection again.

Section 7

Remote Operation of Model 2110

The Model 2110 Fraction Collector may be controlled remotely.

7.1 Remote Operation with Model EP-1 Econo

Pump

Use System Cable 1 (catalog number 731-8261) to connect the Econo

Pump to the fraction collector. Connect the 9-pin “D” connector to rear of

the Model 2110, and the mini-DIN plug to the rear port of the Econo

Pump with the collector icon. (See Econo Pump manual if further

explanation is required.) In order for the Econo Pump to remotely operate

the Model 2110, a method must be programmed into the Econo Pump that

calls for fraction collection. You will be prompted to program the fraction

size (volume), the void volume, and the total volume collected. Please

note that to correctly use the void volume function, a Model SV-3

Diverter/Bypass valve (catalog number 731-8322) must be connected.

When programming is complete, the LED display underneath the fraction

collector icon on the front panel of the Econo Pump will light and the

Model 2110 display will read “---” indicating that the collector is

controlled by a system.

15

Page 20

7.2 Remote Operation with BioLogic LP

Use System Cable 1 (catalog number 731-8261) to connect the

BioLogic LP to the fraction collector. Connect the 9-pin “D” connector to

rear of the Model 2110, and the mini-DIN plug to the rear port of the

BioLogic LP controller in the port marked FRACTION COLLECTOR.

(See BioLogic LP manual if further explanation is required.) The

BioLogic LP enables sophisticated collection, including programmed

collection windows, peak detection, and a combination of peak detection

and collection windows. The BioLogic LP sends “advance” commands to

the fraction collector.

7.3 Remote Operation with BioLogic System

Use System Cable 5 (catalog number 731-8265) to connect the

BioLogic System to the fraction collector. Connect the 9-pin “D” connector to rear of the Model 2110. Connect the black wire to the FC ADV port

of the AUX connector, which is port #5. Connect the white wire to the

GND port of the AUX connector, which is port #9. Refer to the separate

instruction sheet for the wiring diagram and color code for System Cable

5.

To connect the wires to the AUX port of the BioLogic System, turn

the small flathead screwdriver counterclockwise to back out the screw.

Insert the bare wire into the port and turn the screwdriver clockwise to

secure the connection. The BioLogic System enables sophisticated

collection, including programmed collection windows, peak detection,

and a combination of peak detection and collection windows. The

BioLogic System sends “advance” commands to the fraction collector.

7.4 Remote Operation with other Instruments

Use System Cable 5 (catalog number 731-8265) to connect the Model

2110 Fraction Collector to other instruments. Signals are accessible via

the 9-pin “D” connector on the back of the instrument. All of the input and

output signals, with the exception of the Advanced Contact pins 7 and 8,

are TTL active low.

Drop counting is performed by the sensor in the drop arm.

Pin Function Signal Type

1 External Advance Input

2 Drops Output

3 Advanced Output

4 Ready Output

5 Alarm Output

16

Page 21

Pin Function Signal Type

6 External Start Input

7 Advanced Contact 1 Output

8 Advanced Contact 2 Output

9 Logic Ground

External Advance (Pin 1)

The External Advance line performs two functions. It causes the

instrument to enter the Remote mode when held low for longer than two

seconds, and it causes the carousel to advance one position each time a

high-going pulse is applied. To use the control line to advance the

carousel, connect pin 1 of the 9-pin “D” connector to pin 9 and hold for

at least 100 msec, then release. Alternatively, the carousel will advance by

applying an external signal (TTL low logic level ) to pin 1 for at least 100

msec (with a return to TTL high logic level state). Be sure to connect the

controlling instrument’s ground to the fraction collector’s logic ground,

pin 9. When remote mode is entered (by holding pin 1 low for greater than

2 seconds) the time and drop mode features of the collector are disabled

and the front panel control function is lost, with the exception of the manual tubing advance key, which will function normally. The remote mode

is indicated by three horizontal bars on the fraction collector display.

Drops

The fraction collector will generate a 50 msec TTL pulse on pin 2

every time a drop is detected.

Advanced

Each time the carousel is advanced, a low-going TTL pulse is generated on pin 3. This signal is useful for triggering the event mark input of

a chart recorder to indicate fraction intervals. If the recorder being used

does not support TTL signals, then see below under “Advanced Relay

Contacts to trigger the event input.

Ready

A low level signal on pin 4 indicates that the fraction collector is functioning properly and that it is ready to accept input from a controlling

device.

Alarm

If the fraction collector is unable to carry out an external advance

command due to a malfunction (such as a jammed carousel), a low level

will be held on pin 5 until the problem is cleared.

17

Page 22

External Start

The external start line is used to allow another instrument to remotely start and stop the fraction collector’s programmed functions. Applying

a low pulse of at least 100 msec to pin 6 has the same effect as pressing

the Run/Stop key on the front panel. That is, the first pulse will start the

previously selected mode (drops or time) and the second pulse will stop

the program.

Advanced Relay Contacts

Pins 7 and 8 provide a normally open set of contacts that are momentarily closed each time the carousel is advanced. This signal is a convenient way to interface with equipment that does not support TTL level signals. The maximum current and voltage which can be put across these

pins is 24 V DC and .25 A.

SSeeccttiioonn 88

AAcccceessssoorriieess

8.1 Instrument Dust Cover

The dust cover (catalog number 731-8136) is intended for use only

when the drop arm is in the collect (forward) position. The inlet tube may

be directed out the top opening or through the small opening at the bottom/rear of the instrument.

8.2 Micro Tube Adaptor

The micro tube adaptor is intended to convert a carousel for use with

1.5 ml micro test tubes (catalog number 223-9500).

Align the step in the outline of the adaptor with the step of the outline

of the carousel. Position the adaptor so that its four legs fit into the four

openings in the inner wall of the carousel. Push the adaptor downward

until it is fully seated on the carousel.

Operation with micro tubes is identical to operation with standard test

tubes. To prevent splashing, collect no more than 1 ml of eluant in each

micro tube.

18

Page 23

Section 9

Cleaning and Maintenance

The Model 2110 Fraction Collector requires very little maintenance to

insure reliable operation. Two procedures are outlined below.

9.1 Drop Sensor

The Model 2110 Fraction Collector counts drops through an optical

sensor located in the drop area inside the drop former arm. Precipitates or

other foreign debris may obscure the optical path and cause erroneous

drop counts. To prevent this problem, the drop sensor should be cleaned

periodically. An ordinary cotton swab moistened with water can be used

to clean the sensor.

9.2 Instrument Case, Carousel, and Drainage Tube

During normal operation, spills and splashes may result in precipitates forming on the case and carousel. Use a squirt bottle and soapy water

to wash down carousel and case. The water will drain out the back of the

unit through the drainage tube. Prior to squirting the instrument case,

make sure the rubber seal around the gear device is in place. Insure that

the waste tube is draining properly to avoid instrument damage.

Section 10

Troubleshooting

Problem Cause Remedy

Drops miss tubes Carousel misaligned Reposition carousel

Drop former missing Replace drop former

Drop head misaligned Align

Unit not level Place unit on level surface

Drops miss tube Flow rate greater Reduce flow rate

during advance than 5 ml/min

Drops not counted Drop sensor is dirty Clean drop sensor

or E08 error code

Flow rate greater than Use Time collection mode

5 ml/min

Operating in a windy Try relocating unit, or put

environment a piece of tape over slot in

No power Fuses Check fuses, replace if

drop arm

necessary

19

Page 24

Fraction Collector Error Codes

There are several self-diagnostics built into the software of the Model

2110 Fraction Collector. Below are the principal error numbers and codes

which occur. If other error codes appear, try unplugging and replugging

the instrument, or call Bio-Rad Technical Service.

20

Page 25

Error

Number Cause Remedy

E00 Hardware failure Unplug and replug to

E01 mains power. If error perE04 sists, contact your local

Bio-Rad representative.

E02 Motor jam Reposition carousel;

unplug and replug to

mains power. If problem

persists, apply WD-40 to

the motor shaft. If motor

must be replaced, order

part number 8006484.

E08 Drop sensor If problem persists after

E10 cleaning the drop sensor

with a wetted cotton

swab, follow the

Procedure for

Adjusting Drop Detector

Signal Level. See

Appendix B. If drop sensor must be replaced,

order part number

8006481.

Appendix A

Technical Specifications

Capacity

Collection basis 1 to 999 drops in 1 drop increments

Materials of construction Case and carousel: polypropylene

Eighty 13 x 100 mm glass or plastic test

tubes, or 1.5 ml micro test tubes, when

using adaptor (catalog number 731-8135)

0.05 to 9.99 minutes in 0.01 minute

increments

10.0 to 99.9 minutes in 0.1 minute

increments

See Econo Pump manual for other collection options when connected to the Econo

System

Front panel: hard-coated polycarbonate

Drop former: silicone rubber

Waste outlet tube: polyurethane

21

Page 26

Operating temperature + 4 to + 40 °C

Storage temperature - 5 to + 71 °C

Line voltage 90-132 VAC or 180-265 VAC, 47 Hz

to 63 Hz

Power consumption 25 VA max, 15 W max, fused

Fuse rating

100,120 V Operation 200 mA, 250 V, 5 x 20 mm, Fast Acting,

UL/CSA approved

Ref: Schuter 034.3923 or Bussmann

GMA200mA

220,240 V Operation 100 mA,250 V, 5 x 20 mm, Time Lag

(FST), VDE approved

Ref: Schuter 034.3107

Size 24.0 x 33.0 x 25.0 cm (W x D x H)

Carousel does not overhang base at any

point in operation

Weight 2.3 kg

Output signals See Section 6.5 of the manual

Regulatory CSA: C22.2 No. 151-M1986

Compliance TÜV:EN61010-1: 1993

CE: EN55011: 1991 CLASS A,

EN50082-2: 1995

Appendix B

Model 2110 Fraction Collector

Procedure for Adjusting Drop Detector

Signal Level

This procedure should be performed:

1. After replacing the drop arm on the Model 2110 Fraction Collector.

2. Whenever "EO8" is displayed. In this situation, clean the optical window

and light source prior to performing this procedure.

Safety: The Model 2110 Fraction Collector should be purged of all hazardous

chemicals and be disconnected from the main power supply prior to conducting this procedure. Ensure the case is dry. Perform this procedure on a dry surface. During the actual adjustment of the signal level (step 10), potentially

dangerous voltages are present inside the case - do not touch exposed wires.

Use a plastic-handled screwdriver to minimize the risk of electric shock.

22

Page 27

Tools required: Small phillips-head screwdriver, small slot-head screw

driver.

Procedure:

1. Disconnect the Model 2110 collector from the power source.

2. Disconnect any tubing leading to the fraction collector, remove the yellow

plastic arm cap, white rubber drop former, and carousel.

3. Clean the optical window and light source (located in drop arm), using the

a cotton swab moistened with water.

4. Set fraction collector on its side with underside of the instrument facing

toward you.

5. Remove the four phillips-head screws from the underside of the instrument. Pull gently on the rubber feet to remove the underside panel.

6. Locate the large circuit board with the power transformer. On this board,

locate a small rectangular potentiometer, identified as "R3" on the circuit

board. R3 is located near where the ribbon cable connects to the circuit

board.

7. Read safety warning above. Use a plastic-handled screwdriver to min-

imize the risk of electric shock.

8. Press and hold down both the "up" and "down" arrow keys on the front

panel.

9. While continuing to press down arrow keys, connect the fraction collector to the power source. Continue to press down both keys for five seconds, then release.. The "time" LED will glow steadily, and the display

will show a decimal point, followed by three characters (._ _ _). The fraction collector is now in a "diagnostic" mode.

10. Using a small flat-bladed screwdriver, adjust R3 by turning the small

screw until the display reads between "0A0" and "0A5".

If a reading between "0A0" and "0A5" cannot be obtained, contact your

local Bio-Rad representative.

11. Disconnect unit from the power source.

12. Replace underside panel.

13. Connect fraction collector to a power source. The Model 2110 Fraction

Collector is now ready for operation.

23

Page 28

Appendix C

Ordering Information

Model 2110 Fraction Collector

Catalog

Number Product Description

731-8122 Model 2110 Fraction Collector, 100/120 VAC (USA

power cord), includes 80-tube carousel and tubing

connectors

731-8120 Model 2110 Fraction Collector, 220/240 VAC (no

power cord), includes 80 tube carousel and tubing

connectors

731-8130 Carousel, 80 tube capacity

731-8131 Replacement Drop Former Kit, includes 2 drop

and 2 drop caps

731-8135 Micro Tube Adaptor

731-8136 Instrument Dust Cover

731-8261 Econo System Cable 1, 8-pin Mini-DIN to DB-9 con-

nector, to connect the Model 2110 Fraction Collector

to the Econo Pump or BioLogic LP

731-8265 Econo System Cable 5, DB-9 connector to bare

wires, to connect the Model 2110 Fraction Collector to

the BioLogic System or other external instruments

731-8268 Econo System Cable 8, 8-pin standard DIN to DB-9

connector, for connecting the Model 2110 Fraction

Collector to Model 1327 Recorder

731-8322 Model SV-3 Diverter/Bypass Valve

Model EP-1 Econo Pump

731-8140 Model EP-1 Econo Pump, 100/120 VAC (USA power

cord), includes tubing set and starter fittings kit

731-8142 Model EP-1 Econo Pump, 220/240 VAC (no power

cord), includes tubing set and starter fittings kit

Bio-Rad sells a complete line of integrated chromatography systems

for protein purification. For information on the BioLogic System family

of products, contact your local Bio-Rad representative.

24

Page 29

Life Science

Group

Web site www.bio-rad.com USA (800) 4BIORAD Australia 02 9914 2800

Austria (01) 877 89 01 Belgium 09-385 55 11 Brazil 55 21 507 6191

Canada (905) 712-2771 China 86-10-8201-1366/68 Denmark 45 44 52-1000

Finland 358 (0)9 804 2200 France 01 47 95 69 65 Germany 089 318 84-177

Hong Kong 852-2789-3300 India (91-124) 6398112/113/114 Israel 03 951 4124

Italy 34 91 590 5200 Japan 03-5811-6270 Korea 82-2-3473-4460

Latin America 305-894-5950 Mexico 52 5 534 2552 to 54

The Netherlands 0318-540666 New Zealand 64-9-4152280 Norway 47-23-38-41-30

Russia 7 095 979 98 00 Singapore 65-2729877 Spain 34-91-590-5200

Sweden 46 (0)8-55 51 27 00 Switzerland 061-717-9555 United Kingdom 0800-181134

00-000 0000 Sig 1200Bulletin 0000 US/EG Rev A

Bio-Rad

Laboratories

M7318120 Rev G

Loading...

Loading...