Page 1

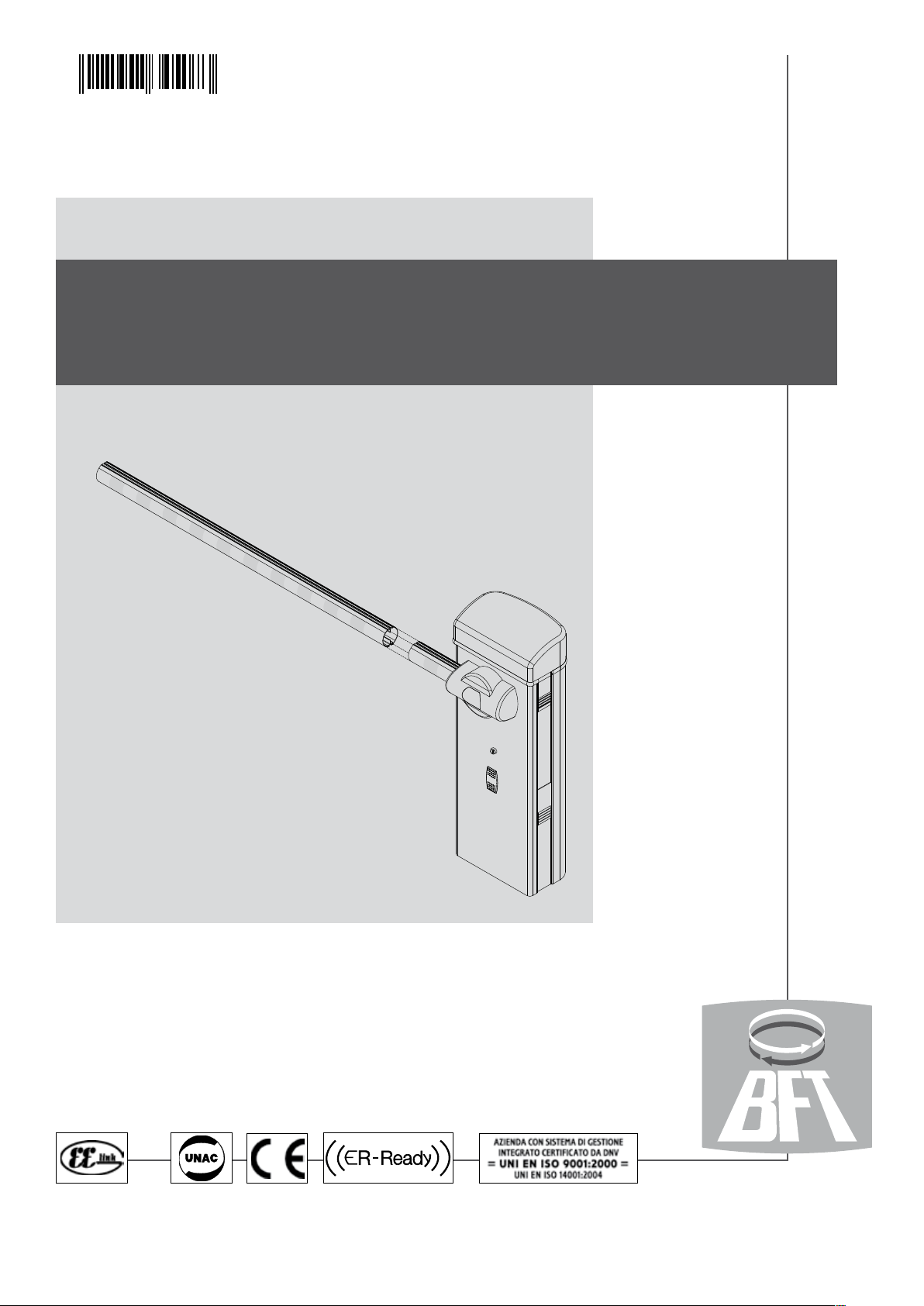

AUTOMATISMO ELETTROMECCANICO PER BARRIERA VEICOLARE

8

027908 345073

ELECTROMECHANICAL CONTROL DEVICE FOR VEHICULAR BARRIERS

AUTOMATISME ELECTROMECANIQUE POUR BARRIERE POUR VÉHICULES

ELEKTROMECHANISCHER ANTRIEB FÜR FAHRZEUGSCHRANKEN

AUTOMATISMOS ELECTROMECANICOS PARA BARRÉRAS VEHICULAR

ELEKTROMECHANISCH AUTOMATISERINGSSYSTEEM VOOR SLAGBOOM

D811528 00100_03 10-11-09

MICHELANGELO

MICHELANGELO

ISTRUZIONI D’USO E DI INSTALLAZIONE

INSTALLATION AND USER’S MANUAL

INSTRUCTIONS D’UTILISATION ET D’INSTALLATION

INSTALLATIONS-UND GEBRAUCHSANLEITUNG

INSTRUCCIONES DE USO Y DE INSTALACION

GEBRUIKS- EN INSTALLATIEAANWIJZINGEN

Attenzione! Leggere attentamente le “Avvertenze” all ’interno! Caution! Read “Warnings” inside carefully! Attention! Veuillez lire attentivement les Avertissements qui se trouvent à l’intérieur!

Achtung! Bitte lesen Sie aufmerksam die „Hinweise“ im Inneren! ¡Atención¡ Leer atentamente las “Advertencias” en el interior! Let op! Lees de “Waarschuwingen” aan de binnenkant zorgvuldig!

Page 2

Con scavo di fondazione:

With foundation plate embedded in ground:

Avec tranchée de fondation:

Mit Fundamentgraben:

Con excavación de cimentación:

Met uitgraving:

Non in dotazione /

Not supplied /

Ne sont pas fournis /

Nicht im lieferumfang

/

No asignadas en el

equipamiento base

/

Niet meegeleverd

*

Con tiranti:

With anchor bolts:

Avec tirants:

Mit Ankerbolzen:

Con tirantes:

Met spankabels:

1

2

3

5

4

3

B1

B2

A

V

V

12

35

*

1

2

INSTALLAZIONE VELOCE-QUICK INSTALLATION-INSTALLATION RAPIDE

SCHNELLINSTALLATION-INSTALACIÓN RÁPIDA - SNELLE INSTALLATIE

S

F

Ft

CF

T

CS

A

IM

QR

AL

RMM

Fr

4

4

2 x 0,75

3 x 1,5

3 x 0,75

MICHELANGELO - 3

D811528 00100_03

Page 3

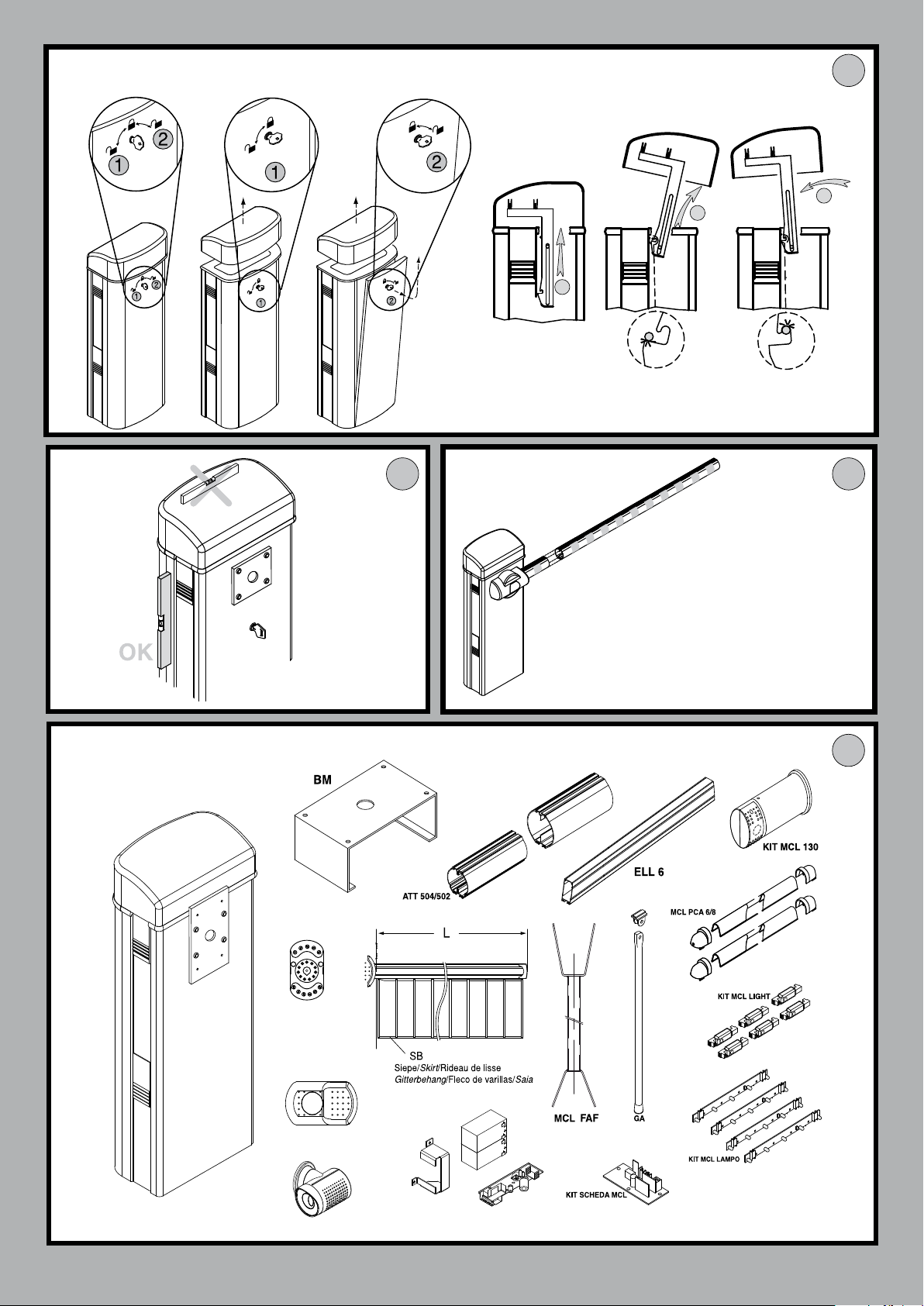

E

F

D

1

2

3

Per montaggio aste fare riferimento ai manuali ATT e ELL,

See manuals ATT and ELL for boom assembly,

Pour monter la barre consultez les manuels ATT et ELL,

Für die Montage der Stange auf die Handbücher ATT und ELL

Bezug nehmen,

Para montaje de los mástiles consultar los manuales ATT y ELL,

Voor montage stangen de ATT- en ELL-handboeken raadplegen.

Apertura e chiusura coperchio e portina, Opening and closing cover and door, Ouverture et fermeture du couvercle et portillon,

Önung und Schließung Abdeckung und kleine Tür, Apertura y cierre de la tapa y de la portezuela, Opening en sluiting deksel en klepje.

ACC MCL ELL

MICHELANGELO

KIT MCL BAT

RMM

MCL RFL

G

Accessori opzionali, Optional extras, Accessoires facultatifs, Sonderzubehör, Accesorios Opcionales, Optionele Accessoires.

ATT 704/706

4 - MICHELANGELO

D811528 00100_03

Page 4

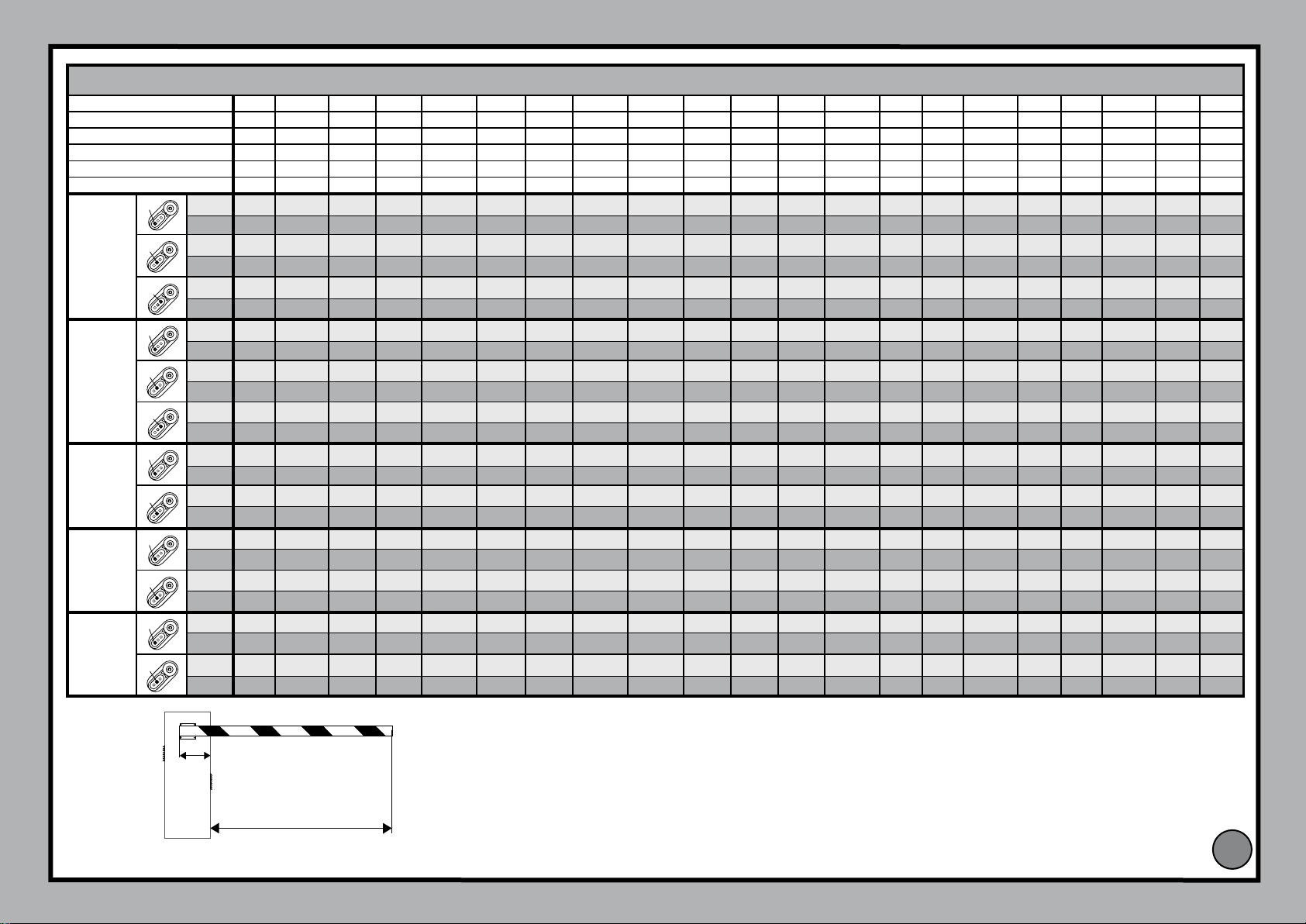

Accessori MICHELANGELO: lunghezza utile asta e bilanciamento. / MICHELANGELO Accessories: working length of boom and balancing. / Accessoires MICHELANGELO: longueur utile de la barre et équilibrage. /

MICHELANGELO - 5

D811528 00100_03

MICHELANGELO Zubehör: Nutzlänge Schranke und Auswuchtung. / Accesorios MICHELANGELO: longitud útil mástil y balance. / Accessoires MICHELANGELO: nuttige lengte slagboom en balancering.

SB + SB + SB + SB + SB + SB + SB

MCL PCA (solo sopra l’asta)*

MCL PCA (solo sotto l’asta)*

KIT MCL LIGHT + LIGHT + LIGHT + LIGHT + LIGHT + LIGHT + LIGHT + LIGHT

GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM

BIR + BIR + BIR + BIR + BIR + BIR + BIR

A

MCL 40 +

ATT704

B

C

A

MCL 40 +

ELL6

B

C

A

MCL 60 +

ELL6

B

A

MCL 60 +

ATT704 +

ATT502

B

A

MCL 60 +

ATT706

B

1

2

MIN L 2,8 2,8 2,9 3,2 3,3 3,4 3,5 3,6 3,5 3,7 3,9 3 3 3,1 3,5 3,5 3,6 3,8 3,8

MAX L 3 3,1 3,1 3,4 3,5 3,6 3,7 3,9 3,8 3,9 4 3,2 3,2 3,3 3,7 3,8 3,9 4 4

MIN L 3,4 2,1 2,1 2,2 2,4 2,4 2,5 2,6 2,7 2,6 2,7 2,8 2,3 2,3 2,4 2,6 2,7 2,8 2,8 2,9 3

MAX L 4 2,5 2,6 2,6 2,9 2,9 3 3,1 3,3 3,2 3,3 3,5 2,7 2,7 2,8 3,1 3,2 3,3 3,4 3,5 3,6

MIN L 2,6 1,6 1,6 1,7 1,9 2 2 2,1 2,2 2,1 2,2 2,3 1,8 1,8 1,9 2,1 2,1 2,2 2,3 2,3 2,4

MAX L 3,2 2,1 2,1 2,2 2,4 2,5 2,5 2,6 2,8 2,7 2,8 2,9 2,3 2,3 2,4 2,7 2,7 2,8 2,9 3 3,1

MIN L 3 3,1 3,2 3,6 3,6 3,8 3,9 3,3 3,3 3,4 3,9 3,9

MAX L 3,3 3,3 3,4 3,8 3,9 4 4 3,5 3,5 3,7 4 4

MIN L 3,8 2,3 2,3 2,4 2,6 2,7 2,8 2,9 3,1 3 3,1 3,3 2,5 2,5 2,6 2,9 3 3,1 3,3 3,3 3,3

MAX L 4 2,7 2,8 2,9 3,2 3,3 3,4 3,5 3,7 3,6 3,8 4 2,9 3 3,1 3,5 3,6 3,7 3,9 4 4

MIN L 3 1,8 1,8 1,9 2,1 2,2 2,3 2,3 2,4 2,3 2,5 2,6 2 2 2,1 2,3 2,4 2,5 2,6 2,7 2,8

MAX L 3,8 2,3 2,3 2,4 2,7 2,8 2,9 3 3,1 3 3,2 3,4 2,5 2,5 2,6 3 3 3,2 3,3 3,4 3,6

MIN L 5,3 4,2 4,3 4,4 4,9 5 5,4 5,3 5,4 5,4 5,5 5,6 4,5 4,6 4,7 5,3 5,4 5,4 5,5 5,6 5,7

MAX L 6 4,7 4,8 4,9 5,5 5,6 5,9 6 6 6 6 6 5 5,1 5,2 5,9 6 6 6 6 6

MIN L 4,8 3,2 3,2 3,3 3,9 4 4,3 4,2 4,4 4,3 4,4 4,5 3,6 3,7 3,8 4,3 4,4 4,5 4,4 4,5 4,8

MAX L 6 4 4,1 4,2 4,9 4,9 5,3 5,3 5,5 5,5 5,5 5,5 4,4 4,4 4,5 5,3 5,3 5,5 5,5 5,6 5,9

MIN L 5,2 4,5 4,5 4,7 4,9 5,1 5,2 5,2 5,3 4,7 4,8 5 5,2 5,3 5,4

MAX L 6 5,2 5,3 5,5 5,7 5,9 5,9 6 6 5,5 5,6 5,8 6 6 6

MIN L 3,8 2,8 2,9 3,1 3,1 3,4 3,4 3,5 3,6 3,3 3,4 4,2 3,8 3,8 3,9

MAX L 5,1 4,1 4,2 4,5 4,5 5 4,9 5 5,1 4,5 4,6 5 5,1 5,1 5,1

MIN L 5,3 3,6 3,7 3,8 4,2 4,3 4,4 4,5 4,7 4,6 4,8 5 3,8 3,9 4 4,4 4,5 4,6 4,8 4,9 5,1

MAX L 6 4,1 4,2 4,3 4,7 4,8 4,9 5,1 5,3 5,2 5,4 5,6 4,3 4,4 4,5 4,9 5 5,2 5,4 5,5 5,7

MIN L 4,2 2,9 2,9 3 3,3 3,3 3,5 3,6 3,7 3,6 3,8 3,9 3 3,1 3,2 3,5 3,6 3,7 3,8 3,9 4

MAX L 5,3 3,6 3,7 3,8 4,2 4,2 4,4 4,5 4,7 4,6 4,8 5 3,8 3,9 4 4,4 4,5 4,6 4,8 4,9 5,1

+

PCA+ PCA

+

PCA+ PCA

+

PCA + PCA+ PCA+ PCA

+

PCA

+

PCA

+

PCA+ PCA

+

PCA+ PCA

+

PCA+ PCA+ PCA

+

PCA+ PCA

35 cm

L

L: Lunghezza utile asta.

L: Working boom length.

L: Longueur utile de la barre.

L: Nutzlänge der Schranke.

L: Longitud útil mástil.

L: Nuttige lengte slagboom.

1

*

(above boom only)

(uniquement sur la barre)

(nur über der Schranke)

(sólo sobre el mástil)

(alleen boven de slagboom)

2

*

(below boom only)

(uniquement sous la barre)

(nur unter der Schranke)

(sólo debajo el mástil)

(alleen onder de slagboom)

G1

Page 5

1

4

Bilanciamento Asta, Boom balancing, Equilibrage de la barre, Auswuchtung der Stange, Balance del mástil, Balancering stang.

2

0°

45°

G3

3

5

+ 45 °

- 45 °

90 °

0 °

+ 45 °

- 45 °

45° OK

6 - MICHELANGELO

D811528 00100_03

Accessori MICHELANGELO 80: lunghezza utile asta e bilanciamento. / MICHELANGELO 80 Accessories: working length of boom and balancing. / Accessoires MICHELANGELO 80: longueur utile de la barre et équilibrage. /

MICHELANGELO 80 Zubehör: Nutzlänge Schranke und Auswuchtung. / Accesorios MICHELANGELO 80: longitud útil mástil y balance. / Accessoires MICHELANGELO 80: nuttige lengte slagboom en balancering.

G2

SB + SB + SB + SB + SB + SB + SB

MCL PCA (solo sopra l’asta)*

MCL PCA (solo sotto l’asta)*

KIT MCL LIGHT + LIGHT + LIGHT + LIGHT + LIGHT + LIGHT + LIGHT + LIGHT

GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM + GAM

BIR + BIR + BIR + BIR + BIR + BIR + BIR

MCL 80 +

ATT706

MCL 80+

ATT704+

ATT504

A

A

1

2

MIN L 5,4 5,5 5,6 5,6 5,6 5,8

MAX L 5,6 5,7 5,8 5,8 5,9 6

MIN L 7,9 6,4 6,5 6,8 7,1 7,4 7,1 7,5 7,9 6,9 7 7,3 7,6 7,8 7,9

MAX L 8 7,1 7,2 7,5 7,8 8 7,6 8 8 7,3 7,4 7,8 8 8 8

+

PCA+ PCA

+

PCA+ PCA

+

PCA + PCA+ PCA+ PCA

+

PCA

+

PCA

+

PCA+ PCA

+

PCA+ PCA

1

*

(above boom only)

(uniquement sur la barre)

(nur über der Schranke)

(sólo sobre el mástil)

(alleen boven de slagboom)

35 cm

+

PCA+ PCA+ PCA

+

PCA+ PCA

2

*

(below boom only)

(uniquement sous la barre)

(nur unter der Schranke)

(sólo debajo el mástil)

(alleen onder de slagboom)

L: Lunghezza utile asta.

L: Working boom length.

L: Longueur utile de la barre.

L: Nutzlänge der Schranke.

L: Longitud útil mástil.

L: Nuttige lengte slagboom.

L

Page 6

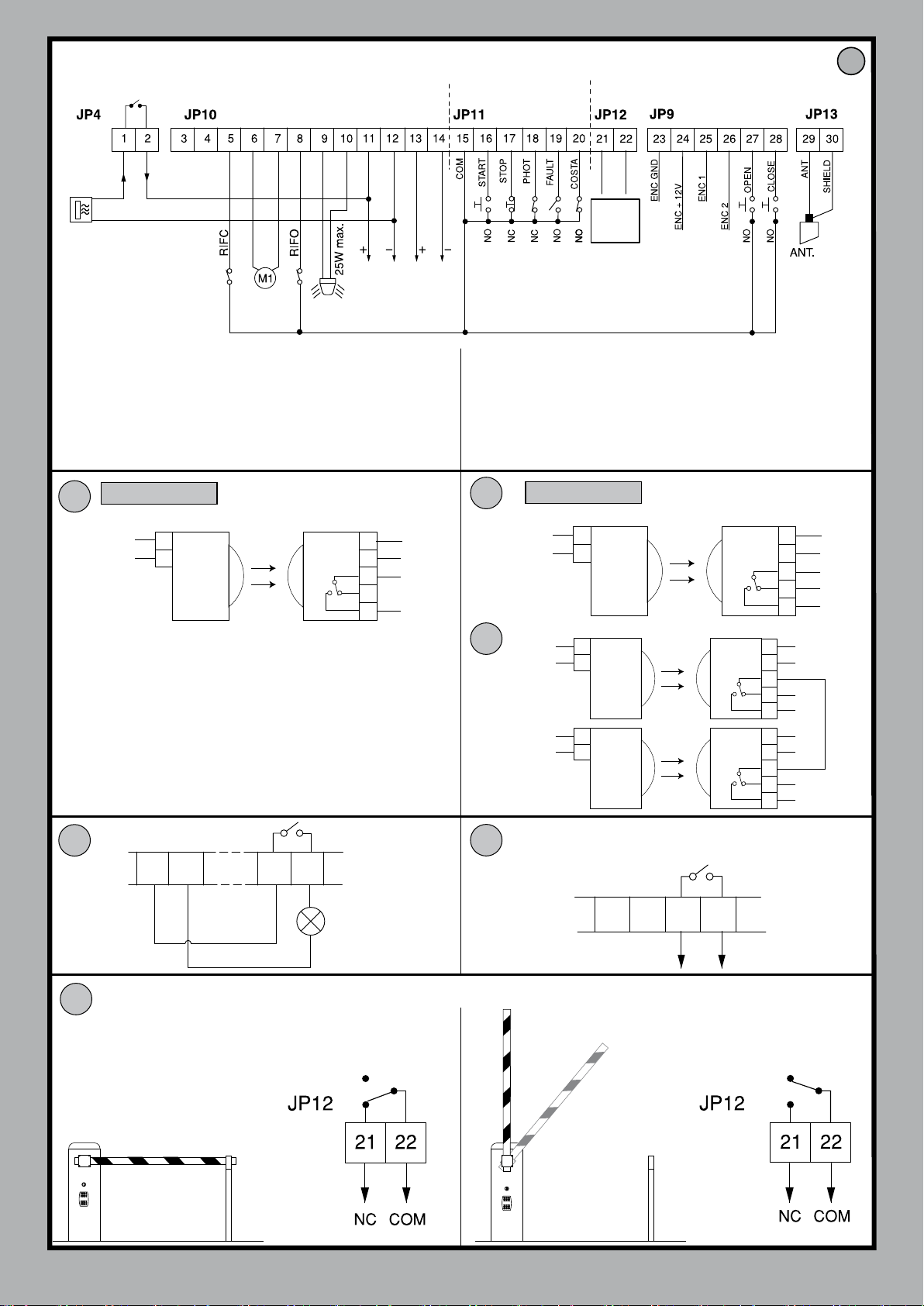

H

Collegamenti morsettiera, Terminal board wiring, Branchements sur le bornier, Anschlüsse Klemmleiste,

Conexiones tablero de bornes, Aansluitingen aansluitkast.

1

2

1

2

3

4

5

11

12

11

12

15

18

TX1 RX1

1-PHOT

TEST PHOT=OFF

TEST PHOT=ON

1

2

1

2

1

2

3

4

5

13

14

11

12

15

18

TX1 RX1

19

1-PHOT

3

4

5

6

1

2

1

2

3

4

5

13

14

11

12

15

18

TX1 RX1

2-PHOT

1

2

1

2

3

4

5

13

14

11

12

19

15

TX2 RX2

LOGICA test fotocellule OFF, Photocell test LOGIC OFF, LOGIQUE essai

photocellules Désactivée, LOGIK Test Fotozellen OFF, LÓGICA prueba

fotocélulas OFF, LOGICA test fotocellen OFF.

JP9

11 12 21

SCA

22

JP9

19 20 21 22

24 V~

Fig. H

Rif. 4, 5, 6

Uscita Allarme, Alarm Output, Sortie Alarmes

Alarmausgang, Salida Para Alarma, Uitgang Alarm

Connessione A Sistema Gestione Parcheggi Parky, Connection To Parky Car-park Management System, Connexion Au Système De Gestion Des

Parkings Parky, Anschluss An Das Parkplatzbewirtschaftungssystem Parky, Conexion Al Sistema De Gestion De Aparcamientos Parky, Erbinding

Met Beheersysteem Parky-parkeerplaatsen

24V ~

24V ~

Vsafe ~

Vsafe ~

MICHELANGELO - 7

D811528 00100_03

Page 7

2

3

4

1

I

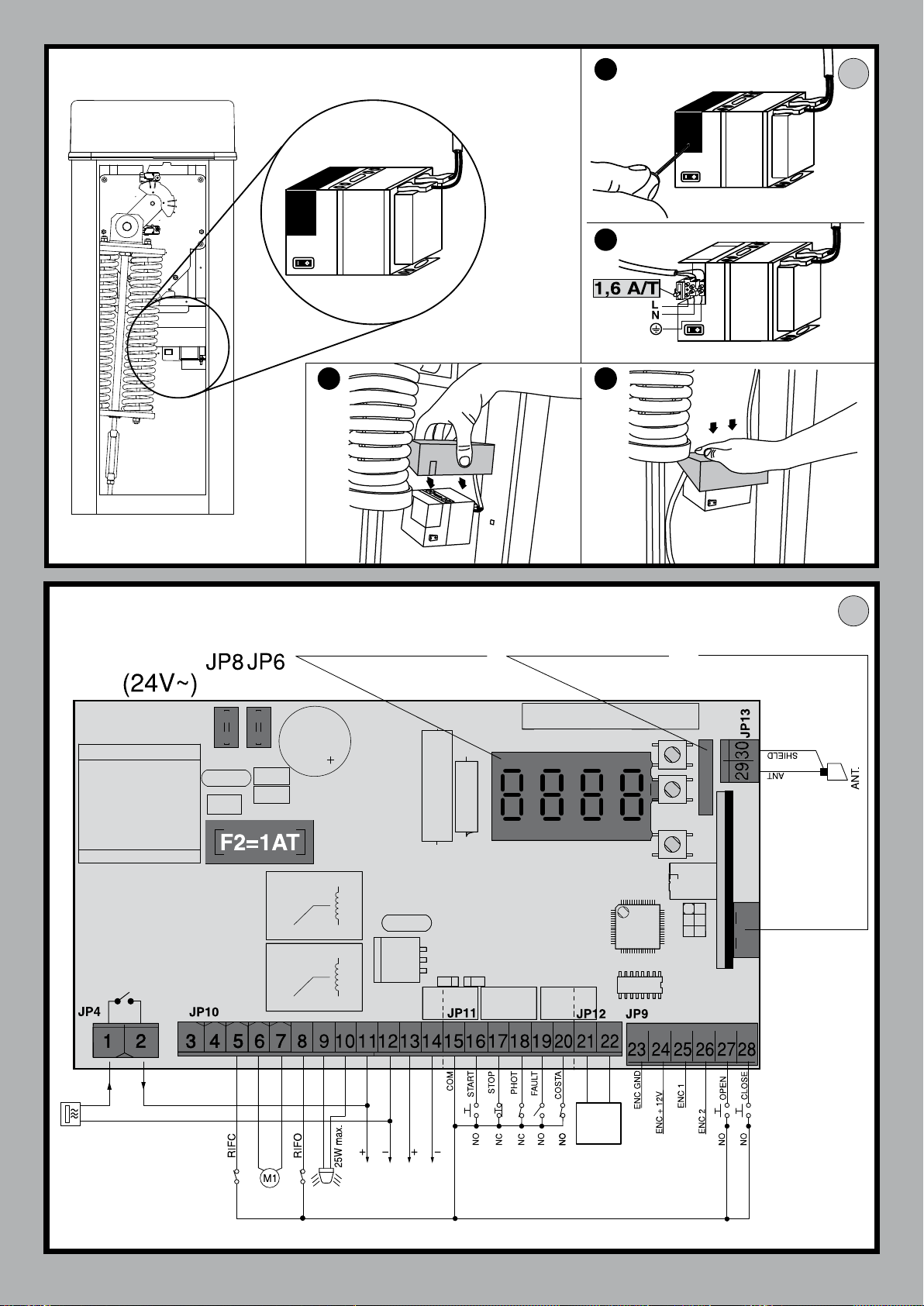

L

Cablaggio Trasformatore, Transformer wiring, Câblage du transformateur,

Verkabelung Transformator, Cableado Transformador, Bekabeling Transformator.

+

-

Connettore scheda opzionale,

SCS1 optional board connector,

Connecteur carte facultative,

Steckverbinder Zusatzkarte,

Conector de la tarjeta opcional,

Connector optionele kaart.

Display + tasti programmazione,

Display plus programming keys,

Acheur et touches de programmation,

Display und Programmierungstasten,

Pantalla mas botones de programacion,

Display meerdere toetsen programmeur.

Connettore programmatore palmare,

Palmtop programmer connector,

Connecteur programmateur de poche,

Steckverbinder Palmtop-Programmierer,

Conector del programador de bolsillo,

Connector programmeerbare palmtop.

Fig. H

Rif. 4, 5, 6

24V ~

24V ~

Vsafe ~

Vsafe ~

8 - MICHELANGELO

D811528 00100_03

Page 8

M

fine-end-fin

Coppia-TOrque

couple-Drehmom-Par

accel.-Beschl.-acel.

PRG ok

[085]

PArAM

PArAM

AGG.START- adjouter

start-zufueg.startanad.start

tasto nascosto-

hidden button-

touche cacheeverst.taste

rilascia-release

relache-loslassen

suelte

ok 01 . . .

end

tasto desiderato-

desider button -

touche desireegevue tastetecla deseada

OK

x 2

OK

x 2

8888

+

OK

logic

radio

OK

O

N

MEMORIZZAZIONE RADIOCOMANDO

MEMORIZING REMOTE CONTROLS

MÉMORISATION DE LA RADIOCOMMANDE

ABSPEICHERUNG DER FERNBEDIENUNG

MEMORIZACIÓN DEL RADIOMANDO

MEMORISEREN AFSTANDSBEDIENING

+

-

OK

OK

P1 +

P2 -

Vel.Ap.-Op.speed

vit. ouv.-off. ges.

freno - brake

frein - bremse

PRG ok

[099 - 050]

OK

P1 +

P2 -

PRG ok

[075]

OK

P1 +

P2 -

PRG ok

OK

P1 +

P2 -

[50]

cal. ap. - open. calib.

cal. ouv. - off. kal.

cal.ap.

cal. ch. - clos. calib.

cal. ferm. - sch. kal.

cal. cie.

PRG ok

OK

P1 +

P2 -

[082.0]

PRG ok

OK

P1 +

P2 -

[021.0]

x 2

OK

default

default

default

MICHELANGELO 60: [099]

MICHELANGELO 80: [050]

default

default

default

Modificare i valori seguenti fino a raggiungere

il movimento dell’asta desiderato,

Edit the following values until you are happy

with boom movement,

Modifiez les valeurs suivantes jusqu'à ce que la

barre se déplace de la façon voulue,

Die folgenden Werte verändern, bis die

gewünschte Bewegung der Stange erzielt wird,

Modificar los siguientes valores hasta lograr el

movimiento deseado del mástil,

Onderstaande waarden wijzigen tot de

beweging van de gewenste stang bereikt wordt.

REGOLAZIONI PRELIMINARI, PRELIMINARY ADJUSTMENTS,

RÉGLAGES PRÉALABLES, VORLÄUFIGE EINSTELLUNGEN,

REGULACIONES PRELIMINARES, VOORLOPIGE AFSTELLINGEN.

MICHELANGELO - 9

D811528 00100_03

Page 9

1

AA

Assicurarsi che la molla non sia in tensione, e l’asta non sia montata.

Make sure the spring is not under tension and the boom is not fitted.

Vérifiez si le ressort n'est pas en tension et si la tige n'est pas montée.

Sicherstellen, dass die Feder nicht gespannt und die Stange nicht montiertist.

Asegurarse de que el muelle no esté tensado y de que el mástil no esté

montado.

Controleren of de veer niet onder spanning staat, en de stang niet

gemonteerd is.

Smontare il gruppo molla.

Remove the spring assembly.

Démonter le groupe ressort.

Die Feder-Baugruppe ausbauen.

Desmontar el grupo muelle.

De groep veer demonteren.

2

3

Montaggio Asta Destra, Assembly of right boom, Montage de la barre droite,

Rechte Montage der Stange, Montaje mástil derecho, Montage rechterstang.

4

19 19

10 - MICHELANGELO

D811528 00100_03

Page 10

Rimontare il gruppo molla a destra, Ret the right-hand spring assembly,

Remontez le groupe ressort à droite, Die Baugruppe neu montieren, Feder rechts,

Volver a montar el grupo muelle a la derecha, De veergroep opnieuw rechts monteren.

7

8

6

5

9

AB

MICHELANGELO - 11

D811528 00100_03

Page 11

1

2

3

2 mm

2 mm

Assicurarsi che la molla non sia in tensione, e l’asta non sia montata.

Make sure the spring is not under tension and the boom is not fitted.

Vérifiez si le ressort n'est pas en tension et si la tige n'est pas montée.

Sicherstellen, dass die Feder nicht gespannt und die Stange nicht montiertist.

Asegurarse de que el muelle no esté tensado y de que el mástil no esté montado.

Controleren of de veer niet onder spanning staat, en de stang niet gemonteerd is.

AC

19

12 - MICHELANGELO

D811528 00100_03

Page 12

4

5

6

30 mm

AD

19

13

MICHELANGELO - 13

D811528 00100_03

Page 13

1

3

4

5

2

Montaggio Fotocellule CELLULA 130, Fitting Photocell 130, Montage de CELLULA 130,

Montage CELLULA 130, Montaje CELLULA 130, Montage CELLULA 130.

AE

14 - MICHELANGELO

D811528 00100_03

Page 14

6

8

7A

7B

Fori verticali CELLULA 130,

PHOTOCELL 130 vertical holes,

Trous verticaux CELLULA 130,

Vertikale Bohrungen CELLULA 130,

Oricios verticales CELLULA 130,

Vertikale Bohrungen CELLULA 130.

Fori orizzontali cellula 130,

PHOTOCELL 130 horizontal holes,

Trous horizontaux CELLULA 130,

Horizontale Bohrungen CELLULA 130,

Oricios horizontales CELLULA 130,

Horizontale openingen CELLULA 130.

Fare riferimento al manuale Cellula 130,

Refer to PHOTOCELL 130 manual,

Consultez le Manuel CELLULA 130,

Auf das Handbuch CELLULA 130 Bezug nehmen,

Consultar el manual CELLULA 130,

Het handboek CELLULA 130 raadplegen.

Per montaggio colonnine fare riferimento al manuale MCL 130,

Refer to MCL 130 manual for assembly of stations,

Pour monter les colonnes consultez le manuel MCL 130,

Für die Montage der Säulen auf das Handbuch MCL 130 Bezug nehmen,

Para montar las columnas consultar el manual MCL 130,

Voor montage kolommen het handboek MCL 130 raadplegen.

ATTENZIONE! Solo per MCL 80 asta con apertura a destra: installare il

gruppo colonnina prima di spostare il gruppo molla.

WARNING! For MCL 80 boom with opening on right only: install station

unit before moving spring assembly.

ATTENTION! Uniquement pour MCL 80 barre avec ouverture à droite:

montez le groupe colonne avant de déplacer le groupe ressort.

ACHTUNG! Nur für MCL 80 Stange mit Öffnung rechts: Die Baugruppe

Säule installieren, bevor die Baugruppe Feder versetzt wird.

¡ATENCIÓN! Sólo para MCL 80 mástil con apertura a la derecha: instalar

el grupo columna antes de desplazar el grupo muelle.

OPGELET! Alleen voor MCL 80 stang met opening rechts: de kolommengroep installeren, alvorens de veergroep te verplaatsen.

Montaggio Fotocellule CELLULA 130, Fitting Photocell 130, Montage de CELLULA 130,

Montage CELLULA 130, Montaje CELLULA 130, Montage CELLULA 130.

AF

MICHELANGELO - 15

D811528 00100_03

Page 15

1

3

5 6

4

2

Montaggio RMM, Fitting RMM, Montage de RMM, Montage RMM, Montaje RMM, Montage RMM.

AG

A

B

*

8

4

Non in dotazione /

Not supplied / Ne sont pas fournis /

Nicht im lieferumfang

/

No asignadas en el equipamiento base

/

Niet meegeleverd

*

16 - MICHELANGELO

D811528 00100_03

Page 16

param. 1

param. 2

param. . . .

logic. 1logic

logic. 2

logic. . . .

PRG

ITA

FRA

DEU

ENG

esp

OK

OK

OK

OK

OK

-

+

-

+

-

+

-

+

add. start

hidden button

release ok 01

desired button

PRG.

read

erase 64

COD RX

1A9C

OK

22FD

OK

0 1

OK

+/-

01 t1

See PARAMETERS MENU

See LOGIC MENU

See RADIO MENU

radio

ACCESS TO MENUS

Cancel/return to main menu

Scroll up

end

end

end

end

end

language

default

Scroll down

Control unit software version

N. total manoeuvres (in tens)

N. manoeuvres since latest maintenance (in tens)

N. radio control devices memorised

Press the OK key

Description

STRT STARTinput activation

STOP

STOP input activation

PHOT PHOT input activation

Fltf FAULT input activation for checked photocells

time TIMER input activation

tTca waiting time for automatic closing on TIMER release

BAR EDGE input activated (obstacle alarm)

CLOS CLOSE input activation

OPEN OPEN input activation

Swo barrier in opening position

Suc barrier in closing position

REfo reference input on opening activated

refc

reference input on closing activated

th

check on safety devices failed

AmP

ER0x

ER1x

ER2X

ampere-stop triggering (obstacle alarm)

Enc encoder stopped detected (obstacle alarm)

Logic

35.40

Set torque threshold %

Maximum motor torque %

ER4x

EREF

check on motor control failed

power supply cables for motor or encoder signal reversed

error due to position references both active.

overload signal indication (the system completes the manoeuvre in progress

and does not allow new ones until the signal indication has been eliminated).

overload error (the system remains under protection lock until the error has

been corrected).

Confirm/Switch on display

v

MICHELANGELO - 23

D811528 00100_03

ENGLISH

Page 17

INSTALLATION MANUAL

WARNING! Important safety instructions. Carefully read and comply with

the Warnings booklet and Instruction booklet that come with the product as

incorrect installation can cause injury to people and animals and damage to

property. They contain important information regarding safety, installation,

use and maintenance. Keep hold of instructions so that you can attach them

to the technical le and keep them handy for future reference.

1) GENERAL SAFETY

WARNING! An incorrect installation or improper use of the product can

cause damage to persons, animals or things.

• The “Warnings” leaet and “Instruction booklet” supplied with this

product should be read carefully as they provide important information

about safety, installation, use and maintenance.

• Scrap packing materials (plastic, cardboard, polystyrene etc) according

to the provisions set out by current standards. Keep nylon or polystyrene

bags out of children’s reach.

• Keep the instructions together with the technical brochure for future

reference.

• This product was exclusively designed and manufactured for the use

specied in the present documentation. Any other use not specied in

this documentation could damage the product and be dangerous.

• The Company declines all responsibility for any consequences resulting from

improper use of the product, or use which is dierent from that expected

and specied in the present documentation.

• Do not install the product in explosive atmosphere.

• The units making up the machine and its installation must meet the require-

ments of the following European Directives: 2004/108/EEC, 2006/95/EEC,

98/37/EEC, 99/05/EEC (and later amendments). For all countries outside

the EEC, it is advisable to comply with the above-mentioned standards,

in addition to any national standards in force, to achieve a good level of

safety.

• The Company declines all responsibility for any consequences resulting

from failure to observe Good Technical Practice when constructing clos-

ing structures (door, gates etc.), as well as from any deformation which

might occur during use.

• The installation must comply with the provisions set out by the following

European Directives: 2004/108/EEC, 2006/95/EEC, 98/37/EEC, 99/05/EEC

and subsequent amendments.

• Disconnect the electrical power supply before carrying out any work on

the installation. Also disconnect any buer batteries, if tted.

• Fit an omnipolar or magnetothermal switch on the mains power supply,

having a contact opening distance equal to or greater than 3,5 mm.

• Check that a dierential switch with a 0.03A threshold is tted just before

the power supply mains.

• Check that earthing is carried out correctly: connect all metal parts for

closure (doors, gates etc.) and all system components provided with an

earth terminal.

• Fit all the safety devices (photocells, electric edges etc.) which are needed

to protect the area from any danger caused by squashing, conveying and

shearing, according to and in compliance with the applicable directives

and technical standards.

• Position at least one luminous signal indication device (blinker) where it

can be easily seen, and x a Warning sign to the structure.

• The Company declines all responsibility with respect to the automation safety

and correct operation when other manufacturer’s components are used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorised

by the Company.

• Instruct the product user about the control systems provided and the

manual opening operation in case of emergency.

• Do not allow persons or children to remain in the automation operation

area.

• Keep radio control or other control devices out of children’s reach, in

order to avoid unintentional automation activation.

• The user must avoid any attempt to carry out work or repair on the automation system, and always request the assistance of qualied personnel.

• Anything which is not expressly provided for in the present instructions,

is not allowed.

• Installation must be carried out using the safety devices and controls

prescribed by the EN 12978 Standard.

USE OF AUTOMATION

As automation can be remotely controlled and therefore not within sight, it is

essential to frequently check that all safety devices are perfectly ecient.

WARNING! In case of any malfunction in the safety devices, take imme-diate

action and require the assistance of a specialised technician.

It is recommended to keep children at a safe distance from the automation

eld of action.

CONTROL

The automation system is used to obtain motorised access control. There are

dierent types of control (manual, remote, magnetic badge, mass detector

-Fig. AH- etc.) depending on the installation requirements and characteristics.

For the various control systems, see the relevant instructions.

MAINTENANCE

WARNING: before opening the door, the spring must be unloaded

(vertical boom). WARNING: Before carrying out any maintenance to the

installation, disconnect the mains power supply. The following points need

checking and maintenance:

- Photocell optics. Clean occasionally.

- Electric edge. Carry out a periodical manual check to ensure that the edge

stops the bar in case of obstacles.

- Dismantle the gearmotor and replace the lubricating grease every two

years.

- When any operational malfunction is found, and not resolved, disconnect the mains power supply and request the assistance of a specialised

technician (installer). When the operator is out of order, activate the

emergency release (see Fig. Y), if necessary, so as to release the manual

boom opening and closing operations.

SCRAPPING

Materials must be disposed of in conformity with the current regulations.

In case of scrapping, the automation devices do not entail any particular

risks or danger. In case of recovered materials, these should be sorted out

by type (electrical components, copper, aluminium, plastic etc.).

DISMANTLING

WARNING: before opening the door, the spring must be unloaded (vertical boom). When the automation system is disassembled to be reassembled

on another site, proceed as follows:

- Disconnect the power supply and the entire electrical installation.

- Remove the actuator from its xing base.

- Disassemble all the installation components.

- In the case where some of the components cannot be removed or are

damaged, they must be replaced.

D811528 00100_03

WARNINGS

Correct controller operation is only ensured when the data contained in the

present manual are observed. The Company is not to be held responsible

for any damage resulting from failure to observe the installation standards

and the instructions contained in the present manual.

The descriptions and illustrations contained in the present manual are not

binding. The Company reserves the right to make any alterations deemed

appropriate for the technical, manufacturing and commercial improvement

of the product, while leaving the essential product features unchanged, at

any time and without undertaking to update the present publication.

24 - MICHELANGELO

Page 18

INSTALLATION MANUAL

2) GENERAL OUTLINE

Compact electromechanical barrier suitable for limiting private areas, parkings, access areas for vehicles only. Available for passageways from 4 to 8

D811528 00100_03

metres. Adjustable electronic limit switches, they guarantee correct boom

stopping position. In case of intensive use, a thermal sensor activates the

cooling fan.

The emergency release device for manual manoeuvre is controlled by a

personalised key lock.

The actuator is always supplied for left-hand side tting. However, when

necessary, the opening direction can be reversed by means of simple

operations.

The BM mod. foundation base (on request) makes barrier installation

easier.

Appropriate ttings make it easy to install accessories.

The LIBRA C MV control panel is supplied by the manufacturer with standard

setting. Any change must be set by means of the incorporated display or by

means of the universal programmer.

3) TECHNICAL SPECIFICATIONS

Power supply: 230V±10% 50Hz(*)

Power absorbed: 300W

Absorption (with accessories): 1 A

Internal lubrication:

permanent grease

Max torque: 600 Nm

Opening time: 6s (5-6m), 8s (8m)

4m (MICHELANGELO 40)

Boom length:

5-6m (MICHELANGELO 60)

da 6m a 8m (MICHELANGELO 80)

Impact reaction: encoder

Manual mechanical release: customised key

Type of boom: rectangular/round

Limit devices:

electrical incorporated and electronically adjustable

Maximum no. manoeuvres in 24h: continuous operation

Working temperature: from -20°C to +55°C

Degree of protection: IP 24

55 Kg (MICHELANGELO 40)

Operator weight (without boom):

58 Kg (MICHELANGELO 60)

68 Kg (MICHELANGELO 80)

Dimensions: see g. A

Mains/low voltage insulation: > 2MOhm 500V

Dielectric strength:

mains/low voltage 3750V~ for 1

minute

20A max (MICHELANGELO 40)

Motor output current:

25A max (MICHELANGELO 60)

30A max (MICHELANGELO 80)

Cooling intervention

temperature:

80°C

Supply to accessories: 24V~ (180 mA max absorption)

Barrie-open warning light: 24V~ 3W max

Blinker: 24V~ 25W max

Fuses: see gure I-L

N° of combinations:

Max. n° of remotes that

can be memorized:

4 billion

63

(*)= special power supply voltages on request.

Usable transmitter versions:

All ROLLING CODE transmitters compatible with

4.1) FOUNDATION PLATE (Fig. B1).

4.2) FASTENING ANCHOR BOLTS (Fig. B2).

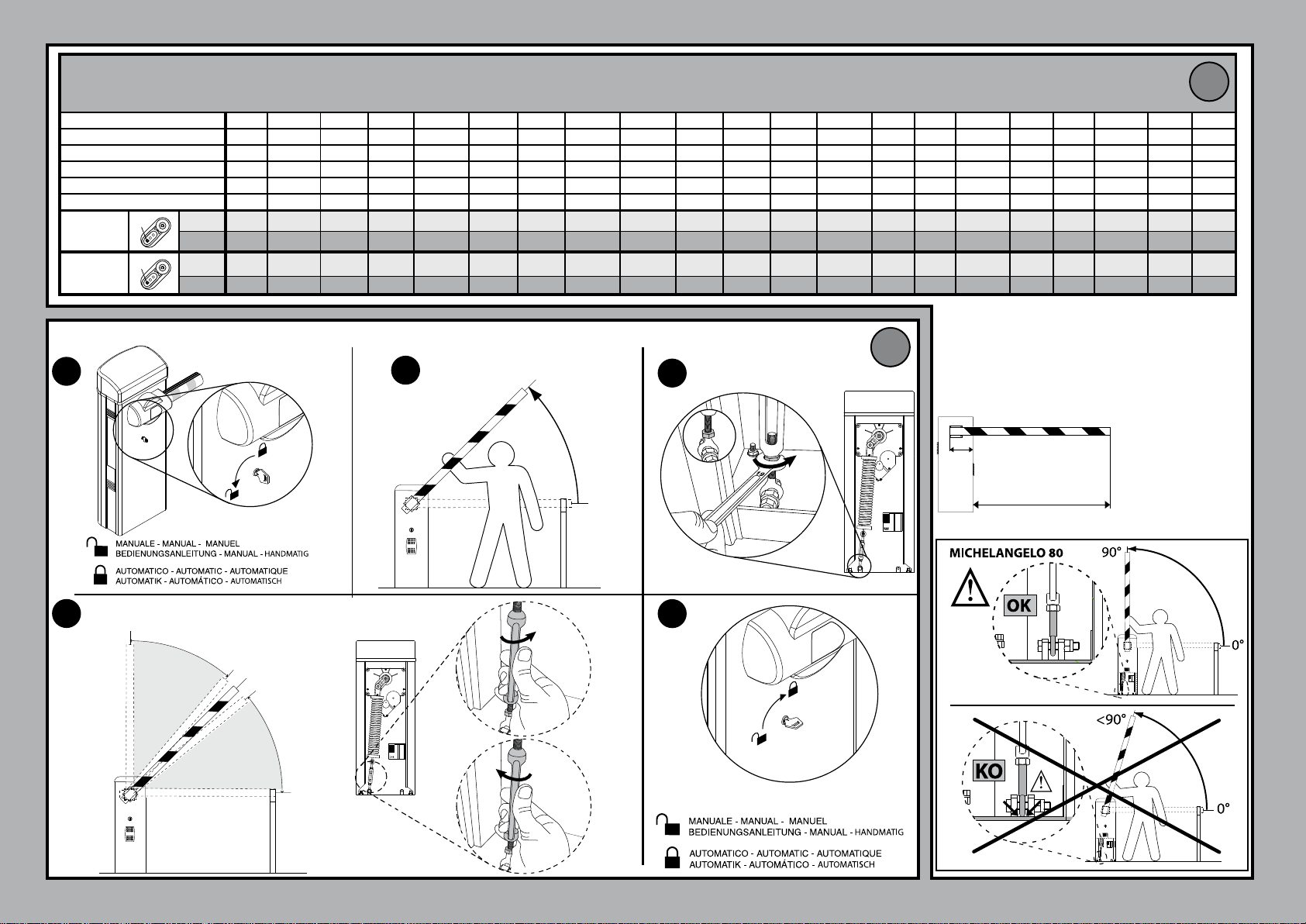

5) FITTING OF THE ACTUATOR

WARNING! The barrier must be exclusively used for vehicles to

drive through. Pedestrians must not walk within the operator

manoeuvring area. An appropriate pedestrian passageway must be

provided for.

The passageway must be suitably indicated by means of the warning

signs illustrated in Fig.A.

WARNING: before opening the door, the spring must be unloaded

(vertical boom). The door of the box must be facing towards the inside

of the property. When you stand in the middle of the passageway, facing

outwards, if the box is on your left, the barrier is left-hand tted, if the box

is on your right, the barrier is right-hand tted.

The actuator is always supplied for left-hand side tting.

5.1) COVER AND DOOR OPENING AND CLOSING (Fig. D).

5.2) POSITIONING OF ENCLOSURE FIG.E

5.3) BOOM FIXING (Fig. F).

6) OPTIONAL ACCESSORIES (Fig. G)

Foundation Base - BM

Boom light kit - KIT MCL LIGHT

Blinker kit - KIT MCL LAMPO

Moveable boom rest rod - GA

Fixed boom support fork - FAF (compulsory with 7-8m boom).

Cellula130 post xing kit - KIT MCL 130 (only when GA and SB are absent)

Skirt already assembled to the boom - SB (only for boom - ELL 6)

BIR passive safety edge

Lower and/or upper boom covering contour - MCL PCA 6/8

ELL 6 - ATT 704/706 - ATT 504/502 Booms.

ACC MCL ATT KIT (for ATT 704/706 - ATT 504/502)

ACC MCL ELL KIT (for ELL 6)

SCHEDA MCL KIT

LOOP

RMM (metal object detector 24V) (Fig. AG)

KIT MCL BAT,

KIT MCL RFL

6.1) MICHELANGELO 40-60 accessories: boom length limits and balancing (Fig. G1).

For further information about the installation and use of accessories, refer

to the respective instruction manuals.

6.2) MICHELANGELO 80 accessories: Fig.G2.

6.3) BAR BALANCING (Fig. G3).

6.4) ATTACHMENT AND TENSIONING OF SPRING g. AC-AD

7) Right-hand tting (Fig. AA, AB)

- Carry out bar balancing as described in Fig. G3.

- Set the Direction Reversal logic to ON in the control panel.

Warning: the Direction Reversal logic must be congured to OFF for

left-hand tted barriers, and to ON for right-hand tted barriers.

Otherwise, the limit devices will not operate or an encoder direction

error will be displayed.

8) Cellula 130 tting (Fig. AE-AF)

9) MCL 130 tting (Fig. AF)

----------------------------------------------------------

10) ELECTRICAL INSTALLATION SET-UP

WARNING: before opening the door, the spring must be unloaded (vertical boom). Set up the electrical installation (g. A) with reference to the

current regulations for electrical installations. Keep the mains power supply

con-nections denitely separate from the service connections (photocells,

electric edges, control devices etc.).

Warning! For connection to the mains, use a multipolar cable having

minimum 3x1.5mm

2

cross section and complying with the previously

mentioned regulations (for example, if the cable is not protected, it

must be at least equal to H07 RN-F, whereas if it is protected it must be

at least equal to H07 VV-F with a 3x1.5 sq mm

2

cross section).

Fig. A shows the number of connections and section for a 100m length of

power supply cables; for greater lengths, calculate the section for the true

automation load. When the auxiliary connections exceed 50 metre lengths

or go through critical disturbance areas, it is recommended to decouple the

control and safety devices by means of suitable relays.

The main automation components are (g. A):

I) Type-approved adequately rated omnipolar circuit-breaker with

at least 3,5 mm contact opening, provided with protection against

overloads and short circuits, suitable for cutting out automation from

the mains. Place, if not al ready installed, a type-approved dierential

switch with a 0.03A threshold just before the automation system.

MICHELANGELO - 25

Page 19

INSTALLATION MANUAL

26 - MICHELANGELO

D811528 00100_03

QR) Control panel and incorporated receiver.

S) Key selector.

AL) Blinker

M) Actuators.

A) Bar.

F) Rest fork.

CS) Electric edge.

Ft,Fr) Pair of photocells.

CF) Photocell post.

T) 1-2-4 channel transmitter.

RMM) Inductive metal mass detector.

LOOP) Mass detector loops.

11) CONNECTION (FIg. H-I)

WARNING: The electrical connections must be carried out workmanlike by

qualied experienced personnel, in conformity with all the current standards

and with the use of appropriate materials.

Lay out the electrical installation with reference to the current electrical

standards.

Keep the mains supply connections clearly separated from the service connections.

In the initial section of the electrical installation, t a circuit breaker with a

contact opening distance equal to or greater than 3,5 mm, provided with

magnetothermal protection and a dierential switch having adequate capacity for the appliance consumption. For the wiring, only use cables conforming

to the harmonised or national standards, having a cross section corresponding to the initial protection, the appliance consumption and the installation

conditions, for example a 3x1.5 sq mm (H 05 VV-F) cable.

Proceed as explained below:

1. Remove the transformer cover.

2. Unscrew the screw which locks the cap (Fig. I Rif. 1) and take the cap out.

3. Fix the cables to the terminal bar (Fig. I Rif. 2)

L PHASE

N NEUTRAL

EARTH

4. To close the cap, reverse the actions in step 2.

5. Ret the transformer cover and secure in place by means of the slots

located on top of the transformer (Fig. I Rif. 3-4).

TERMINAL

1-2

3-4

DESCRIPTION

Control for cooling fan

Not used

6-7 Motor connections

15-5 Motor connections, closing reference

15-8 Motor connections, opening reference

9-10 Blinker connection (24 V~, 25W)

11-12

13-14

24 V~ 180mA max output – power supply for photocells or

other devices (11+,12-).

24 V~ 180mA max output – power supply for photocell

transmitters with check (Vsafe 13+, 14-).

15-16 START button (N.O.)

15-17 STOP button (N.C.). If not used, leave the jumper bridged

15-18 Photocell input (N.C.). If not used, leave the jumper bridged

19

15-20

Photocell FAULT input (N.O.) for photocells provided with

N.O. check contact

Safety edge input (N.C.). If not used, leave the jumper

bridged

Barrier-open warning light output (N.O. contact, 24V~/ 3W max)

21-22

or, in alternative, alarm output (see conguration paragraph)

and Connection To Parky Car-Park Management System

23-24-

25-26

Encoder inputs

Open button (OPEN N.O.). If the TIMER logic on OPEN is enabled

and the input remains engaged for over 3 sec., it commutes

to clock input (TIMER N.O.).

The TIMER input opens and keeps the barrier open when

15-27

engaged; on disengagement, after waiting for the time set

in the Automatic Closing Time parameter, it starts the closing

movement (regardless of the TCA Logic status). If the command is interrupted by the STOP button being pressed or

by the safety devices being triggered, it can be reset using

the START input

15-28 Close button (CLOSE N.O.)

JP8-JP6 Board power supply (24V~) (JP8 +,JP6-)

12) ADJUSTMENTS

RECOMMENDED ADJUSTMENT SEQUENCE:

Adjusting the limit switches (

See reference section) FIG.M

Programming remote controls (Fig. O)

Setting of parameters/logic, where necessary

13) PARAMETERS MENU para

(TABLE “A” PARAMETERS)

14) LOGIC MENU logic

(TABLE “B” LOGIC)

15 RADIO MENU RADIO

Logic Description

add start

Add Start Key

associates the desired key with the Start command

Read

read

Checks a key of a receiver and, if memorized, returns the

number of the receiver in the memory location (from 01

to 64) and number of the key (T1-T2-T3 or T4).

Erase List

erase 64

WARNING! Erases all memorized remote controls

from the receiver’s memory.

Read receiver code

cod RX

Displays receiver code required for cloning remote

controls.

ON = Enables remote programming of cards via a previously me-

v

morized W LINK transmitter. It remains enabled for 3 minutes

from the time the W LINK remote control is last pressed.

OFF=W LINK programming disabled.

- IMPORTANT NOTE: THE FIRST TRANSMITTER MEMORIZED MUST BE

IDENTIFIED BY ATTACHING THE KEY LABEL (MASTER).

In the event of manual programming, the rst transmitter assigns the RECEIVER’S KEY CODE: this code is required to subsequently clone the radio

transmitters.

The Clonix built-in on-board receiver also has a number of important advanced features:

• Cloning of master transmitter (rolling code or xed code)

• Cloning to replace transmitters already entered in receiver

• Transmitter database management

• Receiver community management

To use these advanced features, refer to the universal handheld programmer’s

instructions and to the CLONIX Programming Guide, which come with the

universal handheld programmer device.

16 LANGUAGE MENU language

Used to set the programmer’s language on the display.

17 DEFAULT MENU default

Restores the controller’s default factory settings.

18) CONNECTION TO PARKY CAR-PARK MANAGEMENT SYSTEM

The board can be congured in order to make an output available for controlling the barrier status. When the SCA Alarm logic is disabled (OFF) and

the Alarm Time parameter is set to 0 s, the SCA contact (21-22) is congured

as follows (Fig. H Rif. 6):

- contact closed between terminals 21-22 with the barrier lowered

- contact open between terminals 21-22 with the barrier lifted

19) LIMIT SWITCH SETTING

WARNING: before opening the door, the spring must be unloaded (vertical

boom). The barrier is provided with programmable electronic limit switches

and mechanical stop devices. There must be a rotation margin (about 1°) on

closing and opening between the electrical limit switches and mechanical

stop devices (Fig. N). The adjustment is carried out as follows:

The end-of-stroke opening and closing positions must be set by modifying

the parameters of the control panel for Opening value Calibration and Closing value Calibration: if the value is increased, the end-of-stroke positions

move towards the opening direction. The extent of the movement depends

on the eective boom length: in the case of a 6-m boom, a unit change (1.0)

entails a movement of about 4,4 cm which, proportionally, becomes about

5,8 cm for an 8-m boom.

The eective closing value also depends, in part, on the manoeuvring speed.

It is therefore convenient to proceed to end-of-stroke calibration only after

having set the other opening parameters.

Page 20

INSTALLATION MANUAL

MICHELANGELO - 27

D811528 00100_03

To evaluate correctly the values set, you are advised to carry out a few complete consecutive manoeuvres.

20) EMERGENCY RELEASE (Fig. Y)

WARNING! When an actuator without bar needs to be released, ensure that

the balancing spring is not compressed (bar in the opening position).

4) Use the control unit self-diagnosis (see “Acces to Menus”), to check whether

the functions are correct. Identify any possible cause for the fault. If selfdiagnosis indicates that a start command persists, check that there are

no radio transmitters, start buttons or other control devices keeping the

start contact activated (closed).

5) If the control unit does not work, it must be replaced.

6) Check the activation of the reference microswitches by checking the

21) MALFUNCTION: CAUSES and REMEDIES

21.1) The bar does not open. The motor does not turn.

messages appearing on the control panel display.

7) Lubricate the guide-ressort tirants in case of rumors or vibrations.

WARNING: before opening the door, the spring must be unloaded

(vertical boom).

1) Check that the photocells are not dirty, or engaged, or not aligned. Proceed accordingly. Check the electric edge.

2) Check the correct connection of the drive motor and capacitor.

21.2) The bar does not open. The motor turns but there is no movement.

1) The manual release was left engaged. Reset the motorised operation.

2) If the release is in the motorised operation position, check the gearmo- tor

for integrity.

3) Check that the electronic appliance is correctly supplied. Check the

integrity of the fuses.

4) Use the control unit self-diagnosis (Fig. I-O), to check whether the functions are correct. Identify any possible cause for the fault. If self-diagnosis

indicates that a start command persists, check that there are no radio

transmitters, start buttons or other control devices keeping the start

contact activated (closed).

TABLE “A” PARAMETERS MENU - PARA

Logic min. max. default Denition Description

[s]

tca

1 180 10

Automatic Closing Time

Automatic Closing Time

Set the numerical value of the automatic closing time from 1 to 180

seconds. Automatic closing can be deactivated by the TCA Logic, but

it is always carried out on releasing the TIMER.

Maximum torque [%]

torque

60 99 85

Maximum torque

Set from 60% to 99% the maximum torque that activation must be able

to provide before generating an obstacle alarm. With the maximum

value set, the control is disabled.

Acceleration [%]

accel.

1 99 75

Acceleration

Special parameter 14 on second-generation universal programmers.

Set a value from 1% to 99% for the acceleration to be applied at the

beginning of each movement.

Op. speed

1 99

99 M60

50 M80

Opening speed/Closing

Opening speed/Closing [%]

Set the numerical value of the speed: 1% corresponds to the slowdown speed, 99% to the maximum speed.

Braking [%]

bra

e

0 85 50

Braking

Set from 0% to 85% the braking to be applied during the slow-down

phase. The initial slow-down value is automatically calculated according to this parameter and the eective movement speed.

Emergency braking [%]

e

er.bra e

75 99 75

Emergency braking

Set a value from 75% to 99% for the braking intensity in case of reversing

movement or emergency braking: any values lower than those set in the

“braking” parameter will be ignored.

Opening value calibration [%]

cal. ap.

0 100 82

Opening value calibration

Special parameter 1 on second-generation universal programmers.

Set the reference value from 0,0 to 100,0 for the required opening

position (see Paragraph Limit Switch Setting).

Closing value calibration [%]

cal. ch.

0 100 21

Closing value calibration

Special parameter 2 on second-generation universal programmers.

Set the reference value from 0,0 to 100,0 for the required closing

position (see Paragraph Limit Switch Setting).

Alarm time [%]

In the case of obstacle detection or photocell engagement for a period

exceeding the time set (ranging from 10 s to 240 s), the SCA contact

alar

. ti e

10 240 30

Alarm time

closes. The contact is subsequently opened by the STOP command

or by triggering of the closing limit switch. Only active when the SCA

Alarm logic is set to OFF.

If set to 0 s, the SCA contact becomes a connection to the Parky system

(see Paragraph Connection To Parky Car-Park Management System).

Zone [ ]

Zone

0 127 0

Zone

Set the zone number between a minimum value of 0 and a maximum

value of 127.

Page 21

INSTALLATION MANUAL

28 - MICHELANGELO

D811528 00100_03

TABLE “B” LOGIC MENU - logic

Logic default Denition Description

tca

2 step

3 step

ON

OFF

ON

Automatic

closing time

2-step logic

3-step logic

ON: Activates automatic closing

OFF: Excludes automatic closing

Note: automatic closing on TIMER release cannot be deactivated.

ON: Enables the 2-step logic (prevails over the “3-step logic”).

O

FF: Disables the 2-step logic, activating the 4-step logic if the “3-step logic” is OFF.

ON: Enables the 3-step logic (if the “2-step logic” is OFF).

OFF: Disables the 3-step logic, activating the 4-step logic if the “2-step logic” is OFF.

Response to the START impulse

Barrier 2 steps 3 steps 4 steps

closed

on closing stop

open

on opening stop + TCA stop + TCA

opens opens

closes

after stop opens opens opens

opens

closes closes

ibl open

ibl TCA

pre-alar

hold-to-run

fast cls

photc. open

test phot

inv. dir

er

ti

sca

alar

fixed code

radio prog

aster

Opening Impulse

ON

lock

OFF

Impulse lock TCA

OFF

Pre alarm

Hold-to-run

OFF

control device

OFF

Rapid closing

Photocells on

ON

opening

OFF

Photocell test

Direction

OFF

Reversal

OFF

TIMER OPEN

ON

SCA Alarm

OFF

Fixed code

Radio transmitter

ON

programming

OFF

Master/Slave

ON: The Start impulse has no eect during the opening phase.

OFF: The Start impulse becomes eective during the opening phase.

ON: The Start impulse has no eect during the TCA dwell period.

The Start impulse becomes eective during the TCA dwell period.

OFF:

ON: The blinker comes on about 3 seconds before the motor starts.

OFF: The blinker comes on at the same time as the motor starts.

ON: Hold-to-run operation: the manoeuvre continues as long as the OPEN and CLOSE control keys

are kept pressed. The radio transmitter cannot be used.

OFF: Normal impulse operation.

ON: Closes barrier after photocell disengagement, before waiting for the end of the TCA (automatic

closing time) set.

OFF: Command not entered.

ON: In case of obscuring, this excludes photocell operation on opening. During the closing phase, it

immediately reverses the motion.

OFF: In case of obscuring, the photocells are active both on opening and on closing. When a photocell

is obscured on closing, it reverses the motion only after the photocell is disengaged.

ON: Activates photocell check

OFF: Deactivates photocell check

ON: For right-hand tted barrier (see Par. Right-hand tting)

OFF: For left-hand tted barrier

IMPORTANT: Default has no eect on the logic.

Special dip switch 1 on second-generation universal programmers.

ON: OPEN pressed for over 3s becomes TIMER

OFF: TIMER input disabled

Signaling output on second-generation universal programmers.

ON: The SCA contact (terminals 21-22) behaves as follows:

with barrier open and on opening: contact closed (warning light on)

with barrier closed:contact open: (warning light o)

on closing: intermittent contact (blinking)

OFF: The SCA contact closes according to the modes set by the Alarm Time parameter.

ON: The receiver is congured for operation in xed-code mode.

OFF: The receiver is congured for operation in rolling-code mode.

ON: This enables transmitter storage via radio:

1 – First press the hidden key (P1) and then the normal key (T1, T2, T3 or T4) of a transmitter

already memorised in standard mode by means of the radio menu.

2 – Within 10s press the hidden key (P1) and the normal key (T1, T2, T3 or T4) of a transmitter to

be memorised.

The receiver exits the programming mode after 10s, other new transmitters can be entered before

the end of this time.

This mode does not require access to the control panel.

OFF: This disables transmitter storage via radio.

The transmitters can only be memorised using the appropriate Radio menu.

ON: The control panel is set as Master in a centralised connection.

OFF: The control panel is set as Slave in a centralised connection.

Page 22

MICHELANGELO - 53

D811528 00100_03

MANUALE D’USO: MANOVRA MANUALE - USER’S MANUAL: MANUAL OPERATION-

MANUEL D’UTILISATION: MANŒUVRE MANUELLE - BEDIENUNGSANLEITUNG: MANUELLES MANÖVERMANUAL DE USO: ACCIONAMIENTO MANUAL - GEBRUIKSHANDLEIDING: MANUEEL MANOEUVRE

Fig. Y

Page 23

MANUALE D’USO ( I ) USER’S MANUAL (GB)

54 - MICHELANGELO

D811528 00100_03

Nel ringraziarVi per la preferenza accordata a questo prodotto, la Ditta è

certa che da esso otterrete le prestazioni necessarie al Vostro uso. Questo

prodotto risponde alle norme riconosciute della tecnica e della disposizioni

relative alla sicurezza. Confermiamo che è conforme alle seguenti direttive

europee: 2004/108/CEE, 2006/95/CEE, 98/37/CEE, 99/05/CEE (e loro modiche successive).

1) SICUREZZA GENERALE

ATTENZIONE Importanti istruzioni di sicurezza. Leggere e seguire attentamente l’opuscolo Avvertenze ed il Libretto istruzioni che accompagnano

il prodotto poiché un uso improprio può causare danni a persone, animali

o cose. Conservare le istruzioni per consultazioni future.

Questo prodotto è stato progettato e costruito esclusivamente per l’utilizzo

indicato in questa documentazione. Usi non indicati potrebbero essere fonte

di danni al prodotto e fonte di pericolo.

- La Ditta declina qualsiasi responsabilità derivante da un uso improprio o

diverso da quello per cui è destinato ed indicato nella presente documentazione nonché dall’inosservanza della Buona Tecnica nella costruzione

delle chiusure (porte, cancelli, ecc.) e dalle deformazioni che potrebbero

vericarsi durante l’uso.

L’automazione, se installata ed utilizzata correttamente, soddisfa il grado di

sicurezza richiesto.

Tuttavia è opportuno osservare alcune regole di comportamento per evitare

inconvenienti accidentali:

- Tenere bambini, persone e cose fuori dal raggio d’azione dell’automazione,

in particolare durante il funzionamento.

- Quest’ applicazione non è destinata all’uso da parte di persone (inclusi i

bambini) con ridotte capacità mentali, siche e sensoriali, o persone che

mancano di conoscenze adeguate, a meno che non siano sotto supervisione o abbiano ricevuto istruzioni d’uso da persone responsabili della

loro sicurezza.

- I bambini devono essere controllati affinché non giochino con

l’applicazione. Non lasciare radiocomandi o altri dispositivi di comando

alla portata dei bambini onde evitare azionamenti involontari.

- Controllare spesso l’impianto, in particolare cavi, molle o supporti per

scoprire eventuali sbilanciamenti e segni di usura o danni.

- Per ogni operazione di pulizia esterna o altra manutenzione, togliere

l’alimentazione di rete

- Tenere pulite le ottiche delle fotocellule ed i dispositivi di segnalazione

luminosa. Controllare che rami ed arbusti non disturbino i dispositivi di

sicurezza (fotocellule).

- Non utilizzare l’automatismo se necessita di interventi di riparazione. In

caso di malfunzionamento, togliere l’alimentazione, attivare lo sblocco di

emergenza per consentire l’accesso e richiedere l’intervento di un tecnico

qualicato (installatore professionale).

- Per qualsiasi intervento diretto all’automazione, avvalersi di personale

qualicato (installatore professionale).

- Annualmente far controllare l’automazione da personale qualicato.

- Tutto quello che non è espressamente previsto in queste istruzioni, non

è permesso.

- ll buon funzionamento dell’operatore è garantito solo se vengono rispettati

i dati riportati in questo manuale. La ditta non risponde dei danni causati

dall’inosservanza delle norme di installazione e delle indicazioni riportate

in questo manuale.

- Le descrizioni e le illustrazioni del presente manuale non sono impegnative. Lasciando inalterate le caratteristiche essenziali del prodotto, la

Ditta si riserva di apportare in qualunque momento le modiche che

essa ritiene convenienti per migliorare tecnicamente, costruttivamente e

commercialmente il prodotto, senza impegnarsi ad aggiornare la presente

pubblicazione.

Thank you for choosing this product. The Firm is condent that its performance

will meet your operating needs. This product meets recognized technical

standards and complies with safety provisions. We hereby conrm that it is in

conformity with the following European directives: 2004/108/EEC, 2006/95/

EEC, 98/37/EEC, 99/05/EEC (and later amendments).

1) GENERAL SAFETY

WARNING Important safety instructions. Carefully read and comply with

the Warnings booklet and Instruction booklet that come with the product

as improper use can cause injury to people and animals and damage to

property. Keep hold of instructions for future reference.

This product has been designed and built solely for the purpose indicated

herein. Uses not contemplated herein might result in the product being

damaged and could be a source of danger.

- The Firm disclaims all responsibility resulting from improper use or any

use other than that for which the product has been designed, as indicated

herein, as well as for failure to apply Good Practice in the construction of

entry systems (doors, gates, etc.) and for deformation that could occur

during use.

If installed and used correctly, the automated system will meet the required

level of safety. Nonetheless, it is advisable to observe certain rules of behaviour

so that accidental problems can be avoided:

- Keep adults, children and property out of range of the automated system,

especially while it is operating.

- This application is not meant for use by people (including children) with

impaired mental, physical or sensory capacities, or people who do not have

suitable knowledge, unless they are supervised or have been instructed

by people who are responsible for their safety.

- Children must be supervised to ensure they do not play with the application. Keep remote controls or other control devices out of reach of children

in order to avoid the automated system being operated inadvertently.

- Check the system frequently, especially cables, springs or supports, to

detect any loss of balance and signs of wear or damage.

- When cleaning the outside or performing other maintenance work, always

cut o mains power.

- Keep the photocells’ optics and illuminating indicator devices clean.

Check that no branches or shrubs interfere with the safety devices (photocells).

- Do not use the automated system if it is in need of repair. In the event of

a malfunction, cut o the power, activate the emergency release to allow

access and call in qualied technical personnel (professional installer).

- If the automated system requires work of any kind, employ the services

of qualied personnel (professional installer).

- Have the automated system checked by qualied personnel once a

year.

- Anything that is not explicitly provided for in these instructions is not

allowed.

- The operator’s proper operation can only be guaranteed if the information

given herein is complied with. The Firm shall not be answerable for damage

caused by failure to comply with the installation rules and instructions

featured herein.

- Descriptions and illustrations herein are not binding. While we will not

alter the product’s essential features, the Firm reserves the right, at any

time, to make those changes deemed opportune to improve the product

from a technical, design or commercial point of view, and will not be

required to update this publication accordingly.

Loading...

Loading...