Page 1

ISTRUZIONI D’USO E DI INSTALLAZIONE

INSTALLATION AND USER’S MANUAL

INSTRUCTIONS D’UTILISATION ET D’INSTALLATION

INSTALLATIONS-UND GEBRAUCHSANLEITUNG

INSTRUCCIONES DE USO Y DE INSTALACION

MAXIMA ULTRA 36

MAXIMA ULTRA 36

Attenzione! Leggere attentamente le “Avvertenze” all’interno! Caution! Read “Warnings” inside carefully! Attention! Veuillez lire attentivement les Avertissements qui se trouvent à l’intérieur!

Achtung! Bitte lesen Sie aufmerksam die „Hinweise“ im Inneren! ¡Atención¡ Leer atentamente las “Advertencias” en el interior! Let op! Lees de “Waarschuwingen” aan de binnenkant zorgvuldig!

BARRIERA AUTOMATICA

AUTOMATIC BARRIER

BARRIÈRE AUTOMATIQUE

AUTOMATISCHE SCHRANKE

BARRERA AUTOMÁTICA

D813758 20398_01_ 16-07-18

Page 2

- 9 -

ENGLISH

1.1 INTRODUCTION

Carefully read the handbook before installing and using the product, and before performing

routine or corrective maintenance.

The directions preceded by this symbol contain information of particular importance. Non-

compliance with such directions can result in the loss of the contractual warranty.

THE OPERATIONS THAT, IF CARRIED OUT INCORRECTLY, CAN POSE RISKS, ARE INDICATED WITH THE SYMBOLS:

ELECTROCUTION CRUSHING

The INSTALLATION USE AND MAINTENANCE handbook is intended for installers, users and maintenance

operators.

The Company is not liable for any damage caused to persons, animals or property caused by use of the

product exceeding the limits reported in the attached data sheet or not complying with the intended use.

ATTENTION! Follow all instructions. An incorrect installation can cause serious injury.

1.2 GENERAL SAFETY

• Dispose of the packaging materials (plastics, cardboard, polystyrene, etc.) as required by the standards in force.

Do not leave envelopes in nylon and polystyrene within the reach of children.

• Cut o the power supply before carrying out any work on the equipment. Also disconnect any bu er batteries if

present.

• Provide on the mains power supply of the automation a switch or an omnipolar thermal magnetic circuit breaker

with contact opening distance equal to or greater than 3.5 mm.

• Check that upstream of the power supply system there is a di erential switch with 0.03A threshold.

• The outputs are not of type SELV (safety extra low voltage), therefore no reachable part is allowed.

• Apply all safety devices (photocells, sensitive edges, etc.) necessary to protect the area from crushing, conveying,

shearing hazards, according to and in compliance with the relevant directives and technical standards.

• The Company accepts no responsibility in terms of safety and good operation of the automation if components

from other manufacturers are used.

• Use only genuine parts for any maintenance or repair.

• Do not carry out any modi cation to the components of the automation if not expressly authorized by the Company.

• Instruct the user of the system as regards the control systems applied and the execution of the manual opening

in the event of an emergency.

• Do not allow persons and children to stay in the operating area of the automation.

• Do not leave remote controls or other control devices within the reach of children to prevent accidental operation of the automation.

• Do not allow children to play with the equipment.

• The equipment can be used by children aged 8 years or over and by people with reduced physical, sensory or

mental capacities, or lacking experience or the necessary knowledge, provided they are supervised or after the

same have received instructions relating to the safe use of the equipment and to the understanding of the relevant

hazards.

• Cleaning and maintenance intended to be performed by the user must not be carried out by children without

supervision.

• Everything not expressly provided for in these instructions is not allowed.

1.3 OVERVIEW

The automatic electromechanic barrier was designed to manage openings whose maximum width is 6 meters.

It is the ideal solution for vehicle management.

1.4 TECHNICAL DATA

Power....................230Vac/115Vac ±10% 50/60 Hz

Motor...........................

230Vac 910RPM 0.25 kW

Absorbed power........................................................

370 W

Control unit...............................................CSB-Xtreme

Safety to impact..............................................Encoder

Opening time.....................................

0.7 ÷ 3.9 s **

Bar length.........................................................

2 ÷ 6 m

Operating temp.............-40*** +60°C

Actuations over 24h

...........

20.000 bar length up to 3 m

...........5.000 bar length up to 6 m

Protection class...............................IP 55

Net weight.........................................69 kg

Gross weight....................................72 kg

Sound pressure level at 1 mt.

...............................................................LpA≤70 dB (A)

** The opening times are evaluated starting

from bar in closed position at the beginning of

the slowdown, at ambient temperature.

*** With built-in heater ON

1. General information

EN

Page 3

- 10 -

ENGLISH

1.5 OVERALL DIMENSIONS

RIGHT barrier

LEFT barrier

2.1 INSTALLATION EXAMPLE

2.2 SECURING THE STRUCTURE

1) Single-phase line (2+G) x 1.5mm

2) Transmitting Photocell 2 x 0.5 mm

3) Receiving Photocell 4 x 0.5 mm

4) Key selector switch 3 x 0.5 mm

5) Receiver 4 x 0.5 mm

5) Antenna RG58

6) Magnetic coil

347347

54

1030

870

40106

338338

5

6

3

1

2

4

Check the direction of travel indicated on the template, for precise

overlapping of the rounded corners of the barrier body

Arrange in the foundation corrugated tubes for power supply

and system cables (not supplied)

Cement

(not supplied)

200

200

500

500

400

Template

Cramps

It is recommended to re-

move the template before

securing the barrier

19 mm

1. General information / 2. Installation

EN

Page 4

- 11 -

ENGLISH

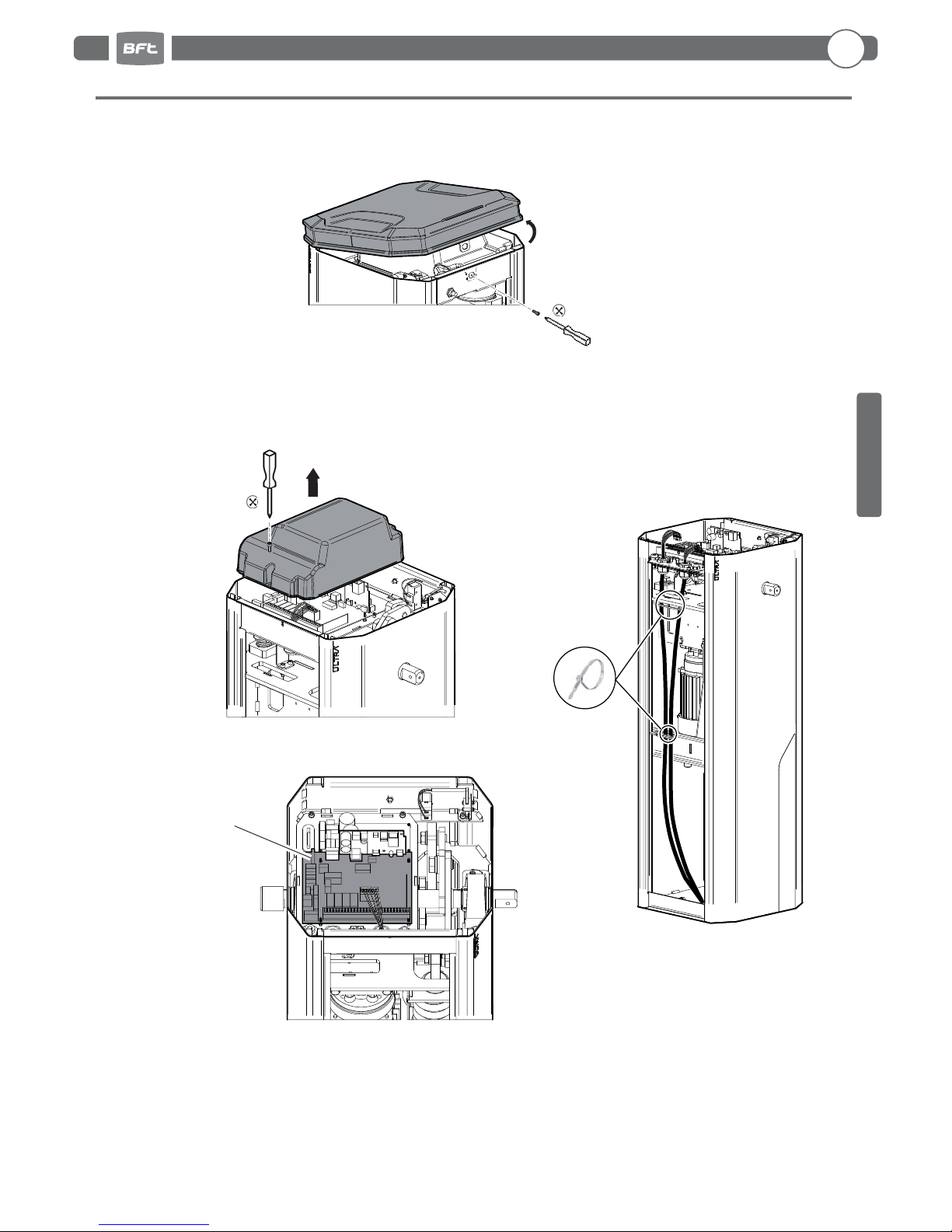

Open the cover and access inside the barrier

to remove of the doors

Refer to the use and

installation manual

of the control unit

CSB-Xtreme

2.3 ELECTRICAL CONNECTIONS

Remove the cover of the

internal control unit

Secure with

cable ties

Control board

2. Installation

EN

Page 5

- 12 -

ENGLISH

Use the "START" command to bring

the bar to vertical position

Opening micros-

witch cam

Check that the bar is in

vertical position

ADJUST THE BAR VERTICALLY OPERATING

THE CAM OF THE OPENING LIMIT SWITCH.

Electrically connect the control unit (see CSB-Xtreme

instructions)

TO ALIGN THE BAR WITH THE ROAD

PAVING, OPERATE THE ADJUSTABLE BAR

HOLDER.

Use the "Start" command to bring

the bar in horizontal position

Check that the bar is in horizontal

position

2.4 BAR INSTALLATION

2.5 BAR ALIGNMENT

2 x 10 mm

Adjustable bar holder

M6x20

4.2x16

Ø14

Ø6x12

M5x8

Ø6

M14x70

Ø5

M14

Ø6

Ø14

M6

Installation is mandatory in XL con guration (supplied).

For STD version, it is optional (not supplied).

HYPHEN PS

2. Installation

EN

BOOM PS

Page 6

- 13 -

ENGLISH

For the value “A” see

TAB.1 page 37

A

45°

Check that the bar is balanced

at approximately 45° position.

If necessary, adjust again the

distance "A".

Bring the bar to verti-

cal position

2.6 BAR BALANCING

24 mm

22 mm

DO IT ONLY WITH THE BAR MOUNTED

AND POSITIONED VERTICALLY

Remove the screw which secures the lever

Before performing any task

on the equipment, cut o

the power supply.

2.7 OPTIONAL ITEMS

ADDITIONAL

LIMIT SWITCHES

2. Installation

EN

Page 7

- 14 -

ENGLISH

RELEASE CRANK

2.8 MANUAL OPERATION

Manual release

DO IT ONLY WHEN THE BAR IS MOUNTED

Before performing any task on the equipment, cut o the power supply.

2. Installation

EN

Page 8

- 15 -

ENGLISH

3.1 GENERAL SAFETY

• The barrier is intended exclusively for vehicle use. Indicate and delimit any walkways using a speci c sign.

• Keep children, people and objects out of the operating range of the automation, in particular during operation.

• For safety reasons and in compliance with the regulations in force, it is advisable to use the appropriate control

unit.

• The installation must be performed following the prescriptions contained in the attached sheet "GENERAL

INSTRUCTIONS FOR SAFETY".

• Electrical connections must be carried out in compliance with the laws in force.

• The installer must instruct the user about the correct operation of the automatism, the manual emergency

operation, and the possible risks during operation.

• Perform risk assessment taking appropriate measures to eliminate them as prescribed by the machinery directive

2006/42/EEC, installing the safety devices.

• Before performing any task on the equipment, cut o the power supply using a cut-o switch.

• Cleaning and maintenance intended to be performed by the user must not be carried out by children without

supervision

3.2 NOTICES

The good operation of the automation is guaranteed only if the data reported in this manual is respected.

The Company is not liable for damage caused by failure to observe the rules of installation and the directions given in this manual.

The descriptions and illustrations in this manual are not binding. Leaving unchanged the essential characteristics of the product, the Company reserves the right to make at any time any changes which it considers

useful to improve in technical, construction and commercial terms the product, without committing itself

to update this publication.

3.3 USE

• Strictly follow the directions contained in the attached sheet "GENERAL INSTRUCTIONS FOR SAFETY".

• In the event of manual emergency operation, follow the directions outlined in item 2.8.

• Refer to the use and installation manual of the control unit.

3.4 ROUTINE MAINTENANCE (EVERY SIX MONTHS)

• Maintenance must only be performed by quali ed personnel.

• Record the on site servicing tasks in the form at page 38.

1

Check the condition of the barrier structure.

2

Check the condition of the bar clamping.

3

Check the condition of the spring, of the chain and of its anchors.

4

Check bar balance.

5

Check that at run end the bar is horizontal and/or vertical

6

Check the operation of the control unit and of the safety devices

7

Monitor the manual emergency operation.

3. Use and maintenance

EN

Page 9

- 37 -

1

2

3

A

Spring coupling holes

Do not weigh the arm down by applying other accessories

TA B. 1

Springs calibration (APPROXIMATE DATA)

REV.01

85

45

L

The values in the table are the same for the version with lights.

BTM-SKIRT

ADJ-FOOT

Special spring included in version XL. In these confi gurations, it is mandatory the installation of the bar reinforcement HYPHEN PS (see chap. 2.4 ref. )

ESDEFRENIT

MAXIMA ULTRA 36 •

BALANCING THE ARM

BOOM PS

BOOM PS

L 2000 2500 3000 3500 4000 4500 5000 5500 6000

BOOM PS

POSITION 1 1 1 1 1 2 2 3 3

A (mm) 130 125 110 90 125 115 100 120 105

BOOM PS

+ ADJ-FOOT

POSITION / 1 1 2 2 2 3 3

2

A (mm) / 110 90 125 115 100 125 110

95

BOOM PS

+ BTM-SKIRT

POSITION / 1 1 2 2 3 3

3

3

A (mm) / 110 85 120 100 120 105

125

115

BOOM PS

+ BTM-SKIRT

+ ADJ-FOOT

POSITION / 1 2 2 3 3 3

3

3

A (mm) / 95 120 105 125 110 95

120

105

Page 10

Dati impianto / Installation data

Installatore

Installer

Cliente

Customer

Matricola

Serial number

Data installazione

I

nstallation date

Data attivazione

Activation date

Luogo

Location

Dati manutenzione / Maintenance date

Nr. Data • Date Descrizione intervento • Intervention description Firma • Signature

1

Tecnico • Technician

Cliente • Customer

2

Tecnico • Technician

Cliente • Customer

3

Tecnico • Technician

Cliente • Customer

4

Tecnico • Technician

Cliente • Customer

5

Tecnico • Technician

Cliente • Customer

6

Tecnico • Technician

Cliente • Customer

7

Tecnico • Technician

Cliente • Customer

8

Tecnico • Technician

Cliente • Customer

- 38 -

REGISTRO DI MANUTENZIONE

MAINTENANCE LOG

REGISTRE DES OPÉRATIONS D’ENTRETIEN

INSTANDHALTUNGSPLAN

RESISTRO DE MANTENIMIENTO

Page 11

Nr. Data • Date Descrizione intervento • Intervention description Firma • Signature

9

Tecnico • Technician

Cliente • Customer

10

Tecnico • Technician

Cliente • Customer

11

Tecnico • Technician

Cliente • Customer

12

Tecnico • Technician

Cliente • Customer

13

Tecnico • Technician

Cliente • Customer

14

Tecnico • Technician

Cliente • Customer

15

Tecnico • Technician

Cliente • Customer

16

Tecnico • Technician

Cliente • Customer

17

Tecnico • Technician

Cliente • Customer

18

Tecnico • Technician

Cliente • Customer

19

Tecnico • Technician

Cliente • Customer

20

Tecnico • Technician

Cliente • Customer

21

Tecnico • Technician

Cliente • Customer

- 39 -

Page 12

ITALY

INSTALLATORE

INSTALLER

INSTALLATEUR

INSTALLATEUR

INSTALATOR

DA TA

DATE

DATE

DATUM

FECHA

Loading...

Loading...