Page 1

ISTRUZIONI D'USO E DI INSTALLAZIONE

INSTALLATION AND USER'S MANUAL

INSTRUCTIONS D'UTILISATION ET D'INSTALLATION

MONTAGE- und BEDIENUNGSANLEITUNG

INSTRUCCIONES DE USO Y DE INSTALACION

INSTRUÇÕES DE USO E DE INSTALAÇÃO

I

GB

F

D

E

P

Via Lago di Vico, 44

36015 Schio (VI)

Tel.naz. 0445 696511

Tel.int. +39 0445 696533

Fax 0445 696522

Internet: www.bft.it

E-mail: sales@bft.it

BOTTICELLI

VENERE

8

027908 2 8 8 1 2 7

AUTOMAZIONI PER PORTE BASCULANTI E SEZIONALI

AUTOMATION FOR OVERHEAD AND SECTIONAL GARAGE DOORS

AUTOMATION POUR PORTES BASCULANTES ET SECTIONALES

GARAGENTORANTRIEB FÜR SCHWING UND SEKTIONALTORE

AUTOMATIZACIONES PARA PUERTAS BASCULANTE Y SECCIONALES

AUTOMATIZAÇÕES PARA PORTAS BASCULANTES DE MOLAS E SECCIONAIS

D811492_02 20-02-07

Page 2

2 - BOTTICELLI VENERE

D811492_02

Page 3

USER’S MANUAL

ENGLISH

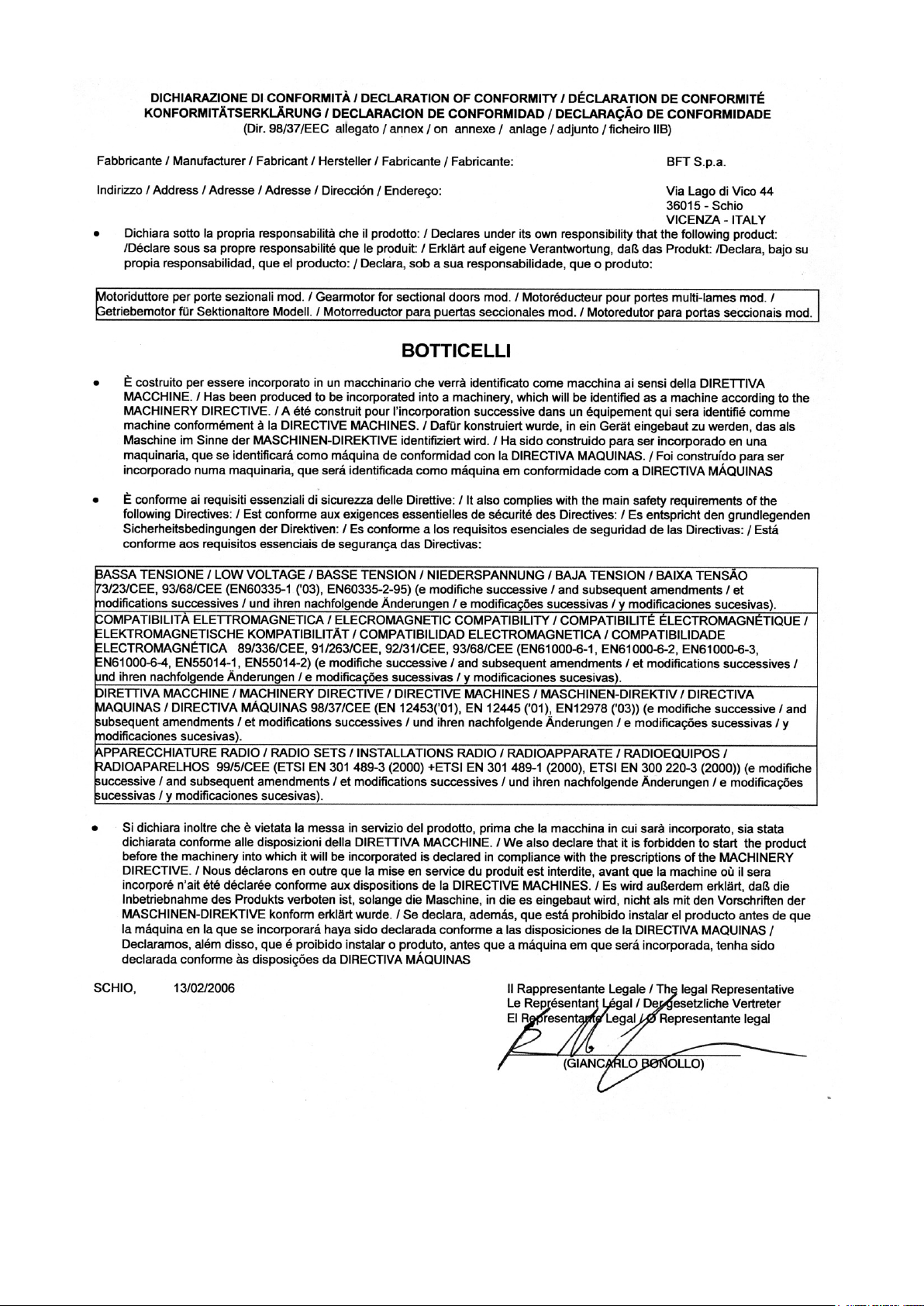

Thank you for buying this product, our company is sure that you will be more

than satisfied with the product’s performance. The product is supplied with

a “Warning” leaflet and an “ Instruction booklet ”. These should both be

read carefully as they provide important information about safety, installation, operation and maintenance. This product complies with the recognised

technical standards and safety regulations. We declare that this product is in

conformity with the following European Directives: 89/336/EEC, 73/23/EEC,

98/37/EEC, 99/05/EEC (and subsequent amendments).

1)GENERAL OUTLINE

The BOTTICELLI system is compatible with the EElink protocol for fast installation and maintenance. It is suitable for motorising sectional doors, protruding fully retracting spring operated overhead doors and counterweight

overhead doors provided with an appropriate towing arm. The overhead door

must not be higher than 3 metres. It is easy to install and fast to fit and does

not need the door to be modified. The irreversible gearmotor keeps the door

locked in the closing position. The control unit is builtin. It controls the operation relays and the safety devices (photocell, rubber skirt) before performing

every manoeuvre.

This product was designed to motorise the types of door mentioned

above. Any other use is considered contrary to that intended by the

manufacturer who,therefore,cannot be held responsible for any injuries

to persons or animals,or damage to things which might derive from

misuse.

2)SAFETY

If correctly installed and used, this automation device satisfies the required

safety level standards. However, it is advisable to observe some practical rules

in order to avoid accidental problems. Before using the automation device,

carefully read the operation instructions and keep them for future reference.

• Keep children, persons and things outside the automation working area,

particularly during operation.

• Keep radio control or other control devices out of children’s reach, in order

to avoid any unintentional automation activation.

• Do not intentionally oppose the leaf movement.

• Do not attempt to open the door manually, if the internal locking system has

not been released by pulling the appropriate wire connected to the carriage

(fig.1), or the external lock (SM1 or SET/S fig.2-fig.3) activated.

• Do not modify the automation components.

• In case of malfunction, disconnect the power supply, activate the emergency release to gain access to the automation device and request the

assistance of a qualified technician (installer).

• Before proceeding to any external cleaning operation, disconnect the

mains powers supply.

• Keep the photocell optical components and luminous signal indication devices clean. Check that the safety devices (photocells) are not obscured by

branches or shrubs.

• For any direct assistance to the automation system, request the assistance

of a qualified technician (installer).

• Have qualified personnel check the automation system once a year.

• Check the installation frequently, in particular cables, springs and supports

to find out any unbalance, sign of wear or damage. Do not use the operator

in the case where any repairs or adjustments are required, given that an

installation malfunction or an incorrectly balanced door could cause injuries.

• Once a month, check that the motor reverses when encountering on obstacle

50 mm away from the floor. Should operation show to be incorrect, request

the assistance of a qualified technician, given that an incorrect adjustment

could be dangerous.

3) EMERGENCY MANOEUVRE

In case of electric power failure or system malfunction, the manoeuvre must

be carried out manually by pulling the wire connected to the carriage, as in

fig.1. For garages which are not provided with a second exit, it is compulsory

to fit an external key release device like Mod. SM1 (fig.2) or Mod. SET/S

(fig.3).

WARNING: If the door is not correctly balanced, activation of the carriage

manual release could provoke an uncontrolled door movement.

4) BULB REPLACEMENT

To replace the courtesy light bulb, remove its transparent cover (fig.4).

WARNING: Only 24V 25W max E14 bulbs must be used.

E14 24V

25W max

4 - BOTTICELLI VENERE

D811492_02

Page 4

INSTALLATION MANUAL

ENGLISH

Thank you for buying this product, our company is sure that you will be more

than satisfied with the product’s performance. The product is supplied with a

“Warnings” leaflet and an “Instruction booklet”. These should both be read

carefully as they provide important information about safety, installation,

operation and maintenance. This product complies with the recognised

technical standards and safety regulations. We declare that this product is in

conformity with the following European Directives: 89/336/EEC, 73/23/EEC,

98/37/EEC, 99/05/EEC (and subsequent amendments).

1) GENERAL SAFETY

WARNING! An incorrect installation or improper use of the product can cause

damage to persons, animals or things.

• The “Warnings” leaflet and “Instruction booklet” supplied with this product

should be read carefully as they provide important information about

safety, installation, use and maintenance.

• Scrap packing materials (plastic, cardboard, polystyrene etc) according

to the provisions set out by current standards. Keep nylon or polystyrene

bags out of children’s reach.

• Keep the instructions together with the technical brochure for future

reference.

• This product was exclusively designed and manufactured for the use

specified in the present documentation. Any other use not specified in

this documentation could damage the product and be dangerous.

• The Company declines all responsibility for any consequences resulting from improper use of the product, or use which is different from that

expected and specified in the present documentation.

• Do not install the product in explosive atmosphere.

• The construction components of this product must comply with the following

European Directives: 89/336/CEE, 73/23/EEC, 98/37/EEC and subsequent amendments. As for all non EEC countries, the abovementioned

standards as well as the current national standards should be respected

in order to achieve a good safety level.

• The Company declines all responsibility for any consequences resulting

from failure to observe Good Technical Practice when constructing closing structures (door, gates etc.), as well as from any deformationwhich

might occur during use.

• The installation must comply with the provisions set out by the followingEuropean Directives: 89/336/CEE, 73/23/EEC, 98/37/EEC and subsequent

amendments.

• Disconnect the electrical power supply before carrying out any work on

the installation. Also disconnect any buffer batteries, if fitted.

• Fit an omnipolar or magnetothermal switch on the mains power supply,

having a contact opening distance equal to or greater than 3,5 mm.

• Check that a differential switch with a 0.03A threshold is fitted just before

the power supply mains.

• Check that earthing is carried out correctly: connect all metal parts for

closure (doors, gates etc.) and all system components provided with an

earth terminal.

• Fit all the safety devices (photocells, electric edges etc.) which are needed

to protect the area from any danger caused by squashing, conveying and

shearing.

• Position at least one luminous signal indication device (blinker) where it

can be easily seen, and fix a Warning sign to the structure.

• The Company declines all responsibility with respect to the automation safety

and correct operation when other manufacturers’ components are used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorised

by the company.

• Instruct the product user about the control systems provided and the

manual opening operation in case of emergency.

• Do not allow persons or children to remain in the automation operation

area.

• Keep radio control or other control devices out of children’s reach, in

order to avoid unintentional automation activation.

• The user must avoid any attempt to carry out work or repair on the automation system, and always request the assistance of qualified personnel.

• Anything which is not expressly provided for in the present instructions,

is not allowed.

• Installation must be carried out using the safety devices and controls

prescribed by the EN 12978 Standard.

• Fit any fixed control within sight of the door but away from moving parts,

higher than 1.5 m.

• Add a label bearing the following notices:

“Keep children away from the moving door”.

“WARNING: risk of squashing”.

Regularly check that the door reverses its movement when colliding with an

obstacle 50 mm away from the floor and, if necessary, set it correctly.

2) GENERAL OUTLINE

The BOTTICELLI system is suitable for motorising sectional doors (fig. 3),

protruding fully retracting spring-operated overhead doors (fig. 2) and counterweight overhead doors provided with an appropriate towing arm (fig. 4).

The overhead door must not be higher than 3 metres. Its easy installation

allows fast fitting without needing the door to be modified. The irreversible

gearmotor keeps the door locked in the closing position.

3) TECHNICAL SPECIFICATIONS

3.1) Actuator

Power supply:..................................230V~±10%, 50/60Hz single-phase (*)

Motor voltage:........................................................................................24V

Max. power absorbed from mains:......................................................236W

Lubrication:......................................................................permanent grease

Towing and pushing force:...................................................................600N

Working stroke:....................TRACK L.=2900 working stroke=2400 mm(**)

............................................TRACK L.=3500 working stroke=3000 mm(***)

Average speed:................................................................................5 m/min

Impact reaction:............................integrated torque limiter on control panel

Manoeuvres in 24 hours:..........................................................................20

Limit switch:........................................................Electronic with ENCODER

Courtesy light:......................................................24V~ 25W max, E14 bulb

Working temperature:.............................................................-15°C / +60°C

Degree of protection:............................................................................IPX0

Motor head weight:.................................................................................5kg

Noise level:....................................................................................<70dB(A)

Dimensions:....................................................................................see fig.1

(*) Available in all mains voltages.

(**)By turning the motor head by 90° (Fig.11) the useful stroke will be 2580 mm.

(***) By turning the motor head by 90° (Fig.11) the useful stroke will be 3180 mm.

4) ACTUATOR INSTALLATION

4.1) Preliminary checks

• Check that the door is balanced.

• Check that the door slides smoothly along its entire travel.

• If the door has not been newly installed, check the wear condition of all

its components.

• Repair or replace faulty or worn parts.

• The automation reliability and safety are directly influenced by the state

of the door structure.

• Before fitting the motor, remove any superfluous ropes or chains and

disable any unnecessary appliances.

4.2) FITTING

After unpacking, dispose of the parts which make up the package properly,

by separating the different type of materials (cardboard, polystyrene, PVC,

etc.) according to the national rules in force.

1) Remove the existing locking bolt from the cremone bolt of the door.

2) In order to fix the track correctly, mark the mid-point of the door, posi-In order to fix the track correctly, mark the mid-point of the door, posi-

tion the BIN on the ceiling and mark the holes (Fig. 6).

3) Drill the ceiling with a 10-dia. drill bit following the previously madeDrill the ceiling with a 10-dia. drill bit following the previously made

marks, and insert the Fischer plugs.

4) Secure the track at the base, fig.7 (ref.1-2) and fig.8 (ref.3-4-5).

5) With the help of an adequate support, lift the entire motor, screw theWith the help of an adequate support, lift the entire motor, screw the

screws onto the track-holding bracket without fixing them to the door

frame (Fig.9A) or, if the height allows it, fit the bracket to the masonry

lintel by means of plugs (Fig.9B).

6) Lift the motor-driven head until everything rests against the ceiling, andLift the motor-driven head until everything rests against the ceiling, and

insert the fixing screws which lock the track (including the anchoring

bracket screws).

7) If the motor head and the track are not fixed directly to the ceiling, see

Fig.10 (always check that the track is level and perpendicular to the cei-(always check that the track is level and perpendicular to the ceiling).

8) In the case where the track is turned by 90° with respect to the motor

head, use the reference template in Fig. 11A to cut out the guard, keeping to the measurements indicated. For fixing the BIN to the ceiling, seeFor fixing the BIN to the ceiling, see

Fig.6 and in case the track is not fixed directly to the ceiling, see Fig.12.

9) In the case where the track is made in two halves, see Fig.13; for the

different types of fixing methods, see the previous figures.

10)

Release the carriage and fix the anchoring brackets to the door panelRelease the carriage and fix the anchoring brackets to the door panel

(Fig.14). The distance allowed between track and sectional door is 108

to 166 mm. In case of greater distance, it is necessary to use the brackets and lower the motor; in case of shorter distance, it is necessary to

shorten the towing plate.

11)

Stick the adhesive labels supplied next to the dangerous points (Fig. 5).

5) CHAIN TIGHTENER ADJUSTMENT (BOTTICELLI)

The operator supplied is already calibrated and inspected. Should the chain

tension need to be adjusted, proceed as shown in fig. 15.

12 - BOTTICELLI VENERE

D811492_02

Page 5

INSTALLATION MANUAL

ENGLISH

WARNING: the anti-tear rubber element must never be completely

compressed. Scrupulously check that the rubber does not become

totally compressed during operation.

6) ELECTRICAL INSTALLATION SET-UP (Fig.16)

M) Actuator

Ft) Transmitter photocell

Fr) Receiver photocells

T) 1-2-4 channel transmitter.

Arrange for the connections of accessories and safety and control devices

to reach the motor unit, keeping the mains voltage connections clearly

separate from the extra low safety voltage connections (24V) by means of

the appropriate cable holder (fig. 8 ref. 5P1).

Proceed to connection following the indications given in the wiring diagram.

The cables for connecting the accessories must be protected by a raceway

(fig. 8 ref. 5C1).

7) VENERE Control panel (Fig.17)

Supply to accessories: ..................................................24V~ (180mA max)

.............................................................24V~ Vsafe VENERE (180mA max)

Torque limiter setting:..............................................on closing and opening

Automatic closing time:.........................................................from 3 to 120s

Blinker connection:..............................................................24V~ max 25W

Service light switching-on time:..............................................................90s

Incorporated rolling-code radio receiver:..................frequency 433.92 MHz

Coding:.......................................................................rolling-code algorithm

No. combinations:...........................................................................4 milliard

Antenna impedance:............................................................50Ohm (RG58)

Max no. radio controls to be memorised:..................................................10

Slow-down distance:................closing: ~24 cm ............... opening: ~24 cm

Fuses:......................................................................................see figure 17

7.1) Terminal board connections (Fig.17)

WARNINGS - For wiring and installation operations, refer to the current

standards and good technical principles.

The wires supplied with extra low safety voltage (24V) must be kept physically separate from the low voltage wires, or else they must be provided with

adequate additional insulation of at least 1mm.

The wires must be clamped by an extra fastener near the terminals, for

example by bands.

TERMINAL DESCRIPTION

JP6

transformer wiring

JP7

motor wiring

1-2

Antenna input for integrated radio-receiver board

(1: BRAID. 2: SIGNAL)

3-4

START input (N.O.)

3-5

STOP input (N.C.) If not used, leave the jumper inserted.

3-6

PHOTOCELL input (N.C.) If not used, leave the jumper

inserted.

3-7

FAULT input (N.O.)

Input for photocells provided with checking N.O. contact

8-9

24 V~ output for blinking light (25 W max)

10-11

24V~ 180mA max output – power supply for photocells

or other devices

12-13

24V~ Vsafe 180mA max output – power supply for checking

photocell transmitters.

7.2) LED (Fig.17)

The led functions are as follows:

“RADIO”:Incorporated radio-receiver led.

“SET”: Limit device setting led - power ON.

7.3) DIP-SWITCH SELECTION (Fig.17)

DIP1) IBL – Locks impulses.

ON: During the opening phase, does not accept START commands.

OFF: During the opening phase, accepts START commands.

DIP2) TEST PHOT

ON: Enables photocell checking (5-connector photocells must be used

- see Fig.17A-).

OFF: Disables photocell checking.

7.4) TRIMMER SETTING (Fig.17)

TCA

Sets the automatic closing time, after which the gate closes automatically

(can be set from 3 to 120 sec). If the trimmer is turned all the way, the TCA

is disabled.

OPENING TORQUE

Sets the ampere-stop sensitivity on opening.

CLOSING TORQUE

Sets the ampere-stop sensitivity on closing.

NOTE: In case of obstacle detection, the Ampere-stop function halts

the leaf movement, reverses the motion for 1 sec. and stays in the

STOP state.

WARNING: check that the impact force value measured at the

points established by the EN 12445 standard is lower than that

specified in the EN 12453 standard.

Incorrect sensitivity setting can cause injuries to persons or animals, or damage to things.

7.5) BUTTONS

“UP”: limit device setting and opening command. An autoset operation

of the torque will be performed by keeping this button pressed

for 5 seconds (Fig.19).

“DOWN”: limit device setting and closing command.

“OK”: radio programming.

8) LIMIT DEVICE SETTING (Fig.18)

1) Simultaneously press the “UP” and “DOWN” keys for 5 seconds. The

“SET” led blinks to indicate that the limit device setting is activated.

2) Bring the leaf to the required closing position, using the “UP” and “DOWN”

buttons on the control unit, and keeping in mind that the “DOWN” button

closes the leaf, while the “UP” button opens the leaf.

3) As soon as the leaf reaches the required closing position, press the “OK”

button in order to memorise the limit device closing position. The “SET”

led confirms data storage by blinking for 1 second.

4) Bring the leaf to the required opening position, using the “UP” and “DOWN”

buttons on the control unit, and keeping in mind that the “DOWN” button

closes the leaf, while the “UP” button opens the leaf.

5) As soon as the leaf reaches the required opening position, press the

“OK” button in order to memorise the limit device opening position. The

“SET” led confirms data storage by blinking for 1 second and then lits up

again.

6) Correctly position the “carriage lock” against the carriage (fig.18 ref.6 A-B).

NOTE 1: These manoeuvres are carried out in “hold-to-run” mode at reduced

speed and with no safety devices activated.

NOTE 2: In case of errors, the “SET” led remains off on for 5 seconds.

9) OPENING / CLOSING TORQUE AUTOSETTING (Fig.19)

1) After reaching the closing end-of-stroke position, press the “UP” button

for 5 seconds.

2) The “SET” led blinks rapidly and the leaf starts to open until it reaches

the opening end-of-stroke.

3) 3 second down time.

4) The “SET” led blinks rapidly and the leaf starts to close until it reaches

the closing end-of-stroke

5) After completing the autoset adjust the opening/closing torque trimmers

so as to obtain the desired sensitivity to the obstacle.

Any input activation (START, RADIO TRANSMITTER, STOP, PHOTOCELL)

during autosetting will annul the autoset in progress.

10) INTEGRATED RECEIVER

Transmitter versions which can be used:

all Rolling Code transmitters compatible with .

10.1)ANTENNA INSTALLATION

Use an antenna tuned to 433MHz.

For Antenna-Receiver connection, use RG8 coaxial cable.

The presence of metallic masses next to the antenna can interfere with radio

reception. In case of insufficient transmitter range, move the antenna to a

more suitable position.

10.2) MANUAL TRANSMITTER PROGRAMMING (Fig.20)

1) Press the “OK” button on the control unit.

2) When the “RADIO” LED blinks, press the transmitter P1 hidden key, and

the “RADIO” LED will stay on permanently.

3) Press the key to be memorised on the transmitter, LED “RADIO” will start

blinking again.

4) To memorise another transmitter, repeat steps 2) and 3).

5) To exit the storage mode, wait until the LED is switched off completely.

BOTTICELLI VENERE - 13

D811492_02

Page 6

INSTALLATION MANUAL

ENGLISH

10.3) REMOTE TRANSMITTER PROGRAMMING (Fig.20)

1) Press the hidden key (P1) of a transmitter that has been already memorised in standard mode by means of manual programming.

2) Press the normal key (T1-T2-T3-T4) of a transmitter that has been already

memorised in standard mode by means of manual programming.

3) The courtesy lamp blinks. Press the hidden key (P1) of a transmitter to

be memorised within 10s.

4) The courtesy lamp stays on permanently. Press the normal key (T1-T2T3-T4) of a transmitter to be memorised.

The receiver exits the programming mode within 10s., within this time new

additional transmitters can be memorised.

This mode does not require access to the control panel.

10.4) TRANSMITTER CANCELLATION (Fig.20)

To cancel the control unit memory totally, press the “OK” button on the control

unit for 10 seconds (“RADIO” LED blinking). Correct memory cancellation

will be indicated by the “RADIO” LED staying on permanently. To exit the

storage mode, wait until the LED is switched off completely.

11) EMERGENCY MANOEUVRE

In case of electric power failure or system malfunction, the manoeuvre

must be carried out manually by pulling the wire connected to the carriage,

as in fig.21. For garages which are not provided with a second exit, it is

compulsory to fit an external key release device like Mod. SM1 (fig.22) or

Mod. SET/S (fig.23).

12) AUTOMATION CHECK

Before the automation device finally becomes operational, scrupulously

check the following conditions:

• Check that all the safety devices (limit microswitches, photocells, electric

edges etc) operate correctly.

• Check that the door (antisquash) thrust is comprised within the limits set

out by the current standards, and anyway not too strong for the installation

and operating conditions.

• Check that the chain-tightening rubber element is not completely com-

pressed during the manoeuvre.

• Check the manual opening control operation.

•

Check the opening and closing operations using the control devices fitted.

• Check the normal and customised operation electronic logics.

13) AUTOMATION DEVICE USE

Since the automation device can be remotely controlled by means of a radio control device or a Start button, and therefore when not in sight, all the

safety devices must be frequently checked in order to ensure their perfect

efficiency. In the event of any malfunction, request immediate assistance

from qualified personnel. Children must be kept at a safe distance from the

automation operation area.

14) AUTOMATION CONTROL

The use of this control device allows the gate to be opened and closed

automatically. There are different types of controls (manual, radio control,

magnetic card access etc.) depending on the installation requirements and

characteristics. For the various control systems, see the relevant instructions.

The automation device users must be instructed on control and operation.

15) ACCESSORIES

SM1 External release device to be applied to the cremone bolt already

fitted to the overhead door (fig.22).

SET/S External release device with retracting handle for sectional doors

measuring max 50mm (fig.23).

ST Automatic bolt release device for spring-operated overhead doors.

Fitted to the control arm, it automatically releases the side door bolts

(fig.24).

16) MAINTENANCE

Before carrying out any maintenance operation, disconnect the system

power supply.

• Periodically check the tension of the chain/belt (twice a year).

• Occasionally clean the photocell optical elements, if installed.

• Have a qualified technician (installer) check the correct setting of the

electronic clutch.

• When any operational malfunction if found, and not resolved, disconnect

the system power supply and request the assistance of a qualified technician (installer). When the product is out of service, activate the manual

release device to allow the door to be opened and closed manually.

If the power supply cable is damaged, it must be replaced directly by

our company or our technical service department or by a technician

having similar qualification so as to avoid any risks.

16.1) FUSE REPLACEMENT (Fig.25)

WARNING! Disconnect the mains voltage.

Remove the rubber protection from the fuse-carrier. Remove the fuse (Fig.25,

Ref.A) to be replaced and replace it with a new one. After completing this

operation, re-fit the rubber protection.

17) SCRAPPING

Warning! This operation should only be carried out by qualified personnel.

Materials must be disposed of in conformity with the current regulations.

In case of scrapping, the automation devices do not entail any particular risks

or danger. In case of materials to be recycled, these should be sorted out by

type (electrical components, copper, aluminium, plastic etc.).

18) DISMANTLING

Warning! This operation should only be carried out by qualified personnel.

When the automation system is disassembled to be reassembled on another

site, proceed as follows:

• Disconnect the power supply and the entire external electrical installation.

• In the case where some of the components cannot be removed or are

damaged, they must be replaced.

The descriptions and illustrations contained in the present manual are

not binding. The Company reserves the right to make any alterations

deemed appropriate for the technical, manufacturing and commercial

improvement of the product, while leaving the essential product features unchanged, at any time and without undertaking to update the

present publication.

14 - BOTTICELLI VENERE

D811492_02

Page 7

146

253.16

65

3

7

8

35

3

3

8

0

-

2

7

8

0

3

7

6

0

-

3

1

6

0

1

2

2

5

0

E14 24V

25W max

BOTTICELLI VENERE - 27

D811492_02

Page 8

28 - BOTTICELLI VENERE

D811492_02

Page 9

BOTTICELLI VENERE - 29

D811492_02

Page 10

24VSafe MAX 180mA

24V MAX 180mA

Eventuali passaggi per cavi,

Possible cable passages,

Passages éventuels pour les câbles,

Eventuelle Kabelführungen,

Eventuales accesos para cables,

Eventuais passagens para cabos.

3 1245678910111213

ANT

SHIELD

JP6

JP7

Luce di cortesia, Courtesy lamp,

Lampe de courtoisie, Hilfsbeleuchtung,

Luz interior, lâmpada de cortesia.

Fusibile,Fuse,Fusible,

Schmelzsicherung,Fusible,

Fusível (Fig.26):

1,25 AT

Trimmer regolazioni, Adjustment trimmer, Trimmer réglages,

Einstelltrimmer, Trimmers para las regulaciones, trimmer regulações.

DIP SWITCH

M

Fr

Ft

T

17

UP

DOWN

Fig.17A

36710111213

36710111213

DIP TEST PHOT= ON

DIP TEST PHOT= ON

30 - BOTTICELLI VENERE

D811492_02

Page 11

5 sec.

ERROR!

2

SET

4

SET

1

SET

5 sec.

3

SET

SET

SWC

AUTO

OPEN

AUTO

CLOSE

SWO

1

5 sec.

2 3

4

5

SET

SET

1 sec.

1 sec.

SET SET

REGOLAZIONE FINECORSA, LIMIT DEVICE SETTING,ÉGLAGE FIN DE COURSE, EINSTELLUNG DER ENDSCHALTER, REGULACION DEL

GRUPO DE FIN DE CARRERA, REGULAÇÃO DO FIM-DE-CURSO.

AUTOSET COPPIA APERTURA / CHIUSURA, OPENING / CLOSING TORQUE AUTOSETTING, RÉGLAGE AUTOMATIQUE COUPLE

OUVERTURE / FERMETURE, AUTOSET DREHMOMENT ÖFFNUNG / SCHLIESSUNG, AJUSTE AUTOMATICO DEL PAR EN FASE DE

APERTURA / CIERRE, AUTOSET BINÁRIO DE ABERTURA / FECHO.

CHIUSURA

CLOSING

FERMETURE

SCHLIESSUNG

CIERRE

FECHO

APERTURA

OPENING

OUVERTURE

ÖFFNUNG

APERTURA

ABERTURA

SET

6

BOTTICELLI VENERE - 31

D811492_02

Page 12

Fig. 20

1

2

3

RADIO RADIO RADIO

1

1 2 3

2 3 4

Radiocomando già memorizzato

Radio transmitter already memorised

Radiocommande déjà mémorisée

Bereits gespeicherte Funksteuerung

Radiomando ya memorizado

Radiocomando já memorizado

Radiocomando già memorizzato

Radio transmitter already memorised

Radiocommande déjà mémorisée

Bereits gespeicherte Funksteuerung

Radiomando ya memorizado

Radiocomando já memorizado

RADIO RADIO RADIO

Cancellazione in corso

Cancellation in progress

Annulation en cours

Löschvorgang läuft

Cancelación en curso

Cancelamento em curso

Cancellazione effettuata

Cancellation completed

Annulation effectuée

Löschung ist erfolgt

Cancelación efectuada

Cancelamento efectuado

Radiocomando da memorizzare

Radio transmitter to memorise

Radiocommande à mémoriser

Zu speichernde Funksteuerung

Radiomando que memorizar

Radiocomando a memorizar

Radiocomando da memorizzare

Radio transmitter to memorise

Radiocommande à mémoriser

Zu speichernde Funksteuerung

Radiomando que memorizar

Radiocomando a memorizar

Fig. 21 Fig. 22

Fig. 23

Fig. 24

Fig. 25

10 sec.

PROGRAMMAZIONE TRASMETTITORI MANUALE, MANUAL TRANSMITTER PROGRAMMING, PROGRAMMATION ÉMETTEURS MANUELLE,

MANUELLE SENDERPROGRAMMIERUNG, PROGRAMACION DE TRANSMISORES MANUAL, PROGRAMAÇÃO MANUAL DOS TRANSMISSORES.

PROGRAMMAZIONE TRASMETTITORI REMOTA, REMOTE TRANSMITTER PROGRAMMING, PROGRAMMATION ÉMETTEURS A DISTANCE,

FERNPROGRAMMIERUNG DER SENDER, PROGRAMACION DE TRANSMISORES REMOTA, PROGRAMAÇÃO REMOTA DOS TRANSMISSORES.

CANCELLAZIONE TRASMETTITORI, TRANSMITTER CANCELLATION, TION ÉMETTEURS, LÖSCHEN VON SENDERN, CANCELACION DE TRANSMISORES.

3 1245678910111213

JP7

UP

32 - BOTTICELLI VENERE

D811492_02

Page 13

Fig. 26

Tappi, Caps, Bouchons,

Stopfen, Tapon, Tampões.

2 -3 cm

2 -3 cm

PORTA CHIUSA, DOOR CLOSED,

PORTE FERMEE, TÜR TAGSÜBER,

PUERTA CERRADA, PORTA FECHADA.

Montaggio tappi per operatore BOTTICELLI.

Assembly of caps for BOTTICELLI operator.

Montage bouchons pour opérateur BOTTICELLI.

Montage der Stopfen für Antrieb BOTTICELLI.

Montajie topones para automatisacio’n BOTTICELLI.

Montagem de tampões para operador BOTTICELLI.

BOTTICELLI VENERE - 33

D811492_02

Page 14

Loading...

Loading...