Page 1

Instruction Manual

Page 2

Page 3

TABLE OF CONTENTS

NAME OF PARTS 7

Details of machine 7

ACCESSORIES 9

Standard 9

Needle Information 9

HOW TO OPEN LOOPER COVER 10

Principal Parts behind the Looper Cover 10

PREPARATION TO SEWING 10

Power Switch 10

Foot Controller 10

Cut-offs Bin 11

PREPARATION FOR THREADING 12

Setting up the Retractable thread stand 12

Spool net 12

Spool Cap 12

HOW TO DISENGAGE UPPER KNIFE 13

UPPER LOOPER CONVERTER (ULC) 14

Use the upper looper converter 14

Disengage To Upper Looper 14

STANDARD OVERLOCK AND ROLLED HEM

STITCHING 14

Sew Standard Overlock 14

Sew Rolled Hem 15

HOW TO REMOVE AND INSERT NEEDLES 15

Needle Position 15

To Remove Needle(s) 16

To Insert Needle(s) 16

Threading the Lower Looper (Red) 21

Threading the Overlock Right Needle (Green) 23

Threading the Overlock Left Needle (Yellow) 24

HOW TO CHANGE THREADS 26

Tie on method 26

HOW TO ADJUST 27

Stitch lenght dial 27

Seam Width 27

The presser foot pressure 28

DIFFERENTIAL FEED 29

Gathered Overlock (1–2.0) 29

Stretch Overlock (1–0.6) 30

CHAINING OFF AND TEST SEWING 31

HOW TO SEW AN OVERLOCK STITCH 32

2–Thread Wrapped Overlock (9/10) 32

2–Thread Overlock (14/15) 33

3–Thread Overlock (3/4) 34

3–Thread Flatlock (5/6) 35

2–Thread Flatlock (11/12) 36

3–Thread Super Stretch (2) 37

4–Thread Overlock with integrated safety

seam (1) 38

HOW TO SEW A ROLLED HEM 39

Machine set up 39

Additional information about rolled hemming 40

3–Thread Narrow Seam (7) 41

3–Thread Rolled Hem (8) 41

2–Thread Rolled Hem (13) 42

SELECTION OF STITCHES 17

THREADING THE MACHINE 19

Threading Diagram 19

Tension Color Code 19

Threading the Upper Looper (Blue) 20

STITCH VARIATIONS AND SEWING

TECHNIQUES 43

How To Sew a Flatlock Decorative Seam 43

Machine Set Up 43

Flatlocking a Seam 43

3

Page 4

Decorative Flatlocking 44

Additional Information about Flatlocking 44

How to sew an Overlock Blind Hem 45

How to sew Pin Tucks 45

How to turning Square Corners 46

MACHINE MAINTENANCE 48

Cleaning The Machine 48

Oiling The Machine 48

Replace the Upper Knife 49

OPTIONAL ACCESSORIES 50

Snap–On Type Presser Foot 50

Optional Presser Foot 51

TROUBLESHOOTING 52

FABRIC, THREAD AND NEEDLE CHART 53

SPECIFICATION 54

Technical Summary 54

IMPORTANT

Precautions should always be followed,

including the following:

Read all the instructions before using this

machine.

In general when the machine is not in

use, it should be disconnected from

the electricity supply.

DANGER!

As a protection against electrical shock:

1. The machine should never be left

unattended when plugged in.

2. Always unplug this machine from

the electrical outlet after using and

before cleaning.

3. LED Radiation. Do not view directly

with optical instruments. Class 1M

LED product.

WARNING!

As a protection against burns, fire, electric shock or injury to persons:

1. Use this machine only for purposes

as described in this manual. Use

only attachments, accessories and

parts recommended by the manufacturer.

2. Do not allow this machine to be

used as a toy. Close attention is

necessary when this machine is

used by or near children. The

machine is not intended for use by

persons (and children) with reduced

physical, sensory or mental capabilities or lack of experience and

knowledge. Unless they have been

given supervision or instruction concerning use of the machine by a

person responsible for their safety.

To ensure children do not play with

4

Page 5

the machine they must be supervised.

Never operate this machine if:

⦁

the cord or the plug are damaged,

⦁

it is not working properly,

⦁

it has been dropped or damaged,

⦁

it has fallen into water.

3. Return the machine to your local

authorized BERNINA dealer for

examination or repair.

4. Never operate the machine with any

air openings blocked. Keep ventilation openings of the machine free

from the accumulation of lint, dust

and loose cloth.

5. Keep fingers away from all moving

parts. Special care is required

around the sewing needle and the

knife.

6. Never insert any objects into any

openings on the machine.

7. Do not use the machine outdoors.

8. Do not operate the machine where

aerosol products (sprays) or oxygen

are being used.

9. Do not pull or push the fabric while

stitching. This can result in needle

breakage.

10. Switch the machine off «0» when

making any adjustments in the needle area, such as threading the

needle, changing the needle, threading the looper, or changing the

presser foot.

11. Always unplug the machine from the

electrical outlet when removing covers, when covers are opened to

raise the knife or thread the loopers,

when lubricating or when making

any other user servicing adjustments mentioned in the instruction

manual.

12. Do not use bent needles.

13. Always use the original BERNINA

stitch plate. The wrong stitch plate

can cause needle breakage.

14. This machine is provided with double insulation (except for USA and

Canada). Use only original spare

parts. See instructions for servicing

of double–insulated products.

15. Use only foot controller provided

with this machine. (Type 4C–316B

for USA & CANADA only).

5

Page 6

All rights reserved

For technical and product improvement reasons, the machine‘s features, parts and

accessory are subject to unannounced

changes and alterations at any time. The

accessory included can differ from country

to country.

WARNING:

This machine is intended for household

use only. If used intensively or commercially, regular cleaning and especially

attentive care is required.

Signs of wear and tear owing to intensive

or commercial use are not covered automatically, even if they occur within the

warranty period. The decision on how to

deal with any such cases rests with the

local authorised servicing staff.

PLEASE NOTE:

If the machine is stored in a cold room, it

should be brought to a warm room about

one hour before use.

SERVICING OF

DOUBLE–INSULATED

PRODUCTS

In a double–insulated product two systems of insulation are provided instead of

grounding. No grounding means is provided on a double–insulated product, nor

should a means for grounding be added

to the product. Servicing a double–insulated product requires extreme care and

knowledge of the system and should be

done only by qualified service personnel.

Replacement parts for a double–insulated product must be identical to the

original parts in the product. A double–

insulated product is marked with the

words: «Double insulation» or «Double

insulated».

The symbol may also mark such a

product.

SAVE THESE

INSTRUCTIONS!

Europe only: This appliance may only be

used by children over eight and by persons with reduced physical, sensory or

mental capabilities or by persons who

lack experience and knowledge of how to

operate the machine under supervision,

after instruction on how to use the equipment safely and once they have understood the potential dangers. Children

shall not play with the appliance. Cleaning

and user maintenance shall not be made

by children without supervision.

Outside of Europe (except for the USA

and Canada): This appliance may only be

used by persons (including children) with

reduced physical, sensory or mental

capabilities or by persons who lack experience and knowledge of how to operate

the machine under supervision and after

instruction on how to use the equipment

safely by a person responsible for their

safety. Children should be supervised to

ensure that they do not play with the

appliance.

6

Page 7

1

2

4

8

9

10

11

15

16

3

5

6

7

14

12

13

NAME OF PARTS

Details of machine

Retractable thread stand

Carrying handle

Thread Tension Adjustment dial (yellow)

Thread Tension Adjustment dial (green)

Thread Tension Adjustment dial (blue)

Thread Tension Adjustment dial (red)

Spool pin

Stitch plate

Sewing table

Looper cover

Power / Light switch

Stitch length dial

Handwheel

Thread stand

Spool stabilizer

Cut-offs Bin

7

Page 8

17

18

19

20

21

Presser foot lifter

Differential feed dial

Cutting width dial

Presser foot pressure regulator

Standard presser foot Overlock

8

Page 9

13

1412

7

11

10

6

98

12

3

5

4

ACCESSORIES

Standard

Screw driver (large size)

Oiler

Spool net (4x)

Spare upper knife

Spool cap (4x)

Brush

Needle set (ELx705)

Needle Threader / inserter

Allen screw driver (small)

Tweezers

Upper looper converter (ULC)

Spool stabilizer (4x)

Dust cover

Cut-offs Bin

Needle Information

This overlock uses a flat shank industrial needle

(ELx705).

Do not attempt to use a standard household

sewing machine needle of any size or type in

this overlock.

Needle ELx705 size 80/12 is furnished with the

machine.

Only use needles of system ELx705 sizes 70/10

- 90/14 .

9

Page 10

OFF

ON

2

1

2

3

6

4

5

1

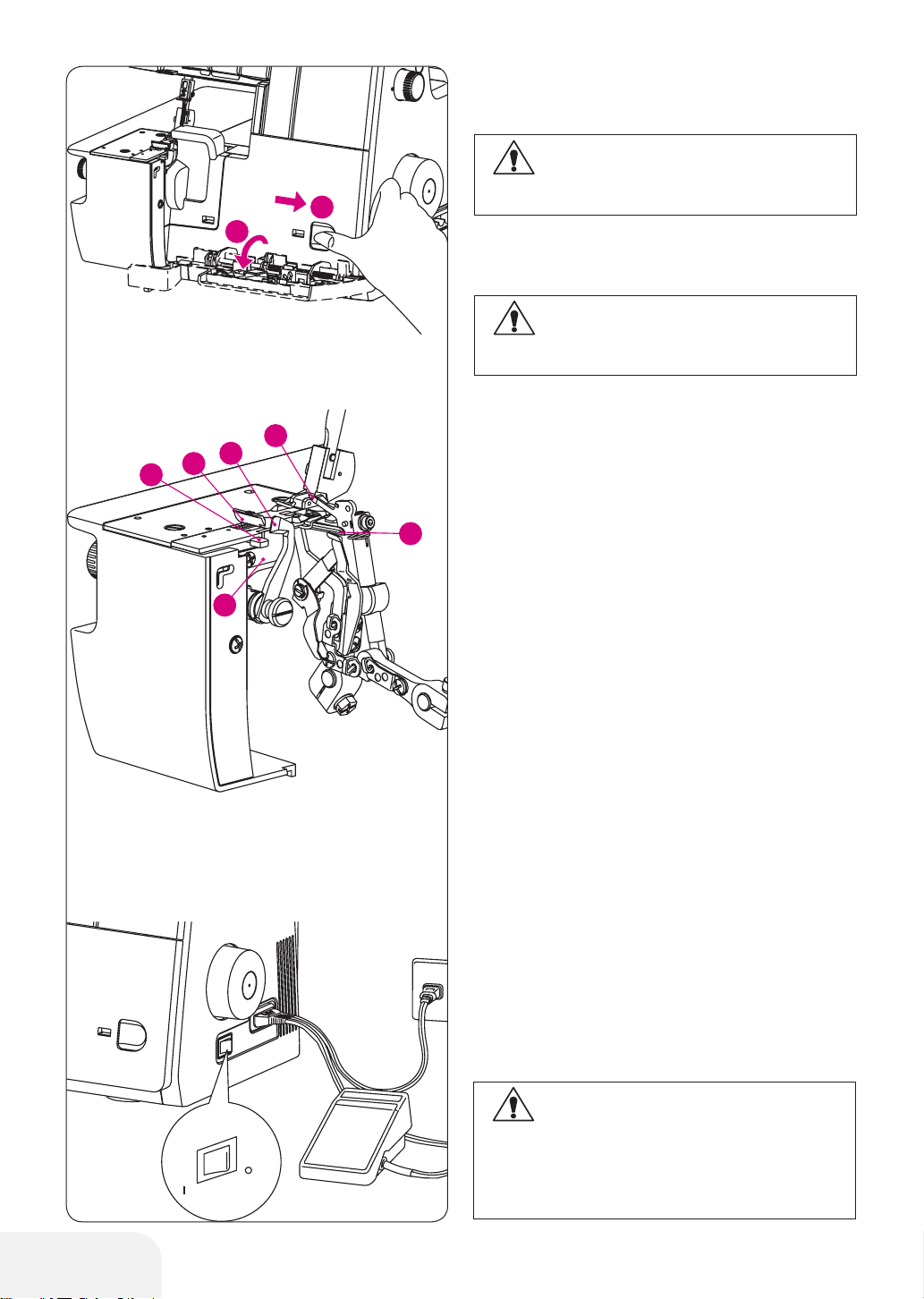

HOW TO OPEN LOOPER

COVER

CAUTION:

Be sure to turn off power switch.

1. Push the cover to the right as far as it will go.

2. Pull cover down toward you.

CAUTION:

Be sure looper cover is closed when sewing.

Principal Parts behind the Looper

Cover

(1) Upper looper

(2) Upper knife (moveable)

(3) Standard presser foot

(4) Fixed position lower knife

(5) Lower looper

(6) Rolled Hem lever

10

PREPARATION TO SEWING

Power Switch

– Connect the controller/electric plug to the

machine receptacle.

– Plug power line into electric outlet.

– Push " l " mark side to turn "ON"

– Push "O" mark side to turn "OFF"

Foot Controller

– To run the machine and control the speed,

press the controller.

– The harder you press, the faster the machine

will sew.

– To stop the machine from sewing, remove your

foot from the controller

CAUTION:

Use only foot controller provided with this

machine. (Type 4C–316B for USA & CANADA

only). Be sure to make reference to “Warning”

on following Page.

Page 11

• Polarized plug information

5

1

3

4

2

(FOR USA & CANADA ONLY)

This appliance has a polarized plug (one blade wider

than the other). To reduce the risk of electric shock,

this plug is intended to fit in a polarized outlet only way.

If the plug does not fit fully in the outlet, reverse the

plug.

If it still does not fit contact a qualified electrician to

install the proper outlet. Do not modify the plug in any

way.

CAUTION:

– Be sure that the electrical voltage of the electric outlet (wall receptacle) is the same as the rated voltage

of the motor.

– Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place anything on

top of it when not in use.

– Disconnect the power line plug from the electric outlet when changing needles, presser feet or when

leaving the machine unattended. This eliminates the possibility of starting the machine by accidentally

pressing the controller.

Cut-os Bin

• To attach

– Insert the Cut-offs Bin (1) in the looper cover.

– Be sure to press the Cut-offs Bin downward (2).

– Be sure the left side of Cut-offs Bin (3) is

mounted near the cutter where the scraps drop.

• Removal

– Pull the Cut-offs Bin upward as the instruction

(4).

– To remove (5), hold the Cut-offs Bin as shown

and pull it outward.

11

Page 12

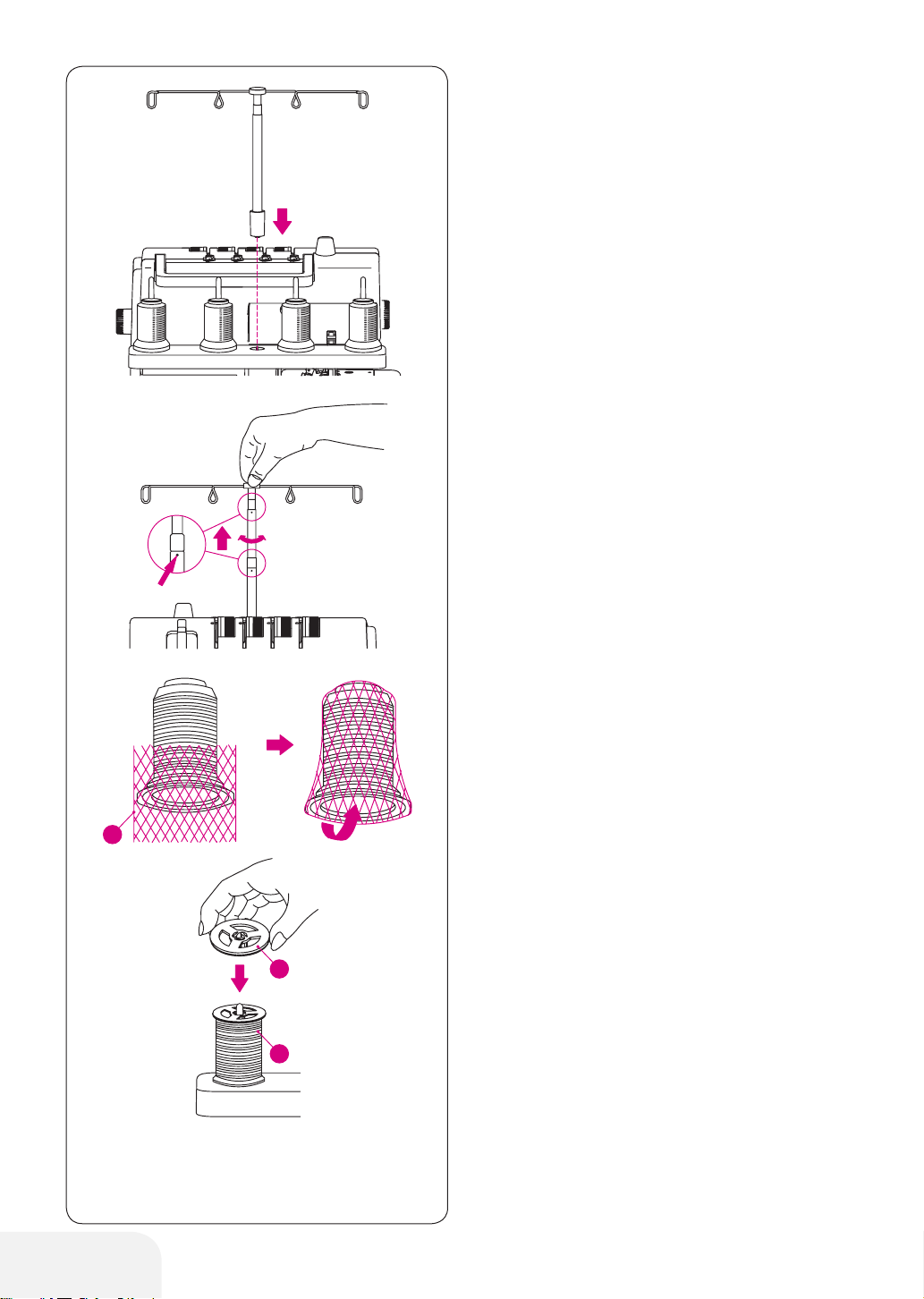

PREPARATION FOR THREAD-

3

2

1

ING

Setting up the Retractable thread

stand

– Take out the retractable thread stand from the

top of Styrofoam, and insert it as shown on the

left illustration.

– This machine is shipped with the retractable

thread stand on the top of styrofoam.

– Fully extend the retractable thread stand.

– The two joints on the telescope will click into

place when they are correctly positioned.

– Center the retractable thread stand above the

spool pins.

– Place thread over the cone adapters on the

spool pins.

Spool net

When using synthetic threads that easily spill off the

cone, slip the spool net (1) furnished with the machine

over the thread from the bottom of the cone leaving

the thread end hanging free at the top the spool net.

Spool Cap

When using a regular thread spool, fit the spool cap

(2) supplied with the machine onto the thread spool

(3).

12

Page 13

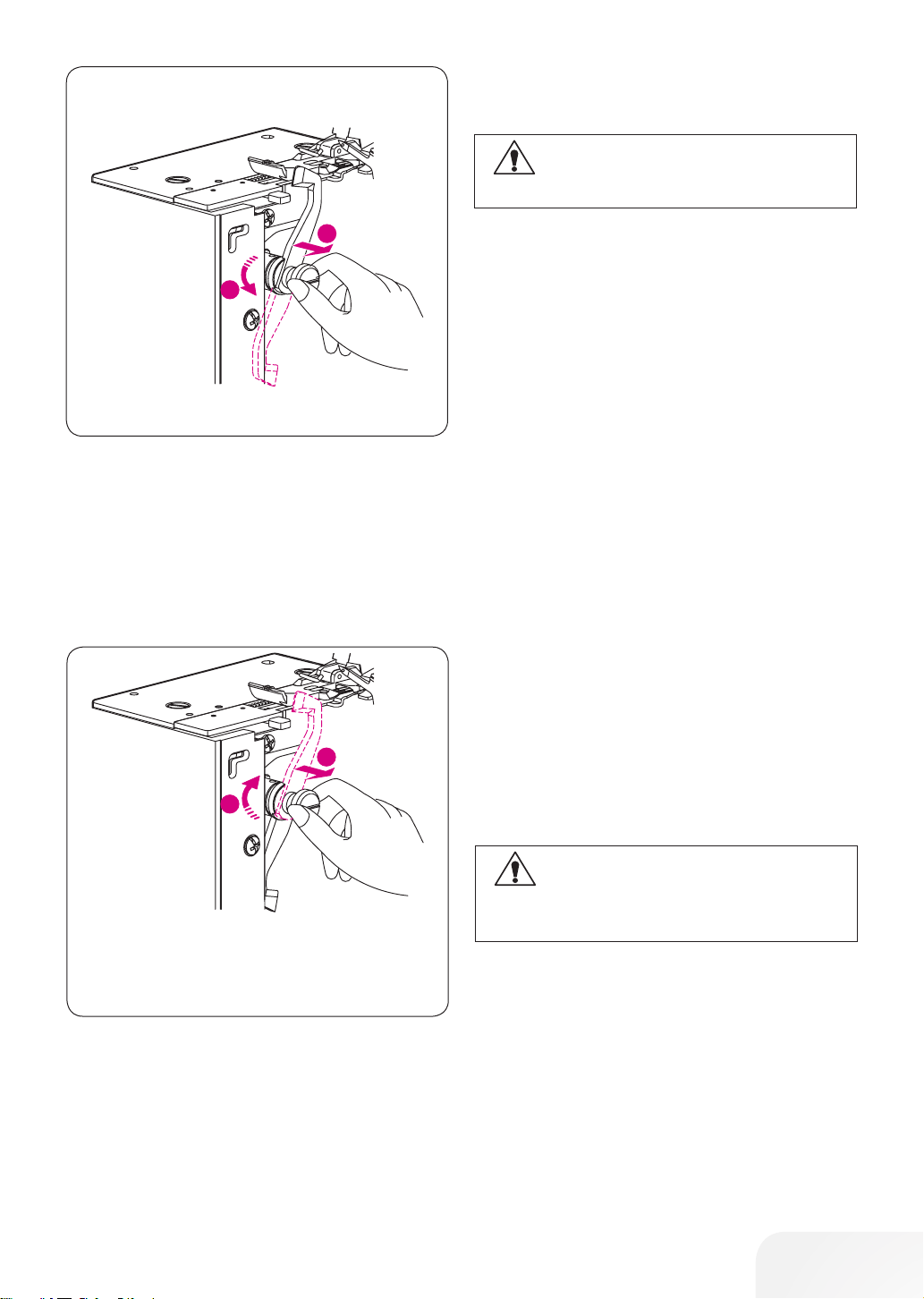

HOW TO DISENGAGE UPPER

2

1

2

1

1

2

KNIFE

CAUTION:

Be sure to turn off power switch.

• To place upper knife in nonworking

position

– Open looper cover (refer page 10).

– Pull the upper knife holder (1) to the right as far

as it will go.

– Turn the holder (2) toward counter clockwise

until the knife clicks into a lock position.

• To place upper knife in working position

– Open looper cover.

– Pull the upper knife holder (1) to the right as far

as it will go.

– Turn the holder (2) clockwise until the knife

clicks into the working position.

CAUTION:

Always close looper cover before operating

machine.

13

Page 14

UPPER LOOPER CONVERTER

1

2

1

2

3

R

N

R

N

(ULC)

CAUTION:

Be sure to turn off power switch.

When not threading the upper looper, the upper

looper converter must be engaged into the upper

looper eye.

Attach the Upper Looper Converter

– To engage the upper looper converter, insert

the sharp part (1) into the eye of upper looper.

– A raised point located in the trough of upper

looper converter must be inserted and fixed (2)

in the eye of the upper looper converter.

Remove the Upper Looper Converter

When using the upper looper, the upper looper converter must be disengaged.

– To disengage the upper looper converter, raise

the handle (3) of upper looper according to

picture.

STANDARD OVERLOCK AND

ROLLED HEM STITCHING

Sew Standard Overlock

Set seam width finger knob to "N" to move seam width

finger to standard overlock sewing position.

PLEASE NOTE:

Be sure to push seam width finger knob as far as

it will go in the direction of setting "N".

14

Page 15

Sew Rolled Hem

R

N

A

B

B

A

BAB

Set seam width finger knob to "R" to retract the seam

width finger and set it for rolled hem.

PLEASE NOTE:

Be sure to push seam width finger knob as far as

it will go in the direction of setting "R".

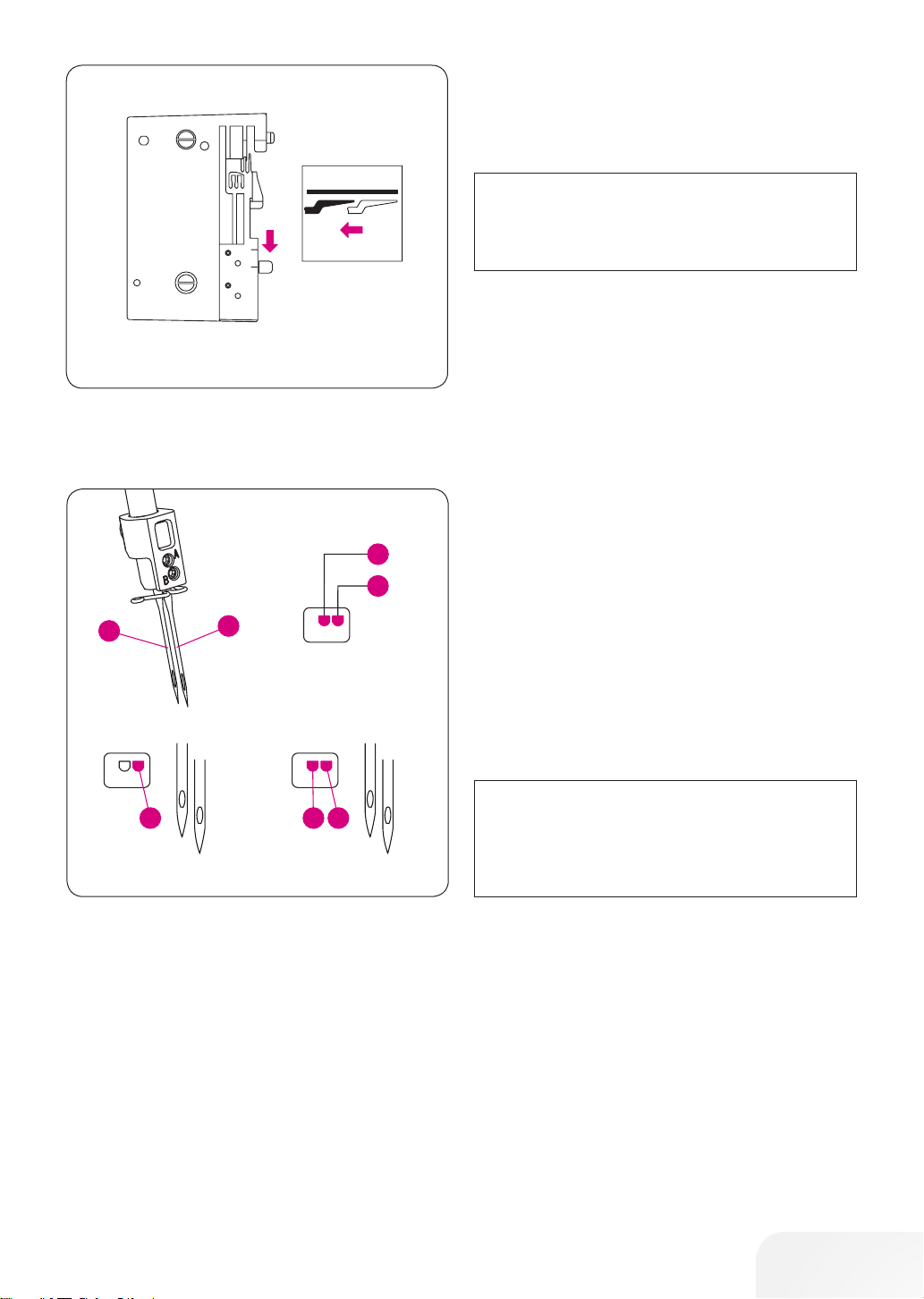

HOW TO REMOVE AND INSERT

NEEDLES

Needle Position

– With this machines, two needles can be inserted

to the needle clamp.

– The Stitch overview refers to different needle

positions by illustrating the needle clamp.

PLEASE NOTE:

When both the left and right overlock needles are

inserted, the left needle will be slightly higher

than the right.

(A) Left Needle (LN)

(B) Right Needle (RN)

15

Page 16

To Remove Needle(s)

B

A

1

A

B

B

A

BAB

B

A

1

2

3

A

B

B

A

BAB

PLEASE NOTE:

Be sure to disconnect the machine from the electric outlet before removing needle(s).

– Turn the hand wheel counterclockwise until the

needles are at their highest position.

– Hold the needle to be removed with the needle

holder (stored in the looper cover).

– Loosen the setscrew and remove the needle.

(A) Left needle (LN)

(B) Right needle (RN)

To Insert Needle(s)

– Hold the needle with the flat surface (1) to the

back.

– Insert the needle into the needle socket as far

as it will go.

– When inserting a needle, if you first lower it

down into the hole in the stitch plate it will line

up with the needle socket. Then direct it

upwards.

16

PLEASE NOTE:

When inserting needles into the (A) or (B) sock-

ets it is necessary to loosen (3) both (A) and

(B) Allen Screws.

After inserting the needles equally tighten both

Screws (2).

Page 17

STITCH OVERVIEW

This machine is capable of producing various types of stitches according to the combination of needle positions,

threading methods, tension adjustment and the use of upper looper converter ULC.

# Stitch Type Use

4–Thread Overlock with integrated

1

safety seam

3–Thread Super Stretch

2

3–Thread Overlock wide

3

3–Thread Overlock narrow

4

3–Thread Flatlock wide

5

3–Thread Flatlock narrow

6

3–Thread Narrow Seam

7

3–Thread Rolled Hem

8

2–Thread Wrapped Overlock wide

9

2–Thread Wrapped Overlock narrow

10

2–Thread Flatlock wide

11

2–Thread Flatlock narrow

12

2–needle 4–Thread stitch that is ideal for medium

to heavyweight stretchy fabrics such as double

knits and swim wear.

2–needle 3–Thread stitch that is ideal for light

weight, extremely stretchy fabrics such as tricot

and spandex.

1–needle 3–Thread stitch is used for overedging

and seaming on common fabrics.

A 4 mm and 6 mm overlock seam width can be

obtained by changing the needle position.

1–needle 3–Thread stitch is used for butted or

lapped seams and ornamental stitching with

decorative thread.

Also a 4 mm and 6 mm flatlock width can be

obtained by changing the needle position.

1–needle 3–thread stitch is for edging light

weight fabrics.

1–needle 3–thread stitch is used for sewing narrow rolled hems.

For a beautiful rolled hem, thread the upper

looper with decorative thread and the needle and

lower looper with light weight regular thread.

1–needle 2–Thread stitch is used for seaming

light weight or stretch fabrics.

A 4 mm and 6 mm overlock seam width can be

obtained by changing the needle position.

1–needle 2–Thread stitch is used for butted or

lapped seams and ornamental stitching with

decorative thread.

Also a 4 mm and 6 mm flatlock width can be

obtained by changing the needle position.

Page

38

37

34

35

41

41

32

36

2–Thread Rolled Hem

13

2–Thread Overlock wide

14

2–Thread Overlock narrow

15

1–needle 2–thread stitch is used for fine rolled

hems.

1–needle 2–Thread stitch is used for overedging

common fabrics.

A 4 mm and 6 mm overlock seam width can be

obtained by changing the needle position.

17

42

33

Page 18

Depending on the needle positions used, this machine can sew 2-/3- and 4-Thread Overlock Stitches at a width

of 4mm and 6 mm.

Also, for overedging heavyweight fabrics, the seam width can be increased still more by turning the cutting width

dial. (Refer page 27).

Overlock width 4.0 mm (narrow) 6.0 mm (wide)

Needle used Overlock right needle Overlock left needle

Needle thread tension dial Green Yellow

SL = Stitchlength

DF = Differential feed dial

CW = Cutting Width

RHP = Rollhemlever position

NP = Needle Position

LN = Left Needle

RN = Right Needle

UL = Upper Looper

LL = Lower Looper

Suggested Machine Settings Thread Tension

Stitch Type

SL DF CW RHP NP Yellow Green Blue Red

1

2

3

4

5

6

7

8

9

10

11

12

13

4–Thread Overlock with integrated

safety seam

3–Thread Super Stretch

3–Thread Overlock wide

3–Thread Overlock narrow

3–Thread Flatlock wide

3–Thread Flatlock narrow

3–Thread Narrow Seam

3–Thread Rolled Hem

2–Thread Wrapped Overlock wide

2–Thread Wrapped Overlock narrow

2-Thread Flatlock wide

2-Thread Flatlock narrow

2–Thread Rolled Hem

2.5 1 6 N 4.0 4.0 4.0 4.0

2.5 1 6 N 4.0 4.0 3.5

2.5 1 6 N 3.0 – 4.0 3.5

2.5 1 6 N – 4.0 4.0 4.0

2.5 1 6 N 0.0 – 4.0 7.5

2.5 1 6 N – 0.0 4.5 7.5

1.5 1 5 R – 4.0 5.0 4.5

1 1 5 R – 4.0 4.5 6.5

2.5 1 6 N 2.5 – 3.0

2.5 1 6 N – 4.5 3.5

2.5 1 6 N 0.0 – 4.0

2.5 1 6 N – 0.0 4.5

1 1 5 R – 4.5 4.0

14

15

2–Thread Overlock wide

2–Thread Overlock narrow

2.5 1 6 N 0.0 – 4.0

2.5 1 6 N – 0.0 4.5

The thread tension becomes tighter as the dials are tumed to higher numbers. The tension settings shown on this page as well as throughout

the Instruction book are suggested default settings.

Adjust thread tensions to suit the fabric and size of thread of thread used. For best results make tension adjustments in small increments of no

greater than half a number at a time.

18

Page 19

THREADING THE MACHINE

21

4

3

21

4

3

1

2

5

6

4

3

Threading Diagram

• Overlock Stitches

– A color coded threading diagram is located

inside the looper cover for quick reference.

– Thread the machine in the order (1)–(4).

PLEASE NOTE:

Threads go through the take–up lever cover for

Overlock as shown.

Tension Color Code

• Overlock Stitches

(1) Upper looper thread (Blue)

(2) Lower looper thread (Red)

(3) Right needle thread (Green)

(4) Left needle thread (Yellow)

(5) Topside of fabric

(6) Underside of fabric

19

Page 20

2

3

8

6

4

5

7

1

1

2

3

8

6

4

5

7

1

2

2

3

3

Threading the Upper Looper (Blue)

CAUTION:

Be sure to turn off power switch.

– Raise the presser foot to open the tension

discs.

– Thread the upper looper as indicated (1)–(8).

– Pass thread from back to the front through the

thread guide (1).

– Thread the pre-tension guide by pulling the

thread towards the left until it slips under guide

(2). Then pull thread along the right side of pre-

tension as illustrated.

– While holding thread with fingers, pass it

20

between the tension discs and pull thread down

to make certain it is properly located in between

the tension discs (3).

Page 21

– Thread the looper area of the machine following

10cm

(4")

7

8

6

7

8

4

5

10cm

(4")

7

8

2

3

9

6

4

5

7

1

8

1

2

2

6

7

8

4

5

the blue color coded thread guides (4)–(8).

– Thread the upper looper eye from front to back

(8).

PLEASE NOTE:

Make sure thread passes behind lower looper.

Use tweezers provided in the accessory case to

aid in threading the looper.

Threading the Lower Looper (Red)

– Raise the presser foot to open the tension

discs.

– Thread the lower looper as indicated (1)–(9).

– Pass thread from back to the front through the

thread guide (1).

– Thread the pre-tension guide by pulling the

thread towards the left until it slips under guide

(2). Then pull thread along the right side of pre-

tension as illustrated.

21

Page 22

– While holding thread with finger, pass it between

3

3

3

9

6

4

5

7

8

3

3

9

6

4

5

7

8

5

6

7

4

C

98

D

B

A

3

the tension discs and pull thread down to make

certain it is properly located in between the tension discs (3).

– Turn the handwheel anticlockwise until the

lower looper extends out 5–10 mm from the

stitch plate edge.

– Thread the looper area of the machine following

the red color coded thread guides (4)–(9).

PLEASE NOTE:

Use tweezers provided in the accessory case to

aid in threading the looper.

– Place the thread with the point of the tweezers

slightly from left and to the right of threading

guide (4).

– Thread the looper eye (A) from front to back.

– Pull about 4“ (10 cm) of thread.

– Position thread into V cutout (B) on threader.

22

– Firmly hold thread tail with left hand and pull

Threader lever (C) up into place (D).

Page 23

Threading the Overlock Right Needle

2

3

4

1

5

6

7

8

9

3

2

3

4

1

1

2

2

5

6

7

8

9

3

(Green)

(B On Needle Clamp)

CAUTION:

Be sure to turn off power switch.

discs.

– Thread the right needle as indicated (1)–(9).

– Raise the presser foot to open the tension

– Pass thread from back to the front through the

thread guide (1).

– Thread the pre-tension guide by pulling the

thread towards the left until it slips under guide

(2). Then pull thread along the right side of pre-

tension as illustrated.

– While holding thread with fingers, pass it

between the tension discs and pull thread down

to make certain it is properly located in between

the tension discs (3).

23

Page 24

– Continue to thread points (4)–(9).

4

5

6

7

8

9

10cm

(4”)

9

7

8

4

5

6

7

8

9

10cm

(4”)

9

7

8

1

2

3

4

5

7

6

8

9

4

5

6

7

8

9

10c m

(4” )

1

9

7

8

1

2

3

4

5

7

6

8

9

4

5

6

7

8

9

10c m

(4” )

PLEASE NOTE:

Slip thread into the rear slot on the thread guide

(5) and bottom slot of take–up lever cover (6).

Then slip thread into the right slot on the thread

guide (7), and into the right slot on the thread

guide (8).

Before threading eye of needle, slip thread behind

thread guide located on the bottom of the needle

clamp.

– Thread the eye of the right needle (9).

PLEASE NOTE:

Use of tweezers in the accessory case will make

needle eye threading easy.

– The position of the thread must be behind the

thread guide.

– Draw about 4" (10 cm) of thread through needle

eye towards the rear of machine.

– Place the thread to the back, under the presser

foot.

Threading the Overlock Left Needle

(Yellow)

(A On Needle Clamp)

CAUTION:

Be sure to turn off power switch.

– Raise the presser foot to open the tension

discs.

– Thread the left needle as indicated (1)–(9).

24

– Pass thread from back to the front through the

thread guide (1).

Page 25

– Thread the pre-tension guide by pulling the

2

2

3

3

10cm

(4”)

2

2

3

3

7

6

5

4

8

9

10cm

(4”)

2

2

3

3

9

7

8

7

6

5

4

8

9

thread towards the left until it slips under guide

(2). Then pull thread along the right side of pre-

tension as illustrated.

– While holding thread with fingers, pass it

between the tension discs and pull thread down

to make certain it is properly located in between

the tension discs (3).

– Continue to thread points (4)–(9).

PLEASE NOTE:

Slip thread into the front slot on the thread guide

(5) and bottom slot of take–up lever cover (6).

Then slip thread into the left slot on the thread

guide (7), and into the left slot on the thread

guide (8).

Before threading eye of needle, slip thread behind

thread guide located on the bottom of the needle

clamp.

– Thread the eye of the left needle (9).

PLEASE NOTE:

Use of tweezers in the accessory case will make

needle eye threading easy.

– The position of the thread must be behind the

thread guide.

– Draw about 4" (10 cm) of thread through needle

eye towards the rear of machine.

– Place the thread to the back, under the presser

foot.

25

Page 26

HOW TO CHANGE THREADS

Tie on method

– To change thread type or color, clip thread near

the spool.

– Place new thread on stand.

– Tie new thread and old thread ends together

with a square knot. Clip thread tails to 2–3cm

(1") length. If clipped too short, threads may

come untied.

– Firmly pull both thread to test knot security.

– Raise the presser foot to open the tension

discs.

26

– Pull the threads through the machine once at a

time.

– If threads do not pull easily, check for tangles on

thread guides or looping under thread stand.

– When pulling thread through the needles,

STOP when the knot is in front of the needle.

– Cut the knot and thread the needle eye.

Page 27

1

2

●

3

(10/64")

(15/64")

6.0 mm

4.0 mm

1

2

●

3

b

a

(13/64")

7 mm

(17/64")

5 mm

3 mm

(1/8")

5 mm

(3/16")

(10/64")

(15/64")

6.0 mm

4.0 mm

1

2

●

3

b

a

b

a

HOW TO ADJUST

Stitch lenght dial

– The stitch length dial should be set on the • =

2.5 setting for most sewing conditions.

– Adjust the stitch length to 2.5 – 4 when sewing

heavy weight fabrics.

– For rolled hems and narrow seams set the

stitch length between 1 and 2.

– A shorter stitch length can be used to avoide

fabric from puckering.

Seam Width

Overlock seam width can be achieved by repositioning

the needle position and also with the cutting width dial.

• Width adjustment by changing needle

position

Overlock seam width can be adjusted by changing the

needle position.

(a) When using left needle

6 mm (15/64")

(b) When only right needle is used

4 mm (10/64")

• Cutting width dial

Use of cutting width dial will permit further adjustment

within the width range shown below.

(a) When using left needle

5–7 mm (13/64"–17/64")

(b) When only right needle is used

3–5 mm (1/8"–17/64")

27

Page 28

6.5

N

5.5

6.5

N

5.5

– Turn the cutting width dial counter clockwise to

increase width of cutting, and clockwise to

decrease width of cutting.

The presser foot pressure

The presser foot pressure of this machine is pre–

adjusted at the factory to suit the sewing of medium

weight fabrics.

Most of the materials do not require adjustment of

presser foot pressure. However, there are some

instances where adjustment is necessary, such as

when sewing light weight and heavyweight fabrics.

In such case, use "•" for normal, "L" for the lightest

pressure, and "H" for the heaviest.

– For light weight fabric Decrease the pressure.

– For heavy weight fabric Increase the pressure.

– Testsew to define the optimal pressure for your

sewing project.

28

Page 29

DIFFERENTIAL FEED

– Differential feed is a system which "stretches"

or "gathers" the fabric, when the amount of feed

of front feed dogs in relation to the rear feed

dogs is changed.

– The differential feed ratio ranges from 0.6–2.0.

Adjustment is made by means of the differential

feed dial pictured at left.

– Use of differential feed is very effective in over-

edging stretch fabrics and fabrics cut on the

bias.

– Setting "1" is differential feed dial setting for

ratio 1:1.

Gathered Overlock (1–2.0)

Gathered overlock is most suited for shirring sleeves,

yokes, front and back bodices, skirt hems, etc. in

stretch fabrics such as well as knits and jersey before

assembling into garment.

• To set the dierential feed dial for gath-

ering

– Set differential feed dial above setting "1".

– Setting of adjusting dial depends on material

being sewn as well as the amount of desired

gather.

– Therefore set dial to suit the fabric and test sew

before sewing your garment.

PLEASE NOTE:

For normal overlock stitching, set differential

feed dial to graduation “1”.

29

Page 30

Stretch Overlock (1–0.6)

Stretch overlock is ideal for sewing decorative collars,

sleeves, skirt hems, etc. on loosely knit and woven

fabrics. It is also used to prevent seam puckering in

fine fabrics.

• To set the dierential feed dial for

stretch

– To stretch, set the differential feed between 1

and 0.6.

– To sew a seam, apply gentle tension to the fab-

ric by holding the seam lightly in front and back

of the presser foot.

PLEASE NOTE:

If amount of “stretch” is not correctly set in relation to the fabric being sewn, the fabric is apt to

shift away from the needle resulting in improperly sewn overlock seam.

In such case, reset differential feed dial closer to

the center mark.

Be sure to reset the differential feed dial to

graduation “1” for normal overlock stitching.

30

Page 31

1

1

CHAINING OFF AND TEST

SEWING

– When the machine is completely threaded,

bring all of the threads across the stitch plate

and slightly to the left under the presser foot.

– Lower the presser foot to activate the thread

tensions.

– Hold the threads and apply a slight tension.

– Turn the handwheel toward you 2 or 3 complete

turns to start the thread chain.

– Continue holding the chain and press on the

foot controller until the chain is 5–7.5 cm (2–3")

in length.

– Place fabric under the front of the presser foot

and sew a test sample.

PLEASE NOTE:

Do not pull on the fabric while sewing as this

may deflect the needle, causing it to break.

– At the end of the sample, continue to run the

machine with the presser foot down until the

chain reaches 15–20 cm (6–8") in length.

PLEASE NOTE:

In case it is difficult to chain off and pull the fabric lightly backward.

– Cut threads.

PLEASE NOTE:

Anytime you have rethreaded the machine

always chain off and sew a text sample to test

tensions and make adjustments as necessary.

Information

A mark (1) to indicate the needle location is provided

on the presser foot fitted on this machine. Use this

mark as a guide when sewing.

31

Page 32

NP

2

3

4

6

5

2

3

4

6

5

2

3

4

6

5

2

3

4

6

5

2

3

4

6

5

RHP

HOW TO SEW AN OVERLOCK

STITCH

2–Thread Wrapped Overlock (9/10)

PLEASE NOTE:

– These are suggested tension settings only.

– Tension settings are effected by;

1. Type and thickness of fabric

/

N

Refer page 15

Refer page 14/15

2. Needle size

3. Size, type and fiber content of thread

SL

ULC

Thread Color Code refer page 19.

2.5–4

Refer page 27

Refer page 14

• Correct balance

– Set each tension dial to recommended setting

and test sew on a sample of your fabric.

2–Thread Wrapped Overlock wide 9

Medium weight

fabric

Thread tension

Yellow Green Blue Red

2.5 3.0

2–Thread Wrapped Overlock narrow 10

Medium weight

fabric

Thread tension

Yellow Green Blue Red

4.5 3.5

• How to balance the thread tension

When the lower looper thread tension is too tight or

needle thread tension is too loose;

– Turn the lower looper thread tension dial (red)

toward a lower number.

– Or, turn the needle thread tension dial (yellow

or green) toward a higher number.

32

When the lower looper thread tension is too loose;

– Turn the lower looper thread tension dial (red)

toward a higher number.

Page 33

NP

6

5

2

3

4

6

5

2

3

4

6

5

2

3

4

6

5

2

3

4

6

5

2

3

4

/

2–Thread Overlock (14/15)

PLEASE NOTE:

– These are suggested tension settings only.

– Tension settings are effected by;

1. Type and thickness of fabric

2. Needle size

3. Size, type and fiber content of thread

Refer page 15

RHP

SL

N

2.5–4

ULC

Thread Color Code refer page 19.

Refer page 14/15

Refer page 27

Refer page 14

• Correct balance

– Set each tension dial to recommended setting

and test sew on a sample of your fabric.

2–Thread Overlock wide 14

Medium weight

fabric

Thread tension

Yellow Green Blue Red

0.0 4.0

2–Thread Overlock narrow 15

Medium weight

fabric

Thread tension

Yellow Green Blue Red

0.0 4.5

• How to balance the thread tension

When the lower looper thread lies on the underside of

the fabric;

– Turn the lower looper thread tension dial (red)

toward a higher number.

When the needle thread tension is too loose;

– Turn the needle thread tension dial (yellow or

green) toward a higher number.

– Or, turn the lower looper thread tension dial

(red) toward a lower number.

33

Page 34

NP

1

2

6

5

3

4

1

2

6

5

3

4

1

2

6

5

3

4

1

2

6

5

3

4

1

2

6

5

3

4

1

2

6

5

1

3

4

2

6

5

3

4

1

2

6

5

3

4

1

2

6

5

3

4

RHP

SL

3–Thread Overlock (3/4)

PLEASE NOTE:

– These are suggested tension settings only.

– Tension settings are effected by;

1. Type and thickness of fabric

2. Needle size

/

N

2.5–4

Refer page 15

Refer page 14/15

Refer page 27

• Correct balance

– Set each tension dial to recommended setting

3. Size, type and fiber content of thread

and test sew on a sample of your fabric.

ULC

Thread Color Code refer page 19.

– Refer page 14

3–Thread Overlock wide 3

Medium weight

fabric

Thread tension

Yellow Green Blue Red

3.0 4.0 3.5

3–Thread Overlock narrow 4

Medium weight

fabric

Thread tension

Yellow Green Blue Red

4.0 4.0 4.0

• How to balance the thread tension

When the upper looper thread lies on the underside of

the fabric;

– Turn the upper looper thread tension dial (blue)

to a higher number.

– Or, turn the lower looper thread tension dial

(red) to a lower number

When the lower looper thread appears on the top of

the fabric;

– Turn the lower looper thread tension dial (red)

toward a higher number.

– Or, turn the upper looper thread tension dial

(blue) to a lower number.

34

When the needle thread is too loose;

– Turn the needle tension dial (yellow or green) to

a higher number.

Page 35

NP

6

5

1

3

4

2

6

5

1

3

4

2

6

5

1

3

4

2

6

5

1

3

4

2

6

5

1

3

4

2

6

5

1

3

4

2

RHP

SL

N

2.5–4

/

Refer page 15

Refer page 14/15

Refer page 27

3–Thread Flatlock (5/6)

PLEASE NOTE:

– These are suggested tension settings only.

– Tension settings are effected by;

1. Type and thickness of fabric

2. Needle size

3. Size, type and fiber content of thread

• Correct balance

– Set each tension dial to recommended setting

and test sew on a sample of your fabric.

ULC

– Refer page 14

Thread Color Code refer page 19.

3–Thread Flatlock wide 5

Medium weight

fabric

Thread tension

Yellow Green Blue Red

0 4.0 7. 5

3–Thread Flatlock narrow 6

Medium weight

fabric

Thread tension

Yellow Green Blue Red

0 4.5 7. 5

• How to balance the thread tension

When the upper looper thread lies on the underside of

the fabric;

– Turn the lower looper thread tension dial (red) to

a higher number.

When the upper looper thread tension is too loose;

– Turn the upper looper thread tension dial (blue)

toward a higher number.

– Turn the lower looper thread tension dial (red)

toward a higher number.

When the needle thread tension is too loose;

– Turn the needle thread tension dial (yellow or

green) toward a higher number.

– Or, turn the upper looper thread tension dial

(blue) toward a lower number.

35

Page 36

NP

2

3

4

6

5

2

3

4

6

5

2

3

4

6

5

RHP

SL

N

2.5–4

/

Refer page 15

Refer page 14/15

Refer page 27

2–Thread Flatlock (11/12)

PLEASE NOTE:

– These are suggested tension settings only.

– Tension settings are effected by;

1. Type and thickness of fabric

2. Needle size

3. Size, type and fiber content of thread

• Correct balance

– Set each tension dial to recommended setting

and test sew on a sample of your fabric.

ULC

Thread Color Code refer page 19.

Refer page 14

2–Thread Flatlock wide 11

Medium weight

fabric

Thread tension

Yellow Green Blue Red

0 4.0

2–Thread Flatlock narrow 12

Medium weight

fabric

Thread tension

Yellow Green Blue Red

0 4.5

• How to balance the thread tension

When the lower looper thread tension is too tight or

needle thread tension is too loose;

– Turn the lower looper thread tension dial (red)

toward a lower number.

– Or, turn the needle thread tension dial (yellow

or green) toward a higher number.

When the lower looper thread tension is too loose;

– Turn the lower looper thread tension dial (red)

toward a higher number.

36

Page 37

4

3

2

6

5

4

3

2

6

5

4

3

4

3

2

6

5

2

6

5

4

3

2

6

5

4

3

4

4

3

3

2

6

5

2

6

5

2

6

5

4

3

2

6

5

NP

RHP

SL

3–Thread Super Stretch (2)

PLEASE NOTE:

– These are suggested tension settings only.

– Tension settings are effected by;

1. Type and thickness of fabric

N

2.5–4

Refer page 15

• Correct balance

Refer page 14/15

Refer page 27

2. Needle size

3. Size, type and fiber content of thread

– Set each tension dial to recommended setting

and test sew on a sample of your fabric.

ULC

Thread Color Code refer page 19.

Refer page 14

3–Thread Super Stretch 2

Medium weight

fabric

Thread tension

Yellow Green Blue Red

4.0 4.0 3.5

• How to balance the thread tension

When the lower looper thread tension is too loose;

– Turn the lower looper thread tension dial (red)

toward a higher number.

When the left needle thread tension is too loose;

– Turn the left needle thread tension dial (yellow)

toward a higher number.

When the right needle thread tension is too loose;

– Turn the needle thread tension dial (green)

toward a higher number.

37

Page 38

NP

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

1

3

6

5

4

2

RHP

SL

ULC

N

2.5–4

– Refer page 14

Thread Color Code refer page 19.

Refer page 15

Refer page 14/15

Refer page 27

4–Thread Overlock with integrated

safety seam (1)

PLEASE NOTE:

– These are suggested tension settings only.

– Tension settings are effected by;

1. Type and thickness of fabric

2. Needle size

3. Size, type and fiber content of thread

• Correct balance

– Set each tension dial to recommended setting

and test sew on a sample of your fabric.

4–Thread Overlock with integrated safety

seam 1

Medium weight

fabric

• How to balance the thread tension

When the upper looper thread lies on the underside of

the fabric;

– Turn the upper looper thread tension dial (blue)

toward a higher number.

– Or, turn lower looper thread tension dial (red) to

a lower number.

When the lower looper thread appears on the top of

the fabric;

– Turn the lower looper thread tension dial (red)

toward a higher number.

– Or, turn the upper looper thread tension dial

(blue) toward a lower number

When the left needle thread tension is too loose;

– Turn the needle thread tension dial (yellow)

toward a higher number.

Thread tension

Yellow Green Blue Red

4.0 4.0 4.0 4.0

38

When the right needle thread tension is too loose;

– Turn the right needle thread tension dial (green)

toward a higher number.

Page 39

R

R

N

1

2

●

3

R

R

N

HOW TO SEW A ROLLED HEM

– This machine can sew three types of rolled

hems.

– Rolled hemming is done by rolling and overedg-

ing the fabric edge.

– Light weight fabrics such as lawn, voile, organdy,

crepe, etc. perform the best.

– Rolled hemming is not suited for heavy or stiff

fabrics.

PLEASE NOTE:

Rolled hemming can only be performed with the

overlock right needle.

PLEASE NOTE:

For a beautiful rolled hem thread the upper

looper with wooly nylon and the needle and

lower looper with lightweight regular thread.

Machine set up

CAUTION:

Be sure to turn off power switch.

– Remove the overlock left needle.

– Move seam width finger knob to setting R.

– Set a cutting width between 5 and 6.

– Set stitch length dial to 1–2 and a fine seam will

be sewn.

Needle:

ELx705

Thread:

A variety of thread combinations can be used for rolled

hemming.

39

Page 40

Additional information about rolled

hemming

– Hold the thread chain when you begin sewing to

keep it from curling into the seam.

– Place a slight tension on the material in the

sewing direction and a finer seam finish can be

obtained.

– The minimum overlock stitch width that can be

obtained for rolled hemming is approximately

1/16" (1.5 mm) since the cutting width cannot

be set below 9/64" (3.5 mm).

40

• To secure the rolled hem thread chain

– Apply a small drop of liquid seam sealant to the

end of the seam. Allow to dry, then cut the chain

close to the stitches.

PLEASE NOTE:

Test the liquid seam sealant for color fastness

before use.

Page 41

3–Thread Narrow Seam (7)

43

5

6

6

1

2

1

6

5

3

2

1

6

5

3

2

PLEASE NOTE:

For a beautiful narrow seam thread the upper

and lower looper with wooly nylon and the needle with fine normal overlock thread.

NP

RHP

SL

ULC

R

1–2

– Refer page 14

Thread Color Code refer page 19.

Refer page 15

Refer page 14/15

Refer page 27

• Correct balance

– Set each tension dial to recommended setting

and test sew on a sample of your fabric

3–Thread Narrow Seam 7

Light weight fabric

Polyester

Woolly nylon

Thread tension

Yellow Green

4.0 5.0 4.5

4.0 3.0 4.0

Blue Red

3–Thread Rolled Hem (8)

PLEASE NOTE:

For a beautiful rolled hem thread the upper

looper with wooly nylon and the needle and

lower looper with light weight regular thread.

NP

RHP

SL

ULC

• Correct balance

Refer page 15

R

1–2

– Refer page 14

Refer page 14/15

Refer page 27

– Set each tension dial to recommended setting

and test sew on a sample of your fabric

3–Thread Rolled Hem 8

Light weight fabric

Polyester

Woolly nylon

Thread tension

Yellow Green Blue Red

4.0 4.5 6.5

4.5 0 6.5

41

Page 42

NP

6

5

3

2

Refer page 15

2–Thread Rolled Hem (13)

PLEASE NOTE:

For a beautiful rolled hem thread the lower

looper with wooly nylon and the needle with light

weight regular thread.

• Correct balance

– Set each tension dial to recommended setting

and test sew on a sample of your fabric

RHP

SL

R

1–2

ULC

Thread Color Code refer page 19.

Refer page 14/15

Refer page 27

Refer page 14

2–Thread Rolled Hem 13

Light weight fabric

Yellow Green

Polyester

Woolly nylon

Thread tension

Blue

4.5 4.0

4.0 3.5

Red

42

Page 43

3

4

1

2

5

6

3

4

1

2

5

6

STITCH VARIATIONS AND

SEWING TECHNIQUES

How To Sew a Flatlock Decorative

Seam

A flatlock stitch is achieved by adjusting the tension of

the 2–thread or 3–thread overlock stitch, sewing the

seam, and then pulling the fabric apart to flatten the

seam.

The flatlock stitch can be used as a construction and

decorative stitch or for ornamentation only.

Machine Set Up

– Use either overlock right needle or overlock left

needle.

– Begin with the machine threaded and tension

balanced for the 2–thread flatlock (page 36) or

3–thread flatlock stitch (page 35).

Thread Color Code refer page 19.

Flatlocking a Seam

– Place the fabric wrong sides together to sew a

decorative stitch on the right side of the garment.

– Sew the seam, trimming the excess fabric.

– The needle thread (yellow or green) will form a

V on the underside of the fabric.

– In the 3-thread flatlock, the lower looper thread

will form a straight line on the fabric edge. The

upper looper thread will lie on top of the stitch.

– In the 2-thread flatlock, the lower looper thread

will lie on top of the stitch.

– Pull on opposite sides of the seam to pull the

stitches flat.

43

Page 44

A

1

2

6

5

Decorative Flatlocking

– Disengage the upper knife (page 13). The fabric

is not trimmed on this stitch.

– Fold fabric wrong sides together.

– Position the fabric so the seam is sewn with part

of the stitch extending off the fabric.

– Pull on opposite sides of the stitch to flatten

Additional Information about Flatlocking

– The tensions must be correctly adjusted for the

fabric to pull flat.

– The upper looper thread is the prominent thread

in a 3-thread flatlock.

– The lower looper thread is the prominent thread

in a 2-thread flatlock.

– Thread decorative yarn in the prominent thread-

ing path accordingly.

– For a ladder stitch, sew seam with right sides

together.

– The needle thread will be the prominent thread

that creates the ladder (A).

44

Page 45

1

2

●

3

1

2

●

3

1

2

●

3

1

2

How to sew an Overlock Blind Hem

The excess fabric is trimmed and the hem is sewn and

the raw edges are overlocked in one operation.

The overlock blind hem is best suited for sewing knit

wear. It provides a durable finish that is almost invisible.

Use overlock right needle and adjust machine for a

narrow 3–thread overlock stitch. (Refer page 34)

– Set the stitch length dial at 4.

– Fold the hem to the wrong side of the fabric,

then back to the right side with 1/4" (6 mm)

beyond the fold.

– Stitch on the extended hem edge, allowing the

machine needle to barely catch the edge of the

fold.

PLEASE NOTE:

An optional blindstitch foot is available (Refer

page 51).

How to sew Pin Tucks

– Sew decorative pin tucks on the fabric before

cutting out the garment.

– Use overlock right needle and adjust machine

for a narrow 3–thread overlock stitch. (Refer

page 34)

– Place the movable upper knife in the nonwork-

ing position. (Refer page 13)

– Mark the fabric with the desired number of pin

tucks using a water–soluble fabric marker.

PLEASE NOTE:

For this technique also a 3-thread rolled hm or a

3-thread narrow seam can be used.

45

Page 46

2 cm

2 cm

A

A

– Fold the fabric with the wrong sides together

and sew.

– Press the pin tucks in the same direction.

How to turning Square Corners

• Outside Corner

– Cut out approximately 2 cm (51/64") from the

corner, in line with the overlock seam edge.

– Sew one stitch beyond point (A) and stop.

– Raise needle and presser foot.

– Pull the fabric to the rear of the machine just

enough to release the thread caught on the

finger of the stitch plate.

PLEASE NOTE:

Presser foot has been removed to show detail.

– Turn the fabric and lower the presser foot so

that the upper knife is positioned in line with the

cut edge.

– Pull slack threads up, then start to sew.

46

Page 47

1

1

• Inside Corner

– Cut inside corner up to seam line (1) as shown.

– Sew along seam line.

– Sew up to end of fold. (Leave needle in fabric)

PLEASE NOTE:

Presser foot has been removed to show detail.

– Raise presser foot. (Leave needle in fabric)

– Spread fold and re–fold so that seam line is

straight

– Turn the fabric and lower the presser foot so

that the upper knife is positioned in line with the

cut edge.

– Pull slack threads up, then start to sew.

CAUTION:

Sewing over pins will damage and /or destroy

the cutting edge of the knives.

• Pin Placement

– Insert pins to the left of the presser foot. The

pins will be easy to remove and are away from

the cutting action of the knives.

• Securing The Thread Chain

– Thread a large eye, hand sewing needle (such

as a tapestry needle) with the thread chain.

– Pull the thread chain into the overlock stitches

or between two layers of fabric.

47

Page 48

Oil

B

A

MACHINE MAINTENANCE

An overlock machine requires more maintenance than

a conventional machine for two reasons:

1. A lot of lint is produced due to the cutting action

of the knives.

2. An overlock runs at a very high speed and needs

to be oiled frequently to lubricate the internal

working parts.

Cleaning The Machine

CAUTION:

Before cleaning your machine, disconnect

power line plug from the wall receptacle.

– Clean the lint from the looper and knife area

often with a dry lint brush.

Oiling The Machine

CAUTION:

Before lubricating your machine, disconnect

power line plug from the wall receptacle.

– The oiling points shown in the diagram, should

be oiled periodically.

PLEASE NOTE:

Use only sewing machine oil. Do not use any

other oil or damage could result.

48

Page 49

c

b

a

mm1~5.0

c

b

a

b

d

Replace the Upper Knife

CAUTION:

Before replacing the upper knife, disconnect

power line plug from the wall receptacle.

– The upper knife should be changed when it

becomes dull.

– The upper knife can be replaced according to

the directions provided, however if there are any

difficulties experienced, consult your dealer

representative to make the replacement.

– Be sure that the power line plug is disconnected

from the electric source.

(a) Open the looper cover and set the upper knife

in the working position.

(b) Loosen the upper knife set screw

(c) Remove the upper knife and turn the handwheel

to lower the upper knife holder to its lowest position.

(d) In this position, put a new upper knife in the

groove of the upper knife holder, making sure

that the edge of the upper knife is approximately

0.5–1.0 mm below the surface of the fixed cutting blade.

(b) Tighten upper knife set screw.

49

Page 50

OPTIONAL ACCESSORIES

A

C

A

C

B

The following optional presser feet specially prepared

for this machine are available at extra–charge.

PLEASE NOTE:

Do not use presser foot made for other machines.

Use of such presser foot may result in interference with the needle and knife and can be hazardous.

The snap–on type presser foot of this machine permits easy removal and replacement.

Snap–On Type Presser Foot

• Removal

– Turn the handwheel to raise the needles to the

highest position.

– Raise the presser foot.

– Press red colored lever (A) located on back of

clamp under the presser foot shank, raise

presser foot shank to its High Lift position and

while holding the presser foot shank in this position, remove the presser foot sole.

• Replacement

– Place presser foot sole on stitch plate under

presser foot shank so that hinge pin (C) will fit

in slot (B) of the shank. Then lower presser foot

shank.

– If presser foot sole can not be placed under

presser foot shank easily, raise presser foot

shank to its High Lift position and while holding

it in this position, place presser foot sole under

presser foot shank. Then lower presser foot

shank.

– Raise presser foot shank and make sure the

presser foot sole is properly attached to the

presser foot shank.

50

Page 51

Optional Presser Feet

• Elasticator Foot

– This foot is used for attaching elastic tape to the

garment and the amount of contraction of the

elastic tape can be adjusted as required.

• Blind stitch Foot

– This foot is ideal for sewing blindstitch and

blindhem.

• Gathering Foot

– This foot is most suited for gathering when sew-

ing tiered skirts, yokes, cuffs and frills on skirts,

etc.

– This foot is also suited for sewing two fabrics

together and gathering the bottom fabric in one

operation.

• Beading/Sequins Foot

– This foot is used for sewing on strands of beads

and pearls.

• Piping Foot

– This foot is ideal to produce and sew in piping.

• Ribbon–couching Foot

– This sewing foot is suited for sewing on tapes,

etc.

51

Page 52

TROUBLESHOOTING

Condition Cause Remedy Page

Fabric does not

feed well.

Needle breaks.

Thread breaks.

Stitch skip.

1. Lengthen stitch length.

2. Increase presser foot pressure for heavy weight fabric.

3. Decrease presser foot pressure for light weight fabric.

1. Insert needle correctly.

2. Do not pull fabric while sewing.

3. Tighten needle set screw.

4. Use a larger needle on heavy fabrics.

1. Check threading.

2. Check for tangled or caught thread.

3. Insert needle correctly.

4. Insert new needle, current needle may be bent or have a

blunt point.

5. Use only high quality thread.

6. Loosen thread tension.

1. Insert new needles, current needles may be bent or have

a blunt point. Use only ELx705 overlock needles.

2. Tighten needle set screw.

3. Insert needles correctly.

4. Change type or size of needles.

5. Check threading.

6. Increase presser foot pressure.

7. Use a high quality thread.

27

28

28

16

31

16

16

19–25

26

16

9

53

31–38

9

16

16

16

19–25

28

53

Irregular stitches.

Fabric puckers.

Irregular trimming.

Fabric jams.

Machine does not

operate.

52

1. Balance thread tension.

2. Check for tangled or caught thread.

3. Check threading.

1. Loosen thread tension.

2. Check for tangled or caught thread.

3. Use high quality light weight thread.

4. Shorten stitch length.

5. Decrease presser foot pressure for light weight fabrics.

1. Check alignment of knives.

2. Replace one or both knives.

1. Close looper cover before sewing.

2. Check for tangled or caught thread.

3. Compress thick layers of fabric with conventional machine

before sewing with overlock.

1. Connect machine to power source and switch it on.

2. Close the looper cover.

31–38

26

19–25

31–38

26

53

27

28

49

49

10

26

10

Page 53

FABRIC, THREAD AND NEEDLE CHART

Woven

Fabric Thread Needle ELx705

Light weight

Medium weight

Heavy weight

Lawn

Organdy

Voile

Crepe

Muslin

Seersucker

Satin

Gabardine

Broadcloth

Oxford

Denim

Tweed

Serge

Corduroy

Cotton: #100

Silk/ Rayon: #100

Spun: #80 – #90

Polyester: #80 – #100

Cotton: #60 – #80

Silk/ Rayon: #50

Spun: #60 – #80

Polyester: #60 – #80

Cotton: #40 – #60

Silk/ Rayon: #40 – #60

Spun: #60 – #80

Polyester: #50 – #80

#80/12

#90/14, #80/12

#90/14

Knit

Fabric Thread Needle ELx705

Light weight Tricot

Medium weight Jersey

Heavy weight

Wool (woven,

knit)

Spun: #80 – #90

Polyester: #60 – #80

Spun: #60 – #80

Polyester: #60 – #80

Cotton: #60 – #80

Spun: #60 – #80

Polyester: #50 – #60

Woolly nylon

Woolly Polyester

#80/12

#90/14, #80/12

#90/14, #80/12

53

Page 54

SPECIFICATION

Technical Summary

Stitch Formations 15 stitches

1–2 needles

2 loopers

Needle system ELx705

Cutting width 5–7 mm from the left needle

3–5 mm from the right needle

Stitch length 1–4 mm (standard: rolled hemming 1–2, standard: overlock 2.5)

Differential feed stretching 1–0.6

gathering 1–2

Presser foot lift 4.5 mm

Sewing light LED

Sewing speed 1300 stitches/minutes.

Foot control Type 4C–316B

for (USA/Canada)

Dimensions (L x B x H) mm 336 x 263 x 294

Weight (kg) 7.2 kg

Type 4C–316C / 4C–326C / 4C–326G /

4C–345G

for other countries

54

EN – 02/2017 – 3rd Edition

5040005.0.04 / G8P01

© BERNINA International AG

Steckborn CH, www.bernina.com

Page 55

Page 56

www.mybernette.com/yellow-shirt

EN – 02/2017 – 3rd Edition

5040005.0.04 / G8P01

© BERNINA International AG

Steckborn CH, www.bernina.com

Loading...

Loading...