Page 1

‘Ornette’

715

740 E

r //y.y hWML'f

Instruction Manual

Livret d’instructioo

Handlet

"5^Zî®^e740E

•“ ■(»«(* ^

Page 2

Congratulations on th« purchase of your new

sewing machine!

Nous vous félicitons d'avoir acquis votre nouvelle

machine à coudre*

HarteUjk gefelicieerd mei de aankoop van uw

nieuwe naaimachine!

You have bought a quality product which was

manufacturedwiihcareartdatiention Yoursewmg

machine is easy to use but this instruction book has

been written to hefp you get the most out of your

machine. We suggest you read it before starting to

sew.

You will no ckxibt have questions now and then for

which you cannot find an answer m this book Your

dealer is always on hand to help with advice and

tips.

We wish you many hours of sewing pleasure.

Vousavez, en effet, opté pour un produit de qualité

qui a été fabnqué avec le plus grand soin. Votre

machine à coudre est facile à utiliser, mais il faut,

naturellement suivre les règles du jeu. Nous les

avons rassemblées pour vous dans ce livret

d'instructions. Si vous tes respectez, vous réussi

rez. dès le commencement ce que vous entrepre

nez.

Sûrement, en tant que créatrice de mode pour la

famille, vous aurez, de temps à autre, des ques

tions auxquelles nous n'avons pas répondu

entièrement dans ce livret. Alors, il vous suffit de

demander à votre agent. Il sera toujours là pour

vous.

Maintenant, nous vous souhaitons bien du plaisir

durant vos loisirs pour l'habillement. Avec votre

machir>e. donnez libre cours à votre imagination.

U heeft een kwaiiteitsprodukt gekocht dat mei veel '

zorgvuidigheid werd vervaardigd. Uw naaimachi

ne is eenvoudig te bedienen en deze handleidmg

heipt u om alle mogelijkheden van uw machine te

ontdekken. Lees deze aandachtig door voordat u

met het naaien begint.

Af en toe zuit u wei eens een vraag hebben die dit

boek met kan beantwoorden. Uw Bernette vakhandeiaar is dan altijd graag bereid om u advies en

hps te geven.

Wij wensen u veel plezier bij het naaien.

Page 3

01992 Fnte Gegairf Ltd.

Bemina Sewing Machines

CH-8266 Steckborn (Switzerland)

e I9d2 Fritz Gegaut SA

Fabrique de rnachines à coudre Bernina

CH-6266 Steckborn (Suisse)

91992 Fritz Gegaut AG

Bernmâ Naaimachinelabriek

CH-8266 Steckbom (Zwitserland)

We reserve (he right to make technical changes in

the interest of progress

Sous réserve des modifications apportées dans

hmérèt du progrès technique.

Veranderir)gen in het belang van de technische

vooruitgang voorbehouden.

Page 4

List of contents

Accessones

Aulomatic needte stop

(Model 740E onty)

Automatic needle throader

(Model 74oe ontyi

Bsnd hen%'1>ngene sMch

SoObin • msertng

Bobbin • tension

Bobbin • winding............................

Bnnging up die lowo'

thread...........................—

Butb - chanoing

Buttons • sewing on

(Model 740E oniyi

Buttonholes...................................

Colour code green and blue

Colour code red and yeiiow

Cixmeciing the rischine

Corcingtoot

(Model 740E onlyi

Darrwig

Decorative stitches

(Model 740E ootyi......................

Details oi the machine

Feed d^ • lo'wenng

Foot control

Hemmer loot.................................

......................-................

.....................

......................

.............

..........................

............................

........

.............................

..........

.....

......

............

.............

...................

......................

........................................

....................

.......

................

..................................

Noatening edges

10

Noodle - inserting....................

.

......

......

......

.....

......

.38.40

......

.....

......

.14.16

......

.....

.72. 74 Triple straighl stitch;z<g-zag

.....6. 8 Trouble shooting guide

.....

.14.16

Needle positions.....................

20

NeediO'Thread table

36

Overlock stitches

78

.26 Practical stitches.................. .66, 68. 70

Pressor loot - removing

26

Prosser foot • attachng ............

Presser foot lifter

18 Reverse sewing .....................

84

Safety regulations

Smocking stitch

76

Speed control..Stitch selection

48 Stitch table

Straight sUclvzig-zag

88 Tension - upper thread

Tension ' lower thread..............

Threading - upper thread ...

60

Three-step zig-zag

Twin needle

20 (Model 740E only)...............

Zips - sewing «

....

................

...............

....................

............

....................

...................

......................

......................

.......................

.............................

...............

............

..................

............

...................

.

...........

52

...........

28

...........

44

...........

30

......

56. 58

............

............

............

............

..............

............

............

......

60.62

............

............

............34

............

............

............

......

60.62

............

.

...........

22

22

13

42

5

64

14

12

50

26

32

54

92

82

Inserting the neetse

inserting the seam guxJe...............

LED display ..................................

Light.........................................

Mamtonanco..........................—

.......................

.....

.....

....

......

28

14

48

14.16

90

Page 5

IMPORTANT SAFETY INSTRUCTIONS

When ustng an eiectncai appliance, basic safety

precautions should always be followed, including

the following:

Read all instructions before using this sewing

machine.

DANGER

To reduce the risk of electric shock:

1 An appliance should never be left unattended

when plugged in.

2. Always unplug this appliance from the electric

outlet immediately after u$ir>g and before cle

aning.

3 Alwaysunplugbeforerelamping Reptacebulb

with same type rated IS Watts.

WARNING

To reduce the nsk of bums. fire, electric shock, or

injury to persons:

1 Do not allow to be used as a toy. Close atten

tion is necessary when this appliance is used

by or near children.

2. Use this appliance only lor its intended use as

described in this manual. Use only attach

ments reoynmended by the manufacturer as

contained in this manual.

3. Never operate this appliance if it has a dama

ged cord of plug, if it is not working properly, if

It has been dropped or damaged, or ckopped

into water. Return the appliance to the nearest

authorized dealer or service center for exami

nation. repair, electrical or mechanical adjust

ment.

4 Never operate the appliance with any air

openings block. Keep ventilation openings of

the sewing machine and foot controller free

from accumulation of lint. dust, and loose cloth.

5. Keep fingers away from all moving parts

Special care is required arourxf the sewing

machine needle.

6. Always use the proper needle plate. The wrong

plate can cause the needte lo break.

7. Do not use bent needles.

8. Do not pull or push fabric while stltchir>g, It may

detlect the needle causing it to break.

9. Switch the sewing machine off (*0’> when ma

king any adjustmenfs in the needle area, such

as threading needle, changing needle, threadir>g bobbin, or changing pressor foot, and the

like.

10. Always unplug sewing machine from the

electrical outlet wen removing covers, lubncatmg. or when making an other user servicir>g

adjustments mentioned m the instruction ma

nual.

11- Never dtof> or insert any objeci into any

opening.

12 Do not use outdoors

13. Do not operate where aerosol (spray) products

are being used or where oxygen is being

administered.

14. To disconnect, turn all controls to the off <*0*j

position, then remove plug from outlet

15. Do not unplug by pulling on cord To unplug,

grasp the plug, not the cord.

16 This appliance 1$ provided with double insula

tion. Use onfy identical replacement parts. See

instructions lor Servidnq of Double-Insulated

Appliances (except USA/Canada)

Servicing of Double-Insulated Products

17. In a double-insulated product, two systems of

insulation are provided instead of grounding.

No grounding means is provided on a doubleinsulated product, nor should a means for

grounding bo added to the product. Servicing

of a double-insulated (xodud requires extre

me care and knowledge of the system, and

should be done onfy by qualified service per

sonnei. Replacement parts for a double-insu

lated produd must bo indentical to those parts

in the product. A double-insulated product is

marked with the words "double insulation"

or DOUBLE INSULATED".

Page 6

Consignes de sécurité

Velligheldsvoorschriften

The symbol D may also be marked on the product.

SAVE THESE

INSTRUCTIONS

Th(S sewing machine Is intended for household

use only.

Les consignes de sécurité énumérées d-après

doiverjf éfre »mpérai/vemenf respectées:

Dès qu’elle est en mouvement, l'aiguille est source

de danger (risque de blessure pour les doigts). Il

convient dor>c d'obsen/er en permanence

remplacement où s'effectue la couture.

Toute manipulation dans la гопе d’action de

l'aiguille (remplacement de l'aiguille, du pied-de-

biche. de la plaque à aiguille ou mise en route du

dispositif automatique d'enfilage) ne doit

s'effectuer que lorsque la machine est débranchée

(interrupteur princip^ sur 'D'^.

Pour tous les travaux d’entretien (nettoyage et

huilage), ainsi que pour le remplacement de

l'ampoule. ilconv>ent de débrancher la macNne en

retirant la fiche de la prise électnque. Procéder de

rrrème lors d’interruptions ou à la fin d'un travail

Ne jamais intervertir dans la partie électrique de la

machine, notamment pour le remplacement du

raccorderrtent de la pé^e de commande. Ce type

de travail doitétreconliéà un technicien du service

après-vente.

De navoigerxie veiligheidsvoorschnften dienen

aPsotuut in acht te worden genomen:

Oe bewegende naaM is een gevaar voor uw vingers. Het naa>oppervlaK dient dar ook steeds in

het oog te worden gehouden.

Alle handeiingen binnen het bereik van de bewe

gende naaki. bijv. het vervangen van de naaid. de

naah/oet. de steekplaat of hei bedienen van de

aulorrratische inrijger, rrtogen alleen uitgevoerd

worden wanneer de machine uitgeschakeld is

(hoofdschakelaar op *0* zetten).

Bij alle onderhoudswerkzaamheden (reinigen en

olidn), alsrrtede bij het verwisselen van het gioeilampje dient de naaimachirte uitgeschakeld te

worden door middel van de stekker uit het siopkontakt te trekken. Oe machirte dient eveneerts bij

onderbreking en na be^irrdigirrg van het naaiwerk

uitgeschakeld te worden door de stekker uit het

stopkontakt te venmjdeten.

Alle reparaties aan het elektrische gedeeite van de

machine, in het bijzonder het vervangen van de

aansluiting naar de voetweerstand. mögen alleen

door uw Semette vakharrdelaar worden uitge

voerd.

Page 7

Details of the machine

■i/oaet$ 740EJ30I

1 LED display 1

2 Stitch selection doi 2

3 Needle position Knob 3

4 Stitch width dial 4

5 Stitch length dial 5

6 Reverse sewing button

7 Speed adiustment knob 6

8 Hinged bobbir> cover 7

9 Bobbin case

10 Drop teed control 8

11 Stitch plate 9

12 Needle damp screw 10

13 Automatic needle threader 11

14 Thread take-up sprir>g 12

1 s Needle stop up 13

16 Needle stop down 14

17 Thread tension control 15

18 Thread take-up lever 16

Carrying handle

^xrol holder pms

Thread guide

Two-step presser foot lifter

Thread cutter on presser tool

holder

Presser toot release

Extension table and open ac

cessory box

Foot control socket

Mam plug socket

Power switch

Light switch

Bobbin winder cover

Bobbin wir>der

Bobbin winder thread cutter

Handwheel

Bobbin thread guide

Page 8

0^

*>

--------

<»

Details of the machine

Mowi nS)

1 Carrying handle

2 Stitch selection dial

3 Handwheel

4 Stitch length dial

A

6

5 Reverse sowing button

6 Bobbin winder cover

7 Hinged bobbin cover

8 Bobbin case

9 Drop feed control

to Stitch plate

It Thread cutter on pressor tool

holder

12 Needle damp screw

13 Thread take-up spnng

14 Thread take-up

15 Thread tension control

Page 9

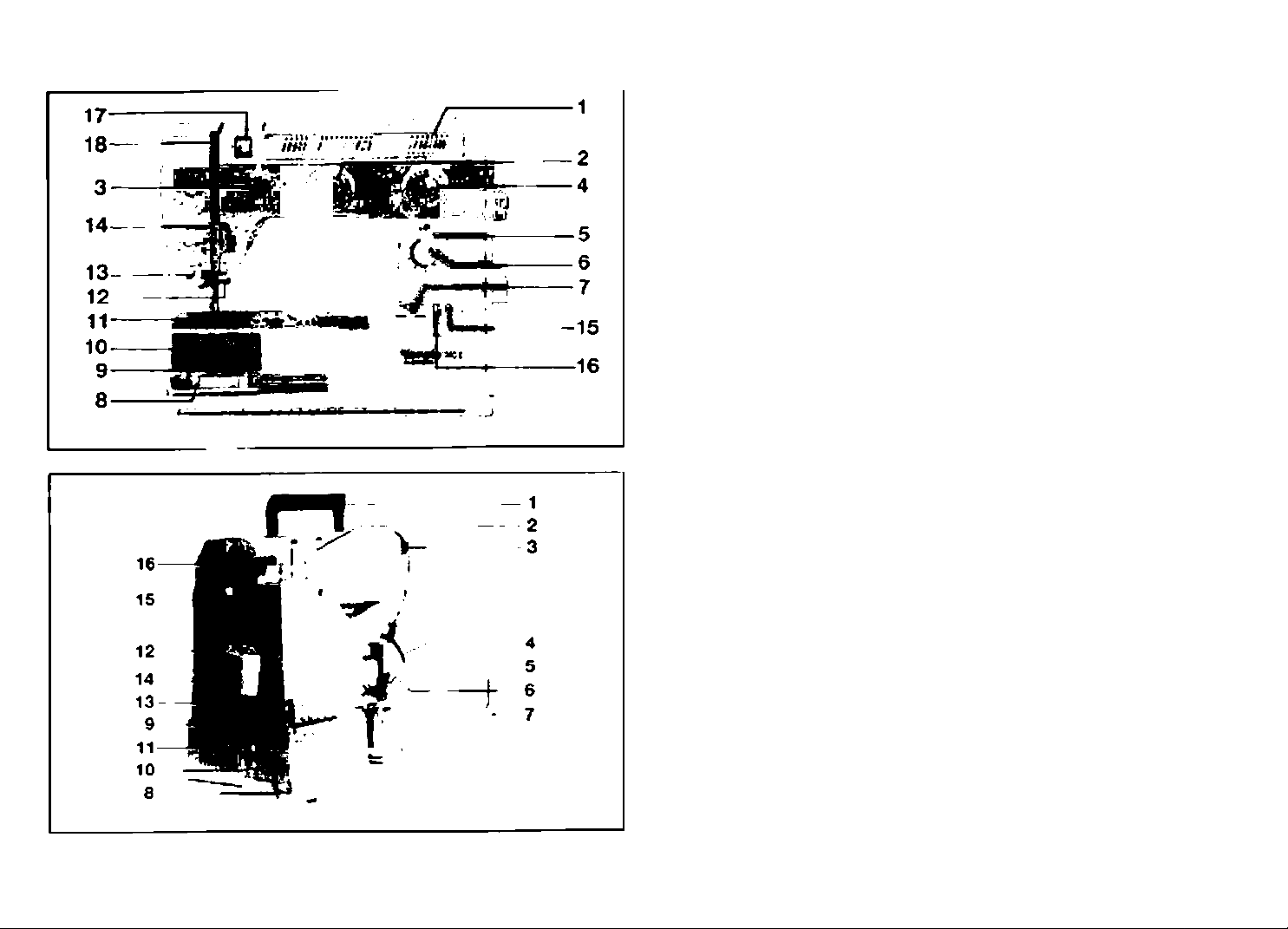

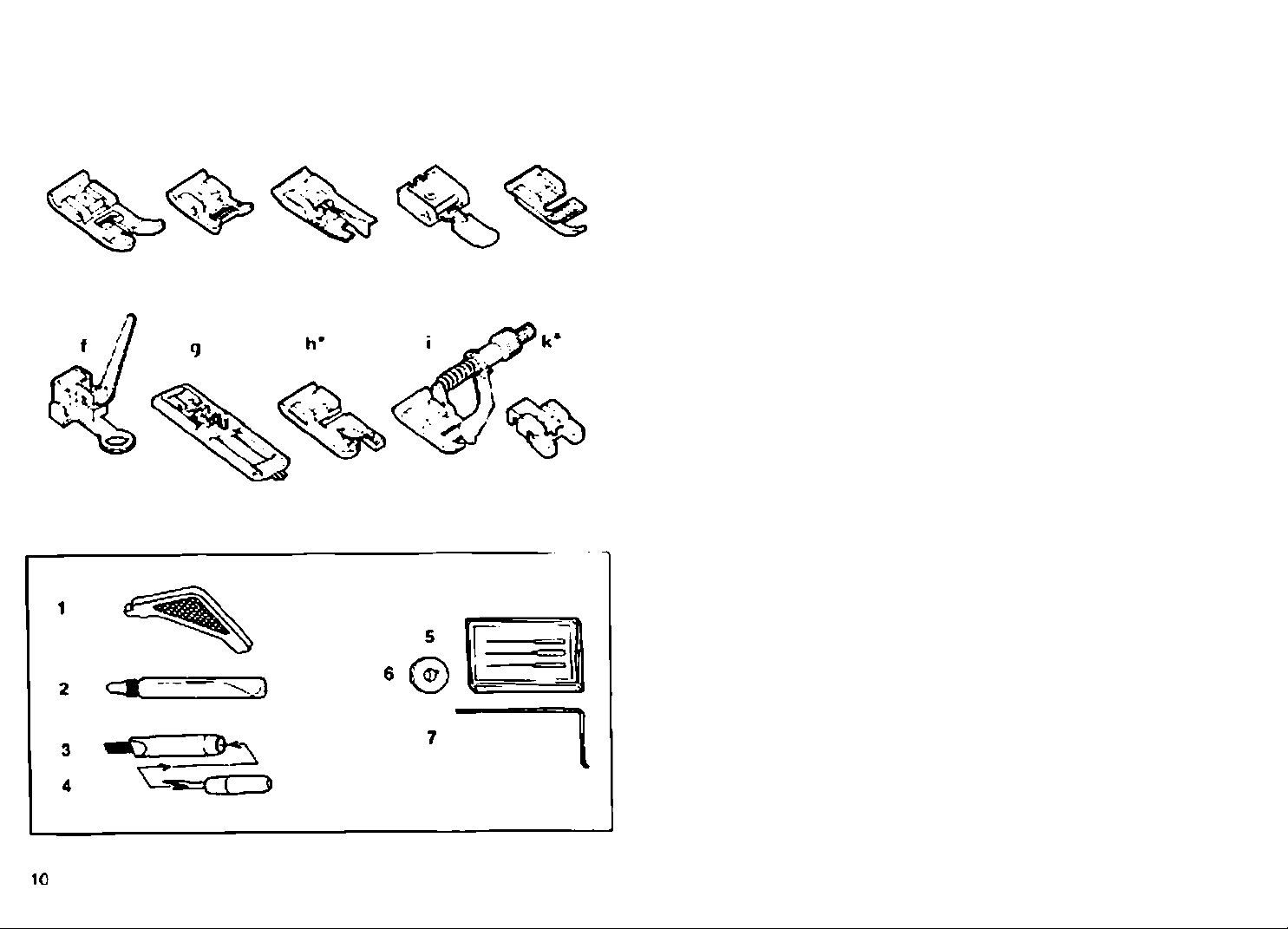

Accessories

a General purpose foot No- 3

D Embroidery loot No. 4

c OvertocK foot No 8

d Zipper foot No. N

e* Cording foot No- 2

f Darning foot

g Buttonhole foot

h* Hemmer No t

i Btirxl hem toot No. 9

k* Button sewing foot No. 6

We recommend the use of these

specialy designed presser feet for

perfect results.

’ Those 3 presser feet are not

supplied with Models 715 and 730.

They are however available as

special accessories from your local

dealer

1

Large screwdriver

Oiler

2

3

Cleaning brush

4

Seam npper

5

Needles (3x)

6

Bobbins (3x)

7

Seam guide

Page 10

stitch choice for each model

Stitch

III

Buttonhole

Straight stitch

Tnple straight stitch

i

Zig-zag

i Triple zig-zag

3-Step zig-zag

Smocking stitch

Shell hem

Rampart

Double oveilock

Stretch Blindhem

i

1 Double arrow

• Blindhemtingehe

Single overtook

1

i Elastic overlook

Stretch overtock

1

Standard overtook

■1

6ridgir>g

Feather sMch

%

Ribbon

) Scallop

1 Double scallop

t Triangle long

Square stitch

>

) Cross stitch

»

» Diamond sttch

715

• •

• •

• •

•

•

•

•

• •

• •

•

730

e

•

•

•

•

•

•

•

•

•

•

12

Page 11

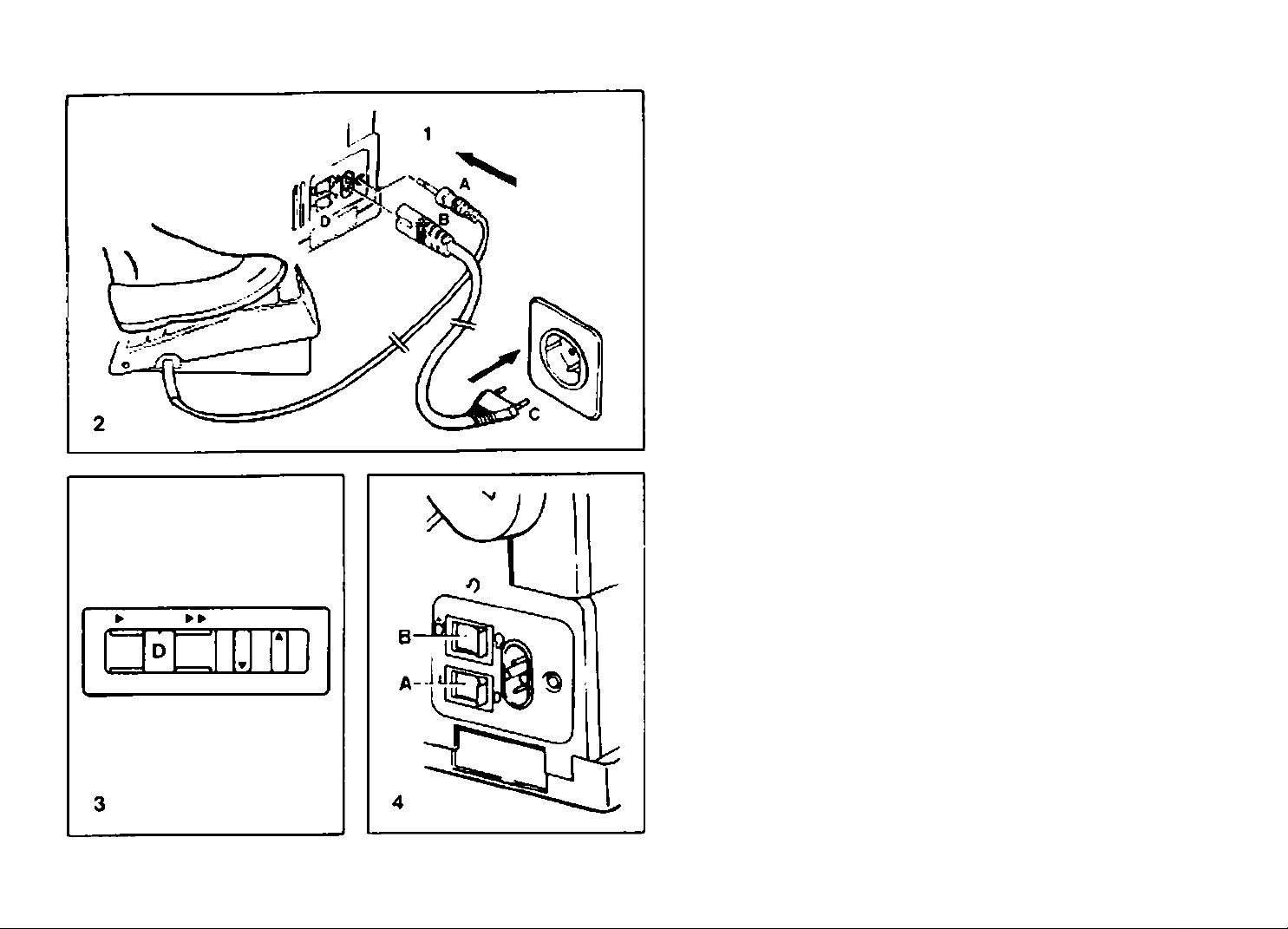

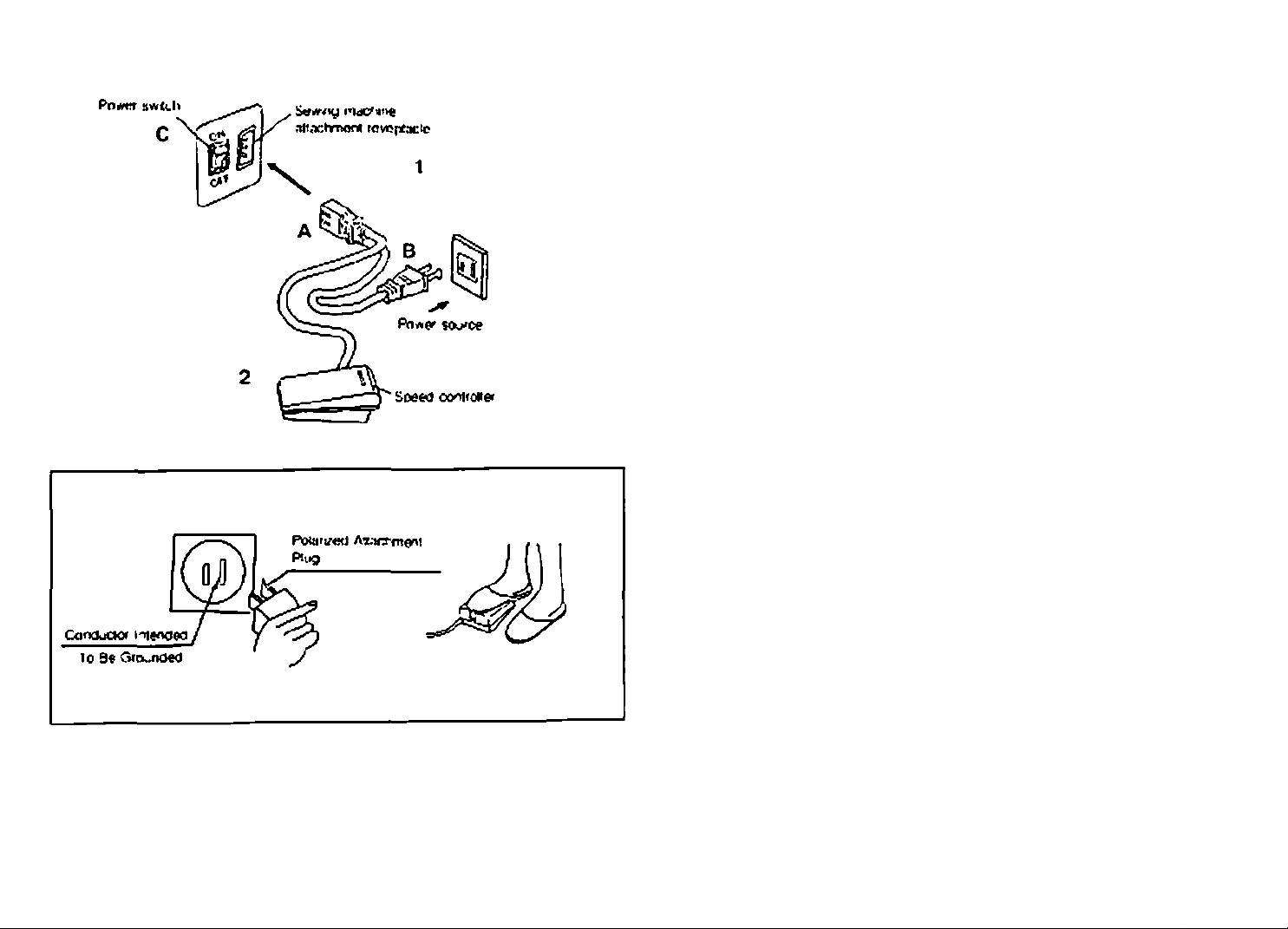

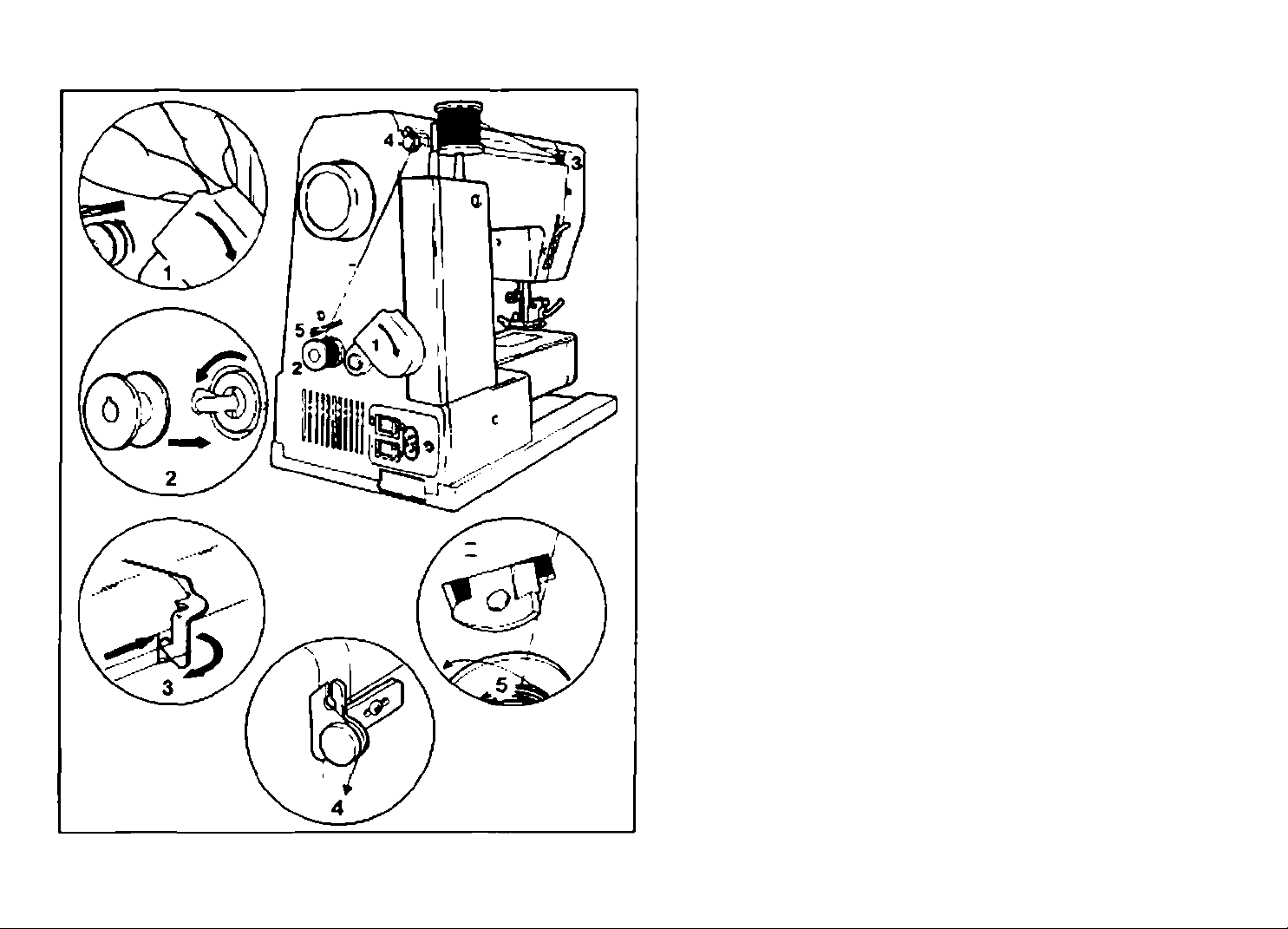

Connecting the machine to the power source

(MOIW 74061

Conned plug *A" and plug '6' to the

machine and plug 'C into the mams

socket. Turn on power switch *0“. {1)

This appliance has a polarued plug

(one blade wider than ihe other)

To reduce the nsk ol electric shock,

this plug is intended to lit in a polariz

ed outlet only one way.

If the plug does not lit tulty in Ihe outlet,

reverse the plug

If it still does not fit, contact a qualified

electrician to install the proper outlet.

Oo not modify the plug m any way.

Caution; The Foot Controller Model

4C-337B is for using with

Sewing Machine Model

740E.

Foot control

The speed of the machine can bo

regulated by applying pressure to the

fool control. (2)

Speed control

\UC69* J*0(i

The maximum speed of the machirve

can be reduced with the speed con

trol knob "O*. (3)

The speed control function is particularty useful for intricate work, e g

sewing corners, matching up pat

terns etc and is ideal lor beginners

> minimum

► ► maximum

Sewing light

740t)

14

Press pov/er switch ’A". Press light

switch 'B-. (4)

High power, high frequency

interference can cause variations in

the motor speed of up to 50%.

These will disappear however, as

soon as the interference stops.

Page 12

Connecting the machine to the power source

Connect plug 'A' to the machine and

plug 'B* to the mams socket. Turn on

power switch *c^ (1)

This appliance has a polarized plug

(one blade wider than the other).

To reduce the risk o< electric shock,

this plug is intended to lit in a polariz

ed outlet only one way.

If the plug does fwt fit fully in the Outlet. Turn on powei switch C

leverse (he plug.

If il still does not fit, cor^aci a qualified

electrician to install the proper outlet

Do not modify the plug in any way

Caution- The Foot Controller Model

3C-135B or 4C-3168 IS for

using with Sewing

Machine Model 71$ and

730A

Foot control

The speed of tne machine can be

regulated by applying pressure to

the ^ooi control (2)

Sewing light

iMexJe's 7;5. 730i

16

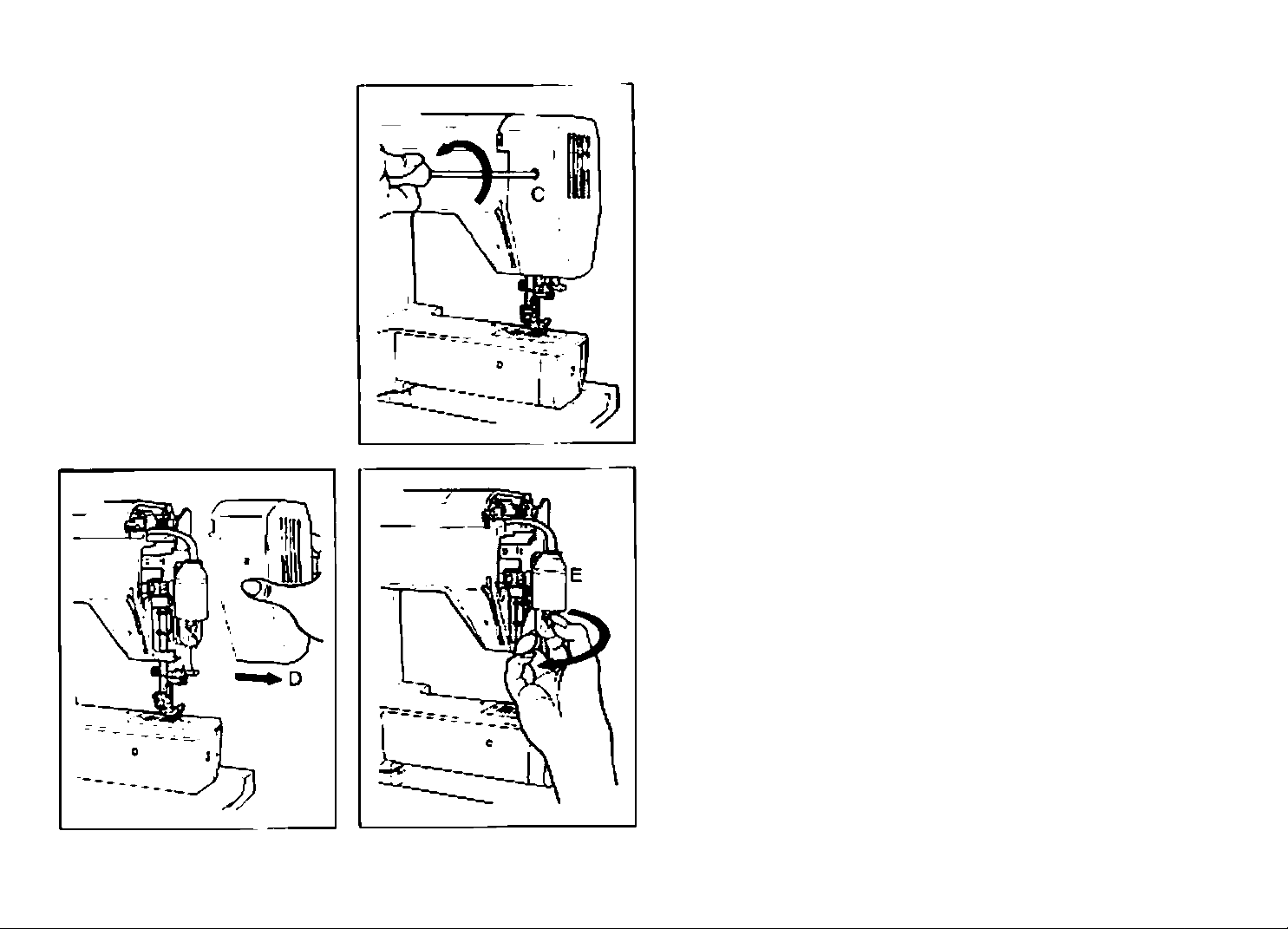

Page 13

Changing the bulb

Disconnect the machine trom the

power suppty by removing the plug

from the mains socketl

- Loosen screw X* on the back of

the head cover

- Remove the head cover "D“.

- Unscrew the bulb *E" and fit new

bulb.

Replace the head cover and tigh

ten screw.

Should there bo any problem, ask

your local dealer for advice.

16

Page 14

Automatic neodio stop

(Moca- 740E only]

When the machine stops, tho needle

stops at its highest position. (1)

Certain types ol sewing tasks are

made easier if the needle is lowered

in the labric. e.g. sewing corners,

starting to sew.

Press button *A" for needle down

- Press button *B’ for needle up

Two-step presser foot lever

When sewir>g several layers or thick

fabrics, the presser loot can be

raised a second stage for easy po$>tk>r>ing of the work. (2)

Drop feed control

20

For normal sewing, the feed dog

should be in the raised pdsit>on.

Press 'A'. {3f

For certain types of work. e.g. dar

ning or free-hand embroidery, the

feed dog must be lowered. Press "B’.

Page 15

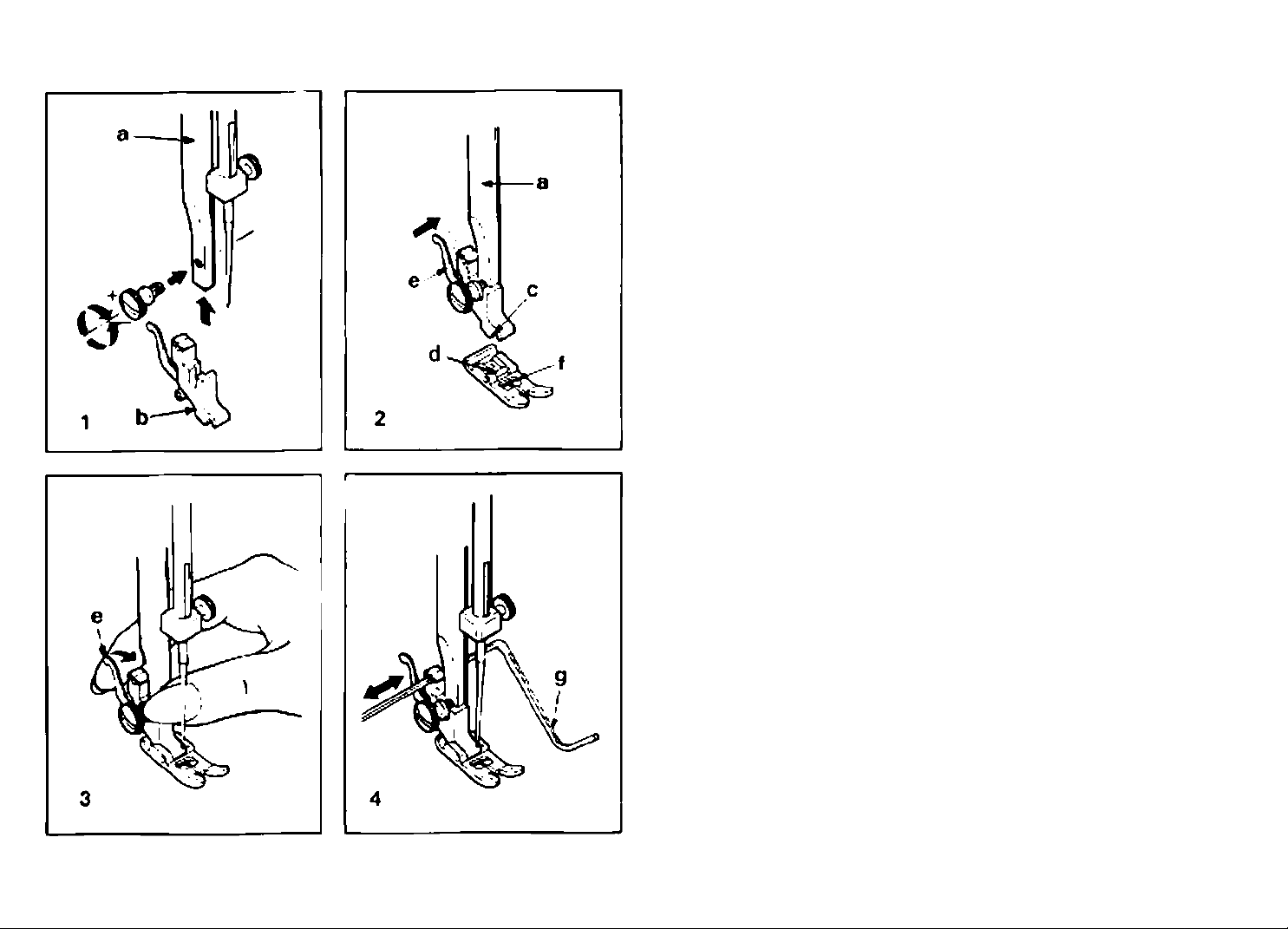

Attaching the presser foot holder

Raise the presser foot clamp "a". <i)

Attach the presser foot holder V as

illustrated.

Attaching the presser foot

Lower the presser foot holder *a*until

the cut-out V is directly above the

pin -d". (2)

Raise the lever *e’.

Lower №e presser fool holder *a' and

The presser foot T will engage auto

matically.

Removing the presser foot

Raise the presser foot. (3)

Raise the lever *e* and the foot disen

gages.

22

Attaching the seam guide

Attach the seam guide 'g' in the slot

as iHustrated. Adjust according to

need for hems, pleats, etc (4)

Attentfon:

Turn power switch to ’0' when

carrying out any of the above

operations!

Page 16

Winding the bobbin

Open the bobbin winder cover. (1)

Place empty bobbin on spindle.

Movement of the needte is automati*

cally cut out. (2)

Take the thread from the spool

through the guide to the bobbin. (3/4)

Wind thread a lew times by hand

round the empty bobbin in a clock

wise direction. Press the foot control.

As soon as the bobbin is full, wirxing

will stop and the thread will be cut

automaticalty. Remove the bobbin

and dose the boMxn winder case. (5)

24

Page 17

Inserting the bobbin

When inserting or removing the bobb«n. the needle must be fully raised.

Open the hinged cover. (1)

Hold the bobbin case with one hand.

Insert the bobbin so that the thread

rurts in a clockwise direction (arrow).

(2)

Pull the Oiread through the slit and

under the finger. (3)

Hold the boli^n case by the hinged

latch. (4)

Insert it into the shuttle. (5)

Anentfon:

Turn power switch to "X)*.

Bobbin thread tension

Note:

The bobbin thread tension

does not normally have to be

adjusted.

26

To test the bobbin thread tension,

remove the bobbin case and bobbin

and hold it by suspending it by the

thread. Jerk it once or twice. If the

tension is correct, the thread will unwir>d by about an inch or two. K the

tension is too tight, it does not unwind

at all. If the tension is too loose, it will

drop too much. To ad)ust. turn the

smalt screw on the side of the bobbin

case. (6)

Page 18

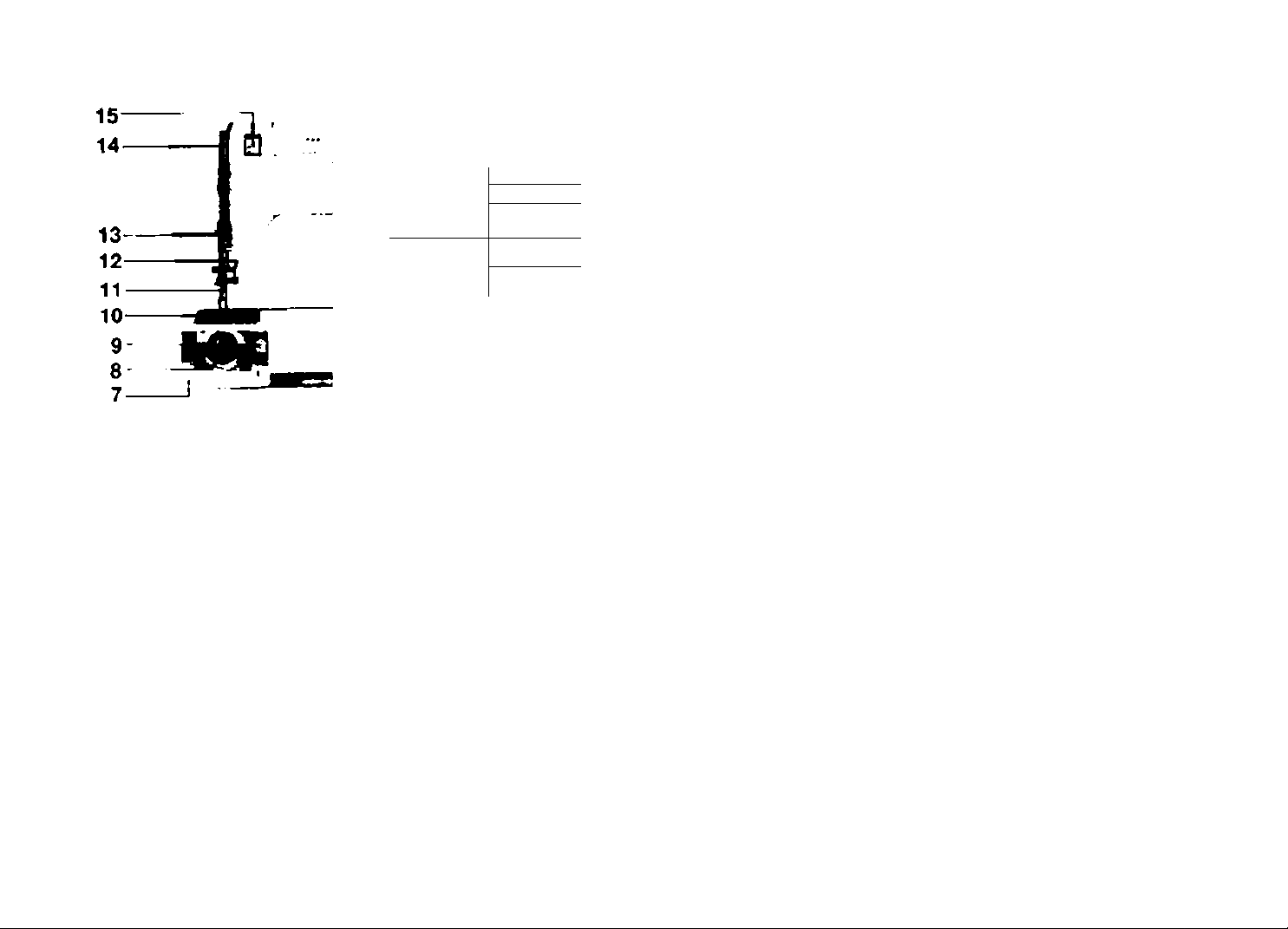

Inserting the needle

(SyiteiTi 13O705H)

I Change the needle regularly.

I especially if it is showing signs of

wear ar>d causing problems.

Insert the needle as illustrated as

follows:

A Loosen the needle damp screw

arxf lighten again after inserting

the new needle. (1)

B The flat side of Ihe shaft should

be towards the back.

C/D Insert Ihe needle as far up as it

will go.

Attontion:

Turn power switch to “O’!

26

Needles must be in p»^eci condition.

(2)

Problems can occur with:

A bent needles

B blunt needles

C damaged points

Page 19

Needle-Thread table

Tableau des aiguilles et fils

Au/e of fhumb.'Tbe thicker the fabric and the thicker

the thread, the higher the count of needle.

Type of fabric

Fine fabric, e.g. Bastiste

silk

Medium-weight fabric.

e.g. cotton

Thick fabric.

corduroy, tweed

Hard, firm fabrics.

e.g. denim

Stretch fabrics.

e.g. iersey. knits

For alt types of fabric

For fine to mediumweight fabrics

For thick fabrics Pintucks

Leather, imitation leather All work Leather needle 80-100

Sewing task

Seams

Topstitching

Seams

Topstkchir>g

Seams

Topstitching

Seams

Topstitching

Seams

Topstitching (ball point)

Damirtg, n>endir>g, Universal needle 70-90

neatening. buttonholes, fine embroidery

Pintucks

Decorative seams

Decorative seanis

Needle system 130/705H

Universal needie 70

Universal needle 80

Universal needle 90-110

Jeans needle 90-U0

Stretch needle 80-90

Double needle 70

Double needle 80

Type of thread

Conon №read Etoffes fines coutures

Cotton thread

Synthetic thread

Cotton thread p. ex. velours cdtelé. tweed surpiqûres

polyester thread

Jeans thread.

polyester thread

Polyester thread

Embroidery and boutonnières.

darning thread cotton

thread

Cotton thread

Embroidery thread

Cotton thread

Polyester thread

Polyester thread couture

туре d'étoffe

p. ex. batiste, soie surpiqûres

Etoffes moyennes

p. ex. coton, linge surpiqûres

Etoffes épaisses coutures

Etoffes dures et stables coutures

comme les jeans

Etoffes élastiques

p. ex. jersey, tricot

pour tous types

d'ôtoffes surfUage.

Pour types d'étoffes couture de nervures

fir>es à moyennes

Pour types d'éloftes couture de nervures

épaisses

Cuir, simili-cuir

Travaux de couture

coutures

surpiqûres

coutures

surpiqûres

reprisage, rapiéçage.

broderies fines

coutures décoratives

coutures décoratives

tous travaux de

30

Page 20

Threading the upper thread

Attention: Turn power switch to

*0*. Raise the r>eedle bar.

- Take the thread through the guide

on the back of the machine from

right to left, then (1)

- between the thread tension disc^

and (2)

- from ri^t to left in the thread takeup spring (3)

- upa^fromrighttoleftthroughthe

thread lake-up lever (4)

- down through the guides (5/6)

and thread the needle, always from

front to back (see next page).

32

Page 21

Upper thread tension

Basic thread tension setilrtg; 4

To increase the tension, turn the dial

to the next number up.

To reduce the tension, turn the dial to

the next number down.

A NormaJ thread tension

B Thread tertsion too loose

C Thread tertsion too tight

34

Page 22

Automatic needle threader

(Modol 740E only)

- Raise the r>eodlo to its highest

position

- Press lever *A* right down

- Thethreaderauiomaiicallyswir>gs

to the threading position "B*

- TaKethethieadrourtdthehook'C

- Take the thread in tront of the

needle round the hook ~D' from

bottom to top

- Release lever 'A'

- Pull the thread through the needle

eye.

Anenbon:

Turn power switch to “O"!

Page 23

Bringing up the lower thread

:Mo0tl7«)C оПу)

The lower thread can be brought up

by using the needle stop lurx^ion or

by tapping the foot control-

1 Hold the upper thread in your left

hand

2 Press button “A"

Press button 'B*

3 Pull gently on the upper thread to

bring up the lower thread. Lay both

threads to the back urrder the

presser foot.

The lower thread can also be brought

up by u&ng the handwheel: HoM the

upper thread in the left hand, turn the

handwheel forwards until the needle

israised artd pull on the upper thread.

38

Page 24

Bringing up the lower thread

iMoOwnS. 733)

Hold the upper thread with the left

hand Turn the handwheel forwards

until the rreedie is raised. <1)

Pull on the upper thread to bring the

lower thread up through the stitch

plate hole. Lay both threads to Ihe

back under Ihe presser foot. (2)

Page 25

Reverse sewing

At the end ol the seam, press the

Reverse sewing button. Saw a few

reverse stitches. Release the button

arid the machine will sew forwards

again. (1)

Removing the work

Turn the handwheel forwards to bring

the thread take-up lever to its highest

position, raise the presser foot and

remove work towards the back (2)

Cutting the thread:

Hold the threads behind the presser

foot with both hands, guide them to

the slit “A* and press down.

42

Page 26

lìiree needle positions

(Model 7406 omyl

Turn the stitch selection dial to straig

ht stitch. (1)

The needle position can be altered

with the lever *A*. For twrual work,

the needle position is Centre. For

edge stitching or sewing parallel lines

of lop stitching, select needle posi

tion Lett or Right.

B Needle position: C (aH normal

work)

C Needle position; L (edge stitching,

etc.)

D Needle position: R (top stitching,

etc.)

Sewing with a Twin needle

(Modal 7406 fifXyl

For Visible seams in jerseys, decora

tive work, pintucks. (2)

Seams in jersey can be sewn and

neatened In or>e operation. Attractive

effects can be obtained in woven

fabrics, depending on the type of

stitch.

Always sew on the right side of the

fabric with a Twin needle.

Attention:

Use needle position 'Centre*

only. The stitch width should r>ot

be more than 3. .For safety's

sake, turn the har>dwheet to

check that the needle does not

go into the stitch plate.

44

Attention:

Turn power switch to tTI

Insert the Twin needle, thread both

threads, see Illustration Page 30,

thread needle eyes separately.

Page 27

Colour coded stHch selection

lUocM 71S)

Turn the stitch select>on dial to the

desired position. (1)

Note the colour of the chosen stitch.

Turn the stitch length dial In the range

of the same colour. (2)

The stitch length can be adjusted

within the same coloured area.

The stitch width Is given (with the

exception of Zig-zag).

46

Page 28

LED Display

(MocW 740E onirl

o o o o o

una2%9

oooeooooooo

rc a

W • ff M S M OltH'-«-

mnm^

• • r « I 4 I 21

SUlch selection with hght diode and

colour code.

Colour code Green arKl Blue.

Turn the stitch selection dial (1 > until

the green diode lights up at the stitch

desired.

Note the colour of the chosen stitch.

Colour indicator

{tMti 730

Stitch selection with coloured mar

king and colour code.

Adjustments as described.

Turn the stitch width dial (2) and the

stitch length dial to the same colour

code.

Stitch width and length can be adju

sted within the same area of colour.

Note the colour of the chosen stitch.

Turn the stitch width dial (2) to the

same colour code. The stitch width

can be adjusted within the red mar

ked area

Stitch Balance (4) for stitches A:

+ lengthen

• shorten

(model 740E only)

48

Colour code Red and Yellow

Turn the stitch length dial (3) to the

position il you want to select *redV

'yellOM/' stitches.

The siitch lertgth is given automaticaRy.

Turn the stitch seiection dial (1) until

the red diode lights up at the stitch

desired.

Page 29

straight stitch

Set the machine as illustrated.

Rule of thumb: The thicker the fabric,

tiuead and needle, the longer the

stitch should be. (1)

Zig-zag

Adjust the stitch width. (2)

Adjust to the zig-zag width desired.

(3)

50

Page 30

Neatening edges

Set the machine as illustrated. (1)

Ouide the fabric so that the needle

goes in just over the edge oí the

fabric. (2)

Attention:

Use Foot No. 6 for fabrics which

tend to pucker. Select Zig-zag

and stitch width 4-5.

52

Page 31

3*Step Zig-zag

Sewing on lace and elastic, darning,

mending, reinlorong edges.

Set the machine as illustrated. (1)

Place patch in position. The stitch

ler>gth can be shortened to produce

very close stitches. (2)

When mending tears, it is advisable

to use a piece ot backing fabric to

reinforce. The stitch density can be

varied by adjustir>g the stitch lertgth.

First sew over the centre and then

overlap on both sides. Oeperxfing on

the type of fabric and damage, sew

between 3 and 5 rows. (3)

54

Page 32

Overtock stitches

Seams, neatenmg, visible hems.

Turn stitch length dial (3) to 'A'.

Turn the stitch selechon dial until the

red diode lights up at the desired

stitch.

The stitch vridth (2) can be adjusted

to suit the fabric. (4-S)

Standard overlock

<MoO»l 740€ only)

For fine knits, jerseys, neck edges,

ribbing.

Double overtock stitch

(Model 740E only)

For fine knits, handknits. seams.

Anenaon:

Use new needles or ball point

needles'

56

Overlock stitch

For fine knits, jerseys, neck edges,

hbbing.

All overlock stitches are suitable for

sewing and neatemng edges and vi

sible seams in one operation.

When neatenir>g, the needle should

just go over the edge of the fabric.

Page 33

Overlook

IMOM 730)

Stretch overlock

iMod«i 730)

Seams, nealening e<)ges. visible

hems.

Set machine as illustrated. (1)

E for fine fabrics

C for thick fabrics

Both stitches are suitable for sewing

and neatenir>g edges and visible

hems in one operation When neatenir>g. the needle should just go over

the edge of the fabric.

58

Page 34

o o o o o

OOOOOOOOOOO

ooooopo#

StUch election

Triple straight stitch

(MocMi8 79(V740E only)

1«::

»< 1» 22 » »

1» • fl H » M t»tin'-10-

nunm.

715/730 740 E

i 21

For hardwearing seams.

Turn the stitch length dial (3) to *A'.

Turn the stitch selection dial (1) until

the red dKxle lights up as illustrated.

Turn the stitch width dial (2) to *0*.

The machine sews two stitches for

wards and one stitch backwards.

This gives triple reinforcement.

Triple zig-zag

For hardwearirtg seams, hems and

decorative seams.

Turn the stitch length dial (3) to *A'.

Adjust the stitch width dial (2) to

between 3 and 5.

Triple zig-zag is suitable for firm fab

rics like denim, corduroy, etc.

60

Page 35

Stitch selection

Triple straight stitch

<Uod«i7iSo-'ly)

For hardwearirtg seams.

Set the machine as illustrated. The

machine sews two stitches forward

and or>e stitch backwards. This gives

triple reinforcement.

Triple 2ig*2ag

iModel 7l5only>

For hardwearirtg seams, hems and

decorative seams.

Triple zig-zag is ideal for firm falxics

such as denim, corduroy, etc.

62

Page 36

Smocking stitch

(ModM 73Q740E only)

00090 O^OOOOOOOQO

tun

Mn»»n a«iT»»w oofl

oooooowo

f I ) t i 4 ) 21

Seams, hems. T-shirts, underwear,

etc.

Set the machine as illustrated. This

stitch can be used for all types of

Jersey as well as for woven fabrics.

0)

Sew at 1 cm (V4") from the fabric

edge and trim the surplus fabric. (2)

64

Page 37

Practical stitches

Set the machine as illustrated

Turn the sMch selection dial (1) until

the green diode lights up ai the

desired sWch.

Turn the stitch width dial (2}andstitch

length dial (3( to the same colour

code and adjust to suit the fabric.

Shell hem 16

For decorative edges.

Suitable tor edges on sheer, line and

stretch fabrics The larger stitch

should go just over the edge of the

labric to create the shell effect

Bridging 17

(Models 73O7a0C oriyl

For seams, place mats, tabtedoths.

This stitch can be used for firm, thikker fabrics

66

Decorative joining seam for a fagotted effect Gattierir>g with cord or

starring elastic

Rampart 18

iMooei 740E only)

For flat joining seams, sewing on

elastic, visible hems.

Page 38

OOOOO OOOC0090000

itili isiim

i*anm I» N » » IS 14 non'-h_>

00400400

1 I >4 » 4 1 } I

Practical siitchaa

Set the machine as illustrated.

Turn the stitcti selection dial (1) until

the red diode lights up at the desired

stitch. Turn the stitch length dial {3) to

*A* The stftch width dial (2) can be

ac^usted to between 3 and 5.

Elastic overiock 4

iNmIoi I^e4 71S)

For hems, decorative seams. Suita

ble for hems or decorative seams in

stretch fabrics

Double arrow 7

(OfVy lor Mcdol 740E)

For seams arKj hems. This stitch is

suitable for sewing arid neatening

stretch fabrics and as a decorative

seam in thicker fabrics

68

Page 39

Practical stitches

000000 #00000 000

mm

IVHOU II «9 9119 «12 <-!-■

ED]

Set the machine as illustrated.

Turn the stitch selection dial (1) until

the red diode goes on at the stitch

desired

Turn the stitch length dial (3) to "A*

and adjust the stitch length diai (2) to

between 3 and 5.

Feather stitch 6

(Model 730 artfi

sloining seams, decorative seams

For seams in stretch fabrics, joining

seams in fine and thick fabrics.

70

Page 40

Decorative stttches

iUodd740e orly)

• ooo

ant

}«;j 77 n II N ir « n 1« nan > M -

00000000

1 I 7 « $ « J 2 I

cufls. embroidery.

19 Square slitcb

20 Diarrxmd stitch

21 Ribbon

22 ScaHop

23 Double scallop

24 Triangle long

Turn the stitch length dial (1} until the

green diode lights up at the stitch

desired. For anattractive. decorative

effect, adjust the stitch width (2) to

maximum and the sDtch length accorcfir>g to the desired etfect. For

better results, use a paper or tear

away backing.

Embroidery thread adds to the ef

fect.

For edges, tabledoths. bed linen,

72

Page 41

Decorative stitches

lMOOe< 740E only)

Edges, tablecloths, bed lirten. cufts.

embroHMry.

Cross stitch 9

Turn the stitch selection dial (1) until

the rod diode lights up at the stitch

desired. Cross stitch: Turn the stitch

ier>gth dial (3) to 'A’

For an attractive, decorative e«ect.

adjust the stitch width (2) to maxi

mum arid the stitch ler>gth according

to the desired effect. For better re

sults, use a paper or tear-away bac-

King.

Embroidery thread adds to the effect

74

Page 42

Buttonholes

Set the machine as illustrated. (i)

(Adjust the stitch length dial >n the

green marked area for a correct stitch

density - varies according to the fab

ric). Always test sew a buttonhole.

Follow the sequence- (2)

Position the button on the loot as

iDustraied Loosen the large screw

*6" of the part *A" and slide it towards

the button until it lightly touches the

other edge, then re-tighten screw "B*

Remove the button ar>d attach the

Bunonhole foot. The gauge is now

set for sewing perfectly even length

buttonholes. (3)

When starting to sew the buttonhole,

the gauge on the foot should be

pushed fully forwards. (4)

Use the seam ripper and cut button

hole open from both ends towards

the middle.

76

r<ps:

- A slightly reduced upper thread

tension produces better results.

- Use a bacKir>g for fine or stretchy

fabrics.

- It IS advisable to use gimp cord for

stretch or knit fabrics The zig-zag

should sew over the gimp.

Page 43

Blind hem lingerie stitch

For hems, curtains, trousers, skkts.

etc.

u Biind hem for stretch fabrtcs.

15 BlirKt hemlingerie for firm fab

rics.

Set the machine as illustrated. <1)

Note:

It takes practice to sew blind

hems. Always rrtake a sewing

tesi first

Fold the fetbric as illustrated with the

wrong Side uppermost. (2)

Place the ft^ic under the foot. Turn

the handwheel forwards by hand until

the needle swings fully to the left. It

shoutd just pierce the fokf of the fab

ric. If it does not. adjust the stitch

width accordingly. (3)

78

Adjust the guide (4) by turning the

Knob (5) so that the guide just rests

against the foW.

Sew slowty. guiding the tabnc care

fully along the edge of the guide.

Turn the speed control to Mtnimumf

Page 44

o 0 o o o

ooeooOQ*Ooa OOOOODOO

Darning

Set the machine asillustraled. Lower

the feed dog. (1)

tint i$iE51i:llECJ

M » 22 m

e « n « K M oen <-n-‘ ( I 2 < S 4 S 21

Remove the presser foot clamp. (2)

Attach the Oarnir>g foot to the pres

ser fool hotder. The lever 'A* should

t>e behind the needle clamp screw

■B". Press the Darning foot on firmly

from b^ind with your index finger

and tighten the screw ’C* (3)

Rrst sew round the edge of the hole

(to secure the threads). (4)

Rrst row: Always work from left to

right. Turn work by 'A and oversew,

A darning ring is recommended for

easier sewing arKl better results.

Note:

When darmng is completed,

raise the feed dogi

80

Page 45

.0600 OOOOOOnoOO'*

nziniti« ti M I) « « It nan'-«-'

Sewing in zips

Set the machine as illustrated. (1)

oooouoOO

The zip foot can be inserted right or

left. depend’Pg on which side of the

toot you are going to sew. (2*3)

To sew past the zip pull, lower the

needle into the fabric, raise the presser loot and push the zip pull behind

the presser foot. Lower the foot and

continue to sow.

Page 46

OOOOO OOOOCOv*fO*

iuli

9 9 9

<33

» « ?i » t» a II It 8 u IJ Kti - a-'

y O O I- •• 'i

Sewing on buttons

iMooe 740feonty,

Set the machine as illustrated. Lower

the feed dog. Needle position righi

<i>

Position the worK under the foot.

Place the button on the marked posi

tion. lower the foot, adjust stitch width

to 'O' arid sew a tew securing stit

ches. Adjust the stitch width (rv^rmally between 3 and 4). Turn the handwheel to check that the needle goes

cleanly into the leM hole ol the button

(adjust the stitch width according to

the button), and sew on the buttort.

Adjust the stitch width to '0* and sew

a tew securing stitches. (2}

If a shank is required, place adarnmg

needle on top ot the button and sew.

(3) For buttons with 4 holes, sew

through the front two holes first (Ftg.

2). push work forward arxf ttien sew

ttuough the back two holes as des

cribed. (3)

84

Page 47

Sewing wfth the Hemmer foot

>U00el 704E

For hems in fine or sheer fatKics.

Set the machine a$ illustrated. (1)

Neaten the edge of the tabnc. At the

beginrung of the hem. turn under the

edge twice by about 3 mm ('/»’) and

sew 4-5 stitches to secure Pull the

thread slightly towards lire back. In

sert the r>eedie into the fabric, raise

the presser foot and guide the fold

into the scroll on the tool. (2)

Gently pull the fabric edge towards

you and lower the presser foot. 8egm

sewing, guiding the fabric into the

scroll by hokjif^g it upright and slightly

to the left (3)

Page 48

Sewing with the Cording foot

it/Mei /*0E onff)

Oecorairve effects, cushtons. ta

blecloths. etc.

Set the machine as illustrated. Vanous stitches are suitable for sewmg

on cord. e.g. Zig zag. Triple zig-zag.

decorahve stitches. (i)

Insert the cord between the spnng

coverirtg the cord groove and the

loot. The cord should run in the

groove Orie. two or three cords can

be sewn on. The stitch width is adju

sted according to the number of

cords and the stitch selected. (2/3)

88

Page 49

Maintenance

Attention:

Disconnect the machine from

the eiectncity su|^ by remo

ving the plug from the mains

socket- When cleaning the ma

chine. it must always be dis

connected from the electricity

supply.

Remove the stitch plate:

Turn the handwheel until the needle

is fully raised. Open the hinged front

cover and push the release lever

upwards. (1)

Cleaning the feed dog:

Remove the bobbin case (see Page

26) and use the brush supplied to

dean the whole area <2)

two hook retaining arms. Insert ttie

bobbin case and bobbin and replace

the stitch plate

Impoftant:

Fabric fluff and threads must be re

moved regularly. Your machine

should be serviced at regular inter

vals at one of our service agencies.

90

Cleaning arxf lubricating the hook:

Remove the bobbin case (see Page

26) Snap Ihe two hook retaining

arms (3) outwards. Remove the hook

race cover (4) ahd the hook (5) arvd

dean with a soft doth. Lubricate at

the points (6) (1 ~2 drops) with sewing

machir>e pit. Turn the handwheel until

the hook race (7) is in the left position.

Replace the hook (5). Replace the

hook race cover and snap back the

Page 50

Trouble shooting guide

AffeniKjH.

O$connecl rnacbne from otoceidty supply

РгоЫпт

Upper ihread break«

Lower iivead break»

SkrppeO sMches

Neede break«

Loo«« stncrros

Seams gather or pucker

Cause

t. The macNne'» not threaded correcer

2. The thread tension >s юо dght

3. The ihrersd cs too thick tor the needle

<1 The tteade is not inserted correct^

S The ihtetMi a rourd wound the «pool holder pm

6. The need« is damaged

t. The bobom case le not ineened correctly

2. The bobom case is threaded wrortgiy

3. The lower thread tension it loo l^hi

t The neede is not msonod oomcOy

2. The neede is damaged

3 The wrong size neodo has been used

4 The loot is not anached correctly

t. The needte Is damaged

2. The neede is not correcdy msorted

3 Wrong neerSe size tor the fabro

4 The wrong toot >8 attached

1. The machine « not correctly trreadt>d

2 The bobbin case is not conecPy threaded

3 Needle-labrtcilhread combmaten e wrong

4 Thread lenaon wrong

I The neodo is too thick lot the tabric

2. The stitch length « wrongly adiusteo

3 The thread tension it loo tight

Correction

1 Rethread the machine 32

2 Reduce the tireed tension (tower number) 3<

3 Seed a larger needle 30

4 Remove and reinsert the r«ede (flat sbe towards the back) 28

5 Remove the reel and witvl dvead onto reel

6 Reptaca me needte 28

1

Remove and reinsert the bobbn case and put on the thread. The thread

shoiid p<4 eastly 26

2. Chet* both bobbm and bobbin case 26

3 Loosen lower thread tension as deserbed 26

1. Remove and remsen rteerSe {Rat sde towards the back) 28

2 insert a new neerRe 28

3 Cttoose a nee^ to sun the thread and tabnc 30

4 Chedr and attach oorteclly 22'tO

t Insert a new rteedle 28

2

been the needle conectly {hat s>de towards the back)

28

3 Choose a needle to sun the thread and fabr« 30

4 se-ect the correct toot 22rto

1. Check me threading 32

2 Thread the bobbin case as illustrated 26

3. The neede size must eutl the istnc and ihread 30

4 Correct the thread tensón 34

1 SeTecI a finer needle X

2 Read(u$i ire stiicn length

3 Loosen the thread tensón 34

Uneven stitches, uneven feed

The machine is noojr

The rrtachne |em»

92

I Poor quaMy ttiroad

2- The bobbin case « wrongly threaded

3 Pebric has been pullrxl

t The machine must be lubricated

2. rtutl or ol have cotiecied on the hoc* or neede bar

3 Poor диаЧу 0> has been used

4 The needle is damaged

I Thread is caught tn the hoc*

1 Select a belter quality thread

2

Remove bobtxn case and remread and msert oorrectly 26

3 Oo not putt on the tabnc while smvng. W I be taken up by the macNne

1 Lubncaieasdescnbed 90

2 Clean me hook and leed dog as descrioed 90

3 Ody use good quality sewing machine oil 90

4 Replace the r>eede 28

1 Remo-ze the upper thread and boObm case, turn the nardwheei

backwards and forwards by hand and remove the tivead remants.

Lubricale as described 90

Page 51

021ОЮ102<С)

Loading...

Loading...