Bernina 530, 550 QE Owner's Manual

BERNINA 530 | 550 QE

Introduction

033471.52.04_2014-02_Manual_B530_550_EN

Dear Bernina Customer,

Congratulations! You’ve decided on BERNINA, a reliable choice that will delight you for

years to come. For over 100 years, our family has placed the highest value on satisfied

customers. For myself, it is a matter of personal pride to offer you Swiss precision at the

height of perfection, future-oriented sewing technology, and a comprehensive customer

service.

5 Series, BERNINA launches three ultramodern models. Apart from the highest demand

on technology, we have also focused on the design; after all we sell our products to

creative people like you, who expect a high standard of best quality and appreciate the

design vocabulary.

1

Enjoy the creative sewing with BERNINA and find out about our varied range of accessory. Let yourself be inspired by new sewing projects and visit us at www.bernina.com.

And don’t forget to make use of service and maintenance offers from our highly trained

BERNINA dealers.

I wish you lots of pleasure and many creative hours with your new BERNINA.

H.P. Ueltschi

Owner

BERNINA International AG

CH-8266 Steckborn

www.bernina.com

3nd Edition

2

033471.52.04_2014-02_Manual_B530_550_EN

Safety Instructions

SAFETY INSTRUCTIONS

IMPORTANT

INFORMATION

When using an electrical appliance, basic safety

precautions should always be followed, including

the following:

Read all instructions before using this sewing

computer.

When the sewing computer is not in use, it

should be disconnected from the electricity

supply by removing the plug from the outlet.

DANGER!

To reduce the risk of electrical shock:

1. The sewing computer should never be left

unattended when plugged in.

2. Always unplug the sewing computer from the

electrical outlet immediately after using and

before cleaning.

3. LED Radiation – Do not view directly with

optical instruments. Class 1M LED product.

WARNING!

To reduce the risk of burns, fire, electric shock or

injury to persons:

1. Use the sewing computer only for purposes

as described in this manual. Use only attachments/accessory recommended by the manufacturer.

2. Do not allow the sewing computer to be used

as a toy. Close attention is necessary when

this sewing computer is used by or near

children and infirm persons. This sewing

computer is not intended for use by persons

(including children) with reduced physical,

sensory or mental capabilities, or lack of

experience and knowledge, unless they have

been given supervision or instruction concerning use of the sewing computer by a person

responsible for their safety. Children must be

kept under supervision to ensure that they do

not play with the sewing computer.

3. Never operate this sewing computer if:

⦁

it has a damaged cord or plug,

⦁

it is not working properly,

⦁

it has been dropped or damaged,

⦁

it has fallen into water

Take the sewing computer to the nearest

authorized BERNINA dealer for examination

or repair.

4. Never operate the sewing computer with any

air vents blocked. Keep ventilation openings

of the sewing computer free from lint, dust

and/or fabric bits.

5. Keep fingers away from all moving parts.

Special care is required around the sewing

needle.

6. Never drop or insert any objects into any

opening on the sewing computer.

7. Do not use the sewing computer outdoors.

8. Do not operate the sewing computer where

aerosol products (spray) or oxygen is being

administered.

9. Do not pull or push the fabric while stitching.

This may deflect the needle, causing it to

break.

10. Do not use bent needles.

11. Always use the original BERNINA stitch plate.

The wrong stitch plate can cause needle

breakage.

12. To disconnect, turn power switch to «0» (off),

then remove the plug from the outlet. Do not

unplug by pulling the cord, instead grasp the

plug to pull it from the outlet.

13. Turn power switch to «0» (off) when making

any adjustments in the needle area, such as

changing the needle or the presser foot, etc.

14. Always unplug the sewing computer from the

electrical outlet when carrying out cleaning or

maintenance work or any other user servicing

adjustments mentioned in this manual.

15. This sewing computer is provided with double

insulation (except USA and Canada). Use

only genuine replacement parts. Please note

the advice on the servicing of double-insulated products.

Safety Instructions

033471.52.04_2014-02_Manual_B530_550_EN

3

SERVICING DOUBLEINSULATED PRODUCTS

In a double-insulated product, two systems of

insulation are provided instead of grounding. No

grounding means is provided on a doubleinsulated product nor should a means for

grounded be added to the product. Servicing a

double-insulated product requires extreme care

and knowledge of the system and should only be

done by qualified service personnel. Replacement

parts for a double-insulated product must be

identical to the original parts in the product.

The symbol

product.

may also be marked on the

DISCLAIMER

No liability will be assumed for any possible

damage which arises from misuse of this sewing

computer.

This sewing computer is intended for household

use only.

This sewing computer meets the European

Standard 2004/108/EC concerning the

electromagnetic tolerance.

Environmental Protection

BERNINA is committed to the protection

of the environment. We strive to

minimize the environmental impact of

our products by continuously improving

product design and our technology of

manufacturing.

When your sewing computer won't be

used anymore, dispose this product in

an environmentally

responsible way according to the

national directive. Do not throw away

this product with your household waste.

In case of doubt, please contact your

BERNINA dealer.

If the sewing computer is stored in a cold

room, it should be brought to a warm

room about one hour before use.

SAVE THESE

INSTRUCTIONS!

Please find the latest version of your

instruction manual at www.bernina.com

4

033471.52.04_2014-02_Manual_B530_550_EN

Notes

Notes

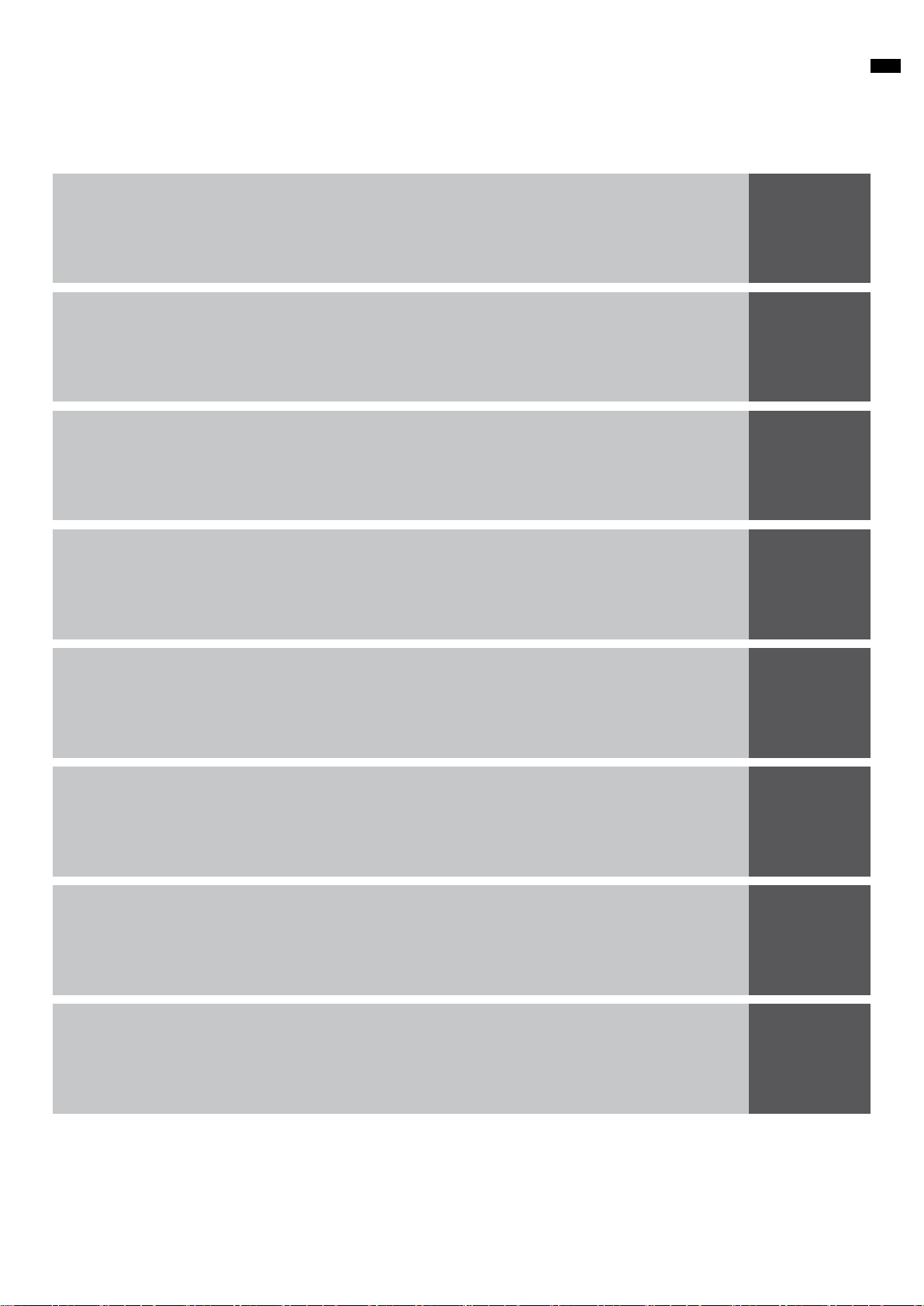

Contents

033471.52.04_2014-02_Manual_B530_550_EN

Accessory 7

Preparation 10

█

Overview sewing computer 10

█

Sewing preparation 12

Functions 26

█

«Function»-buttons sewing computer 26

█

Overview Display 30

█

Setup Program 32

█

Tutorial 34

█

Creative consultant 35

█

Balance 36

5

Sewing stitches 37

█

Practical stitches 37

█

Buttonholes 51

█

Decorative stitches 62

█

Quilt stitches 63

█

BSR 66

█

Alphabets 70

█

Combi mode 71

Cleaning 75

Troubleshooting 76

Stitch patterns 78

Index 86

6

033471.52.04_2014-02_Manual_B530_550_EN

Key to Signs

DANGER!

Very important!

Risk of injury!

DANGER!

Very important!

Risk of damage!

Tips!

* Not supplied as standard with the BERNINA 530

** Not supplied as standard with the BERNINA 550 QE

Glossary

Balance Correcting abnormalities in stitch formation due to the fabric

Fabric fold Folded edge of material

BSR BERNINA Stitch Regulator. Quilting with consistent stitch length within certain speed

clr Deleting settings or data

Hook «Catches» the needle-thread loop, forming the stitch together with the lower thread

LMS Length Measuring System for buttonhole

Memory Long Term Memory

Satin stitching Dense zig-zag

Bartack Buttonhole-bead cross-connections

All rights reserved

For technical and product improvement reasons, the sewing computer's features, parts and accessories are subject to

unannounced changes and alterations at any time. The accessories included can differ from country to country.

Standard Accessory

033471.52.04_2014-02_Manual_B530_550_EN

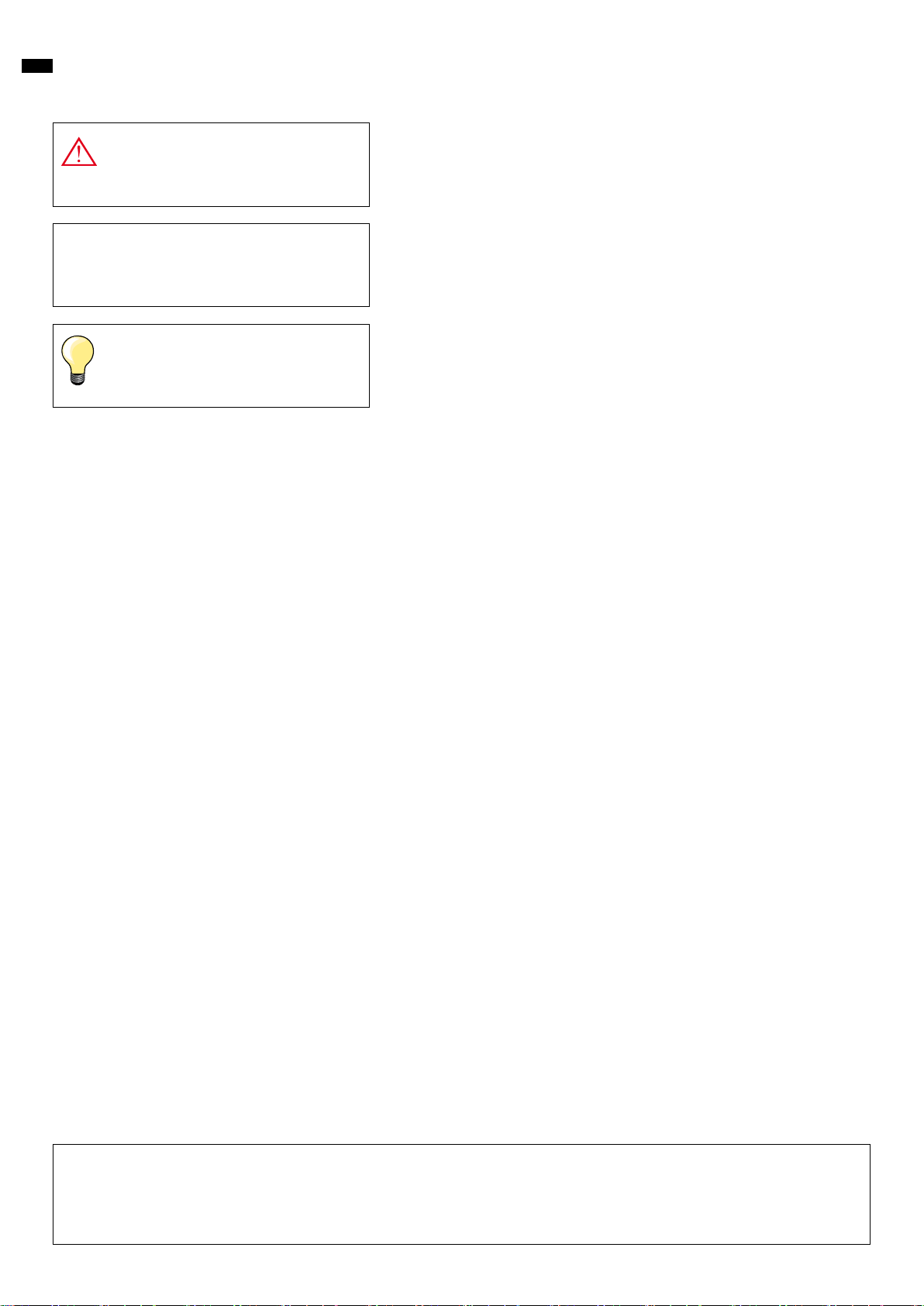

Carrier bag

Accessories box

Foot control

Power cable

Slide-on table

Seam Guide

Free Hand System (FHS)

Accessory

7

C

D

H

B

E

F

G

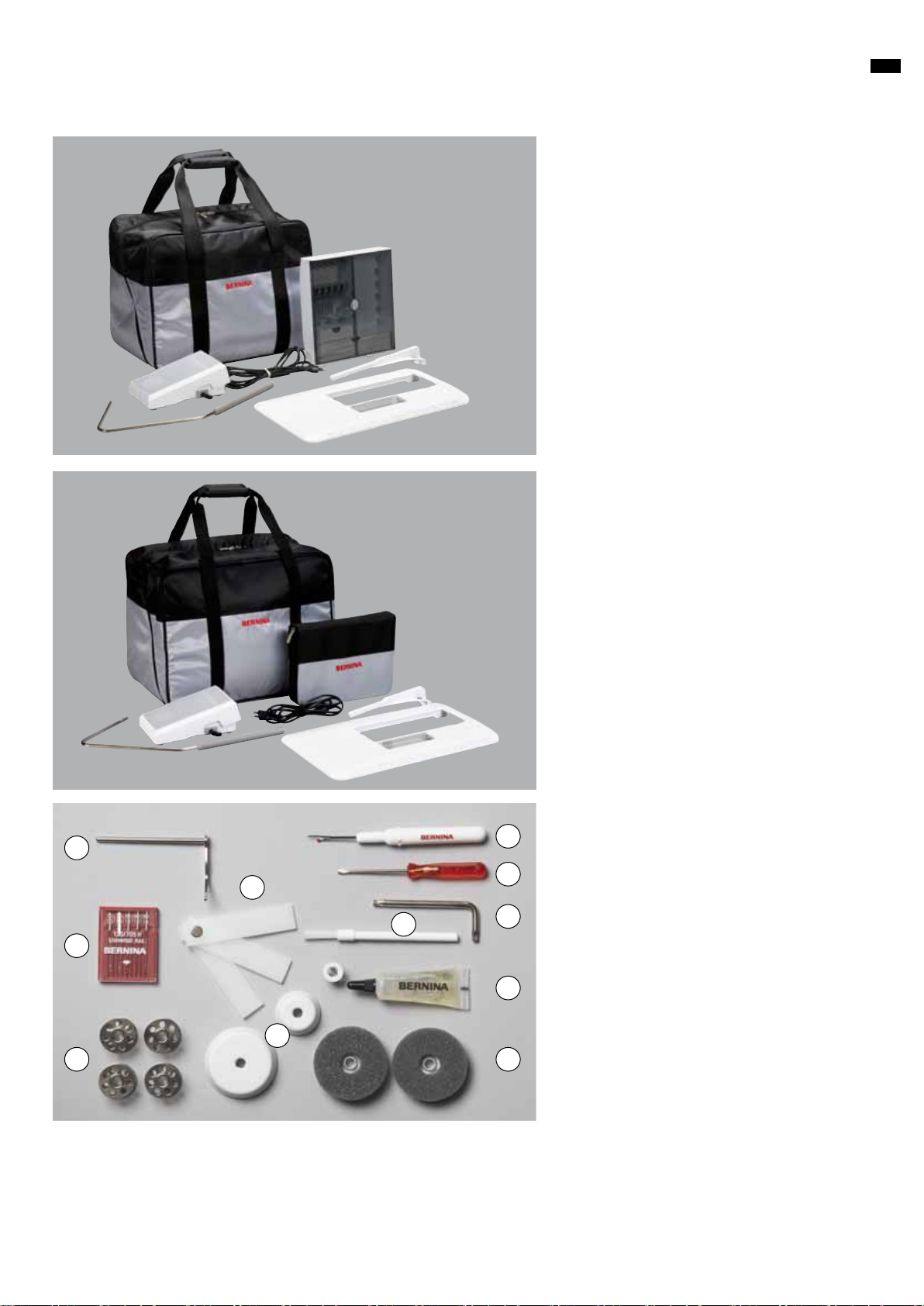

B Selection of needles

C Seam guide, right

D Height compensation tool

E Seam ripper

F Screwdriver, red

G Angular Torx wrench

H Lint brush

I Lubricator

J 2 foam pads

A 5 bobbins (one of them in the bobbin case)

I

K

A

J

K 3 spool discs

8

033471.52.04_2014-02_Manual_B530_550_EN

Accessory

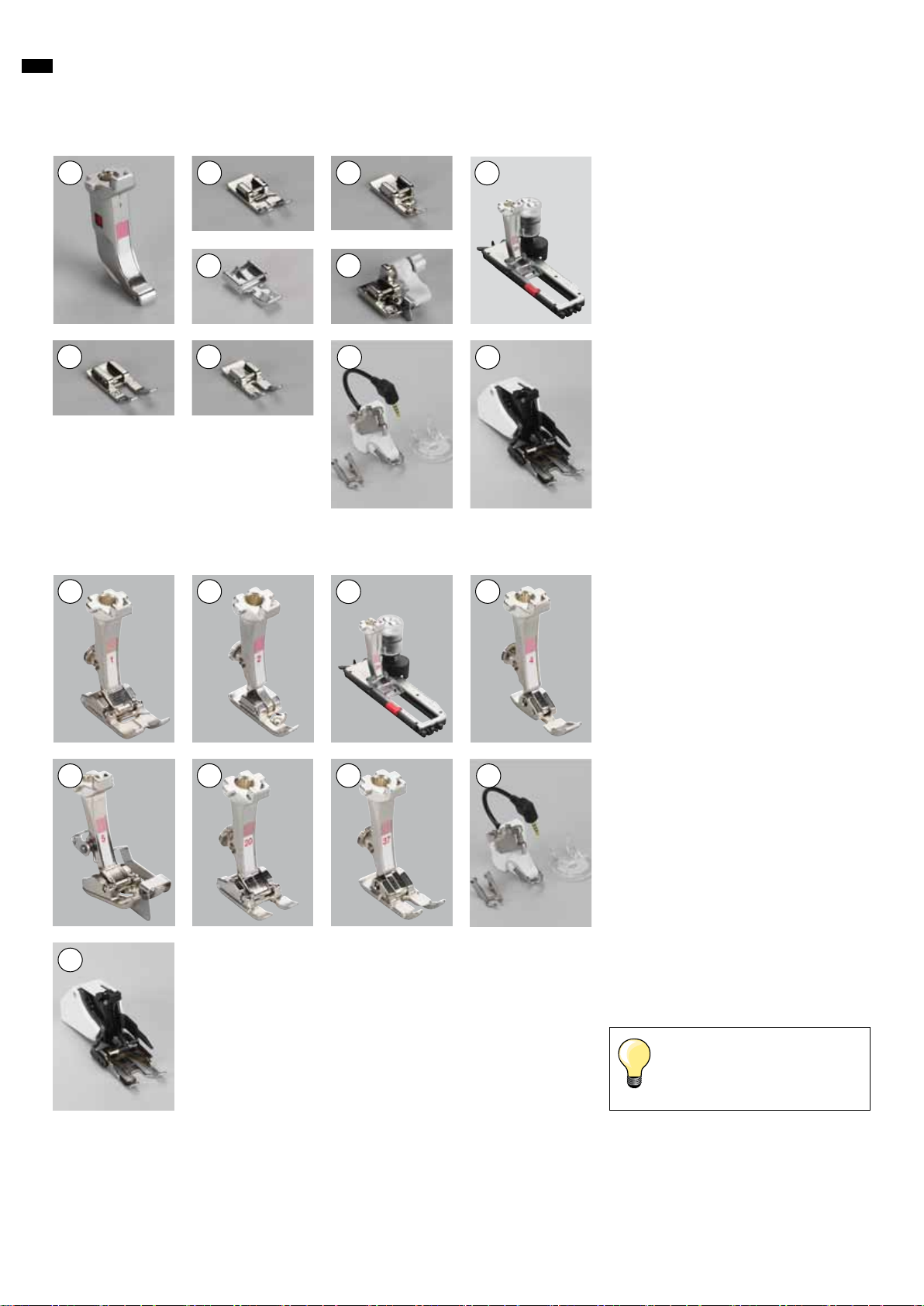

Presser foot shank and soles (BERNINA 530/550 QE)

21

5

7

8

Presser feet (BERNINA 550 QE)

1

2

3

6

9 10

3

4

1 Presser foot shank

2 No. 1 Reverse pattern sole

3 No. 2 Overlock sole **

4 No. 3A Automatic buttonhole foot with

slide

5 No. 4 Zipper sole

6 No. 5 Blindstitch sole

7 No. 20 Open embroidery sole *

8 No. 37 Patchwork sole *

9 No. 42 BSR foot *

10 No. 50 Walking foot *

4

1 No. 1 Reverse pattern foot

2 No. 2 Overlock foot **

3 No. 3A Automatic buttonhole foot with

slide

4 No. 4 Zipper foot

5 No. 5 Blindstitch foot

6 No. 20 Open embroidery foot

7 No. 37 Patchwork foot

8 No. 42 BSR foot

9 No. 50 Walking foot

5

9

6

7

8

The presser foot system can vary depending on the market (presser feet or pressor foot

shank and soles).

Visit www.bernina.com for

more accessory information.

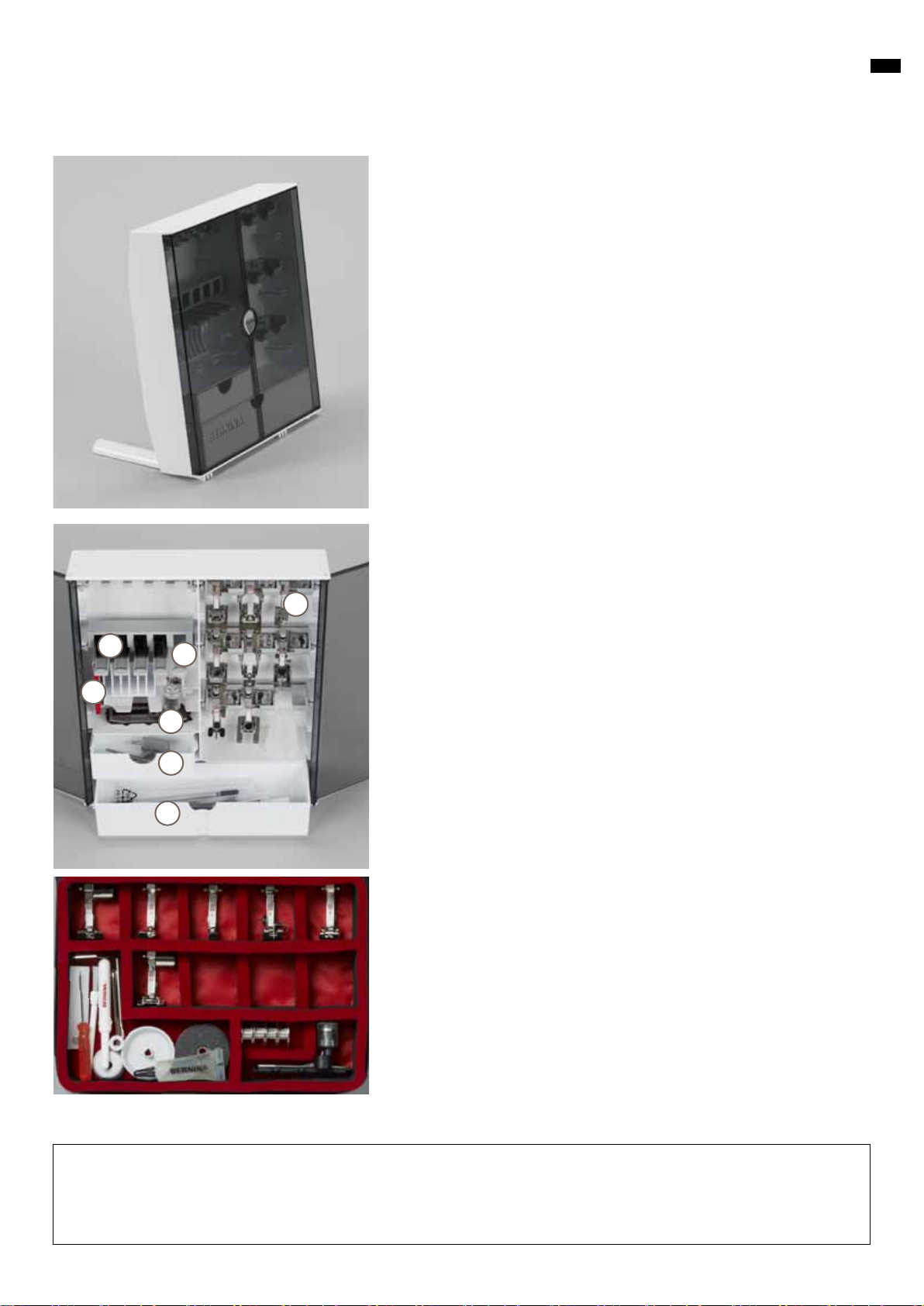

Accessory box

033471.52.04_2014-02_Manual_B530_550_EN

Accessory

Storing accessory

█

on the back of the box, pull both extensions out until they click into place

9

Storage example

The box is equipped as standard with one small A and one large B drawer as

well as a compartment for bobbin holders C and presser feet D.

█

to remove a bobbin, press the compartment holder E lightly

█

D

C

G

E

F

A

B

buttonhole foot with slide no. 3A can be stored in the left compartment F

█

store the needle range supplied in the special compartment G

All rights reserved

For technical and product improvement reasons, the sewing computer's features, parts and accessory are subject to

unannounced changes and alterations at any time. The accessory included can differ from country to country.

10

033471.52.04_2014-02_Manual_B530_550_EN

Preparation - Overview sewing computer

Front view

10

9

11

12

13

8

6

5

4

2 3

14

1716

7

15

18 19

20

21

22

23

24

25

26

27

28 29

Detail view

44

53

1

45

46

48

50

1

30

51

47

49

52

Preparation - Overview sewing computer

033471.52.04_2014-02_Manual_B530_550_EN

11

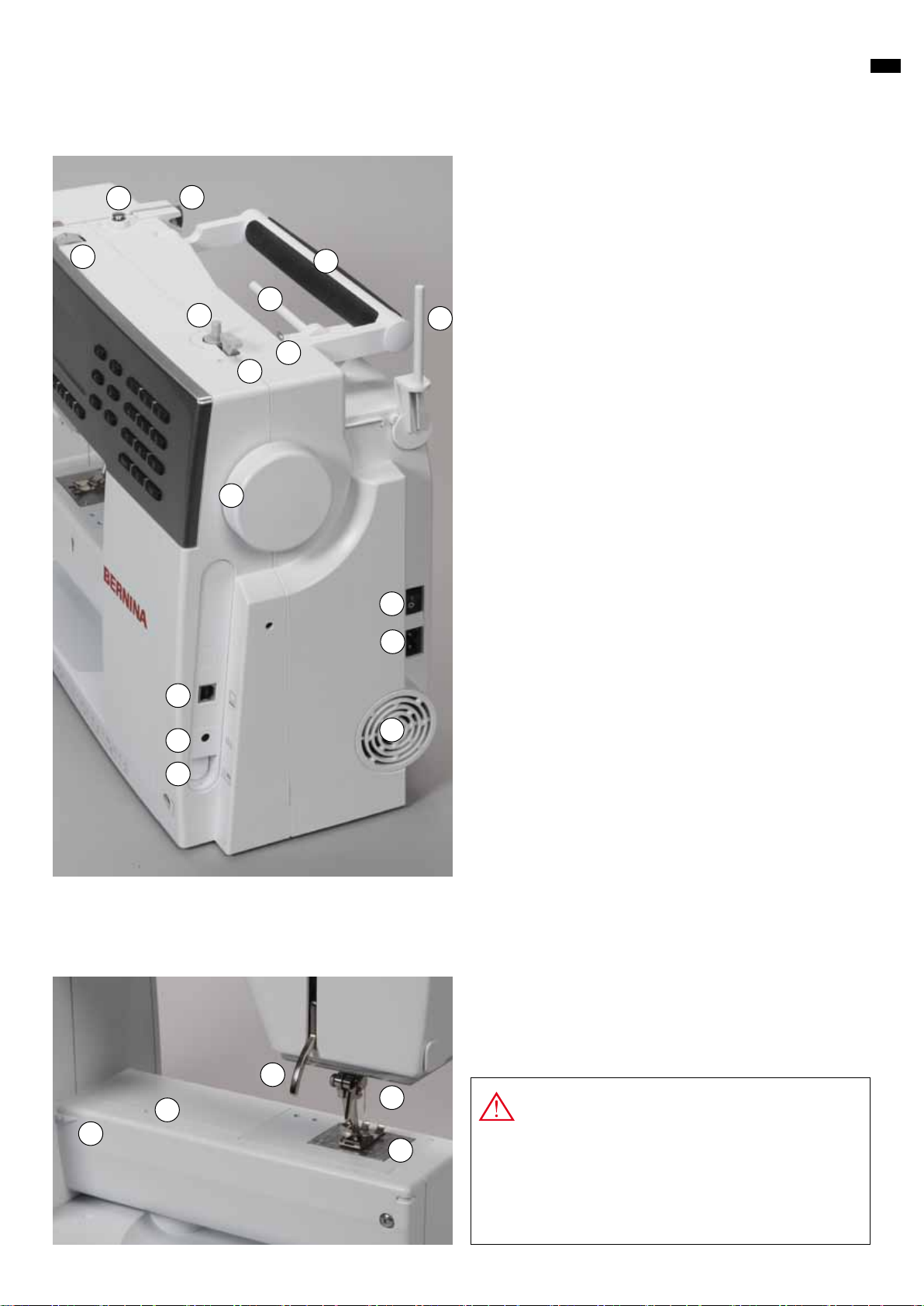

31

10

38

39

40

32

25

37

26

35

36

33

41

42

43

1 Bobbin cover

2 Stitch plate

3 Attachment base for

special accessories

4 LED sewing light

5 «Quick reverse»-button

6 «Pattern end/pattern

repeat»-button

7 «Start/Stop»-button

34

8 Thread take-up cover

9 Thread take-up lever

10 Bobbin winder pre-tension

11 «Navigation»-buttons left/

right/down/up

12 «OK»-button

13 «Home»-button

14 «Back»-button

15 Display

16 Speed control

17 «Needle stop»-button

down/up

18 «Securing»-button

19 «Mirror image»-button

20 «Pattern begin»-button

21 «Balance»-button

22 «Stitch width»-buttons

23 «Needle position»-buttons

24 «Stitch length»-buttons

25 Bobbin winder device

26 Thread cutter on bobbin

winder

27 «Stitch selection»-buttons

28 «BSR»-button

29 «clr»-button

30 Free hand system

connection

31 Thread tension adjustment

wheel

32 Rear thread guide

33 Carrying handle

34 Vertical spool pin

35 Horizontal spool pin

36 Eyelet thread guide

37 Handwheel

38 PC-Connection for

software update

39 Foot control socket

40 Feed dog drop

41 Power switch

On «I»/Off «0»

42 Power plug socket

43 Air vents

44 Needle threader

45 Thread guide

46 Needle clamp

47 Presser foot

48 Feed dog

49 Thread cutter in hook

opening

50 Presser foot pressure

adjustment wheel

51 Headframe fixing screw

52 Thread cutter on the

headframe

53 Slide-on table socket

54 Darning hoop connection

55 Presser foot lifter

56 BSR-connection

54

53

55

56

USA/Canada only: The sewing computer has a

polarized plug (one blade wider than the other). To

2

reduce the risk of electrical shock, this plug is

intended to fit in a polarized outlet only one way. If

the plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified

electrician to install the proper outlet. Do not

modify the plug in any way!

12

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

Foot control

A

B

D C

Before beginning to sew

█

unwind the cable

█

plug the cable in the outlet provided A

█

unwind the cable to the desired length and slip into B or C

Sewing speed control

Control the sewing speed by pressing the foot control more or less.

Adjust needle down or up

█

adjust the down/up position of the needle by sinking the heel back on the

foot control

After sewing

█

wind the cable around the spool

█

plug cable into D

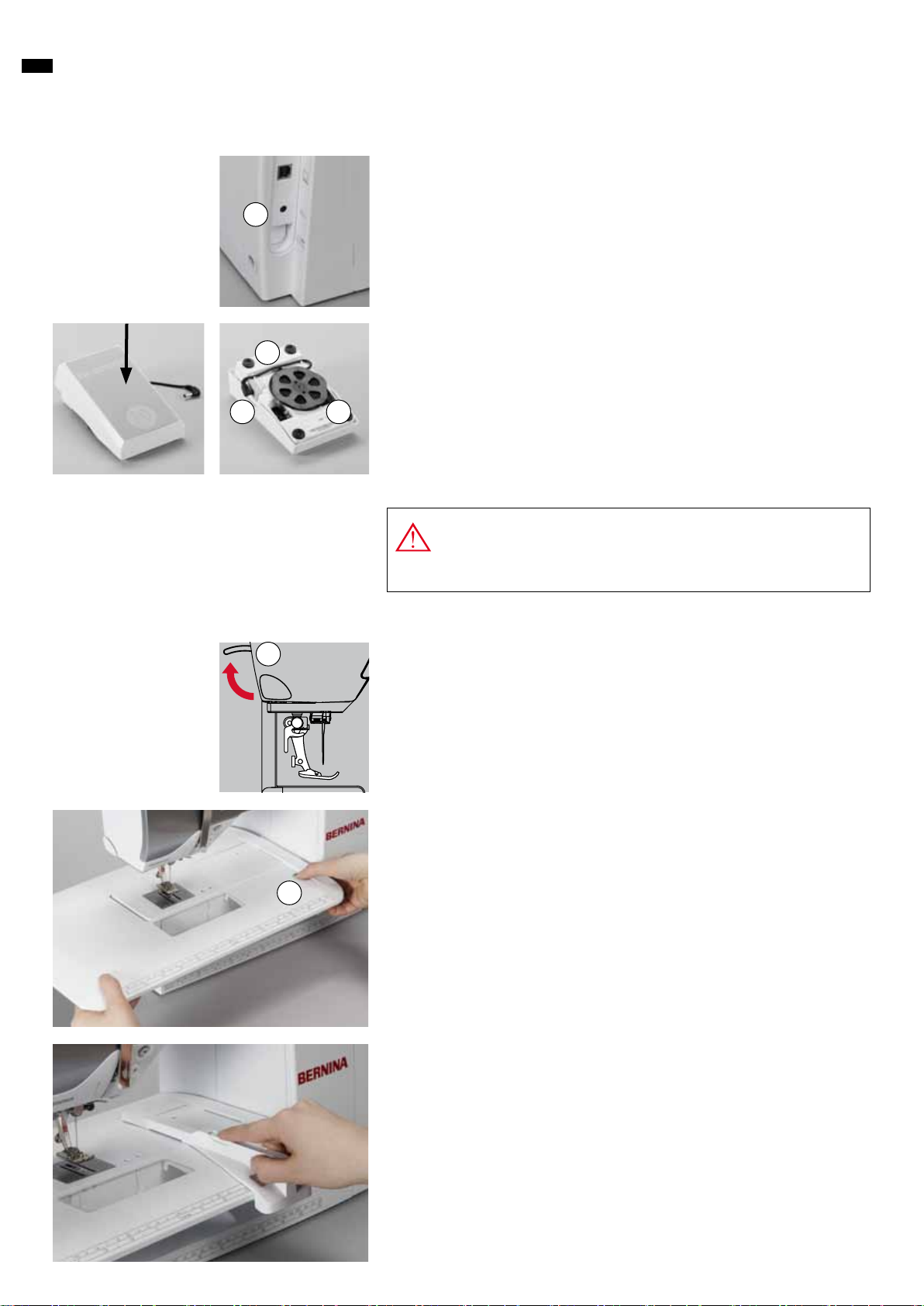

Slide-on table

USA/Canada only: Use only foot controller type LV-1 with

sewing computer B 530 and B 550 QE.

█

1

turn the handwheel (see page 11)

►

needle is raised

█

raise presser foot lifter 1 up

►

presser foot is lifted

The slide-on table increases sewing surface.

Attaching the slide-on table

█

raise the needle and presser foot

█

A

slide over free-arm to the right until it engages

Removing the slide-on table

█

raise the needle and presser foot

█

press button A down

█

pull slide-on table to the left

Seam Guide

█

press the release button and insert into the groove (underside of table) from

left or right

Can be moved over the entire table length.

Free Hand System (FHS)

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

The FHS raises and lowers the presser foot.

Attaching the lifter

█

insert into the opening

Raising and lowering the presser foot

█

with your knee push lever to the right

You should be able to operate the FHS with your knee in your normal sitting

position.

►

the presser foot is raised; the feed dog is lowered simultaneously. The

thread tension is released

The feed dog is raised as soon as the first stitch is sewn.

Your dealer can adjust the FHS if necessary.

13

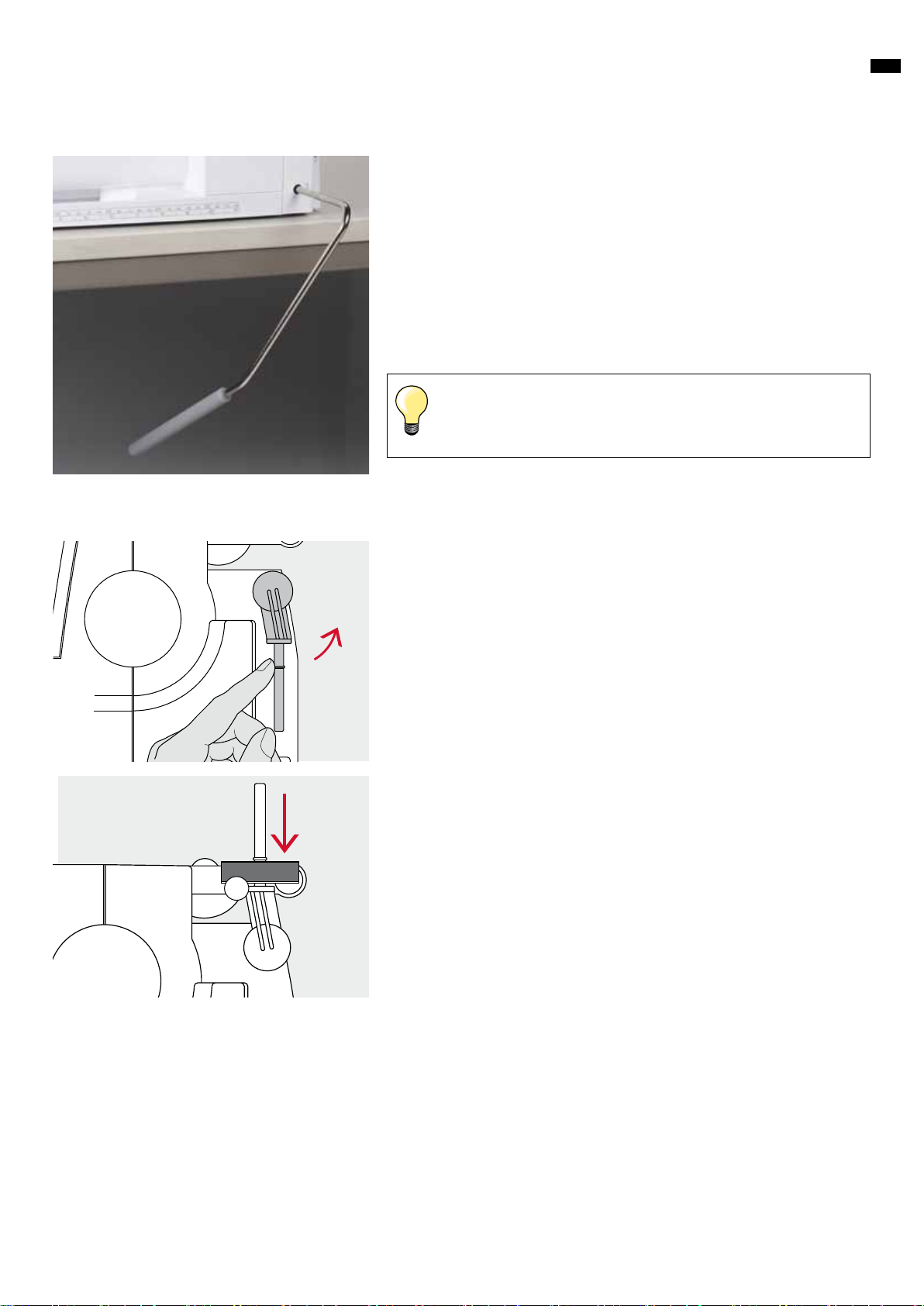

Vertical spool pin

The vertical spool pin is on the side behind the handwheel.

It is an essential aid for sewing with more than one thread, i.e. double needle

work and can also be used for winding the bobbin while sewing.

█

turn the spool pin as far it will go

█

when using all reels, add the foam pad A for stability

A

14

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

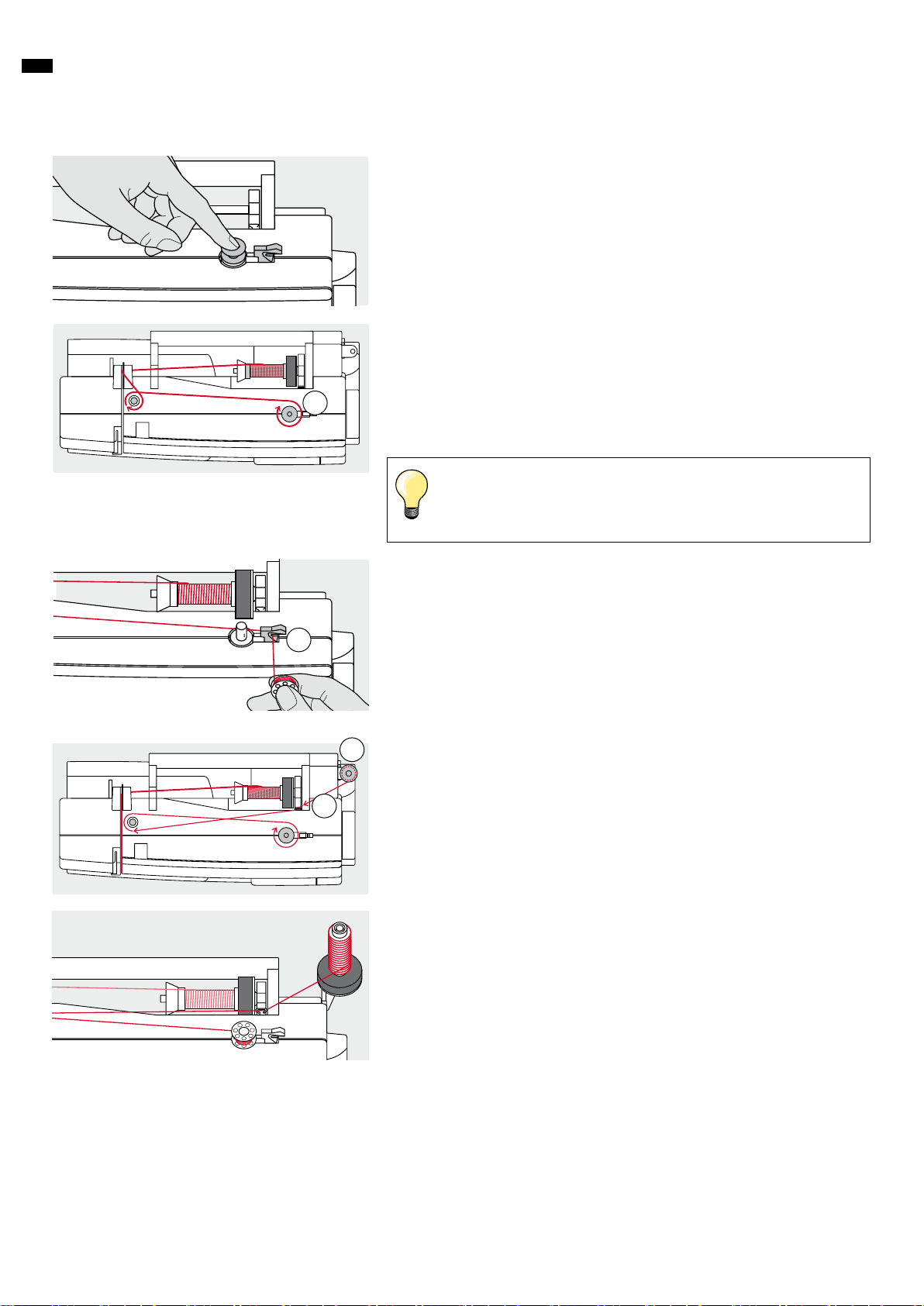

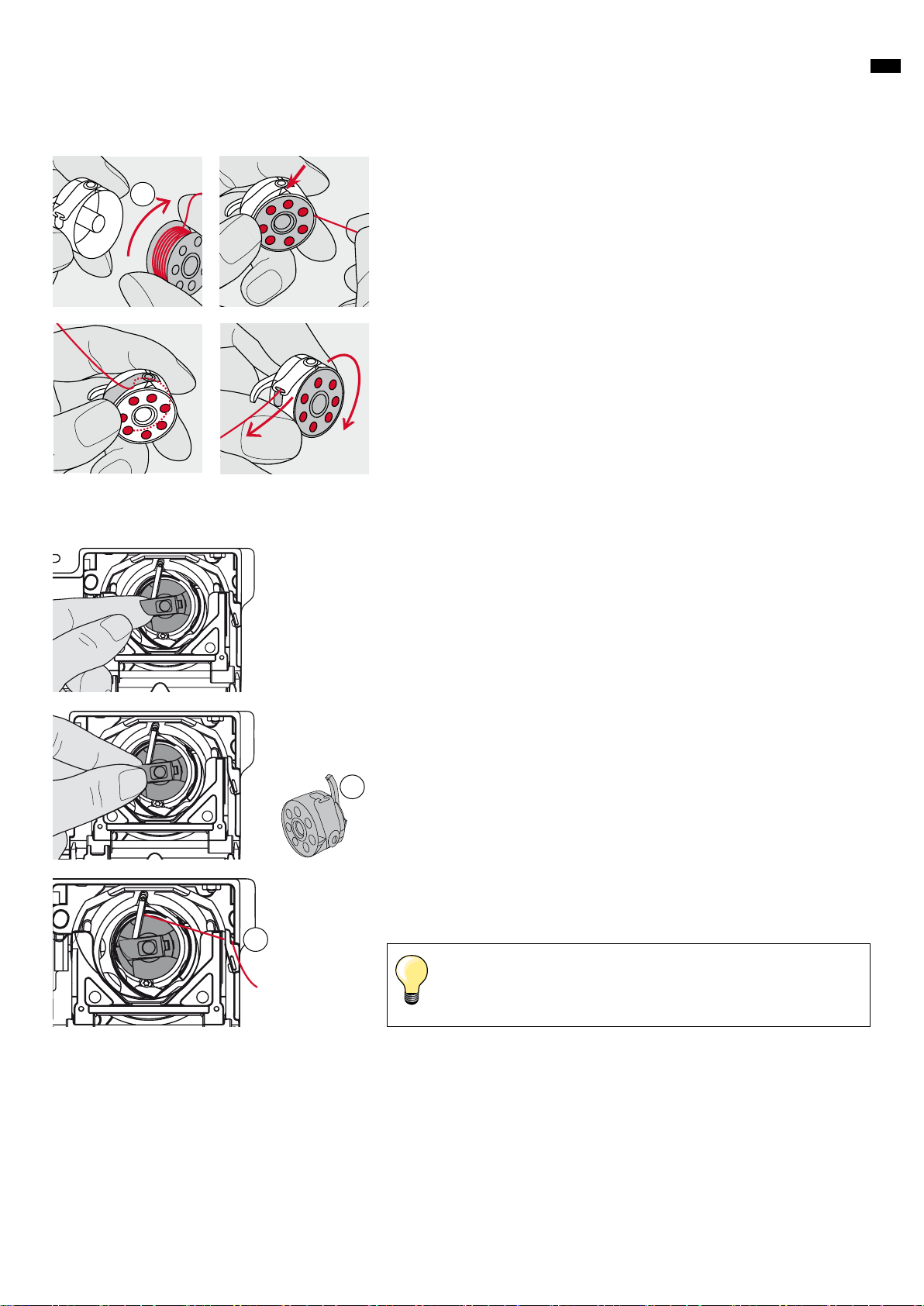

Winding a bobbin

█

turn power switch to «I»

█

place empty bobbin on spindle

█

place foam pad on the spool pin

█

place thread on the spool pin

█

attach appropriate spool disc

█

following the direction of the arrow, take thread through the rear guide and

A

round the pre-tension stud

█

wind the thread two to three times around the empty bobbin

█

cut off any excess thread on the thread cutter A

Appropriate spool disc

Diameter of thread spool determines disc size, there must be no gap

between the disc and the spool.

█

push engaging lever A against bobbin

►

the winder works automatically

►

the motor will stop automatically when the bobbin is full

█

remove bobbin and

█

A

B

C

pull the thread over thread cutter A to cut it

Bobbin winding while sewing

█

attach foam pad on the vertical spool pin B

█

place thread on the vertical spool pin

█

following the direction of the arrow, take thread through the thread guide C

and

█

guide around the pre-tension stud

Then proceed as mentioned above.

Inserting a bobbin/Threading lower thread

033471.52.04_2014-02_Manual_B530_550_EN

█

insert the bobbin so that the thread runs clockwise A

A

█

pull the thread from the right into the slot

█

pull the thread to the left under the spring

█

until it lies in the T-shaped slit at the end of the spring

█

pull the thread

►

the bobbin must turn clockwise

Sewing preparation

15

Exchanging bobbin case

B

Remove the bobbin case

█

raise needle

█

turn power switch to «0» (off)

█

open bobbin cover

█

grasp the latch of the bobbin case

█

remove bobbin case

Insert the bobbin case

█

hold the bobbin case latch

Finger of the bobbin case A points upwards.

█

insert the case so that it clicks into place

A

Bobbin thread cutter

█

pull the thread over cutter B to cut it

█

close the bobbin cover

The bobbin thread does not have to be brought up as the loose end

is just the right length to start sewing.

16

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

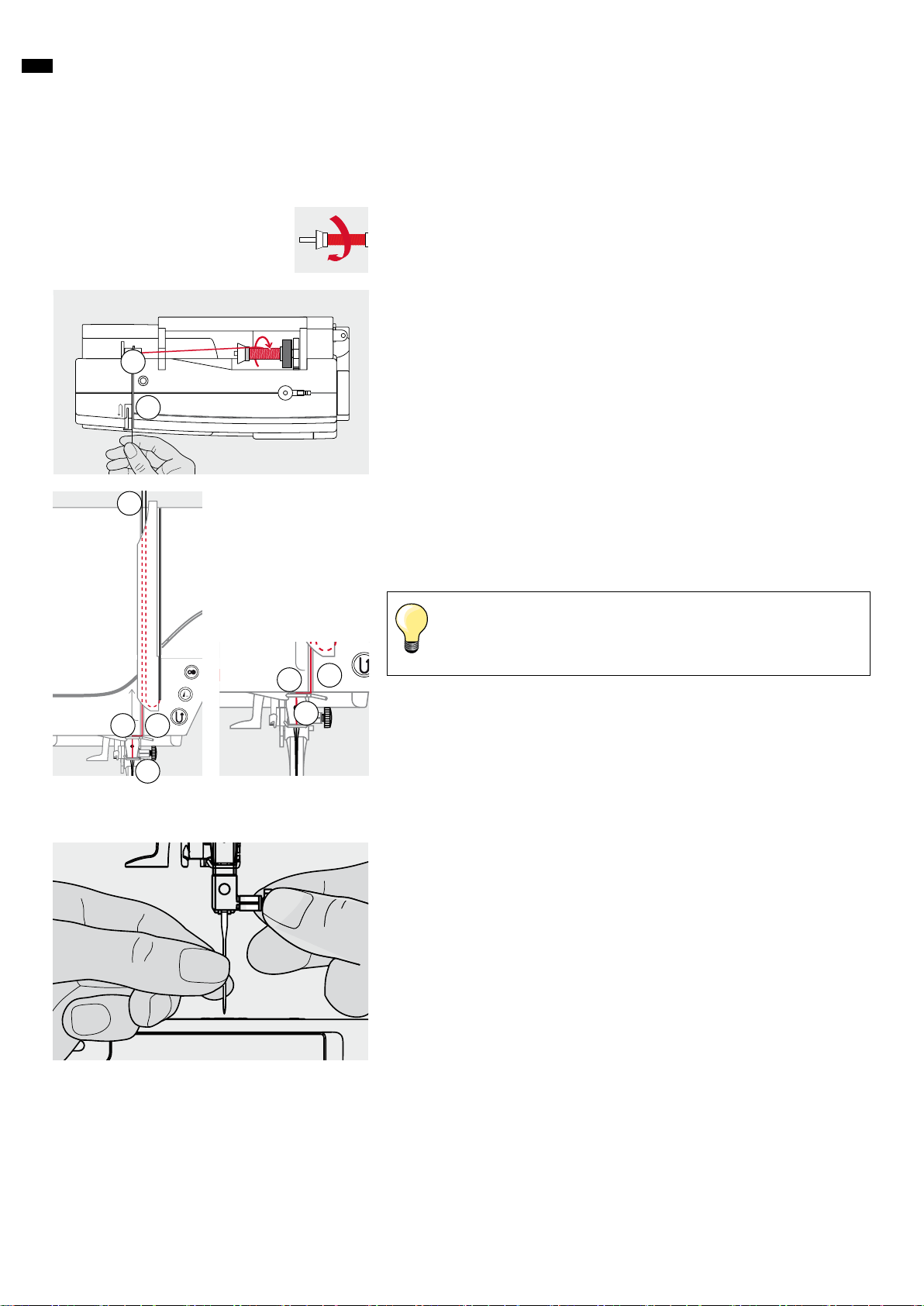

Threading the upper thread

A

B

█

raise the needle and presser foot

█

turn power switch to «0» (off)

█

place foam pad on pin base

█

place spool on pin so that the thread unwinds clockwise

█

attach appropriate spool disc

█

take thread through rear guide A

█

then into slit of upper thread tension B

D

CE

F

Changing the needle

█

pull thread down to the right of the take-up cover and around C

█

take thread up to the left of the cover and around D, placing it in the

take-up lever

█

take thread down and through guides E and F

█

thread the needle (see page 18)

Appropriate spool disc

Diameter of thread spool determines disc size, there must be no gap

between the disc and the spool.

C

E

F

Removing the needle

█

raise needle

█

lower or remove presser foot (see page 12)

█

turn power switch to «0» (off)

█

loosen the needle clamp screw

█

pull the needle down to remove

Inserting the needle

█

flat side of needle to the back

█

insert the needle as far as it will go

█

tighten the needle clamp screw

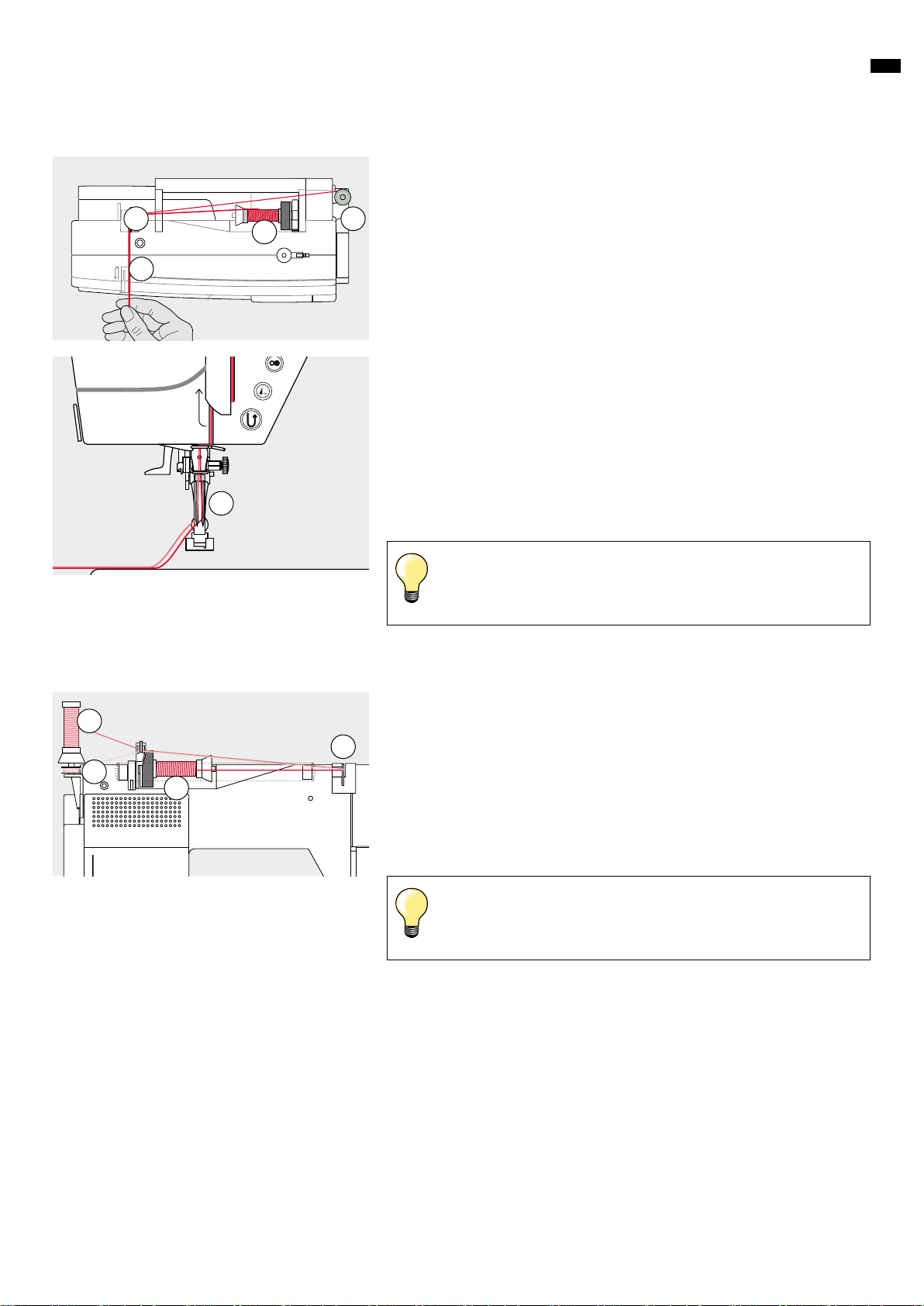

Threading the double needle

033471.52.04_2014-02_Manual_B530_550_EN

B

C

A

E

Threading the first thread

█

turn power switch to «0» (off)

█

insert double needle

█

D

raise the needle and presser foot

█

place foam pad on pin base

█

place thread spool C on horizontal spool pin

█

attach appropriate spool disc

█

take thread through rear guide B

█

guide the thread to the front in the slit and past the tension disc A on the

right side

█

guide the thread to the needle as usual and

█

thread the right needle manually

Threading the second thread

█

place foam pad on vertical spool pin

█

place the second thread spool D on the vertical spool pin

█

take thread through rear guide B

█

guide the thread to the front in the slit and past the tension disc A on the

left side

█

guide the thread to the needle as usual and

█

thread the left needle manually

Threads E must not be twisted together.

Sewing preparation

17

Threading the triple needle

3

2

1

When using the vertical spool pin, always add a foam pad.

Two thread spools and one full bobbin are needed.

█

insert triple needle

█

A

A

place one thread spool 1 on horizontal spool pin

█

place second thread spool 3 and the bobbin 2, separated by a spool disc,

on vertical spool pin (both spools must to turn in the same direction)

█

thread as usual and

█

guide two threads on the left side of the tension disc A and one thread

past the right side

█

guide threads to the needle as usual

█

and thread every needle manually

The thread deduction of the superimposed thread spools can be

improved by the additional eyelet for metallic and silk threads

(optional accessory).

18

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

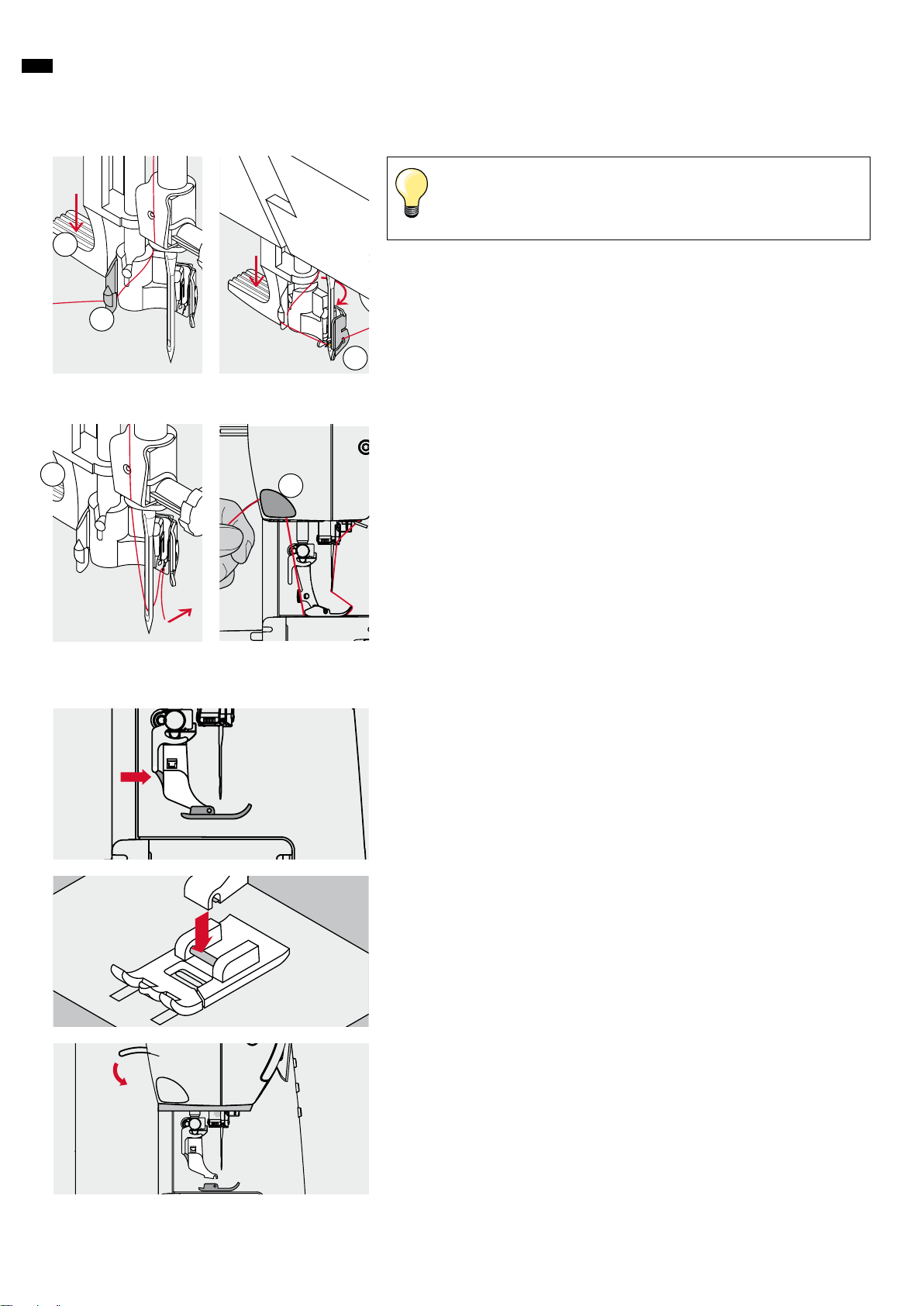

Thread needle

A

B

A

Position the needle upper by pressing the foot control once

(1 stitch).

█

raise needle

█

lower presser foot

█

turn power switch to «0» (off)

█

hold thread to the left and back

█

press lever A down and hold it

█

C

guide thread around the hook B to the right in front of the needle

█

put the thread from the front into the guide C until it catches in the wire

hook

█

release lever A

►

needle is threaded

█

pull the thread to the back and

D

█

put the thread under the foot and pull it from front to back over the thread

cutter on left side of the head frame D, cut

Threads release automatically as soon as the first stitch is sewn.

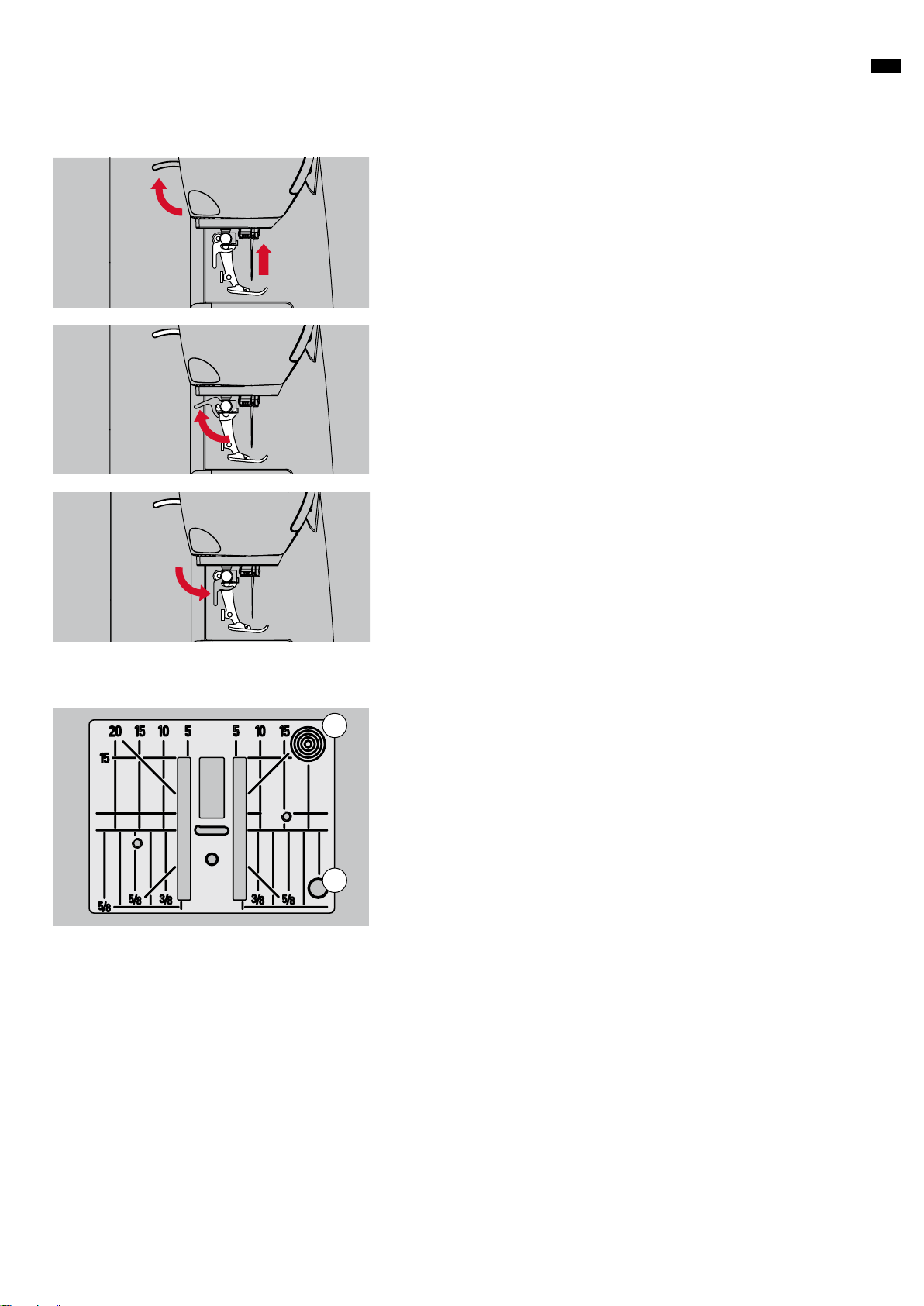

Changing the presser foot sole

3

Remove presser foot sole

█

raise the needle and presser foot

█

turn power switch to «0» (off)

█

press the button on the shaft

►

the sole is released

Attaching the presser foot sole

█

place the presser foot sole under the shaft

█

the peg sits under the opening of the shaft

█

lower the presser foot lifter

►

the foot sole will click into position

Changing the presser foot

033471.52.04_2014-02_Manual_B530_550_EN

Remove presser foot

█

raise the needle and presser foot

█

turn power switch to «0» (off)

█

raise the clamping lever

█

remove the presser foot

Attaching the presser foot

█

guide the foot upwards over the cone

█

press the clamping lever down

Sewing preparation

19

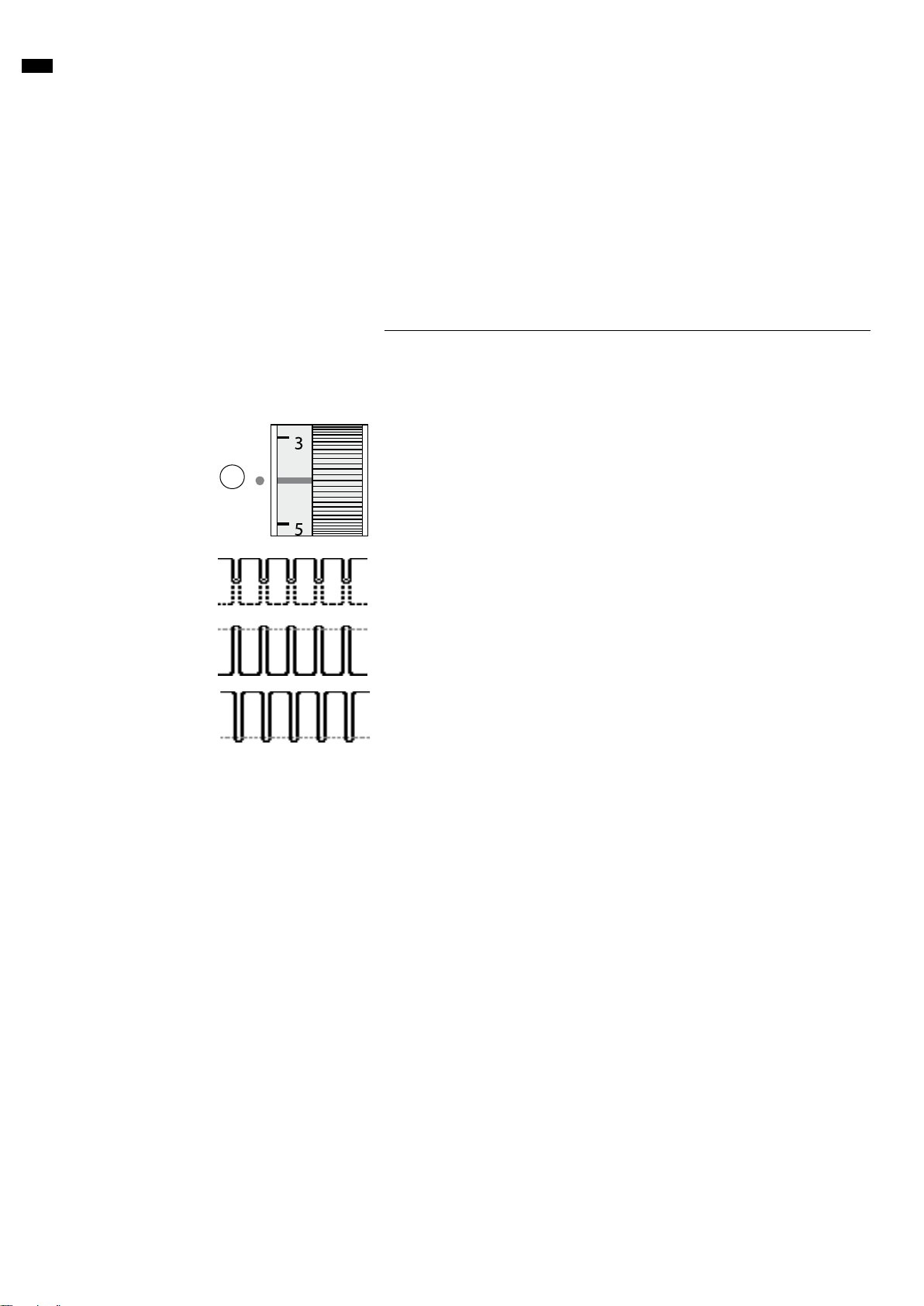

Stitch plate

A

Stitch plate markings

the stitch plate is marked with vertical, horizontal and diagonal lines in mm

and inches

the lines help to guide the fabric for sewing seams and precise

topstitching, etc.

the horizontal markings are helpful for sewing corners and buttonholes, etc.

the diagonal markings are useful for quilting

needle insertion point is position «0» (center needle position)

the vertical measurements correspond to the distance between the needle

B

and the line

the measurements are marked to the right and left, measuring from the

center needle position

Remove the stitch plate

█

press «Feed dog»-button (see page 11)

►

the feed dog is lowered

█

turn power switch to «0» (off)

█

remove presser foot and needle

█

press the stitch plate down at the right back corner A until it flips up

█

remove the stitch plate

Replace the stitch plate

█

place the stitch plate over the opening B

█

press down until it clicks into place

█

press «Feed dog»-button

►

the feed dog is raised as soon as the first stitch is sewn

20

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

Thread tension

The upper thread tension is set optimally at the BERNINA factory

and the sewing computer has been tested. Metrosene-/Seralon thread

size 100/2 (Company Mettler, Switzerland) are used for upper and lower

thread.

In case of using other types of sewing or embroidery threads, the optimal

tension may vary. Therefore it may be necessary to adjust the tension to suit

the fabric and the desired stitch pattern.

For example:

Tension Needle

Metallic thread approx. 3 90

Monofilament thread approx. 2-4 80

The basic setting

is indicated when the red line on the tension adjustment wheel is in line with

A

the marking A

the thread tension needn't be altered when sewing standard fabric

for special fabric, the tension can be adjusted by turning the tension

adjustment wheel to suit the material

Perfect Stitch Formation

The interlooping of the threads is in the material.

Upper thread tension too tight

The lower thread is pulled more up, i.e. to the right side of the material.

█

to reduce the upper thread tension = turn tension adjustment wheel to 3-1

Upper thread tension too loose

The upper thread is pulled more down, i.e. to the wrong side of the material.

█

to increase the upper thread tension = turn tension adjustment wheel

to 5-10

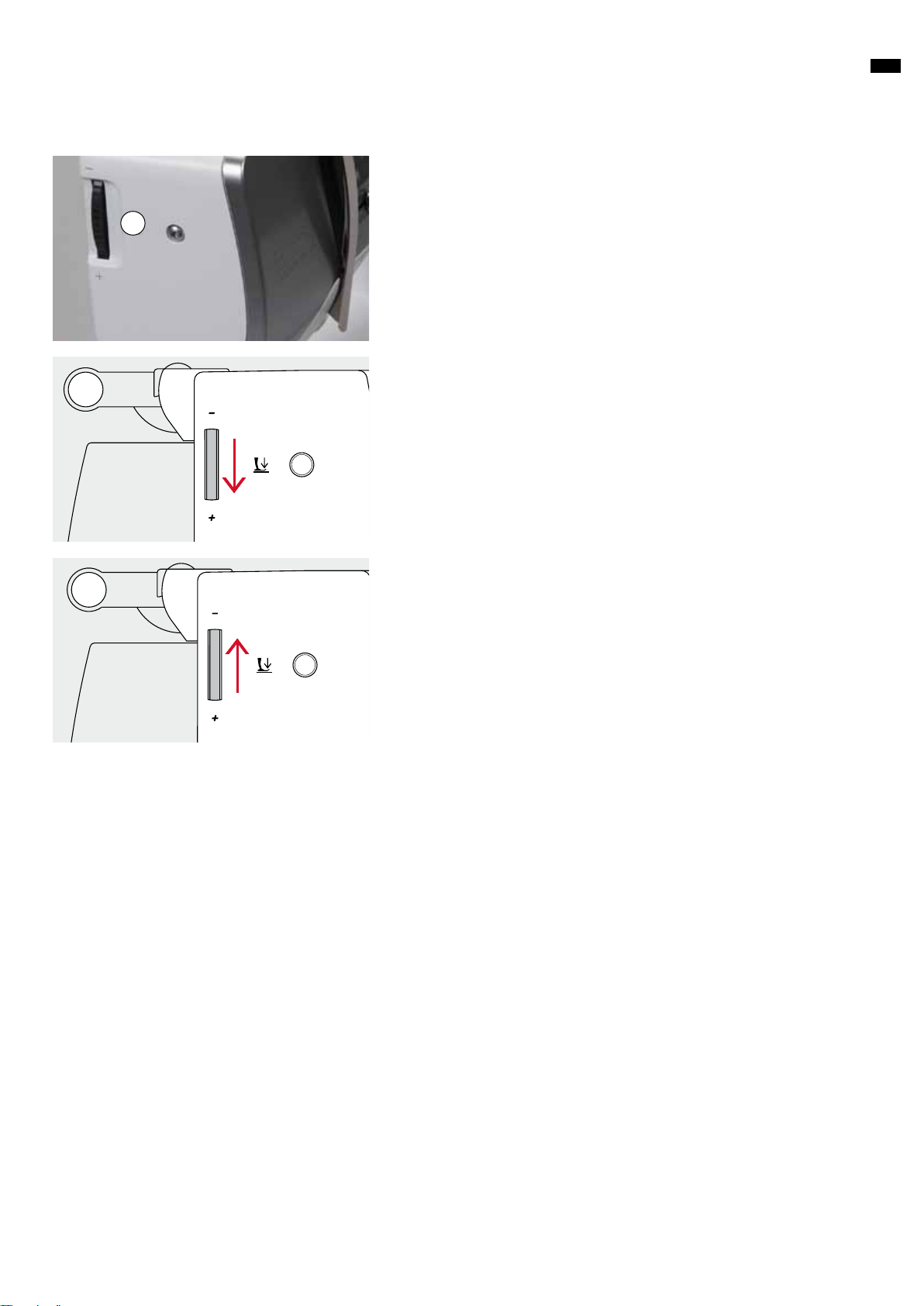

Adjusting presser foot pressure

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

The presser foot pressure is adjusted by the presser foot pressure adjustment

wheel A on the left side of the headframe.

21

A

Presser foot pressure

Basic setting = 46

►

the basic setting is always visible

for basic fabric

Increase presser foot pressure

for sturdy material e.g. denim

improves the fabric feed

Loosen pressor foot pressure

for jersey fabrics and loose knits

to prevent fabric from stretching

█

adjust pressure so that the fabric still feeds correctly

22

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

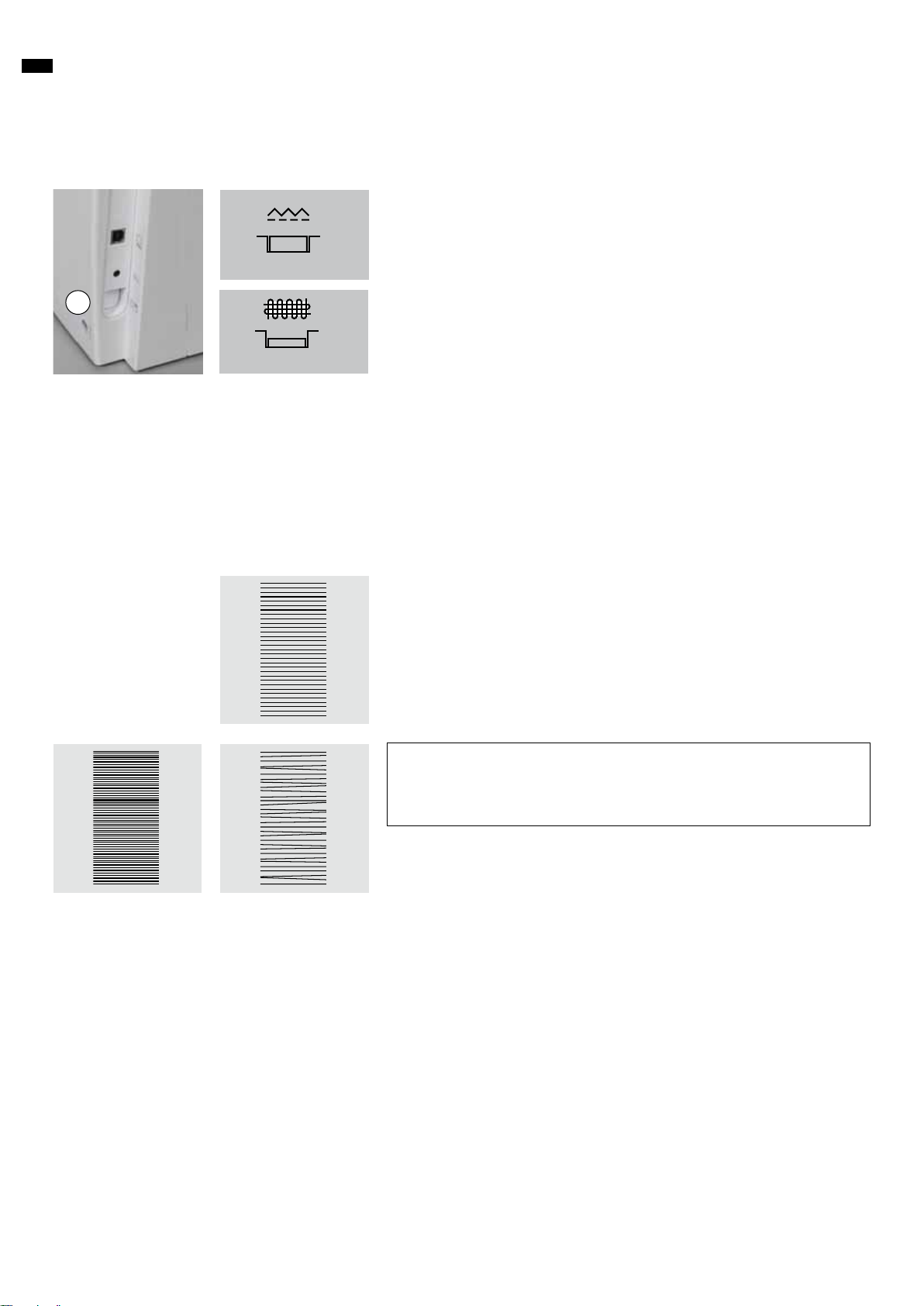

Feed dog

Feed dog lowered/ready to sew

«Feed dog»-button A flush with housing.

►

feed dog is ready to sew

A

Feed dog and fabric feed

«Feed dog»-button A pressed.

►

feed dog is lowered

For free-motion sewing (darning, embroidery, quilting, etc.).

With each stitch the feed dog moves forward by one step. The length of this

step is determined by the stitch length selected.

With an extremely short stitch length, the steps are also very short. The fabric

moves away from the foot quite slowly, even at full sewing speed. e.g. buttonholes, satin stitch and decorative stitches are all sewn with a very short stitch

length.

Let the fabric feed evenly.

ATTENTION!

Pulling, pushing or holding back the fabric can result in

damages of the needle and stitch plate.

Pulling, pushing or holding back the fabric will result in uneven stitches.

Important facts about thread and needle

033471.52.04_2014-02_Manual_B530_550_EN

Thread

The thread is chosen according to use. For a perfect sewing result, thread and

fabric quality play an important role. It is recommended to use quality brands.

Cotton thread

cotton thread has the advantage of being a natural fiber and therefore is

especially suitable for sewing cotton fabrics

if cotton thread is mercerized, it has a slight sheen that is not lost with

washing

Polyester thread

polyester thread has a high tensile strength and is particularly colorfast

polyester thread is more flexible and is recommended where a strong and

elastic seam is required

Rayon threads

rayon threads are made of natural fibers and have a brilliant sheen

rayon threads are suitable for decorative stitches and achieve a more

beautiful effect

Sewing preparation

23

Needle, thread and material

ATTENTION!

Check the needle condition.

As a guideline: Replace the needle before starting a new

sewing project. A defective needle does not only damage the

sewing project but also the sewing computer.

Care must be taken when choosing needle and thread.

The correct needle size depends on the selected thread and fabric. The fabric

weight and type determine the thread weight, needle size and point form.

24

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

Needles, threads

Correct needle/thread combination

When sewing, the thread should travel smoothly down the long groove on the

front of the needle.

Too thin thread or too thick needle

The thread has too much clearance in the long groove. Skipped stitches and

damage to the thread can occur.

Too thick thread or too fine needle

The thread rubs on the edges of the long groove and can get jammed. This

can cause thread breakage.

Guidelines

Material and thread Needle size

Light materials:

Fine thread (darning thread, embroidery thread) 70-75

Medium materials:

Sewing thread 80-90

Heavy materials:

Sewing thread (quilting thread, topstitching) 100, 110, 120

130/705 H-S/70

2

1

5

3

4

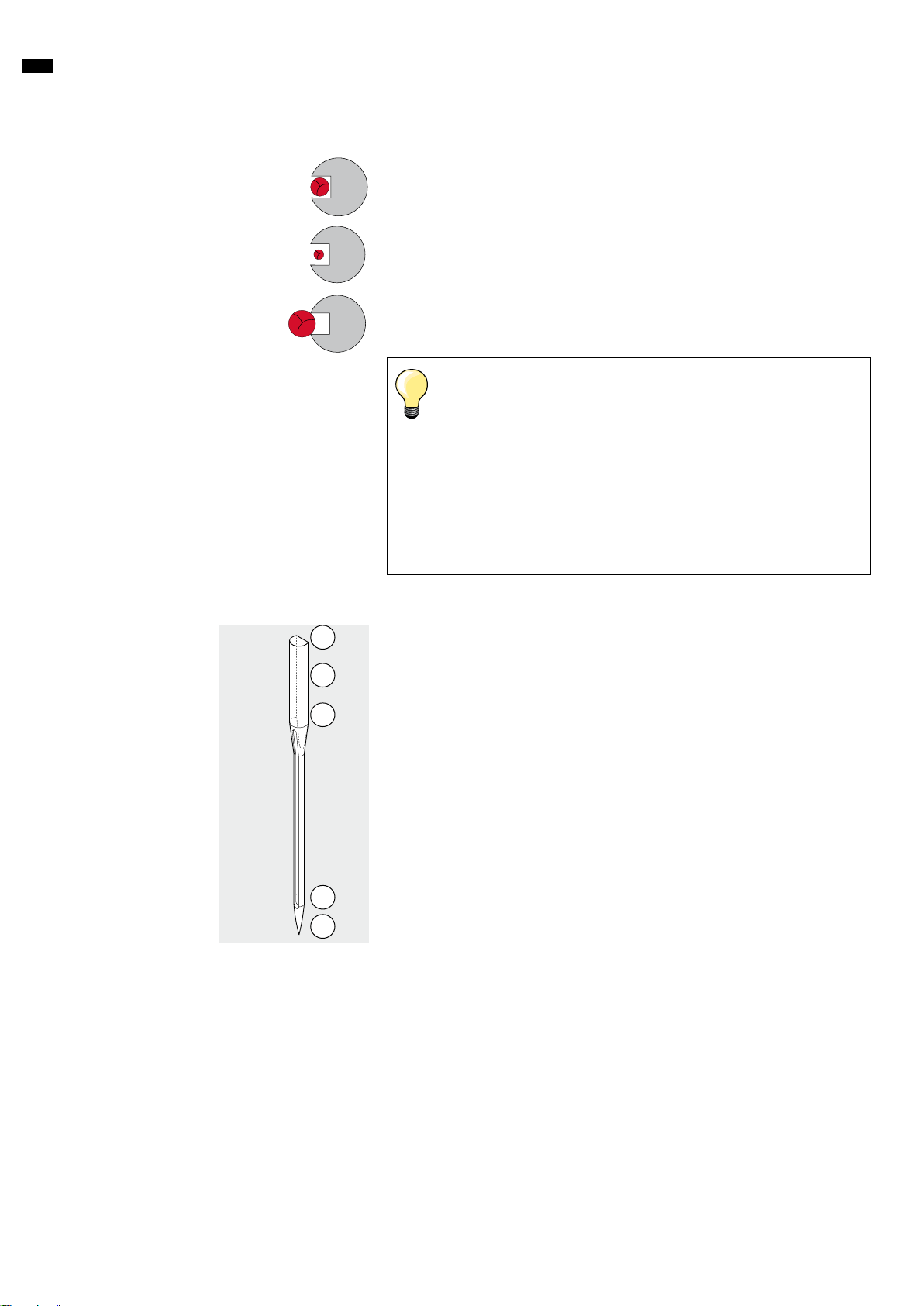

1 130 Shank length

2 705 Flat shank

3 H Needle scarf

4 S Needle point (here e.g. medium ball point)

5 70 Needle size (shank diameter)

Overview needles

033471.52.04_2014-02_Manual_B530_550_EN

Sewing preparation

25

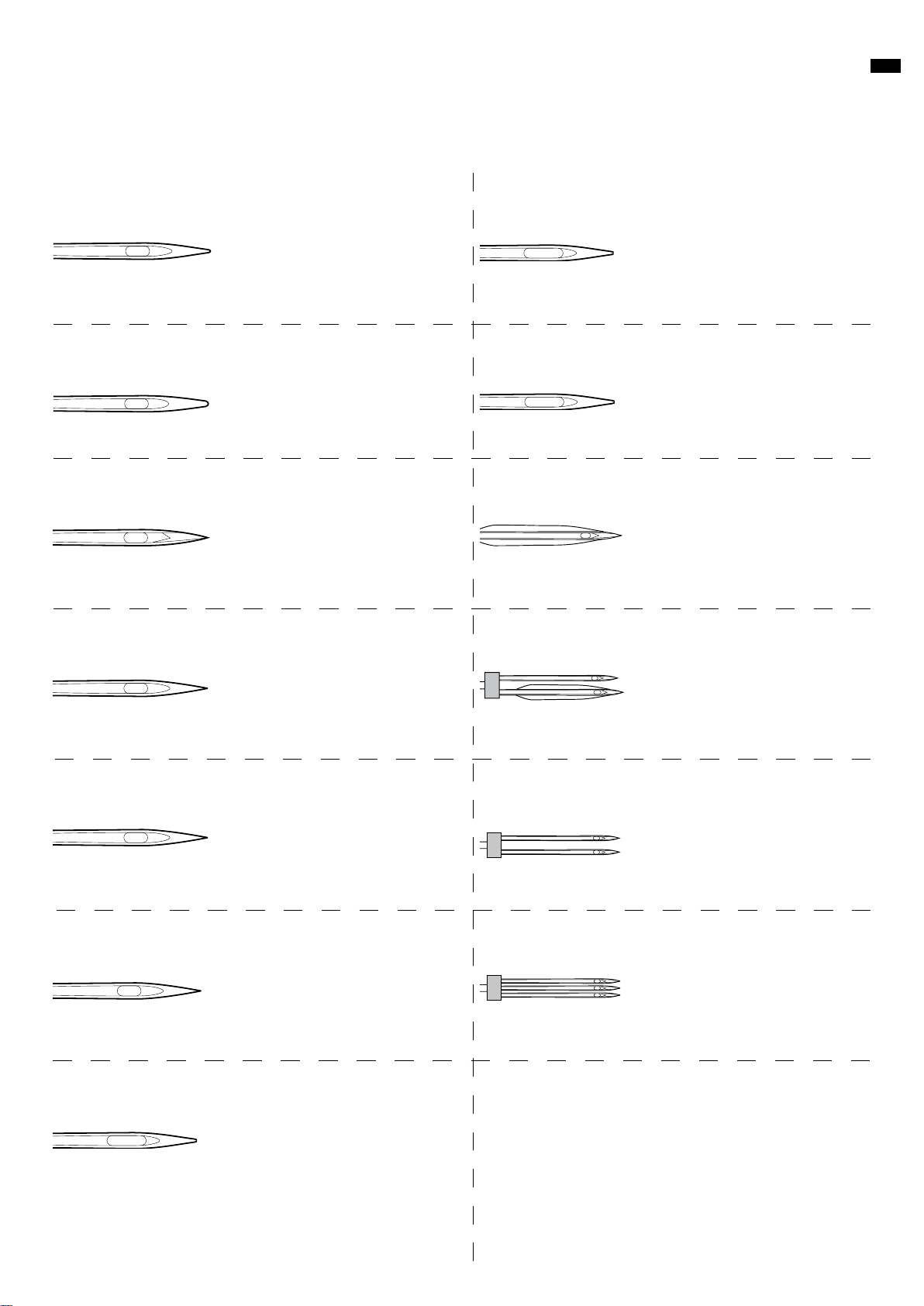

Universal

130/705 H/60-100

Normal point, slightly rounded

For nearly all natural and synthetic

fabrics (woven and knitted)

Jersey/Stretch

130/705 H-S, H-SES, H-SUK/70-90

Ball point

Jersey, knit and stretch material

Leather

130/705 H-LL, H-LR/90-100

With cutting point

All types of leather, synthetic leather,

plastic, sheeting

Metafil

130/705 H-MET/75-80 or

H-SUK/90-100

Large eye

Sewing with metallic threads

Cordonnet (Topstitching)

130/705 H-N/80-100

Small ball point, long eye

Topstitching with thick thread

Wing needle (hemstitch needle)

130/705 HO/100-120

Wide needle (wing)

Hemstitching

Jeans

130/705 H-J/80-110

Very fine sharp point

Heavy weight fabrics such as jeans,

canvas, overalls

Microtex

130/705 H-M/60-90

Especially fine sharp point

Mircro fiber fabrics and silk

Quilting

130/705 H-Q/75-90

Fine sharp point

Straight and topstitching

Double wing needle

130/705 H-ZWI-HO/100

Special effects with hemstitch

embroidery

Double needle

130/705 H-ZWI/70-100

Needle distance: 1.0/1.6/2.0/2.5/3.0/4.0

Visible hems in stretch fabrics, pintucks,

decorative sewing

Triple needle

130/705 H-DRI/80

Needle distance: 3.0

Visible hems in stretch fabrics, pintucks,

decorative sewing

Embroidery

H-SUK/70-90

Large eye, slight ball point

Embroidery on all natural and synthetic

fabrics

26

033471.52.04_2014-02_Manual_B530_550_EN

Functions - «Function»-buttons sewing computer

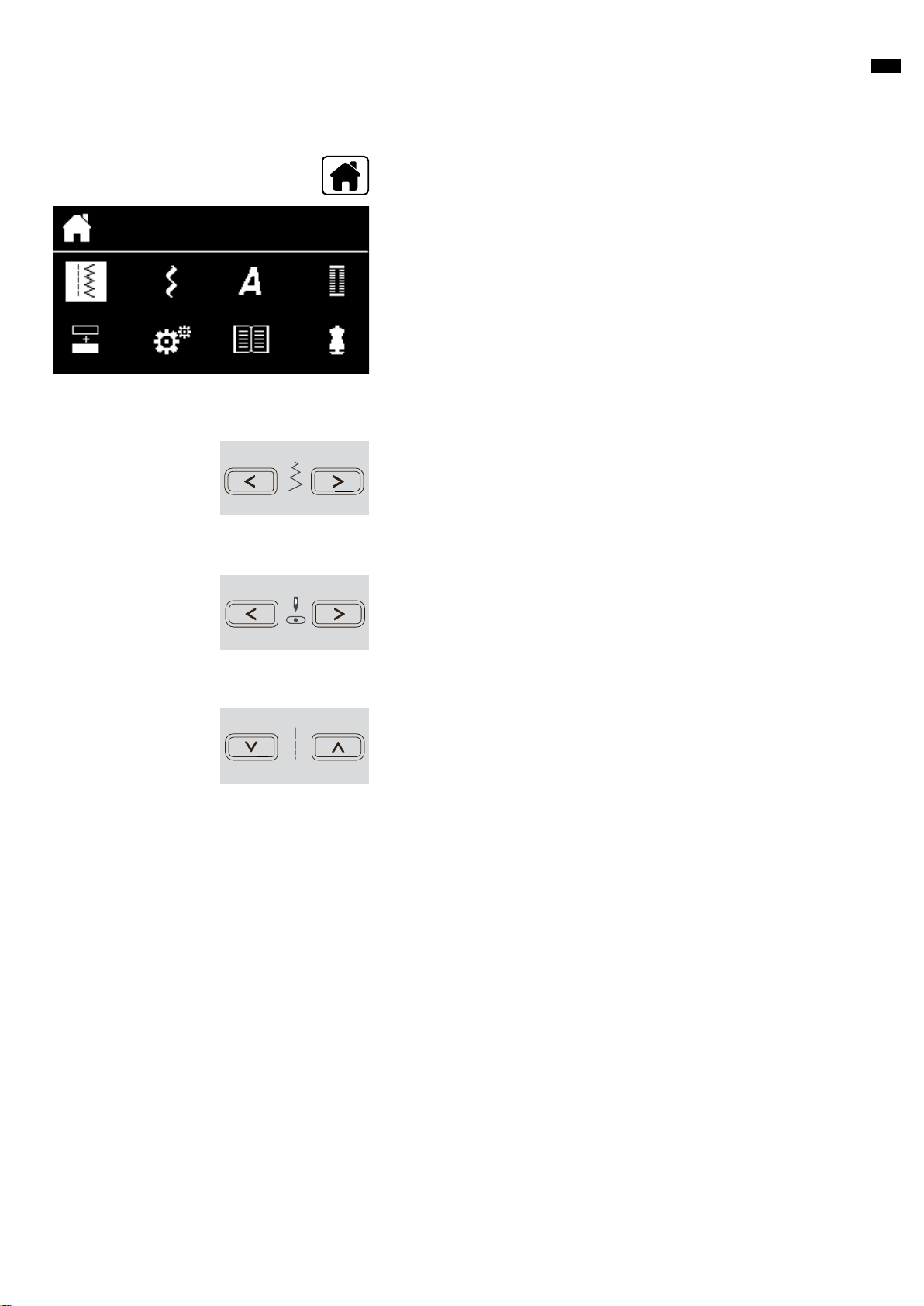

Overview «Function»-buttons sewing computer

Stitch selection

«Direct-selection»-buttons

█

select the desired stitch pattern via the «Direct-selection»-buttons

►

stitch pattern, stitch number, stitch length and width are all visible on the

display

The «Direct selection»-button 0 selects stitch number 51 (standard buttonhole).

Stitch categories

033471.52.04_2014-02_Manual_B530_550_EN

Adjusting individually

█

press «Home»-button

█

choose the desired stitch category in the main menu via the

«Navigation»-buttons (see page 29)

█

confirm by pressing the «OK»-button

Altering stitch width

█

press the left button

►

narrows the stitch width

█

press the right button

►

widens the stitch width

█

keep button pressed

►

quick alteration

Functions

27

Altering needle position

█

press the left button

►

needle moves to the left

█

press the right button

►

needle moves to the right

█

keep button pressed

►

quick alteration

Altering stitch length

█

press the left button

►

shortens the stitch length

█

press the right button

►

elongates the stitch length

█

keep button pressed

►

quick alteration

28

033471.52.04_2014-02_Manual_B530_550_EN

Functions

«Function»-buttons sewing computer

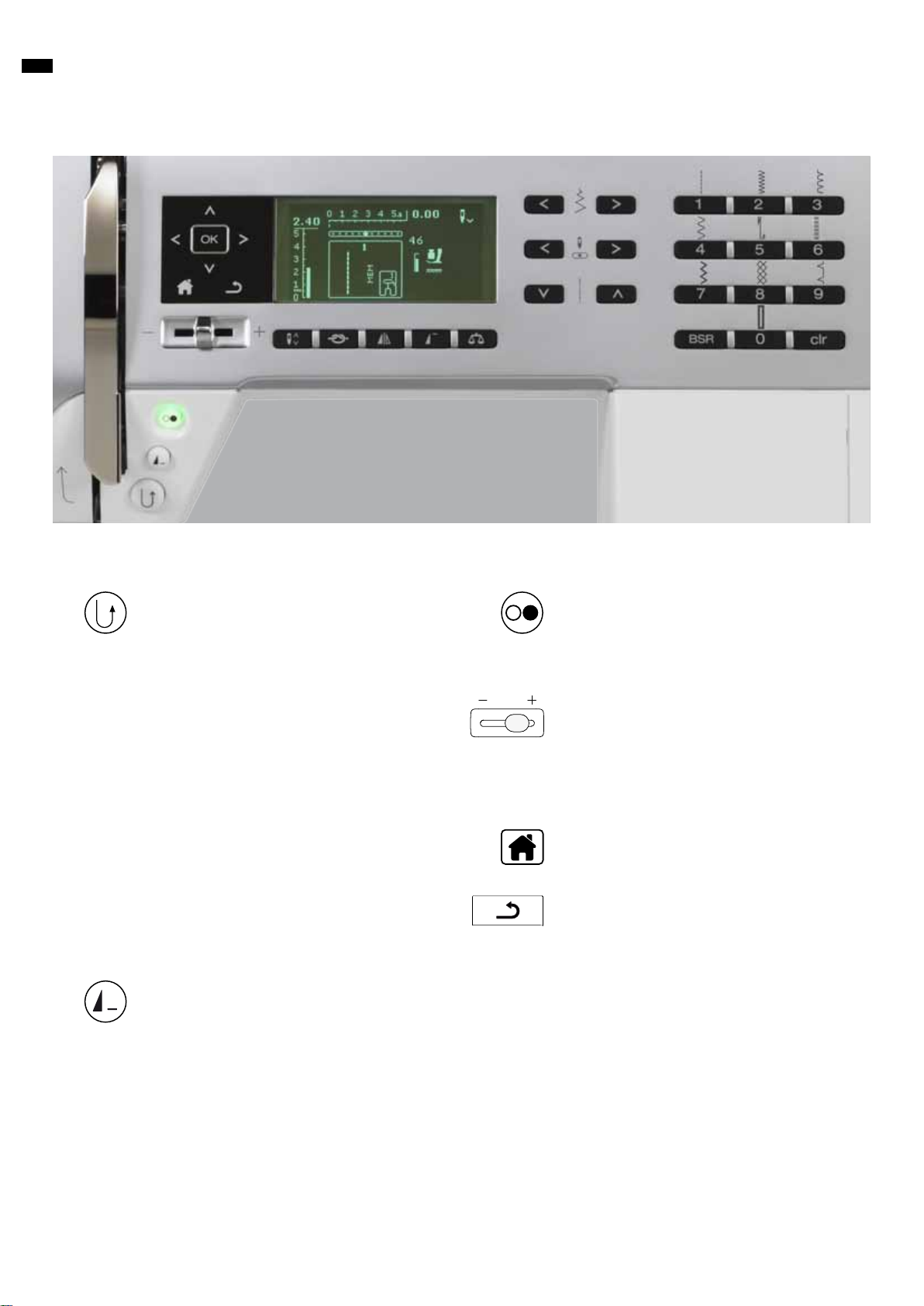

Overview «Function»-buttons

«Quick reverse»-button

temporary:

█

press the button

█

the sewing computer sews stitch pattern in

reverse until button is released

Application:

programs buttonhole length

programs darning length

for switching when in the straight stitch

securing program no. 5

manual securing (seam begin and end)

used for securing in quilters securing program

no. 1324

continuous reverse:

█

press the button at hold until you hear a beep

and

►

the symbol appears on the display

►

the sewing computer sews the chosen stitch

in reverse

█

finish reverse sewing: press button at hold

until you hear a beep

►

the symbol disappears from display

«Pattern end/pattern repeat»-button

█

press button while sewing

►

the sewing computer stops at the end of the

active single pattern or the active pattern in a

pattern combination (in Memory)

█

press the button 1-9x before sewing

►

the pattern end symbol appears on the

display along with the set number of repeats

selected

A single pattern or a pattern combination sews

out the number of repeats set.

«Start/Stop»-button

starts and stops the sewing computer when

operating it with and without foot control

starts and stops the BSR-Function if the BSR

foot is attached and activated

Slide speed control

with the slide of the Slide Speed Control the

sewing speed can be regulated infinitely

variable

while winding the bobbin thread, the speed of

the bobbin winder can be regulated if the

sewing computer is in an idle state

«Home»-button

█

press the button

►

opens the Main Display

«Back»-button

goes one step back

Exception:

decorative stitches

alphabets

Loading...

Loading...