Page 1

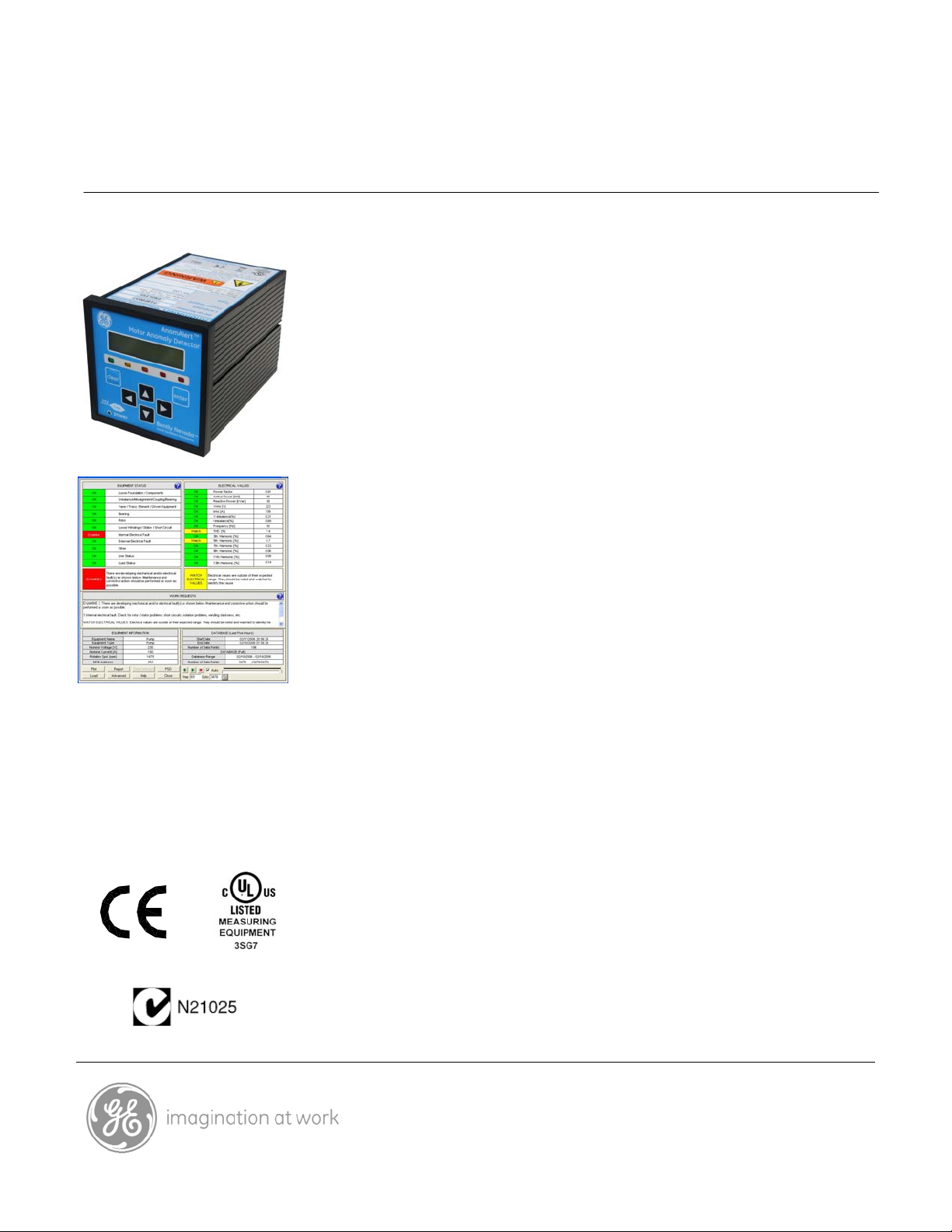

AnomAlert* Motor Anomaly Detector

Bently Nevada* Asset Condition Monitoring

Description

AnomAlert Motor Anomaly Detector continuously identifies existing and

developing faults on electric motors and their driven equipment. AnomAlert

utilizes an intelligent, model-based approach to provide anomaly detection by

measuring the current and voltage signals from the electrical supply to the

motor. It is permanently mounted, generally in the motor control center and is

applicable to 3-phase AC, induction or synchronous, fixed or variable speed

motors. Accompanying AnomAlert Software is used to view the data.

AnomAlert provides both mechanical (unbalance, misalignment, roller bearings,

etc.) and electrical (loose windings, short circuits, etc.) anomaly detection as well

as electrical parameters such as voltage and current imbalances and power

factor. In addition, it can detect changes in the load the motor is experiencing

due to anomalies in the driven equipment or process such as cavitations or

plugged filters and screens. Since it doesn't require any sensor installation on the

motor itself or associated load, AnomAlert is especially attractive for inaccessible

driven equipment and is applicable to most types of pumps, compressors, and

similar loads.

Each motor requires one AnomAlert and it can be configured entirely from the

front panel. Additionally, each AnomAlert includes the AnomAlert Software

necessary to obtain and display data in real-time from the device, to configure

the performance of the device, and to save and subsequently retrieve data for

display from its database. Networking protocols enable monitoring of motors

and processes on remote machines using TCP/IP protocols over the Ethernet.

Specifications and Ordering Information

Part Number 286754-01

Rev. B (10/10)

Page 1 of 8

Page 2

Specifications

Measurement

Voltage Inputs

General

Information

Motor Type

Operation Type

Environmental

Operating

Temperature

Humidity

Inputs

Power Input

Required

3-phase, AC (not suitable for DC

motors)

Fixed speed (line driven)

Variable speed (inverter driven)

Motor current load variation must

be less than 15% during 6 sec data

acquisition period

Not for use with soft-starter

systems unless they are

automatically bypassed

immediately after motor start-up

and during subsequent use

Continuous

32 – 104⁰ F (0 – 40⁰ C)

Up to 90% RH, non-condensing

Use UL listed fuse with proper

voltage rating:

100-240 Vac (-15%, +10%), 47 – 64

Hz, 19 VA, 200 mA

Low Voltage

AnomAlert

Models (≤480

Vac)

High Voltage

AnomAlert

Models (>480Vac)

Measurement

Current Inputs

Fixed Speed (Line

Driven)

AnomAlert

Models

NOTE: Voltage transformers must

meet local standards and

regulations. For North America,

current and voltage transformers

must be certified by an OSHA

appointed NRTL to appropriate

product safety standards such

as UL or CSA.

Can tap directly off voltage lines to

motor

Three Cat II Voltage Transformers

(supplied by customer): 0.3% to

0.6% accuracy; 100 V, 110 V, or 120

V secondary voltages

NOTE: Current transformers must

meet local standards and

regulations. For North America,

current and voltage transformers

must be certified by an OSHA

appointed NRTL to appropriate

product safety standards such

as UL or CSA.

or

120-300 Vdc, 19 VA, 200 mA

Three 250 Vac, Cat II Current

Transformers (supplied by

customer): 0.3% to 0.6% accuracy,

with either 5A or 1A secondary

outputs depending on AnomAlert

model.

Specifications and Ordering Information

Part Number 286754-01

Rev. B (10/10)

Page 2 of 8

Page 3

Variable Speed

(Inverter Driven)

AnomAlert

Models

Outputs

Alarms

4 Alarm

Parameters:

3 Hall-effect Current Sensors

(supplied by customer): selected

based on the power of the motor to

be monitored; secondaries to be

50-400 mA output, 30 Vac SELV.

Note: Hall-effect Current Sensors

need external power sources,

generally installed in the motor

control panel, too.

Line Change (unexpected change in

incoming power)

Load Change (unexpected change

in process)

Physical

Weight

Line: 2.58 lb (1170 g)

Inverter: 2.16 lb (980 g)

Dimensions

WxHxL

3.78 in x 3.78 in x 5.51 in

(96 mm x 96 mm x 140 mm)

Mounting

Front Panel Mounting (indoor)

Protection Class

Front Panel: IP 40

Whole Unit: IP 20

Indicators

6 LEDs and LCD Readout

Keypad

6 tactile membrane keys

Warnings

Relay

Communications

Examine 1: plan maintenance

Examine 2: perform maintenance

Any measured or calculated

parameter outside its expected

range based on internal data base

and learned mode.

One assignable relay output, user

programmable; NC/NO contacts

RS422/485

RS232 (with additional appropriate

converter)

Ethernet (with additional

appropriate converter)

Compliance &

Certifications

EMC:

Europe:

EMC Directive 2004/108/EC

EN 61000-6-2 Immunity for

Industrial Environments

EN 61000-6-4 Emissions for

Industrial Environments

Australia/New Zealand:

C-tick

IEC 61000-6-2 Immunity for

Industrial Environments

IEC 61000-6-4 Emissions for

Industrial Environments

Specifications and Ordering Information

Part Number 286754-01

Rev. B (10/10)

Page 3 of 8

Page 4

Electrical Safety:

Europe:

Electrical Safety Directive 2006/95/EC

EN 61010-1 Safety

Requirements for Electrical

Equipment

North America:

UL Listed, Canada and US

UL 61010-1 Safety

Requirements for Electrical

Equipment

Australia/New Zealand:

C-Tick

IEC 61010-1 Safety

Requirements for Electrical

Equipment

Ordering Information

Order one AnomAlert per motor to be monitored. Each

AnomAlert includes the AnomAlert Software on CD.

Additionally, the CD includes the AnomAlert Manual,

AnomAlert Software Manual and Quick Install Guides.

The CTs, PTs, and CSs are customer supplied. Refer to

Measurement Inputs section of Specifications Section

above.

AnomAlert Motor Anomaly Detector

390100 – AXX – BXX – CXX - DXX

A: Motor Voltage

0 1 Low ( ≤ 480 Vac)

0 2 Medium/High ( > 480 Vac)

B: Motor Speed Type

0 1 Fixed (line driven)

0 2 Variable (inverter driven)

C: Motor Amperage (or CT secondary output)

For use with fixed speed only (B=01)

0 1 1 A (CT secondary)

0 2 1 - 5 A (CT secondary)

For variable speed only (B=02)

0 3 5 - 100 A

0 4 100 – 500 A

0 5 500 – 1000 A

0 6 1000 – 2000 A

D: Language

0 1 English

Converters

287127-01

RS 232/485 to RS 422 converter, with

power supply adapter. Kit includes sam

ple

cable for connection to AnomAlert, and

sample cable for interconnection betwee

converter and PC (1 required for each PC

to which daisy-chained AnomAlerts will be

connected).

287128-01

Moxa* Nport* DE-311 RS422 to TCP/IP

Ethernet converter with null modem mi

ni

adapter. Kit includes sample cable for

connection to AnomAlert and a sample

cross-cable for Ethernet connection.

AnomAlert Manuals

Are included in electronic format on AnomAlert Software disk

that comes with each AnomAlert. Can be ordered as

hardcopies using the following part numbers.

286868-01 Software Manual

286869-01 Users Manual

AnomAlert Quick Install Guides

Are included in electronic format on AnomAlert Software disk

that comes with each AnomAlert. Can be ordered as

hardcopies using the following part numbers.

286870-01 Low Voltage, Line

286871-01 Low Voltage Invert

286872-01 Med/High Voltage, Lin

286873-01 Med/High Voltage, Inverter Mod

er

e Model

el

286874-01 RS485-RS422

286875-01 TCP/IP

286876-01 Software TCP/IP

AnomAlert Software

Comes with each AnomAlert unit. Can be ordered separately

using the following part number.

390120-01 AnomAlert Sof

tware

n

Specifications and Ordering Information

Part Number 286754-01

Rev. B (10/10)

Page 4 of 8

Page 5

Graphs and Figures

Figure 1: Model Number Selection: Fixed Speed

Specifications and Ordering Information

Part Number 286754-01

Rev. B (10/10)

Page 5 of 8

Page 6

Figure 2: Model Number Selection: Variable Speed, Low Voltage

Specifications and Ordering Information

Part Number 286754-01

Rev. B (10/10)

Page 6 of 8

Page 7

Figure 3: Model Number Selection: Variable Speed, Medium Voltage

Specifications and Ordering Information

Part Number 286754-01

Rev. B (10/10)

Page 7 of 8

Page 8

*Denotes a trademark of Bently Nevada, Inc., a wholly owned subsidiary of General Electric Company:

AnomAlert

Bently Nevada

**The following are trademarks of the legal entities cited:

Moxa® is a trademark of Moxa, Inc.

Nport® is a trademark of Moxa, Inc.

© 2010 Bently Nevada, Inc. All rights reserved.

Printed in USA. Uncontrolled when transmitted electronically.

1631 Bently Parkway South, Minden, Nevada USA 89423

Phone: 775.782.3611 Fax: 775.215.2873

www.ge-energy.com/bently

Specifications and Ordering Information

Part Number 286754-01

Rev. B (10/10)

Page 8 of 8

Loading...

Loading...