Page 1

3701/40 ADAPT Machinery Dynamics

Monitor

Datasheet

Bently Nevada Machinery Condition Monitoring

Advanced Distributed Architecture Platform Technology - ADAPT

The Bently Nevada Advanced Distributed Architecture

Platform Technology, or ADAPT 3701, is a family of compact,

high performance safety and machinery protection and

condition monitoring solutions. ADAPT products are targeted

at specific assets and applications, and excel at the intensive

signal processing necessary to identify early indicators of

machine failure modes long before an alarm.

Description

The 3701/40 Machinery Dynamics (MD) Monitor is designed for

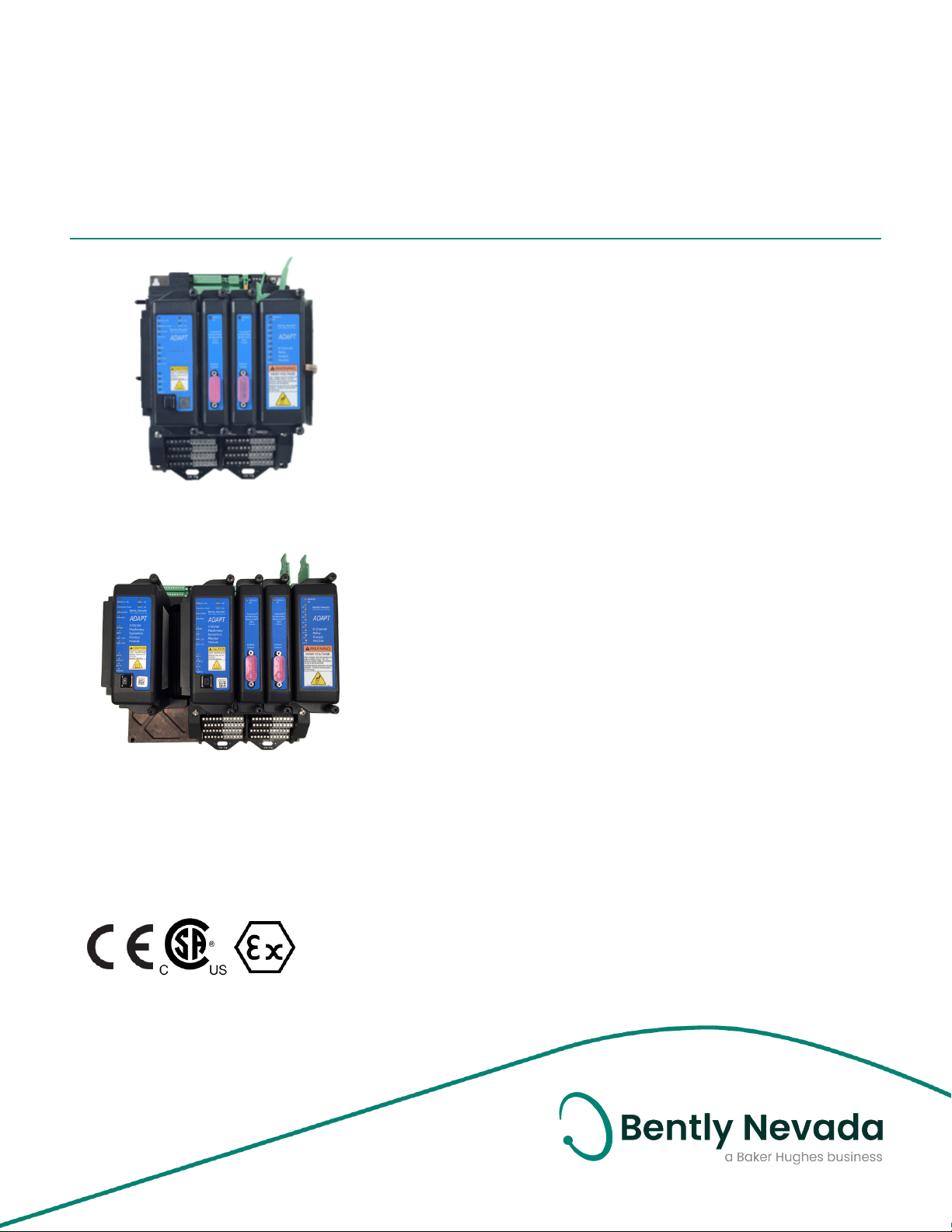

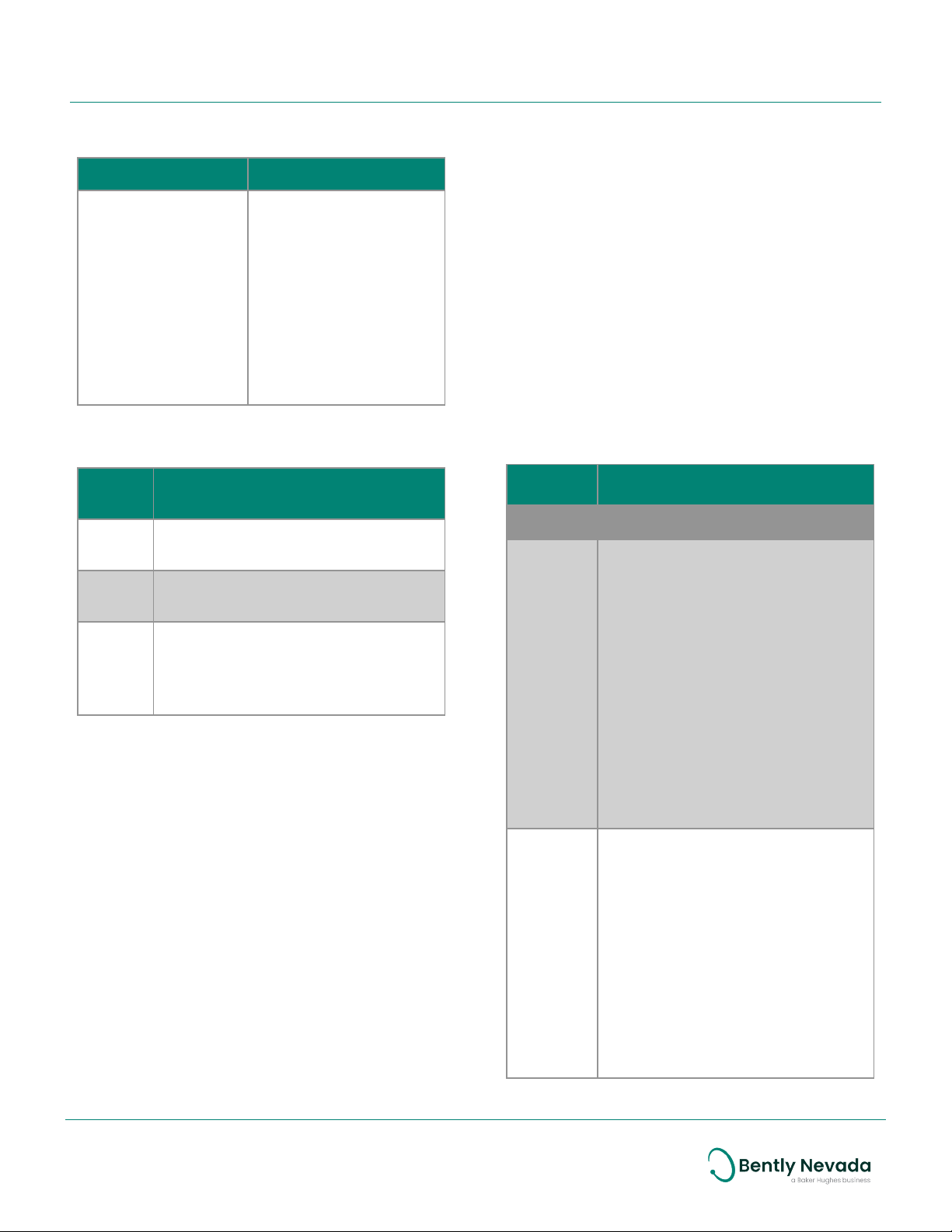

3701/40 Simplex

use on a broad range of machine trains or individual casings

where the sensor point count fits the monitor’s channel

count and where advanced signal processing is desired. The

3701/40 is optimized for intensive signal processing required

on complex machinery such as gearboxes, planetary

gearboxes, and roller element bearing (REB) machines as well

as offering advanced measurement capabilities on

conventional monitoring methods such as radial vibration,

thrust position, and casing absolute vibration. The 3701/40

Dual Redundant (DR) monitor is designed for applications

that require a higher level of reliability from the vibration

system.

103M2037 Rev. J

3701/40 Duplex

The 3701/40 has a rugged industrial design allowing it to be

skid mounted close to the machine and reduce installation

wiring. Its compact size provides more mounting options

compared to traditional rack based solutions. It is capable of

accepting a wide array of sensor types, including eddy

current proximity probes, accelerometers, velocity,

acceleration, dynamic pressure, Integrated Circuit

Piezoelectric Sensors (IEPE), and magnetic speed pick-ups.

The 3701/40 is configured and validated with Bently Nevada

Monitor Configuration (BNMC) software. BNMC is a simple and

powerful configuration and verification software. It is ordered

separately and is required for operation.

Page 2

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

The 3701/40 MD Monitor is a self-contained

device that is ordered with a single part number

for either a simplex or duplex terminal base and

is made up of the following major components:

Part

3701 Simplex

Terminal Base

3701 Processor

Module

3701 Input Module 1 or 2

3701 Output

Module

Part

3701 Duplex

Terminal Base

3701 Processor

Module

3701 Input Module 1 or 2

3701 Output

Module

Quantity Required in

each 3701/40

1

1

1 or none

Quantity Required in

each 3701/40

1

2

1 or none

3701/40 Overview

protection system that utilizes dual redundant

processor modules.

In the DR version, each processor module is

identically configured and redundantly digitizes

and processes all sensor inputs, executes

identical logic, and each processor module

independently drives separate alarm relays.

3701 Digital Communications

The 3701/40 has two independent Ethernet

physical RJ45 connections per CPU for digital

communication with Bently Nevada software

products hosted on network computers and

plant automation systems. It uses a

proprietary Ethernet protocol for

communicating with System_1_Evolution

software and the BNMC configuration software.

The 3701/40 includes two Ethernet ports per CPU

which provide Ethernet TCP/IP communications

capabilities. Standard industrial protocols are:

l Modbus TCP/IP

Modbus over Ethernet is available for

connection to HMI’s, unit control systems, or

other plant automation equipment. The 3701

can only be configured as a server.

l Ethernet Global Data (EGD)

EGD is a GE protocol used on Mark VI and Mark

Vie controllers and by GE Programmable

Automation Controllers and certain 3rd party

automation equipment.

The 3701/40 is a robust, compact, selfcontained 12-channel device with

sophisticated signal processing capability and

with a form-factor suitable for distribution close

to machinery. It has a modular construction

that allows field changing of components and

is fully-configurable. It combines protection

and condition monitoring (CM) in a single

package. With the ability to define

measurements and alarms within the monitor,

it can act as a stand-alone protection and CM

system. There is no need for any interaction

with external software to trigger or control the

monitor during operation.

The 3701/40 DR Machinery Dynamics Monitor is

a compact, field mountable, vibration

3701/40 System Description

The 3701/40 monitor is powered by single or

dual redundant external +24 V DC power. It

consists of four main physical components: the

terminal base (single or dual), one or two

processor modules, one or two input modules,

and an output module.

The terminal base is the mounting platform for

the monitor. The different modules install into

the terminal base and two pluggable field

wiring termination blocks plug into the terminal

base. Sensor wiring terminates on the wiring

blocks and terminations for discrete inputs

(Reset, Trip Multiply, etc.) terminate directly on

2/25

Page 3

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

the base but on the opposite side from sensor

wiring.

The processor module is the monitor’s CPU. It is

the center of the logic and signal processing for

the monitor.

There are two terminal base configurations:

l A simplex base, which contains 1 CPU

processor card

l A duplex base which contains 2 CPU

processor cards.

The use of 2 processor cards allows for

redundancy for all the dynamic

measurements; both processors have access

to all signal channels from each input module.

The input modules are the interface to the

sensors. Each input module type covers

multiple sensor varieties but due to the number

of sensor types there are different input

modules. The input modules condition the

analog sensor signals for delivery to A/D

conversion on the processor module. The input

modules are simple, reliable, analog circuitry

but with a simple microcontroller (outside the

protection path) to provide diagnostics and

fault detection on each module. Buffered

transducer outputs are provided at a multi-pin

Dsub connector on each input module. An

accessory cable is available to fan the buffered

outs to BNC or ADRE 408 Dspi compatible

connectors.

Processor Module

The processor module, or CPU module,

performs A/D conversion, digital signal

processing, alarm and logic processing, and

communications to Bently Nevada software

and plant automation systems. The CPU

module employs sophisticated diagnostics

and fault detection processing to enhance

reliability, availability, and maintainability of the

protection and monitoring system.

Input Modules

3701 Proximitor Accelerometer

Velomitor (PAV) Input Module

The 3701 PAV input module is a 6-channel +

Keyphasor/speed input module that interfaces

to a variety of sensors such as: -24 Volt

Proximitor sensors, -24 Volt 3-wire

Accelerometers, Velomitors, and constant

current 2-wire sensors that are compatible with

the -24 Volt 2-wire Velomitor interface.

Any of the PAV’s six channels (1 – 6) can be

independently configured for one of the

supported transducers. Each PAV supports one

dedicated Keyphasor or speed measurement

on channel 7 that is configurable for Proximitor

sensors or magnetic pick-ups.

3701 Proximitor Accelerometer

Seismic (PAS) Input Module

The output modules are for monitor outputs

such as relay contacts. At the current time only

the 8-Channel Relay Output Module is

available. It contains 8 programmable SPDT

relays and a dedicated monitor Protection

Fault (OK) Relay. Relay logic is created in the

BNMC software using the graphical logic editor.

The 3701 PAS input module is a 6-channel +

Keyphasor/speed input module that interfaces

to a variety of sensors such as: -24 Volt

Proximitor sensors, -24 Volt 3-wire

Accelerometers, 2-wire Seismoprobes and

compatible 3rd party inertial mass velocity

sensors, or dynamic pressure sensors.

Any of the PAS’s six channels (1 – 6) can be

independently configured for one of the

supported transducers. Each PAS supports one

dedicated Keyphasor or speed measurement

on channel 7 that is configurable for Proximitor

sensors or magnetic pick-ups.

3/25

Page 4

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

3701 Positive (PoV) Input Module

The 3701 PoV input module is a 6-channel +

Keyphasor/speed input module that interfaces

to a variety of positively powered sensors such

as: +24 V Proximitor sensors, +24 V Interface

modules, and 2 wire IEPE sensors using 3.3 mA

constant current.

Any of the PoV's six channels (1-6) can be

independently configured for one of the

supported transducers. Each PoV supports

one dedicated negatively powered Keyphasor

or speed measurement on channel 7 that is

configurable for Proximitor sensors or magnetic

pick-ups.

The POV is intended for interfacing to industry

standard 3rd party ICP sensors and also

sensors that use a 3 wire (power, common,

signal) positive voltage interface.

The POV is available for use with the 3701/40,

3701/44 Aeroderivative Gas Turbine Monitor, and

3701/46 Hydro Monitor.

Output Modules

3701 8-Channel Relay Output

Module

The 3701 8-Ch Relay Output Module provides 8

SPDT relay outputs or 4 "virtual" DPDT outputs

and a dedicated Protection Fault relay. Relay

logic is user programmable in the BNMC

software using the graphical logic editor. The

processor module operates on the relay logic

to drive relay state.

The Protection Fault relay is a normally

energized SPDT relay that will de-energize on

fault conditions that can compromise the

monitor’s availability to protect machinery. The

protection fault relay is similar to a traditional

OK relay but certain conditions that do not

compromise protection will not cause the

Protection Fault relay to de-energize.

The relays are configured for Normally DeEnergized (NDE) or Normally Energized (NE) in

four banks of two relays each by using switches

on the relay module. The relays are set for NE for

operation in the dual redundant system.

Relay wiring terminates on the output module

using pluggable connectors and exits on the

opposite side of the monitor from the sensor

inputs.

In dual redundant operation, processor

module one drives relays 1, 3, 5, and 7 and

processor module two drives relays 2, 4, 6, and

8. The relay alarm logic is identical. External

connection to an Emergency Shutdown Device

can use a 1oo2 or 2oo2 configuration

depending on the user’s needs. Users are

recommended to perform a system analysis

using functional safety methods (IEC 61511, IEC

61508 or ISA SP84) before selecting a voting

scheme.

4/25

Page 5

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

l Six discrete inputs (DI) for dedicated dry

Terminal Base

3701 Simplex Terminal Bases

The term “simplex terminal base” identifies, or

distinguishes this type of terminal base as one

with a single (simplex) processor module as

opposed to a dual (or duplex) terminal base

with two processor modules.

The 3701 simplex terminal base is the mounting

and installation component of the monitor. It

supports a single processor module, one or two

input modules, and an output module.

contact DIs: Trip Multiply, Alarm/Relay

Inhibit, Latch Reset, Special Alarm Inhibit,

Run Mode, and IP/Account reset. There

are two sets of these six inputs on the

dual terminal base.

l The terminal base also supports one

conditioned Keyphasor/Speed output for

each processor module and one input.

The conditioned I/O is for connecting

Keyphasors or Speed signals between

two or more 3701 monitors.

The terminal base mounts to a bulkhead, or

enclosure or wall sub-panel using the four

mounting holes at the corners of the base.

Mount vertically for optimal convection cooling.

3701 Dual Terminal Base

The Dual Terminal Base is similar in function to

the Simplex Terminal Base except that it has

two CPU processor modules instead of one.

The extra CPU module allows the user to use the

two input modules redundantly. Both CPU

modules have access to all the signal channels

from each of the input modules.

Terminal base features:

l Two pluggable terminal blocks provide

sensor wiring terminations that are

individually marked for the sensor wire

type. The termination blocks can be

removed for wiring ease or maintenance

work and, when installed, are fixed in

place with a locking mechanism.

l A dedicated connection terminal for

single point connection to system earth.

l A single point earth connection switch to

separate physical (chassis) earth from

system common (instrument earth) to

enable system common connection to

an external intrinsic safety earth.

l Primary and Secondary connectors for

single or redundant +24 V DC power

input.

Channel Types, Sensors, and Measurements

The 3701/40 Machinery Dynamics Monitor

supports a set of standard channel types and

the common sensors used with those channel

types as well as custom configurable sensors.

Support for sensor types is dependent on input

module type as listed in tables located below in

this datasheet section. Each channel type has

default measurements that can be enabled or

disabled and each channel type can have user

customizable nX and bandpass

measurements added to the channel and then

customized to the application.

The 3701/40 can have up to 12 vibration input

channels (Six per input module) and 2

Keyphasor/Sspeed inputs (one per input

module). The monitor supports the channel

types listed here:

l Acceleration

l Dynamic Pressure

l Radial Vibration

l Thrust Position

l Velocity

l Keyphasor/Speed

5/25

Page 6

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Table 1: Channel Type Support by Input

Module

less than 10,000 rpm, and uses a Proximitor

sensor, but cannot be done with PoV.

Input Module Channel Types

PAS

Channels 1 - 6

PAS Channel 7

PAV

Channels 1 - 6

PAV Channel 7

Acceleration

Dynamic Pressure

Radial Vibration

Thrust Position

Velocity

Proximitor Speed

Magnetic Pickup Speed

Proximitor Speed (single

and multi-event)

Acceleration

Dynamic Pressure

Radial Vibration

Thrust Position

Velocity

Proximitor Speed

Magnetic Pickup Speed

Proximitor Speed (single

and multi-event)

PoV

Channels 1-6

Acceleration

Dynamic Pressure

Radial Vibration

Thrust Position

Velocity

PoV Channel 7

Keyphasor/Speed

(Proximitors, single and

multi-event or Mag

pickup, single and multi-

event).

PAV and PAS channels 1 – 6 can also be

configured to support an additional Keyphasor

input provided it is a single event per revolution,

6/25

Page 7

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Table 2: Input Module Compatibility with

Acceleration Inputs

Input

Module

Accelerometer or Accelerometer

Interface Module

Input

Module

Accelerometer or Accelerometer

Interface Module

PAS 155023-01 High Freq 200g Accel I/F

Module

23733-03 Accel I/F Module

24145-02 High-Freq Accel I/F

Module

330400 100 mV/g Accelerometer

330425 25 mV/g Accelerometer

330450 High Temp Accelerometer

350501 Acceleration Charge

Amplifier

49578-01 Accel I/F Module

Custom

PAV 155023-01 High Freq 200g Accel I/F

Module

23733-03 Accel I/F Module

24145-02 High-Freq Accel I/F

Module

330400 100 mV/g Accelerometer

330425 25 mV/g Accelerometer

330450 High Temp Accelerometer

350501 Acceleration Charge

Amplifier

786-500 Wilcoxon Accelerometer

626B02 PCB Accelerometer

HS-170 Hansford Accelerometer

HS-100F series Hansford

Accelerometer

CMSS-2100 SKF Accelerometer

351M35 PCB Accelerometer

Table 3: Input Module Compatibility with

Velocity Inputs

Input

Module

Velomitors, Seismoprobes, and

Interface Modules

PAS 9200 Seismoprobe

74712 Hi Temp Seismoprobe

47633 Seismoprobe

86205 BoP Seismoprobe

Custom

PAV 330500 Velomitor

330525 Velomitor XA

190501 Velomitor CT

330750 High Temp Velomitor

330752 High Temp Velomitor

49578-01 Accel I/F Module

Custom

PoV GSI 122, 124 and 127 Galvanic

Interface Unit

TP100 Commtest Accelerometer

TP500 Commtest Accelerometer

200350 Accelerometer

200355 Accelerometer

330505 Low Freq Velocity Sensor

330530 Radiation Resistant

Velomitor

Custom

PoV HS-160 Velocity Sensor

7/25

Page 8

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Table 4: Input Module Compatibility with

Measurements

Proximitor Sensors

Each channel type has a set of default

Input Module Proximitor Sensor

measurements typical of the channel type. In

addition, user customizable nX vectors and

PAS or PAV

PoV (Keyphasor)

3300XL 8 & 11 mm

3300XL NSV

3300 RAM Proximitor

3300 5 & 8 mm

bandpass measurements may be added to

each channel.

The number of measurements that can be

added and enabled depends on the signal

processing capability of the processor module.

There is no limitation, other than processor

3300 16 mm HTPS

7200 5, 8, 11, 14 mm

Custom

performance, to the number of measurements

that can be added to a single channel or

across all channels. A performance calculator

in the BNMC software provides feedback during

the configuration process on performance

Table 5: Input Module Compatibility with

Dynamic Pressure Inputs

margin as measurements are added or

removed and their attributes modified.

Input

Module

Dynamic Pressure Sensor

PAS 3-Wire (Com/Sig/-24VDC) 350500

DPCA

PAV 3-Wire (Com/Sig/-24VDC) 350500

DPCA orPCB 102M206

PoV 2-wire PCB 121A21

2-wire PCB 121A44

2-wire PCB 121A22

Measure Configurable Attributes (1)

Accelerometer

Bandpass

Full scale range

Units (g’s or m/s2 peak or rms; or

integrated accel: in/s or mm/s

peak or rms)

High pass corner frequency

Low pass corner frequency

High pass filter order (1,2,4,6, or 8

)

Low pass filter order (1, 2, 4, 6, or

8th)

Clamp value (amplitude)

nX Full scale range

Keyphasor association

Integer or non-integer order in

increments of 0.1x from 0.1x to 100x

(phase not valid for non-integer

orders).

th

8/25

Units (g’s or m/s 2 peak or rms; or

integrated accel: in/s or mm/s

peak or rms)

Clamp value (amplitude and

Page 9

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Measure Configurable Attributes (1)

phase)

Velocity

Bandpass

Full scale range

Units (in/s or mm/s peak or rms;

or integrated veloc: mils or µm

peak-peak or rms)

High pass corner frequency

Low pass corner frequency

High pass filter order (1,2,4,6, or 8

)

Low pass filter order (1, 2, 4, 6, or

8th)

Clamp value (amplitude)

nX Full scale range

Keyphasor association

Integer or non-integer order in

increments of 0.1x from 0.1x to 100x

(phase not valid for non-integer

orders).

th

Measure Configurable Attributes (1)

Low pass filter order (1, 2, 4, 6, or

8th)

Clamp value (amplitude)

nX >Full scale range

Keyphasor association

Integer or non-integer order in

increments of 0.1x from 0.1x to 100x

(phase not valid for non-integer

orders).

Units (mils or µm peak-peak or

rms)

Clamp value (amplitude and

phase)

Gap Low Pass Corner Frequency

Clamp Value (Volts)

Thrust Position

Bandpass

Full scale range

Units (mils or µm peak-peak or

rms)

High pass corner frequency

Units (in/s or mm/speak or rms;

or integrated veloc: mils or µm

peak-peak or rms)

Clamp value (amplitude and

phase)

Bias Low Pass Corner Frequency

Clamp Value (Volts)

Radial Vibe

Bandpass

Full scale range

Units (mils or µm peak-peak or

rms)

High pass corner frequency

Low pass corner frequency

High pass filter order (1,2,4,6, or 8

th

Low pass corner frequency

High pass filter order (1,2,4,6, or 8

)

Low pass filter order (1, 2, 4, 6, or

8th)

Clamp value (amplitude)

nX Full scale range

Keyphasor association

Integer or non-integer order in

increments of 0.1x from 0.1x to 100x

(phase not valid for non-integer

orders).

Units (mils or µm peak-peak or

rms)

th

9/25

Page 10

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Measure Configurable Attributes (1)

Clamp value (amplitude and

phase)

Bias Low Pass Corner Frequency

Clamp Value (Volts)

Dynamic Pressure

Bandpass

Full scale range

Units (psi dpp, psi pp, psi rms,

mbar dpp, mbar pp, mbar rsm)

High pass corner frequency

Low pass corner frequency

High pass filter order (1,2,4,6, or 8

)

Low pass filter order (1, 2, 4, 6, or

th

8

Clamp value (amplitude)

Measure Configurable Attributes (1)

Magnetic Pickup Speed

Speed Top Scale

Clamp Value

(1) Technically feasible configurations

depend on the interaction between

many factors. Certain selections may

not be feasible. Use the BNMC software

to create an off-line configuration to

determine technical feasibility.

th

nX Full scale range

Keyphasor association

Integer or non-integer order in

increments of 0.1x from 0.1x to 100x

(phase not valid for non-integer

orders).

Units (psi dpp, psi pp, psi rms,

mbar dpp, mbar pp, mbar rsm)

Clamp value (amplitude and

phase)

Bias Low Pass Corner Frequency

Clamp Value (Volts)

Proximitor Speed

Speed Top Scale

Clamp Value

Gap Low Pass Filter Frequency

Clamp Value (Volts)

10/25

Page 11

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Spectral Bands

Waveforms and Spectral Data

Acquisition of multiple synchronous and

asynchronous waveforms can be configured

for each 3701 channel in the BNMC software.

These waveforms are used as the data source

for extraction of measurements that require

spectral data such as nX vectors and peak

extractions.

Waveform configuration for spectral data

consists of f

spectral data.

Asynchronous spectral waveforms:

F

can be set between 10 Hz and 40 kHz

max

in 12 discrete steps. F

The number of spectral lines can be set

from 12.5 to 3200 in 12 discrete steps.

Synchronous spectral waveforms:

Number of samples per revolution can be

set from 8 to 4096.

Number of revolutions per waveform can

be set from 1 to 1024.

Amplitude Extractions

An amplitude extraction is the amplitude at a

user configured center frequency and with a

user configured bandwidth. The band around

the center frequency is limited in size and can

range from a single spectral line (bucket)

closest to the configured center frequency, to

the center spectral line plus 5 lines on each side

(11 total buckets).

The source data for amplitude extractions are

asynchronous spectrums.

Multiple amplitude extractions can be

configured on a single channel and across

multiple channels.

and the number of lines in the

max

is always at 0 Hz.

min

Spectral bands are user configured with a start

and a stop frequency and return the average

energy in the band.

The source data for spectral bands are

synchronous and asynchronous spectrums

using either enveloped spectral or ordinary

spectral data.

Multiple spectral bands can be configured on a

single channel.

Applications for spectral bands and other

signal processing features are described in the

Applications section of this datasheet.

Alarming and Setpoints

Alert and Danger over and under alarm

setpoints can be created individually for each

measurement. Additionally, alarm attributes

such as enable/disable, alarm time delay

(ATD), and latching/non-latching can be

independently configured on each

measurement.

In addition, the alarming attributes

(enable/disable, ATD, and latching/nonlatching) can be set independently on the Alert

and Danger alarms on the same

measurement.

Relay logic is created in the graphical relay

logic editor in BNMC software by mapping the

enabled alarms to OR and AND gates to drive a

relay.

Individual relays can be configured as

latching/non-latching or enabled/disabled

independently (or in addition to) the settings

on the measurement alarms.

Network Operation

The processor module supports two Ethernet

RJ45 physical connections located on the

terminal base. The two connectors are termed

Net A and Net B and each has its own

configurable IP address. All configuration and

interface to Bently Nevada software as well as

communication using an industrial protocol is

with one or both of these connections.

11/25

Page 12

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Display and HMI Options

Bently Nevada offers System 1 Basic as a simple,

low cost, easily installed, and light footprint HMI.

System 1 Basic is part of the System_1_

Evolution platform and offers a subset of

System_1_Evolution functionality to provide a

basic operator display.

The Modbus TCP or EGD industrial protocols can

be used to serve data to an HMI where users

can build display environments using standard

3rd party HMI software.

Bently Nevada Configuration Software (BNMC)

BNMC software is necessary to configure and

verify the 3701/40 Machinery Dynamics Monitor.

BNMC is simple configuration software with a

nominal price that is used for monitor

configuration. It also has snapshot viewing of

timebase waveforms (including

Keyphasor/Speed) and spectrums to support

commissioning and setup of the 3701 and

sensor instrumentation system. Bently Nevada

Monitor Configuration software will run on most

Windows desktop or notebook computers and

is designed and fully tested for operation on

Microsoft Windows 7 and 8.1 (32 bit and 64 bit)

and Microsoft Windows 2008 and 2012 Server

(64 bit).

Language support at the current time is English

version operating systems with keyboard

preference set to English.

BNMC is ordered separately from the monitor

hardware. See the spares section in the

Specifications portion of this datasheet for the

part number.

System_1_Evolution Connectivity

3701 monitors connect to System_1_Evolution

and support current value and time-based

data collection of all static values, waveforms,

and spectral data. This includes System 1

software's full suite of plots and tools for

conditioned monitoring and asset

management.

When an event is triggered on the 3701/4x

monitor, the following high resolution alarm

data is forwarded to System 1 *.

Trended Measurements:

Duration Intervals

Pre-event

Data

20 seconds 100

Post-event

Data

1 minute 1 second

Spectrums/Waveforms:

Duration Intervals

Pre-event Data 2.5 minutes 10 seconds

Post-event Data 1 minute 10 seconds

*Requires System_1_Evolution 17.2 or

newer and Firmware release 4.1 or newer

for 3701/4x.

10 minutes 1 second

milliseconds

10 seconds 100

milliseconds

12/25

In case of network disruption between

the 3701 and System 1*, the 3701 can

store up to 512MB of Alarm data and

512MB of transient data.

Page 13

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

sensors can be used partially or entirely.

Applications

This section describes selected applications

where 3701 function and feature offers

particular benefits.

Dual Redundant Protection

A typical dual redundant protection only

application has these basic elements:

Non-redundant sensor points, such as XY

radial shaft vibration probes, on the

same bearing can also be split between

input modules.

l Redundant industrial protocols can

operate independently from each

processor module to automation and

control systems.

Dual Redundant Protection with a

System 1 Connection

This optional configuration operates the same

as described above but Processor Module 1

connects to System 1 using one of its Ethernet

ports. Cyber security is the key design element

that must be addressed in this configuration.

l Each processor module processes all

sensor and Keyphasor input signals and

has communication (Ethernet)

connections only to the controls and

automation system.

l Each processor is configured the same

and executes identical logic.

l Processor module 1 drives relays 1, 3, 5,

and 7. Processor module 2 drives relays 2,

4, 6, and 8. The same alarm logic is used

for each relay pair (1, 2), (3,4) etc.

l An external shutdown system connects

to relay pairs and votes 1oo2 or 2oo2

depending on application requirements.

l The dedicated protection fault relay is

driven by a protection fault in either of the

processor modules and is driven if one

processor module is removed.

l If redundant sensors are required, they

can be voted 2oo2 or 1oo2 in the 3701

processor modules.

l System configuration can be varied in a

number of ways to meet different

reliability requirements. Redundant

Radial Shaft Vibration, Axial

Position, and Casing Vibration

3701 supports the standard industry

measurements for these applications but, in

addition, users can create custom

measurements on these channels using

spectral bands, bandpass timebase

measurements, amplitude extractions, nX

measurements, integrated and nonintegrated, and rms or peak measurements.

Detection of certain mechanical, aerodynamic,

and hydraulic, faults can be enhanced by

improved measuring capability. For example,

on an axial compressor there may be

increased sub-synchronous axial vibration at

the onset of a surge condition – a bandpass

timebase measurement or synchronous

13/25

Page 14

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

spectral band measurement on an axial

position probe can enhance detection of this

specific fault mode.

(A simple bandpass with an

appropriately set high pass filter

can be configured in addition.)

Roller Element Bearings

Gear Boxes

Use spectral bands to focus on bearing fault

frequencies. ( nX measurements can also be

used but the spectral band allows customizing

the bandwidth to the bearing fault frequency

response whereas the nX measurement is

narrow band.)

There are many types of gear boxes with

correspondingly different vibration monitoring

needs. This short section is intended only to

highlight some particular features of the 3701

system.

Outer Race

Ball Pass

(ORBP)

Inner Race

Ball Pass

(IRBP)

Cage A spectral band using

Ball Spin 1X A spectral band using

Ball Spin 2X

A spectral band using

synchronous enveloped or

non-enveloped data can be set

around the expected ORBP

A spectral band using

synchronous enveloped or

non-enveloped data can be set

around the expected IRBP

synchronous enveloped or

non-enveloped data can be set

around the expected cage

frequency

synchronous enveloped or

non-enveloped data can be set

around the expected ball spin 1X

frequency

A spectral band using synchronous

enveloped or non-enveloped data can

be set around the expected ball spin 2X

frequency

Feature Description

Gear Mesh

(GM) 1X, 2X, or

3X

Gear Mesh Side

Bands

Enhanced

measurements

from Radial

Vibration

Proximitors

Set a synchronous spectral

band, or an nX

measurement (or both) on

the 1X, 2X, and 3X GM. For

each gear set.

If you know the

fundamental frequency of

an expected side band

based on your gear

kinemantics then you can

set a synchronous spectral

band on a specific

sideband.

For API 613 gearboxes where

XY radial vibration probes

are typically specified you

can set the GM related

spectral bands described

above as well as nX’s based

on hi and low speed shaft

Keyphasors.

Overall and

non-REB

fault

frequencies

HF band Set a spectral band using

Set one or more bandpass

measurements to look at overall

vibration at frequencies where

rotor, casing, or structural

vibrations are expected.

nX measurements can also be

used for rotor related vibration.

enveloped synchronous or

asynchronous data sources on

a broader high frequency band

to detect low level impact

events.

Enhanced

measurements

from Thrust

Position

Proximitors

For API 613 gearboxes where

axial position probes are

typically specified. Axial

vibration can be measured

by setting bandpass filtered

or nX measurements in

addition to the conventional

thrust position

measurement.

Gas Turbine Combustion Dynamic

Pressure

14/25

Page 15

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Spectral bands and/or amplitude extractions

as well as bandpass filtered timebase

measurements can be configured to selectively

monitor the different tones produced by

pressure pulsations in combustion turbines.

15/25

Page 16

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Specifications

3701/40 Monitor Power

Requirements

Input Voltage

Minimum 18 Vdc

Maximum 36 Vdc

Non-isolated 24 Vdc

nominal

Current

(Simplex) 2.3 amps

max current

(Duplex) 3.0 amps

max current

Inrush Current

3.0 amps max inrush less than 5 mS (Per

processor card)

Supply must be 2006/95/EC Low Voltage

Directive compliant for CE installations.

Two

Independent

Ethernet

ports

Buffered

Signal

Outputs

LEDs

Module OK

LED

Protection

Fault LED

User Inhibit

LED

Attention

LED

Danger LED

Alert LED

Net A: 10/100 BaseT

Net B: 10/100 BaseT

15 pin DSUB connector,

available accessory cable for

BNC and SMC options.

550 ohm output impedance

Indicates when the module is

functioning properly.

Indicates that the monitor has

experienced a fault that is

affecting protection.

Indicates that there has been a

user initiated inhibit of

alarming functionality.

Indicates a condition on the

monitor has occurred that

may require action.

Indicates a Danger condition.

Indicates and Alert condition.

Supply must be Class I, Div 2 or Class I,

Zone 2, (CL2 SELV), compliant for

hazardous area Installations.

3701/40 Processor Module

Specifications

Inputs

Maximum 12 dynamic signals and 2

Keyphasor/speed signals

Signal/Noise

Ratio

A/D

Conversion

Bandwidth 0.0625Hz to 40Khz

Outputs

110db @ 102.4 ksps

Sigma- Delta 24 bit.

KPH 1 OK LED Indicates that Keyphasor

signal 1 is triggering

KPH 2 OK LED Indicates that Keyphasor

signal 2 is triggering

NetA Indicates that Network A has a

valid link

TX/RX A Indicates that network traffic is

flowing on Network A.

Net B Indicates that Network B has a

valid link.

TX/RX B

PWR 1 OK Indicates that the first power

PWR 2 OK

Indicates that network traffic is

flowing on Network B.

input is functioning correctly.

Indicates that the second

power input is functioning

correctly.

16/25

Page 17

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Accuracy

Direct pk

or rms

Bias

Tracking

filters

Within ± 0.5% of full-scale typical

1.1% Worst Case

+0.4 V / -0.8 V typical

+0.8V / -1.34 V Worst Case.

nX tracking filters are have a

bandwidth of 0.075X, where X is

the speed of the associated

speed channel.

Alarming

Setpoints Over/under user configurable.

Time

Delay

Latching User configurable alarming or

100mS – 60 minutes

relay latching

Input Impedance

Gap

Phase Accuracy

Dedicated Speed

Input

Auxiliary

Proximitor Speed

Input

Auto Threshold Use for any input above 1

Manual Threshold ±150mV, User selectable

Hysteresis User selectable from 0.2 to

Signal Amplitude Minimum signal amplitude

Refer to Hazardous Area Special

Considerations Section for Maximum

Magnetic Pickup amplitude

requirements for hazardous area

applications.

±8.2 mV typical

±22.3 mV Worst Case

± 1 degree up to 120,000

rpm

± 1 degree up to 10,000 RPM

rpm for 1 event/resolution

from +3.5 to -23.5 Vdc.

10 volts.

for trigger is 2 volts peakto-peak.

All 3-wire Inputs

(PAS & PAV)

2-Wire Input – PAS

(Seismaprobes)

2-Wire Input – PAV

(Velomitors)

Nominal input

impedance is 10 kΩ.

Nominal differential input

impedance is 9.98 kΩ.

Nominal constant

current is 3.3267 mA.

Speed Signal Inputs

Speed Range

Dedicated

Speed/Keyphasor

Input

Auxiliary

Proximitor

Keyphasor Input

Conditioned

Speed/Keyphasor

Input

Speed Resolution

1 to 120,000 rpm

1 to 10,000 rpm

1 to 120,000 rpm

1 to 100 rpm ± 0.1 rpm

100 to 2000 rpm ± 1 rpm

Relay Output Specifications

Relay Type

Contact

Ratings

Minimum

Switching

Current

Normally DeEnergized

(NDE) or

Normally

Energized

(NE)

Single Pole Double Throw (SPDT).

Normally Open (NO), Normally

Closed (NC), and Armature (ARM)

contacts

5A/250 Vac/1500 VA Max.

5A/250 Vdc/150 VA Max.

12Vdc/100mA

NDE/NE independently

selectable for relay pairs 1-2, 34, 5-6 and 7-8.

17/25

Page 18

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Refer to Hazardous Area Special

Considerations Section for Relay

specifications when used in hazardous

area applications.

3701/40 Environmental

Specifications

Indoor Use Only

Operating

Temperature

Range

Storage

Temperature

Range

-30° C to +65° C†

(-22° F to 149° F)

†

If the 3701 is operated 100% at

+65C, its life will be reduced to

approximately 11 years. Any

portion of the time it is

operated below +65C or any

convective airflow will increase

its lifespan.

-40°C to +85°C

(-40° F to 185° F)

Simplex Weight

Duplex Base

Dimensions

Duplex Weight

(fully loaded)

Mounting

(Simplex and

Duplex)

4.5 kg (9.9 lbs)

26.7 x 27.7 x 18.2 cm (10.5 x

10.9 x 7.15 in)

7.7 kg (17.1 lbs)

Bulkhead 4 mounting bolts

or screws at corners.

Relative

Humidity

Vibration

Shock

Altitude < 2000 m (6,562 ft)

Pollution

Degree

Installation

Category

0% to 95% rH non-condensing

Operating and Storage

5g @ 57-500 Hz.

IEC 60068-2-6

15g, 11ms

IEC 60068-2-27

Pollution Degree 2

Category II

Physical

Simplex Base

Dimensions

26.7 x 20 x 18.2 cm (10.5 x

7.87 x 7.15 in)

18/25

Page 19

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

l 2015 Steel Vessels Rules

l 2015 Offshore units and Structures

Compliance and Certifications

FCC

This device complies with part 15 of the

FCC Rules. Operation is subject to the

following two conditions:

l This device may not cause harmful

interference.

l This device must accept any

interference received, including

interference that may cause

undesired operation.

EMC

EN 61000-6-2

EN 61000-6-4

EMC Directive 2014/30/EU

Electrical Safety

EN 61010-1

LV Directive 2014/35/EU

RoHS

RoHS Directive 2011/65/EU

ATEX

EN 60079-0

EN 60079-15

ATEX Directive 2014/34/EU

Cyber Security

Achilles Communications Certification

Level 1

Maritime

ABS 2009 Steel Vessels Rules

1-1-4/7.7,4-8-3/1.11.1,4-9-7/13

Complies with ABS Rules for Condition of

Classification, Part 1

19/25

Page 20

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

contact with the internal earth

Hazardous Area Approvals

For the detailed listing of country and

product specific approvals, refer to the

Approvals Quick Reference Guide

(108M1756) available from

www.Bently.com.

connection facility on the equipment.

l The relay output circuits shall not be

connected to circuits which exceed 30V,

5A.

CSA/NRTL/C

Class I, Zone 2: AEx nA nC IIC T4 Gc;

Class I, Zone 2: AEx ec nC IIC T4 Gc;

Class I, Division 2, Groups A, B, C, and D;

T4 @ Ta= -30˚C to +65˚C

When installed per drawing 100M1872

ATEX/IECEx

II 3 G

Ex nA nC IIC T4 Gc

T4 @ Ta= -30˚C to +65˚C

ATEX Special Conditions of Safe Use

l The equipment shall only be used in an

area of not more than pollution degree 2,

as defined in IEC 60664-1.

l The equipment shall be installed in an

enclosure that provides a degree of

protection of not less than IP54 and

which meets the enclosure requirements

of EN 60079-0 and EN 60079-7/EN 60079-

15. The enclosure shall be suitable for an

ambient temperature range of -30°C to

+65°C and a service temperature of 80°C.

l Transient voltage protection shall be

provided by the external circuits to

ensure that transient overvoltages to the

equpment cannot exceed 140% of 85 V.

l When installed in a metal enclosure, the

enclosure shall have an external facitlity

for an earth bonding connection which

complies with EN 60079-0:2012/A11:2013

clause 15.1.2 and which is electrically in

20/25

Page 21

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Ordering Information

For the detailed listing of country and product

specific approvals, refer to the Approvals Quick

Reference Guide (108M1756) available from

Bently.com.

3701/40–AA-BB-CC-DD-EE

A: Redundancy

01

02

B: Input Module 1

00 None

01 Prox/Accel/Velom

02 Prox/Accel/Seismoprobe

03

C: Input Module 2

00 None

01 Prox/Accel/Velom

Simplex

Duplex

Positive Voltage Module

Spares

Part Number Description

3701/40 3701/40 Machinery Dynamics

Monitor

177896-05

177988-01 Prox Accel Seismic (PAS)

177989-01 Prox Accel Velom (PAV)

105M6001-01 Positive Input (PoV) Module

177897-01

175794 3701 Simplex Terminal Base

177992-01

178372-01

100M9465-01

3701/40 Processor Module

Module

Module

3701 Output Relay Module

3701 Terminal Block –

Standard

3701 Terminal Block - Duplex

Bently Nevada Monitor

Configuration (BNMC) SW

DVD

02 Prox/Accel/Seismoprobe

04

D: Output Module

00 None

01 8 CH SPDT Relay Module

E: Approvals

00 None (This does include the non-

01

02

XX Country specific

Positive Voltage Module

Hazardous area general safety

certification)

CSA

ATEX/IECEx

Accessories

Part Number Description

323314-01

323314-02

324343 Nema 4 Weatherproof

Bently_

Manuals

Buffered Output cable 15 pin

D-Sub to 7 SMA connectors.

(SMA connectors work with

the ADRE 408)

Buffered Output cable 15 pin

D-Sub to 7 BNC connectors

Housing Kit

Customer DVD containing all

Bently Manuals, FWD, App

Notes, and Install Guides in all

available languages.

21/25

Page 22

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Graphs and Figures

1. Processor Module

2. Input Module 1

3. Input Module 2

4. Output Module

5. Terminal Base

Figure 1: 3701/40 Simplex Terminal Base Top View

22/25

Page 23

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

1. Processor Module (2)

2. Input Module 1

3. Input Module 2

4. Output Module

5. Terminal Base

Figure 2: 3701/40 Duplex Terminal Base Top View

Figure 3: 3701/40 Simplex Terminal Base Side View

23/25

Page 24

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Figure 4: 3701/40 Duplex Terminal Base Side View

24/25

Page 25

3701/40 ADAPT Machinery Dynamics Monitor

Datasheet 103M2037 Rev. J

Copyright 2020 Baker Hughes Company. All rights reserved.

Bently Nevada, Orbit Logo, ADAPT, System 1, Keyphasor, Proximitor and Velomitor are registered trademarks of Bently

Nevada, a Baker Hughes Business, in the United States and other countries. The Baker Hughes logo is a trademark of

Baker Hughes Company. All other product and company names are trademarks of their respective holders. Use of

the trademarks does not imply any affiliation with or endorsement by the respective holders.

Baker Hughes provides this information on an “as is” basis for general information purposes. Baker Hughes does not

make any representation as to the accuracy or completeness of the information and makes no warranties of any

kind, specific, implied or oral, to the fullest extent permissible by law, including those of merchantability and fitness

for a particular purpose or use. Baker Hughes hereby disclaims any and all liability for any direct, indirect,

consequential or special damages, claims for lost profits, or third party claims arising from the use of the

information, whether a claim is asserted in contract, tort, or otherwise. Baker Hughes reserves the right to make

changes in specifications and features shown herein, or discontinue the product described at any time without

notice or obligation. Contact your Baker Hughes representative for the most current information.

The information contained in this document is the property of BakerHughes and its affiliates; and is subject to

change without prior notice. It is being supplied as a service to our customers and may not be altered or its content

repackaged without the express written consent of Baker Hughes. This product or associated products may be

covered by one or more patents. See Bently.com/legal.

1631 Bently Parkway South, Minden, Nevada USA 89423

Phone: 1.775.782.3611 or 1.800.227.5514 (US only)

Bently.com

25/25

Loading...

Loading...