Bently Nevada 177230 Specifications

177230 Seismic Transmitter

Datasheet

Bently Nevada Machinery Condition Monitoring

Description

The 177230 Seismic Transmitter is a simple, loop-powered

device that can be quickly and easily installed. It can be

integrated into your programmable logic controller (PLC)or

controls system linked to a plant asset condition monitoring

solution. Its simple design reduces training, maintenance,

and service costs. The transducer helps you better manage

downtime, optimize maintenance planning, and avoid

unforeseen catastrophic failures of machinery assets.

The 177230 Seismic Transmitter incorporates robust CM

design for reliability and implements an industry-standard 4

to 20 mA loop-powered transmitter.

Easily Installed and Integrated

l Interfaces with PLCs and control systems (including

DCS and SCADA)

l Requires only a short learning curve for operations and

maintenance –through a familiar interface similar to

that for connecting other PLC or control system inputs

l Requires no field configuration or adjustments

l Needs few additional parts for a complete system

l Includes technical support for customers on how to

monitor their equipment

l Includes self-test

l Incorporates protected interface

l Supports a variety of interface cables

177232 Rev. O

Data Quality

l Provides accurate and repeatable data

l Uses simple data format

l Provides raw vibration signal for verification and

analysis

177230 Seismic Transmitter

Datasheet 177232 Rev. O

EHS Compliant

l Implements safe and ergonomic design

l Supports access to hazardous areas

2/10

177230 Seismic Transmitter

Datasheet 177232 Rev. O

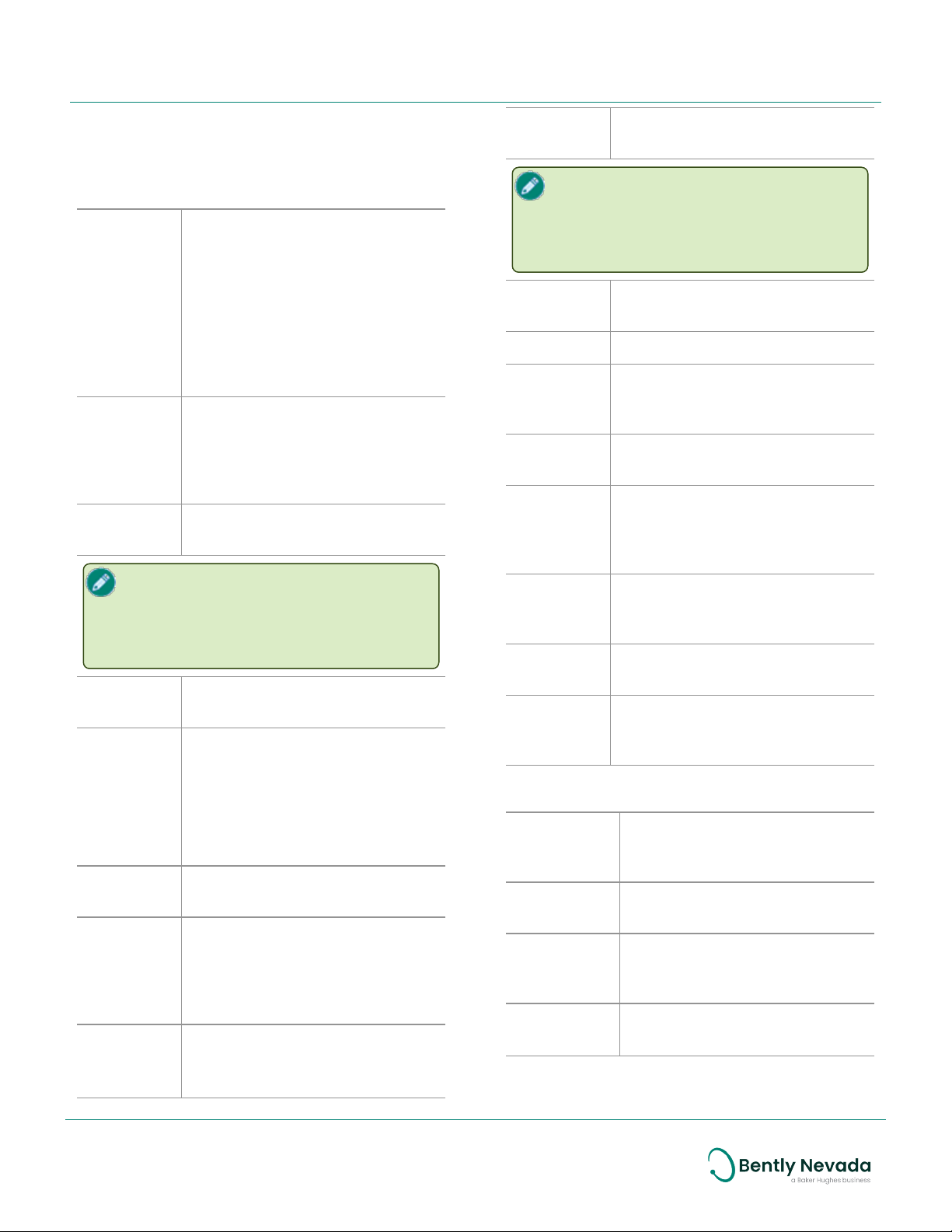

Referenced

Specifications

to Pin B

Electrical

Sensitivity –

Main Loop

(Signal

One)

Output

Format, Pin

A

Referenced

to Pin B

Excitation

Voltage

This product is for use with PLCs, DCS

and SCADA systems that have internal

power supplies which are typically

current limited in the range of 30 mA to

35 mA.

Settling

Time

Connector

Wiring

Convention

Frequency

Response

Sensitivity –

Dynamic

Signal

(Signal

Two)

Output

Format, Pin

C

n 0.0 to 12.7 mm/s (0 to 0.5 in/s)

n 0.0 to 25.4 mm/s (0 to 1.0 in/s)

n 0.0 to 50.8 mm/s (0 to 2.0 in/s)

± 10% FS, broadband rms (root

mean square)

[4 ± 0.3 mA equals 0.0 mm/s

and 20 ± 2 mA equals 25.4

mm/s]

4 to 20 mA current loop Velocity

vibration

12 to 30 Vdc (current limited to

40 mA)

Less than 15 seconds within 2%

of final value

n Pin A: 4-20 mA Positive Loop

n Pin B: 4-20 mA Negative Loop

and common for Dynamic

Signal

n Pin C:Dynamic Signal in

voltage, unbuffered

10 Hz to 1 kHz (600 cpm to 60

kcpm) ± 10%

10.2 mV/m/s2 (100 mV/g) ± 20%

Voltage, Acceleration vibration

The Dynamic Signal Negative (Pin B)

requires isolation from any grounding.

If this terminal is grounded, the 4-20

mA loop will short, resulting in no

output.

Frequency

Response

Linearity ±1%

Output Bias

Referenced

to Pin B

Full Scale

Range

Velocity

Range (see

Option AA

and BB)

Mounted

Resonant

Frequency

Transverse

Sensitivity

Sensing

Element

Type

2.5 Hz to 10 kHz (150 cpm to 600

kcpm) ± 10%

2.5 V ± 0.1 V

147 m/s2 ( 15 g’s) peak

n 0 – 12.7 mm/s (0 – 0.5 in/s)

n 0 – 25.4 mm/s (0 – 1.0 in/s)

n 0 – 50.8 mm/s (0 – 2.0 in/s)

Greater than 12 kHz

Less than 5% of sensitivity

Ceramic / Shear

Environmental Limits

Operating

Temperature

Range

Electrical

Isolation

Isolation

Breakdown

Voltage

Shock

Survivability

-40 °C to +85 °C

(-40 °F to +185 °F)

Greater than 108 ohms

600 Vrms with less than 1 mA

leakage current

9.810 m/s2 (1.000 g peak),

maximum drop test

3/10

Loading...

Loading...