Beijer Electronics T7A User Manual

iXT7A

InstallationManual

MAEN016F,2013-09

English

Foreword

InstallationmanualforiXT7A

Foreword

All operator panels aredeveloped to satisfy the demands of human-machine

communication. Built-in functions such as displaying and controlling text,

dynamic indication, time channels, alarm and recipe handling are included.

The operator panel works primarily in an object-oriented way, making it easy to

understand and use. Configuration is carriedout on a PC using the iXDeveloper

configuration tool. The project can then be transferred and stored in theoperator

panel itself.

Various types of automation equipment such PLCs,servos or drives can be

connected tothe operator panels. In this manual, the term “thecontroller” refers

to the connected equipment.

This manual explains howto install the operator panel. Please refer to the

iX Developer reference manual for further information.

Order no: MAEN016F

Copyright ©2013-09 Beijer Electronics AB. All rights reserved.

The information in this document is subjecttochangewithoutnoticeandisprovidedasavailableatthe

time of printing. Beijer Electronics AB, including allits group companies, reserves the right to changeany

information without updating this publication. Beij er Electronics AB, including all its group companies,

assumesnoresponsibilityforanyerrorsthatmayappearinthisdocument. Readtheentireinstallation

manual prior to installing and using this equipment. Only qualified personnelmay install, operate or repair

this equipment. Beijer Electronics AB, includingall its group companies, are not responsiblefor modified,

altered or renovated equipment. Because the equipmenthas a wide range of applications, usersmust acquire

the appropriate knowledge to use the equipment properly in their specific applications. Persons responsible

for the application andthe equipment must themselves ensurethat each application is incompliance with

all relevant requirements, standards and legislationinrespecttoconfigurationandsafety. Onlypartsand

accessoriesmanufacturedaccordingto specificationsset byBeijer Electronics AB, including all its group

companies, may be used.

BEIJER ELE CTRONICS AB, INCLUDING ALL ITS GROUP

COMPANIES,SHALL NOTBE LIABLETO ANYONE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL ORCONSEQUENTIAL

DAMAGES RESULTINGFROM THE INSTALLATION, USE OR

REPAIROF THIS EQUIPMENT, WHETHER ARISING IN TORT,

CONTRACT, OR OTHERWISE.BUYER'S SOLE REMEDY SHALL

BE THE REPAIR, REPLACEMENT, OR REFUND OF PURCHASE

PRICE, AND THE CHOICEOF THE APPLICABLE REMEDY SHALL

BE AT THE SOLE DISCRETION OF BEIJER ELECTRONICS AB,

INCLUDING ALL ITS GROUP COMPANIES.

BeijerElectronics, MAEN016F

Contents

Contents

1 Safety Precautions ....................................................... 4

1.1 General ...........................................................

1.2 UL and cUL Installation .........................................

1.3 During Installation ..............................................

1.4 During Use .......................................................

1.5 Service and Maintenance ........................................

1.6 Dismantling and Scrapping .....................................

1.7 Appearance of Air in Touch Screen .............................

2 Installation ............................................................... 8

2.1 SpaceRequirements .............................................

2.2 Installation Process ..............................................

2.2.1 Connections tothe Controller ......... .........................

2.2.2 Other Connections and Peripherals .............................

3 TechnicalData ........................................................... 12

4 Chemical Resistance .................................................... 14

4.1 MetalCasing .....................................................

4.2 Touch Screen and Overlay .......................................

4.2.1 AutoflexEBA180L ..............................................

4.2.2 Touch ScreenSurface ........................................ ....

4.2.3 AutoflexEBA180L ..............................................

5 Operator PanelDrawings .............................................. 17

5.1 Connectors .......................................................

5.2 Communication Ports ...........................................

5.3 iX T7A Outline ..................................................

6 Additional Installation Tips .. . ......................................... 20

6.1 Grounding the Operator Panel .................................

6.2 Ethernet Connection in theOpe

6.3 To Achieve BetterEMC Protec

rator Panel ...................

tion .............................

6.4 AmbientTemperature ...........................................

6.5 Safety .............................................................

6.6 GalvanicIsolation ................................................

6.7 Cable and Bus Terminati

on RS485 .............................

11

11

14

15

15

16

16

17

17

19

20

21

23

24

25

26

27

4

4

6

6

6

6

7

8

9

BeijerElectronics, MAEN016F

Safety Precautions

1SafetyPrecautions

Both the installer and the owner and/or operator of the operator panel must read

and understand this installation manual.

1.1 General

• Read thesafety precautions carefully.

• Check the delivery for transportationdamage. If damage is found, notify the

supplier as soon as possible.

• Do not use the operator panel inan environment with high explosive hazards.

• The supplier is not responsible for modified, altered orreconstructed

equipment.

• Use only parts and accessories manufactured according to specifications of

the supplier.

• Read the installation andoperating instructions carefully before installing,

using or repairing the operator panel.

• Neverallowfluids,metalfilingsorwiringdebristoenteranyopeningsinthe

operator panel. This may cause fire or electrical shock.

• Only qualified personnel may operate the operator panel.

• Storing the operator panelwhere the temperature is lower/higherthan

recommended inthis manual can cause theLCD displayliquid to

congeal/become isotopic.

• The LCD display liquid contains a powerfulirritant. In case of skin contact,

wash immediately with plenty of water. In case of eye contact, hold the eye

open,flushwithplentyofwaterandgetmedicalattention.

• Thefiguresinthismanualservesanillustrativepurpose. Becauseofthemany

variables associatedwith any particular installation, the supplier cannot

assume responsibilityfor actual use based on the figures.

• The supplier neither guarantees that the operator panel is suitablefor your

particular application, nor assumes responsibility for your product design,

installation or operation.

• It is recommended to turn on and shut down the operator panel at least once

before installing any components/cardsor before connecting the operator

panel to external devices, likefor exampleserial devices.

1.2 ULandcULInstallation

Caution:

ThissectionisonlyvalidforUL labelediXT7Apanels.

• This equipment is suitable for use in Class 2 non-hazardous locations only.

[Combinations ofequipment in your system are subject to investigation by

the local authority having jurisdiction at the time of installation].

BeijerElectronics, MAEN016F

4

Safety Precautions

• All devices have to be supplied by a Class 2 power supply.

Warning:

Donotdisconnect equipmentunlesspowerhasbeenremovedortheareais

knowntobenon-hazardous

• ForCanada also AVERTISSEMENT – AVANT DE DECONNECTER

L’EQUIPEMENT, COUPER LE COURANT OUS’ASSURER QUE

L‘EMPLACEMENT EST DESIGNE NON DANGEREUX.

Warning:

OnlyULand cULapprovedexpansionunitsareallowedtobeconnectedto

theportdesignated “EXPANSION”. Atthemoment therearenosuchunits

evaluatedorallowed.

Warning:

Donotreplace expansionunitunlesspower hasbeenswitch

isknowntobenon-hazardous.

edofforthearea

• This product contains a battery; this must only be changed in anarea known

to be non-hazardous.

• Replace thebattery with aBR 2032 battery. Use of another type of battery

may present a risk of fire or explosion.

Warning:

Batterymayexplode ifmistreated. Donotrecharge, disassembleordispose

ofinfire.

• Foruse on a flat surface of a type 4X enclosureindoor use only.

• Use75 degree conductors only

• Use copper conductors only

• To make wiring connections to the power supply connector, follow the table

with cableand torque specifications below:

TerminalBlock No. WireSizeAWG TQLb.In.

X1/X100Phoenixconnectors AWG30–12 5–7

X1/X100Anytekconnectors AWG24–12 3.5

• These de

for the

panel m

vicesareClass2suppliedprogrammablecontrollers(industrialPCs)

use in industrial control equipment and are intended to be (front)

ounted (Type 1 and 4x for indoor use only).

BeijerElectronics, MAEN016F

5

Safety Precautions

1.3 DuringInstallation

• The operator panel is designed for stationary installation on a plane surface,

where the followingconditions are fulfilled:

– no high explosive risks

– no strong magnetic fields

– no direct sunlight

– no large, suddentemperature changes

• Install the product accordingto theaccompanying installation instruc tions.

• Ground the product accordingto the accompanying installation instructions.

• Only qualified personnel may install the operator panel.

• Separate the high voltage, signal and supplycables.

• Make sure that the voltage andpolarity of the power source is c orrect before

connecting the product to the power outlet.

• Peripheralequipment mustbe appropriate for the application and location.

1.4 DuringUse

• Keep theoperator panel clean.

• Emergency stopand other safety functions maynot be control

operator panel.

• Do not use too much force or sharp objects when touching the

touchscreen etc.

led from the

keys,

1.5 ServiceandMaintenance

• Only qualified personnel should carry out repairs.

• The agreed warranty applies.

• Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electricalsupply.

• Clean the display and surrounding front coverwith a soft cloth andmild

detergent.

• Replacing thebattery incorrectly may result in explosion. Only use batteries

recommended bythe supplier. During the warranty period, the battery needs

to bereplaced by an authorized Beijer Electronics service center.

1.6 DismantlingandScrapping

• The operator panel or parts thereof shall be recycledaccording to local

regulations.

• The following components contain substances that might be hazardous

to health and theenvironment: lithium battery, electrolytic capacitorand

display.

BeijerElectronics, MAEN016F

6

Safety Precautions

1.7 AppearanceofAirinTouchScreen

• Thelayerstructureofthetouchscreencontainsairandinrarecases

appearance of bubbles can arise. This is purelycosmetic and does not affect

any functio nality of the panel. The appearance can occurunder certain

environmental conditions such as temperature, humidity, and atmospheric

pressure.

BeijerElectronics, MAEN016F

7

2Installation

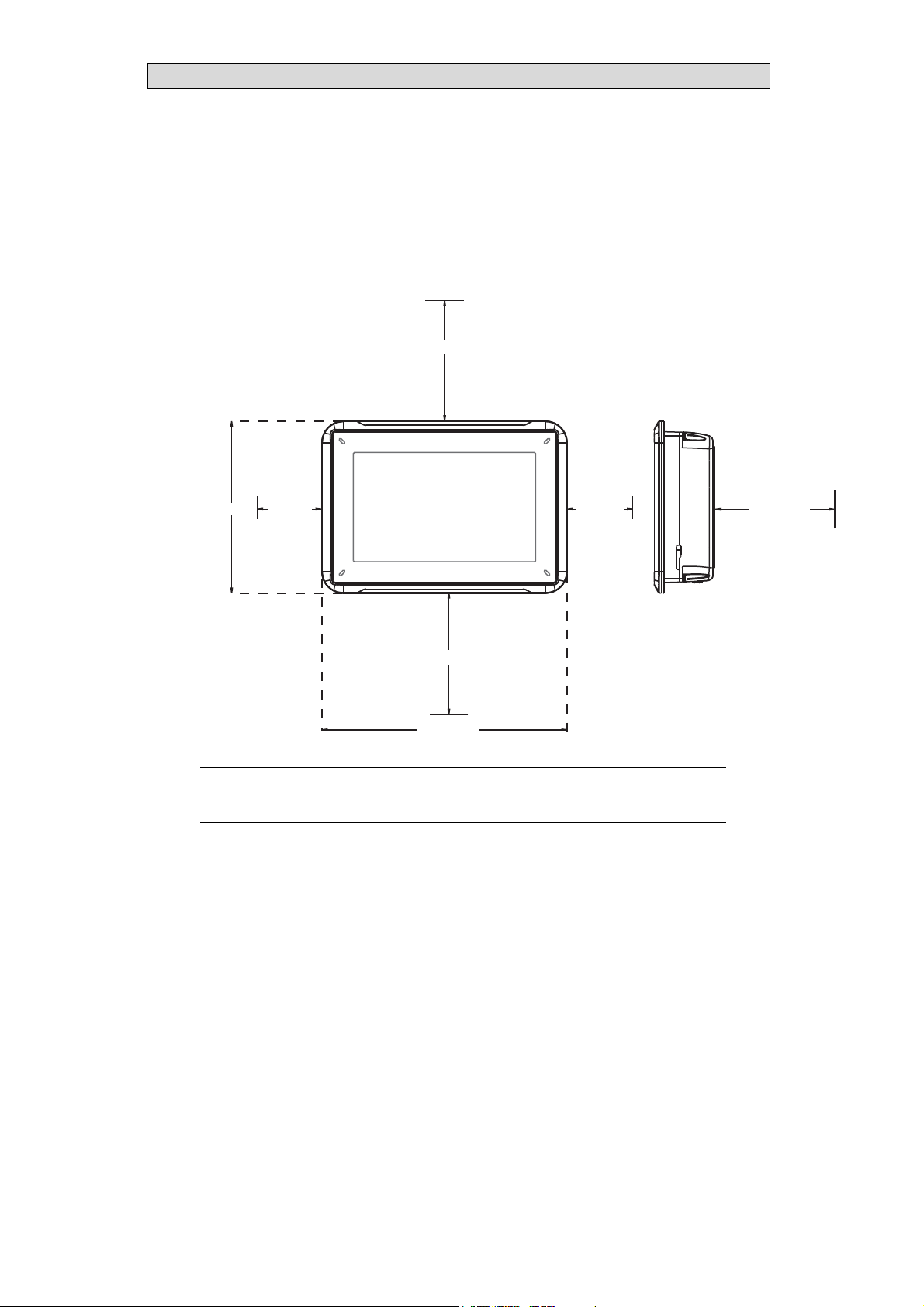

2.1 SpaceRequirements

• Maximum installation plate thickness: 11 mm

• Space requirements in millimeters when installing the operator panel:

100 mm

Installation

143 mm

100 mm

204 mm

Note:

Thedimensionsonthedrawingarenotproportional.

50 mm50 mm

100 mm

BeijerElectronics, MAEN016F

8

2.2 InstallationProcess

The following is needed:

• A Phillips/slot screwdriver

1.

Unpackand check the delivery. If damage is found, notify the supplier.

Note:

Placetheoperator panelonastablesurfaceduringinstallation.

Droppingthe panelorlettingitfallmaycause damage.

2.

Usethecutoutdimensionsthatareincludedontheoutlinedrawing,found

in section Operator Panel Drawings and in the Technical Data table, to cut

a correct opening in the cabinet. A separate cut out drawing is available for

download from the Beijer Electronicsweb site.

3.

Securethe operator panel in position using all the fastening holes and the

provided brackets and screws:

Installation

x 4 0.5 - 1.0 Nm

BeijerElectronics, MAEN016F

9

Loading...

Loading...