Userss Manual

DSP110

®

ENGLISH

Version 1.2 April 2001

SHARK

www.behringer.com

SHARK DSP110

2

SHARK DSP110

1. INTRODUCTION

Thank you very much for expressing your confidence in BEHRINGER products by

purchasing the SHARK DSP110.

+ This manual first describes the terminology used, so that you can fully

understand the DSP110 and its functions. Please read the manual carefully

and keep it for future reference.

1.1 The concept

With the SHARK DSP110 you purchased a device that combines an automatic Feedback

Destroyer using the ingenious search algorithms of our FEEDBACK

DESTROYERPRO DSP1124P, a variable Delay Line (adjustable in msec, feet and

meter), a ULN (Ultra-Low Noise) microphone pre-amp with Phantom Power, an

automatic Noise Gate, a variable Low Cut filter and a Compressorall in one ultrarugged and compact case. Still, the SHARK can be operated intuitively and expanded

to a multi-channel system using another four SHARKs and an optionally available 19"

rack mount kit. The SHARKs 24-bit A/D and D/A converters guarantee a precise

reproduction of your program material.

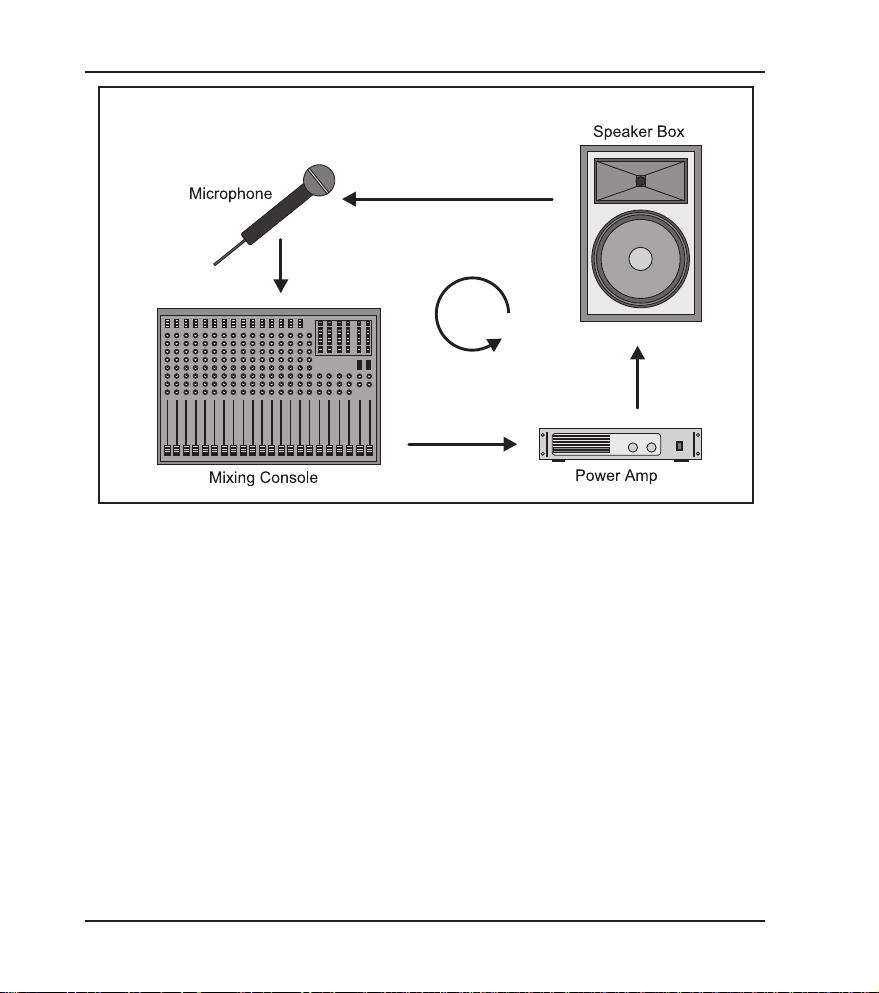

High volume levels and the use of ever more sophisticated monitoring systems with

a multitude of speaker cabinets have led to a greater potential risk of feedback loops

in sound reinforcement systems. So far, audio engineers have been using conventional

1/3-octave equalizers to suppress unwanted feedback. However, the individual filters

of such an EQ, with their relatively wide bandwidth, have quite an impact on the sound

image. With the BEHRINGER SHARK (minimum bandwidth: 1/60 of an octave) you

are now free to either choose the trial and error method to suppress feedback with

graphic equalizers, or to assign this task to the DSP110, so that you can give your

music your undivided attention. Using extremely narrow-bandwidth filters, the

SHARKDSP110 eliminates only unwanted feedback, without affecting your music.

1. INTRODUCTION

3

SHARK DSP110

Fig. 1.1: Typical feedback loop

1.2 Before you begin

Your SHARK was carefully packed in the factory and the packaging is designed to

protect the unit from rough handling. Nevertheless, we recommend that you carefully

examine the carton and its contents for any signs of physical damage, which may have

occurred during transit.

+ If the unit is damaged, please do not return it to BEHRINGER, but notify

your dealer and the shipping company immediately, otherwise claims for

damage or replacement may not be granted. Shipping claims must be made

by the consignee.

The optionally available rack mount kit allows you to mount your BEHRINGER SHARK

in a standard 19" rack, together with another four SHARKs. The rack mount kit requires

2U of rack space.

4

1. INTRODUCTION

SHARK DSP110

Be sure that there is enough air space around the unit for cooling and please do not

place the SHARK on high-temperature devices such as power amps, etc. to avoid

overheating.

Please use the enclosed power supply to connect the unit to the mains. The supply

complies with all applicable safety standards.

+ Please note that all units must be grounded properly. For your own safety,

you should never remove any ground connectors from electrical devices

or power cords or render them inoperative.

Further information can be found in chapter 3 INSTALLATION.

As a standard the audio inputs and outputs of the BEHRINGER SHARK DSP110 are

fully balanced. If possible, connect the unit to other devices in a balanced configuration

to allow for maximum interference immunity. The automatic servo function detects

unbalanced connections and compensates the level difference automatically (6dB

correction).

1. INTRODUCTION

5

SHARK DSP110

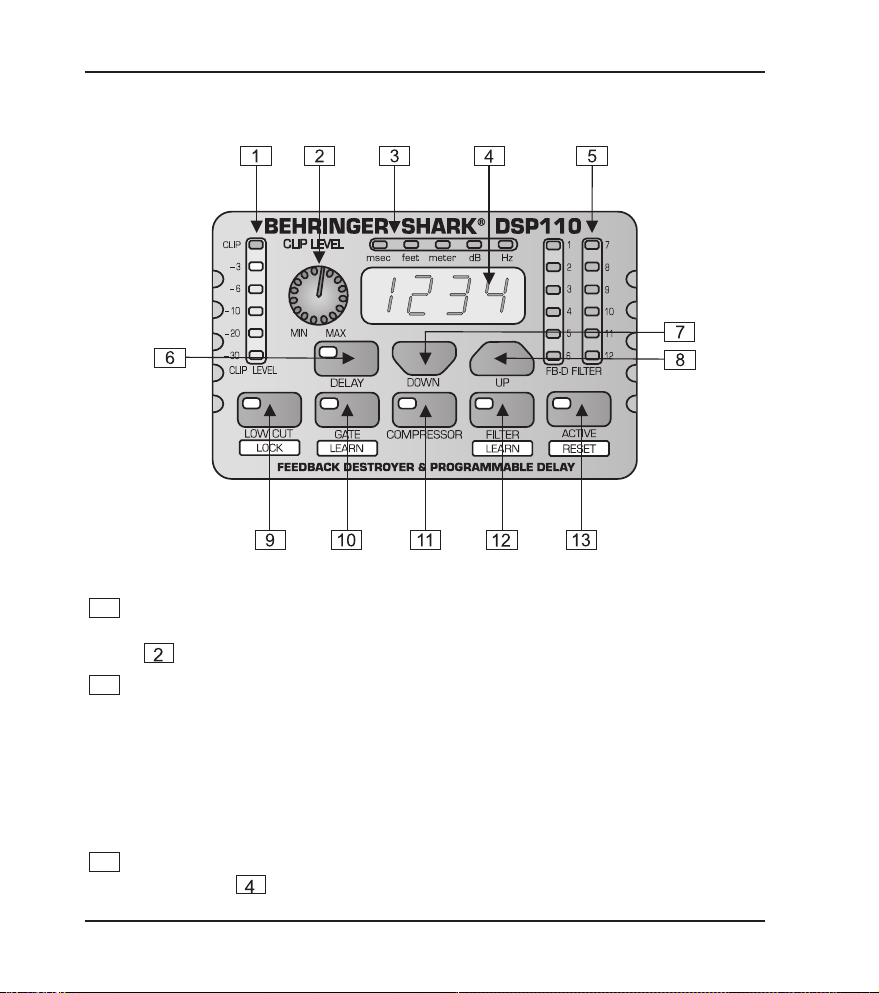

1.3 Control elements

Fig. 1.2: Front panel control elements of the DSP110

1

The CLIP LEVEL METER shows you whether or not the digital circuitry is

driven correctly. Any corrections can be made with the CLIP LEVEL control

. Be sure that the CLIP LED wont light up.

2

The CLIP LEVEL control lets you adapt the internal gain optimally to the digital

circuitry. If gain is too high (CLIP LED lights up), raise the CLIP LEVEL value by

turning the control to the right (and vice versa). Thus, you can shift the operating

level upwards/downwards.

+ The CLIP LEVEL control does not affect the input/output levels, but adapts

the audio signal as optimally as possible to the threshold of the digital

circuitry.

3

These five LEDs symbolize the units of the parameters that can be adjusted on

the display

.

6

1. INTRODUCTION

SHARK DSP110

4

The 4-digit DISPLAY reads the absolute values of the adjusted parameters.

5

The FB-D FILTER STATUS LEDs display the status of each of the 12 individual

filters. The SHARK uses four different filter modes:

s

Disabled filters (which can be re-enabled with the ACTIVE button). When a

filter is off, its LED is not lit.

Free filters which automatically search for feedback frequencies and whose

s

activity is shown by a flashing LED.

s Set filters which can be reconfigured as free (searching) filters, when all filters

are currently in use.

s

Permanently set filters which must be RESET to be reconfigured as free filters.

Once a filter has been set, its LED lights up.

6

The DELAY button allows you to adjust the Delay Line time. Press the button

several times to either choose msec, feet or meter. The last unit selected will be

stored and recalled next time you use the DELAY function. The control LED

lights up while you are making your entries. The setting range is from 0 to

2,500.0 msec, 0 to 2,818.2 feet, and 0 to 859.00 meters. When you are using

high values, the 4-digit display reads the last figure only when you start editing

with the UP/DOWN buttons. Example: for a value of 1,500.0 msec, the display

reads 1500 when you press the DELAY button, and 500.0 when you start

editing. In this way, you can use extremely small steps when editing parameters.

+ To speed up the selection, briefly press the key located next to the UP or

DOWN key. The selection speed will be increased with each additional key

press. This function can be used for all parameter edits.

7

The DOWN button lowers the parameter values shown in the display .

8

The UP button raises these parameter values.

1. INTRODUCTION

7

SHARK DSP110

9

The LOW CUT button lets you enter the high pass filters cut-off frequency

(20 to 150 Hz). When set to OFF the filter is inoperative. The control and Hz

LEDs light up while you are entering a value. Use the UP/DOWN buttons to

edit. Pressing the LOW CUT button for a longer time (please wait, until all

five parameter LEDs light up) enables the keypad lock feature which prevents

inadvertent editing of parameters and settings. When the keypad lock is enabled,

the LOW CUT keys control LED starts flashing.

10

Use the GATE button to adjust the threshold of the internal Noise Gate (-96 dB

through -44 dB). When set to OFF, the Noise Gate is inoperative. The control

LED of the GATE button lights up while you are entering a value. Pressing the

GATE button for a longer time (please wait, until all five parameter LEDs light

up) enables the GATE LEARN function, which automatically sets the Noise

Gate threshold by analyzing the program material and adjusting the value

accordingly (value detected plus 2 dB). In GATE LEARN mode, the GATE keys

control LED starts flashing. As long as the LED flashes, the detected value is

read on the display, when the LED stops flashing, the value is raised by +2 dB.

11

The COMPRESSOR button gives you access to two parameters that let you

adapt the DSP110s Compressor function to the program material. Press the

button once to adjust the DENSITY parameter, which controls the compression

density from 0 (no processing) to 100 (maximum compression). Press the

COMPRESSOR button a second time to adjust the SPEED parameter which

controls the Compressors attack and release times from 10 to 1000 msec. The

msec LED lights up as soon as you select the SPEED parameter.

12

The FILTER key allows you to set the feedback detection sensitivity within a

range from 1 (no sensitivity) through 100 (full sensitivity). The default value is

50. The control LED lights up during data entry. Briefly press the FILTER key a

second time to edit the maximum attenuation of the FB-D filter (from -3 dB

through -48 dB in steps of 3). Pressing the FILTER key longer (please wait, until

all five parameter LEDs light up) activates the FILTER LEARN function, which

automatically searches for feedback frequencies and assigns free filters to the

frequencies found. Now you can enter the number of filters (standard: 9) to be

used for permanent feedback suppression. Although the remaining filters are

also used to eliminate feedback frequencies, they are released once new

feedback occurs. Pressing the FILTER key once again activates the FILTER

LEARN function.

8

1. INTRODUCTION

SHARK DSP110

+ When both FILTER LED and display stop flashing, the FILTER LEARN function

has been completed. Press the FILTER key to cancel the function. After a

short delay, the unit returns to the FILTER menu.

The FILTER LEARN function generates short feedback-causing signals that

are sent back to the DSP110s input, where feedbacks are detected and

suppressed. The FILTER LEARN function is an useful tool for live concerts that

prevents filters from being released prematurely. Fixed filters can only be

reconfigured as free, searching filters by means of a RESET. In normal mode,

which is activated after power-up, set filters are automatically released one after

the other, when free filters are needed to search and destroy feedback

frequencies.

+ To ensure that the FILTER LEARN function works properly, the short

feedback-causing signals are output with a level of -18 dB below digital

maximum. However, the feedback caused during the FILTER LEARN

procedure will be limited by the compressor to -30 dB below digital

maximum. Please note that considerable volume levels can still occur,

which is why you should use the FILTER LEARN function only before the

concert/event begins.

13

Enable the ACTIVE button to set inoperative filters to automatic search mode.

When this button is up (control LED is off), those filters are inoperative which

have not yet found a feedback frequency. Pressing the ACTIVE button for a

longer time (please wait, until all five parameter LEDs light up) enables the

RESET function. All filters will be reset, i.e. set to automatic search mode.

1. INTRODUCTION

9

SHARK DSP110

10

SHARK DSP110

20

This is the SHARKs balanced JACK input, which is wired in parallel to the XLR

input.

21

Use the INPUT LEVEL switch to select the input sensitivity (microphone or line

levels). In LINE mode, you can use the CLIP LEVEL control to adapt the internal

level settings to the digital circuitry. Please make sure that the CLIP-LED will

not light up.

22

The PHANTOM switch enables the Phantom Power supply required for

condenser microphones.

23

The PHANTOM CONTROL LED lights up when Phantom Power is on.

2. APPLICATIONS

2.1 Wiring the DSP110: general remarks

With its great versatility the SHARK can be used for a variety of applications. This

chapter describes connection and configuration examples of the most common

applications.

2.1.1 Connection between microphone and mixing console

In live applications it is often useful to protect specific single microphones against

feedback. We therefore recommend that you connect the SHARK between your

microphone and a microphone input on your mixing console (OUTPUT LEVEL switch

set to MIC). If all mic inputs are in use, you can set the SHARKs OUTPUT switch to

+4dBu (switch pressed) and adapt the output signal of your SHARK to a line input on

your console using the MIC GAIN control. To prevent the occurrence of subsonics you

can activate the SHARKs Low Cut filter. Switch on Phantom Power when you are

using condenser microphones.

2. APPLICATIONS

11

SHARK DSP110

12

SHARK DSP110

2.1.3 Connection between mixing console and power amplifier

When you use the SHARK as a Delay Line unit for speaker systems placed at various

positions (see chapter 2.3), you should connect the SHARK between the consoles

output and the input of the power amp driving the delayed speakers.

13

SHARK DSP110

2.1.4 The SHARK used in the monitor path

Inserting the DSP110 in the monitor path of your mixing console gives you utmost

protection against unwanted feedback. Monitor paths are particularly susceptible to

feedback, because on stage there are usually several microphones and speakers placed

close to each other. Especially vocal microphones pose some problems, because their

volume levels must be fairly high to be able to compete with other instruments, and

often these microphones are hand-held and hence carried around on stage. It is therefore

useful to protect the monitor path against feedback. In particular, when used in the

monitor path, the SHARK produces a positive side effect in that it improves both sound

and volume of the monitors. By filtering interference it makes the sound more transparent

and by eliminating unwanted feedback it allows for raising the volume of the monitors,

an effect that is usually welcomed by musicians on stage. Another advantage when

using this configuration: one SHARK can control several microphones. As at least four

monitor paths are used in a typical live application, all you need are four SHARKs to

give you optimum feedback protection.

14

2. APPLICATIONS

SHARK DSP110

Fig. 2.4: Two SHARKs in the monitor path

2.1.5 The SHARK used in single channels and subgroups

Whenever you want to make sure that wanted feedback such as the feedback sounds

produced by a guitar wont be removed, you should insert one or several DSP110 into

feedback-prone single channels (e.g. vocals) or subgroups of your mixing console!

Route all channels that are susceptible to feedback (e.g. all vocal mics) to one or

several subgroups, in which you insert one or several SHARKs. In this way, all channels

that are less liable to produce feedback (e.g. those carrying line-level signals, or

instrumental microphones with lower volumes) can pass the console unaltered, while

only critical microphone channels are controlled by the DSP110. Thus, you can protect

your sound reinforcement system against feedback and still use wanted feedback

sounds.

2. APPLICATIONS

15

SHARK DSP110

16

SHARK DSP110

2.2 The Feedback Destroyer in the SHARK

The SHARK identifies feedback by splitting the entire frequency spectrum (20 Hz to

20 kHz) into sections of 1/60 of an octave and determining the level of each of these

bands. The values calculated are then referenced to the level of the overall signal. The

resulting level difference determines whether or not a filter is set. The SHARK allows

you to adapt these decisive parameter to your needs: within a range from 1 through

100 you can edit the feedback detection sensitivity. The standard setting is 50, which

ensures the best possible detection of feedback for the majority of applications. For

speech-only applications you can raise the feedback detection threshold towards 100,

which enables the algorithm to detect and remove feedback even more quickly. Vice

versa, lower values provide for a more stable feedback suppression responding less to

wanted feedback-like signal portions produced by guitars or keyboards.

In FILTER LEARN mode, feedback is generated and suppressed automatically.

Whenever it detects feedback, the DSP110 selects the filter parameters automatically

to efficiently remove the feedback. As the filter is set to the frequency detected, this

mode is ideally suitable for suppressing constant feedback frequencies produced by

fixed microphones, e.g. those used on drums. Once set, the filters automatically enters

lock mode, i.e. the frequency remains fixed but width and depth of the filter are still

being adapted to the signal. The filter width is enlarged whenever the feedback frequency

shifts slightly. If feedback persists, gain is reduced even more and kept low to prevent

feedback from recurring.

All microphones that are moved during a performance (e.g. hand-held vocal

microphones) are usually susceptible to varying feedback frequencies, which should

be suppressed in automatic search mode (entered when you power up the SHARK).

Much like in FILTER LEARN mode, a filter automatically determines the ideal settings

for all parameters, in order to suppress feedback. However, once all filters have been

set, the filter first activated gets reset to automatic search mode. Thus, the SHARK

makes sure that there is always one free filter to identify and remove new feedback

frequencies. If your music contains wanted feedback elements (e.g. guitar feedback),

the SHARK will suppress these too, because it is impossible from a physical point of

view to distinguish wanted from unwanted feedback. Section 2.1.6 provides some

information on how to get around this physical problem.

2. APPLICATIONS

17

SHARK DSP110

2.3 The integrated Delay

In addition to speakers on or near the stage, major-scale installations often have

speaker groups positioned at a distance to the stage or flown above the audience, in

order to provide listeners away from the stage with direct sound. However, since

sound needs some time to travel around (343.6 m/sec at 20°C, accelerates by 0.6 m/

sec per °C), it reaches the audience not simultaneously but gets delayed by a certain

amount. To make up for the different run times between stage and remote speakers,

the latter must be provided with an electronically delayed signal, which is usually

done by means of special-purpose Delay devices. You wont need them, however,

when youve got a SHARK, as the DSP110 integrates a Delay Line circuit giving you

the same convenience of operation as dedicated devices. Simply measure the

distance between the various speaker groups and enter this value (in meters or feet).

Chapter 2.1.3 shows you how to wire the DSP110 in this type of application.

Fig. 2.6: Sound reinforcement application with different speaker positions

2.4 The Noise Gate function

The main task of a Noise Gate is to separate unwanted background noise from

wanted signals and remove noise inaudibly. A so-called downward Expander

automatically reduces the overall level of all signals below an adjustable threshold

and thus expands the dynamic range of the program material.

In live or stage applications and multi-microphone systems, in particular, the SHARK

has a variety of possible uses: as a moderately and accurately set Gate it efficiently

suppresses background noise, compressor-induced noise build-up and crosstalk

18

2. APPLICATIONS

SHARK DSP110

between microphones, without producing any unpleasant side effects.

A typical Gate application is the processing of vocal tracks. Especially when using a

Compressor, the distance between microphone and singer is critical: as the distance

increases, more and more disturbing background noise is picked up. Use the Gate

function to fade out unwanted interference inaudibly during music pauses. In live

applications, e.g. crosstalk of drum and piano tracks can be suppressed or acoustically

contaminated recordings can be cleaned.

When a singer sings into a stage microphone, the background noise is masked and

hence not perceived. During music pauses, however, the microphone picks up the

noise produced by the P.A. system and monitor speakers, which can lead to unpleasant

feedback.

When you insert the SHARK in a vocal channel and adjust it so that it mutes the

channel, as long as the microphone is not in use, susceptibility to feedback can be

reduced enormously. Basically, all stage microphones should be treated in this way.

The GATE LEARN function helps you adjust the Gate threshold. Use this function

before the concert and after the sound check. If the adjusted value yields unsatisfactory

results, the UP/DOWN buttons can be used to fine-tune the Gate, until it closes only

during signal pauses and suppresses interference efficiently.

2.5 The Low Cut filter in the SHARK

In miking it is quite common to fade out low-frequency signal portions such as stage

rumble, pop sounds or other types of interference. Frequencies of that kind often have

high amplitudes and not only affect the sound image but can also damage power amps

and/or loudspeakers. The SHARK is equipped with a tunable high pass filter that features

a very high slope. Press the LOW CUT button to tune the cutoff frequency from 20 Hz

through 150 Hz with the UP/DOWN buttons, so that interference noise is faded out as

perfectly as possible, while the wanted signals remains unaffected.

2.6 The Compressor function

In broadcast and recording applications, signal levels often exceed the headroom of

signal-processing devices, which means that the dynamic range must be reduced to

avoid distortion. This is usually accomplished by the use of Compressors or Limiters,

which use an automatic gain control circuit to reduce the signal level during loud

passages. In this way, it is possible to compress the dynamics of a microphone channel

2. APPLICATIONS

19

20

SHARK DSP110

Unbalanced use of

mono 1/4" jack plugs

2 1

3

Balanced use of

stereo 1/4" jack plugs

Ring

Balanced use with XLR connectors

1 2

3

21

SHARK DSP110

4. SPECIFICATIONS

AUDIO INPUTS

Connectors XLR and 1/4" jack

Type RF filtered, servo-balanced input

Impedance 6 kOhms balanced, 3 kOhms unbalanced

Nominal Operating Level microphone or line level source (switchable)

Max. Input Level +19 dBu at microphone level and line level

AUDIO OUTPUTS

Connectors XLR and 1/4" jack

Type electronically servo-balanced output stage

Impedance 60 Ohms balanced, 30 Ohms unbalanced

Nominal Operating Level microphone level source or +4 dBu (switchable)

Max. Output Level +20 dBu at +4 dBu nominal level, -12 dBu at microphone level

SYSTEM SPECIFICATIONS

Frequency Response 10 Hz to 21 kHz

Noise > 92 dB at line level, unweighted, 22 Hz to 22 kHz

THD 0.007 % typ. @ +4 dBu, 1 kHz, gain 1

DIGITAL PROCESSING

Converters 24-bit Sigma-Delta, 64/128-times oversampling

Sampling Rate 46.875 kHz

DISPLAY

Type 4-digit numeric LED display

POWER SUPPLY

Mains Voltages USA/Canada 120 V ~, 60 Hz, PSU DSP110UL

PHYSICAL

Dimensions (H * W * D) approx. 2 1/4" (56 mm) x 3 1/2" (88 mm) x 5 1/8" (130 mm)

Net Weight approx. 0.5 kg

> 89 dB at microphone level, unweighted, 22 Hz to 22 kHz

U.K./Australia 240 V ~, 50 Hz, PSU DSP110UK

Europe 230 V ~, 50 Hz, PSU DSP110EU

Japan 100 V ~, 60 Hz, PSU DSP110JP

General export model 100 - 120 V ~, 200 - 240 V ~, 50 - 60 Hz

BEHRINGER is constantly striving to maintain the highest professional standards. As a result of these efforts,

modifications may be made from time to time to existing products without prior notice. Specifications and appearance

may differ from those listed or illustrated.

22

4. SPECIFICATIONS

SHARK DSP110

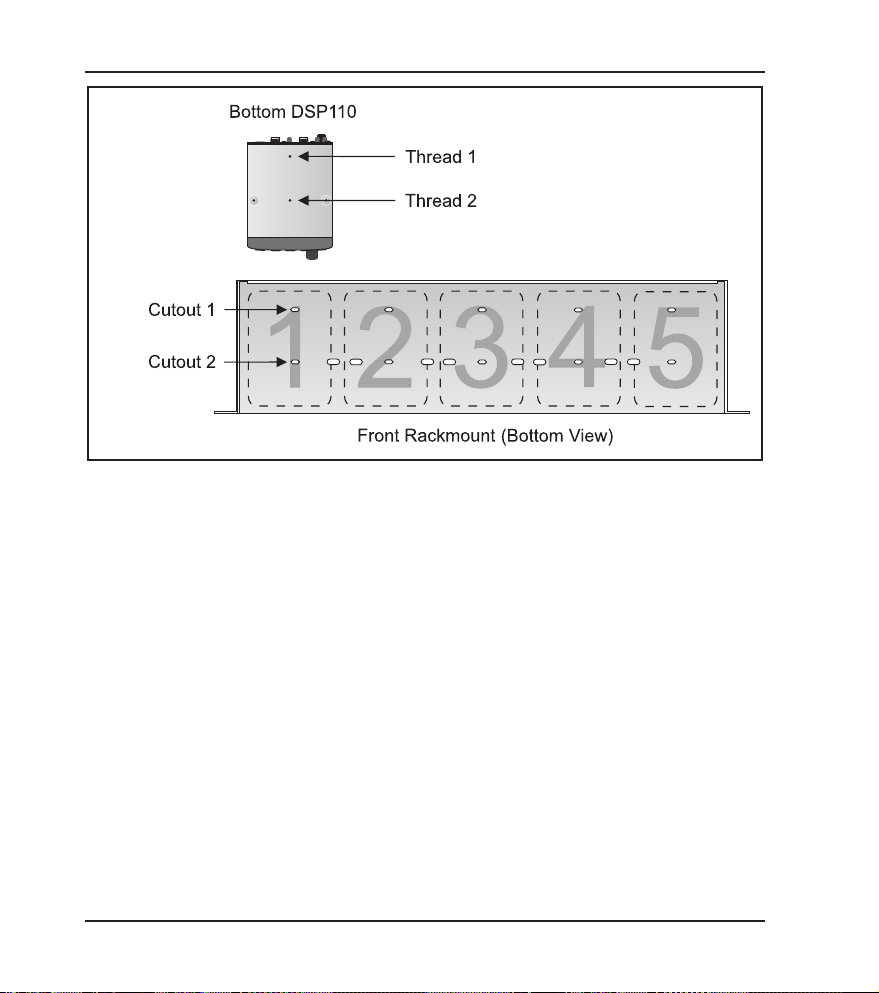

5. RACKMOUNT (OPTIONAL)

With the available rackmount (optional) you have the possibility to place five SHARKs

on two units of space in your rack.

+ Before you begin with the work, please disconnect the Power Supply Units

from the SHARKs!

To mount the SHARKs on the rackmount you should use the supplied screws (type

M3). You need two screws to fix one DSP110 onto the rackmount. In the bottom of your

SHARK you will find two little threads. You have to position the single SHARKs on the

rackmount, so that the threads correspond to the cutouts of the rackmount (see fig.5.1).

Now you can fix the DSP110 onto the rackmount. Just take a cross-point screwdriver

and tighten both screws loosely. After you have fixed all SHARKs on the rackmount,

you can adjust the devices and tighten all screws solidly.

5. RACKMOUNT (OPTIONAL)

23

SHARK DSP110

Fig. 5.1: Installation of the DSP110 on the available rackmount (optional)

+ Please, only use the supplied screws to install the SHARKs on the

rackmount. Longer or thicker screws can damage the electronics inside

of the device and doing so will void your warranty rights.

You will need 2 units of space for the DSP110 rackmount. For technical reasons a little

gap remains above the rackmount.

24

5. RACKMOUNT (OPTIONAL)

SHARK DSP110

not cover any such modification/adaptation, irrespective of whether it

6. WARRANTY

§ 1 WARRANTY CARD/ONLINE REGISTRATION

To be protected by the extended warranty, the buyer must complete

and return the enclosed warranty card within 14 days of the date of

purchase to BEHRINGER Spezielle Studiotechnik GmbH, in accordance

with the conditions stipulated in § 3. Failure to return the card in due

time (date as per postmark) will void any extended warranty claims.

Based on the conditions herein, the buyer may also choose to use the

online registration option via the Internet (www.behringer.com or

www.behringer.de).

§ 2 WARRANTY

1. BEHRINGER (BEHRINGER Spezielle Studiotechnik GmbH including

all BEHRINGER subsidiaries listed on the enclosed page, except

BEHRINGER Japan) warrants the mechanical and electronic

components of this product to be free of defects in material and

workmanship for a period of one (1) year from the original date of

purchase, in accordance with the warranty regulations described below.

If the product shows any defects within the specified warranty period

that are not due to normal wear and tear and/or improper handling by

the user, BEHRINGER shall, at its sole discretion, either repair or replace

the product.

2. If the warranty claim proves to be justified, the product will be returned

to the user freight prepaid.

3. Warranty claims other than those indicated above are expressly

excluded.

§ 3 RETURN AUTHORIZATION NUMBER

1. To obtain warranty service, the buyer (or his authorized dealer) must

call BEHRINGER (see enclosed list) during normal business hours

BEFORE returning the product. All inquiries must be accompanied by a

description of the problem. BEHRINGER will then issue a return

authorization number.

2. Subsequently, the product must be returned in its original shipping

carton, together with the return authorization number to the address

indicated by BEHRINGER.

3. Shipments without freight prepaid will not be accepted.

§ 4 WARRANTY REGULATIONS

1. Warranty services will be furnished only if the product is accompanied

by a copy of the original retail dealers invoice. Any product deemed

eligible for repair or replacement by BEHRINGER under the terms of

this warranty will be repaired or replaced within 30 days of receipt of the

product at BEHRINGER.

2. If the product needs to be modified or adapted in order to comply with

applicable technical or safety standards on a national or local level, in

any country which is not the country for which the product was originally

developed and manufactured, this modification/adaptation shall not be

considered a defect in materials or workmanship. The warranty does

The information contained in this manual is subject to change without notice. No part of this manual may be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying and recording of any kind, for any purpose, without the express wri tten permission of

BEHRINGER, SHARK and FEEDBACK DESTROYER are registered trademarks. ALL RIGHTS RESERVED.

BEHRINGER Spezielle Studiotechnik GmbH, Hanns-Martin-Schleyer-Str. 36-38, 47877 Willich-Münchheide II, Germany

BEHRINGER Spezielle Studiotechnik GmbH.

© 2001 BEHRINGER Spezielle Studiotechnik GmbH.

Tel. +49 (0) 21 54 / 92 06-0, Fax +49 (0) 21 54 / 92 06-30

was carried out properly or not. Under the terms of this warranty,

BEHRINGER shall not be held responsible for any cost resulting from

such a modification/adaptation.

3. Free inspections and maintenance/repair work are expressly excluded

from this warranty, in particular, if caused by improper handling of the

product by the user.

This also applies to defects caused by normal wear and tear, in particular,

of faders, potentiometers, keys/buttons and similar parts.

4. Damages/defects caused by the following conditions are not covered

by this warranty:

s misuse, neglect or failure to operate the unit in compliance with

the instructions given in BEHRINGER user or service manuals.

s connection or operation of the unit in any way that does not comply

with the technical or safety regulations applicable in the country

where the product is used.

s damages/defects caused by force majeure or any other condition

that is beyond the control of BEHRINGER.

5. Any repair or opening of the unit carried out by unauthorized personnel

(user included) will void the warranty.

6. If an inspection of the product by BEHRINGER shows that the defect

in question is not covered by the warranty, the inspection costs are

payable by the customer.

7. Products which do not meet the terms of this warranty will be repaired

exclusively at the buyers expense. BEHRINGER will inform the buyer

of any such circumstance. If the buyer fails to submit a written repair

order within 6 weeks after notification, BEHRINGER will return the unit

C.O.D. with a separate invoice for freight and packing. Such costs will

also be invoiced separately when the buyer has sent in a written repair

order.

§ 5 WARRANTY TRANSFERABILITY

This warranty is extended exclusively to the original buyer (customer of

retail dealer) and is not transferable to anyone who may subsequently

purchase this product. No other person (retail dealer, etc.) shall be entitled

to give any warranty promise on behalf of BEHRINGER.

§ 6 CLAIM FOR DAMAGES

Failure of BEHRINGER to provide proper warranty service shall not

entitle the buyer to claim (consequential) damages. In no event shall

the liability of BEHRINGER exceed the invoiced value of the product.

§ 7 OTHER WARRANTY RIGHTS AND NATIONAL LAW

1. This warranty does not exclude or limit the buyers statutory rights

provided by national law, in particular, any such rights against the seller

that arise from a legally effective purchase contract.

2. The warranty regulations mentioned herein are applicable unless they

constitute an infringement of national warranty law.

6. WARRANTY

25

Loading...

Loading...