Page 1

®

IMMAGE® 800

Immunochemistry System

A11409-AA

March 2004

REPEC

Beckman Coulter Ireland, Inc.

Mervue Business Park,

Mervue Galway,

Ireland 353 91 774068

BECKMAN COULTER, INC. • 4300 N. Harbor Blvd., Fullerton, CA U.S.A. 92835

Instructions For Use

For In Vitro Diagnostic Use

© Copyright 2004 Beckman Coulter, Inc.

Page 2

TABLE OF CONTENTS

CHAPTER 1 General Information ..................................................................................................... 1-1

Introduction ............................................................................................................... 1-1

Precautions And Hazards .......................................................................................... 1-3

CHAPTER 2 System Description ...................................................................................................... 2-1

System Description ................................................................................................... 2-1

System Specifications and Characteristics .................................................................. 2-4

Instrument Specifications ......................................................................................... 2-4

Sample Container Information ..................................................................................... 2-6

Sample Containers Allowed ..................................................................................... 2-6

CHAPTER 3 Theory of Operations ................................................................................................... 3-1

Principles of Methodologies ..................................................................................... 3-1

Antigen Excess Testing ............................................................................................ 3-2

CHAPTER 4 System Power On/Off .................................................................................................. 4-1

System Power On ...................................................................................................... 4-1

System Power Off ..................................................................................................... 4-2

CHAPTER 5 System Software Configuration ................................................................................... 5-1

Overview ................................................................................................................... 5-1

Selecting Non-Standard Dilutions as Default for Each Chemistry ........................... 5-6

User-Defined Reagent Chemistry Setup .................................................................... 5-10

UDR Chemistry Overview and Precautions ........................................................... 5-10

Setting Up a UDR Chemistry ................................................................................. 5-11

Defining a UDR Chemistry .................................................................................... 5-16

Defining UDR Calibration Information .................................................................. 5-25

Deleting UDR Chemistries ..................................................................................... 5-26

Editing UDR Definitions ........................................................................................ 5-27

Loading UDR Reagent Cartridges .......................................................................... 5-29

Loading/Clearing UDR Buffer and Diluent ............................................................ 5-32

Programming Rate Mode ........................................................................................ 5-34

Calibrating a UDR Chemistry ................................................................................. 5-37

Approving a Calibration ......................................................................................... 5-44

Printing UDR Reports ............................................................................................. 5-54

Setting Up UDR Reference Intervals and Panels ................................................... 5-56

Defining UDR Quality Control ............................................................................... 5-57

Programming a UDR Sample ................................................................................. 5-58

Instrument Setup ........................................................................................................ 5-59

Overview ................................................................................................................. 5-59

Placing Labels on a Rack ........................................................................................ 5-60

Wash Solution Box and Waste Container Placement ............................................. 5-61

IMMAGE 800 Instructions For Use A11409 Table of Contents

March 2004 Page 1 of 2

Page 3

CHAPTER 6 Reagents/Calibration .................................................................................................... 6-1

Reagents .......................................................................................................................6-1

Overview ................................................................................................................... 6-1

Calibration ................................................................................................................... 6-6

Overview ................................................................................................................... 6-6

Calibration History ................................................................................................... 6-8

CHAPTER 7 Preparing for Programming/Running .......................................................................... 7-1

Overview ................................................................................................................... 7-1

Programming a Sample ................................................................................................ 7-3

Overview ................................................................................................................... 7-3

Selecting Sample Options ......................................................................................... 7-6

Entering an Off-line Dilution Factor ........................................................................ 7-8

Programming a Batch of Samples .......................................................................... 7-12

Loading and Starting a Run ....................................................................................... 7-15

Loading Samples ..................................................................................................... 7-15

Pre-run Checklist .................................................................................................... 7-17

Starting the Run ...................................................................................................... 7-18

Pausing a Run ............................................................................................................ 7-19

Overview ................................................................................................................. 7-19

System Pause .......................................................................................................... 7-20

Pausing to Load Samples ........................................................................................ 7-21

CHAPTER 8 Results Recall .............................................................................................................. 8-1

Overview ................................................................................................................... 8-1

Displaying Recalled Results on the Screen .............................................................. 8-2

Printing Recalled Results .......................................................................................... 8-3

Sending Results to the Host ...................................................................................... 8-4

CHAPTER 9 Quality Control ............................................................................................................ 9-1

Overview ................................................................................................................... 9-1

Defining a Control .................................................................................................... 9-2

CHAPTER 10 Utilities ....................................................................................................................... 10-1

Maintenance ............................................................................................................ 10-1

Troubleshooting ...................................................................................................... 10-3

CHAPTER 11 System Status/Instrument Commands ....................................................................... 11-1

System Status/Instrument Commands .................................................................... 11-1

APPENDIX A Additional Information ............................................................................................... A-1

Pre-run Checklist ..................................................................................................... A-1

Quick References Using the IMMAGE 800 Immunochemistry System Operations

Manual ..................................................................................................................... A-2

INDEX

IMMAGE 800 Instructions For Use A11409 Table of Contents

March 2004 Page 2 of 2

Page 4

Introduction

Intended Use

The Beckman Coulter IMMAGE® 800 Immunochemistry System (Refer to Figure 1.1.) is a

fully automated, computer controlled, bench-top analyzer designed for the in vitro

quantitation of biological fluid components and therapeutic drugs. The system methodologies

are rate turbidimetry and rate nephelometry.

The IMMAGE 800 is a high throughput, random access analyzer that features bar code

identification of samples and reagents to perform sample testing. It automatically dilutes the

samples and delivers them to the reaction cuvette along with other reaction constituents. The

system analyzes up to 72 samples per run with up to 24 analytes per sample.

Scope of Manual

This manual provides information on the operation of the IMMAGE 800. Diagnostic

interpretation or the clinical significance of the assay results provided by the system are not

discussed in this manual. Typical and actual results are shown only to demonstrate the

operating procedures, parameters, and characteristics of the system.

CHAPTER 1 General Information

Reference Materials

Detailed information is available in the following manuals that accompany the IMMAGE 800

Immunochemistry System. Those manuals include:

• IMMAGE 800 Immunochemistry System Operations Manual. This manual contains a

detailed system description, comprehensive operating instructions, theory of operation,

system calibration and programming procedures, and quality control information for the

IMMAGE 800 analyzer.

• IMMAGE Immunochemistry Systems Chemistry Information Manual. This manual

contains specific chemistry information for the full range of analytes available on the

IMMAGE 800 analyzer.

• IMMAGE Immunochemistry Systems Host Interface Specifications.

• IMMAGE Immunochemistry Systems Sampling Template.

IMMAGE 800 Instructions For Use A11409 General Information

March 2004 Page 1-1

1

Page 5

1 2 3 4

5 6

7

8

1. Reagent Probe and Mixer

2. Sample Probe and Mixer

3. Reagent Syringe

4. Sample Syringe

5. Computer

6. Monitor

7. Printer

8. Waste Container

9. Wash Solution

Figure 1.1 IMMAGE 800 Immunochemistry System

Shipping Damage

Each IMMAGE 800 System is carefully examined and checked by Beckman Coulter before it

is shipped. When you receive your new IMMAGE 800 System, visually inspect the shipping

container for any possible damage, It there is damage, notify the Beckman Coulter Service

Representative before his/her arrival at your facility to install your system.

®

9

Immage 800

11 12

141310

10. Reagent Compartment

11. Reaction Module

12. Cuvette Wash Station

13. Advance Button

14. Sample Carousel

15. Keyboard

16. Mouse

17. Uninterruptible Power Supply

-not shown

15

16

A011426L.EPS

If no damage is found to the shipping container, the Beckman Coulter Service Representative

will supervise the unpacking of your system. If there is damage in any way, the customer

should file a claim with the carrier. If no damage is found, a visual and operational check of

your system will be performed.

IMMAGE 800 Instructions For Use A11409 General Information

March 2004 Page 1-2

1

Page 6

Precautions And Hazards

Precautions

• Do not store or place a diskette near electrical motors, power supplies, generators, magnets,

or magnetic fields.

• Hold a compact disk (CD) by the edges and replace it in its case after use. DO NOT place a

CD in direct sunlight or excessive heat or humidity.

• Sample containers must contain an adequate volume of test specimen to ensure accurate

aspiration.

Hazards

• Connect the three-pronged power plug from all system components of the IMMAGE 800

Immunochemistry System to a three-wire grounded power source. DO NOT use an adapter

to connect the power plug to a two-pronged outlet. If the electrical outlet will not accept the

three-pronged plug, notify a qualified maintenance personnel.

UNDER ANY CIRCUMSTANCES, DO NOT OPERATE THE SYSTEM UNTIL AN

ELECTRICAL GROUND IS PROVIDED AND THE POWER CORD IS PROPERLY

CONNECTED TO GROUND.

• Close reagent and sample carousel covers and keep clear of all mechanical assemblies when

booting up the system.

• Keep clear of both cranes while the instrument is running.

• Keep all covers and shields in place while the instrument is running.

• Confirm that the instrument status is Standby when adding or changing reagents, buffers,

diluents, or dilution segments. The instrument status must be in Standby or "Pausing-OK to

load samples" when adding or removing samples. Keep reagent and sample carousel covers

closed while the instrument is running.

• Confirm that the system is turned off before replacing any defective mechanical or electrical

part in the system.

• DO NOT tamper with or remove the housing of any bar code reader.

• Dispose all waste liquids from the IMMAGE 800 Immunochemistry System in an approved

method for handling biohazardous material.

• Observe all laboratory policies or procedures pertaining to the handling of biological

samples that may contain pathogens.

•To EMERGENCY STOP, turn the instrument main power switch off if the stop button on

the screen is unavailable, and the instrument must be stopped immediately.

• PRESERVATIVES: Sodium azide preservative may form explosive compounds in metal

drain lines. See National Institute for Occupational Safety and Health bulletin: Explosive

Azide Hazards (8/16/76).

• Incineration of used reagent cartridges may produce toxic fumes.

IMMAGE 800 Instructions For Use A11409 General Information

March 2004 Page 1-3

1

Page 7

Symbols and Labels

High Voltage-Electric Shock Risk

This symbol indicates high voltage or risk of electric shock.

Read Manual

This symbol cautions that the manual should be read before using the system.

General Biohazard Caution

This symbol is the international symbol for biohazardous material.

High Voltage-Electric Shock Risk

Read Manual

Biohazard Label

Caution Biohazard

This cautionary label is located between the sample and reagent carousels. Operate the

system with all covers in place.

Caution Biohazard Label

Barcode Caution Label

This label is placed on the cover of any laser-based bar code reader. Do not stare into laser

light beam when cover is open or removed.

Bar Code Caution Label

IMMAGE 800 Instructions For Use A11409 General Information

March 2004 Page 1-4

1

Page 8

Laser

This label is placed near any opening through which a bar code reading beam emits. Avoid

exposure to laser light emitted from the opening.

Laser Caution Label

Class II Laser Caution

This cautionary label is located between the sample and reagent carousels. Do not stare into

laser light beam.

Class II Laser Caution Label

Class III B Laser Caution

This cautionary label is located at the top of the optics module. Avoid direct exposure to laser

light beam.

A010648L.EPS

Class III B Laser Caution Label

Compartment Cover Notice

This label is located on the reagent compartment cover. The instrument will stop if the cover

is opened.

A010647L.EPS

Reagent Compartment Cover Label

IMMAGE 800 Instructions For Use A11409 General Information

March 2004 Page 1-5

1

Page 9

System Description

Introduction

The IMMAGE® 800 Immunochemistry System is a bench-top analyzer composed of the

IMMAGE 800 instrument, computer and printer. (Refer to Figure 2.1.) The system is shipped

complete for installation. The system will be installed by a Beckman Coulter Representative.

CHAPTER 2 System Description

1

1. Instrument

2. Computer

3. Printer

2

Figure 2.1 The IMMAGE 800 Immunochemistry System

3

A011408P.EPS

IMMAGE 800 Instructions For Use A11409 System Description

March 2004 Page 2-1

2

Page 10

System Components

IMMAGE 800 Instrument

The IMMAGE 800 instrument is the analytical unit where the samples and reagents are loaded

and where the chemical reactions take place. (Refer to Figure 2.2.)

1

2

6

5

1. Reagent Compartment

2. Reagent Crane

3. Reaction Module

4. Sample Carousel

3

5. Sample Crane

6. Upper Instrument Subsystems

7. Sample Carousel Advance Button

4

A011409P.EPS

Figure 2.2 IMMAGE 800 Instrument

Computer

The computer supplies the user interface to the IMMAGE 800 Immunochemistry System and

stores data.

The user performs all software interaction in the computer portion of the system. This

software interaction is stored in the computer and is sent to the instrument at the appropriate

time.

Additionally, patient results, control results, and setup parameters are stored in the computer.

NOTICE

Only the computer supplied by Beckman Coulter is to be used with the

IMMAGE 800 Immunochemistry System.

IMMAGE 800 Instructions For Use A11409 System Description

March 2004 Page 2-2

2

Page 11

Changing the Date on the PC

The PC supplied with some IMMAGE 800 system contains a battery that provides power to

the computer’s internal clock during power off. The status of the battery is checked every time

the Power On sequence is performed.

Printer

The printer supplied with the IMMAGE 800 Immunochemistry System is a Hewlett Packard

DeskJet printer. The printer is designed to use single sheet paper.

The printer is set up to use 8.5 × 11 inch paper. Paper size can be chosen in Printer Setup.

Program Structure

The software or interface of the IMMAGE 800 Immunochemistry System is divided into

functional areas based on different tasks. The icons in the menu bar at the top of the screen

represent the various functional areas.

CAUTION

The date and time must be reset each time the Power On sequence is

performed on a computer with a dead CMOS (Complementary Metal Oxide

Semiconductor) battery. Contact Beckman Coulter Clinical Support or the

nearest local Beckman Coulter Field Service office for assistance in

replacing the battery.

The MAIN operator screen consists of:

• Stop - Instrument stops immediately

• Home - Reagents, sample carousels, cuvettes and probes return to the home position

• Pause - Instrument stops after current samples are completed

• Run - Starts a run

IMMAGE 800 Instructions For Use A11409 System Description

March 2004 Page 2-3

2

Page 12

System Specifications and Characteristics

Instrument Specifications

Placement

The surface on which the unit rests must be free of vibration and must be level, 1° or <0.75

inch (1.9 cm) slope across the length and the width of the instrument. Do not place instrument

in direct sunlight or drafts or near a heating or cooling duct.

Clearance

Sides: 6 inches (15.2 cm) minimum

Back: None

Front: 3 inches (7.6 cm) minimum

Top: 4 inches (10.1 cm) from top of instrument

Dimensions (Excluding Wash and Waste Bottles)

Height = 30 inches (76.2 cm)

Depth = 25.5 inches (64.8 cm)

Length = 43.5 inches (110.5 cm)

Weight

250 lb. (120 kg)

Power Requirements

Operating Range 115 (90 to 132) VAC RMS, Single Phase

Frequency 50/60 Hz nominal (47 to 63 Hz)

Transient Suppression Recommended

BTU Generated 2,900 BTU/hour

Electrical Outlet Grounded per Local Code

Surge Protector Recommended

Current 8.0 Amps (normal) 12 Amps surge

230 (180 to 264) VAC RMS, Single Phase

IMMAGE 800 Instructions For Use A11409 System Description

March 2004 Page 2-4

2

Page 13

Temperature and Humidity

Ambient Temperature +15°C to +32°C

Ambient Relative Humidity

(RH)

Reagent Compartment

Temperature

Reaction Module

Temperature

Environmental Conditions

System can operate up to 8000 ft (2,438m) elevation.

Drain Requirements

Flow Rate: 3 Liters/hour minimum

Waste Container Placement: The opening should be no higher than the top of the instrument.

Regulatory Agency Approvals

The IMMAGE 800 meets the safety requirements for the following agencies: CE, UL, CSA,

IEC and CENFLEC.

Environmental Conditions

System can operate up to 8000 ft. (2,438m) elevation.

15% to 85% (non-condensing)

+13°C to +22°C (+32°C Ambient, <45% RH)

+37°C ± 0.5°C

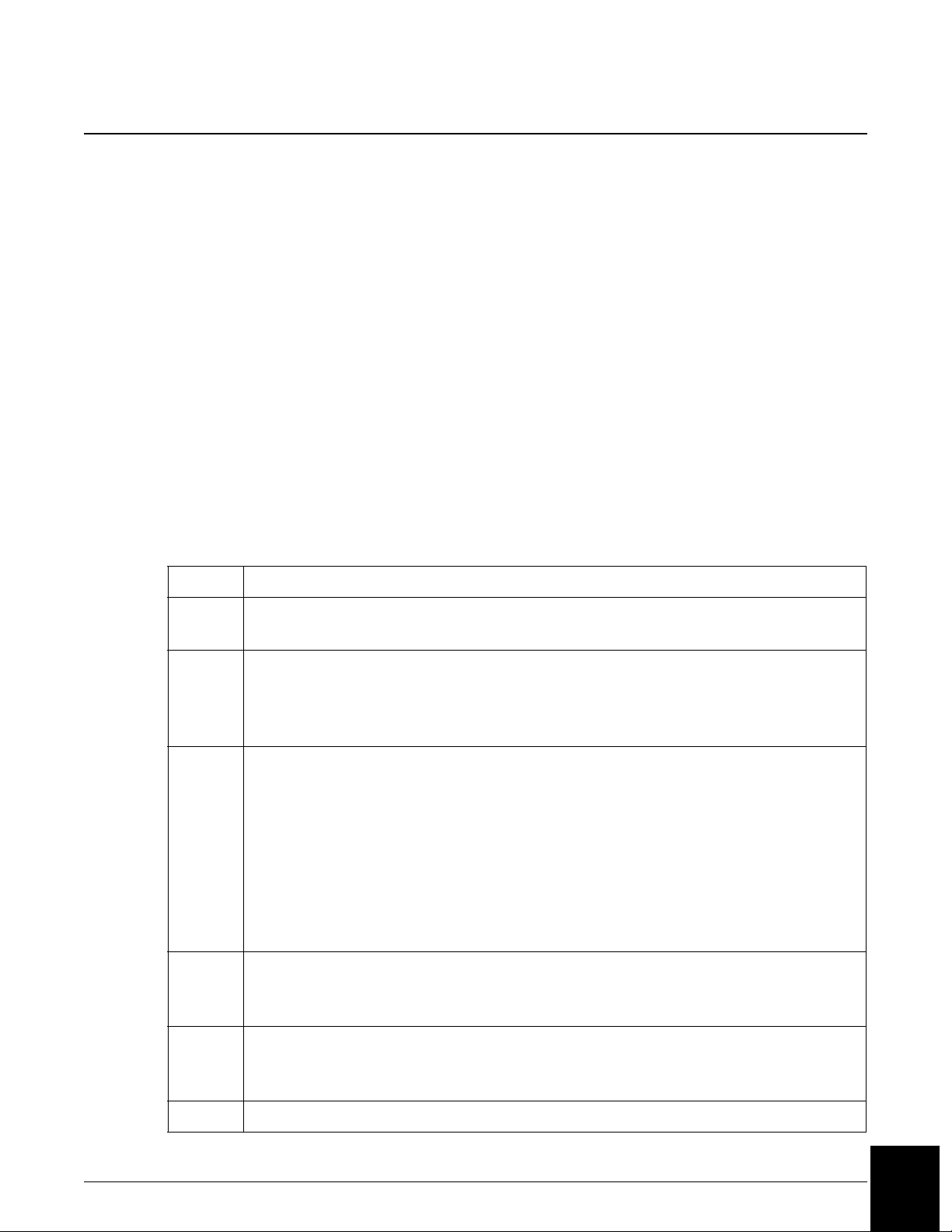

Capacities

The following table lists various system capacities.

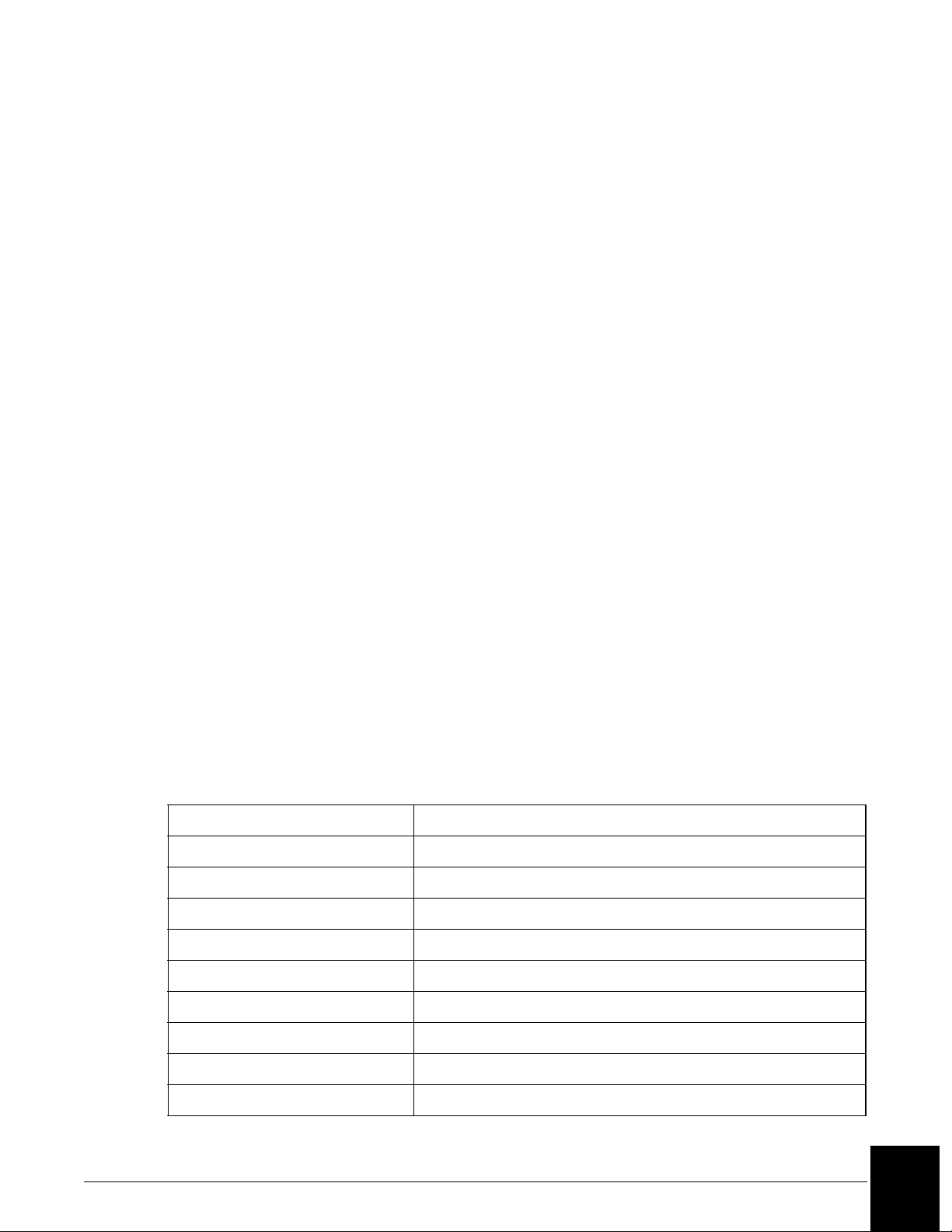

Table 2.1 System Capacities

Item Capacity

Reagents 24 reagent cartridges can be loaded.

Reagent cartridge 40, 150, or 300 tests per cartridge.

Reaction buffers 4 bottles can be loaded.

Buffer bottle 120 mL: 350 tests.

Samples 72 samples can be loaded.

Sample diluents 4 bottles can be loaded.

Diluent bottles 120 mL: number of dilutions is workload dependent.

Sample dilution segments 4 segments of 36 wells each.

Dilution well 300 µL.

(1 of 2)

IMMAGE 800 Instructions For Use A11409 System Description

March 2004 Page 2-5

2

Page 14

Table 2.1 System Capacities, continued

Item Capacity

Wash solution 1 box/10 L/approximately 1,000 tests.

Waste container 5 gallons (18.9 L).

(2 of 2)

IMMAGE 800 Instructions For Use A11409 System Description

March 2004 Page 2-6

2

Page 15

Sample Container Information

Sample Containers Allowed

Introduction

The following categories document specifications for sample containers that can run on the

IMMAGE 800 Immunochemistry System.

Primary Tubes

16 × 100 mm (10 mL)

16 × 75 mm (7 mL)

13 × 100 mm (7 mL)

13 × 75 mm

16.5 × 92 mm

Secondary (Aliquot) Tubes

16 × 100 mm

16 × 75 mm

13 × 100 mm

12 × 75 mm

Microtubes

13 × 100 mm SYNCHRON® Microtube

Sample Cups

2 mL (placed into a sample cup holder)

0.5 mL (placed into a sample cup holder)

™

NOTICE

Low humidity and high ambient temperature may cause evaporation when

using small volumes of sample in sample cups. To minimize evaporation:

• Program samples in positions A or B on the sample carousel, or

• Program samples as STATS.

IMMAGE 800 Instructions For Use A11409 System Description

March 2004 Page 2-7

2

Page 16

CHAPTER 3 Theory of Operations

Principles of Methodologies

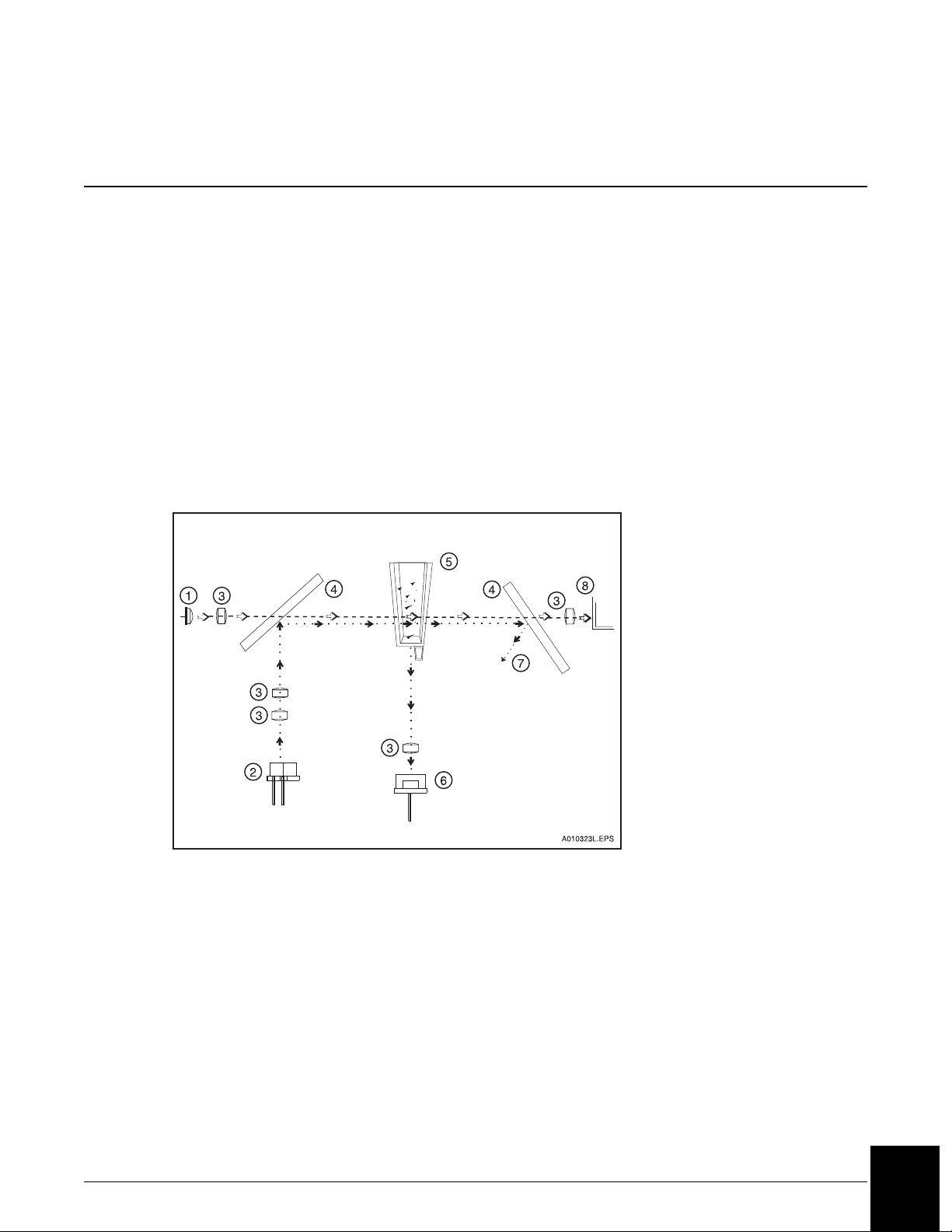

Principles of Rate Nephelometry

The rate nephelometer measures the increase in the intensity of light scattered by particles

suspended in a cuvette. The light source for the rate nephelometer is a 670 nm laser. The

detector is placed at a 90° angle from the laser beam to measure light scatter, as shown in

Figure 3.1.

Principles of Rate Turbidimetry

The rate turbidimeter measures the decrease in the intensity of light as it passes through a

solution of light scattering particles in a cuvette. The light source for the rate turbidimeter is a

light emitting diode (LED) at a wavelength of 940 nm. Turbidimetric measurements are made

at 0° from the incident beam as shown in Figure 3.1.

1. LED Light Source (Turbidimetric)

2. Laser Light Source (Nephelometric)

3. Focus Lens

4. Beam Splitter

5. Reaction Cuvette

6. Nephelometric Detector

(90° angle to incident laser beam)

7. Laser Light Bounces Into Light Trap

8. Turbidimetric Detector

(0° angle to the incident LED beam)

Figure 3.1 IMMAGE 800 Rate Nephelometer and Rate Turbidimeter Basic Components

IMMAGE 800 Instructions For Use A11409 Theory of Operations

March 2004 Page 3-1

3

Page 17

Antigen Excess Testing

Overview

Antigen excess (AGXS) testing is only necessary for some IMMAGE 800 protein reagents.

Immunoglobulin G (serum IGG, urine IGU), Immunoglobulin A (IGA), Immunoglobulin M

(IGM), Kappa (KAP), Lambda (LAM), Haptoglobin (HPT), Urine Transferrin (TRU),

Alpha-1-Microglobulin (A1M), Microalbumin (MA) and Albumin (ALB) which are

identified by the system as ambiguous, are tested for antigen excess condition if AGXS testing

is enabled. A reaction is ambiguous if the rate response could represent either an antigen

excess or an antibody excess reaction.

Antibody Excess

When the reaction is to the left of the optimal antibody-antigen proportions the reaction is in

antibody excess (AbXS). This indicates all the antigen in the sample is bound, forming

complexes. This is the ideal condition for the reaction to take place.

Antigen Excess

When the reaction is to the right of the optimal antigen-antibody proportions the reaction is in

antigen excess (AgXS) and the rate response will start to decrease due to excessive levels of

antigen.

IMMAGE 800 Instructions For Use A11409 Theory of Operations

March 2004 Page 3-2

3

Page 18

System Power On

Introduction

After the IMMAGE® 800 Immunochemistry System installation, the system can be powered

on.

Power On Sequence

Follow the steps below to power on the IMMAGE 800 system.

Step Action

1 Check that the floppy disk drive is empty.

2 Turn on the printer.

3 Turn on the monitor.

4 Turn on the CPU.

5 Verify that the UPS is on. (The UPS power switch is on and the power indicator

CHAPTER 4 System Power On/Off

light is on.)

6 Turn on the instrument.

7 Close reagent and sample carousel covers.

8 When the note is displayed to check dilution segment status, select <OK>.

9 When the temperature warning note displays, select <OK>.

• The system will continue to bring the reagent chamber and reaction cuvettes to

the appropriate temperature range.

• The system will not allow a run to start until the reaction cuvettes are within the

appropriate temperature range.

10 Refer to the appropriate chapters in this manual to operate the system.

IMMAGE 800 Instructions For Use A11409 System Power On/Off

March 2004 Page 4-1

4

Page 19

System Power Off

Power Off Sequence

The instrument status must be Standby in order to proceed with the steps below to power off

the IMMAGE 800 system.

Step Action

1 Check that the floppy diskette drive is empty.

2Select Utilities from the menu bar.

3Select <Shutdown>.

4 When the message Shutdown Complete is displayed, turn off the printer, monitor,

Emergency Stop

Turn the instrument main power switch off if the stop button on the screen is unavailable and

the instrument must be stopped immediately.

NOTICE

The database may become corrupted if power is turned off before the Power

Off sequence is completed.

CPU (computer), UPS, and instrument.

NOTICE

When an emergency stop or unplanned power loss occurs during a run, and

power is restored within 24 hours, the cuvettes must be washed 1 time before

a run can be started. (Refer to IMMAGE 800 Immunochemistry System,

Operations Manual, Chapter 10, Utilities, As-Indicated Maintenance, "Washing

Cuvettes.")

If power is restored after 24 hours, the cuvettes must be replaced. (Refer to

IMMAGE 800 Immunochemistry System Operations Manual, Chapter 10,

Utilities, As-Indicated Maintenance, "Replacing Cuvettes.")

IMMAGE 800 Instructions For Use A11409 System Power On/Off

March 2004 Page 4-2

4

Page 20

Overview

Introduction

CHAPTER 5 System Software Configuration

In System Setup several features of the IMMAGE® 800 Immunochemistry System interface

can be customized for the individual laboratory’s requirements. Setup maintains the default

parameters used for configuring the IMMAGE 800 interface. The instrument must be in

Standby in order to proceed.

This chapter includes:

• configure the chemistry menu

• set up panels

• set up bar codes

• set up reference intervals

• set up reports

• set up special calculations

• set up units/non-standard dilutions

• configure antigen excess testing

• set up date and time

• set up host communications

• set up default

• set up sample comments

• set up demographics

• set up the printer

• set up the language

• read the chemistry protocol diskette

• enter the instrument serial number

• set up user-defined reagent chemistries

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-1

5

Page 21

Accessing Setup

Select Setup from the menu bar. Choose the desired setup option from a numbered button.

(Refer to Figure 5.1.) Refer to the IMMAGE 800 Immunochemistry System Operations

Manual for further details.

E011414S.EPS

Figure 5.1 Setup Screen

Configuring the Chemistry Menu

The chemistry menu available in the sample programming, quality control, panel definition

and other screens is defined by the individual laboratory. The menu contains up to 72

chemistries.

From the Setup screen, select <1> Chemistry Configuration.

Panel Setup

The IMMAGE 800 holds up to 50 chemistry panels in its memory. Each panel is defined with

a name and the chemistries that it contains.

From the Setup screen, select <2> Panels.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-2

5

Page 22

Bar Code Setup

The bar code symbologies recognized by the IMMAGE 800 can be selected. Additionally, the

bar code parameters can be configured to match those of the sample bar codes being read.

From the Setup screen, select <3> Bar Code. (Refer to Figure 5.2.)

E010218S.EPS

Figure 5.2 Bar Code Setup Screen

Bar Code Priority

If the bar code priority is disabled, the batch programming WILL autonumber the racks and

positions.

If the bar code priority is enabled, the batch programming will NOT autonumber the racks and

positions.

• The instrument reads bar coded samples whether or not the Bar Code Priority is enabled.

• Disabling the Bar Code Priority is recommended.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-3

5

Page 23

Reference Interval Setup

When a reference interval and critical range are defined, they are printed beside the result on

the report. A result outside of the reference interval or critical range is flagged. The interval

and range are defined per chemistry or calculation with distinction made for sample type, sex,

and age group.

Chemistries must be configured and calculations must be enabled before intervals can be

defined.

The minimum entries necessary to save a reference interval are low age, low age unit, high

age, high age unit, low reference interval number and high reference interval number.

From the Setup screen, select <4> Reference Interval.

Selecting the Default

The default interval and range will be printed when an age is not specified in sample

programming or when age is specified but the reference interval has not been defined for that

age.

Only one default can be chosen for a particular interval and range definition grouped by

chemistry/calculation, sample type and sex.

Report Setup

Report formats can be selected for patient reports. A report header, including a facility name

and address, can also be defined. Automatic printing of calibration, control, and patient

reports can also be enabled.

From the Setup screen, select <5> Report Setup.

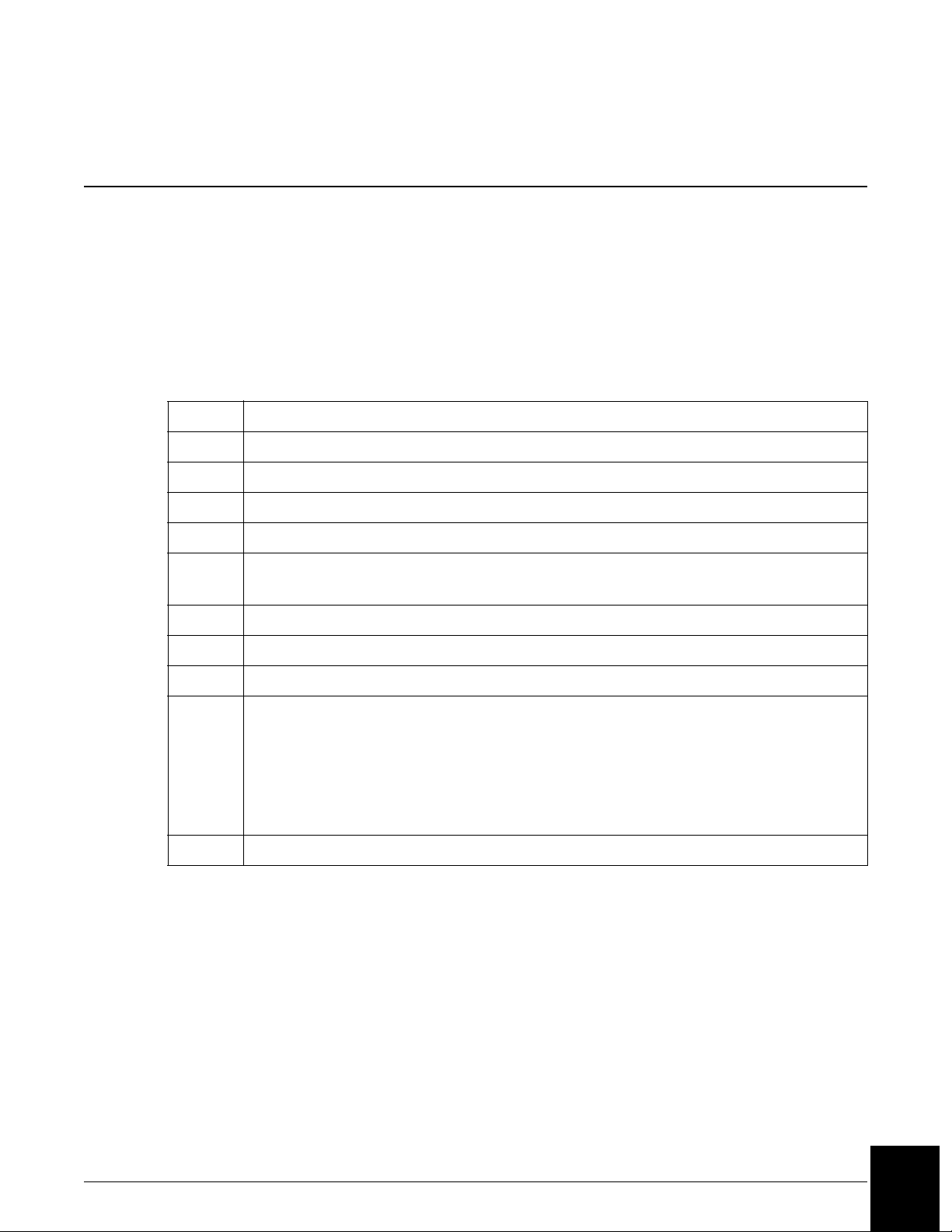

Calculations Setup

There are 12 Beckman Coulter defined calculations that can be enabled for the IMMAGE 800.

The system will automatically calculate and print the final calculation on reports when the

chemistries necessary for the calculation are run.

The system provides a maximum of 28 additional calculations that may be defined, edited,

and/or deleted by the operator. The Custom Calculations feature provides for the reporting of

operator-defined calculations using sample results when chemistries necessary for the

calculations are run. The calculations may involve results from one sample or two linked

samples.

The default for calculations is disabled.

From the Setup screen, select <6> Calculations. (Refer to Figure 5.3.)

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-4

5

Page 24

Units Setup

S

E014091S.EP

Figure 5.3 Calculations Summary Screen

Units can be selected for reporting with the results and displayed throughout the IMMAGE

800 system for each chemistry.

From the Setup screen, select <7> Units.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-5

5

Page 25

Selecting Non-Standard Dilutions as Default for Each Chemistry

Introduction

The instrument status must be in Standby in order to select a non-standard dilution for a

chemistry. The system allows the user to select a non-standard dilution to use as the initial

dilution every time a particular assay is run.

Selecting a Non-Standard Dilution

Step Action

1 From the Setup screen, select <7> Units/Non-Standard Dilutions.

2 Select the sample type. Then select the options button < > beside the desired

chemistry. Standard and non-standard dilutions are displayed.

3 Select the number beside the desired dilution for the selected chemistry and

sample type. Note that the current default dilution is highlighted. If the chosen

dilution is a non-standard dilution, that dilution will appear on the Units/NonStandard Dilutions screen.

OR

Select <Cancel> to return to the Units/Non-Standard Dilutions screen without

changing the non-standard dilution.

OR

Select <Default> to return to the standard default dilution.

4 Repeat Steps 2-3 for additional chemistries.

When a non-standard dilution has been selected for a chemistry and sample type, whenever

this chemistry is run in this sample type, the system uses the selected non-standard default

dilution as the initial dilution. If the test is out of range at this dilution, the system will step up

or step down to a different dilution.

If the original sample was programmed to run with a standard dilution, and later you changed

the default dilution to a non-standard dilution, the sample will be rerun with the standard

dilution.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-6

5

Page 26

Configuring Antigen Excess Testing

Antigen excess (AGXS) testing can be enabled or disabled for each appropriate chemistry

configured on the chemistry menu.

The default for AGXS testing is enabled for all the appropriate chemistries.

If AGXS testing is enabled, AGXS testing is always performed for the associated chemistry.

If AGXS testing is disabled, AGXS testing will not be performed for the associated chemistry.

AGXS can be enabled or disabled for an individual sample in Sample Programming.

From the Setup screen, select <8> Antigen Excess.

Date and Time Setup

At installation the system requires the date and time to be set. After this, changing the date or

time is optional. The format of the date and time for the appropriate screens and printouts

may be changed as well.

From the Setup screen, select <9> Date/Time.

Host Communications Setup

When connecting a laboratory information system (LIS) to the IMMAGE 800, several

parameters must be set. These parameters should be set by the person configuring the

connection between the IMMAGE and the LIS. Further information about all of the host

communications parameters is found in the IMMAGE Immunochemistry Systems Host

Interface Specifications.

From the Setup screen, select <10> Host Communications. (Refer to Figure 5.4.)

E010227S.EPS

Figure 5.4 Host Communications Parameters Screen

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-7

5

Page 27

Default Setup

Default Setup is used to:

• define the default sample type for all samples programmed. The sample type can be

changed for individual samples from the Program Sample screen.

• define the default number of replicates to be run for each sample.

• define the Post Run Summary time (none - 72 hours).

From the Setup screen, select <11> Default Setup.

Sample Comments Setup

Up to 20 sample comments may be predefined on the IMMAGE 800 Immunochemistry

System for use when programming samples on the instrument. These will be presented in a

numbered menu when programming samples.

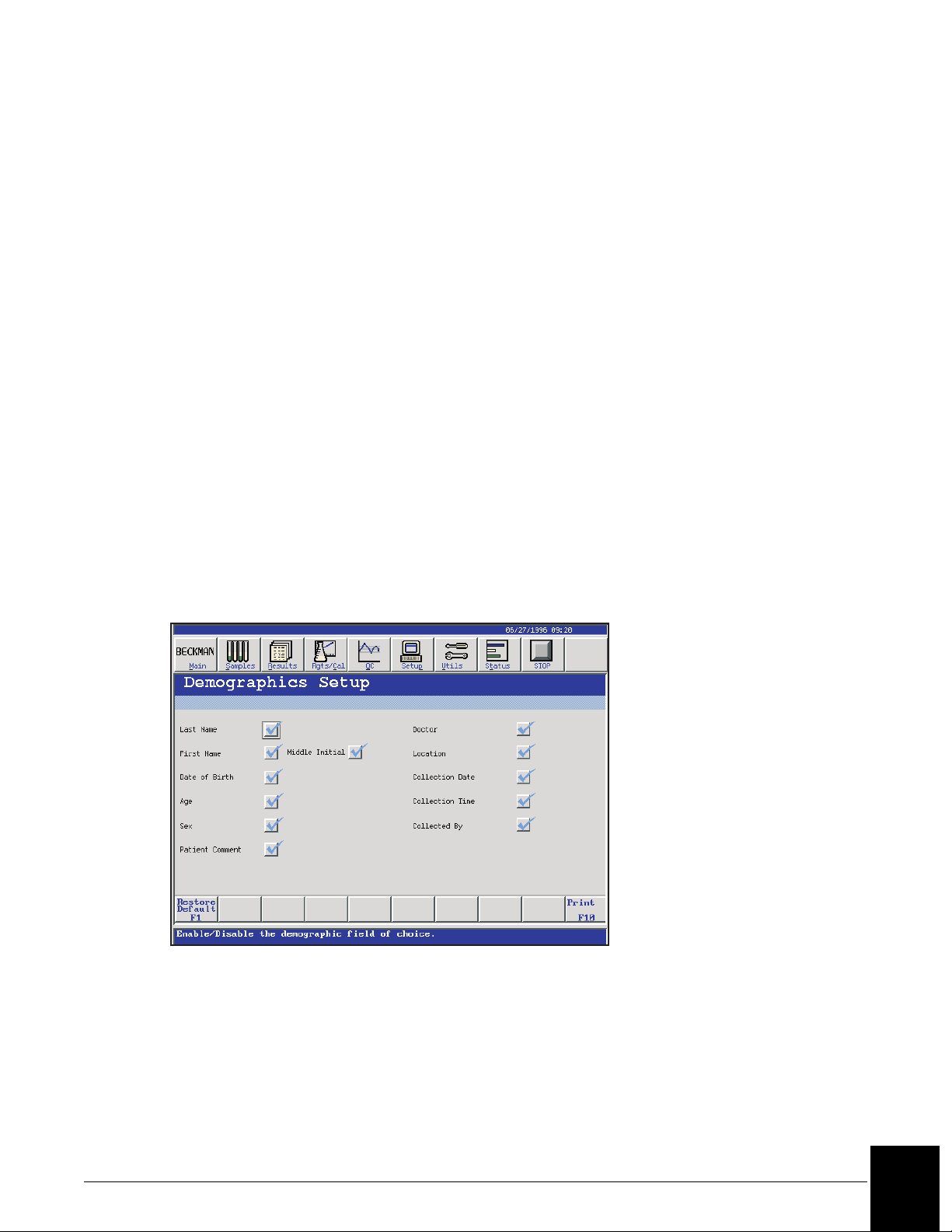

Demographics Setup

The fields which are accessible in the demographics screen of sample programming can be

selected.

To select fields to be displayed in Sample Programming, from the Setup screen, select <13>

Demographics Setup. (Refer to Figure 5.5.)

E010230S.EPS

Figure 5.5 Demographics Setup Screen

Printer Setup

The printer type is a Hewlett Packard Deskjet® or compatible. The paper size can be selected.

From the Setup screen, select <14> Printer Setup.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-8

5

Page 28

Language Setup

A language can be selected for use for system operations and printouts on the IMMAGE 800.

The keyboard should match the language.

• From the Setup screen, select <15> Languages/Keyboard.

• Select a language from the options button <▼>.

Selecting Japanese from the Language options will cause the Language/

Keyboard selection to become unavailable. Reloading of the software is

necessary to restore the Language/Keyboard Selection option.

• Perform the power off sequence and then the power on sequence. (Refer to IMMAGE 800

Immunochemistry System Instructions for Use CHAPTER 4, System Power On/Off, Power

On Sequence, Power Off Sequence.)

Loading the Chemistry Protocol Diskette

The chemistry protocol diskette is provided with each IMMAGE 800 Immunochemistry

system. It contains essential non-lot specific information about how to run each chemistry.

The chemistry protocol diskette is loaded when the IMMAGE 800 is installed. When new

chemistries become available, a new diskette is provided.

NOTICE

From the Setup screen, select <16> Chemistry Protocol Diskette.

Instrument Serial Number Setup

The serial number of the instrument is entered through the Instrument Serial Number option.

The instrument serial number will be printed on all reports.

From the Setup screen, select <17> Instrument Serial Number.

UDR Chemistry Overview and Precautions

Each laboratory can define its own user-defined reagent (UDR) chemistry protocols using the

templates from the chemistry protocol diskette. After the chemistry protocol diskette is

loaded and the UDR protocol is defined, the UDR chemistry name is available for placement

on the list of configured chemistries for selection in UDR rate mode programming, reference

intervals, UDR calibration, sample programming, control definitions and panels. Refer to the

IMMAGE 800 Immunochemistry System Operations Manual for further details.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-9

5

Page 29

User-Defined Reagent Chemistry Setup

UDR Chemistry Overview and Precautions

Introduction

Each laboratory can define its own user-defined reagent (UDR) chemistry protocols using the

templates from the chemistry protocol diskette. After the chemistry protocol diskette is

loaded and the UDR protocol is defined, the UDR chemistry name is available for placement

on the list of configured chemistries for selection in UDR rate mode programming, reference

intervals, UDR calibration, sample programming, control definitions and panels.

Precautions

Since Beckman Coulter does not manufacture or otherwise control the sample and

reagents that may be used in user-defined reagent applications, Beckman Coulter

makes no warranty whatsoever with respect to such sample and reagent

performance (including sample carryover, test results, reagent and cartridge

handling), their effect on the system or required system maintenance or the

frequency thereof, or their effect on operator safety. User assumes full responsibility

for use of the proper test protocol and test result generation for the reagent(s)

selected by the user and for any errors or omissions associated therewith. BECKMAN

COULTER EXPRESSLY DISCLAIMS ALL WARRANTIES WITH RESPECT TO THIS

PRODUCT WHETHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

CAUTION

CAUTION

Non-Beckman Coulter reagents, calibrators, and controls can contain components,

not listed on the insert, which may carry over into the system causing chemical or

optical interference. This carryover could adversely affect results on a properly

performing system. Manufacturers of user-defined reagents should be contacted for

disclosure of potentially interfering substances, such as preservatives.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-10

5

Page 30

Setting Up a UDR Chemistry

Loading the Protocol Diskette

Follow the instructions under Loading the Chemistry Protocol Diskette, earlier in this chapter,

to load the user-defined reagent chemistry protocol templates.

Password Setup Procedure

Once a UDR chemistry has been defined and saved, the user must log in and perform a

password setup procedure. This password protection feature is recommended for security

purposes. The password setup is used to identify specific information, such as:

• who logged in

• which field was updated

• what screen was entered

• what field was changed

This and other information are described in the Display Events log. The password setup is

described in the following steps.

Step Action

1 Select the Password Setup box near upper right corner of the User-Defined

Chemistries screen. Refer to Figure 5.6.

2 The User Log in screen appears. Refer to Figure 5.7. Note that the Username field

defaults to ADMIN. Enter ADMIN in the Password field and select <OK>.

OR

Select <Cancel> to return to the User-Defined Chemistries screen.

3 If <OK> was selected above, the UDR User Setup/Password Protection Mode

screen appears. Refer to Figure 5.8. This screen is used to add or delete a user. Up

to 16 users are allowed. Password protection is enabled by default (i.e., the

Password Protection Mode box is checked.) If the Password Protection Mode box

is disabled (not checked), the password protection feature is not available (i.e., no

prompt after Define and Save.)

To add another user, select a new user name number. Then select <Define Edit

User> and proceed to Step 4.

4 A Define/Edit User screen appears. Refer to Figure 5.9. Enter a new user name in

the Username field. Enter your password in the Password field. Enter the same

password in the Confirm Password field.

5 To delete a user, select the username number and select <Delete User>.

OR

Select <Cancel> to return to the Password Protection Mode Screen.

6 Select <Exit> to return to the User Defined Chemistries screen.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-11

5

Page 31

Figure 5.6 User-Defined Chemistries Screen

E011417S.EPS

E011434S.EPS

Figure 5.7 User Login Screen

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-12

5

Page 32

E011435S.EPS

Figure 5.8 UDR User Setup/Password Protection Mode Screen

E011436S.EPS

Figure 5.9 Define/Edit User Screen

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-13

5

Page 33

Accessing Define/Edit

The instrument status must be in Standby in order to proceed with the steps below to access

the Define/Edit screen.

Step Action

1 From the Setup screen, select <18> User-Defined Chemistries.

2 Select the UDR Option Number. (Refer to Figure 5.6.)

3Select Define/Edit [F1]. (Refer to Figure 5.10 and Figure 5.11.) Continue to

"Beginning a New UDR Protocol Definition" in this chapter.

E011418S.EPS

Figure 5.10 Define/Edit User-Defined Chemistry Screen, Page 1

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-14

5

Page 34

E011428S.EPS

Figure 5.11 Define/Edit User-Defined Chemistry Screen, Page 2

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-15

5

Page 35

Defining a UDR Chemistry

Description of Definition Fields

The following table describes the fields of the Define/Edit User-Defined Chemistry screen,

Page 1. (Refer to Figure 5.10.) Use the tab key to navigate.

Table 5.1 Protocol Definition Fields, Page 1

Field Entries Allowed Function

Chem Name Two to five alphanumeric

characters

Reagent Lot Number A maximum of eight

alphanumeric characters

Cartridge Lot Number A maximum of eight

alphanumeric characters

Cartridge Serial Number A maximum of four

alphanumeric characters

AGXS Limit 1-9999 Identifies Antigen Excess limit

Comments A maximum of 20

alphanumeric characters

Units Selection from list Concentration Units of UDR

Conversion Factor Not applicable • Displays the conversion

Unique name for chemistry.

Identifies reagent lot number.

Identifies cartridge lot number.

Identifies unique serial number

of UDR cartridge.

rate.

Provides additional vendor

information, or other

comments.

results.

factor input from the Units

option button.

Protocol Selection from list:

• Non-Competitive

nephelometric

• Competitive nephelometric

• Non-Competitive NIPIA

• Competitive NIPIA

Reagent Expiration Date Date in order as defined in

Date Setup

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-16

• Immunoprecipitin reaction

detected by rate

nephelometry.

• Inhibition immunoprecipitin

reaction detected by rate

nephelometry.

• Immunoprecipitin reaction

detected by rate turbidimetry.

• Inhibition immunoprecipitin

reaction detected by rate

turbidimetry.

Reagent will be flagged on

reports as expired after this

date.

(1 of 2)

5

Page 36

Table 5.1 Protocol Definition Fields, Page 1, continued

Field Entries Allowed Function

Tests per Cartridge 1-300 Identifies the number of tests

available in the reagent

cartridge.

AGXS Enabled Select (check) to enable Allows usage of AGXS Limit

field.

(2 of 2)

The following table describes the protocol fields of the Define/Edit User-Defined Chemistry

screen, Page 2. (Refer to Figure 5.11.)

Table 5.2 Protocol Definition Fields, Page 2

Field Entries Allowed Function

Buffer BUF 1 to 4, or

BUF 10 to 15

Diluent DIL 1 to 4, or

DIL 10 to 15

Sample or Dilution

Volume

Reaction Buffer Volume "0"; or from

Compartment A Volume

(Refer to Figure 5.12.)

Compartment B Volume

(Refer to Figure 5.12.)

Gain 1, 2, 3, 4 Signal amplification. As gain

Cal Dilution 1:1; or 1:5 to 1:50 Determines dilution ratio for

3 µL to 21 µL or

3 µL to 75 µL, depending

on the sample dilution

195 µL to 300 µL

5 µL to 235 µL Reagent volume aspirated from

"0" ; or from

5 µL to 235 µL

Identifies type of buffer used in

test.

Identifies type of diluent used in

test.

Sample or dilution volume

dispensed to reaction cuvette.

Reaction buffer volume dispensed.

cartridge, compartment A.

Reagent volume aspirated from

cartridge, compartment B.

number increases, signal

amplification increases.

calibration.

Sample Dilution 1:1; or 1:5 to 1:50 Determines dilution ratio for

sample predilution.

Reaction Time Select from list: 1.5 to 10

minutes

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-17

Interval in which reaction readings

are taken after addition of the last

reagent to the reaction mixture.

5

Page 37

A

6

1

77

B

2

3

1. Reagent Compartment Cover

2. Reagent Carousel

3. Reaction Buffer Bottle

4. Reagent Cartridges (Compartments A and B)

4

5. Reagent Bar Code Reader

6. Fans

7. Temperature Sensor

5

A011410P.EPS

Figure 5.12 The Reagent Compartment

The following table describes the calibration fields of the Define/Edit User-Defined

Chemistry screen, Page 3. (Refer to Figure 5.13.)

Table 5.3 Calibration Definition Fields, Page 3

Field Entries Allowed Function

Levels 4 to 9 Identifies the number of calibrators

used in test.

Replicates 1 to 9 Allows a number of tests to be

repeated for each calibration level.

Update Level 1 to 9 Single-point calibration setpoint

update level.

Replicates 1 to 9 Set point update replicate.

Cal Level Setpoints Up to 6 digits with a decimal

point, or seven digits.

Identifies concentration value for

each calibration level in ascending

order where Level 1 is the lowest

concentration value.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-18

5

Page 38

Figure 5.13 Define/Edit User-Defined Chemistry Screen, Page 3

Order of Reaction

The following table describes the order of reaction as determined by the type and volume of

reaction components defined.

Table 5.4 Order of Reaction

E011419S.EPS

If the Reaction

Buffer Volume is…

and the

Compartment B

the Order of Reaction is…

Volume is…

Between 195-300 µL 0 µL UDR buffer > Incubate > Neat or

Diluted Sample > Compartment A

Reagent starts reaction

Between 195-300 µL Between 5-235 µL UDR buffer > Compartment B

Reagent > Incubate > Neat or Diluted

Sample > Compartment A Reagent

starts reaction

0 µL Between 195-235 µL Compartment B Reagent > Neat or

Diluted Sample > Incubate >

Compartment A Reagent starts

reaction

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-19

5

Page 39

Recommended Order for UDR AGXS Flagging Limit Use

Step Action

1 Define UDR parameters

2 Perform UDR multi-point calibration.

3 Approve UDR multi-point calibration.

Note: If calibration verification is desired, run the calibration verification

BEFORE changing the sample dilution.

4 Change UDR sample dilution (optional).

5 Perform UDR AGXS Limit determination testing using UDR Rate Mode.

6 Enter UDR AGXS Limit (rate value) and select (check) the AGXS Enable box to

begin UDR AGXS flagging. The AGXS Enable box is located in the Define/Edit

User-Defined Chemistry screen (Refer to Figure 5.10).

7 Run UDR samples and perform single-point UDR calibration updates.

Additional Information

Refer to IMMAGE 800 Immunochemistry System Operation Manual CHAPTER 3, Theory of

Operations, Principles of Methodologies for theory of operation information.

Beginning a New UDR Protocol Definition

The instrument status must be in Standby to proceed with the steps below. Refer to the

Define/Edit User-Defined Chemistry screen shown in Figure 5.10.

Step Action

1 From Page 1 of the Define/Edit User-Defined Chemistry screen, enter the UDR

chemistry name in the Chem Name field. This field is limited to 2-5 alphanumeric

characters. The chemistry name must not be in use for any other chemistry or

calculation.

2 Select the options button <▼> beside the Units field.

3 Select the number for the desired unit.

4 Enter the reagent lot number in the Reagent Lot Number field.

5 Select the options button <▼> beside the Protocol field.

6 Select the number for the desired protocol.

7 Select the Cartridge Lot Number field.

8 Enter the cartridge lot number from the UDR cartridge. The lot number is found

on the bar code label of the UDR cartridge supplied by Beckman Coulter.

(1 of 2)

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-20

5

Page 40

Step Action, continued

9 Select the options button <▼> beside the Reagent Expiration Date field.

10 Enter the reagent expiration date.

NOTICE

The expiration date must not be the current date. Recalibration will be necessary

when the expiration date is changed.

11 Select <OK> to enter the expiration date into system.

OR

Select <Cancel> to exit the dialog box without entering the date. Continue to

“Defining UDR Sample/Reagent Volumes.”

12 Enter the reagent cartridge serial number in the Cartridge Serial Number field.

The serial number is found on the bar code label of the UDR cartridge supplied by

Beckman Coulter.

13 Enter the number of tests in the Tests per Cartridge field. The maximum number

of tests is 300.

14 If desired, select the Comments field and enter vendor information or other

comments. This field is limited to 20 alphanumeric characters.

(2 of 2)

Defining an AGXS Limit

The AGXS Limit is a user-defined value. The AGXS Limit feature will only be available if the

UDR has a status of "calibrated" and uses a "Non-Competitive Nephelometric" or "NonCompetitive NIPIA" protocol. Entry of this value in the AGXS Limit field is only available

after a UDR multi-point calibration has been performed and approved.

Entering an AGXS Limit value into the UDR definition will clear the calibration program of

the defined UDR. The AGXS limit is calibration specific; therefore, recalibrating a UDR

using a multi-point calibration will clear the AGXS Limit field and disable AGXS flagging.

During the sample run, if the calibrated rate for a UDR sample reaction is equal to or greater

than the value entered for the AGXS Limit in the UDR definition, the system will suppress the

results and display ******* in the results column on the results display and printout instead of

a numerical result. AGXS flagging shall not apply during UDR Rate Mode runs.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-21

5

Page 41

Refer to follow the steps to enter an AGXS flagging rate value.

Step Action

1 From the User-Defined Chemistries screen, select the chemistry for AGXS

flagging. (Refer to Figure 5.6.)

2Select Define Edit.

3 A user defined warning message appears. Read the message and select <OK>.

4 Select the AGXS Enable box.

5 Enter Rate Units into AGXS Limit field.

6Select Save [F9].

7 If your password is protected, then refer to the Password Setup Procedure in this

chapter and enter your user name and password.

8Select <OK>.

Defining UDR Sample/Reagent Volumes

The minimum total cuvette volume of reagent(s) and sample is 195 µL.

The maximum total cuvette volume of reagent(s) and sample is 365 µL.

The instrument status must be in Standby in order to proceed with the steps below to define

UDR sample and reagent volumes. (Refer to Figure 5.11.)

Step Action

1 From Page 2 of the Define/Edit User-Defined Chemistry screen, select the Buffer

options button beside the Buffer field.

2 Select the buffer type from the list.

3 Select the Diluent options <▼> button beside the Diluent field.

4 Select the diluent type from the list.

(1 of 3)

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-22

5

Page 42

Step Action, continued

5 Enter the volume of sample or sample dilution to be aspirated and dispensed in the

Sample or Dilution Volume field.

If the Sample Dilution field

entry is...

the Sample or Dilution Volume field

may be...

1:5 to 1:50 3 µL to 75 µL

1:1 (undiluted) 3 µL to 21 µL

NOTICE

Aspiration of neat serum and/or plasma sample volumes greater than 15 µL may

result in carryover and is not recommended.

6 Enter the reaction buffer volume to be aspirated and dispensed in the Reaction

Buffer Volume field. Entries may be "0" or from 195 µL to 300 µL.

7 Enter the volume of reagent to be aspirated and dispensed from Compartment A in

the Compartment A Volume field. Entries may be from 5 µL to 235 µL.

8 Enter the volume of reagent to be aspirated and dispensed from Compartment B in

the Compartment B Volume field.

If the Reaction Buffer

Volume field entry is...

the Compartment B Volume

field entry may be...

0 195 µL to 235 µL

195 µL to 300 µL 0 or 5 µL to 235 µL

9 Enter the gain in the Gain field. Entries may be 1, 2, 3, or 4. The gain increases

as the number increases.

10 Enter the calibration dilution in the Cal Dilution field. Entries may be from 1:5 to

1:50.

OR

Enter 1:1 for an undiluted sample.

The Sample Dilution field automatically displays the same value as the Cal

Dilution field. No input is allowed until after calibration and approval.

(2 of 3)

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-23

5

Page 43

Step Action, continued

11 After calibration and approval, if the desired sample dilution is different from the

calibration dilution, enter the sample dilution in the Sample Dilution field.

Entries may be from 1:5 to 1:50.

OR

Enter 1:1 for an undiluted sample.

12 Select the options button <▼> beside the Reaction Time field.

13 Select the reaction time number from the list.

14 Select the <Page Down> button to go to Page 2 of the Define/Edit User-Defined

Chemistry screen.

15 Continue to "Defining UDR Calibration Information."

(3 of 3)

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-24

5

Page 44

Defining UDR Calibration Information

Defining UDR Calibration Information

The out-of-range low value for the protocol is the lowest non-zero calibrator setpoint

concentration. The out-of-range high value for the protocol is the highest calibrator setpoint

concentration.

The instrument status must be in Standby in order to proceed with the steps below to define

the calibration information on Page 3 of the Define/Edit User-Defined Chemistry screen.

Refer to Figure 5.13

Step Action

1 From Page 3 of the Define/Edit User-Defined Chemistry screen, enter the

number of Cal Setpoint levels in the Levels field. Entries may be from

four to nine.

2 Enter the number of replicates to be run per Cal Setpoint level in the

Replicates field. Entries may be from one to nine.

3 Enter a Cal Level number in the Update Level field for a single-point

calibration update. Entries may be from one to nine.

4 Enter the number of replicates to be run for the Update Level in the

Replicates field. Entries may be from one to nine.

5 Enter the concentration value in each of the Cal Setpoint fields. The

concentration values must be in ascending order with Level 1 being the

lowest concentration. Each field entry is limited to seven digits or six

digits with a decimal point.

NOTICE

The number of calibration levels limits the type of curve-fit model

applicable to the UDR. (Refer to Approving a Calibration, "Curve-Fit

Model Descriptions", later in this chapter.)

6Select Save [F9] to save the protocol and calibration information.

OR

Select Cancel [F10] to exit the screen without saving the protocol.

7 Go to the User-Defined Chemistries screen (Figure 5.6) and select Chem

Config [F9] to configure the UDR chemistry. (Refer to Configuring the

Chemistry Menu in this chapter.)

8 From the Chemistry Configuration screen, select UDR Main [F9] to return

to the User-Defined Chemistries screens.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-25

5

Page 45

Deleting UDR Chemistries

Removing a UDR Chemistry from the Chemistry Menu

This function removes the UDR chemistry from the chemistry configuration menu, from any

configured control, and from any configured panel.

Deleting a UDR Definition

The Delete function deletes a UDR definition only if the chemistry has been removed from the

chemistry menu. When the UDR definition is deleted, the UDR reference intervals and all

associated, non-archived patient results are deleted. Refer to IMMAGE 800

Immunochemistry System Operation Manual CHAPTER 10, Utilities, Backup/Restore.

The instrument status must be in Standby in order to proceed with the steps below to delete a

UDR definition.

Step Action

1 From the Setup screen, select <18> User-Defined Chemistries.

2 Choose a number beside the chemistry to be deleted.

3Select Delete [F2]. (Refer to Figure 5.14.)

4Select <OK> to delete the chemistry.

OR

Select <Cancel> to return to the User-Defined Chemistries screen without

deleting the chemistry.

5 Remove the reagent cartridge from the reagent carousel.

E014047S.EPS

Figure 5.14 Delete User-Defined Chemistry Dialog Box

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-26

5

Page 46

Editing UDR Definitions

Introduction

A previously defined UDR definition may be recalled and edited. Editing the sample dilution

and/or AGXS Limit of a defined UDR clears the calibration programs for the UDR. Editing

Comments, the Cartridge Serial Number and/or refilling a cartridge will not affect calibration.

Editing anything else clears the calibration programs, cancels the calibration, clears the AGXS

Limit, and disables AGXS flagging. The edited UDR definition is saved with the same

chemistry name. Refer to Table 5.5 for further information.

Table 5.5 UDR Editing Function

Editing Function Calibration

Clears calibration programs Cleared Calibrated Cannot Change

Clears calibration programs and

Cancels the calibration

Editing a UDR Definition

The units and chemistry name of the UDR cannot be changed unless the UDR is first removed

from the chemistry menu.

The instrument status must be in Standby in order to proceed with the steps below to edit a

UDR definition.

Step Action

1 From the Setup screen, select <18> User-Defined Chemistries.

2 Select a number beside a defined UDR position. (Refer to Figure 5.6.)

3Select Define/Edit [F1].

4 Refer to Defining a UDR Chemistry to edit the UDR definition and calibration

information.

Rack

Calibration

Status

Curve-Fit

Model

Cleared Uncalibrated Cannot Change

NOTICE

Editing the sample dilution or AGXS Limit of a defined UDR clears the calibration

programs for that UDR. Editing Comments, Cartridge Serial and/or Refill numbers

does not affect calibration. Editing anything else clears the calibration programs,

cancels the calibration, clears the AGXS Limit and disables AGXS flagging.

If the serial number is changed in the protocol definition, the cartridge identified

by the overwritten serial number is no longer usable, regardless of the number of

tests remaining.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-27

5

Page 47

Editing a UDR Definition is summarized in Table 5.6 below.

Table 5.6 Editing a UDR Definition

Edited UDR Definition Effect on Calibration Effect on AGXS Flagging

Comments

Serial Number

Refill Cartridge

Sample Dilution

AGXS Limit

All Other Parameters Clears Program

No Effect

Status: Calibrated

Clears Program

Status: Calibrated

Cancels Calibration

Status: Uncalibrated

No Effect

No Effect

Clears AGXS Limit

Disable Flagging

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-28

5

Page 48

Loading UDR Reagent Cartridges

Introduction

The UDR reagent cartridges must be loaded before performing a run.

Description of Cartridge

The UDR cartridge provided by Beckman Coulter contains the following information:

• Cartridge lot number

• Cartridge serial number.

Limits

• Six UDR cartridges may be loaded on the reagent carousel at one time.

• Each UDR cartridge has a set number of 300 tests. When the 300 tests count down to zero,

a new UDR serial number and/or cartridge lot number must be defined and loaded.

• When the cartridge is level sensed as empty, but more tests are available on the Reagent/

Calibration Status screen, the UDR cartridge may be refilled and reused until the tests

remaining is zero.

Loading UDR Cartridges

Follow the instructions in IMMAGE 800 Immunochemistry System Operation Manual

CHAPTER 6, Reagents/Calibration, Loading/Unloading Reagent Cartridges, "Loading

Reagent Cartridges."

Refilling UDR Cartridges

A UDR can be programmed to run a maximum of 300 tests. If the cartridge holds less than

300 tests, the cartridge may be refilled to reach the maximum 300 tests. Follow the steps

below to refill the UDR cartridge.

Step Action

1 Go to the User-Defined Chemistry screen. (Refer to Figure 5.6.)

2 Select a UDR.

3Select Define/Edit [F1].

4Select <OK> to close the warning message.

5Select Refill [F8] at the Defined/Edit-User Defined Chemistry screen. (Refer to

Figure 5.10.)

6 Select the Cartridge Serial Number on the UDR Cartridge Refill screen. (Refer

to Figure 5.15.)

(1 of 2)

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-29

5

Page 49

Step Action, continued

7Select <Refill>. The system will update tests remaining in the cartridge to the

number of tests defined in the Defined/Edit-User Defined Chemistry screen.

OR

Select <Exit> to return to the Defined/Edit-User Defined Chemistry screen

without refilling the cartridge.

8 Refill the cartridge.

(2 of 2)

E011420S.EPS

Figure 5.15 UDR Cartridge Refill Screen

The UDR Cartridge Refill screen (Figure 5.15) is defined in Table 5.7:

Table 5.7 UDR Cartridge Refill Screen

Screen Item Screen Definition

Chem Name Chemistry Name as defined in Figure 5.10.

Reagent Lot Number Reagent Lot Number as defined in Figure 5.10.

Tests per cartridge Tests per cartridge as defined in Figure 5.10.

Serial Number Cartridge Serial number as defined in Figure 5.10

Tests left Number of tests remaining from tests per cartridge defined in

Figure 5.10.

Total tests left Number of tests remaining from 300 total tests per cartridge.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-30

5

Page 50

Removing UDR Cartridges

Follow the instructions in IMMAGE 800 Immunochemistry Operations Manual, CHAPTER

6, Reagents/Calibration, Loading/Unloading Reagent Cartridges, "Removing Cartridges from

The Reagent Carousel."

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-31

5

Page 51

Loading/Clearing UDR Buffer and Diluent

Introduction

Beckman Coulter IMMAGE 800 buffers and diluents, or user-prepared solutions, may be used

as UDR buffer and diluent. However, the UDR buffer and diluent are given a specific name on

the sample or reagent carousel. The positions and lot numbers of UDR buffer and diluent

must be entered into the computer.

• Up to 4 bottles of UDR buffers may be placed on the inner section of the reagent carousel.

• Up to 4 bottles of UDR sample diluents may be placed on the inner section of the sample

carousel.

Checking UDR Buffer/Diluent Status

The instrument status must be in Standby in order to proceed with the steps below to check the

buffer and diluent status before a run.

Step Action

1Select Reagents/Cal from the menu bar.

2Select Buffer/Diluent [F3]. (Refer to Figure 5.16.)

3 Check the % Remaining for a sufficient amount to complete a run.

• The designation for a UDR buffer is BUF1-4 and BUF 10-15. BUF 1-4 is

designated for system buffer. BUF 10-15 is designated for user-defined buffer.

• The designation for a UDR diluent is DIL1-4 and DIL 10-15. DIL 1-4 is

designated for system diluent. DIL 10-15 is designated for user-defined diluent.

E014048S.EPS

Figure 5.16 Buffer/Diluent Status Dialog Box

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-32

5

Page 52

Loading a New Lot of UDR Buffer/Diluent or Changing a Position

Follow the instructions in IMMAGE 800 Immunochemistry Operations Manual, CHAPTER

6, Reagents/Calibration, Loading/Clearing Buffers and Diluents, "Loading A New Lot Or

Changing A Position."

Replacing the Same Lot of UDR Buffer/Diluent

Follow the instructions in IMMAGE 800 Immunochemistry Operations Manual, CHAPTER

6, Reagents/Calibration, Loading/Clearing Buffers and Diluents, "Replacing the Same Lot."

After Loading Buffers and Diluents

NOTICE

Recalibration of affected reagents may be necessary when buffer or diluent lot numbers

are changed.

The system assumes that lot numbers and position numbers for buffers or diluents remain the

same from run to run until changed by the user.

The % Remaining volume on the Buffer/Diluent Status dialog box is updated during a

sample run.

Clearing a UDR Buffer/Diluent Position

Refer to IMMAGE 800 Immunochemistry Operations Manual, CHAPTER 6, Reagents/

Calibration, Loading/Clearing Buffers and Diluents, "Clearing a Buffer or Diluent Position."

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-33

5

Page 53

Programming Rate Mode

Introduction

After the UDR chemistry protocol is defined and the chemistry is configured, Rate Mode is

used to optimize UDR parameters. After running the UDR chemistry, a report with only

instrument responses (IR) is automatically generated. A maximum of six UDRs may be

programmed at one time in rate mode. Rate Mode can be run on a calibrated or uncalibrated

UDR.

Programming Rate Mode

The instrument status must be in Standby in order to proceed with the steps below to program

a UDR for rate mode.

Step Action

1 From the User-Defined Chemistry screen, select Rate Mode [F3]. (Refer to

Figure 5.17.)

2 Select up to six of the UDR chemistries.

3Select <OK> to continue. Rate Mode may be run on a calibrated or uncalibrated

UDR.

NOTICE

Rate results are always uncalibrated rate, whether the UDR is calibrated or

uncalibrated.

OR

Select <Cancel> to exit rate mode and return to the User-Defined Chemistry

screen.

4 From the UDR Rate Mode Assign screen (Refer to Figure 5.18.), enter an

available rack number in the Rack field.

OR

Select Clear Racks [F1] and Enter the racks and/or positions to clear.

Select <OK> to clear or <Cancel> to exit without clearing.

5 Enter a position number in the Pos field. Up to nine positions may be entered.

6 Enter a Sample ID in the Sample ID field for each position assigned. Up to 15

characters may be entered.

7Select Save [F9] to save the program.

OR

Select Cancel [F10] to exit the screen without saving the program.

8 Repeat Steps 1-7 to program additional racks for rate mode.

9 Print a Load List from Sample Programming.

(1 of 2)

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-34

5

Page 54

Step Action, continued

10 Load the samples on the sample carousel.

11 Select Main from the menu bar and Run.

12 Select <OK> in the Check Dilution Segments dialog box to start the run.

OR

Select <Cancel> to exit without starting the run.

E014049S.EPS

(2 of 2)

Figure 5.17 UDR Rate Mode Dialog Box

Figure 5.18 UDR Rate Mode Assign Screen

E014050S.EPS

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-35

5

Page 55

Additional Information

Refer to IMMAGE 800 Immunochemistry Operations Manual, CHAPTER 7, Preparing for

Programming/Running, Clearing a Sample and Requesting a Load List.

Refer to IMMAGE 800 Immunochemistry Operations Manual, CHAPTER 8, Results Recall,

Printing Recalled Results to reprint UDR rate mode results.

Refer to IMMAGE 800 Immunochemistry Operations Manual, APPENDIX C, Reports for an

example of a Rate Mode report.

IMMAGE 800 Instructions For Use A11409 System Software Configuration

March 2004 Page 5-36

5

Page 56

Calibrating a UDR Chemistry

Introduction

A UDR can be calibrated by using a multi-point calibration. Subsequently, this calibration

may be updated using a single-point update calibration. The UDR chemistry calibration, using