Page 1

IMMAGE® 800

A11403-AB

March 2004

®

Immunochemistry System

REPEC

Beckman Coulter Ireland, Inc.

Mervue Business Park,

Mervue Galway,

Ireland 353 91 774068

For In Vitro Diagnostic Use

Operations Manual

© Copyright 2004 Beckman Coulter, Inc.

BECKMAN COULTER, INC. • 4300 N. Harbor Blvd., Fullerton, CA U.S.A. 92835

Page 2

TABLE OF CONTENTS

SAFETY NOTICE

CHAPTER 1 General Information/Precautions and Hazards ................................................ 1-1

CHAPTER 2 System Description .......................................................................................... 2-1

CHAPTER 3 Theory of Operations ....................................................................................... 3-1

CHAPTER 4 System Power On/Off ...................................................................................... 4-1

CHAPTER 5 System Setup .................................................................................................... 5-1

CHAPTER 6 Reagents/Calibration ........................................................................................ 6-1

CHAPTER 7 Sample Programming ...................................................................................... 7-1

CHAPTER 8 Results Recall .................................................................................................. 8-1

CHAPTER 9 Quality Control ................................................................................................ 9-1

CHAPTER 10 Utilities ........................................................................................................... 10-1

CHAPTER 11 System Status/Instrument Commands ........................................................... 11-1

APPENDIX A Part Number List ............................................................................................. A-1

APPENDIX B Instrument Codes .............................................................................................B-1

APPENDIX C Reports .............................................................................................................C-1

GLOSSARY

INDEX

IMMAGE 800 Operations Manual A11403 Table of Contents

March 2004 Page 1 of 1

Page 3

Safety Notice

Introduction

This safety notice summarizes information basic to the safe operation of the

IMMAGE® 800 Immunochemistry System described in this manual. The

international symbol displayed above is a reminder that all safety instructions should

be read and understood before installation, operation, maintenance, or repair of this

instrument. When you see the symbol on other pages, pay special attention to the

safety information presented. Observance of safety precautions will also help to avoid

actions that could damage or adversely affect the performance of the instrument.

Other symbols may also be displayed on the equipment. These are reproduced and

described in the Operating Precautions and Hazards section.

Safety During Installation and/or Maintenance

This instrument is designed to be installed by a Beckman Coulter Field Service

representative. Installation by anyone other than authorized Beckman Coulter

personnel invalidates any warranty covering the instrument.

Introduction

Any servicing of this equipment that requires removal of any covers can expose parts

which involve the risk of electric shock or personal injury. Make sure that the power

switch is turned OFF and that the instrument is disconnected from the main power

source. Refer such maintenance to qualified service personnel.

Electrical Safety

• To reduce the risk of electrical shock, this instrument uses a three-wire electrical

cord and plug to connect to earth-ground. Make sure that the matching wall outlet

receptacle is properly wired and earth-grounded.

• Never remove or install any circuit board, connect or disconnect any plug or cable,

while the power is ON. Always use the antistatic wrist strap located in the electronic

board compartment when removing or installing any circuit board.

• Do not place containers holding liquid on top of the instrument. If a spill occurs,

liquid may get into the instrument and damage electrical or mechanical components.

Safety Against Risk of Fire

Fuses protect certain electrical circuits within this instrument against overcurrent

conditions. For continued protection against the risk of fire, replace only with the

same type and rating specified.

IMMAGE 800 Operations Manual A11403 Safety Notice

March 2004 Page 1 of 2

Page 4

Mechanical Safety

Mechanical Safety

For safe operation of the equipment, observe the following:

• Operate the system with reagent door and covers and shields in place.

• During power up, routine operation, and diagnostic procedures, keep hands and/or

foreign objects out of the path of the carousels and probes.

• Do not attempt to clean around the carousels and probes while they are in motion.

Wait until the instrument is in "standby" to perform cleaning procedure.

Chemical and Biological Safety

Normal operation may involve the use of solutions and test samples that are

pathogenic or infectious. Observe all laboratory policies or procedures which pertain

to the handling of these materials.

• The reagents and other chemical preparations used with the system will not

normally cause adverse reactions; however, those persons with sensitive skin should

wear protective gloves before attempting to work with reagents and other chemical

preparations.

• Do not handle sample or solutions without proper protection. Body fluids and other

infectious samples must be handled according to good laboratory practice to prevent

spread of disease.

• When performing maintenance, service, or troubleshooting on elements of the

system that have contacted sera or other biological fluids, observe standard

laboratory precautions. It is always necessary to wash your hands thoroughly after

performing any routine maintenance.

Dispose of all waste solutions according to appropriate environmental health and

safety guidelines.

Safety Notice IMMAGE 800 Operations Manual A11403

Page 2 of 2 March 2004

Page 5

CHAPTER 1 General Information/Precautions and Hazards

Table of Contents

General Information/Precautions and Hazards ........................................................................... 1-2

Introduction ............................................................................................................................. 1-2

How to Use This Manual ........................................................................................................ 1-3

Warranty and Service Policy Information .............................................................................. 1-5

Precautions .............................................................................................................................. 1-6

Hazards .................................................................................................................................... 1-7

Symbols and Labels ................................................................................................................ 1-9

1

IMMAGE 800 Operations Manual A11403 General Information/Precautions and Hazards

March 2004 Page 1-1

Page 6

Introduction

Intended Use

Introduction

Intended Use

The Beckman Coulter IMMAGE® 800 Immunochemistry System is a fully automated,

computer controlled, bench-top analyzer designed for the in vitro quantitation of

biological fluid components and therapeutic drugs. The system methodologies are rate

turbidimetry and rate nephelometry.

The IMMAGE 800 is a high throughput, random access analyzer that features bar code

identification of samples and reagents to perform sample testing. It automatically

dilutes the samples and delivers them to the reaction cuvette along with other reaction

constituents. The system analyzes up to 72 samples per run with up to 24 analytes per

sample.

General Information/Precautions and Hazards

General Information/Precautions and Hazards IMMAGE 800 Operations Manual A11403

Page 1-2 March 2004

Page 7

How to Use This Manual

Scope of This Manual

This manual provides information on the operation of the IMMAGE 800. Diagnostic

interpretation or the clinical significance of the assay results provided by the system

are not discussed in this manual. Typical and actual results are shown only to

demonstrate the operating procedures, parameters, and characteristics of the system.

IMMAGE Chemistry Information Manual

This manual should be used in conjunction with the IMMAGE Immunochemistry

Systems Chemistry Information Manual which contains specific chemistry

information for the full range of analytes available on the IMMAGE 800.

Manual Conventions

The IMMAGE 800 Immunochemistry System Operations Manual uses the following

printed and visual cues to guide the user in how to respond to printed directions.

How to Use This Manual

Scope of This Manual

1

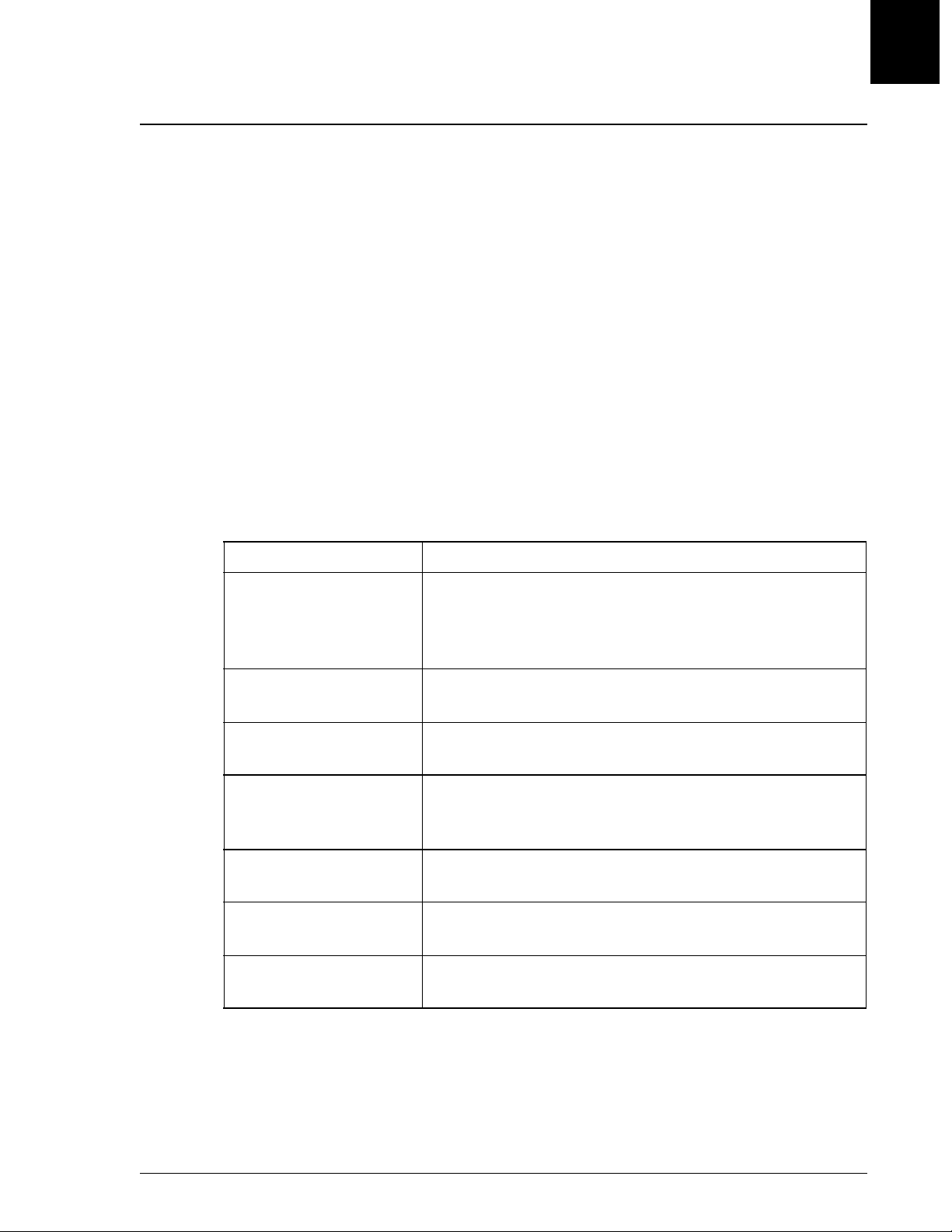

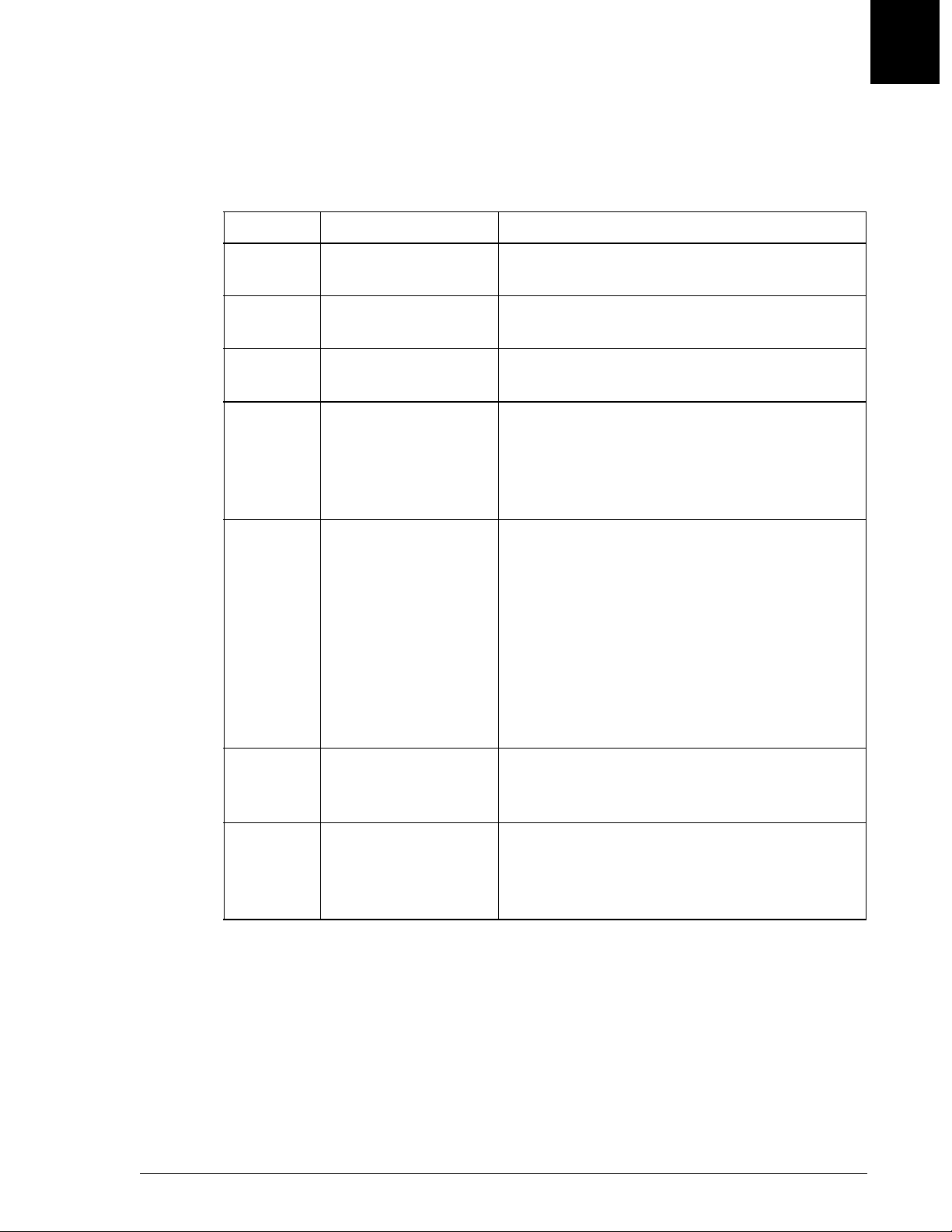

Table 1.1 IMMAGE 800 Conventions

Convention Description

Icon Buttons Icon buttons are in bold with one letter underlined. The

underline indicates which letter to press in combination

with the Alt key to select the icon button from the

keyboard.

Function Buttons [F1] Function buttons are in bold with the corresponding

function key in square brackets ( [ ] ).

<Buttons> The "less than" (<) and "greater than" (>) symbols enclose

a button’s name in bold.

Options button <▼> The "less than" (<) and "greater than" (>) symbols enclose

a black triangle, preceded by the phrase "options button",

all in bold.

Text field Names of text fields are followed by the word "field", all

in bold.

[X], [ → ] or [Tab] Keyboard keys are in bold and enclosed by square

brackets ( [ ] ).

[Alt + X] Combination keys are in bold and enclosed by square

brackets ( [ ] ) with a plus (+) between each key.

Manual Format

Information in this manual is presented in modular units. Each unit of information is

described by a brief title in the left margin.

Many units consist of a table which presents a procedure, process, or description.

IMMAGE 800 Operations Manual A11403 General Information/Precautions and Hazards

March 2004 Page 1-3

Page 8

How to Use This Manual

Procedure Tables

Procedure Tables

Procedure tables are the most common type of table in this manual. They list each step

of a procedure by number with the corresponding action that is to be performed.

A "Refer to Figure x.x." instruction directs the operator to the screen that displays as a

result of the action requested in the step.

Occasionally, a decision must be made at a step within a procedure. A smaller

decision table is then presented which describes the variable conditions in the left

column and the appropriate action for each condition in the right column.

Example of Procedure Table

The following table is an example of a procedure table that contains a decision table.

Step Action

1Select Rerun Samples [F6]. (Refer to Figure x.x.)

2

To enter... type...

individual Sample IDs, the Sample IDs for rerun in the

Sample IDs field.

a range of Sample IDs, the Sample ID at the beginning of

the range in the Range field.

3 Select a button from the bottom of the dialog box.

Read the decision table as complete sentences, using the first heading to introduce the

condition and the second heading to introduce the action. Step 2 of the table is read:

To enter individual Sample IDs, type the Sample IDs for rerun in the Sample IDs

field.

To enter a range of Sample IDs, type the Sample ID at the beginning of the range in the

Range field.

General Information/Precautions and Hazards IMMAGE 800 Operations Manual A11403

Page 1-4 March 2004

Page 9

Warranty and Service Policy Information

Warranty Policy

The IMMAGE 800 Immunochemistry System is covered by and subject to the

exceptions of the standard warranty enclosed with each system. Failure to operate the

system in accordance with this manual voids the warranty.

Service Information

If any fault develops in the system, call the Beckman Coulter Clinical Support Center.

Give full details of the difficulty. Be sure to have the model and serial number (located

on the lower right side of the instrument near the front.)

For USA and Canadian customers only:

Call your local Beckman Coulter office toll-free from anywhere in the continental

United States, Alaska, Hawaii, and Canada at (800) 854-3633.

Warranty and Service Policy Information

Warranty Policy

1

For customers outside the USA and Canada:

Call the nearest Beckman Coulter Field Service Office.

Responsibility During the Warranty Period

The user is responsible for the routine preventive maintenance procedures described in

the maintenance section of this manual. Repairs arising from failure to perform these

maintenance procedures at the indicated time intervals will be made at the user’s

expense.

Shipping Damage

Each IMMAGE 800 System is carefully examined and checked by Beckman Coulter

before it is shipped. When you receive your new IMMAGE 800 System, visually

inspect the shipping container for any possible damage. If there is damage, notify the

Beckman Coulter Service Representative before his/her arrival at your facility to

install your system.

If no damage is found to the shipping container, the Beckman Service Representative

will supervise the unpacking of your system. If it is damaged in any way, the customer

should file a claim with the carrier. If no damage is found, a visual and operational

check of your system will be performed.

IMMAGE 800 Operations Manual A11403 General Information/Precautions and Hazards

March 2004 Page 1-5

Page 10

Precautions

Introduction

Precautions

Introduction

The operational precautions below enable the user to avoid those actions which could

result in an invalid quantitative determination.

Proper Handling of Diskettes

The 3.5 inch floppy diskettes require special handling to prevent damage.

• Do not store or place a diskette near electrical motors, power supplies, or generators.

• Do not store or place a diskette near magnets or a magnetic field.

Proper Handling of Compact Disks

Compact disks (CD-ROMs) require special handling to prevent damage.

• Do not place a CD-ROM in direct sunlight or excessive heat or humidity.

• Hold a CD-ROM by the edges.

• Replace a CD-ROM in its case after use.

Sample Volumes

Sample containers must contain an adequate volume of test specimen to ensure

accurate aspiration. Refer to the IMMAGE Immunochemistry Systems Chemistry

Information Manual and the Sampling Template for information regarding volume

requirements.

CAUTION

Use extreme care when removing bar coded or labeled glass sample tubes from the

IMMAGE 800 sample racks to avoid breakage. Rotating the tube slightly while

pushing from the bottom of the tube may make removal easier.

General Information/Precautions and Hazards IMMAGE 800 Operations Manual A11403

Page 1-6 March 2004

Page 11

Hazards

Introduction

The following hazards are identified to ensure maximum safety of the user.

Booting Up

Close reagent and sample carousel covers and keep clear of all mechanical assemblies

when booting up the system.

Three-pronged Power Plugs

The three-pronged power plug from all system components of the IMMAGE 800

Immunochemistry System must be connected to a three-wire grounded power source.

• Do not use an adapter to connect the power plug to a two-pronged outlet.

• If the electrical outlet will not accept the three-pronged plug, notify qualified

maintenance personnel; they will supply the required electrical ground.

Hazards

Introduction

1

DO NOT UNDER ANY CIRCUMSTANCES OPERATE THE SYSTEM UNTIL AN

ELECTRICAL GROUND IS PROVIDED AND THE POWER CORD IS PROPERLY

CONNECTED TO GROUND.

Emergency Stop

Turn the instrument main power switch off if the stop button on the screen is

unavailable, and the instrument must be stopped immediately.

Cranes

Keep clear of both cranes while the instrument is running.

Covers

Keep all covers and shields in place while the instrument is running.

Adding Samples to an Operating Instrument

The instrument status must be in Standby when adding or changing reagents, buffers,

diluents, or dilution segments. The instrument status must be in Standby or Pausing-

OK to load samples when adding or removing samples. Keep reagent and sample

carousel covers closed while the instrument is running.

Pausing the System to Load Samples

If you pause the system to load or remove samples while the system is running, DO

NOT load or remove samples until the OK to load samples message appears on the

screen. Failure to comply may cause personal injury.

IMMAGE 800 Operations Manual A11403 General Information/Precautions and Hazards

March 2004 Page 1-7

Page 12

Hazards

Replacing Mechanical or Electrical Parts

Replacing Mechanical or Electrical Parts

Before replacing any defective mechanical or electrical part in the system, confirm that

the power to the system is turned off.

Bar Code Readers

DO NOT tamper with or remove the housing of any bar code reader.

Disposal of Waste Liquids

All waste liquids from the IMMAGE 800 Immunochemistry System should be

disposed of in an approved method for handling biohazardous material.

Biological Samples

Observe all laboratory policies or procedures pertaining to the handling of biological

samples that may contain pathogens.

Preservatives

Sodium azide preservative may form explosive compounds in metal drain lines. See

National Institute for Occupational Safety and Health bulletin: Explosive Azide

Hazards (8/16/76).

Incineration of used reagent cartridges may produce toxic fumes.

General Information/Precautions and Hazards IMMAGE 800 Operations Manual A11403

Page 1-8 March 2004

Page 13

Symbols and Labels

Introduction

The following list of symbols and labels is used on the IMMAGE 800

Immunochemistry System. The symbols are affixed to the appropriate components of

the system as described briefly below.

Instrument or Uninterruptible Power Supply (UPS) Power Switch, ON

This symbol is located on the instrument and the UPS main power switches. When the

portion of the switch that displays this symbol is depressed, the instrument is ON.

Instrument or UPS Power Switch ON

Symbols and Labels

Introduction

1

Instrument or UPS Power Switch, OFF

This symbol is also located on the instrument and the UPS main power switches.

When the portion of the switch that displays this symbol is depressed, the instrument is

OFF.

Instrument or UPS Power Switch OFF

Computer Power Switch

This symbol is located above the computer power button. A green light indicates the

power to the computer is ON.

Computer Power Switch

IMMAGE 800 Operations Manual A11403 General Information/Precautions and Hazards

March 2004 Page 1-9

Page 14

Symbols and Labels

Monitor Power Switch

Monitor Power Switch

This symbol is located on the monitor power button. A green light indicates the power

to the monitor is ON.

Printer Power Switch

This symbol is located beside the printer power button. A green light indicates the

power to the printer is ON.

Monitor Power Switch

Printer Power Switch

Connection Between Computer and Mouse

This symbol is located beside the connection between the computer and the mouse.

Computer - Mouse Connection

Connection Between Computer and Keyboard

This symbol is located beside the connection between the computer and the keyboard.

Computer - Keyboard Connection

Connection Between Computer and Printer

This text is located next to the connection between the computer and the printer.

Parallel

General Information/Precautions and Hazards IMMAGE 800 Operations Manual A11403

Page 1-10 March 2004

Page 15

Connection Between Computer and Monitor

This symbol is located beside the connection between the computer and the monitor.

Computer - Monitor Connection

High Voltage - Electric Shock Risk

This symbol indicates high voltage or risk of electric shock.

Connection Between Computer and Monitor

Symbols and Labels

1

Read Manual

This symbol cautions that the manual should be read before using the system.

General Biohazard Caution

This symbol is the international symbol for biohazardous material.

High Voltage - Electric Shock Risk

Read Manual

Biohazard Label

IMMAGE 800 Operations Manual A11403 General Information/Precautions and Hazards

March 2004 Page 1-11

Page 16

Symbols and Labels

Caution Biohazard

Caution Biohazard

This cautionary label is located between the sample and reagent carousels. Operate

the system with all covers in place.

Bar Code Caution

This label is placed on the cover of any laser-based bar code reader. Do not stare into

laser light beam when cover is open or removed.

Caution Biohazard Label

Laser

This label is placed near any opening through which a bar code reading beam emits.

Avoid exposure to laser light emitted from the opening.

Class II Laser Caution

This cautionary label is located between the sample and reagent carousels. Do not

stare into laser light beam.

Bar Code Caution Label

Laser Caution Label

Class II Laser Caution Label

General Information/Precautions and Hazards IMMAGE 800 Operations Manual A11403

Page 1-12 March 2004

Page 17

Class III B Laser Caution

This cautionary label is located at the top of the optics module. Avoid direct exposure

to laser light beam.

Reagent Compartment Cover Notice

This label is located on the reagent compartment cover. The instrument will stop if the

cover is opened.

A010648L.EPS

Class III B Laser Caution Label

Symbols and Labels

Class III B Laser Caution

1

A010647L.EPS

Reagent Compartment Cover Label

IMMAGE 800 Operations Manual A11403 General Information/Precautions and Hazards

March 2004 Page 1-13

Page 18

CHAPTER 2 System Description

Table of Contents

Hardware Components ............................................................................................................... 2-2

Overview ................................................................................................................................. 2-2

Instrument ............................................................................................................................... 2-3

Reagent Compartment ............................................................................................................. 2-4

Reagent Crane ......................................................................................................................... 2-6

Reaction Module ..................................................................................................................... 2-8

Sample Carousel ................................................................................................................... 2-10

Sample Crane ........................................................................................................................ 2-12

Upper Instrument Subsystems .............................................................................................. 2-14

Wash Solution Box and Waste Container ............................................................................. 2-17

Racks ..................................................................................................................................... 2-19

Computer ............................................................................................................................... 2-21

Printer .................................................................................................................................... 2-25

Software Overview ................................................................................................................... 2-26

Overview ............................................................................................................................... 2-26

Screen Format ....................................................................................................................... 2-27

Text Fields ............................................................................................................................. 2-30

Buttons .................................................................................................................................. 2-31

Toggle Buttons ...................................................................................................................... 2-32

Check Boxes ......................................................................................................................... 2-33

Performing Software Functions ............................................................................................ 2-34

Selecting vs. Choosing .......................................................................................................... 2-36

Dialog Boxes ......................................................................................................................... 2-37

Deleting Data From a Text Field and Printing Data from a Screen ...................................... 2-38

Page Up/Page Down ............................................................................................................. 2-39

Program Structure ................................................................................................................. 2-40

Sample Programming Overview ........................................................................................... 2-45

System Specifications and Characteristics ............................................................................... 2-46

Instrument Specifications ......................................................................................................2-46

Peripheral Devices Specifications ........................................................................................ 2-48

Sample Container Information .................................................................................................. 2-49

Sample Containers Allowed .................................................................................................. 2-49

Bar Code Types and Options ................................................................................................ 2-50

Bar Code Label Specifications .............................................................................................. 2-52

Applying Bar Code Labels .................................................................................................... 2-54

Sample Volume ..................................................................................................................... 2-55

Loading Tubes Into Racks .................................................................................................... 2-56

Instrument Operation Overview .............................................................................................. 2-57

Instrument Operation ............................................................................................................ 2-57

2

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-1

Page 19

Overview

Introduction

Overview

Introduction

Hardware Components

The IMMAGE® 800 Immunochemistry System is a bench-top analyzer composed of

the IMMAGE 800 instrument, computer and printer. (Refer to Figure 2.1.) The

system is shipped complete for installation. The system will be installed by a

Beckman Coulter Representative.

1

1. Instrument

2. Computer

3. Printer

2

Figure 2.1 The IMMAGE 800 Immunochemistry System

3

A011408P.EPS

System Description IMMAGE 800 Operations Manual A11403

Page 2-2 March 2004

Page 20

Instrument

Description

The IMMAGE 800 instrument is the analytical unit where the samples and reagents

are loaded and where the chemical reactions take place.

(Refer to Figure 2.2.)

Instrument

Description

6

1

2

2

3

1. Reagent Compartment

2. Reagent Crane

3. Reaction Module

4. Sample Carousel

5. Sample Crane

6. Upper Instrument Subsystems

Figure 2.2 IMMAGE 800 Instrument

5

4

A011409P.EPS

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-3

Page 21

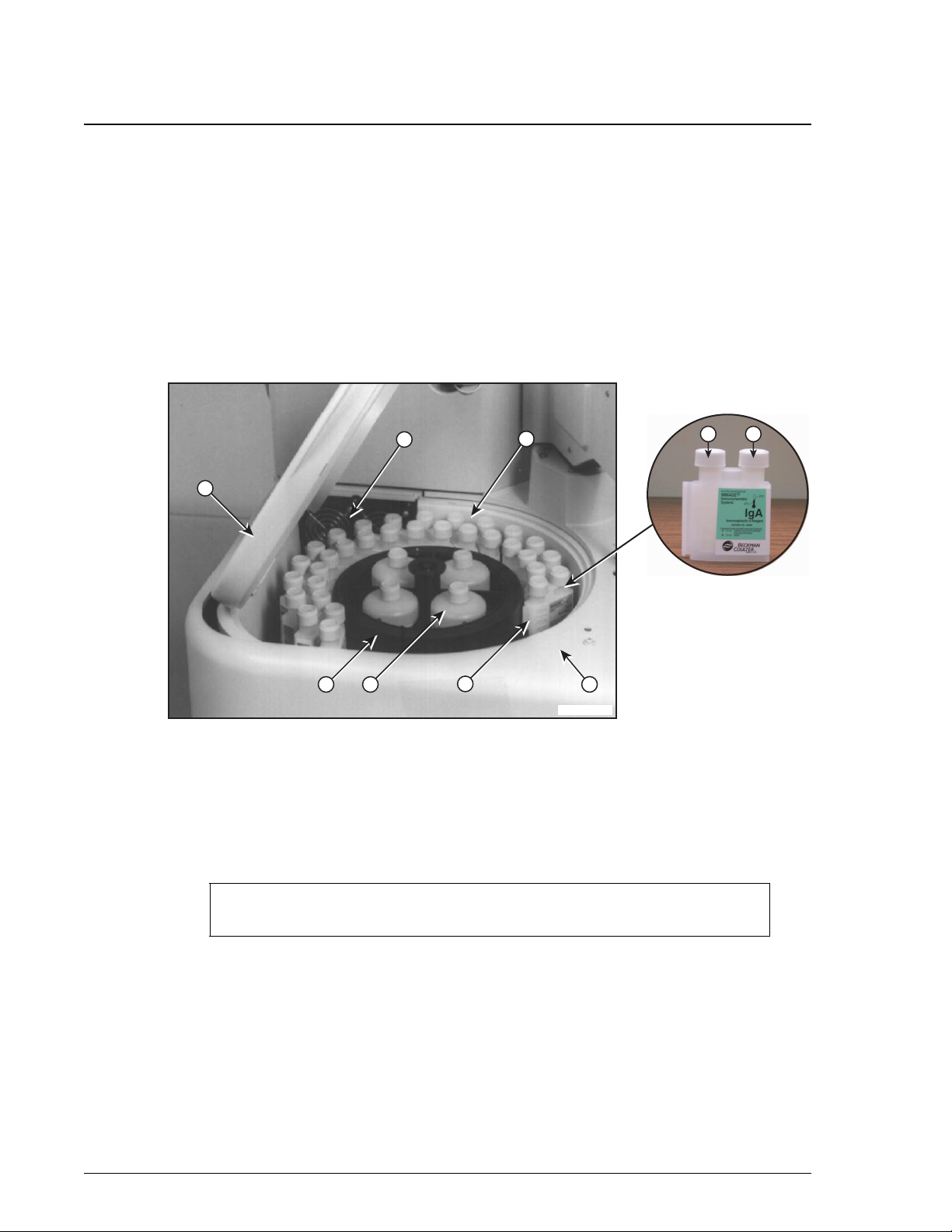

Reagent Compartment

Description

Reagent Compartment

Description

The reagent compartment is the area of the instrument where the removable reagent

carousel is stored. The temperature of the compartment is maintained at

approximately 15°C. (Refer to System Specifications and Characteristics,

"Temperature and Humidity" in this chapter.)

Reaction buffer bottles are placed in the center of the reagent compartment. The

bottles are maintained at room temperature. (Refer to Figure 2.3.)

1

A

6

77

B

2

3

1. Reagent Compartment Cover

2. Reagent Carousel

3. Reaction Buffer Bottle

4. Reagent Cartridges (Compartments A and B)

4

Figure 2.3 The Reagent Compartment

NOTICE

The instrument will stop if the reagent compartment cover is opened.

5

A011410P.EPS

5. Reagent Bar Code Reader

6. Fans

7. Temperature Sensor

System Description IMMAGE 800 Operations Manual A11403

Page 2-4 March 2004

Page 22

Component List

The following table lists each component of the reagent compartment with its

function.

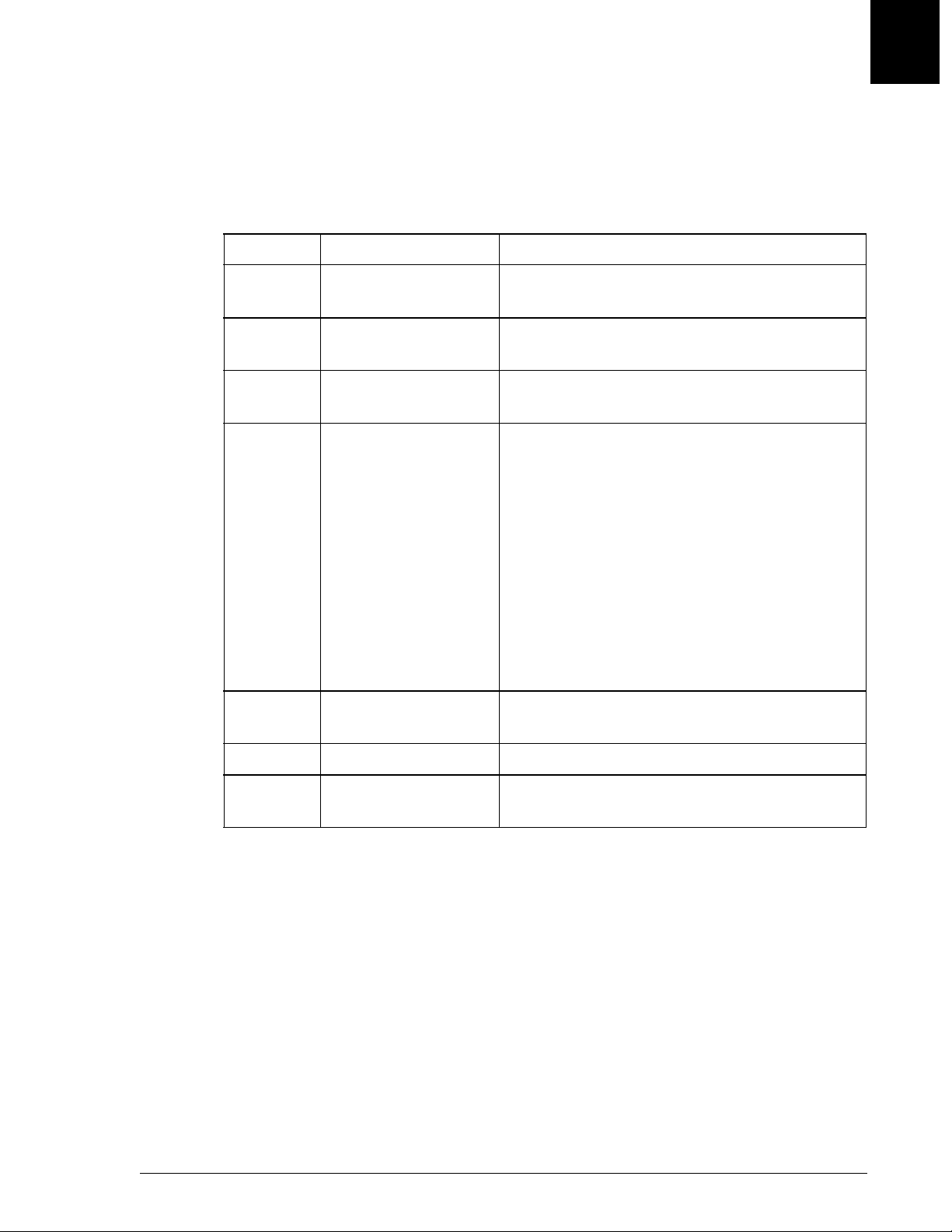

Table 2.1 Reagent Compartment Components

Number Component Function

Reagent Compartment

Component List

2

1 Reagent Compartment

Cover

Necessary to maintain temperature within

compartment.

2 Reagent Carousel Holds up to 24 reagent cartridges and 4 reaction

buffer bottles.

3 Reaction Buffer

Contain reaction buffers.

Bottles

4 Bar Coded Reagent

Cartridges

Contain chemistry specific reagent including

(where applicable):

• Reagent

• AGXS (antigen excess) Solution

• Co-reagent

• Conjugate

• Evaporation Caps

The cartridges are bar coded to allow for

instrument identification of each cartridge.

5 Reagent Bar Code

Reads bar codes on reagent cartridges.

Reader

6 Fans Circulate cool air in reagent compartment.

7 Peltier Temperature

Helps control 15°C in reagent compartment.

Sensor

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-5

Page 23

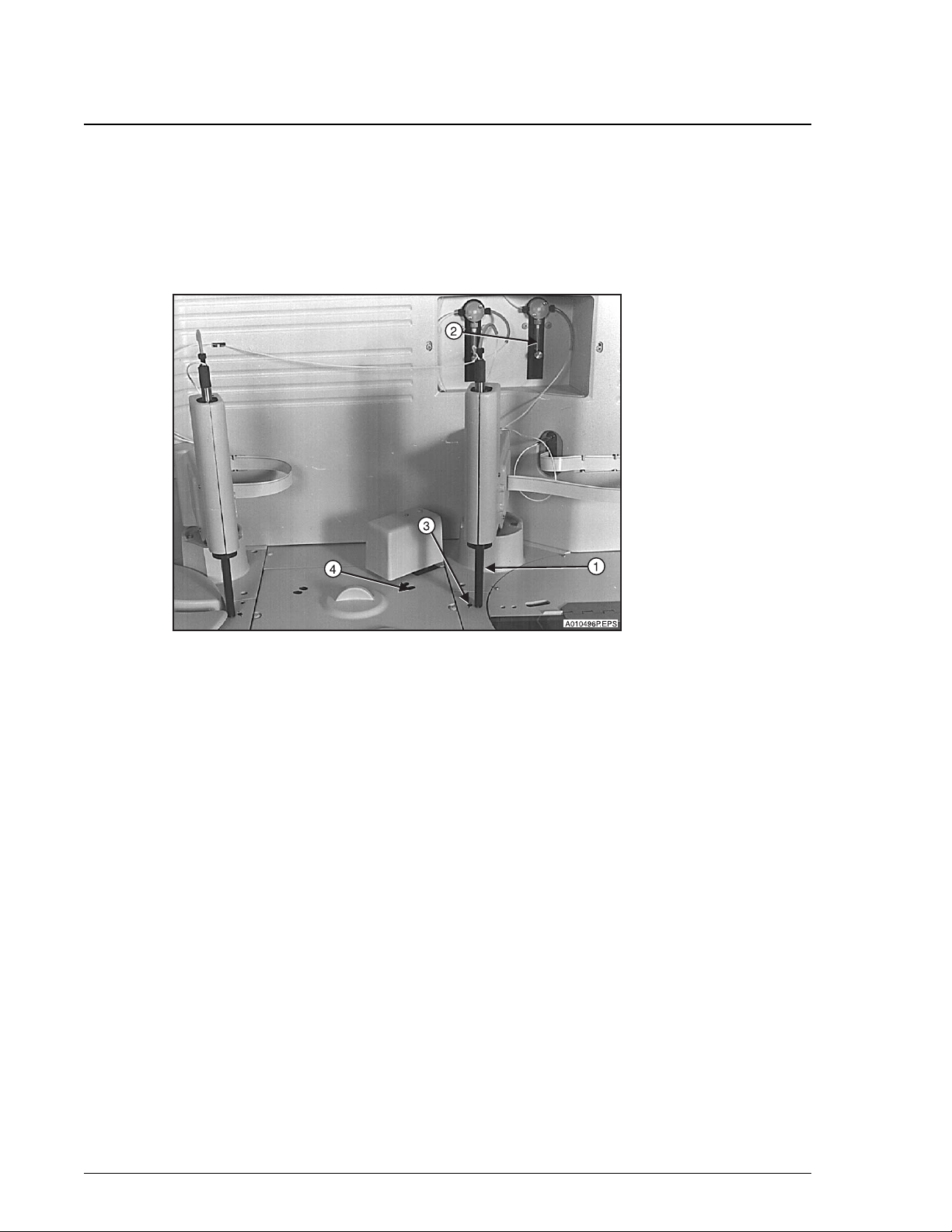

Reagent Crane

Description

Reagent Crane

Description

The reagent crane transfers reagents and buffers from the reagent compartment to the

reaction wheel. (Refer to Figure 2.4.)

1. Reagent Probe/Mixer

2. Reagent Syringe Pump

3. Reagent Crane Wash Station

4. Reagent Addition Ports

Figure 2.4 Reagent Crane

System Description IMMAGE 800 Operations Manual A11403

Page 2-6 March 2004

Page 24

Component List

The following table lists each component of the reagent crane with its function.

Table 2.2 Reagent Crane Components

Number Component Function

Reagent Crane

Component List

1 Reagent Probe Aspirates reagents and buffer from the reagent

compartment and dispenses them into a cuvette

on the reaction wheel.

Reagent Paddle Mixer Mixes the contents of a cuvette after reagent or

buffer has been dispensed.

2

2 Reagent Syringe

Pump (500 µL)

3 Reagent Crane Wash

Station

4 Reagent Addition

Ports

Mechanism for accurate reagent and buffer

aspiration and delivery through the reagent

probe.

Washes interior and exterior of reagent probe/

mixer.

Two openings in reaction module cover to allow

reagents to be added to one of two different

cuvette locations.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-7

Page 25

Reaction Module

Description

Reaction Module

Description

The reaction module is the area of the instrument where the reaction takes place. The

temperature of the reaction module is maintained at approximately 37°C. (Refer to

Figure 2.5 and System Specifications and Characteristics, "Temperature and

Humidity" in this chapter.)

1. Optics

2. Reaction Wheel

3. Cuvette

4. Reference Cuvette

Figure 2.5 Reaction Module

5. Cuvette Wash Station

6. Heat Block Temperature Sensor

7. Status Monitor Temperature Sensor

System Description IMMAGE 800 Operations Manual A11403

Page 2-8 March 2004

Page 26

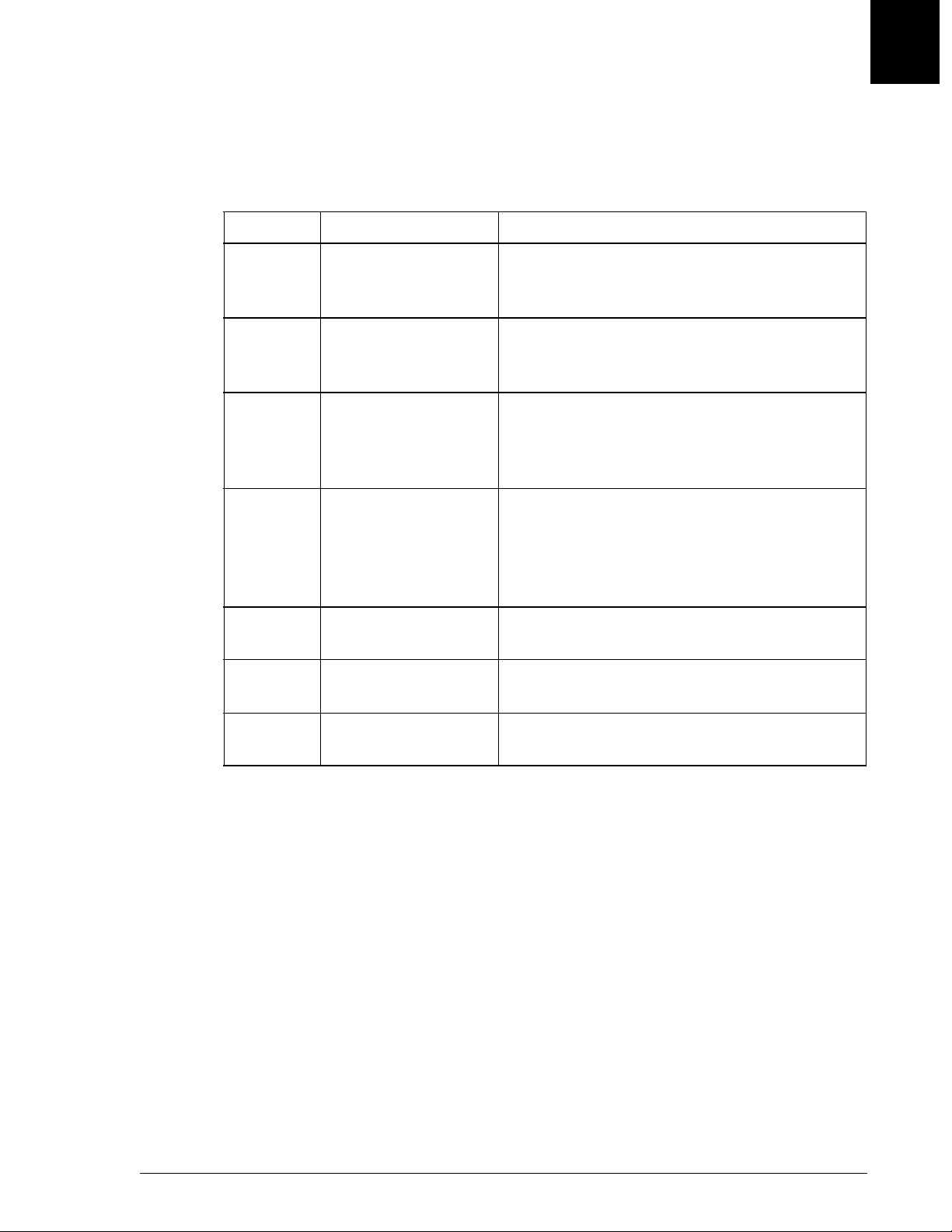

Component List

The following table lists each component of the reaction module with its function.

Table 2.3 Reaction Module Components

Number Component Function

Reaction Module

Component List

1 Optics Measures light scatter in nephelometric

reactions (670 nm wavelength) and

turbidimetric reactions (940 nm wavelength).

2 Reaction Wheel Holds 39 reaction cuvettes and the reference

cuvette. Spins to move individual cuvettes to

correct positions for each stage of the analysis.

3 Cuvettes Hold the combined reactants. The reaction

being measured takes place in the clear, plastic

cuvettes. The optics pass light through the

cuvette to measure scatter.

2

4 Reference Cuvette Has a known scatter value. The instrument

measures the scatter from the on-board

reference cuvette. It then adjusts the optics

based on these measurements and the known

reference values.

5 Cuvette Wash Station Washes the cuvette after the reaction is

complete.

6 Heat Block

Controls 37°C in reaction module.

Temperature Sensor

7 Status Monitor

Monitors reaction module temperature.

Temperature Sensor

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-9

Page 27

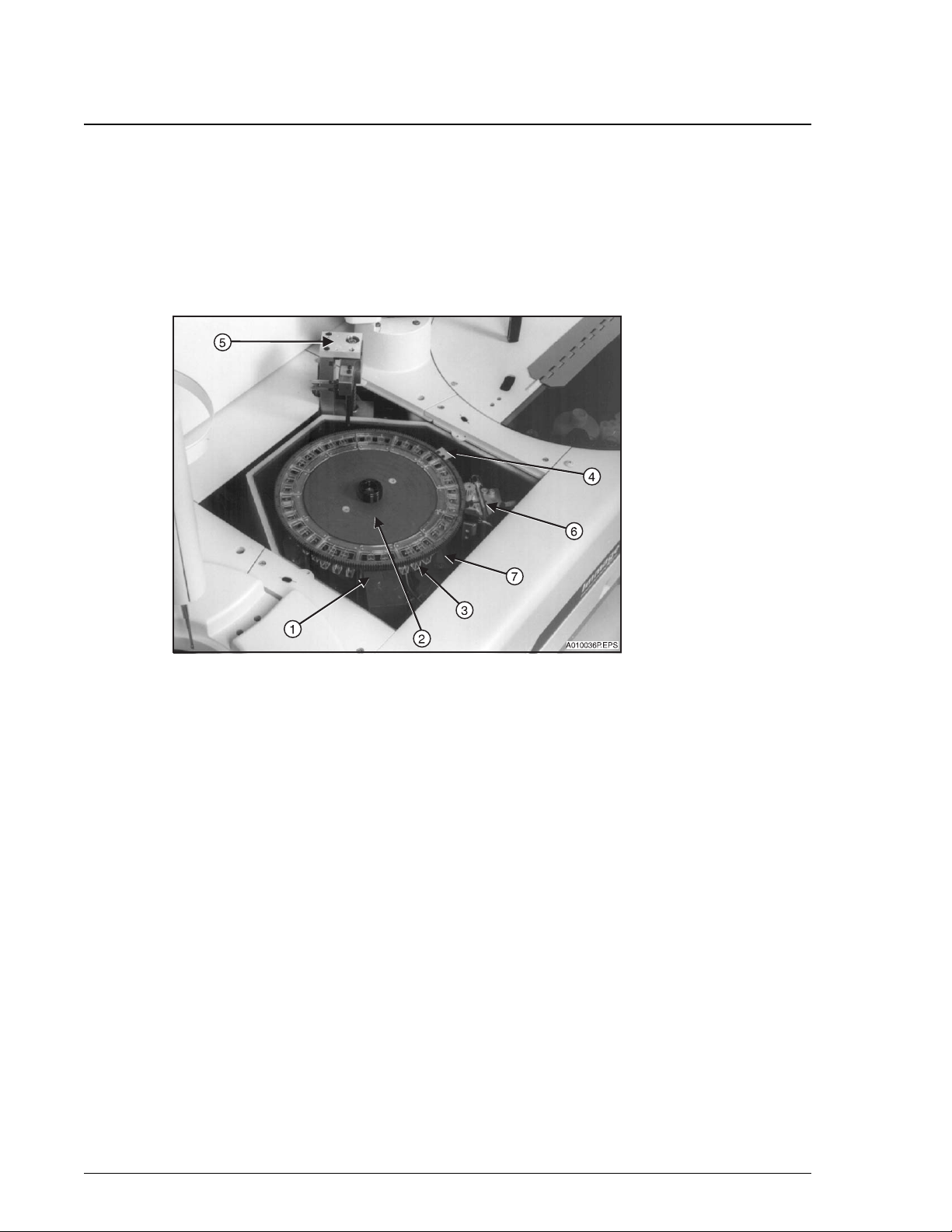

Sample Carousel

Description

Sample Carousel

Description

The sample carousel is the area of the instrument where the samples are loaded onto

the system and where the diluents are placed. Samples are loaded onto the system via

sample racks. All sample cups must be placed on the system using the Sample Cup

Holder Kit. Refer to Appendix A, Part Number List. To ensure sufficient sample

aspiration, do not place sample cups directly into the racks or use 1.0 mL sample cups.

Sample dilutions are made in dilution wells. (Refer to Figure 2.6.)

5

2

6

1. Sample Carousel Cover

2. Sample Diluent Bottle

3. Sample Rack

4. Dilution Segment

Figure 2.6 Sample Carousel

1

4

7

3

A011411P.EPS

5. Sample Bar Code Reader

6. Sample Carousel Advance Button

7. Background Bar Code Label

System Description IMMAGE 800 Operations Manual A11403

Page 2-10 March 2004

Page 28

Component List

The following table lists each component of the sample carousel with its function.

Table 2.4 Sample Carousel Components

Number Component Function

Sample Carousel

Component List

2

1 Sample Carousel

Reduces evaporation of sample.

Cover

2 Sample Diluent

Contain sample diluents.

Bottles

3 Sample Racks Hold sample tubes. (Refer to Racks in this

section of the manual.)

4 Dilution Segments The various sample dilutions are automatically

made in the wells of the dilution segments

before delivery to the reaction wheel. The

disposable dilution segments are placed on the

system by the user.

5 Sample Bar Code

Reader

Scans bar codes on the sample carousel

including:

• bar coded sample tubes

• sample rack bar codes

• background bar codes

• calibrator bar codes

• reagent bar code cards

• calibrator bar code cards

6 Sample Carousel

Advance Button

Rotates the Sample Carousel to allow access for

loading sample racks, dilution segments, and

sample diluent bottles.

7 Background Bar Code

Label

Informs instrument of presence or absence of

sample tube. When the sample bar code reader

can read the background bar code, no sample

tube is present at that position.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-11

Page 29

Sample Crane

Description

Sample Crane

Description

The sample crane transfers samples and diluents. Sample dilutions are made in the

dilution wells and then delivered to the reaction wheel. The Sample Crane functions

in the same manner as the Reagent Crane. (Refer to Figure 2.7.)

1. Sample Probe/Mixer

2. Sample Syringe Pump

3. Sample Crane Wash Station

4. Sample Addition Ports

Figure 2.7 Sample Crane

System Description IMMAGE 800 Operations Manual A11403

Page 2-12 March 2004

Page 30

Component List

The following table lists each component of the sample crane with its function.

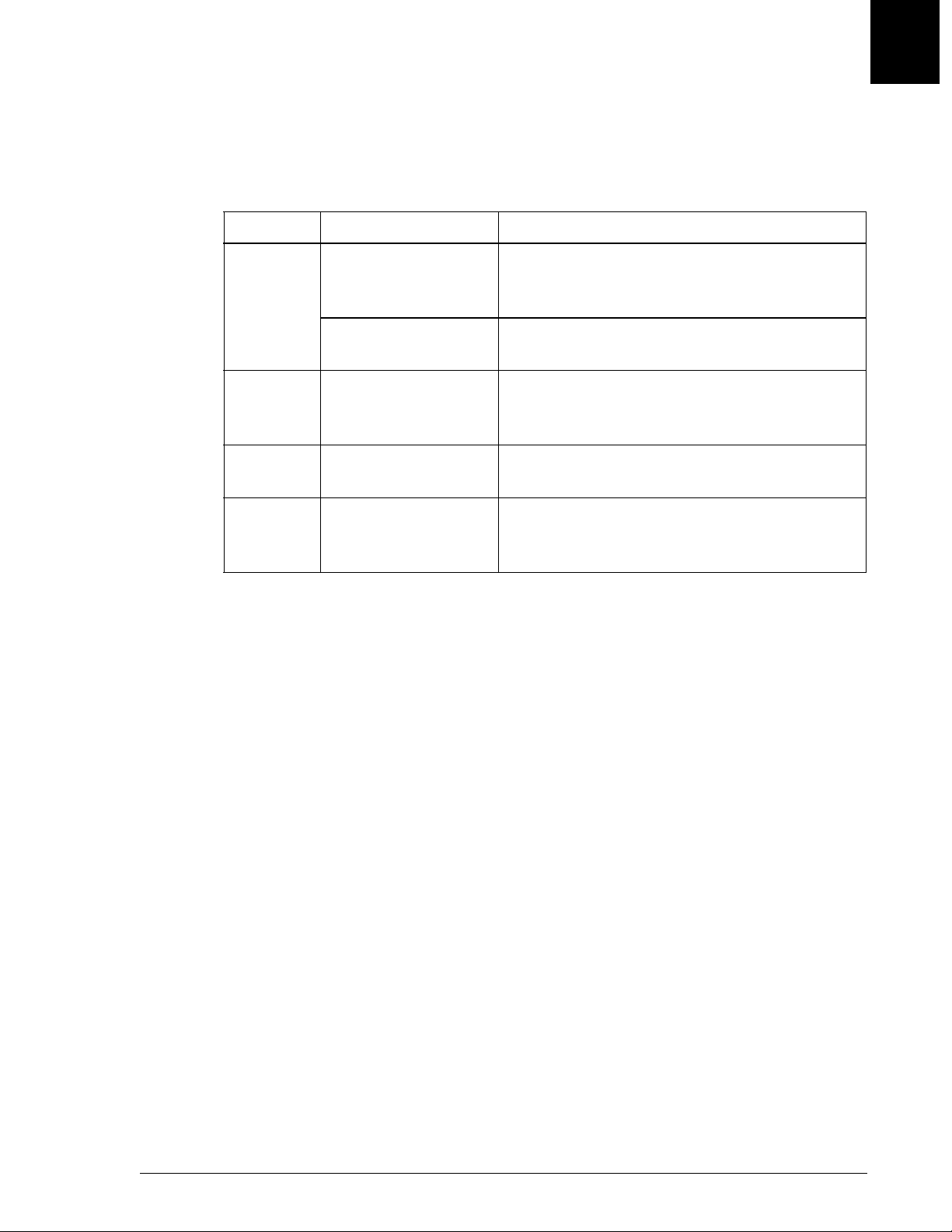

Table 2.5 Sample Crane Components

Number Component Function

Sample Crane

Component List

1 Sample Probe Aspirates sample and diluent and dispenses

them into the dilution well. Aspirates diluted

sample from the dilution well and dispenses it

into a cuvette on the reaction wheel.

Sample Paddle Mixer Mixes the contents of a cuvette while diluted

sample is dispensed. Also mixes in dilution

wells.

2

2 Sample Syringe Pump

(250 µL)

3 Sample Crane Wash

Station

4 Sample Addition

Ports

Mechanism for accurate sample, diluent, and

diluted sample aspiration and delivery through

the sample probe.

Washes interior and exterior of sample probe/

mixer.

Two openings in reaction module cover to allow

samples to be added to one of two different

cuvette locations.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-13

Page 31

Upper Instrument Subsystems

Upper Subsystem List

Upper Instrument Subsystems

Upper Subsystem List

The upper portion of the instrument contains three subsystems.

• Hydro Pneumatics

• Electronics Control Compartment

• Power Supply Assembly

Hydro Pneumatics

The hydro pneumatics control the flow of wash solution through the system and the

flow of waste out of the system. Pressure and vacuum control this fluid motion.

(Refer to Figure 2.8.)

1. Pressure Reservoir-Liquid

2. Pressure Reservoir-Air

3. Vacuum Reservoir

Figure 2.8 Hydro Pneumatics

System Description IMMAGE 800 Operations Manual A11403

Page 2-14 March 2004

Page 32

Electronics Compartment

The electronics compartment contains the electronic circuit boards. (Refer to Figure

2.9.) Electronic circuit boards should only be handled by a Beckman Coulter service

representative.

Upper Instrument Subsystems

Electronics Compartment

2

1. Circuit Boards

Figure 2.9 Electronics Compartment

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-15

Page 33

Upper Instrument Subsystems

Power Supply Assembly

Power Supply Assembly

All of the power supplies used by the IMMAGE 800 instrument are contained in this

area of the instrument. (Refer to Figure 2.10.) Power supply assemblies should only

be handled by a Beckman Coulter service representative.

1. Power Tower

2. Power Switch

3. Electrical Outlet/Voltage Selector

Figure 2.10 Power Supply Assembly

System Description IMMAGE 800 Operations Manual A11403

Page 2-16 March 2004

Page 34

Wash Solution Box and Waste Container

Description

The wash solution box and waste container are stored separately from the IMMAGE

800 instrument. (Refer to Figure 2.11.)

Wash Solution Box and Waste Container

Description

2

1. Wash Solution Box

2. Wash Solution Tubing

3. Waste Container

4. Waste Tubing

Figure 2.11 Wash Solution Box and Waste Container

Component List

The following lists the components depicted in Figure 2.11.

Table 2.6 Wash Solution Box and Waste Container Components

Item Component Function

1 Wash Solution Box Holds wash solution.

2 Wash Solution Tubing

(blue and orange)

Blue: Connects wash solution box to

instrument.

Orange: vents wash solution to box.

3 Waste Container Holds waste. (A drain can be used instead.)

4 Waste Tubing (green) Outlet for waste leading to waste container or

drain.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-17

Page 35

Wash Solution Box and Waste Container

Wash Solution

Wash Solution

The wash solution is used to wash the probes, mixers, and cuvettes.

Wash Solution Box Placement

The wash solution box must be close enough to the instrument to allow connection of

the wash solution tubing.

Waste Container Placement

The waste container must be placed with the opening of the waste container no higher

than the top of the instrument.

System Description IMMAGE 800 Operations Manual A11403

Page 2-18 March 2004

Page 36

Racks

Description

Description

Each sample rack holds up to nine sample tubes. Each rack is bar coded to allow

identification of the rack number by the instrument. (Refer to Figure 2.12.)

2

3

Racks

2

1. Rack Bar Code Label

2. Rack Number

3. Handle

Figure 2.12 Sample Rack

Types of Racks

There are four types of racks. They are identified by the size of sample tube that they

hold. (Refer to APPENDIX A, Part Number List.)

• 16 × 100 mm

• 16 × 75 mm

• 13 × 100 mm

• 13 × 75 mm

1

A012184P.EPS

Applying Rack Labels

Refer to CHAPTER 5, System Setup, Instrument Setup, Placing Labels on a Rack for a

detailed procedure for label placement.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-19

Page 37

Racks

Loading Rack onto the Sample Carousel

Loading Rack onto the Sample Carousel

Follow the steps below to load a rack onto the sample carousel. (Refer to Figure 2.13.)

Step Action

1 Press the Advance button to advance the sample carousel to an empty slot.

2 Lift the rack by its handle.

3 Open the cover of the sample carousel.

4 Align rack pegs over holes in the sample carousel.

5 Lower rack pegs into carousel holes.

Figure 2.13 Loading Rack onto the Sample Carousel

System Description IMMAGE 800 Operations Manual A11403

Page 2-20 March 2004

Page 38

Computer

Description

Computer

Description

The computer supplies the user interface to the IMMAGE 800 Immunochemistry

System and stores data.

The user performs all software interaction on the computer portion of the system. This

software interaction is stored on the computer and is sent to the instrument at the

appropriate time.

Additionally, patient results, control results, and setup parameters are stored on the

computer.

NOTICE

Only the computer supplied by Beckman Coulter is to be used with the IMMAGE 800

Immunochemistry System.

2

Changing the Date on the PC

The PC supplied with some IMMAGE 800 systems contains a battery that provides

power to the computer’s internal clock during power off. The status of the battery is

checked every time the Power On sequence is performed.

The date and time must be reset each time the Power On sequence is performed on a

computer with a dead CMOS (Complementary Metal Oxide Semiconductor) battery.

Contact Beckman Coulter Clinical Support or the nearest local Beckman Coulter Field

Service office for assistance in replacing the battery.

CAUTION

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-21

Page 39

Computer

Changing the Date on the PC

Table 2.7 Computer Components

Number Component Description

1 Personal Computer

The PC contains the:

(PC)

• CPU (Central Processing Unit)

• hard disk drive

• floppy diskette drive

• CD-ROM Drive

2 Floppy Diskette Drive Where a 3.5 inch floppy diskette is placed and

read.

3 CD-ROM Drive Where a CD-ROM is placed and read.

4 Keyboard 101- key enhanced keyboard.

5 Mouse A two-button movable input device.

6 Monitor Displays user interface (touch screen).

7 Uninterruptible Power

Source (UPS)

The backup power source providing temporary

power to the computer for a limited period of

time in the event of brownouts or low line

voltage conditions.

System Description IMMAGE 800 Operations Manual A11403

Page 2-22 March 2004

Page 40

Keyboard

Figure 2.14 depicts the 101- key enhanced keyboard used on the IMMAGE 800.

Computer

Keyboard

2

1. Escape Key

2. Function Keys

3. Tab Key

4. Caps Lock Key

5. Shift Keys

6. Control Keys

7. Alt Keys

8. Backspace Key

9. Enter Key

10. Delete Key

11. Page Up Key

12. Page Down Key

13. Arrow Keys

Figure 2.14 IMMAGE 800 Keyboard

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-23

Page 41

Computer

Port Connections

Port Connections

Figure 2.15 shows the back of the computer and where each cable connects.

1

3

2

4

A011412P.EPS

1. Printer Port

2. Monitor Port

3. Mouse/Keyboard Port

4. Instrument Port

Figure 2.15 CPU Ports

Proper Care and Handling of a Floppy Diskette

Diskettes require special care in handling.

• Recommended diskette: 3.5 inch Double-sided, High-density, IBM formatted

diskette.

• Store away from electrical motors, power supplies, or generators.

• Keep away from magnets and magnetic fields.

Proper Care and Handling of a Compact Disk

Compact disks (CD-ROMs) require special care in handling.

• Store away from direct sunlight, excessive heat, and humidity.

• Hold the CD-ROM by the edges.

• Replace the CD-ROM in its case after use.

System Description IMMAGE 800 Operations Manual A11403

Page 2-24 March 2004

Page 42

Printer

Description

Printer

Description

The printer supplied with the IMMAGE 800 Immunochemistry System is the HP

DeskJet printer. The printer is designed to use single sheet paper.

The printer is set up to use 8.5 × 11 inch paper. Paper size can be chosen in Printer

Setup.

Refer to the manual that accompanies the printer for proper setup, care, and handling

of the printer.

2

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-25

Page 43

Overview

Introduction

Overview

Introduction

Software Overview

The IMMAGE 800 is controlled through a graphical user interface (GUI). This

section describes the basic functions within the interface. The concepts presented in

this section should be understood by the user before attempting to use the IMMAGE

800. The Main Software screen is shown below.

Figure 2.16 Main Screen

E011433S.EPS

System Description IMMAGE 800 Operations Manual A11403

Page 2-26 March 2004

Page 44

Screen Format

Introduction

The IMMAGE 800 Immunochemistry System is designed to have a user friendly

interface. Figure 2.17 shows the sample programming screen of the IMMAGE 800 as

an example of this interface. This screen is broken into six functional areas:

• Status Bar

• Menu Bar

• Title Bar

• Function Buttons

• Message Bar

• Working Area

Screen Format

Introduction

3

2

Status Bar

1

2

4

5

6

1. Status Bar

2. Menu Bar

3. Icon Button

4. Title Bar

5. Function Buttons

6. Message Bar

7. Working Area

Figure 2.17 Sample Programming Screen

7

E011413S.EPS

The blue bar at the top of the screen is the status bar. This bar shows the instrument

status, date and time.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-27

Page 45

Screen Format

Menu Bar

Menu Bar

Below the status bar is a row of icon buttons called the menu bar. These icon buttons

can be selected to access various functional areas of the interface. These areas are:

•Main

•Samples

• Results

• Rgts/Cal (Reagent load and calibration)

• QC (Quality control)

•Setup

• Utils (Utilities)

• Status

• Stop - F12

• About

The menu bar consists of these specific icon buttons regardless of the current screen.

Title Bar

Below the menu bar is a bar containing the title of the current screen with some

possible additional information.

Function Buttons

At the bottom of the screen is an area for up to ten function buttons. These function

buttons perform functions that are specific to the particular screen. Each function

button on the screen corresponds to a function key on the keyboard read from left to

right (F1, F2, F3, etc.). The screen function buttons are labeled with the action the

function button performs and the corresponding keyboard function key.

Options Button

Within the working area, and occasionally on screens or dialog boxes, are buttons that

perform a different function than the "F" numbered function buttons. These buttons,

called options buttons, appear triangular in shape (▼) and often accompany a text

field. When an options button is selected, it presents a list of items, or options, from

which a user may choose.

Message Bar

The blue bar at the bottom of the screen is the message bar. This bar is used for

instructions and error messages. The first line displays instructions and the second

line displays error messages. These messages are related to activities in the working

area. (Refer to Figure 2.18.)

System Description IMMAGE 800 Operations Manual A11403

Page 2-28 March 2004

Page 46

Working Area

The middle portion of the screen is referred to as the working area. The user enters

data into the working area via:

•Text fields

• Buttons

• Toggle buttons

• Check boxes

Screen Format

Working Area

5

1

2

3

2

4

E010270S.EPS

1. Text Field

2. Cursor

3. Options Button

4. Toggle Button

5. Check Box

Figure 2.18 Working Area of Program Sample Screen

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-29

Page 47

Text Fields

Definition of Text Field

Text Fields

Definition of Text Field

Text fields are white areas on the screen in which the user types data.

Definition of Cursor

When a text field is chosen, a cursor displays in that field. This cursor indicates where

text will be entered.

Characteristics of Text Fields

Unless otherwise noted, most text fields can accept any alphanumeric characters. This

means that the user can type in any letter, number, or a space.

Each text field has a limited number of characters that can be entered. Most text fields

have a restricted set of characters that can be entered.

Example: If the user attempts to enter anything other than a number in a numeric field

the character will not be entered. A message will display which reads "Only numeric

characters are allowed."

NOTICE

The alphanumeric characters "|" (piping bar), "\" (backslash), " ^" (caret), and "&"

(ampersand) are not allowed because they are host interface delimiters.

System Description IMMAGE 800 Operations Manual A11403

Page 2-30 March 2004

Page 48

Buttons

Function

Example

Buttons

Function

Buttons on the screen perform as their name implies. When they are selected or

"pressed" an action is performed in the software. Often this action will be used to

access a new screen or dialog box.

The icons in the menu bar and the function buttons on the bottom of the screen operate

like buttons.

The options button <▼> next to the Sample Comment field on the Program Sample

screen is an example of a button.

2

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-31

Page 49

Toggle Buttons

Function

Toggle Buttons

Function

Toggle buttons function in the same manner as buttons, except when they are selected

or "pressed", their state is changed.

Selected or Unselected

Toggle buttons may either be in the selected or unselected state. If a toggle button is

selected it will be highlighted in blue.

Example

Each chemistry button in the list of chemistries on the Program Sample screen is an

example of a toggle button.

System Description IMMAGE 800 Operations Manual A11403

Page 2-32 March 2004

Page 50

Check Boxes

Function

Check boxes are similar to toggle buttons because they are either toggled on or off.

When selected, a check box will change state.

States

A check box is either checked or unchecked. When checked, a check mark will appear

in the check box.

Example

The STAT check box on the Sample Program screen is an example of a check box.

Check Boxes

Function

2

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-33

Page 51

Performing Software Functions

Introduction

Performing Software Functions

Introduction

The IMMAGE 800 Immunochemistry System uses a graphical user interface.

Functions can be performed by using a mouse to point and click, with keyboard

equivalents, or with an optional touch screen.

Using the Mouse

The mouse is the recommended method for performing actions with the IMMAGE

800. When the mouse is moved, the arrow on the screen moves with it. This arrow is

called the pointer. Movements of the pointer correspond to movements of the mouse.

When the pointer tip is touching an item on the screen, the pointer is pointing to that

item. Pressing the left button on the mouse and quickly releasing it is called clicking.

Clicking a button on the screen that the pointer is pointing to will select that button.

Clicking twice in rapid succession is called double-clicking. Pressing and holding

down the left mouse button and moving the mouse is referred to as dragging.

Using Keyboard Equivalents

All actions on the IMMAGE 800 can be performed with keyboard equivalents as well.

The screen navigation will be affected by the location of the cursor on the screen. The

cursor movement is directed either within a partition (local movement), which is a

logical grouping of data fields that may or may not be visually distinct from other

groupings, or is directed globally, which is movement throughout the entire screen.

Keyboard equivalent methods include:

• [Alt + Key]

• Function Buttons

• Tabs + Spacebar

• Arrow Keys + Spacebar

• Page Up/Page Down Keys

• Selecting a number from a list

[Alt + Key]

Icon buttons on the menu bar, at the top of the screen, can be selected by pressing and

holding down the [Alt] key and then pressing the key that corresponds to the

underlined letter in the title of that icon. For example, to show the Main screen, press

the key combination [Alt + m]. Buttons in dialog boxes may be selected using the [Alt

+ key] method as well.

Function Buttons

Functions buttons on the bottom of the screen can be selected by pressing the function

keys at the top of the keyboard (F1, F2, F3, ...). The function buttons on the screen are

numbered from left to right just as they are on the keyboard.

System Description IMMAGE 800 Operations Manual A11403

Page 2-34 March 2004

Page 52

Tab + Spacebar

The items in the working area of the screen can be chosen by using the [Tab] key.

Pressing the [Tab] key moves the highlight forward (generally left to right and top to

bottom) through the various text fields and screen buttons that may be chosen. If the

item is a text field, data may be entered as soon as the item is chosen. If the item is a

button, the button can be selected by pressing the [Spacebar].

Arrow Keys + Spacebar

The Arrow Keys on the keyboard may also be used to move the highlight between the

various items on the screen that may be chosen. The highlight moves in the direction

of the arrow. If a text field is chosen, [ ← ] and [ → ] will move through each letter in

the field before moving to the next item. If the item is a text field, data may be entered

as soon as the item is chosen. If the item is a button, the button can be selected by

pressing the [Spacebar].

Page Up/Page Down Buttons

An exception to the use of the [Tab] key or arrow keys are page up/page down buttons.

These buttons cannot be chosen. The [Page Up] and/or [Page Down] keys on the

keyboard are equivalent to the <Page Up> and <Page Down> buttons, respectively.

Performing Software Functions

Tab + Spacebar

2

Selecting a Number from a List

If there is a list of items to choose from, the user may select an item by typing the

number of the item in the text box and pressing [Enter].

A range of numbers can be entered by entering the first number followed by a dash

followed by the last number in the range (Example: 1-5 selects 1, 2, 3, 4, and 5).

A list of discontinuous numbers can be entered by separating the items with a comma

(Example: 1, 5, 8-10 selects 1, 5, 8, 9, and 10).

Using the Touch Screen

When the touch screen is used, the screen can be touched with a finger or any other

object. Any button on the screen can be selected by touching the button on the screen.

Any text field can be chosen by touching the field on the screen.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-35

Page 53

Selecting vs. Choosing

Introduction

Selecting vs. Choosing

Introduction

Selecting an item or field is different from choosing the item or field. Text fields can

only be chosen. Buttons, toggle buttons, and check boxes can be chosen and selected.

"Choosing" Definition

Using the [Tab] key or arrow keys moves the user to the various items on the screen by

highlighting one item at a time. An item is highlighted when a dark line appears

around it. When the item is highlighted that item is chosen but no action occurs.

"Selecting" Definition

Pressing the [Spacebar] selects the chosen item on the screen. When an item is

selected the software performs the appropriate action.

Text fields cannot be selected, only chosen.

Selecting/Choosing by Mouse or Touch screen

Buttons, toggle buttons, and check boxes are selected with the user’s first action and

the [Spacebar] is not needed when using the mouse or touch screen.

System Description IMMAGE 800 Operations Manual A11403

Page 2-36 March 2004

Page 54

Dialog Boxes

Definition

Dialog boxes are smaller than the total size of the screen and generally do not include

a bottom row of function keys. The purpose of a dialog box is to input a single piece

of data. This piece of data may be as simple as confirming the user’s request for the

system to perform an action. (Refer to Figure 2.19.)

Data is entered into dialog boxes the same as it is entered into the working area of any

screen.

Dialog Boxes

Definition

2

<Cancel>

<OK>

E010254S.EPS

Figure 2.19 Dialog Box Example

Most dialog boxes will have a <Cancel> button. This button closes the dialog box

without entering the requested data or denies confirmation of an action. If this button

is selected:

• no data is entered

• no action is performed

• the dialog box closes

This button can also be selected by pressing [Alt + c].

Some dialog boxes will have an <OK> button. This button accepts the data being

entered or confirms a user’s request for an action. If this button is selected:

• the data is entered into the system or the action is performed

• the dialog box closes

This button can also be selected by pressing [Alt + o].

<Print> or <Display>

Some dialog boxes may contain <Print> or <Display> buttons.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-37

Page 55

Deleting Data From a Text Field and Printing Data from a Screen

Deleting Data from a Text Field

Deleting Data From a Text Field and Printing Data from a Screen

Deleting Data from a Text Field

Follow the steps below to delete data from a text field.

Step Action

1 Choose the text field.

2 Choose one:

• Press the [Delete] key to delete the entire field.

• Press the [Backspace] key to delete a single character prior to the cursor.

• Drag through any portion of the text to highlight it and then press the

[Backspace] key to delete the highlighted text.

Printing Data from a Screen

Many screens contain data that may be printed by selecting Print [F10].

Printing a Screen

Any screen can be printed by pressing [Ctrl] + [P] simultaneously.

System Description IMMAGE 800 Operations Manual A11403

Page 2-38 March 2004

Page 56

Page Up/Page Down

Definition of Multipage

Some screens contain lists of data. If this list contains more data than an individual

screen can show the list is said to be multipage.

Example:

The chemistry list on the Program Sample screen is a multipage list.

Use of Page Up/Page Down

The user can access additional pages of data by selecting the page up and page down

buttons on the right. The page numbers are shown above the buttons. Selecting the

Page Down button will advance the page to the next page. Selecting the Page Up

button will return the page to the previous page. These buttons only appear if more

than one page of data exists.

Page Up/Page Down

Definition of Multipage

2

Keyboard Equivalents

The keyboard equivalent of the screen Page Up and Page Down buttons are the [Page

Up] and [Page Down] keys, respectively.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-39

Page 57

Program Structure

Introduction

Program Structure

Introduction

The software or interface of the IMMAGE 800 Immunochemistry System is divided

into functional areas based on different tasks. The icons in the menu bar at the top of

the screen represent the various functional areas. The following menu tree displays an

overview to the structure of the IMMAGE 800 software divided into its functional

groups.

Main

Home

Pause

Run

Samples Control Batch [F1]

Demog [F2] (Demographics) Program Sample [F1]

Save Next [F10]

Sample Options [F3]

Set Variable

OK

Cancel

End Batch [F10]

Select Control [F5] Sample Options [F3]

Select Control [F5]

Clear Chem [F7]

Cancel/Edit [F9]

Save/Next [F10]

Rerun Samples [F6]

Rerun Samples

Rerun Chems

Cancel

Stop

Link Sample

Program Batch [F4] Select Racks [F1]

Edit Samples

Clear Samples [F7]

Post Run Summary [F8]

Load List [F9]

Save/Next [F10]

E011369L.EPS

Figure 2.20 IMMAGE 800 Program Tree (1 of 5)

System Description IMMAGE 800 Operations Manual A11403

Page 2-40 March 2004

Page 58

Results Display Results [F1] Update Sample [F2]

Send to Host [F6]

Report Format [F7]

Print Report [F8]

Prev Sample [F9]

Next Sample [F10]

Cancel Send [F4]

Send to Host [F8]

Report Format [F9]

Print Report [F10]

Rgts/Cal Read Reagent [F1]

(Reagents/

Calibration) Reagent Summary [F2]

Buffer Diluent [F3]

Program Structure

Introduction

2

Request Cal [F4] Clear Racks [F1]

(Request Calibration) Save [F9]

Cancel [F10]

Cal Options [F5]

(Calibration Options)

Slope/Offset Adjustment

Calibrator Summary

Print Last Calibration Results

Cal LdList [F6]

(Calibration Loadlist)

Cancel Request [F7]

Read Cards [F8]

Figure 2.21 IMMAGE 800 Program Tree (2 of 5)

E011370L.EPS

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-41

Page 59

Program Structure

Introduction

QC Review Control [F1] Control ID [F2]

(Quality Delete Control [F3]

Control) Print Control [F10]

Define/Edit [F2] Add/Del Chems [F1]

Control ID [F2]

Delete Control [F3]

Delete Control [F3]

QC File List [F4] List CtlName [F1]

List File# [F2]

List SelChem [F3]

List AllChem [F4]

Print [F10]

QC Log [F5] QC Log [F1]

Reagent Lot [F2]

Delete Result [F3]

*Action Log [F4]

Print [F10]

QC Summary [F6] Print Inter-Lab [F9]

Print [F10]

QC Chart [F7] Control Chems [F1]

QC File # [F2]

Print [F10]

Figure 2.22 IMMAGE 800 Program Tree (3 of 5)

System Description IMMAGE 800 Operations Manual A11403

Page 2-42 March 2004

Page 60

Program Structure

Introduction

2

Setup

Define PrtName [F3]

(Define Print Name)

Clear All [F4]

Insert Chem [F5]

(Insert Chemistry)

Delete Chem [F6]

(Delete Chemistry)

UDR Main [F9]

Delete Panels [F2] Panels Summary [F2]

Print All [F10] Prev. Panel [F9]

Next Panel [F10]

Select TUrine [F2]

Define Calc [F3]

Delete Calc [F4]

Define Var [F5]

Chemistry

Beckman Chems [F1]

Configuration

Panels

Bar Code

Define/Edit [F1] Clear Chem [F1]

Restore Default [F1]

Reference Interval

Report Setup

Calculations

Restore Default [F1]

View/Edit [F1]

(Beckman Chemistries)

Change Date [F2]

Change Time [F3]

Units/Non-standard Dilutions

Antigen Excess

Date/Time

Host Communications

Restore Default [F1]

Restore Default [F1]

Restore Default [F1]

Default Setup

Restore Default [F1]

Print All [F10]

Sample Comments

Demographics Setup

Printer Setup

Restore Default [F1]

Languages/Keyboard

Chemistry Protocol Diskette

Instrument Serial Number

Figure 2.23 IMMAGE 800 Program Tree (4 of 5)

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-43

Page 61

Program Structure

Introduction

Utils

Prime

(Utilities)

Event Log

Display Events [F1]

Copy to Disk [F2]

Date/Time [F3]

Clear Events [F4]

Print [F10]

Diagnostics

Cycle Count

Call. Diagnostics

Alignment

Format QNX Diskettes

Prev Align [F1] (Previous Alignment)

Backup/Restore

Wash Cuvettes

Fill Internal Wash

Bottle

Stop Print

Reload DAS Code

Calibrate Touch Screen

Shutdown

Status

Dilution Segments

Sample Carousel Status

Figure 2.24 IMMAGE 800 Program Tree (5 of 5)

System Description IMMAGE 800 Operations Manual A11403

Page 2-44 March 2004

Page 62

Sample Programming Overview

Introduction

This section summarizes the sample programming methods for the IMMAGE 800

Immunochemistry System.

Sample Programming Options

The following table will summarize the sample programming options based on the

variables of bar coded samples and host interface. For detailed explanations of sample

programming refer to CHAPTER 7, Sample Programming, of this manual.

Table 2.8 Sample Programming Options

Sample Programming Overview

Introduction

2

Bar Coded

Samples

Yes Host Query None required. Load samples in any rack and

No Bi-directional None required. Load samples in rack and

Yes Bi-directional None required. Load samples in any rack and

No Unidirectional Required. Enter rack and position number,

Yes Unidirectional Required. Enter sample ID, and chemistries.

No None Required. Enter rack and position number,

Yes None Required. Enter sample ID, demographics, and

Host Interface Sample Programming

position.

position assigned by host.

position.

sample ID, and chemistries. Load samples in

assigned rack and position.

Load samples in any rack and position.

sample ID, demographics, and chemistries.

Load samples in assigned rack and position.

chemistries. Load samples in any rack and

position.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-45

Page 63

Instrument Specifications

Placement

System Specifications and Characteristics

Instrument Specifications

Placement

The surface on which the unit rests must be free of vibration and must be level, 1° or

<0.75 inch (1.9 cm) slope across the length and the width of the instrument. Do not

place instrument in direct sunlight or drafts or near a heating or cooling duct.

Clearance

Sides - 6 inches (15.2 cm) minimum

Back - None

Front - 3 inches (7.6 cm) minimum

Top - 4 inches (10.1 cm) from top of instrument

Dimensions (Excluding Wash and Waste Bottles)

Height = 30 inches (76.2 cm)

Depth = 25.5 inches (64.8 cm)

Length = 43.5 inches (110.5 cm)

Weight

250 lb. (120 kg)

Power Requirements

Operating Range 115 (90-132) VAC RMS, Single Phase

Frequency 50/60 Hz nominal (47-63 Hz)

Transient Suppression Recommended

BTU Generated 2,900 BTU/hour

Electrical Outlet Grounded per Local Code

Surge Protector Recommended

Current 8.0 Amps (normal) 12 Amps surge

Temperature and Humidity

Ambient Temperature +15°C to +32°C

Ambient Relative Humidity (RH) 15% to 85% (non-condensing)

Reagent Compartment Temperature 13-22°C (32°C Ambient, <45%RH)

Reaction Module Temperature +37°C ± 0.5°C

230 (180-264) VAC RMS, Single Phase

System Description IMMAGE 800 Operations Manual A11403

Page 2-46 March 2004

Page 64

Drain Requirements

Flow Rate: 3 Liters/hour minimum

Waste Container Placement: The opening should be no higher than the top of the

instrument.

Regulatory Agency Approvals

The IMMAGE 800 meets the safety requirements for the following agencies: CE, UL,

CSA, IEC and CENFLEC.

Environmental Conditions

System can operate up to 8000 ft. (2,438m) elevation.

Capacities

The following table lists various system capacities.

Table 2.9 System Capacities

Instrument Specifications

Drain Requirements

2

Item Capacity

Reagents 24 reagent cartridges can be loaded.

Reagent cartridge 40, 150, or 300 tests per cartridge.

Reaction buffers 4 bottles can be loaded.

Buffer bottle 120 mL: 350 tests.

Samples 72 samples can be loaded.

Sample diluents 4 bottles can be loaded.

Diluent bottles 120 mL: number of dilutions is workload dependent.

Sample dilution segments 4 segments of 36 wells each.

Dilution well 300 µL.

Wash solution 1 box/10 L/approximately 1,000 tests.

Waste container 5 gallons (18.9 L).

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-47

Page 65

Peripheral Devices Specifications

Introduction

Peripheral Devices Specifications

Introduction

Refer to the inserts which accompany the respective peripheral devices (computer,

printer, etc.) for product specifications.

System Description IMMAGE 800 Operations Manual A11403

Page 2-48 March 2004

Page 66

Sample Container Information

Sample Containers Allowed

Introduction

The following categories document specifications for sample containers that can run

on the IMMAGE 800 Immunochemistry System.

Primary Tubes

16 × 100 mm (10 mL)

16 × 75 mm (7 mL)

13 × 100 mm (7 mL)

13 × 75 mm

16.5 × 92 mm

Secondary (Aliquot) Tubes

16 × 100 mm

16 × 75 mm

13 × 100 mm

12 × 75 mm

Sample Containers Allowed

Introduction

2

Microtubes

13 × 100 mm SYNCHRON® Microtube™

Sample Cups

2 mL (placed into a sample cup holder)

0.5 mL (placed into a sample cup holder)

NOTICE

Low humidity and high ambient temperature may cause evaporation when using small

volumes of sample in sample cups. To minimize evaporation:

• Program samples in positions A or B on the sample carousel.

OR

• Program samples as STATS.

IMMAGE 800 Operations Manual A11403 System Description

March 2004 Page 2-49

Page 67

Bar Code Types and Options

Introduction

Bar Code Types and Options

Introduction

Four bar code types are supported by the IMMAGE 800:

•Code 39

• Code 128

• Interleaved 2 of 5

•Codabar

The bar code scanner will read any of these bar code types, provided the type is

enabled in Bar Code Setup and the options match those defined for the bar code label.

The scanner will also automatically discriminate between the symbologies, so tubes

with bar code labels of different types may be intermixed in a run.

Code 39 Options

Check Digit: If a higher degree of data integrity is required, a check digit may be

enabled and added to the bar code ID. The check digit used is a Modulus 43, which is

the sum of all the character values and is the last digit of the bar code ID. Code 39

expects the check digit to be included in the final code length.

Large Intercharacter Gap: In Code 39, the intercharacter gap has a minimum value of

one times the width of the narrow element and a maximum value of three times the

width of the narrow element, or 0.06 inches (0.152 cm), whichever is greater. This

feature should be enabled when the intercharacter gap exceeds four times the narrow

element width.

Fixed Code Length: If the sample IDs being used are all of the same length, Fixed

Code Length may be enabled to ensure that only one length of sample ID is accepted.

Define Code Length: When Fixed Code Length is enabled, the code length may be

defined as from 1 to 15 characters.

Code 128 Options

The options for Code 128 bar codes are fixed in the software and cannot be