Beckhoff CX1010-0020, CX1010-0010, CX1010-0011, CX1010-0012, CX1010-0021 Hardware Documentation

...Page 1

Hardware documentation

for CX1010 Embedded PC

CX1010-0xxx

CX1010-Nxxx

version: 1.4

date: 2008.10.26

Page 2

Page 3

Table of contents

Table of contents

1. Foreword

Notes on the documentation 3

Safety instructions 4

Documentation issue status 6

2. Product overview 7

Product overview 7

System overview 8

Basic modules 11

Technical data 11

Configurations 12

Connections 13

Battery compartment 15

Compact Flash slot 16

Compact Flash card 17

Memory overview 18

PC 104 Bus 20

System interfaces 22

Technical data 22

Connectors CX1010-N010 25

Connectors CX1010-N020 27

Connectors CX1010-N030/40 28

Connectors CX1010-N031/41 29

Connectors CX1010-N060 33

Power supply units 35

Overview power supply units 35

Technical data CX1100-0001 36

Technical data CX1100-0002 37

Technical data CX1100-0012 38

Technical data CX1100-0003 39

Technical data CX1100-0013 40

Technical data CX1100-0004 41

Technical data CX1100-0014 42

Connectors CX1100-0001 43

Connectors CX1100-00x2 44

Connectors CX1100-00x3 45

Connectors CX1100-00x4 46

LCD Display 47

3. Transport 48

Unpacking, installation and transport 48

Embedded-PC 1

Page 4

Table of contents

4. Assembly and connecting 49

Mechanical assembly 49

Dimensions 49

Mechanical assembly of basic module 57

Mechanical assembly of fieldbus connectors 60

Inbetriebnahme 62

Start-up procedure 62

BIOS Setup 63

Standard CMOS Features 65

IDE Primary Master 67

IDE Primary Slave 69

Advanced BIOS Features 71

Advanced Chipset Features 74

Integrated Peripherals 76

Power Management Setup 78

IRQ Wakeup Events 79

PnP / PCI Configuration 81

IRQ Resources 82

DMA Resources 83

Memory Resources 84

PC Health Status 85

5. Error handling and diagnostics 86

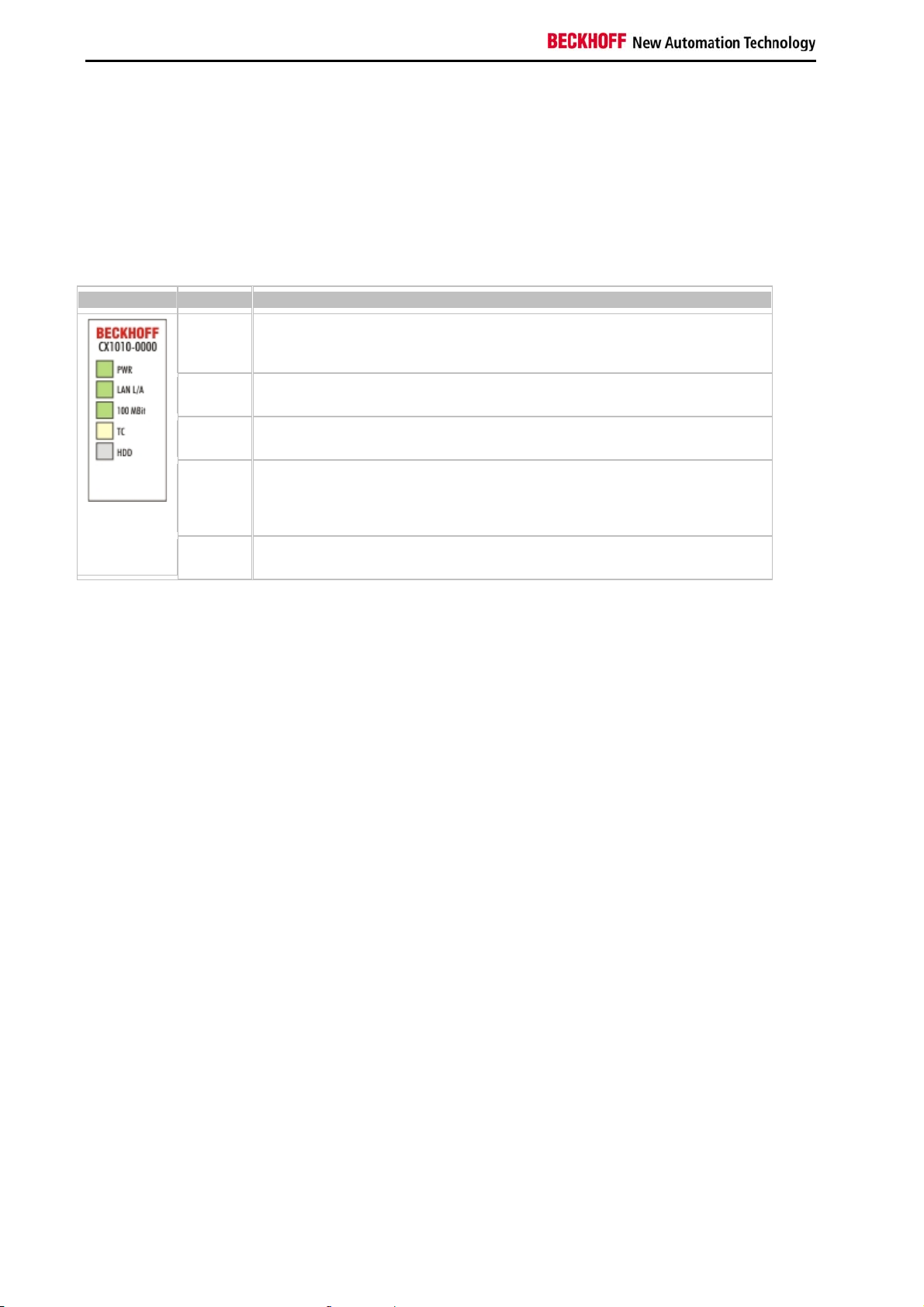

CPU basic module 86

LED CPU basic module 86

Power supply units 87

LED CX1100-0001 87

LED CX1100-0002 88

LED CX1100-0012 90

LED CX1100-0003 92

LED CX1100-0013 95

LED CX1100-0004 98

LED CX1100-0014 99

Faults 100

6. Removal and disposal 101

Removal and disposal 101

7. Appendix 104

Accessories 104

Certifications 105

Support and service 106

2 Embedded-PC

Page 5

Foreword

1. Foreword

Notes on the Documentation

This description is only intended for the use of trained specialists in control and automation engineering who are

familiar with the applicable national standards. It is essential that the following notes and explanations are followed

when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics. None of the statements of this manual represents a guarantee (Garantie) in the

meaning of § 443 BGB of the German Civil Code or a statement about the contractually expected fitness for a

particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In the event that it contains technical or editorial

errors, we retain the right to make alterations at any time and without warning. No claims for the modification of

products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this

documentation.

© This documentation is copyrighted. Any reproduction or third party use of this publication, whether in whole or in

part, without the written permission of Beckhoff Automation GmbH, is forbidden.

Embedded-PC 3

Page 6

Foreword

Safety Instructions

Safety Rules

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the application.

Modifications to hardware or software configurations other than those described in the documentation are not

permitted, and nullify the liability of Beckhoff Automation GmbH.

Personnel Qualification

This description is only intended for the use of trained specialists in control and automation engineering who are

familiar with the applicable national standards.

Description of safety symbols

The following safety symbols are used in this operating manual. They are intended to alert the reader to the

associated safety instructions

Danger

This symbol is intended to highlight risks for the life or health of personnel.

Warning

This symbol is intended to highlight risks for equipment, materials or the environment.

Note

This symbol indicates information that contributes to better understanding.

Operator's obligation to exercise diligence

The operator must ensure that

· the product is only used for its intended purpose.

· the product is only operated in sound condition and in working order.

· the instruction manual is in good condition and complete, and always available for reference at the location where

the products are used.

· the product is operated only by suitably qualified and authorized personnel.

· the personnel is instructed regularly about relevant occupational safety and environmental protection aspects, and is

familiar with the operating manual and in particular the safety notes contained herein.

4 Embedded-PC

Page 7

Foreword

National regulations depending on the machine type

Depending on the type of machine and plant in which the product is used, national regulations governing the

controllers of such machines will apply, and must be observed by the operator. These regulations cover, amongst

other things, the intervals between inspections of the controller. The operator must initiate such inspections in good

time.

Operator requirements

Read the operating instructions

All users of the product must have read the operating instructions for the system they work with.

System know-how

All users must be familiar with all accessible functions of the product.

Embedded-PC 5

Page 8

Foreword

Documentation Issue Status

Version Changes

1.4 annotations to network ports changed

1.3 BIOS changes added

1.2 system interfaces CX1200-xxxx removed

1.1 system interfaces CX1010-N070 and CX1010-N080 renamed

1.0 version at start of series production

0.0.1 preliminarily version

6 Embedded-PC

Page 9

Product overview

2. Product overview

Appropriate Use

The CX1010 device series is a modular control system designed for top-hat rail installation. The system is scalable,

so that the required modules can be assembled and installed in the control cabinet or terminal box as required.

Only switch the PC off after closing the software

Before the Embedded PC is switched off, the software currently running on it should be stopped properly in order to

avoid data loss on the hard disk. Please read the section on “Switching off”.

Switch off all system components and uncouple the Industrial PC from the system if the PC is not used for control

purposes, e.g. during a function test. Disconnect the device by pulling the first terminal after the power supply unit

(CX1100-002 and CX1100-002) (optional) and the fieldbus connectors.

System components that have been switched off must be secured against being switched on again.

The power supply unit of the Embedded PC requires a 24 V DC supply.

Danger

Do not exchange any parts when under power!

When components are being fitted or removed, the supply voltage must be switched off.

Software knowledge

Warning

Mandatory software knowledge!

Every user must be familiar with any of the functions of the software installed on the PC that he can reach.

Embedded-PC 7

Page 10

Product overview

System overview

The system

With the CX series of Embedded PCs Beckhoff has combined PC technology and modular I/O level to form a top-hat

rail unit in the control cabinet. The CX1020 extends the CX product family by a version with higher CPU performance.

The CX1020 enables direct connection of Bus Terminals and EtherCAT terminals.

While the CX1000 features an 266 MHz AMD Geode processor, the CX1010 is equipped with a 500 MHz AMD®

Geode LX 800Intel(r) CPU. It is an energy-saving device that operates with ultra-low core voltage and features low

thermal power dissipation of only 8 W TDP (thermal design power). As a result, no fan is required despite the

compact design of the CX1010 Embedded PC. Since Compact Flash is used as boot and memory medium, no

rotating media are required in the controller. This is an important aspect for increasing the MTBF (Mean Time

Between Failures) of the overall system.

The case and assembly concept of the CX1010 is similar to that of its smaller brother, the CX1000:

It also consists of several components that can be assembled by the user. The simplest configuration consists of a

CPU module and a multi-functional power supply unit. The PC104 bus is used for the connection between these and

all other CX components, although in the CX1020 this was extended with EtherCAT signals. The basic CPU module

is equipped with one RJ-45 socket.

Like the CX1000, the CX1020 can be expanded with optional system interfaces. A DVI-I (=DVI-D + VGA) output, two

USB-2.0 interfaces, up to four RS232 interfaces and audio are available. The four RS232 interfaces feature optodecoupling and can optionally be implemented as RS422/RS.

The same reusability also applies to the multi-functional power supplied units (CX1100-000x) of the CX1020: one

without I/O terminal connection, one with K-Bus connection, one with K-Bus and IP-Link connection for IP-67protected Fieldbus Box modules, and a power supply unit with direct connection facility for Beckhoff EtherCAT

Terminals.

EtherCAT as a fast I/O system

The CX1010 Embedded PC was developed for optimum interaction with EtherCAT. The Ethernet interface of the

CPU module is not primarily intended for EtherCAT operation. The EtherCAT connection is established via the

EK1110 (EtherCAT) extension terminal. The power supply CX1100-0004 establishes the possibility to connect E-Bus

Terminal to the CPU Module.

8 Embedded-PC

Page 11

Product overview

Interestingly, EtherCAT offers several options for connecting conventional fieldbus systems to the CX1010:

either as a CX1500 module directly at the CPU or as an EtherCAT device in terminal form. The PROFIBUS master is

available either as a CX1500-M310 or as a EL6731 EtherCAT terminal. Both types offer the same performance

characteristics - e.g. both support PROFIBUS DP-V2. In practice, this means that the PROFIBUS master can be

positioned exactly where it is required within a machine. It no longer has to be implemented as a plug-in card in the

IPC or a master controller in the control cabinet.

PLC, Motion Control, interpolation and visualisation

As a top-hat rail IPC and in conjunction with the TwinCAT software from Beckhoff, the CX1010 offers the same

functionality as large Industrial PCs. In terms of PLC, up to four virtual IEC 61131 CPUs can be programmed with up

to four tasks each, with a minimum cycle time of 50 µs. All IEC 61131-3 languages can be used.

Moreover, all TwinCAT functionalities are available for Motion Control applications:

In theory, up to 256 axes can be controlled. In addition to simple point-to-point movements, more complex multi-axis

functions such as "electronic gearbox", "cam plates" and "flying saw" can be implemented. In contrast to the CX1000,

due to its higher CPU performance the CX1010 can now also execute interpolating 3D path movements and

DIN66025 programs.

In addition to real-time execution of control tasks, the TwinCAT real-time kernel ensures that enough time remains for

the user interface (HMI), to communicate with the real-time components via software interfaces such as ADS or OPC.

For the CX1010 the same basic principle applies: it is a programming tool for all controllers.

The complete programming of PLC, Motion Control and visualization is transferable to all PC controls from Beckhoff,

which is reassuring in cases where it becomes apparent during a project that more processing power is required after

all. In this case a system with higher performance can be used.

Basic CPU module

Further system interfaces or fieldbus connections can be added to the basic CPU module. The CPU module requires

a CX1100 type power supply module.

All CX1500 fieldbus modules and all CX1100 power supply units from the CX1000 series can be used in combination

with the CX1010.

The CX1100-0004 power supply unit offers a direct interface between the CX1010 and the EtherCAT Terminals. The

combination of CX1010, EtherCAT and TwinCAT enables cycle and response times of less than 1 millisecond.

The CPU module is available in several variants. These relate to:

- System interface configuration: as an option, a DVI and two USB Interfaces can be added to the combination of the

Ethernet RJ 45 port that is always present.

- Operating system: There is a choice between "Microsoft Windows CE.NET" or "Microsoft Windows XP Embedded".

- Pre-installed TwinCAT software: CX1010 can be pre-installed without a TwinCAT system, with TwinCAT CE PLC,

TwinCAT CE NC PTP or TwinCAT CE NCI, or with the associated full version of the individual TwinCAT levels for

PLC and Motion Control.

System interfaces

Further system interfaces for serial communication (2x RS 232 or RS422, RS485), 2 x USB 2.0 interfaces, video

output (DVI +) , CF card reader/writer or audio signals can be ordered separately.

Fieldbus interfaces

All CX1500 fieldbus modules and all CX1100 power supply units from the CX1000 series can be used in combination

with the CX1010.

The fieldbus interfaces are currently available as master and slave versions for the following fieldbuses:

Beckhoff Lightbus, Profibus DP, CANopen, DeviceNet or SERCOS interface (only master)

The master fieldbus connections enable a CX1020 system to use Beckhoff fieldbus components (such as Bus

Coupler, Bus Terminal Controller or Drive Technology) as local control components for complex systems.

Slave fieldbus connections enable the CX1020 system to be used as a subordinate distributed control system for

complex or modular systems.

Note:

Documentation describing the fieldbus connections is available separately.

Embedded-PC 9

Page 12

Product overview

The software

In combination with the TwinCAT automation software, the CX1010 Industrial PC becomes a powerful IEC 61131-3

PLC with up to four user tasks. Additionally, Motion Control tasks can also be executed. Depending on the required

cycle time, several servo axes can be controlled. Even special functions such as flying saw, electronic gearbox and

cam plate can be realized.

The CX1010 system is programmed in the same way as other bus controllers:

Remote programming via Ethernet

This option is used if the basic unit is equipped with “Windows CE.NET”. In this case, the system is programmed via

a laptop or a desktop PC, which is connected to the CX1020 via Ethernet (network or crossover cable). The

programs are developed on the laptop with a standard TwinCAT software licence and then loaded into the target

device.

Visualization

The Beckhoff OPC server is available for interfacing with SCADA packets, if the two operating system variants

“Windows CE.NET” or “Windows XP Embedded” are used. In other words, the CX1010 also offers straightforward

visualization and simultaneous control in real-time on a single system.

10 Embedded-PC

Page 13

Product overview

Basic modules

Dimensions:

The basic configuration of the CX1010 includes a 64 MB Compact Flash card. One Ethernet RJ 45 interface is also

part of the basic configuration. All other CX family components can be connected via the PC104 interface that is

available on both sides. The passive cooling module is included in the scope of supply. For power supply one of the

system power supply modules (CX1100-000x) is needed)

Technical data CX1010-xxxx

Processor Processor AMD Geode® LX 800, 500 MHz clock frequency

Internal Flash Memory 64 MByte Compact Flash card

Internal Memory 256 MByte DDR-RAM

Interfaces 1 x RJ45 (Ethernet)

Diagnose LED 1 x Power, 1 x LAN Link/Activty, 1 x TC, 1 x Flash-Access

Expansion slot 1 x Compact Flash type I+ II insert with eject mechanism

Clock internal battery-backed clock for time and date

Operating system Microsoft Windows CE.NET or Microsoft Windows XP Embedded

Control software TwinCAT PLC Runtime , TwinCAT NC PTP Runtime or TwinCAT NCI

Runtime

System bus 16 Bit ISA (PC104 Standard)

Power supply via system bus (through power supply module CX1100-000x)

Dimensions (W x H x D) 58 mm x 120 mm x 91 mm

Max. power loss 8 W (including CX1010-N0xx system interfaces)

Wight app. 355 g

Operating/storage

temperature

Relative humidity 95% no condensation

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27/29

EMC resistance burst / ESD conforms to EN 61000-6-2/EN 61000-6-4

protection class IP 20

0° C ... +50° C / -25° C ... +85° C

Embedded-PC 11

Page 14

Product overview

Configurations

The Basic CPU-Module can be ordered with different hardware and software variations. As operating systems there

are "Windows CE.NET" and "Windows XP Embedded" available. The TwinCAT automation software transforms a

CX1020 system into powerful PLC and Motion Control system that can be operated with or without visualisation.

The order identifier of the basic CPU module is derived as follows:

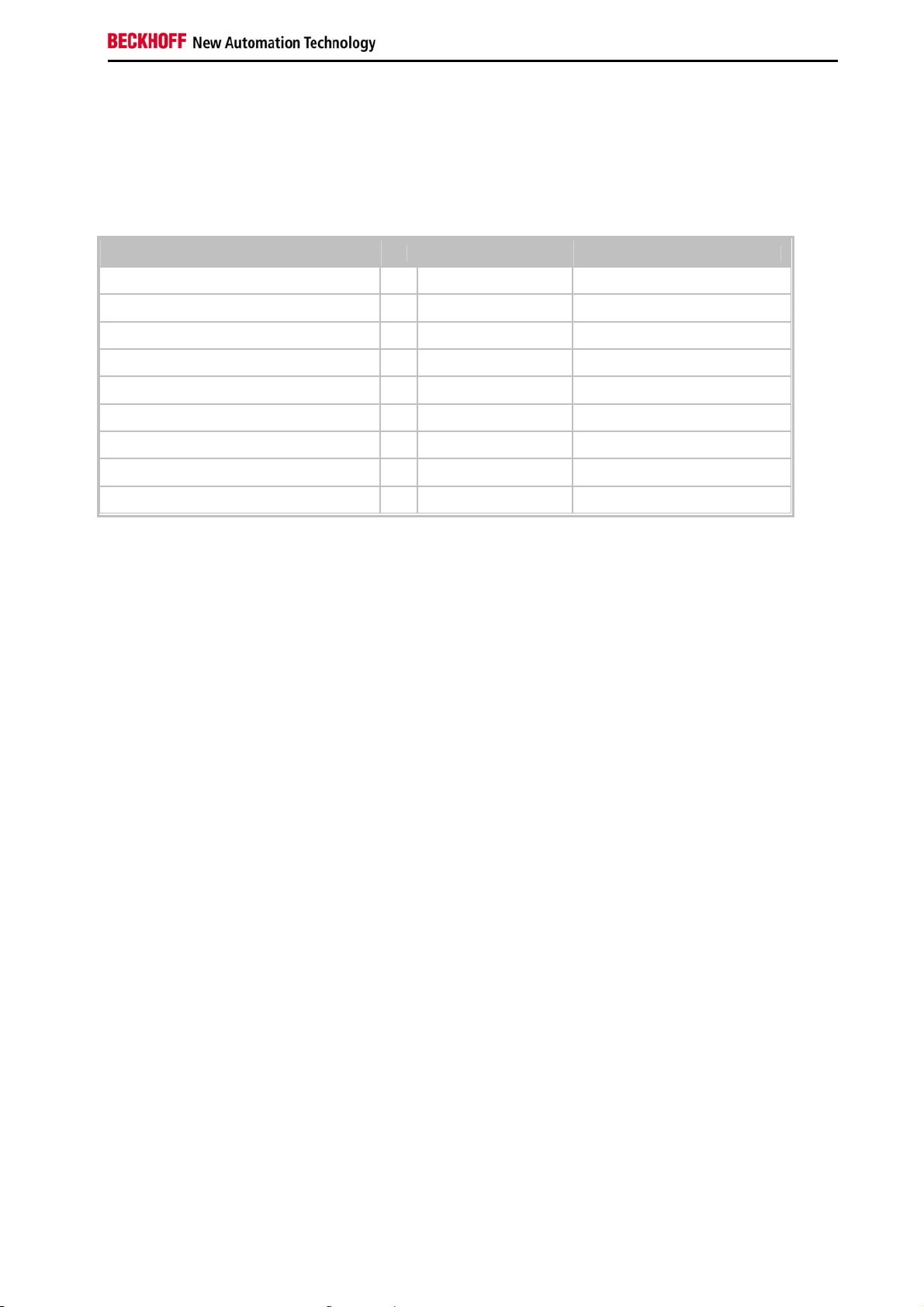

Following CX1020 configurations are available:

Modul

CX10100000

CX10100010

CX10100011

CX10100012

CX10100100

CX10100110

CX10100111

CX10100112

CX10100020

DVI /

USB

no

operating

system

Windows

CE

Windows

XPE

without

TwinCAT

TwinCAT

PLC

Runtime

TwinCAT

NC PTP

Runtime

- X - - X - -

- - X - X - -

- - X - - X -

- - X - - - X

X X - - X - -

X - X - X - -

X - X - - X -

X - X - - - X

- - - X X - -

CX10100021

CX10100022

CX10100120

CX10100121

CX10100122

X1010 Systems with Windows XP Embedded require a Compact Flash card with a capacity of al least 1 GB.

Note:

For detailed information about the software images see the CX10x0 Software Documentation.

- - - X - X -

- - - X - - X

X - - X X - -

X - - X - X -

X - - X - - X

12 Embedded-PC

Page 15

Product overview

Connections

The basic CPU module is available with different hardware and software options. It is supplied from the power supply

unit, so that only the connections are described here.

Basic CPU module with 2 Ethernet RJ 45 interfaces:

RJ 45 interface (socket):

Assignment of the RJ45 interface:

PIN Signal Description

1 TD + Transmit +

2 TD - Transmit -

3 RD + Receive +

4

5

6 RD - Receive -

7

8

TD & RD are exchanged at the hubs or between two PCs.

Schematic structure of the network components:

Connected not used

Connected not used

The CX1010 features two MAC blocks. The first one (MAC1) operates the left network interfaces for the standard IP

network. This port is also used for PLC programming.

The second block (MAC2) operates the extended PC104 bus. The second physical network connection can be

utilized via additional system interfaces. This requires either a CX1100-0004 power supply unit or a CX1020-N060

system interface. A connection to the E-bus for EtherCAT terminals is realized via the power supply unit. The

CX1010-N060 interface establishes the Ethernet connection, thereby making a further network interface available.

Embedded-PC 13

Page 16

Product overview

Operating system perspective:

The operating system only sees the connections for the network interface. The internal connection via the PC104 bus

extension is shown as the second interface. If no expansion module is connected, the line is reported as not

connected. When the CX1100-0004 power supply unit is connected Windows XPe reports "restricted or no

connection" This behavior is normal, since Windows itself does not use this interface, and therefore no IP address is

allocated. If the CX1020-N060 extension is connected, the connection behaves like a 'normal' network port.

Note

The network ports are only for communication with standard network. Do not connect to

telecommunication circuits.

Basic CPU module with DVI/USB interface:

In addition to the Ethernet port, this basic module also features DVI/USB interfaces. The pin assignment of the basic

CPU module with two USB and a DVI-I interface is explained under the associated CX1010-N 010 system interface.

Applicable to all basic CPU modules:

LED

The green power LED (PWR) is on if the basic CPU module is connected correctly to a live power supply unit.

Compact Flash slot

Further information can be found under Compact Flash slot.

PC 104 Bus

The PC 104 bus is a standardized bus with 104 ISA signals for compact embedded systems.

14 Embedded-PC

Page 17

Product overview

Battery compartment

The battery compartment is located on the left-hand side of the CPU module, between the two Ethernet ports.

It can be opened with the aid of a screwdriver (proceed carefully in order to avoid damage).

The battery is a CR2032 type from Panasonic

with the following specification:

Battery type Electrical properties (at 20° C)

CR2032 3.0 V 225 mAh 0.20 mA 20.0 mm 3.20 mm 3.1 g

Danger

nominal

voltage

nominal

capacity

Standard

charge

continuous

load

Diameter Height Weight

Dimensions

Replace Battery Part. No. CR2032 manufactured by Sanyo or Panasonic

Only. Use of Another Battery May Present A Risk Of Fire Or Explosion.

WARNING, Battery may explode if mistreated. Do Not Recharge,

Disassemble or Dispose of in fire.

Note

The battery must be changed every 5 years.

Spare batteries can be ordered from Beckhoff Service.

Embedded-PC 15

Page 18

Product overview

Compact Flash slot

A Compact Flash slot is provided at the front of module. This enables an additional Compact Flash memory medium

(format I or II) to be operated. The change - in case of the Basic CPU module CF slot - is only allowed while the

system is powered down - otherwise the system could crash. In case of using the CF-slot extension (CXxxxx-A001)

the CF card can be removed after signing out the media from the system. The card can be removed for maintenance

or to extend the system storage capacity. The Compact Flash cards (CF cards) are available as accessories with

different storage capacities.

As example the following pictures show the handling of the CF cards with a CX1000 system. Activating the eject

mechanism below the slot with a screwdriver causes the card to be ejected by approx. 4 mm (FIGURE 1), so that it

can be pulled out (FIGURE 2). If the card is pushed in (FIGURE 3), the eject mechanism will re-engage. The card is

positioned correctly, if it is located approx. 1 mm lower than the front of the housing.

FIG1: Ejecting the CF card

FIG2: Removing the CF card

FIG3: Inserting the CF card

Warning

The Compact Flash slot is a memory interface, not an I/O type CF slot.

16 Embedded-PC

Page 19

Product overview

Compact-Flash card

The Compact Flash card (CF card) is a non-volatile memory medium.

Data to be retained in the event of a power failure should be saved on the CF card. The CF card operates similar to a

hard disk.

Warning

It is recommended only use CF cards supplied by Beckhoff Automation GmbH.

The CF cards are made for industrial use. They possess a higher number of read / write cycles

and an enhance temperature range (up to + 85°C).

A proper operation of the CX-System can only be guaranteed with the use of CF cards from

Beckhoff Automation GmbH!

Embedded-PC 17

Page 20

Product overview

Adapter RAM Hardware address overview

available memory addresses CX1020: D0000-DFFFF (hex)

Base Address

(hex)

D0000 D0FFF 1000 R/W CX1100-0002/3 Dual Ported RAM

D1000 D100F 10 R/W CX1100 Auxiliary Control Block( LCD

D1010 D101F 10 R/W CX1100-0900 UPS Control Block

D2000 D3FFF 2000 R/W CX1100 Non Volatile RAM

D4000 D5FFF 2000 R/W CX1500-M310 Profibus Master

D6000 D7FFF 2000 R/W CX1500-M510 CANopen Master

D8000 D9FFF 2000 R/W CX1500-M520 DeviceNet Master

DA000 DBFFF 2000 R/W CX1500-M200 Lightbus Master

DC000 DDFFF 2000 R/W CX1500-M750 Sercos Master

For some fieldbus connections (all Slave modules) the base addresses are mapped in the memory region upper

DFFFF(hex). So this modules must be ordered with other base addresses. The same situation takes place if more

than two or more master modules of same type are used (for more see note below). The order numbers for the

modules are:

End Address

(hex) Size(Bytes)(hex)

Access

Type Description

Display, misc. registers)

DPRAM

DPRAM

DPRAM

DPRAM

DPRAM

order number alternative ISA-address

Master connection

CX1500-Mxxx-0001 D4000

CX1500-Mxxx-0002 D6000

CX1500-Mxxx-0003 D8000

CX1500-Mxxx-0004 DA000

CX1500-Mxxx-0005 DC000

Slave connection

CX1500-Bxxx-0001 D4000

CX1500-Bxxx-0002 D6000

CX1500-Bxxx-0003 D8000

CX1500-Bxxx-0004 DA000

CX1500-Bxxx-0005 DC000

Replace xxx with the following number for the requested fieldbus system:

200 for Lightbus

310 for Profibus

510 for CAN-open

520 for DeviceNet

750 for Sercos (only Master connection available)

18 Embedded-PC

Page 21

Product overview

Note

Two connection modules (master or slave) can be used simultaneously.

If more than two connections are needed call Beckhoff Automation GmbH for further information.

Embedded-PC 19

Page 22

Product overview

PC/104 Bus

The PC 104 bus is a standardized bus with 104 ISA signals for compact embedded systems.

For the functionality of the CX1020 modules eight further signals have been added ( here marked with color).

Pin assignment of 16 Bit PC 104 Bus:

Pin

Number

1 IOCHCHK* GND GND GND

2 SD7 RESETDRV SBHE* MEMCS16*

3 SD6 +5V LA23 IOCS16*

4 SD5 IRQ9 LA22 IRQ10

5 SD4 -5V LA21 IRQ11

Row A

Row B Row C4 Row D4

6 SD3 DRQ2 LA20 IRQ12

7 SD2 -12V LA19 IRQ13

8 SD1 ENDXFR* LA18 IRQ14

9 SD0 +12V LA17 DACK0*

10 IOCHRDY (KEY)² MEMR* DRQ0

11 AEN SMEMW* MEMW* DACK5*

12 SA19 SMEMR* SD8 DRQ5

13 SA18 IOW* SD9 DACK6*

14 SA17 IOR* SD10 DRQ6

15 SA16 DACK3* SD11 DACK7*

16 SA15 DRQ3 SD12 DRQ7

17 SA14 DACK1* SD13 +5V

18 SA13 DRQ1 SD14 MASTER*

19 SA12 REFRESH* SD15 GND

20 SA11 SYSCLK (KEY)² GND

21 SA10 IRQ7 -- --

22 SA9 IRQ6 -- --

23 SA8 IRQ5 -- --

24 SA7 IRQ4 -- --

25 SA6 IRQ3 -- --

26 SA5 DACK2* -- --

27 SA4 TC -- --

28 SA3 BALE -- --

29 SA2 +5V -- --

30 SA1 OSC -- --

31 SA0 GND -- --

32 GND GND -- --

Remarks:

20 Embedded-PC

Page 23

Product overview

1. B10 and C19 are key locations.

2. Signal timing and function are as specified in ISA specification.

3. Signal source/sink current differ from ISA values.

4. in the specification the pins are counted from 0 to 19

Assignment on the 8 additional pins

Pin number (yellow fields)

Row C

Row D

1 LAN TX- LAN TX+

2 LAN RX- LAN RX+

3 USB D- USB D+

4 SMBDAT SMBCLK

Note:

Further information to PC104 Bus can be found in the datasheet or under http://www.pc104.org.

Embedded-PC 21

Page 24

Product overview

System interfaces

Technical Data

Dimensions:

22 Embedded-PC

Page 25

Product overview

Like for the CX1000, a number of optional interface modules are available for the basic CX1010 CPU module that

can be installed ex works. The following interfaces are available:

CX1010-N010 DVI / USB Module

CX1010-N020 Audio interfaces

CX1010-N030/40 serial interface for RS323

CX1010-N031/41 serial interface for RS422 / RS485

CX1010-N060 Ethernet-interface

The CX1010-N010 option can be connected to Beckhoff Control Panels or standard monitors with DVI or VGA input

via the DVI or USB interfaces.Devices such as printer, scanner, mouse, keyboard, mass storage, CR-RW etc. can be

connected via the USB 2.0 interfaces. Multimedia capability is realized via the CX1010-N020 audio interface. The

modules CX1010-N030 and CX1010-N040 offer a total of four serial RS232 interfaces with a maximum transfer

speed of 115 kbaud. These four interfaces can be implemented in pairs as RS422/RS485, in which casethey are

identified as CX1010-N031 and CX1010-N041 respectively.The system interfaces cannot be retrofitted or expanded

in the field. They are supplied ex factory in the specified configuration and cannot be separated from the CPU

module. The system interfaces run through the internal PC104 bus, so that further CX components can

be connected. The power supply of the system interface modules is ensured via the internal PC104 bus.

Embedded-PC 23

Page 26

Product overview

CX1010-N030

Technical data CX1010-N010 CX1010-N020

Interfaces 1 x DVI +

2 x USB 2.0

max. 100 mA

Line IN,

MIC IN,

Line OUT

CX1010-N040

1 x COM1+2, RS232

1 x COM3+4, RS232

per port

Connection type DVI-I 29-pin

socket +

3,5 mm socket for

jack plug

2 x D-Sub plug 9-pin 2 x D-Sub plug 9-pin

2 USB Ports

type A

Properties DVI-I interface

also carries

out VGA

signals (DVIA)

built-in PC-Beeper

Line OUT output,

max. 200 mW,

suitable for

earphones

max. baud rate

115 kbaud,

can not be used

simultaneously with

N031/N041

Power supply via system bus (Through CX1100-000x power supply module)

Dimensions 19 mm x 100 mm x 51 mm

Operating

0 °C ... +55 °C

temperature

Storage

-25 °C ... +85 °C

temperature

Relative humidity 95% no condensations

CX1010-N031

CX1010-N041

1 x COM1+2, RS422/RS485

1 x COM3+4,RS422/RS485

max. baud rate 115 kbaud,

can not be used simultaneously with

N030/N040

Vibration/Shock

conforms to EN 60068-2-6 / EN 60068-2-27/29

resistance

EMC resistance

conforms to EN 61000-6-2/EN 61000-6-4

burst / ESD

Protection class IP 20

weight app. 80 g

Technical data CX1010-N060

Interfaces 1 x Ethernet 10/100 Mbit

Connection type 1 x RJ45

Properties network connection for enhanced PC104 Bus

Power supply via system bus (through CX1100-000x power supply module)

Dimensions 19 mm x 100 mm x 51 mm

Operating

0 °C ... +55 °C

temperature

Storage

-25 °C ... +85 °C

temperature

Relative

95% no condensations

humidity

Vibration/Shock

conforms to EN 60068-2-6 / EN 60068-2-27/29

resistance

EMC resistance

conforms to EN 61000-6-2/EN 61000-6-4

burst / ESD

Protection class IP 20

weight app. 80 g

24 Embedded-PC

Page 27

Product overview

CX1010-N010 connections

This module features a DVI-I and two USB interfaces.

DVI-I interface

The DVI-I interface transfers analog and digital data and is suitable for connection to analog graphics cards with 15

pin D-Sub connector and digital graphics cards with DVI-D output. The resolution at the screen or the Beckhoff

Control Panel depends on the distance (maximum 5 m).

The DVI interface uses VGA signals, so that the connection of CRT VGA monitors to the CX1000 system using a DVI

to VGA adapter is also possible.

This adapter is available as an accessory.

DVI-I socket:

Pin Assignment Pin Assignment Pin Assignment

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 0-

2 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data 2/4 Shield 11 TMDS Data 1/3 Shield 19 TMDS Data 0/5 Shield

4 not connected 12 not connected 20 not connected

5 not connected 13 not connected 21 not connected

6 DDC Clock 14 + 5V Power 22 TMDS Clock Shield

7 DDC Data 15 Ground ( +5V, Analog H/V Sync) 23 TMDS Clock +

8 Analog Vertical Sync 16 Hot Plug Detect 24 TMDA Clock -

Embedded-PC 25

Page 28

Product overview

Assignment cross

Pin Assignment

C1 Analog Red Video Out

C2 Analog Green Video Out

C3 Analog Blue Video Out

C4 Analog Horizontal Sync

Resolution at the monitor:

Resolution in Pixel Distance of the interface from the monitor

1600 x 1200 5 m

1280 x 1024 5 m

1024 x 768 5 m

800 x 600 5 m

640 x 480 5 m

USB interface:

The USB socket is a type A socket. The USB interface complies to USB 2.0 specification

Pin Assignment Typical Assignment

1 VBUS Red

2 D- White

3 D+ Green

4 GND Black

Shell Shield Drain Wire

26 Embedded-PC

Page 29

Product overview

CX1020-N020 connections

This system interface provides the audio interface for the CX1020 system. Two inputs, "LINE IN" and "MIC IN", are

available. The "LINE OUT" connection is used as output for audio signals. It can also be used for connecting

headphones with a maximum output of 200 mW. It also features a PC beeper. The audio interfaces are accessed via

the operating system. "Windows XPe" offers an option for switching the audio module to surround mode.

The 3.5 mm sockets are designed for jack plugs.

Standard / stereo mode:

The audio module operates in stereo mode as standard, using stereo outputs/inputs and a single-channel input for

the microphone. The inputs should be connected as indicated. The pin assignments are described below.

Line In / Line Out stereo jack plugs:

Pin assignment Line In /Line Out:

Signal Assignment

L left channel

R right channel

Ground ground

The left channel is transferred via the tip of the jack plug, the right channel via the first ring. The remainder of the

sleeve is used for signal ground.

Mic In mono jack plug:

The only existing channel is transferred via the tip, the remainder of the sleeve is used for signal ground.

Embedded-PC 27

Page 30

Product overview

CX1010-N030/40 connections

The CX1010-N030 system interface features two RS232 interfaces, COM1 and COM2 (9 pin Sub-D plug connector).

If there is need for more than two serial interfaces two further RS232 interfaces, COM3 and COM4 (9 pin Sub-D plug

connector) can be added to the system via the system interface CX1010-N40. The maximum baud rate on all

channels is 115 kBit. The pin assignment for all interfaces is equal and described below. The interface parameter can

be set in the operating system or in the PLC program.

RS232 COM interface (connector):

Pin assignment COM interface:

PIN Signal Type Description

1 DCD Signal in Data Carrier Detected

2 RxD Signal in Receive Data

3 TxD Signal out Transmit Data

4 DTR Signal out Data Terminal Ready

5 GND Ground Ground

6 DSR Signal in Dataset Ready

7 RTS Signal out Request to Send

8 CTS Signal in Clear to Send

9 RI Signal in Ring Indicator

Note

The system interface CX1010-N30 can only be used instead and not simultaneously with

system interface CX1010-N031.

The system interface CX1010-N40 can only be used instead and not simultaneously with

system interface CX1010-N041.

28 Embedded-PC

Page 31

Product overview

CX1020-N031/41 connections

The CX1010-N031 system interface features two RS422 / RS 485 interfaces, COM1 and COM2 (9 pin Sub-D plug

connector). If there is need for more than two serial interfaces two further RS422 / RS485 interfaces, COM3 and

COM4 (9 pin Sub-D plug connector) can be added to the system via the system interface CX1010-N41. The

maximum baud rate on all channels is 115 kBit. The pin assignment for all interfaces is equal and described below.

The interface parameter can be set in the operating system or in the PLC program.

RS232 COM interface (connector):

Pin assignment COM interface:

PIN Signal Type Description

2 TxD+ Data-Out + Transmit 422

3 RxD+ Data-In + Receive 422

5 GND Ground Ground

6 VCC VCC +5V

7 TxD- Data-Out - Transmit 422

8 RxD- Data-In - Receive 422

For RS 485 Pin 2 and 3 ( Data +) as well as Pin7 and 8 (Data -) have to be connected..

Embedded-PC 29

Page 32

Product overview

Setting the interface parameter

If the system interface CX1010-N031/N041 resides at the end of the CX1010-system block, it is easy to access the

dip switches. The dip switches for the configuration of the RS485/422 interfaces can be found at the left side of the

module. If you remove the grey cover you can see the switch:

The upper switch sets the parameters for the upper interface, the lower switch sets the parameter for the lower

interface. The system must be powered down, if the settings of the switches are changed! The settings for default

use should be mentioned by ordering the interface module.

Settings DIP switches RS485:

RS485 without Echo, End-Point ( Terminated) DEFAULT setting

DIP Status Function

1 off Echo on

2 on Echo off

3 on Auto send on

4 off Always send on

5 on Auto receive on

6 off Always receive on

7 on Term on

8 on Term on

RS485 with Echo, End-Point ( Terminated)

DIP Status Function

1 on Echo on

2 off Echo off

30 Embedded-PC

Page 33

Product overview

3 on Auto send on

4 off Always send on

5 off Auto receive on

6 on Always receive on

7 on Term on

8 on Term on

RS485 without Echo, Drop-Point ( without Termination)

DIP Status Function

1 off Echo on

2 on Echo off

3 on Auto send on

4 off Always send on

5 off Auto receive on

6 on Always receive on

7 off Term on

8 off Term on

RS485 with Echo, Drop-Point ( without Termination)

DIP Status Function

1 on Echo on

2 off Echo off

3 on Auto send on

4 off Always send on

5 off Auto receive on

6 on Always receive on

7 off Term on

8 off Term on

Setting DIP-Switches RS422:

RS422 full duplex end point

DIP Status Function

1 on Echo on

2 off Echo off

3 off Auto send on

4 on Always send on

5 off Auto receive on

6 on Always receive on

7 on Term on

8 on Term on

Embedded-PC 31

Page 34

Product overview

Note

The system interface CX1010-N31 can only be used instead and not at the same time with

system interface CX1010-N030.

The system interface CX1010-N41 can only be used instead and not at the same time with

system interface CX1010-N040.

32 Embedded-PC

Page 35

Product overview

CX1020-N060 connections

The CX1010-N060 system interface provides a further network interface. It can only be used if the CX1100-0004

power supply unit is not connected, since in this case the only internal interface available is used for connecting the

Ethernet port. (Details see Basic module description.)

RJ 45 interface (socket):

Assignment of the RJ45 interface, Port 1:

PIN Signal Description

1 TD + Transmit +

2 TD - Transmit -

3 RD + Receive +

4

5

6 RD - Receive -

7

8

TD & RD are exchanged at the hubs or between two PCs.

connected not used

connected not used

Warning

The CX1020-N060 system interface may only be mounted on the right

module. The setup is shown in the following figures.

Proper mounting position:

The interface is located between the CPU module and the power supply unit.

, directly at the CPU

Embedded-PC 33

Page 36

Product overview

Incorrect mounting position:

The interface is located to the left of the CPU module, in series with the other system interfaces.

Warning

The connected network cable must not have a length of more than 15 meters!

Note

The CX1010-N060 system interface can only be used in place of

supply unit, not at the same time

.

the CX1100-0004 power

34 Embedded-PC

Page 37

Product overview

Power supply units

CX1100-000x | Power supply units and I/O interfaces

A choice of four power supply modules is available for use with a CX10x0 system. The power supply of all other

system components is ensured via the internal PC104 bus; no separate supply lines are required. However, the

CX1100 components offer further important characteristics that go beyond a pure power supply: an integrated

NOVRAM enables the fail-safe storage of process data, an LCD display with two lines of 16 characters each is used

for displaying system and user messages. A 4 + 1 keypad enables user input without additional keyboard or input

panel. Local I/O signals are connected via the CX1100-0002 power supply variant, to which all Beckhoff Bus

Terminals can be connected, or via CX1100-0003, which in addition to the Bus Terminals enables the connection of

Extension Box IExxxx type Beckhoff Fieldbus Box modules. The option to connect Bus Terminals or a fieldbus Box

creates a control system with a very variable, expandable I/O level with large signal variety. The I/O data are stored

in a DPRAM, which is accessible by the CPU via the system bus. The power supply units of the CX system can be

changed in the field: If, for example, local I/O via Bus Terminals is required, CX1100-0001 can be replaced with

CX1100-0002 in the field. EtherCAT terminals can be connected via the CX1100-0004 power supply unit. The I/O

data are stored directly in the main memory of the CX1100-0004 CPU; a DPRAM is no longer required. The CX1100-

0004 power supply unit for EtherCAT terminals can not

module.

be connected in conjunction with the basic CX1000 CPU

The technical data are provided with the individual power supply unit specifications:

CX1100-0001 (no field bus)

CX1100-0002 (K-Bus)

CX1100-0012 (K-Bus for CX1030 and CX10x0 for alternative installation positions)

CX1100-0003 (K-Bus, IP-Link)

CX1100-0013 (K-Bus, IP-Link for CX1030 and CX10x0 for alternative installation positions)

CX1100-0004 (E-Bus)

CX1100-0014 (E-Bus for CX1030 and CX10x0 for alternative installation positions)

An overview of the power supply architecture and a detailed description of the general system components such as

GCB, ACB, NOVRAM, display and keypad can be found in the documentation for the power supply units.

Embedded-PC 35

Page 38

Product overview

Technical data CX1100-0001

Dimensions:

One of power supply modules can be selected for a CX10x0 system. The power supply of all other system

components is ensured via the internal PC104 bus; no separate supply lines are required. However, the CX1100

components offer further important characteristics that go beyond a pure power supply: an integrated NOVRAM

enables the fail-safe storage of process data, an LCD display with two lines of 16 characters each is used for

displaying system and user messages.

The power supply CX1100-N001 has no I/O interfaces.

Technical data CX1100-0001

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2

!

Dielectric strength 500 V

Max. power consumption 2.5 W

Recommended fuse at 24 V 4 A

connection type 1 x Open Pluggable Connector, 5-pin

NOVRAM 8 kByte

Display FSTN display 2 lines x 16 characters of text, illuminated

I/O-DPRAM -

(supply / internal electronics)

eff

Diagnose LED 1 x PWR

Dimensions (W x H x D) 45 mm x 100 mm x 91 mm

weight app.180 g

operating/storage

temperature

Relative humidity 95% no condensation

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27/29

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

protection class IP 20

0° C ... +55° C / -25° C ... +85° C

36 Embedded-PC

Page 39

Product overview

Technical data CX1100-0002

Dimensions:

Technical data CX1100-0002

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

(supply / internal electronics)

eff

Max. power consumption 3.5 W

Recommended fuse at

4 A

24 V

K-bus connection yes (adapter terminal)

E-bus connection -

IP-Link connection -

K-bus power supply to 1.75 A

connection type Cage-Clamp (adapter terminal)

NOVRAM 8 kByte

Display FSTN display 2 lines x 16 characters of text, illuminated

I/O-DPRAM 2 kByte

Diagnose LED 1 x PWR, 1 x I/O Run, 1 x 1/O Err

Dimensions (W x H x D) 40 mm x 100 mm x 91 mm

weight app.250 g

operating/storage

0° C ... +55° C / -25° C ... +85° C

temperature

Relative humidity 95% no condensation

Vibration/shock

conforms to EN 60068-2-6 / EN 60068-2-27/29

resistance

EMC resistance burst /

conforms to EN 61000-6-2 / EN 61000-6-4

ESD

protection class IP 20

Embedded-PC 37

Page 40

Product overview

Technical data CX1100-0012

Dimensions:

Technical data CX1100-0012

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

Max. power consumption 3.5 W

Recommended fuse at

24 V

K-bus connection yes (adapter terminal)

E-bus connection -

IP-Link connection -

K-bus power supply to 1.75 A

connection type Cage-Clamp (adapter terminal)

NOVRAM 8 kByte

Display FSTN display 2 lines x 16 characters of text, illuminated

I/O-DPRAM 2 kByte

4 A

(supply / internal electronics)

eff

Diagnose LED 1 x PWR, 1 x I/O Run, 1 x 1/O Err

Dimensions (W x H x D) 40 mm x 100 mm x 91 mm

weight app.250 g

operating/storage

temperature

Relative humidity 95% no condensation

Vibration/shock

resistance

EMC resistance burst /

ESD

protection class IP 20

0° C ... +55° C / -25° C ... +85° C

conforms to EN 60068-2-6 / EN 60068-2-27/29

conforms to EN 61000-6-2 / EN 61000-6-4

38 Embedded-PC

Page 41

Product overview

Technical data CX1100-0003

Dimensions:

Technical data CX1100-0003

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

Max. power consumption 4 W

Recommended fuse at 24 V 4 A

K-bus connection yes (adapter terminal)

E-bus connection -

IP-Link connection yes

K-bus power supply to 1.75 A

connection type Cage-Clamp (adapter terminal)

NOVRAM 8 kByte

Display FSTN display 2 lines x 16 characters of text, illuminated

I/O-DPRAM 4 kByte

(supply / internal electronics)

eff

Diagnose LED 1 x PWR, 1 x I/O Run, 1 x 1/O Err

Dimensions (W x H x D) 58 mm x 100 mm x 91 mm

weight app.350 g

operating/storage

temperature

Relative humidity 95% no condensation

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27/29

EMC resistance burst /

ESD

protection class IP 20

0° C ... +55° C / -25° C ... +85° C

conforms to EN 61000-6-2 / EN 61000-6-4

Embedded-PC 39

Page 42

Product overview

Technical data CX1100-0013

Dimensions:

Technical data CX1100-0013

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

Max. power consumption 4 W

Recommended fuse at 24 V 4 A

K-bus connection yes (adapter terminal)

E-bus connection -

IP-Link connection yes

K-bus power supply to 1.75 A

connection type Cage-Clamp (adapter terminal)

NOVRAM 8 kByte

Display FSTN display 2 lines x 16 characters of text, illuminated

I/O-DPRAM 4 kByte

(supply / internal electronics)

eff

Diagnose LED 1 x PWR, 1 x I/O Run, 1 x 1/O Err

Dimensions (W x H x D) 58 mm x 100 mm x 91 mm

weight app.350 g

operating/storage

temperature

Relative humidity 95% no condensation

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27/29

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

protection class IP 20

0° C ... +55° C / -25° C ... +85° C

40 Embedded-PC

Page 43

Product overview

Technical data CX1100-0004

Dimensions:

With the CX1100-0004 power supply EtherCAT Terminals can be connected to the CX1020-System. With CX11000004 the I/O data are stored directly in the main memory of the CPU; a DPRAM is no longer required. The CX11000004 power supply unit for EtherCAT Terminals can only be connected in conjunction with the basic CX1020 CPU

module.

Technical data CX1100-0004

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

Max. power consumption 3.5 W

Recommended fuse at 24 V 4 A

K-bus connection -

E-bus connection yes (adapter terminal)

E-bus power supply to 2 A

connection type Cage-Clamp (adapter terminal)

NOVRAM 8 kByte

Display FSTN display 2 lines x 16 characters of text, illuminated

(supply / internal electronics)

eff

I/O-DPRAM -

Diagnose LED 1 x PWR, 1 x L/A Run, 1 x RUN

Dimensions (W x H x D) 40 mm x 100 mm x 91 mm

weight app.250 g

operating/storage

temperature

Relative humidity 95% no condensation

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27/29

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

protection class IP 20

0° C ... +55° C / -25° C ... +85° C

Embedded-PC 41

Page 44

Product overview

Technical data CX1100-0014

Dimensions:

The CX1100-0014 power supply is designed for CX1030.

With the CX1100-0014 power supply EtherCAT Terminals can be connected to the CX10x0-System. With CX11000004 the I/O data are stored directly in the main memory of the CPU; a DPRAM is no longer required. The CX1100-

0014 power supply unit for EtherCAT Terminals can not

module.

Technical data CX1100-0014

Power supply 24 VDC (-15%/+20%) To meet the UL requirements use a 4 A fuse or a power

supply that has to satisfy NEC class 2!

Dielectric strength 500 V

Max. power consumption 3.5 W

Recommended fuse at 24 V 4 A

E-bus connection yes (adapter terminal)

E-bus power supply to 2 A

connection type Cage-Clamp (adapter terminal)

NOVRAM 8 kByte

Display FSTN display 2 lines x 16 characters of text, illuminated

(supply / internal electronics)

eff

be connected in conjunction with the basic CX1000 CPU

I/O-DPRAM -

Diagnose LED 1 x PWR, 1 x L/A Run, 1 x RUN

Dimensions (W x H x D) 40 mm x 100 mm x 91 mm

weight app.250 g

operating/storage

temperature

Relative humidity 95% no condensation

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27/29

EMC resistance burst / ESD conforms to EN 61000-6-2 / EN 61000-6-4

protection class IP 20

0° C ... +55° C / -25° C ... +85° C

42 Embedded-PC

Page 45

Product overview

CX1100-0001 connections

This power supply unit does not have an I/O interface. The power supply is therefore connected through the 5-pin

open pluggable connector. The power supply unit supplies all further system components with a voltage of 24 V DC (15 %/+20%) via the PC104 bus. The dielectric strength of the power supply unit is 500 V

The integrated NOVRAM permits storage of process data that is safe against power failure.

rms

.

Pin Allocation Open Style Connector:

Pin Assignmnet

1

2

3

4

5

+24 V DC

0 V DC

GROUND

reserved / don't use

reserved / don't use

LED:

With proper connection of the power supply unit and with power supply turned on, the power LED (PWR) lights up

green. In the case of a short-circuit, it lights up red.

Embedded-PC 43

Page 46

Product overview

CX1100-00x2 connections

This power supply unit is equipped with an I/O interface, which permits connection of the Beckhoff Bus Terminals.

The power is supplied via the upper spring-loaded terminals labelled “24V” and “0V”.

The supply voltage feeds the CX system and supplies a voltage of 24 V DC (-15 %/+20%) to the Bus Terminals via

the K-Bus. The dielectric strength of the power supply unit is 500 V

on, a further power supply is necessary for the Bus Terminals. This is provided by means of the power contacts,

which are not connected to the power supply.

The integrated NOVRAM permits storage of process data that is safe against power failure.

. Since the K-Bus does no more than pass data

rms

CX1100-0002 for CX1000, CX1010 und CX1020 CX1100-0012 for CX1030

LED:

With proper connection of the power supply unit and with power supply turned on, the power LED (PWR) lights up

green. In the case of a short-circuit, it lights up red.

The I/O LEDs display the operation status of the Bus Terminals. Error-free start-up of the configuration is signalled by

the red "I/O ERR" LED being extinguished. If the ”I/O ERR" LED blinks, an error in the area of the terminals is

indicated. The error code can be determined from the frequency and number of blinks.

PE power contacts

The ”PE" power contact must not be used for other potentials.

44 Embedded-PC

Page 47

Product overview

CX1100-00x3 connections

This power supply unit permits not only the connection of the Beckhoff Bus Terminals, but also the serial connection

of the Beckhoff fieldbus box modules of the type extension box IExxxx. The power is supplied via the upper springloaded terminals labeled “24V” and “0V”.

The supply voltage feeds the CX system and, over the K-Bus, the Bus Terminals. Since the K-Bus does no more

than pass data on, a further power supply is necessary for the Bus Terminals. This is provided by means of the

power contacts, which are not connected to the power supply.

CX1100-0003 for CX1000, CX1010 und CX1020 CX1100-0013 for CX1030

Fieldbus connection:

Plug the IP link connector into the respective connections, i.e. one fibre-optic cable each into IN (x03) and OUT (x04).

You then connect the other end with the corresponding IP link interface of the extension box. The connection must be

made so that the output of the fieldbus connection is connected to the input of the extension box and vice versa.

LED:

With proper connection of the power supply unit and with power supply turned on, the power LED (PWR) lights up

green. In the case of a short-circuit, it lights up red. The I/O LEDs display the operation status of the Bus Terminals.

Error-free start-up of the configuration is signaled by the red "I/O ERR" LED being extinguished. If the ”I/O ERR" LED

blinks, an error in the area of the terminals is indicated. The error code can be determined from the frequency and

number of blinks.

PE power contacts

The ”PE" power contact must not be used for other potentials.

Embedded-PC 45

Page 48

Product overview

CX1100-00x4 connections

This power supply unit is equipped with an I/O interface, which permits connection of the Beckhoff Bus Terminals.

The power is supplied via the upper spring-loaded terminals labeled “24V” and “0V”.

The supply voltage feeds the CX system and supplies a voltage of 24 V DC (-15 %/+20%) to the Bus Terminals via

the E-Bus. The dielectric strength of the power supply unit is 500 V

on, a further power supply is necessary for the Bus Terminals. This is provided by means of the power contacts,

which are not connected to the power supply.

The integrated NOVRAM permits storage of process data that is safe against power failure.

. Since the E-Bus does no more than pass data

rms

CX1100-0004 for CX1000, CX1010 und CX1020 CX1100-0014for CX1030

LED:

With proper connection of the power supply unit and with power supply turned on, the power LED (PWR) lights up

green. In the case of a short-circuit, it lights up red.

PE power contacts

The ”PE" power contact must not be used for other potentials.

Note

Note

This power supply is designed for use with CX1020 systems only. Operation with CX1000

systems is not possible because the EtherCAT protocol is not implemented / designed in the

hardware of the CX1000 systems.

The power supply CX1100-0004 can only be used instead and not simultaneously with system

interface CX1020-N060

Warning

It is important to keep attention to the hardware revision of the power supply. Power supplies

with a hardware revision > 2.0 only work with CX1020 systems with a hardware revision > 2.1

!

46 Embedded-PC

Page 49

Product overview

LC Display

The LC Display of the power supply units has two rows of 16 characters each and is used for displaying system and

user messages.

"Index-Group/Offset" Specification for the LC Display

ADS Port 300

Index

Group

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0x00005000

+ DeviceID

Index Offset Access

0xFFFF90FF R&W

0xFFFF91FF R&W

0xFFFF92FF R&W

0xFFFF93FF R&W

0xFFFF94FF R&W

0xFFFF95FF R&W

0xFFFF96FF R&W

0xFFFF97FF R&W

Data

type

Phys.

unit

Def.

range

Description Remarks

Cursor OFF

Cursor ON

Cursor blink

OFF

Cursor blink

ON

Display OFF

Display ON

Backlight OFF

Backlight ON

0x00005000

+ DeviceID

0x00005000

+ DeviceID

0xFFFFA0FF R&W

0xFFFF00FF R&W

Write Text line

1

Write Text line

2

Embedded-PC 47

Page 50

Transport

3. Transport

Unpacking, installation and transport

The specified storage conditions must be adhered to (see "Technical data").

Dimensions and weight of the individual modules:

Dimensions (W x H x D): 19 x 100 x 91 mm (system interface) , 96 x 112 x 99 mm (basic module) and 58 x 100 x 91

mm (power supply unit with I/O interface)

Weight: 80 g (system interface) to 550 g (basic module)

Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important information for handling the unit.

5. Check the contents for visible shipping damage.

6. If you notice any shipping damage or inconsistencies between the contents and your order, you should notify

Beckhoff Service.

Warning Danger of damage to the unit!

During transport in cold conditions, or if the unit is subjected to extreme temperature swings,

condensation on and inside the unit must be avoided.

Prior to operation, the unit must be allowed to slowly adjust to room temperature. Should

condensation occur, a delay time of approximately 12 hours must be allowed before the unit is

switched on.

Installation

The devices are designed for installation in control cabinets. You will find installation instructions in the chapter

mechanical mounting.

Shipping and relocation

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts. During

transport, your computer should therefore be protected from excessive mechanical stress. Therefore, please use the

original packaging.

48 Embedded-PC

Page 51

Assembly and connecting

4. Assembly and connecting

Mechanical assembly

Dimensions

The CX1000 product range is characterized by small overall installed size and high modularity. For project planning

purposes, a CPU module, a power supply unit and the associated system interfaces and fieldbus interfaces have to

be provided. The overall width of the application is made up of the individual modules. With a height of 100 mm, the

module dimensions exactly match those of the Beckhoff Bus Terminals. Together with the lowered connector

surfaces, this means that it can be used in a standard terminal box with a height of 120 mm.

Warning

To ensure cooling to the device in operation it is important keep the safety distances. Details see

installation position below.

CX1010 Basic CPU-module:

Embedded-PC 49

Page 52

Assembly and connecting

CX1010-N0x0 System interfaces:

50 Embedded-PC

Page 53

Assembly and connecting

CX1100-000x power supply units:

CX1100-0001

power supply without I/O-interface

CX1100-0002

power supply with I/O-interface (K-Bus-connection)

Embedded-PC 51

Page 54

Assembly and connecting

Abmessungen in mm: 39 x 100 x 91

CX1100-0003

power supply with I/O-interface (K-Bus-connection and IP Link)

Abmessungen in mm: 58 x 100 x 91

CX1100-0004

power supply with I/O-interface (E-Bus-connection)

52 Embedded-PC

Page 55

Assembly and connecting

CX1100-09x0 UPS Modules:

CX1100-0900

CX1100-0910

Embedded-PC 53

Page 56

Assembly and connecting

CX1100-0920

54 Embedded-PC

Page 57

Assembly and connecting

CX1500-Mxxx und CX1500-Bxxx fieldbus connections

All modules for the fieldbus connections (master and slave) have the dimensions (W x H x D) 38 mm x 100 mm x 91

mm.

CX1500-Bxxx

Embedded-PC 55

Page 58

Assembly and connecting

CX1500-Mxxx

56 Embedded-PC

Page 59

Assembly and connecting

Mechanical assembly of the basic module

The installation of the modules takes place in three steps:

1. The sequence of the modules

The basic CPU module with system interfaces, which are factory-installed on the left side, is extended with the power

supply unit on the right and with the fieldbus connection (master or slave) left side if available.

2. Assembly of the CPU and the power supply unit

The individual modules are simply plugged together. The PC104 connector plugs should be handled carefully in order

to avoid damage. When correctly assembled, no significant gap can be seen between the attached housings.

3. Engaging on the top-hat rail

On the bottom of the modules, there is a white tension strap, which is connected with a latching mechanism. These

tension straps must be pulled down before attaching to the top-hat rail. This can be done using an ordinary

screwdriver and a slight turn.

Embedded-PC 57

Page 60

Assembly and connecting

Then fix the CX1010 block on the top hat-rail using the latching straps. You should hear a soft click.

Do not force the module or apply

excessive pressure!

Only apply pressure at insensitive points of the housing (edges). Never apply pressure on the display, the buttons or

movable parts of the CX10x0 system.

After successful latching on the top-hat rail the straps should be pushed back to their original position.

Note:

A locking mechanism prevents the individual housings from being pulled off again. Detailed information relating to

disassembly of the CX1010 configuration from the top-hat rail can be found on page "Removal and disposal".

Installation position:

Correct installation position:

The high-performance CX1010 system generates a significant amount of heat, which is dissipated via a passive

ventilation system. This system requires the unit to be mounted correctly. Ventilation openings are located at the top

and bottom of the housing. The system therefore has to be installed horizontally. This ensures optimum air flow.

58 Embedded-PC

Page 61

Assembly and connecting

Incorrect installation positions:

The CX1010 system must not be operated vertically on the top-hat rail. A vertical position would lead to insufficient

CPU ventilation, since the ventilation openings are located on the top and bottom of the housing. Installation of the

system on its side would also lead to inadequate ventilation.

Embedded-PC 59

Page 62

Assembly and connecting

Mechanical installation of the fieldbus connection

Installation of a fieldbus connection involves several steps:

1. Removing the cover of the basic CX1020 module

In order to be able to connect the fieldbus to the basic CX1020 module, the cover of the basic CX1000/CX1020

module has to be removed first. This is achieved by applying slight pressure on the cover.

2. Assembly and connection to the CX1010 configuration

Since the CX1000 configuration is already positioned on the top-hat rail, the assembly first has to be pushed onto the

top-hat rail. To this end the latching mechanism has to be released by pulling the white straps downwards.

The assembly is connected to the existing CX1000/CX1020 configuration by simply plugging the two units together.

Care must be taken that the plug of the PC104 interface is not damaged.

When correctly assembled, no significant gap can be seen between the attached housings. Finally, the white straps

are returned to their original position, so that the locking mechanism engages.

60 Embedded-PC

Page 63

Assembly and connecting

3. Install cover

If the connection area does not have a closing cover on the left-hand side, the cover that was previously removed

should be pressed over the connections until it audibly engages.

Note:

If the CX1000/CX1020 configuration is not positioned on the top-hat rail, it is possible to connect the assembly with

the CX1000/CX1020 configuration first and then latch the whole module onto the top-hat rail. The installation is

described in section Installation and wiring.

Note:

A locking mechanism prevents the individual housings from being pulled off again.

Embedded-PC 61

Page 64

Assembly and connecting

Inbetriebnahme

Switching the PC on and off

Switching on

The power supply for the basic CPU module comes from the power supply unit. The basic CPU module starts

automatically when the power supply unit is connected to the mains.

Switching on for the first time

When you switch on the PC for the first time, the pre-installed operating system (optional) will be started.

Switching off

The Embedded PC switches off when the power supply unit is switched off. The control software typically running on

Embedded PCs should be shut down or stopped correctly. A user who may not close software may also not switch

the Embedded PC off, since data can be lost from the hard disk by switching off while software is running.

Once the software has been stopped, the operating system can be shut down. Only then should the power supply be

interrupted.

62 Embedded-PC

Page 65

Assembly and connecting

Note on using the setup

Warning

Within the individual setup pages, F6 can be used for loading fail-safe defaults, and F7 for optimised default values

for the individual setup entries. These default values are applied irrespective of whether the board was previously

booted successfully with a particular setup setting. The situation is different if the defaults are called from the TOP

menu. Once a setup setting that subsequently led to successful booting was saved, both menu items will load these

values as defaults for the setup pages. See also "Load Fail-Safe Defaults" and "Load Optimized Defaults".

Beckhoff Automation GmbH supplies the CX1020 systems pre-configured, which means they

are READY FOR USE!

The BIOS settings should only be modified by appropriately trained staff

Under Windows CE the BIOS should not be changed at all, since the operating system is

adapted to the hardware configuration. Any change in the addresses or interrupts would lead to

unstable system behaviour or even crashing.

.

Top menu

Phoenix – AwardBIOS CMOS Setup Utility

► Standard CMOS Features ► PC Health Status

► Advanced BIOS Features Load Fail-Save Defaults

► Advanced Chipset Features Load Optimized Defaults

► Integrated Peripherals Set Passwort

► Power Management Setup Save & Exit Setup

► PnP/PCI Configuration Exit Without Saving

ESC: Quit ↑ ↓

→ ← Select Item

F10: Save & Exit Setup

"Brief description of the function selected above"

A „►“ sign in front of the menu item indicates that a submenu is available. A „x“ sign in front of a menu item indicates

that a setting option is available that first has to be activated via a higher-level setting.

Load Fail-Save Defaults

This option is used for absolute security settings. It is not suitable for continuous operation, but can be useful if the

PC malfunctions.

Load Optimized Defaults

This option is used for setting optimum values as recommended by the manufacturer.

Set Passwort

Here you can enter a setup password for preventing unauthorised invoking of the BIOS.

Save & Exit Setup

This option is used to save the settings and exit setup. Input: Y (Please note: enter Z with German keyboard).

Embedded-PC 63

Page 66

Assembly and connecting

Exit Without Saving

Quit setup without saving the settings. Setting: Y (Please note: enter Z with German keyboard).

64 Embedded-PC

Page 67

Assembly and connecting

Standard CMOS Features

This menu is used for setting the date, time, hard disks, graphics mode and start-up behaviour. At the same time,

information about the memory configuration determined by the system is provided. The memory configuration

information cannot be changed. The setting options for date, time, graphics mode and start-up behaviour are

described below. A new menu opens for setting the hard disk data.

Phoenix – AwardBIOS CMOS Setup Utility

Standard CMOS Features

Date (mm:dd:yy) Mon, Jan 30 2006 Item Help

Time (hh:mm:ss) 11 : 11 : 00

► IDE Primary Master [ None]

► IDE Primary Slave [ None]

Halt On [All, But Keyboard]

Base Memory 640K

Extended Memory 228352K

Total Memory 229376K

↑ ↓ → ← :Move Enter:Select +/-/PU/PD:Value F10:Save ESC:Exit F1:Help

F5: Previous Values F6: Fail-Safe Defaults F7: Optimized Defaults

Date (mm:dd:yy)

Options:

mm … month

dd … day

yy … year

Time (hh:mm:ss)

Options:

hh … hours

mm … minutes

ss … seconds

Halt On

This parameter can be used for stopping the boot process in the event of errors. Errors may be ignored. This menu

item is used to configure the settings.

Options:

All Errors (stop for all types of error)

No Errors (ignore all errors and continue system start-up)

All , But Keyboard (missing keyboard is ignored)

Base Memory

This option is used for displaying the conventional memory (0 KB to 640 KB) in order to indicate whether it was

Embedded-PC 65

Page 68

Assembly and connecting

detected by the POST.

Extended Memory

Available memory from the first MB to the maximum memory capacity.

Total Memory

This is the total of base memory, extended memory and other memory.

66 Embedded-PC

Page 69

Assembly and connecting

IDE Primary Master

This menu is used for setting the data of the first hard disk connected to the IDE bus as master. The hard disk data

(size, number of cylinders, heads, sectors, pre-compensation and home position of the heads when the disk is

switched off) are displayed automatically for the connected hard disk.

Phoenix – AwardBIOS CMOS Setup Utility

IDE Primary Master

IDE HDD Auto-Detection [Press Enter] Item Help

IDE Primary Master [Auto]

Access Mode [Auto]

Capacity 0 MB

Cylinder

Head 0

Precomp 0

Landing Zone 0

Sector 0

↑ ↓ → ← :Move Enter:Select +/-/PU/PD:Value F10:Save ESC:Exit F1:Help

F5: Previous Values F6: Fail-Safe Defaults F7: Optimized Defaults

IDE HDD Auto-Detection:

Automatic detection of the hard disk is initiated by pressing the <Enter> key. After a few seconds the physical data of

the connected hard disk should be displayed in the lower section of the menu.

IDE Primary Master:

This parameter is used for configuring the IDE bus. The following options are available:

None (no hard disk connected to this bus connection)

Auto (auto-detection during each boot process)

Manual (the hard disk is addressed with the set parameters)

Access Mode:

This option can be used to select the operating system for the hard disk. Setting options: CHS, LBA, LARGE, or Auto.

Auto is the recommended setting. Normal (standard) mode supports hard disks with a capacity of up to 528 MB. This

mode uses positions for data access that are specified via cylinders (CYLS), heads, and sectors. The older LBA

(Logical Block Addressing) mode can support hard disks with a capacity of up to 8.4 GB. This mode uses a different

method for calculating the position disk data to be accessed. It translates cylinders, heads and sectors into a logical

address for the data location. Large hard disks support this mode. The BIOS supports the INT 13h extension function

that enables the LBA mode to manage hard disk drives with a capacity of more than 8.4 GB. If the number of

cylinders (CYLs) on the hard disk exceeds 1024 and DOS cannot support it, or if your operating system does not

support LBA mode, LARGE mode should be selected. The following options are available for setting the hard disk

access mode:

CHS

LBA

Embedded-PC 67

Page 70

Assembly and connecting

LARGE

Auto

The following parameters are automatically determined and displayed.

Capacity