Page 1

Propane Restrictor

Conversion Kit

Product Description

The Beckett Propane Restrictor Conversion Kit allows for the conversion of CG10, CG15, CG25, and CG50 burners

for use with propane gas. With the proper installation of the restrictor and attached O-ring, adjustments and settings

for propane use will be the same as the adjustments and settings for natural gas use as detailed in the burner manual.

This conversion kit shall be

WARNING

agency in accordance with the manufacturer’s instructions and all applicable codes

and requirements of the authority having

jurisdiction. (In Canada, in accordance with

the requirements of the CAN/CGA-B149 Installation

Code.) If the information in these instructions is not

followed exactly, a fi re, explosion, or production

of carbon monoxide may result causing property

damage, personal injury or loss of life. The qualifi ed

service agency is responsible for the proper installation of this kit. The installation is not proper and

complete until the operation of the converted appliance is checked, as specifi ed in the manufacturer’s

instructions supplied with the kit.

Please carefully read and comply with the instruction

manual supplied with the specifi c burner being convert-

ed.

installed by a qualifi ed service

Figure 1 - Components

Installation

Note that Steps 1 and 2 on the reverse side refer to fully

assembled burners. Skip to Step 3 when converting a

burner without the air tube assembly installed. Refer to

Figures 1 and 2 when performing the following steps.

NOTICE

similar with the exception of having the gas gun assembly mounted into the air tube instead of the housing.

Figure 2 - Assembly Location

CG15 is shown in the illustrations.

CG25 and CG50 are similar. CG10 is

Major Component Key for All

Illustrations

A Air Tube

B Jacking Screw

C Internal Gas Tube

D Burner Housing

Major Component Key for All

Illustrations

E External Gas Manifold

F Propane Restrictor

G Restrictor O-ring

H Gas Tube O-ring

1

Page 2

NOTICE

Use authorized replacement parts

only. Restrictors are precision-ma-

chined parts and O-rings are rated for fuel contact. Do

not attempt to replicate or modify any parts. Refer to

Table 1.

NOTICE

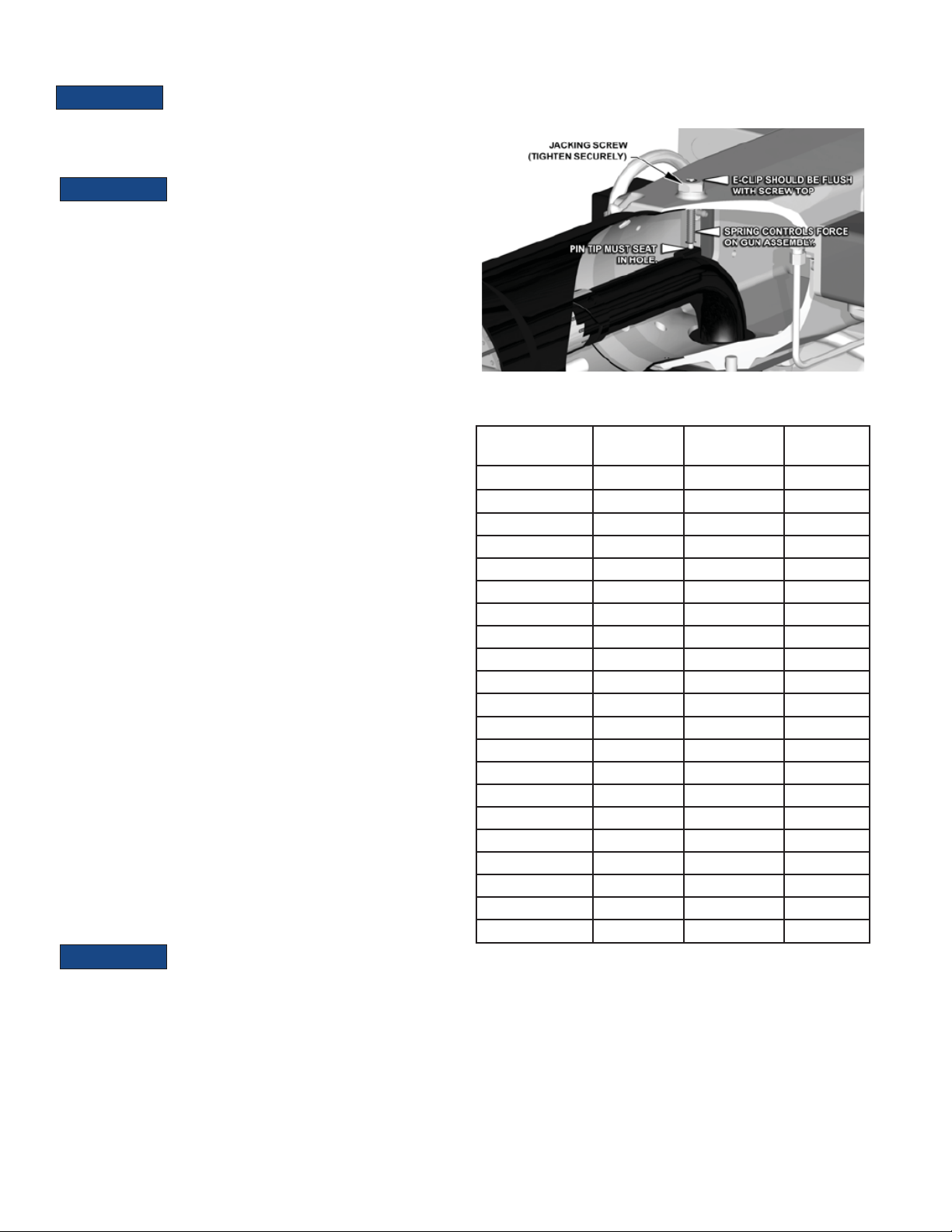

The gun assembly is secured inside

the air tube by a spring-loaded jacking

screw. It is spring loaded in order to control the force it

can impose on the gun assembly. When installing the

jacking screw look inside the air tube to verify that the

pointed tip of the jacking screw pin is seated into the

small slot on the locating pad on top of the gun. There is

also an external verifi cation of correct assembly: when

the screw is fully tightened, the e-clip on the top of the

center pin should come fl ush with the top of the screw.

Refer to Figure 3.

Figure 3 - Gas Gun Installation

1. Remove the jacking screw (B) from the housing to

free the internal gas tube (C).

2. Gently rock the internal gas tube (C) to loosen the

tube from the burner housing (D).

3. Inspect the O-rings and insure that they are properly lubricated. (A silicon O-ring lubricant is recommended, but automotive chassis or bearing grease

is an acceptable substitute.)

4. Referring to Figure 2, place the restrictor (F) with

pre-attached, pre-lubricated O-ring (G) into the

internal gas tube (C). Use your hand to press the

restrictor into the tube. The O-ring will hold the

restrictor in place.

5. Insure that the O-ring (H), attached to the outside

diameter of internal gas tube, is properly lubricated

and seated against the fl ange on the internal gas

tube.

6. Install the internal gas tube (C) back into the housing, refer to Figure 1. Fit the end of the tube into

the external gas manifold (E).

7. Re-install the jacking screw (B). (Refer to the

above notice for installation details.)

8. Fill out and place the supplied Conversion Data

Plate adjacent to the rating plate.

9. Complete and attach the supplied Adjustment Data

NOTICE

With the gas restrictor installed, as

shown in Figures 1 & 2, all burner air

adjustments and gas manifold pressure adjustments for

propane will be approximately the same as the natural

gas adjustments shown in the burner manual, or printed

on the “Mfr’s Settings” label on the burner housing. For

a copy of the current burner manual go to http://www.

beckettcorp.com/protect/tech.asp. If furtherTechnical

assistance is required, call 800-645-2876, Monday thru

Friday, 8AM to 5PM EST.

Table 1 - Replacement Part Numbers

Burner Model Restrictor

Part Number

CG10.1 3246700U 0.401 3226409U

CG10.2 3246701U 0.432 3226409U

CG10.3, CG10.2S 3246702U 0.470 3226409U

CG10.1S 3246703U 0.418 3226409U

CG10.3S, CG10.6S 3246705U 0.510 3226409U

CG10.4S 3246706U 0.459 3226409U

CG10.5S 3246707U 0.482 3226409U

CG15.1S 3246709U 0.532 3226401U

CG15.2S 3246710U 0.576 3226401U

CG15.3S 3246711U 0.623 3226401U

CG15.4S 3246712U 0.677 3226401U

CG25.1S 3246713U 0.712 3226402U

CG25.2S 3246714U 0.742 3226402U

CG25.3S 3246715U 0.796 3226402U

CG25.4S 3246716U 0.833 3226402U

CG25.5S 3246717U 0.889 3226402U

CG50.1S 3246718U 0.925 3226403U

CG50.2S 3246719U 0.980 3226403U

CG50.3S 3246720U 1.031 3226403U

CG50.4S 3246721U 1.103 3226403U

CG50.5S 3246722U 1.150 3226403U

Restrictor

Inside Diameter

O-Ring Part

Number

2

Printed in USA

Canada: R.W. Beckett Canada, Ltd. ● Unit #3, 430 Laird Road ● Guelph, Ontario N1G 3X7

: R.W. Beckett Corporation, P.O. Box 1289 ● Elyria, OH 44036

Form No. 61708 R01, 08/08

Loading...

Loading...