Page 1

INSTRUCTION MANUA L

FOR

RDP-110

Remote Display Panel

Publication: 9318100990

Revision: H 12/14

Page 2

Page 3

9318100990 Rev H i

Caution

Note

Preface

This instruction manual provides information about the installation and operation of the RDP-110 Remote

Display Panel. To accomplish this, the following information is provided:

• Product specifications

• Functional description

• Mounting and wiring

• Testing

Conventions Used in this Ma nua l

Important safety and procedural information is emphasized and presented in this manual through

warning, caution, and note boxes. Each type is illustrated and defined as follows.

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note boxes emphasize important information pertaining to Remote

Display Panel installation or operation.

Remote Display Panel Preface

Page 4

ii 9318100990 Rev H

Basler Electric does not assume any responsibility for compliance or noncompliance with national code, local

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

This publication contains confi dent i al inform at ion of Basler Electric Company, an Illinois corporation. It is loaned for

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

manual.

The English-language version of this manual serves as the only approved manual version.

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2014 by Basler Electric

All rights reserved

First printing: June 1998

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the RDP-110.

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Failure to follow warning and cautionary labels may result in personal injury

or property damage. Exercise caution at all times.

To prevent personal injury or equipment damage, only qualified personnel should install, operate, or

service this system.

code, or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

confidential use, subject to return on request, and with the mutual understanding that it will not be used in any

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide

data for every possible contingency regarding installation or operation. The availability and design of all features

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

Preface Remote Display Panel

Page 5

9318100990 Rev H iii

Manual

Revision and Date

Change

–, 06/1998

• Initial release

A, 10/1998

• Replaced part numbers for surface mount and semi-flush panels with

• Added manual revision information

B, 07/1999

• Added style chart and related information

• Clarified the display functions for the Airbox Closed alarm

C, 01/2000

• Added DGC-1000 front panel illustration to existing DGC-2000 front

• Updated connections diagram to reflect DGC-1000 terminals

D, 04/2002

• Added UL and CSA agency compliance information

• Updated illustrations to show UL and CSA agency logos

E, 06/2007

• Updated style chart to show DGC-2020 compatibility

• Updated style of manual

F, 08/2012

• Added horn specifications

Updated the style of the manual

G, 02/2014

• Corrected RS-485 connection errors in all applicable illustrations

H, 12/2014

• Added coverage of DGC-2020ES, DGC-202 0HD , and UL listed

9318100120

Revision History

The following information provides a historical summary of the changes made to the Remote Display

Panel instruction manual (part number 9318100990 Rev H). Revisions are listed in chronological order.

style number designations

• Added recommended maximum length for RS-485 wiring

• Updated controls and indicators information to reflect style chart

changes for styles RDP-110 X1 and RDP-110 X2

panel illustration

• Added description of programmable pre-alarm and alarm functions

• Added procedure for relabeling programmable pre-alarms and

alarms

• Added note stating that “240” terminal is not functional

• Added illustration showing the location of the RS-485 terminating

resistor

• Added terminal numbers for the DGC-500, DGC-1000, and DGC-

2020 to the typical connections illustration

• Added numbered illustration showing annunciation sequence of test

mode

• Removed all references to the DGC-2000

•

RDP-110 Remote Display Panels, part numbers 9318100119 and

Remote Display Panel Revision History

Page 6

iv 9318100990 Rev H

Revision History Remote Display Panel

Page 7

9318100990 Rev H v

Contents

Contents ........................................................................................................................................................ v

General Information ...................................................................................................................................... 1

Features..................................................................................................................................................... 1

Comprehensive Annunciation Capabilities ............................................................................................ 1

Rugged and Flexible Construction ......................................................................................................... 1

Simple Connections ............................................................................................................................... 1

Style Number ............................................................................................................................................. 1

UL Certification .......................................................................................................................................... 2

Specifications ............................................................................................................................................ 2

Control Power ........................................................................................................................................ 2

Communication ...................................................................................................................................... 2

Audible Alarm ......................................................................................................................................... 2

Temperature .......................................................................................................................................... 2

Weight .................................................................................................................................................... 2

Type Test Data ...................................................................................................................................... 2

Agency Certification ............................................................................................................................... 3

Controls and Indicators ................................................................................................................................. 5

Programmable Alarm and Pre-Alarm Indicator Configuration ................................................................... 6

Functional Description ................................................................................................................................... 9

Inputs ......................................................................................................................................................... 9

Control Power ........................................................................................................................................ 9

Communication Interface ....................................................................................................................... 9

Pushbuttons ........................................................................................................................................... 9

Microprocessor ........................................................................................................................................ 10

Firmware .................................................................................................................................................. 10

Installation ................................................................................................................................................... 11

Mounting .................................................................................................................................................. 11

Connections ............................................................................................................................................. 11

Connector Wiring ................................................................................................................................. 12

RS-485 Communication Connections .................................................................................................. 12

Typical Connections ............................................................................................................................. 13

Testing ......................................................................................................................................................... 15

Test Equipment and Setup ...................................................................................................................... 15

Test Procedure ........................................................................................................................................ 15

Remote Display Panel Contents

Page 8

vi 9318100990 Rev H

Contents Remote Display Panel

Page 9

9318100990 Rev H 1

General Information

The RDP-110 Remote Display Panel provides remote annunciation of engine/generator status. When

used with Basler Electric Digital Genset Controllers DGC-2020, DGC-2020ES, DGC-2020HD, DGC-500,

or DGC-1000, the RDP-110 provides compliance with NFPA 110 Level 1 and Level 2 requirements. The

RDP-110 is suitable for use with isolated generators or paralleled generating systems.

Features

Features of the microprocessor-based RDP-1 10 ar e summ ariz ed bel ow.

Comprehensive Annunciation Capabilities

The RDP-110 is equipped with the following LED (light emitting diode) indicator functions:

• RDP-110 control power applied

• Genset supplying load

• DGC not operating in Auto mode

• Six fixed-function alarms

• Two programmable alarms

• Five fixed-func t ion pre-alarms

• Two programmable pre-alarms

An audible alarm annunciates the presence of alarms, pre-alarms, and when the DGC is taken out of

Auto mode. An Alarm Silence pushbutton resets the audible alarm.

Operation of the audible alarm and all visual indicators can be verified with the Lamp Test pushbutton.

Rugged and Flexible Construction

A rugged metal case provides improved electromagnetic compatibility and makes the RDP-110 resistant

to moisture, salt fog, dust, dirt, and chemical contaminants. Two available mounting configurations

provide the option of semi-flush mounting or surface (projection) mounting. Conduit knockouts on the

case enable the RDP-110 to be used as a “pass-through” or junction box for other site wiring.

Simple Connections

RDP-110 connections consist of control power wiring and wiring for communication between the DGC

and RDP-110. Two-wir e, R S -485 communication between the RDP-110 and DGC simplifies wiring and

ensures noise immunity over long distances.

Style Number

A style number defines the RDP-110

mounting configuration and Digital

Genset Controller compatibility. The

style number appears on a label located

on the right side of the case. Figure 1

illustrates the RDP-110 style chart.

Figure 1. RDP-110 Style Chart

RDP-110 11BGeneral Information

Page 10

2 9318100990 Rev H

UL Certification

RDP-110 Style

RDP-110 Part Number

Recognized

F1

9318100115

Listed

F1

9318100119

Recognized

S1

9318100114

Listed

S1

9318100120

UL Certification

An RDP-110 may be certified as “UL recognized” or “UL listed”. These certifications are specified by part

number as shown in Table 1.

Table 1. RDP-110 UL Certification Part Numbers

Specifications

RDP-110 electrical and physical characteristics are listed in the following paragraphs.

Control Power

DC Input

Range: 8 to 32 Vdc

Burden: 2 W maximum

AC Input

Range: 84 to 144 Vac

Burden: 5 VA maximum

Communication

The RDP-110 communicates through a serial, RS-485 port terminated with a 100 Ω resistor.

Audible Alarm

Frequency: 2,900 Hz, ±500 Hz

Sound Level: 90 dB(A) at 24 in (61 cm)

Temperature

Operating Temperature Range: –40 to 70°C (–40 to 158°F)

Storage Temperature Range: –40 to 85°C (–40 to 185°F)

Weight

3 kg (6.6 lb)

Type Test Data

Dielectric Strength

Withstood 1,800 Vdc for 1 minute between chassis ground and ac control power input. Withstood 700 Vdc

for 1 minute between any combination of the following circuit groups:

• Chassis ground

• DC control power input and RS-485 terminals

• AC control power input

Radio Frequency Interference

Tested using a 5 W, handheld transceiver operating at random frequencies centered around 144 MHz

and 440 MHz with the antenna located within 6 inches (15 centimeters) of the device in both the vertical

and horizontal planes.

11BGeneral Information RDP-110

Page 11

9318100990 Rev H 3

Vibration

Withstood 2 G in each of three mutually perpendicular planes, swept over the range of 10 to 500 Hz for a

total of six sweeps, 15 minutes each sweep. No structural damage or degradation of performance was

observed.

Shock

Withstood 15 G in all planes.

Agency Certification

Underwriters Laboratories

P/N 9318100114, 9318100115: UL recognized per Standard 508, UL file number

E97035

P/N 9318100119, 9318100120: UL listed per Standard 508, UL file number E97035

Canadian Standards Association

Certified per Standard CAN/CS A-C22.2 Number 14-95, CSA file number LR23-23131

RDP-110 11BGeneral Information

Page 12

4 9318100990 Rev H

11BGeneral Information RDP-110

Page 13

9318100990 Rev H 5

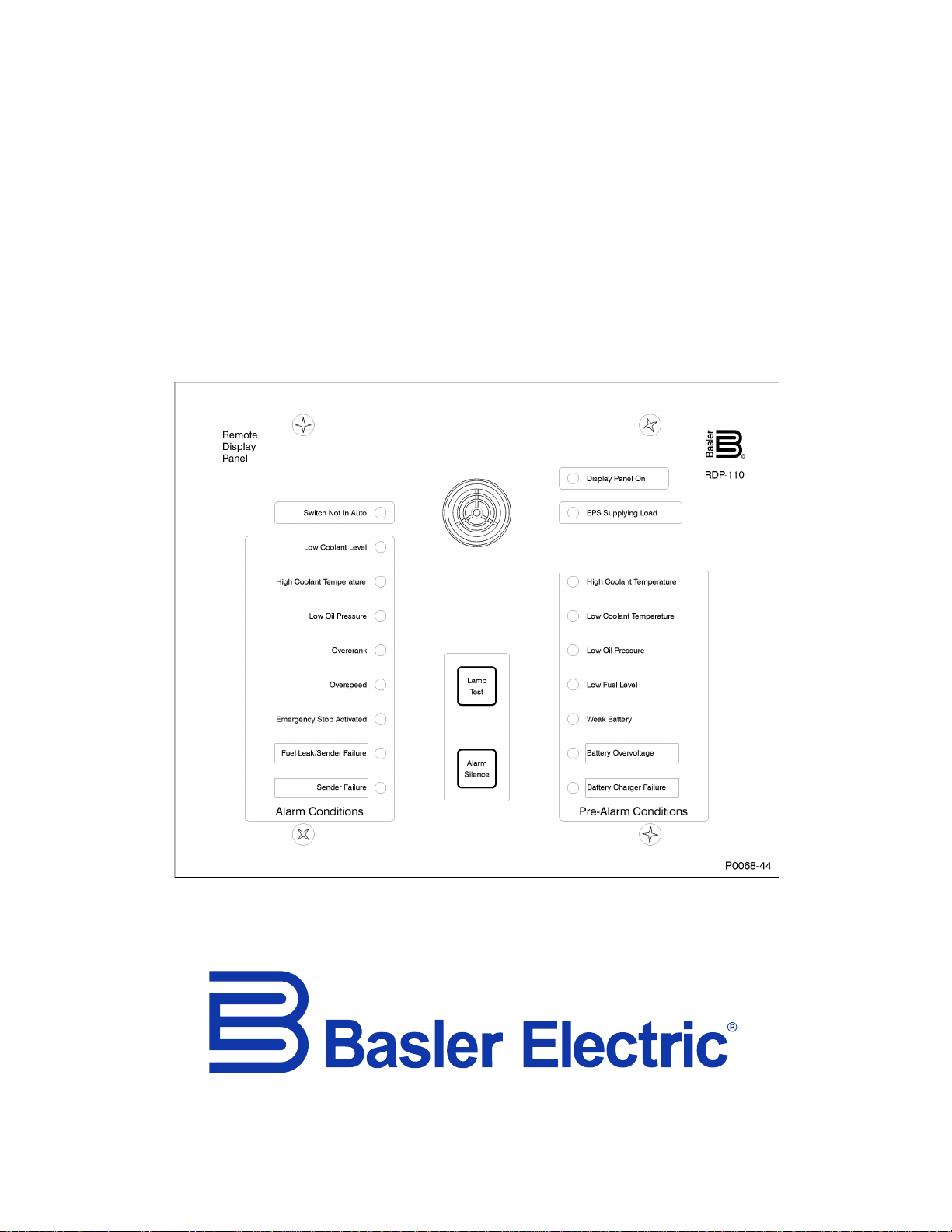

Locator

Description

A

Green Display Panel On LED lights when control power is applied to the RDP-110.

B

Green EPS Supplying Load LED lights when the genset is supplying more than 2% of

rated load.

C

The horn sounds when an alarm or pre-alarm exists or the connected DGC is not operating

in Auto mode. The horn is silenced by pressing the Alarm Silence pushbutton (locator E).

D

The amber Pre-Alarm LEDs light when the corresponding pre-alarm setting is exceeded.

information about configuring the two programmable pre-alarm indicator s .

E

RDP-110 controls consist of two pushbuttons. The Alarm Silence pushbutton silences the

LEDs and the horn.

Controls and Indicators

RDP-110 controls and indicators consist of pushbuttons, LED lamps, and an audible alarm (horn). These

front panel elements are illustrated in Figure 2. Lettered locators in Figure 2 correspond to the lettered

descriptions of Table 2.

Figure 2. Controls and Indicators

Table 2. Control and Indicator Descriptions

Conditions annunciated by the pre-alarm LEDs include high coolant temperature, low

coolant temperature, low oil pressure, low fuel level, weak battery, battery overvoltage, and

battery charger failure. When the RDP-110 is used with a DGC-2020, the bottom two LEDs

(Battery Overvoltage and Battery Charger Failure) can be reprogrammed to indicate other

pre-alarm conditions. See Programmable Alarm and Pre-Alarm Configuration for

RDP-110 1BControls and Indicators

horn (locator C). The Lamp Test pushbutton can be used to verify operation of all RDP-110

Page 14

6 9318100990 Rev H

Locator

Description

F

The red Alarm LEDs light when the corresponding alarm setting is exceeded. Conditions

Configuration for information about configuring the two programmable alarm indicators.

G

Red Switch Not In Auto LED lights when the DGC is not operating in Auto mode.

annunciated by the alarm LEDs include low coolant level, high coolant temperature, low oil

pressure, overcrank, overspeed, emergency stop activated, fuel leak/sender failure, and

sender failure. When the RDP-110 is used with a DGC-2020, DGC-202 0E S, or

DGC-2020HD, the bottom two LEDs (Fuel Leak/Sender Failure and Sender Failure) can be

reprogrammed to indicate other alarm conditions. See Programma ble Alarm and Pr e-Alarm

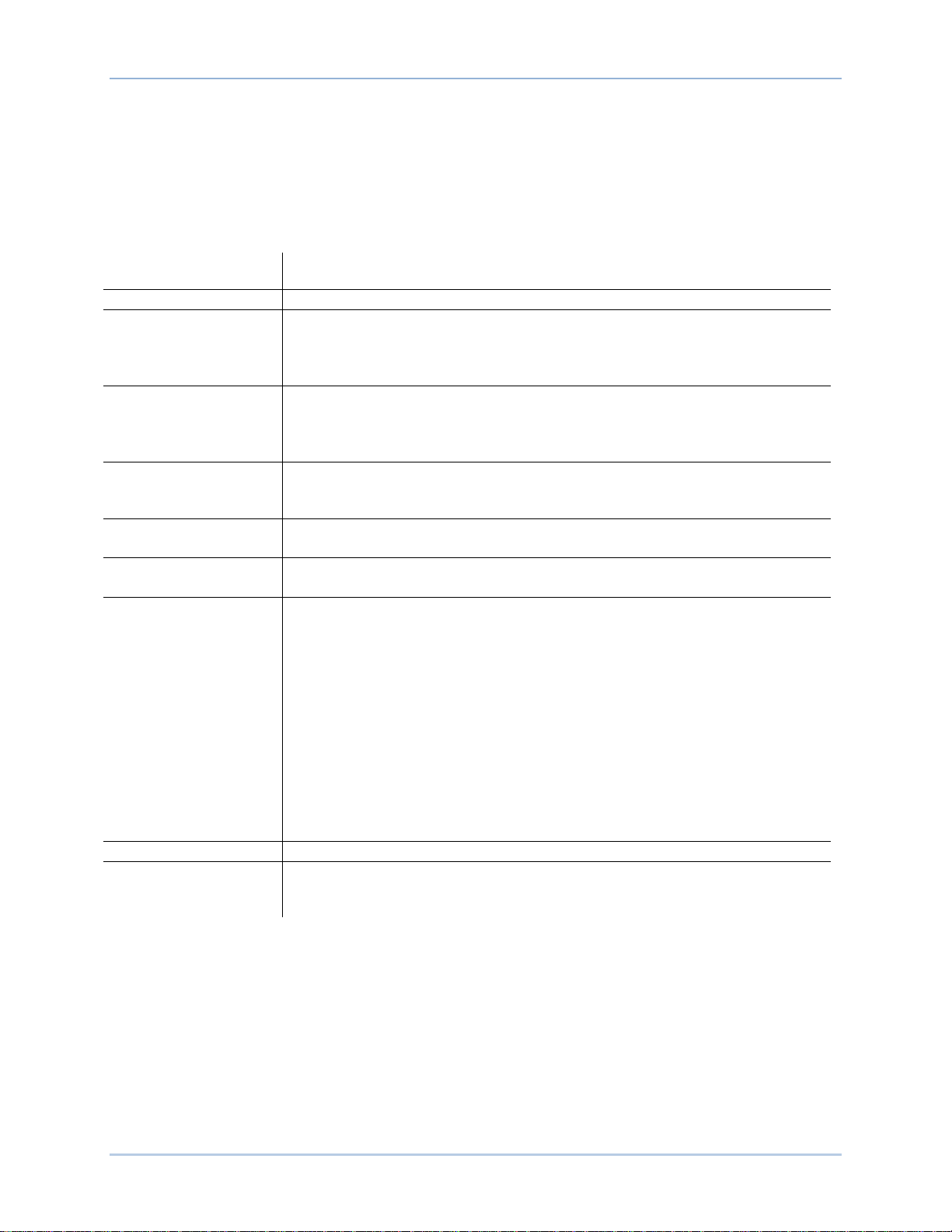

Programmable Alarm and Pre-Alarm Indicator Configuration

When used with a DGC-2020, DGC-2020ES, or DGC-2020HD, the RDP-110 has the added capability of

programmable alarm and pre-alarm indicators. This ability applies only to the DGC-2020, DGC-2020ES,

or DGC-2020HD and is not available when the RDP-110 is paired with the DGC-500 or DGC-1000.

Up to two alarm LEDs and two pre-alarm LEDs may be reprogrammed to suit the needs of a particular

application. The two bottommos t alarm LEDs ar e pre-configured in DGC logic to annunciate a fuel

leak/sender failure and sender failure. The two bottommost pre-alarm LEDs are pre-configured in DGC

logic to annunciate battery overvoltage and a battery charger failure. These LEDs are labeled as such

with replaceable cards (Figure 3) that can be relabeled to match the function of each programmable

indicator.

Figure 3. Programmable Alarm and Pre-Alarm Label Cards

Information about configuring DGC logic to provide other alarm and pre-alarm annunciations is available

in the appropriate DGC instruction manual. To re-label the RDP-110 programmable alarm and pre-alarm

LEDs, perform the following steps.

1. Print the label text on readily-available addr es s label sheets. The label cards accommodate

adhesive-backed labels measuring 0.5 by 1.75 inches. Avery part number 18167 is suitable for

this purpose.

2. Remove all control power from the RDP-110.

3. Remove the four Phillips screws from the front panel and separate the front panel from the

conduit box. Disconnect the two connectors attached to the circuit board mounted to the front

panel. When handling the front panel, avoid touching the circuit board.

4. Lay the front panel face-down on a suitable work surface.

5. Grasp the tab of the label card to be changed and pull free. The two label cards are located near

the two lower corners of the circuit board. When facing the back of the panel, the pre-alarm label

card is on the left and the alarm label card is on the right.

6. Apply the labels created in step 1 to the label cards. The rectangle outlines on each label card

1BControls and Indicators RDP-110

serve as guides for attaching the labels.

Page 15

9318100990 Rev H 7

7. After applying the new labels, insert each label card into the appropriate panel slot. Ensure that

each label card is oriented properly by viewing the custom labels through the label windows of the

front panel.

8. Move the panel assembly adjacent to the conduit box and reconnect the cables to the two circuit

board connectors.

9. Secure the front panel to the conduit box with the four Phillips screws removed in step 3.

Maximum torque for these screws is 17 inch-pounds or 2 newton meters.

10. If desired, verify the function of the reprogrammed indicators before returning the RDP-110 to

service.

RDP-110 1BControls and Indicators

Page 16

8 9318100990 Rev H

1BControls and Indicators RDP-110

Page 17

9318100990 Rev H 9

Microprocessor

Power

Supply

RS-485

Interface

Lamp

Test

Alarm

Silence

LED Indicators Audible Alarm

12/24 Vdc

100/120 Vac

From DGC

D2829-19

Functional Description

The RDP-110 uses microprocessor-based technology to provide remote annunciation of engine and

generator parameters. RDP-110 function blocks are illustrated in Figure 4 and described in the following

paragraphs.

Figure 4. RDP-110 Function Blocks

Inputs

RDP-110 inputs consist of control power inputs, a communication interface, and pushbuttons. Control

power and communication connections are made on the circuit board attached to the front panel.

Control Power

Redundant, isolated control power inputs enable continued RDP-110 operation if one power input is lost.

The dc control power input accepts nominal battery voltage of 12 Vdc or 24 Vdc. The acceptable range of

dc control power is 8 to 32 Vdc.

The ac control power input is rated for a nominal voltage of 100 Vac or 120 Vac at 50 Hz or 60 Hz. The

acceptable range of ac control power is 80 to144 Vac.

Each control power input is applied to an internal switching power supply that provides filtered 5 Vdc

operating power for the RDP-110 circuitry.

Communication Interface

RDP-110 annunciation commands are received from the DGC over an RS-485 serial communication bus.

Received communication inputs are converted to signals suitable for use by the RDP-110

microprocessor.

Pushbuttons

Two front-panel pushbuttons accept local inputs: Lamp Test and Alarm Silence.

LED and horn operation can be verified by pressing the Lamp Test pushbutton.

An audible alarm is reset by pressing the Alarm Silence pushbutton. Once reset, the horn is reactivated

only the occurrence of another, separate pre-alarm or alarm condition.

RDP-110 4BFunctional Description

Page 18

10 9318100990 Rev H

Microprocessor

The microprocessor executes embedded firmware which interprets commands received from the DGC

and annunciates pre-alarm and alarm conditions by lighting the appropriate indicators and sounding the

horn.

Firmware

Embedded firmware controls power-up initialization, annunciation element setup, and serial

communication. When control power is applied to the RDP-110, the firmware initiates a power-up

sequence, checks the onboard memory, activates all annunciation functions, and begins monitoring for

inputs from the DGC.

4BFunctional Description RDP-110

Page 19

9318100990 Rev H 11

Note

Installation

A NEMA 1 enclosure makes the RDP-110 resistant to moisture and dust infiltration. Its metal construction

improves immunity to electromagnetic interference. Conduit knockouts on the case enable the RDP-110

to be used as a “pass-through” or junction box for other site wiring. Two available mounting configurations

provide the option of semi-flush mounting or surface (projection) mounting.

If the RDP-110 will not be installed immediately, store it in the original shipping package in a moistureand dust-free environment.

Mounting

RDP-110 mounting dimensions are illustrated in Figure 5.

Figure 5. RDP-110 Mounting Dimensions

Connections

Display panel connections are made with two plug-in connectors that mate with headers on the lower

edge of the RDP-110 circuit board. Keyed connectors prevent improper connections. These circuit board

connections, illustrated in Figure 6, are accessed by removing the front panel from the conduit box.

Ensure that the RDP-110 is hard-wired to earth ground with no smaller

than 16 AWG (1.5 mm

CHASSIS terminal. An additional ground connection is provided on the

conduit box.

DC control power applied to the 12/24 (+) and DC COM (–) terminals

must be of the correct polarity. Incorrect dc control power polarity will

prevent the RDP-110 from functioning.

RDP-110 4BInstallation

2

) copper wire attached to the circuit board

Page 20

12 9318100990 Rev H

Note

The 240 terminal is not functional and cannot be used. For ac control

power connections, only the 120 and AC COM terminals should be

used for application of 100/120 Vac nominal voltage.

Figure 6. RDP-110 Circuit Board Connections

Connector Wiring

Note the following guidelines when wiring the two circuit board connections:

• The ground terminal connection should be made with wire no smaller than 16 AWG (1.5 mm

• Other than the ground terminal, connections should be made with wire no smaller than 20 AWG

(0.5 mm

• Maximum conductor size for each terminal is 12 AWG (4 mm

2

)

2

)

2

)

• Strip the insulation from each wire to reveal 0.28 inches (7 millimeters) of exposed conductor

• Apply no more than 4.4 in-lb (0.5 N●m) of torque to each terminal screw

RS-485 Communication Connections

Twisted-pair conductors are recommended for the communication wiring between the DGC and

RDP-110.

Overly long wiring runs may impair com mun ic at ion bet ween the DGC and RDP-110 unreliable. Do not

exceed an RS-485 conductor length of 4,000 feet (1,219 meters).

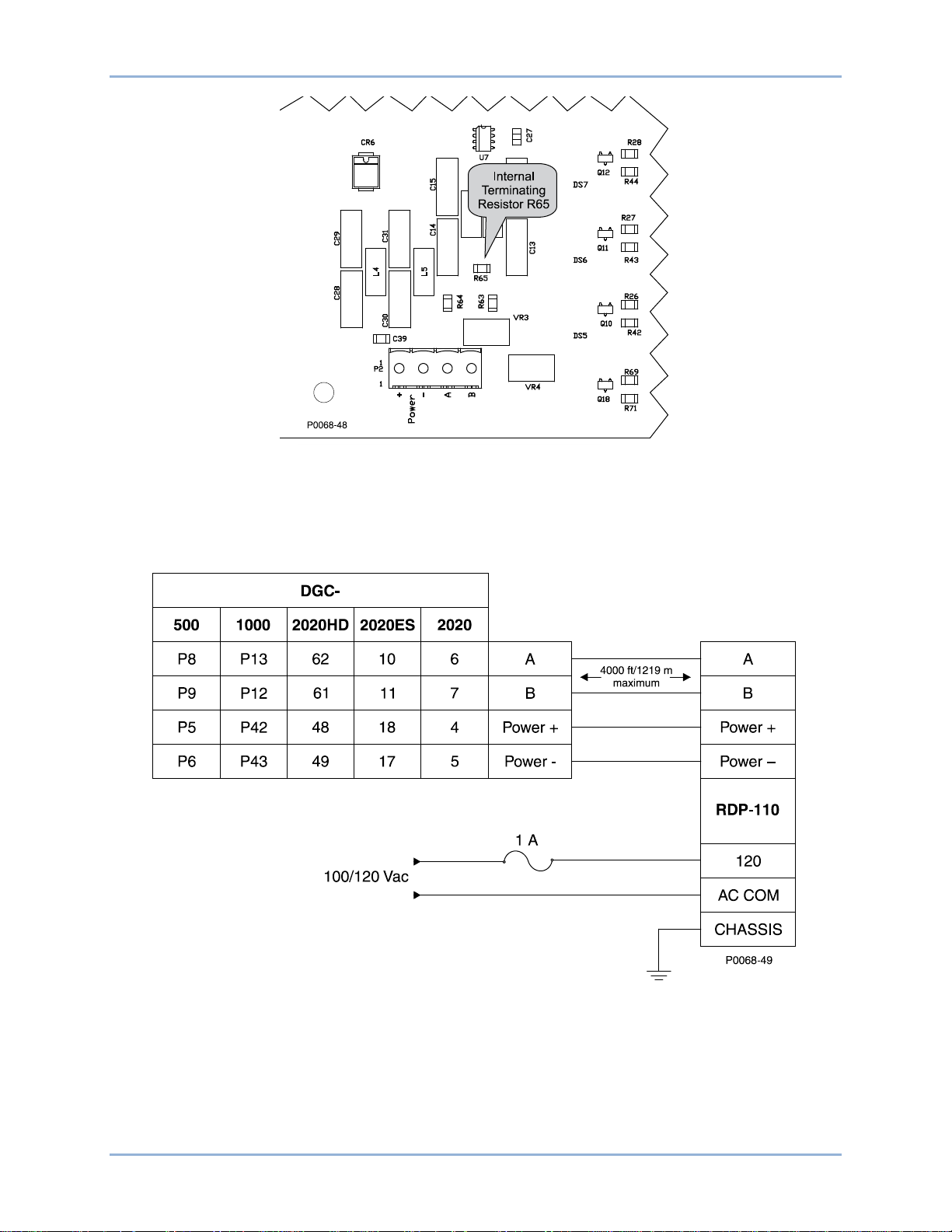

RS-485 Terminating Resistor

The RS-485 communication connection is internally terminated with a 100 Ω resistor. Connecting multiple

display panels may necessitate removal of this terminating resistor (R65). R65 is located in the lower, left

quadrant of the circuit board. The location of R65 is illustrated in Figure 7.

Consult standard TIA/EIA-485 for guidance on the electrical requirements of multipoint communication

systems.

4BInstallation RDP-110

Page 21

9318100990 Rev H 13

Figure 7. RS-485 Terminating Resistor Locati o n

Typical Connections

Typical RDP-110 connections are shown in Figure 8.

Figure 8. Typical RDP-110 Connections

RDP-110 4BInstallation

Page 22

14 9318100990 Rev H

4BInstallation RDP-110

Page 23

9318100990 Rev H 15

Testing

A built-in test mode enables field testing of RDP-110 operation.

Test Equipment and Setup

Equipment needed for testing RDP-110 operation is listed below. Connections for the test are illustrated

in Figure 9.

• Power supply, 24 Vdc

• Power source, 100/120 Vac, 50/60 Hz

• Fuse, 1 ampere (2)

• Signal generator, 10 Hz, square wave, 5 volts peak-to-peak

Figure 9. RDP-110 Test Setup

Test Procedure

1. Connect the RDP-110 tes t setup as sh own in Figure 9.

2. Apply 24 Vdc control power. The Display Panel On LED should light.

3. Press and hold the Lamp Test pushbutton. All LEDs should light and the horn should sound.

4. Release the Lamp Test pushbutton to reset the indicators and horn.

5. Apply the 10 Hz signal.

6. Press and release the Lamp Test pushbutton. Observe that the LEDs and horn annunciate in the

eighteen-step sequence indicated in Figure 10. This sequence will repeat until the Alarm Silence

pushbutton is operated.

7. Press and release the Alarm Silence to end the annunciation sequence.

8. Remove the 10 Hz signal and 24 Vdc control power.

9. Repeat the test with 100/120 Vac control power applied instead of 24 Vdc control power.

RDP-110 1BTesting

Page 24

16 9318100990 Rev H

Figure 10. Test Mode Annunciation Sequence

1BTesting RDP-110

Page 25

Page 26

12570 State R oute 143

Highland IL 62249-1074 USA

Tel: +1 618.654.23 4 1

Fax: +1 618.654.2351

email: info@basler.com

P.A.E. Les Pins

67319 Wasselonne Cedex

FRANCE

Tel: +33 3.88.87.1010

Fax: +33 3.88. 87.0808

email: franceinfo@basler.com

No. 59 Heshun Road Loufeng District (N)

Suzhou Indus trial Park

215122 Suzhou

P.R. CHINA

Tel: +86 512.8227.2888

Fax: +86 512.8227.2887

email: chinainfo@basler.com

111 North Bridge Road

15-06 Peninsul a Plaz a

Singapore 1 79098

Tel: +65 68.4 4.6445

Fax: +65 68.44.8902

email: singaporeinfo@basler.com

Loading...

Loading...