Page 1

INSTRUCTION MANUAL

FOR

ELECTRONIC MANUAL VOLTAGE CONTROL

Model: MVC 301

Part Number: 9 1210 00 107

Publication Number: 9 1210 00 994

Revision B: 12/99

Page 2

WARNING

To prevent personal injury or equipment damage, only qualified technicians/operators should install, operate, or service

this device.

CAUTION

Meggers and high potential test equipment should be used

with extreme care. Incorrect use of such equipment could

damage components contained in the device.

CONFIDENTIAL INFORMATION

of Basler Electric Company, Highland, IL. It is loaned for

confidential use. Subject to return on request and with the

mutual understanding that it will not be used in any manner

detrimental to the interests of Basler Electric Company.

It is not the intention of this manual to cover all details and

variations in equipment, nor does it provide data for every

possible contingency regarding installation or operation.

The availability and design of all features and options are

subject to change without notice. Should further information

be required, call Basler Electric Company, Highland, IL.

Page 3

SECTION 1

GENERAL INFORMATION

1-1. PURPOSE

The Electronic Manual Voltage Control (MVC-301) is used as a back-up control device to provide

manual voltage control in case of voltage regulator failure. The un i t can be mounted on a control

panel in ground vehicles, stationary equipment or shipboard locations.

1-2. OVERALL DESCRIPTION

The MVC-301 is a solid-state device enclosed in a metallic dark grey chassis and designed to be

'through-the-panel' mounted with the control accessible to an operator from the front of the panel.

A terminal strip located on the rear of the device facilitates installation and operation. An

AUTO-OFF-MANUAL

1-3. SPECIFICATIONS

Table 1-1 provides the electrical and physical specifications of the MVC 301.

voltage control mode switch is provided on the front panel.

Table 1-1. Specifications.

Input Power:

Output Adjustment

Range:

120 Vac Input:

240 Vac Input:

Watts Dissipated:

Minimum Residual

Voltage for Buildup:

Ambient Operating

Temperature:

Ambient Storage

Temperature:

Shock

Vibration:

Weight:

120 Vac, Single-Phase.

240 Vac, Single-Phase.

1 to 32 Vdc or 1 to 63 Vdc.

1 to 63 Vdc or 1 to 125 Vdc.

30 W maximum.

6 Vac.

-40 F (-40 C) to +158 F (+70 C)

-85 F (-65 C) to +212 F (+100 C)

Withstands up to 15 G's in each of three mutually perpendicular

axes.

Withstands the following:

5 - 27 Hz @ 1.3 G's,

27 - 52 Hz @ 0.036" double amplitude,

52 - 500 Hz @ 5 G's.

3.0 lbs. (1.36 kg) net, 5 lbs. (2.26 kg) shipping.

1-1

Page 4

Page 5

SECTION 2

PRINCIPLES OF OPERATION

2-1. GENERAL

a. The Electronic Manual Voltage Control (MVC-301) is a phase-controlled, silicon-controlled,

rectifier (SCR) bridge. By adjusting the external

angle of the SCR change providing an adjustable voltage level to the exciter field.

b. During start-up, the build-up circuit holds the SCRs power bridge at maximum output. When the

voltage has built-up to approximately 30 Vac, the internal build-up circuit relinquishes control to the

external

MANUAL VOLTAGE ADJUST

.

MANUAL VOLTAGE ADJUST

control, the firing

c. The

the Manual Voltage Control or from Manual Voltage Control to voltage regulator. A free wheeling

diode remains connected to the field to allow safe switching without arcing.

d. The MVC-301 is designed to operate from 120 or 240 Volt nominal sources without any electrical

changes such as tap selection or terminal connections. Taps are provided to select 32, 63, or 125

volt maximum outputs.

AUTO-OFF-MAN

voltage control mode switch allows transfer from the voltage regulator to

2-1

Page 6

Page 7

SECTION 3

INSTALLATION AND OPERATION

3-1. INSTALLATION

a. The MVC-301 is designed for 'through-the-panel' mounting. Refer to the drilling template of

Figure 3-1 and to the outline drawing Figure 3-2. The front panel of the MVC-301 is detachable by

removal of the four corner screws. The MVC-301 can be installed in any position without affecting

its operating characteristics, however, it is preferable that the device be mounted vertically to

improve ventilation. The

nals 14, 15 and 16 or a Basler motor operated control (MOC 2) with a 10 k ohm control element can

be connected to terminal 14, 15, and 16. See Figure 3-3 Interconnection Diagram. It is imperative

that the MVC-301 be connected to provide an output which corresponds to the voltage regulator

ratings in order to prevent damage to the MVC-301 or the regulator. When the MVC-301 and

voltage regulator are properly matched, the MVC-301 provides smooth control of the generator

output voltage in the manual mode.

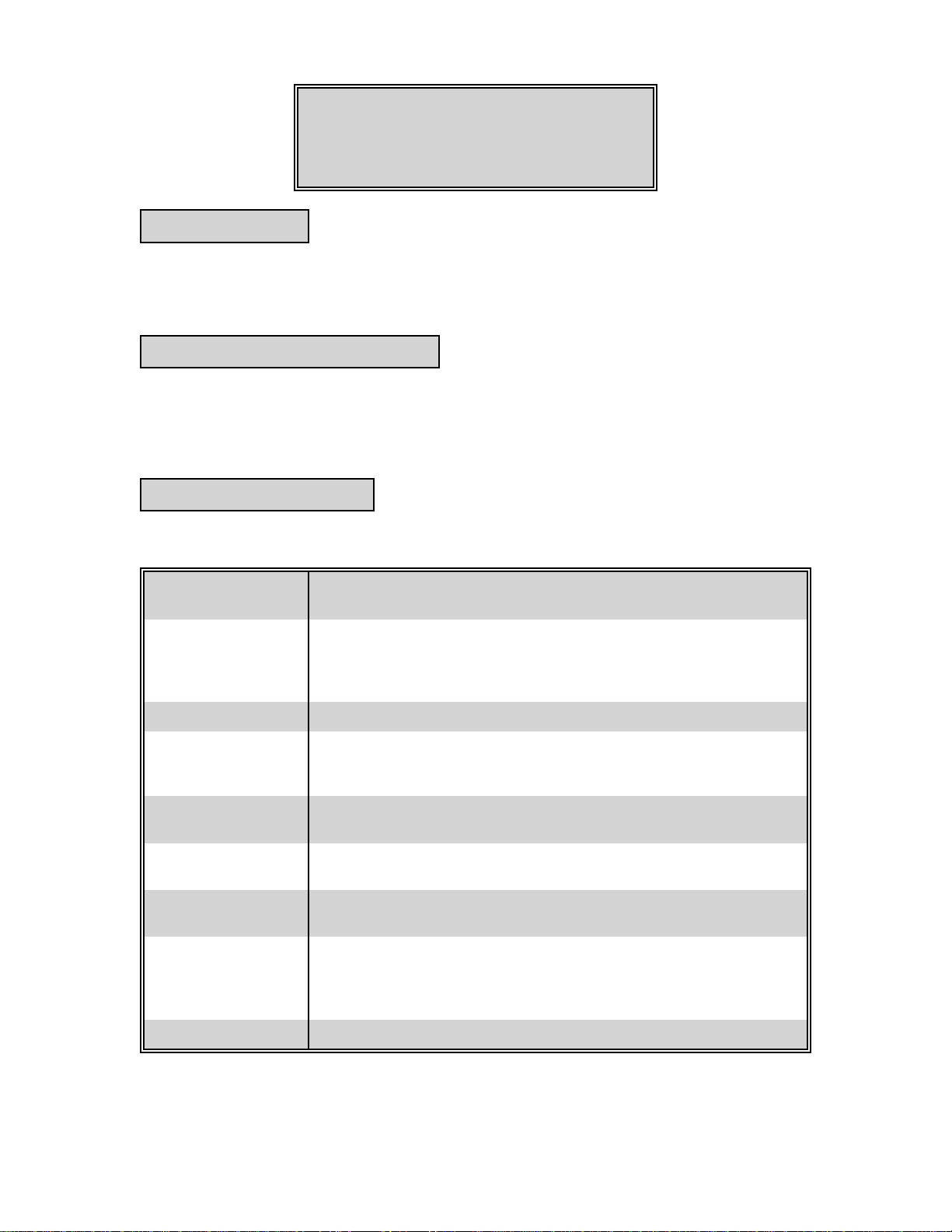

b. The chart (Table 3-1) is used to determine the appropriate input voltage and to select the output

voltage. Based on voltage regulator model, from column 1, the proper voltage input rating from

column 3 is selected and connections are made between the generator and terminals 23 and 24

which will supply the specified voltage. The MVC-301 has a wire jumper connected from the printed

circuit board of the MVC-301 to the barrier strip. Column 4 indicates the correct terminal for this

jumper connection.

MANUAL VOLTAGE ADJUST

control can be connected by using termi-

3-1

Page 8

Figure 3-1. Panel Drilling Template

3-2

Page 9

Figure 3-2. MVC 301 Outline Drawing.

3-3

Page 10

Figure 3-3 MVC 301 Interconnection Diagram, Typical

3-4

Page 11

Table 3-1. Voltage Selection Chart.

Voltage Regulator

Model

KR7F,KR7FF,

SR8A,SR8F

SR4A,SR4F,

KR4F,KR4FF

XR2001,XR2004 63 V @ 7 A or less 240 Vac 63

KR2F,KR2FF 32 V @ 7 A or less 120 Vac 32

APR63-5 63 V @ 7 A or less 240 Vac 63

APR125-5 125 V @ 7 A or less 240 Vac 125

HP63 63 V @ 7 A or less 240 Vac 63

Voltage Regulator

Rating

125 V @ 7 A or less 240 Vac 125

63 V @ 7 A or less 120 Vac 63

MVC Input

Voltage

Voltage Selection

Terminal

3-2. OPERATION

a. With the

voltage regulator is removed from the line and generator output voltage is controlled manually by

MANUAL VOLTAGE ADJUST

the

generator output voltage is controlled by the automatic voltage regulator. Complete excitation

shutdown occurs when the voltage control mode switch is placed in the

AUTO-OFF-MANUAL

voltage control mode switch placed in

control. When placed in the

MANUAL

AUTOMATIC

OFF

position.

, the automatic

position, the

CAUTION

With the voltage control mode switch in either MANUAL or

OFF position, some terminals of the regulator are connected

to the generator and present a potential shock hazard. No attempt should be made to remove or troubleshoot the regulator

while the generator is running.

b. Start the prime mover following the manufacturer's procedure, set the

ADJUST

voltage control mode switch in

if the

c. Allow the generator to build-up and slowly increase the generator output voltage with the

AL VOLTAGE ADJUST

control to minimum (counter-clockwise), and place the

MANUAL

MANUAL VOLTAGE ADJUST

control until the generator output voltage reaches the desired level.

position. Note that the voltage may be unstable (hunting)

control is set below 30 Vac.

AUTOMATIC-OFF-MANUAL

MANUAL VOLTAGE

MANU-

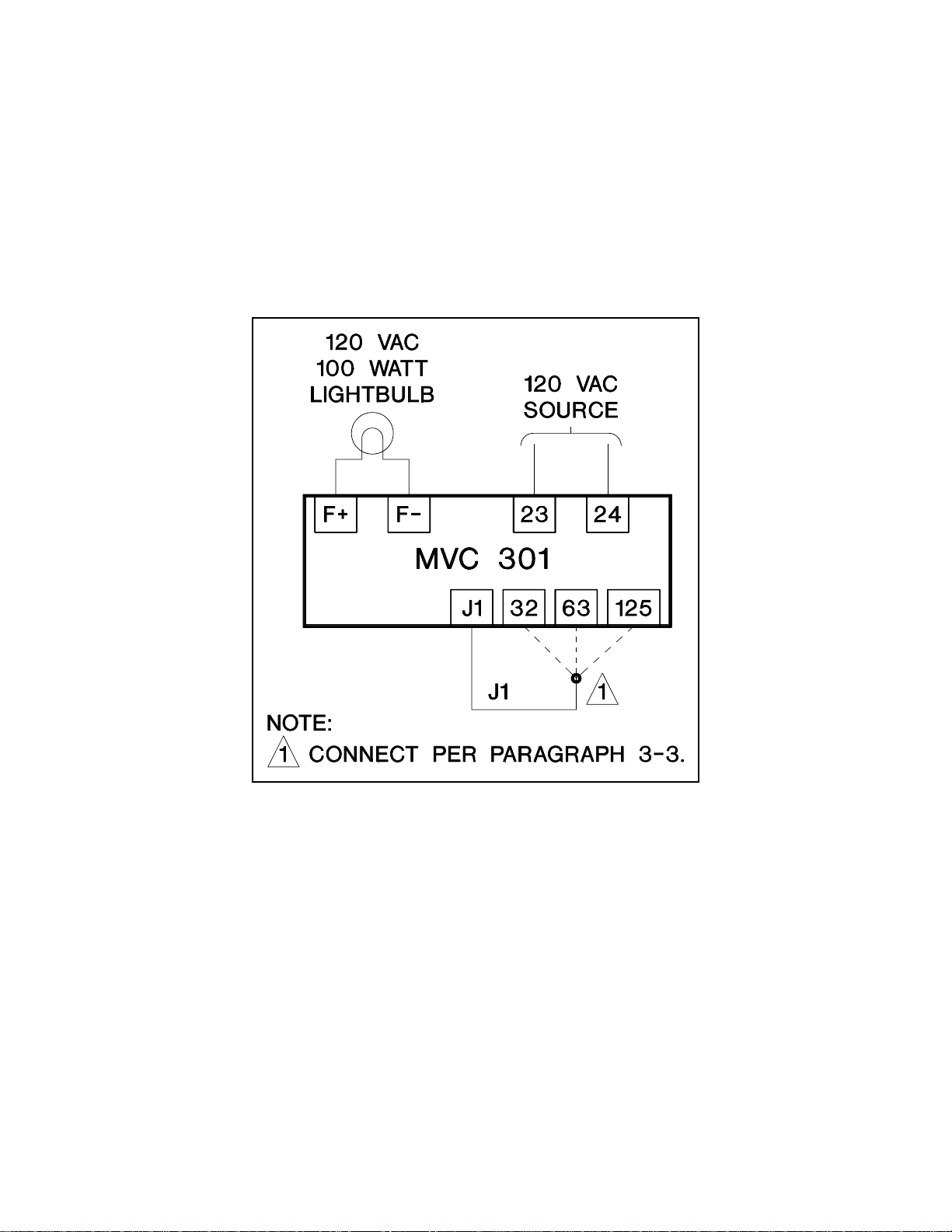

3-3. OPERATIONAL TEST

To verify that the MVC-301 is operating properly, use the following procedure and the connections

of Figure 3-4 for a bench test. Notice that the voltage regulator is not necessary for this test.

(1) With no power applied to the MVC-301 and all connections to the voltage regulator

removed, place the

MANUAL

position.

AUTO-OFF-MANUAL

voltage control mode switch to the

(2) Connect a 120 Vac 100 Watt light bulb to terminals F+ and F- of the MVC-301, and

connect the jumper to Terminal 63.

3-5

Page 12

(3) With the

apply a source of 120 Vac to Terminals 23 and 24 of the MVC-301. Slowly rotate

MANUAL VOLTAGE ADJUST

the

brightness of the light bulb increases proportionally until it reaches full brightness.

MANUAL VOLTAGE ADJUST

control clockwise (CW) and observe that the

control fully counter-clockwise (CCW)

(4) Rotate the

Remove the 120 Vac source from Terminals 23 and 24 and select 32 volt operation

by moving the jumper to Terminal 32. Apply the 120 Vac source to Terminals 23

and 24 of the MVC and observe that the brightness of the light bulb increases as

MANUAL VOLTAGE ADJUST

the

the brightness of the bulb is approximately half of its previous brightness with the

jumper connected to this terminal.

MANUAL VOLTAGE ADJUST

control is moved clockwise (CW). Notice that

control fully counter-clockwise (CCW).

Figure 3-4. Bench Test Connections.

3-6

Page 13

SECTION 4

MAINTENANCE AND TROUBLESHOOTING

4-1. PREVENTIVE MAINTENANCE

A periodic inspection should be made of the unit to insure it is clean and free from accumulations

of dust and moisture. Verify that all terminal connections of the MVC-301 and the voltage regulator

are tight.

4-2. TROUBLESHOOTING

In the event of failure/defective operation of the unit, Table 4-2 provides information to determine

the probable cause of the malfunction and the solution. Refer to Paragraph 3-3 and to Figure 3-4

for the bench test procedure.

4-3. RECOMMENDED SPARE PARTS

Due to a protective coating, repair/replacement of individual components on the printed circuit board

assembly should not be attempted and the complete replacement of the board is recommended.

When ordering replacement parts from Basler Electric always specify the part number, the quantity

and the description of the item.

Table 4-1. Replacement Parts List.

Reference

Designator

---------------- 9 1210 01 104 1 Printed Circuit Board Assembly

F1,F2 04592 2 Fuse, 10 A, 250 V

Part

Number Quantity Description

4-1

Page 14

Table 4-2. Troubleshooting.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

MVC 301 APPEARS TO BE DEFECTIVE.

Step 1.

Step 2.

Step 3.

Step 4.

Verify that wiring is correct and proper in accordance with Figure 3-3.

If wiring is defective or incorrect, repair as needed.

If wiring is not defective or incorrect, proceed to Step 2.

Check that the

If the excitation does not turn off, replace the MVC 301.

If the excitation shuts down, proceed to Step 3.

With the

output voltage builds up.

If the generator output voltage builds up, proceed to Step 6.

If the generator output voltage does not build up, proceed to Step 4.

Verify that internal fuses F1 and F2 are good.

If either fuse is defective or blown, replace fuse and proceed to Step 5.

AUTO-OFF-MAN

AUTO-OFF-MAN

front panel switch turns off the excitation.

front panel switch in

MANUAL

, verify that the generator

Step 5.

Step 6.

Step 7.

If both fuses are not defective or blown, replace the MVC 301.

Verify that the generator output voltage builds-up.

If the generator output voltage does not build-up, replace the MVC 301.

If the generator output voltage builds-up, proceed to Step 6.

Verify that the generator output can be c ontrolled by the MVC 301 front panel

potentiometer.

If the generator output voltage cannot be controlled by the MVC 301,

replace the MVC 301.

If the generator output voltage can be controlled by the MVC 301, proceed

to Step 7.

Verify that the generator works in the front panel switch

If the generator fails to operate with the front panel switch in the

position, troubleshoot the voltage regulator.

AUTO

position.

AUTO

4-2

Page 15

Page 16

ROUTE 143, BOX 269

HIGHLAND, IL 62249 USA

http://www.basler.com, info@basler.com

PHONE +1 618-654-2341 FAX +1 618-654-2351

Loading...

Loading...