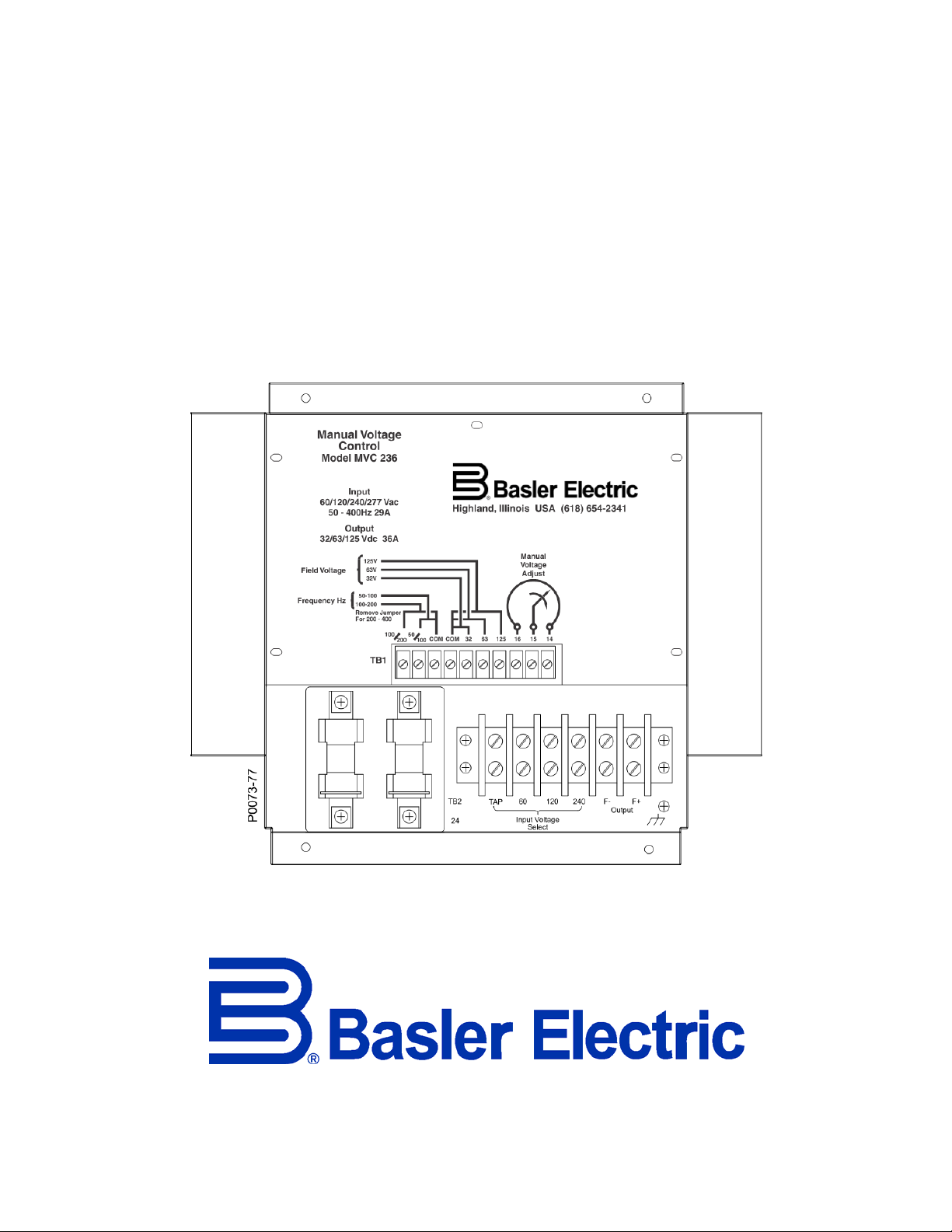

Page 1

INSTRUCTION MANUAL

FOR

MVC 236

Manual Voltage Control

Publication: 9204300990

Revision: J 09/13

Page 2

Page 3

9204300990 Rev J i

Preface

This instruction manual provides information about the installation and operation of the MVC 236 Manual

Voltage Control. To accomplish this, the following information is provided:

Functional description

Mounting

Connections

Operation

Maintenance

Conventions Used in this Manual

Important safety and procedural information is emphasized and presented in this manual through

Warning, Caution, and Note boxes. Each type is illustrated and defined as follows.

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note

Note boxes emphasize important information pertaining to Manual

Voltage Control installation or operation.

Manual Voltage Control Preface

Page 4

ii 9204300990 Rev J

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2013 by Basler Electric

All rights reserved

First printing: August 1988

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the MVC 236.

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Failure to follow warning and cautionary labels may result in personal injury

or property damage. Exercise caution at all times.

To prevent personal injury or equipment damage, only qualified personnel should install, operate, or

service this system.

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It is loaned for

confidential use, subject to return on request, and with the mutual understanding that it will not be used in any

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide

data for every possible contingency regarding installation or operation. The availability and design of all features

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

manual.

The English-language version of this manual serves as the only approved manual version.

Preface Manual Voltage Control

Page 5

9204300990 Rev J iii

Contents

Introduction ................................................................................................................................................... 1

Functional Description ................................................................................................................................... 3

Buildup Circuit ........................................................................................................................................... 3

Auto/Manual Transfer ................................................................................................................................ 3

Output Power ............................................................................................................................................. 3

Spike Suppression ..................................................................................................................................... 3

Mounting ........................................................................................................................................................ 5

Spike Suppression Module ........................................................................................................................ 6

Connections .................................................................................................................................................. 7

Operation..................................................................................................................................................... 11

Operational Test ...................................................................................................................................... 11

Maintenance ................................................................................................................................................ 13

Troubleshooting ....................................................................................................................................... 13

Specifications .............................................................................................................................................. 15

Manual Voltage Control Contents

Page 6

iv 9204300990 Rev J

Contents Manual Voltage Control

Page 7

9204300990 Rev J 1

Introduction

Manual Voltage Control MVC 236 enables manual control of generator output and is intended as a

backup system for an associated automatic voltage regulator. During generator startup, an integrated

buildup circuit maintains maximum MVC 236 output power for reliable buildup of the generator output

voltage.

The MVC 236 is intended for behind-the-panel mounting. MVC 236 components are mounted on a 14gauge, steel chassis with an aluminum cover and heat sinks. MVC 236 modules with part number

9204300100 have a chassis constructed from low-carbon steel while MVC 236 modules with part number

9204300104 have a chassis constructed from 316-grade stainless steel.

Standard Equipment

The MVC 236 is supplied with a potentiometer and spike suppression module.

Potentiometer

The potentiometer is intended for remote mounting and controls the MVC 236 setpoint.

Spike Suppression Module

The spike suppression module protects the MVC 236 from potentially damaging voltage spikes when the

MVC 236 is powered by a high-impedance source.

Optional Equipment

Available optional equipment for the MVC 236 includes an Auto/Off/Manual control switch and a nulling

chassis.

Auto/Off/Manual Switch

An available Auto/Off/Manual switch (P/N 9204306100) enables transfer of control between the MVC 236

and automatic voltage regulator.

Nulling Chassis

An available nulling chassis (P/N 9204304100) provides “bumpless” transfers from the automatic voltage

regulator to the MVC 236.

MVC 236 Introduction

Page 8

2 9204300990 Rev J

Introduction MVC 236

Page 9

9204300990 Rev J 3

Voltage Adjust

Error

Amplifier

Power

Supply

SCR

Control

Output

Input

P0073-70

Functional Description

The MVC 236 supplies power to the generator field through a phase-controlled, silicon-controlled rectifier

(SCR) bridge. By adjusting the remotely-mounted, manual voltage adjust control, the firing angle of the

SCR changes to provide an adjustable voltage level to the exciter field.

A simplified block diagram illustrating MVC 236 operation is shown in Figure 1.

Figure 1. MVC 236 Block Diagram

Operating Power

MVC 236 operating power can be supplied from a source with a nominal rating of 60 Vac, 120 Vac, or

240 Vac. The nominal source voltage is made on the MVC 236 through a tap selection.

The operating power frequency can be within one of three jumper-selectable ranges: 50 to 100 Hz, 100 to

200 Hz, or 200 to 400 Hz.

Buildup Circuit

During generator startup, the MVC 236 buildup circuit holds the SCR power bridge at maximum output.

Once the voltage builds to approximately 30 Vac, the buildup circuit relinquishes control to the remotelymounted, potentiometer for manual control of the field excitation level.

Auto/Manual Transfer

The available Auto/Off/Manual switch (P/N 9204306100) enables transfer from the automatic voltage

regulator to the MVC 236 and vice versa. Circuitry within the MVC 236 allows safe switching without the

risk of arcing.

Output Power

The jumper-selectable MVC 236 power output is rated for a nominal field voltage of 32 Vdc, 63 Vdc, or

125 Vdc.

Spike Suppression

Higher impedance sources, such as power isolation transformers and permanent magnet generators

(PMGs), may have enough inductance to produce damaging voltage spikes in the MVC 236 power output

stage. In these applications, use of the provided spike suppression module is recommended to filter out

MVC 236 Functional Description

Page 10

4 9204300990 Rev J

these potentially damaging voltage spikes. The Installation chapter provides information about mounting

and connecting the spike suppression module.

Functional Description MVC 236

Page 11

9204300990 Rev J 5

Mounting

For maximum cooling, the MVC 236 must be mounted vertically. The mounting location can be anywhere

the ambient temperature does not exceed the environmental conditions listed in the Specifications

chapter. Figure 2 illustrates the overall mounting dimensions of the MVC 236. Maximum mounting depth

for the MVC 236 is 4.375 inches (111 millimeters). Dimensions shown in Figure 2 are in inches with

millimeters in parenthesis.

Figure 2. MVC 236 Mounting Dimensions

Manual Voltage Adjust Potentiometer

Mounting dimensions for the manual voltage adjust potentiometer are shown in Figure 3.

MVC 236 Mounting

Page 12

6 9204300990 Rev J

Figure 3. Manual Voltage Adjust Potentiometer Dimensions

Spike Suppression Module

The spike suppression module can be mounted in any position and location where the ambient

temperature does not exceed the operational limits. Due to the rugged construction of the spike

suppression module, it can be mounted direc t ly on the genera tor . Select module mounting hardware

based on the vibration and shock expected during normal operation. Figure 4 illustrates the overall and

mounting dimensions for the spike suppression module. Dimensions shown in Figure 4 are in inches with

millimeters in parenthesis.

Figure 4. Spike Suppression Module Mounting Dimensions

Mounting MVC 236

Page 13

9204300990 Rev J 7

Caution

Contact

1-2

1-3

5-4

5-6

7-8

9-10

11-12 †

13-14 †

15-16 †

17-18 †

Manual

X X X

∗

X

Off X

∗

Auto X X X X X X X

Connections

High-potential test equipment should be applied with extreme care.

Incorrect application of dielectric test voltages will damage the

MVC 236.

Connection drawings for typical MVC 236 applications are provided in Figure 5 and Figure 6.

Table 1 serves as a legend for the Auto/Off/Manual Switch of Figure 5.

For Figure 6, switch contacts 1 and 2 are closed for manual operation and switch contacts 3 and 4 are

closed for auto operation.

Table 1. Auto/Off/Manual Switch Legend for Figure 5

Switch

Position

∗ Make before break.

† Contacts required for automatic voltage regulator maintenance.

Connection Guideli ne s

Observe the following guidelines when making MVC 236 connections.

Input Power

Operating power is applied at MVC 236 terminals 23 and 24. The MVC 236 and operating power wiring

should be protected with fuses. Configure the MVC 236 for the applied, nominal operating power by

connecting the jumper from terminal TB2-TAP to the proper terminal on TB2 (60, 120, or 240).

Output (Field) Voltage

Select the desired output (field) voltage (32 Vdc, 63 Vdc, or 125 Vdc) by connecting the jumper wire from

terminal TB1-COM (F ield V olta ge) to the proper terminal.

Frequency Selection

Configure the MVC 236 for the operating power frequency. Connect a jumper wire between terminal TB1COM (Frequency Hz) and the appropriate terminal for 50 Hz to 100 Hz operation or 100 Hz to 200 Hz

operation. For an operating power frequency within the range of 200 Hz to 400 Hz, omit the jumper.

Manual Voltage Adjust Potentiometer

Connect the manual voltage adjust potentiometer to MVC 236 terminals TB1-14, TB1 -15, and TB1-16 as

shown in the connection diagrams. If desired, a Basler Electric Motor Operated Control with a 10 kΩ

control element can be used instead of the supplied potentiometer.

MVC 236 Connections

Page 14

8 9204300990 Rev J

Spike suppression module is required when isolation transformer is used.

Manual/Off/Auto switch is required for AVR maintenance.

Pha se rotatio n is ABC.

Connect tap for nominal input voltage used.

Connect jumper for generator frequency. (Jumper is removed for 200 to 400 Hz.)

Connect jumper for application field voltage.

TB1

14

15

16

TB1

COM

125

63

32

MVC 236

10K

+ - A B C

F+ F- 23 24

TAP 60 120 240

COM 50/100

100/200

3

Spike

Suppression

Module

3 4

Operating

Power

Field

Output

Current

Sensing

Voltage

Sensing

2

3

2

P0073-73

4 5

6

TB2 TB1

1098

7

1

3 2 4 6

5

13 15 17

14 16 18

11

12

GEN

A

B

C

Aut om atic Voltage Regulat or

TB2

-+

1

4

5

6

1

Figure 5. Typical MVC 236 Connections

Connections MVC 236

Page 15

9204300990 Rev J 9

Figure 6. MVC 236 Interconnection with Null Meter Circuit

MVC 236 Connections

Page 16

10 9204300990 Rev J

Connections MVC 236

Page 17

9204300990 Rev J 11

Operation

When the Auto/Off/Manual control switch is placed in the Manual position, the automatic voltage regulator

is removed from the circuit and the generator output is manually controlled by the MVC 236. When the

Auto/Off/Manual control switch is placed in the Auto position, the generator output voltage is controlled by

the automatic voltage regulator. Complete excitation shutdown occurs when the Auto/Off/Manual control

switch is placed in the Off position.

Warning!

When the Auto/Off/Manual control switch is placed in the Manual or

Off position, some of the voltage regulator terminals remain connected

to the generator and present a potential shock hazard. No attempt

should be made to remove or troubleshoot the automatic voltage

regulator during generator operation.

Operating Procedure

1. Start the prime mover according to the manufacturer’s procedure and set the manual voltage

adjust potentiometer to its minimum value (fully counterclockwise).

2. Place the Auto/Off/Manual switch in the Manual position. Note that the generator voltage may be

unstable (hunting) if the manual voltage adjust potentiometer is set below 30 Vac.

3. Allow the generator voltage to build and then slowly increase the generator output voltage with

the manual voltage adjust control until the generator output voltage reaches the desired level.

Operational Test

MVC 236 operation can be verified by using the following procedure. Operational test connections are

shown in Figure 7. Note that an automatic voltage regulator is not required for this test.

1. Connect the MVC 236 according to the connections shown in Figure 7.

2. Connect the field voltage jumper for 125 Vdc.

3. Adjust the manual voltage adjust control fully counterclockwise and apply 120 Vac input power.

4. Slowly rotate the manual voltage adjust control clockwise and observe that the brightness of the

light bulb increases proportionally until reaching full luminance.

5. Rotate the manual voltage adjust control fully counterclockwise and remove the 120 Vac input

power.

6. Connect the field voltage jumper for 63 Vdc.

7. Apply power and slowly rotate the manual voltage adjust control c lock wis e and o bser v e that the

brightness of the light bulb increases proportionally. Observe that the light bulb luminance is half

of what is was when the field voltage jumper was set in the 125 Vdc position.

8. Rotate the manual voltage adjust control fully counterclockwise and remove the 120 Vac input

power.

9. Connect the field voltage jumper for 32 Vdc.

10. Apply power and slowly rotate the manual voltage adjust control clockwise and observe that the

brightness of the light bulb increases proportionally. Observe that the light bulb luminance is half

of what is was when the field voltage jumper was set in the 63 Vdc position.

MVC 236 Operation

Page 18

12 9204300990 Rev J

120 Vac, 100 W

MVC

236

240 F– F+

120

60

TAP2423

TB2

120 Vac

Source

32 100/20063125161514 50/100COMCOM TB1

Voltage Adjust Field Voltage Frequency

Jumper for input

frequency used

See steps 2, 6, and 9

of

Operational Test

.

P0073-75

Figure 7. MVC 236 Operational Test Connections

Operation MVC 236

Page 19

9204300990 Rev J 13

Component

Designator

Basler P/N

Quantity

Description

9179201101

1

Printed circuit board assembly

9261500101

1

Spike suppression module

CR5

08608

1

Diode, type S3680

F1, F2

61627

2

Fuse, type JJS40, 40 A

PM1, PM2

42403

2

SCR power module, 800 V, 90 A

R27, R28

21564

2

Resistor, wire-wound, 15 Ω, 50 W

R32

21565

1

Potentiometer, 10 kΩ, 5%, 1 W

T1

BE22746001

1

Transformer

Maintenance

Periodic inspection should be made to ensure that the MVC 236 is clean and free from accumulations of

dust and moisture. Verify that all connections are clean, tight, and free of corrosion.

Corrective Maintenance

Due to a protective, conformal coating, repair of printed circuit components should not be attempted.

Replacement of the printed circuit board is recommended. Table lists the recommended spare parts for

the MVC 236.

Table 2. Recommended Spare Parts

Troubleshooting

If an MVC 236 malfunction is suspected, the troubleshooting chart of Figure 8 can be used to determine the probable cause of the malfunction and determine corrective actions. Refer to the Maintenance chapter for a procedure for bench-testing the MVC 236.

MVC 236 Maintenance

Page 20

14 9204300990 Rev J

Verify wiring

Replace

Auto/Off/Man.

switch

Does control switch

disable excitation?

Does gen voltage

build in Manual

mode?

Can gen voltage be

controlled by pot?

Does generator

function in Auto

mode?

Replace

MVC 236

Replace

voltage

regulator

Are fuses

F1 and F2 good?

Replace

MVC 236

Replace

fuses F1, F2

Does gen

voltage build?

MVC 236 trouble

suspected

System checkout

complete

Replace

MVC 236

NO

YES

NO NO

YES NO

YESYES

NO

YES

NO

YES

P0073-76

Figure 8. MVC 236 Troubleshooting Chart

Maintenance MVC 236

Page 21

9204300990 Rev J 15

Specifications

Power Input

Frequency

50 to 400 Hz, single-phase

Voltage Range

60 Vac Nominal: 45 to 70 Vac

120 Vac Nominal: 90 to 153 Vac

240 Vac Nominal: 170 to 305 Vac

Power Dissipation

85 W

Minimum Residual Buildup Vol tag e

10% of 60 Vac nominal input voltage or 5% of 120/240 Vac nominal input voltage.

Regulation

Accuracy

2% for a 10% change in input power and 5% for a 30% change in input power.

Temperature Stability

±5% for a 50°C temperature change

Power Output

60 Vac Nominal Input

32 Vdc at 36 Adc, nominal. No less than 40 Vdc at maximum potentiometer setting.

120 Vac Nominal Input

63 Vdc at 36 Adc, nominal. No less than 79 Vdc at maximum potentiometer setting.

240 Vac Nominal Input

125 Vdc at 36 Adc, nominal. No less than 156 Vdc at maximum potentiometer setting.

Minimum Field Resistance

32 Vdc Nominal Output: 0.88 Ω

63 Vdc Nominal Output: 1.75 Ω

125 Vdc Nominal Output: 3.47 Ω

Physical

Temperature

Operating: –40 to 70°C (–40 to 158°F)

Storage: –40 to 85°C (–40 to 185°F)

Humidity

98% noncondensing, maximum

Shock

Withstands up to 15 G in each of three mutually perpendicular axes without any degradation of

performance.

MVC 236 Specifications

Page 22

16 9204300990 Rev J

Vibration

Withstands up to 2 G of force over a frequency spectrum of 10 to 500 Hz.

Weight

Unit: 6.8 kg (15.0 lb)

Shipping: 8.2 kg (18.0 lb)

Dimensions

Refer to the Mounting chapter for MVC 236 dimensions.

Specifications MVC 236

Page 23

Page 24

12570 State Route 143

Highland IL 62249-1074 USA

Tel: +1 618.654.2341

Fax: +1 618.654.2351

email: info@basler.com

P.A.E. Les Pins

67319 Wasselonne Cedex

FRANCE

Tel: +33 3.88.87.1010

Fax: +33 3.88.87.0808

email: franceinfo@basler.com

No. 59 Heshun Road Loufeng District (N)

Suzhou Industrial Park

215122 Suzhou

P.R. CHINA

Tel: +86 512.8227.2880

Fax: +86 512.8227.2887

email: chinainfo@basler.com

111 North Bridge Road

15-06 Peninsula Plaza

Singapore 179098

Tel: +65 68.44.6445

Fax: +65 68.44.8902

email: singaporeinfo@basler.com

Loading...

Loading...