Page 1

s

INTRODUCTION

www.basler.com

+1 618.654.2341 (USA)

info@basler.com

Model

Part Number

Maximum Humidity: 98%, non-condensing

MVC 112

9179200100

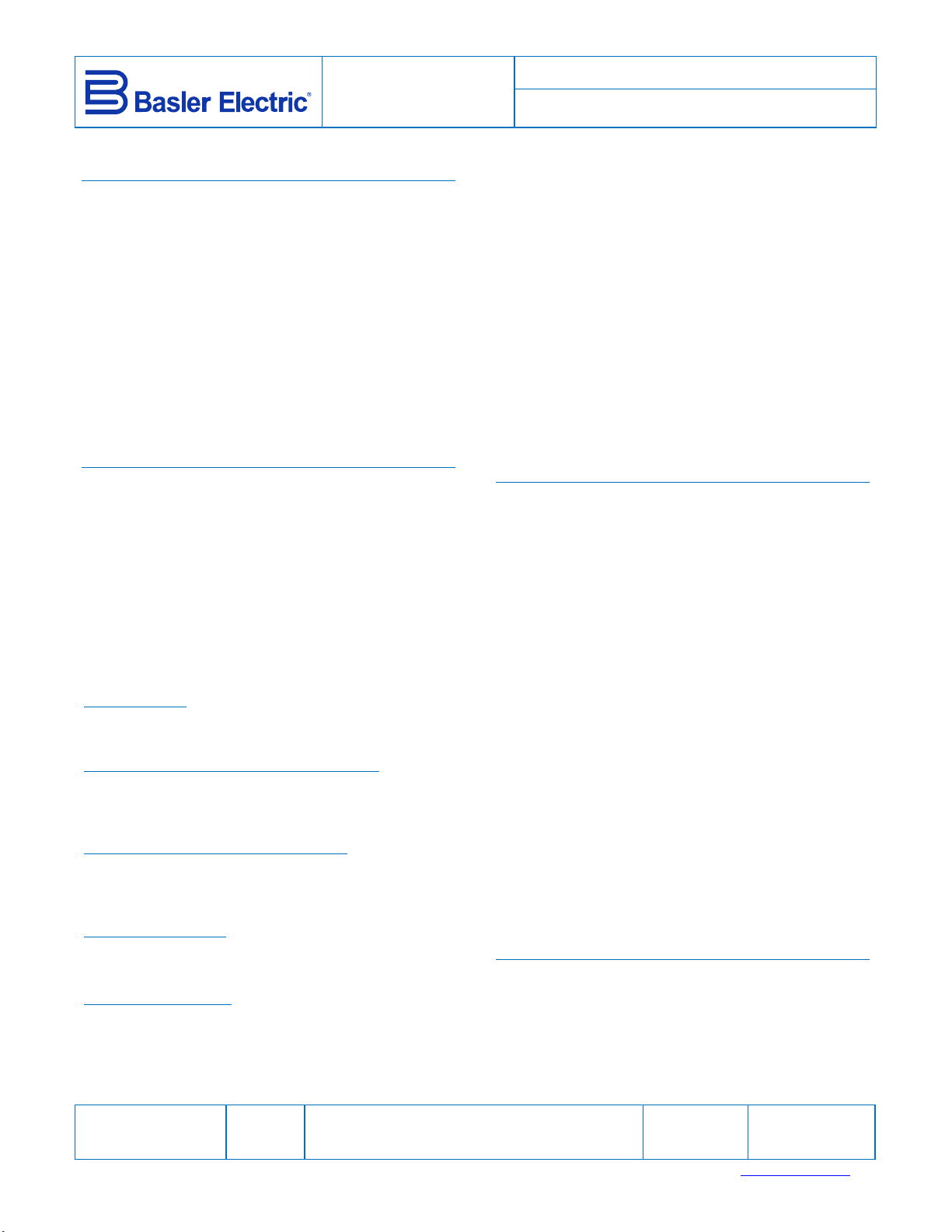

The MVC 112 Manual Voltage Control provides

manual control of field excitation during generator

startup, commissioning, or a voltage regulator failure.

The MVC 112 supplies regulated dc field power

which is adjusted by a front-panel control. An

Auto/Off/Manual switch enables transfer of control

from a voltage regulator to the MVC 112 and vice

versa. MVC 112 controls are illustrated in Figure 1.

The MVC 112 is intended for through-the-panel

mounting. All connections are made at terminal

blocks located on the rear panel. If desired, an

external potentiometer (Basler P/N 21565) may be

used for remote manual voltage adjustment.

SPECIFICATIONS

Input Power

Nominal: 120 Vac or 240 Vac, 1-phase

Operating Range

120 Vac Nominal: 90 to 153 Vac

240 Vac Nominal: 170 to 305 Vac

Frequency: 50 to 400 Hz

Dissipated Power: 35 W

Minimum Residual

Buildup Voltage: 5% of 120/240 Vac, nominal

Output Power

Current Output

12 Adc at 32 Vdc, 63 Vdc, or 125 Vdc nominal

voltage

Voltage at Maximum Potentiometer Setting

At 32 Vdc Nominal Output: 40 Vdc minimum

At 63 Vdc Nominal Output: 79 Vdc minimum

At 125 Vdc Nominal Output: 156 Vdc minimum

Minimum Acceptable Field Resistance

At 32 Vdc Nominal Output: 2.67 Ω

At 63 Vdc Nominal Output: 5.25 Ω

At 125 Vdc Nominal Output: 10.42 Ω

Regulation Accuracy

2% for a 10% change in input power

5% for a 30% change in input power

Temperature Stability

±5% for a 50C (122F) change in temperature

Environment

Operating Temperature: –40 to 70C (–40 to 158F)

Storage Temperature: –40 to 85C (–40 to 185F)

Publication

9179200990

Revision

E

Instruction

Vibration Tolerance: 2 G over a range of 10 to

500 Hz

Shock Tolerance: 15 G in each of three

perpendicular planes

Agency Compliance

EAC Mark (Eurasian Conformity)

TP TC 004/2011

TP TC 020/2011

Physical

Weight: 12 lb. (5.5 kg)

Dimensions (H, W, D): 9.63 in., 7.19 in., 7.85 in.

245 mm, 183 mm, 199 mm

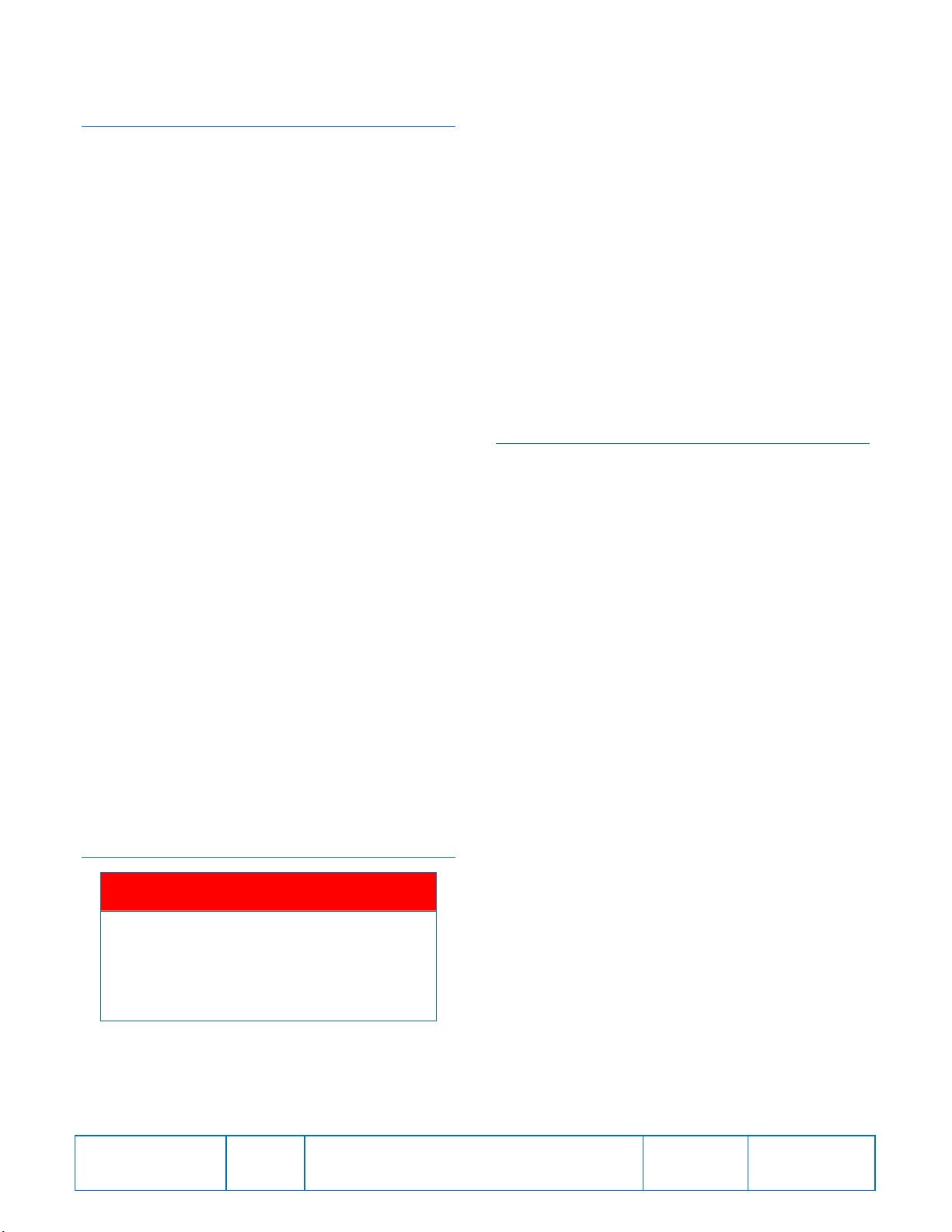

FUNCTIONAL DESCRIPTION

MVC 112 function is illustrated in Figure 2 and

described in the following paragraphs.

The MVC 112 supplies dc power to the field through

a phase-controlled SCR bridge. Adjusting the Manual

Voltage Adjust potentiometer changes the SCR firing

angle and the level of voltage applied to the field.

The MVC 112 is powered by a 120 Vac or 240 Vac

power source selected by positioning a jumper wire.

Input power frequency is also selected by a jumper.

One position selects a range of 50 to 100 hertz and a

second position selects a range of 100 to 200 hertz.

Removal of the jumper selects a range of 200 to 400

hertz.

During startup, an internal buildup circuit holds the

SCR power bridge at maximum output. When the

voltage builds to approximately 30 Vac, the buildup

circuit relinquishes control to the Manual Voltage

Adjust potentiometer.

The Auto/Off/Manual switch provides transfer control

from the voltage regulator to the MVC 112 and vice

versa. A freewheeling diode prevents arcing during

transfers.

MOUNTING

The MVC 112 is intended for through-the-panel

mounting in any location that complies with the

environmental parameters listed in the Specifications

section. It must be installed in an upright position for

maximum cooling. Overall MVC 112 dimensions are

shown in Figure 3. Panel cutting and drilling

Date

04/15

Copyright

2015

For terms of service relating to this product and software, see the Commercial Terms of Products and Servicesdocument available at www.basler.com/terms.

Page 2

s

dimensions are illustrated in Figure 4. All dimensions

are shown in inches with millimeters in parenthesis.

CONNECTIONS

Typical MVC 112 connections are shown in Figure 5.

When making connections, 14 AWG or 12 AWG wire

should be used. Torque applied to the terminal

screws should not exceed 9 inch-pounds (1 newton

meter).

Input Power Configuration

Input power voltage and frequency values are

configured by positioning jumper wires on the

MVC 112 terminal blocks.

A nominal input power voltage of 120 Vac or 240 Vac

is selected by connecting a jumper across either the

“Tap” and “120” terminals or the “Tap” and “240”

terminals.

The MVC 112 is configured for an input power

frequency within the range of 50 hertz to 100 hertz by

connecting a jumper across the “50-100” and “Com”

terminals. A frequency range of 100 hertz to 200

hertz is selected by connecting a jumper across the

“100-200” and “Com” terminals. For a frequency

within the range of 200 hertz to 400 hertz, no jumper

is connected.

Field Output Configuration

A nominal output (field) voltage of 32 Vdc, 63 Vdc, or

125 Vdc is selected through connection of a jumper

wire across the “Com” and “32”, “63”, or “125”

terminals.

External Potentiometer Connections

If a remote potentiometer will be used for control of

the MVC 112 output, the wires of the internal

potentiometer must be disconnected from terminals

14, 15, and 16. Then, the remote potentiometer is

connected with the potentiometer wiper arm

connected at terminal 15. A 10 kΩ, 1 watt

potentiometer (Basler P/N 21565) should be used.

OPERATION

generator output with the voltage regulator. Complete

excitation shutdown occurs when the switch is placed

in the Off position.

Startup

The following steps are provided as a guide for

generator startup with the MVC 112.

1. Start the prime mover and adjust the Manual

Voltage Adjust control to the minimum (fully

counterclockwise) position.

2. Place the Auto/Off/Manual switch in the Manual

position. Allow the generator terminal voltage to

build. Note that the generator voltage may be

unstable (hunting) if the Manual Voltage Adjust

control is set below 30 Vac.

3. Use the Manual Voltage Adjust control to slowly

increase the generator terminal voltage until it

reaches the desired level.

MAINTENANCE AND TROUBLESHOOTING

No preventative maintenance is required other than

periodic inspections to ensure that the MVC 112 is

free of accumulations of dirt and moisture. Verify that

all connections are clean, tight, and free of corrosion.

Operational Test Procedure

Proper MVC 112 operation can be verified with the

following procedure if faulty operation is suspected. A

voltage regulator is not required for MVC 112 testing.

1. Connect the MVC 112 as shown in Figure 6.

Place the field voltage jumper in the 125 Vdc

position (across terminals “Com” and “125”).

Place the input frequency jumper in the

appropriate position for the applied input power.

2. Adjust the Manual Voltage Adjust control fully

counterclockwise and apply 120 Vac power to the

MVC 112.

3. Slowly rotate the Manual Voltage Adjust control

clockwise and observe that the brightness of the

light bulb increases proportionally until reaching

full brightness.

Warning!

When the MVC 112 Auto/Off/Manual switch is

placed in the Manual or Off position, some

voltage regulator terminals remain connected

to the generator and present a potential shock

hazard.

With the Auto/Off/Manual switch in the Manual

position, the voltage regulator is removed from the

circuit and the generator output voltage is manually

controlled by the Manual Voltage Adjust control. The

Auto position enables automatic control of the

Publication

9179200990

Revision

E

Instruction

4. Rotate the Manual Voltage Adjust control fully

counterclockwise and remove the 120 Vac input

power.

5. Place the field voltage jumper in the 63 Vdc

position (across terminals “Com” and “63”).

6. Slowly rotate the Manual Voltage Adjust control

clockwise and observe that the brightness of the

light bulb increases proportionally until reaching

only half the brightness obtained in step 3.

7. Rotate the Manual Voltage Adjust control fully

counterclockwise and remove the 120 Vac input

power.

Date

04/15

Page

2 of 8

Page 3

s

8. Place the field voltage jumper in the 32 Vdc

position (across terminals “Com” and “32”).

9. Slowly rotate the Manual Voltage Adjust control

clockwise and observe that the brightness of the

light bulb increases proportionally until reaching

half the brightness obtained in step 6.

Figure 1. MVC 112 Front Panel Controls

Figure 2. MVC 112 Function Block Diagram

Publication

9179200990

Revision

E

Instruction

Date

04/15

Page

3 of 8

Page 4

s

Figure 3. MVC 112 Outline Dimensions

Publication

9179200990

Revision

E

Instruction

Date

04/15

Page

4 of 8

Page 5

s

Publication

9179200990

Revision

E

Figure 4. MVC 112 Panel Cutting and Drilling Diagram

Instruction

Date

04/15

Page

5 of 8

Page 6

s

Publication

9179200990

Revision

E

Figure 5. Typical MVC 112 Connections

Instruction

Date

04/15

Page

6 of 8

Page 7

s

Publication

9179200990

Revision

E

Figure 6. MVC 112 Operational Test Connections

Instruction

Date

04/15

Page

7 of 8

Page 8

s

Publication

9179200990

Revision

E

Instruction

Date

04/15

Page

8 of 8

Loading...

Loading...