Page 1

INSTRUCTION MANUA L

FOR

IDP-800

Interactive Display Panel

For use with DECS-200, DECS-200N,

DECS-250, DECS-250N, or DECS-400

Digital Excitation Control Systems

Publication: 9437600990

Revision: F Feb-15

Page 2

Page 3

9437600990 Rev F i

Caution

Note

Preface

This instruction manual provides information about the installation and operatio n of the IDP-800. To

accomplish this, the following information is provided:

• Mounting and connections

• Communication requirements

• Display operation and screen navigation

• Product specifications

Conventions Used in this Ma nua l

Important safety and procedural information is emphasized and presented in this manual through

Warning, Caution, and Note boxes. Each type is illustrated and defined as follows.

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note boxes emphasize important information pertaining to IDP-800

installation or operation.

IDP-800 Preface

Page 4

ii 9437600990 Rev F

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It is loaned for

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

manual.

The English-language version of this manual serves as the only approved manual version.

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2015 by Basler Electric

All rights reserved

First printing: February 2010

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the IDP-800. Note

all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with the

product for reference. Failure to follow warning and cautionary labels may result in personal injury or

property damage. Exercise caution at all times.

To prevent personal injury or equipment damage, only qualified personnel should install, operate, or

service this system.

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

confidential use, subject to return on request, and with the mutual understanding that it will not be used in any

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide

data for every possible contingency regarding installation or operation. The availability and design of all features

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

Preface IDP-800

Page 5

9437600990 Rev F iii

Contents

Introduction ................................................................................................................................................. 1

IDP-800 Style Designations ...................................................................................................................... 1

Communication ........................................................................................................................................... 3

Ethernet Communication ........................................................................................................................... 4

IDP-800-A Operation ................................................................................................................................... 7

Main View Screen ...................................................................................................................................... 8

Generator/Motor Monitor ........................................................................................................................... 9

DECS Metering Screen ........................................................................................................................... 10

DECS Control .......................................................................................................................................... 13

Alarms and Status ................................................................................................................................... 15

IDP-800-B Operation ................................................................................................................................. 17

Configuration Screens ............................................................................................................................. 17

Main View Screen .................................................................................................................................... 19

Generator/Motor Monitor ......................................................................................................................... 20

DECS Metering Screen ........................................................................................................................... 21

DECS Control .......................................................................................................................................... 23

Alarms and Status ................................................................................................................................... 25

IDP-800-C Operation ................................................................................................................................. 29

Configuration Screens ............................................................................................................................. 29

Main View Screen .................................................................................................................................... 30

DECS Metering Screen ........................................................................................................................... 32

Modbus™ Communication....................................................................................................................... 43

IDP-800 Register Table ........................................................................................................................... 43

Mounting .................................................................................................................................................... 49

Mounting of Accessories ......................................................................................................................... 51

Connections .............................................................................................................................................. 53

Control Power Connections ..................................................................................................................... 54

Communication Connections .................................................................................................................. 54

Maintenance and Troubleshooting ......................................................................................................... 57

Troubleshooting ....................................................................................................................................... 57

Specifications ............................................................................................................................................ 59

Revision History ........................................................................................................................................ 61

IDP-800 Contents

Page 6

iv 9437600990 Rev F

Contents IDP-800

Page 7

9437600990 Rev F 1

Introduction

The IDP-800 Interactive Display Panel is a high-resolution, 7.5 inch/19 centimeter (measured diagonally)

color touch screen interface that enables a user to monitor and control a Basler Electric DECS-based

excitation system. IDP-800 monitoring and control features include DECS and excitation system status,

system control operations, and routine adjustments of the excitation setpoint. The IDP-800 is compatible

with DECS-200, DECS-200N, DECS-250, DECS-250N, and DECS-400 Digital Excitation Control

Systems.

DECS and synchronous generator or motor system parameters are viewed and controlled through

interactive pages displayed by the IDP-800. Pages are organized according to system functions.

Navigation between pages and control of functions is achieved by touching buttons located on the IDP800 pages.

Communication between the IDP-800 and DECS is facilitated through the serial communication port of

the IDP-800 and the RS-485 port of the DECS. One IDP-800 can monitor both the primary and secondary

DECS in a dual DECS application. The IDP-800 is equipped with an Ethernet communication port which

provides access to Modbus™ registers for system monitoring and control of the DECS. This capability

enables integration of the IDP-800 into an existing Distributed Control System (DCS).

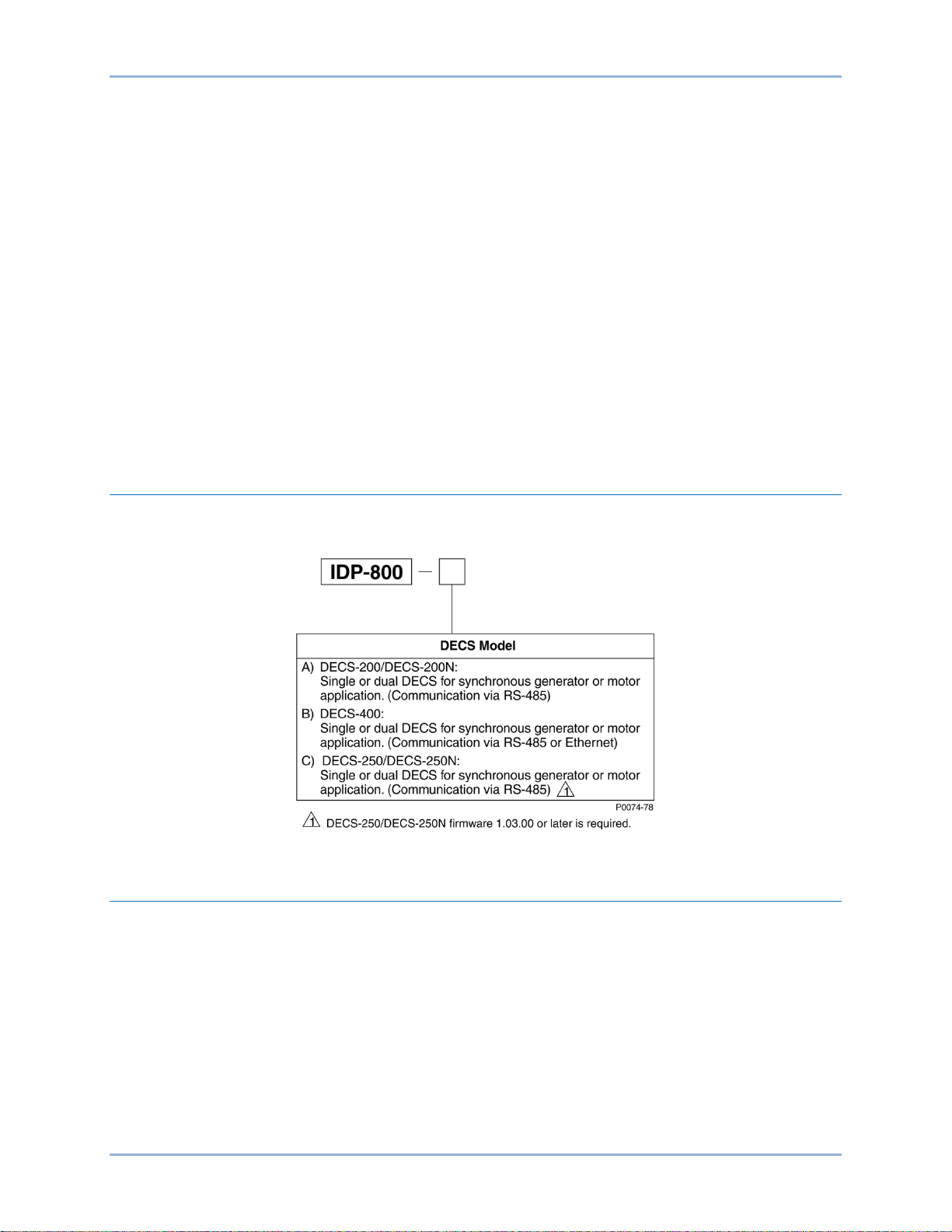

IDP-800 Style Designations

A single-digit style designator determines the DECS application that is compa tib le with the IDP-800. Style

options are shown in Figure 1.

Figure 1. IDP-800 Style Options

Hardware

The IDP-800 is supplied with the following hardware:

• Compact flash memory card

• Terminal conversion adaptor

• Two 680 Ω terminating resistors with sleeving

• Instruction manual (Basler publication 9437600990)

Accessories

The following optional accessories are available for use with the IDP-800:

• Power supply, 24 Vdc, 31 W, Basler P/N 933450310 1

• Ethernet switch, 8 ports, Basler P/N 41133

• DIN mounting rail for Ethernet switch, Basler P/N 9323900001

IDP-800 Introduction

Page 8

2 9437600990 Rev F

Introduction IDP-800

Page 9

9437600990 Rev F 3

Controller Application

{Communication Scheme}

Local Only

Only

Remote †

DCS ∗

DECS-200

{Figure 2}

DECS-200N

{Figure 2}

DECS-250

{Figure 2}

DECS-250N

{Figure 2}

DECS-400

{Figure 2}

DECS-400

{Figure 3}

Communication

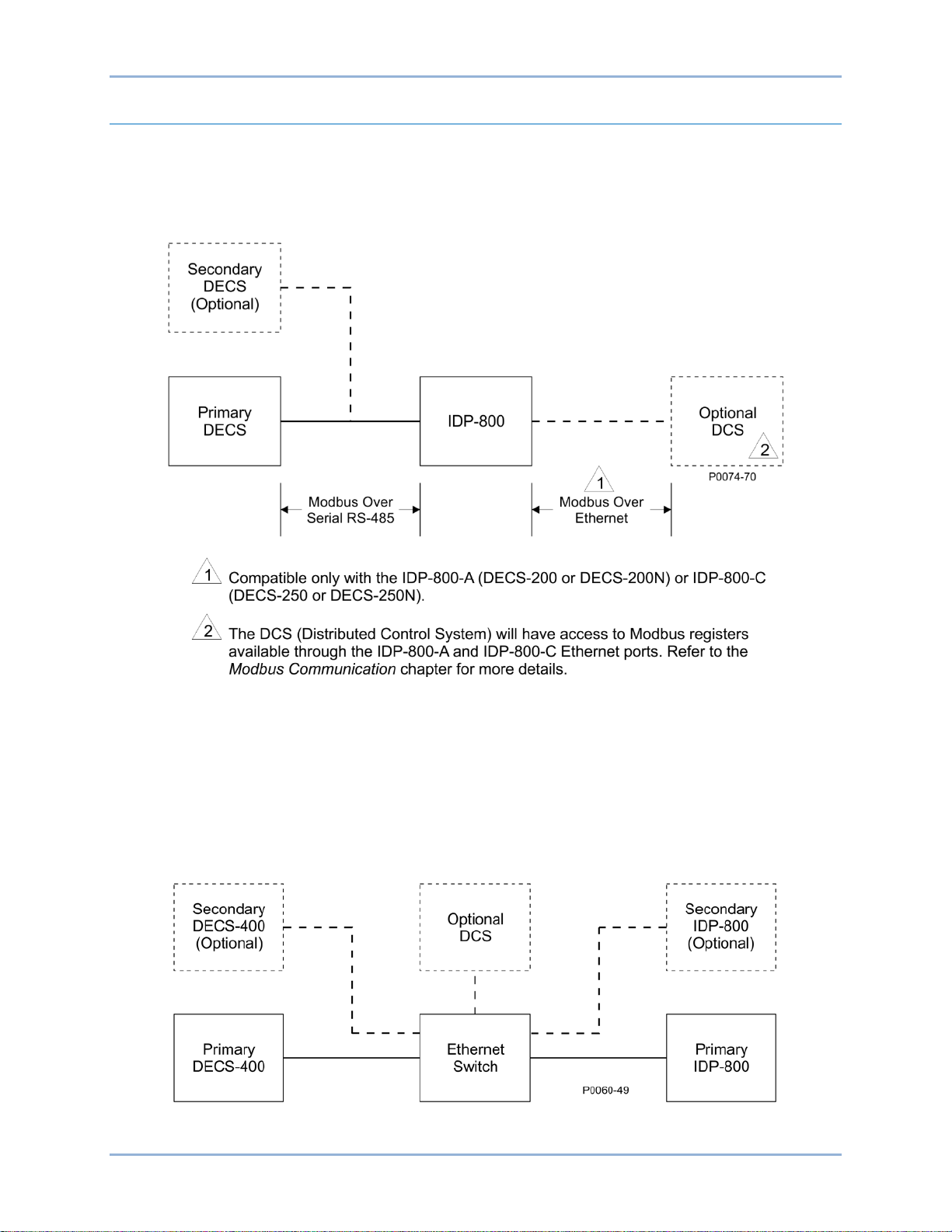

Data and commands can be exchanged between the IDP-800 and DECS-200, DECS-200N, DECS-250,

DECS-250N, or DECS-400 using serial communication. In addition to serial communication, the DECS400 has the added capability of Ethernet communication with the IDP-800. When connected to an

Ethernet LAN, the display can be polled via Modbus to acquire data collected by the DECS-400

connected to the IDP-800.

DECS and IDP-800 communication applications are summarized in Table 1.

Table 1. DECS and IDP-800 Communication Applications

[Communication Method]

[Serial, RS-485]

[Serial, RS-485]

[Serial, RS-485]

[Serial, RS-485]

[Serial, RS-485]

[Ethernet] ‡

∗ Distributed Contr ol Sy stem ( DC S) interfac e offer s pass -through communication to/from the

DECS-200, DECS-200N, DECS-250, or DECS-250N via the IDP-800 Ethernet port.

† Requires two IDP-800 display panels.

‡ Requires a multi-port Ethernet switch between an IDP-800 and single- or dual-DECS-400

controllers. An open port on the switch enables external (DCS) control and monitoring

communication between the IDP-800 and DECS-400.

YES YES N/A YES

YES YES N/A YES

YES YES N/A YES

YES YES N/A YES

YES YES YES N/A

YES YES YES YES

Remote

Local and

Serial Communication

When the IDP-800 will be communicating with a DECS using RS-485 serial communication, the DECS

communication settings should be configured as follows:

• Baud: 9600

• Data length: 8

• Parity: None

• Stop bits: 2

• Single DECS address: 247

• Dual DECS address: 247 (DECS-A) and 246 (DECS-B)

IDP-800 Communication

Page 10

4 9437600990 Rev F

Ethernet Communication

An Ethernet port enables the IDP-800 to be polled over a LAN/Distributed Control System and provide

values of system parameters monitored by the DECS-200, DEC S-200N, DECS-250, or DECS-250N.

Figure 2 serves as a general illustration of how the IDP-800 can be used to retrieve DECS data over an

Ethernet LAN. The IDP-800-A and IDP-800-C’s 10 Base-T Ethernet interface connects to a LAN through

a standard RJ-45 modular jack. This jack is located on the bottom of the display.

Figure 2. IDP-800 Link Between DECS and Ethernet LAN

IDP-800 Modbus registers for the available DECS functions are listed in the Modbus Communication

chapter. Specific information about the Modbus communication protocol, as it is employed by the DECS,

is provided in Basler publication 9360100990 (DECS-200), 9388800990 (DECS-200N), 9440300990

(DECS-250), and 9440500990 (DECS-250N).

An Ethernet port (Com 3) on the DECS-400 enables communication with the IDP-800 at higher speeds

than possible through the DECS-400 RS-485 port. An Ethernet switch is used to route IDP-800 and

DECS-400 communication over a LAN. A general connection scheme for IDP-800 and DECS-400

communication over an Ethernet LAN is illustrated in Figure 3.

Figure 3. IDP-800 and DECS-400 LAN Communication

Communication IDP-800

Page 11

9437600990 Rev F 5

Caution

For IDP-800 polling to take place, its IP address must be configured to accommodate your Ethernet LAN.

Perform the following steps to view the IDP-800 communication settings and configure its IP address.

The following procedure must be performed with the generator or

motor offline. Communication between the IDP-800 and DECS will

cease during configuration of the IP address.

1. Press the upper, right corner of the display screen followed by the lower, left corner in quick

succession.

2. Press the Offline button.

3. When prompted, enter the offline mode access password. The factory-default password is

“basler”.

4. At the next prompt, enter the system password. The factory-default password is “4376”.

5. Press the Main Unit Settings button.

6. Press the Ethernet Local Settings button.

7. Configure the IP address to be compatible with your network. If needed, consult your network

administrator for the proper settings.

8. Press the Exit button.

9. Press the Yes button. The display will restart and activate the new communication settings.

IDP-800 Communication

Page 12

6 9437600990 Rev F

Communication IDP-800

Page 13

9437600990 Rev F 7

IDP-800-A Operation

The IDP-800-A is applied in applications using the DECS-200 and DECS-200N. The IDP-800-B is applied

in applications using the DECS-400. The IDP-800-C is applied in applications using the DECS-250 and

DECS-250N. See Figure 1 for IDP-800 style definitions. This chapter describes IDP-800-A operation and

screen navigation. For DECS-400 applications, see the IDP-800-B Operation chapter. For DECS-250 and

DECS-250N applications, see the IDP-800-B Operation chapter.

IDP-800 screen appearance and availability will vary according to the type of DECS used and the

configuration of the DECS system (single or dual DECS and generator or motor control).

DECS and generator/motor system parameters are viewed and controlled through interactive screens

displayed by the IDP-800. Screens are organized according to function. Navigation between screens and

control of functions are achieved by touching “buttons” on the IDP-800 screens.

Configuration Screens

Two configuration screens establish DECS and IDP-800 o perat ing mo des : IDP-800 Configuration and

Screen Configuration. These configuration screens are available upon initial power-up of the IDP-800.

After initial configuration, these screens can be accessed through the Main View screen by entering the

appropriate password.

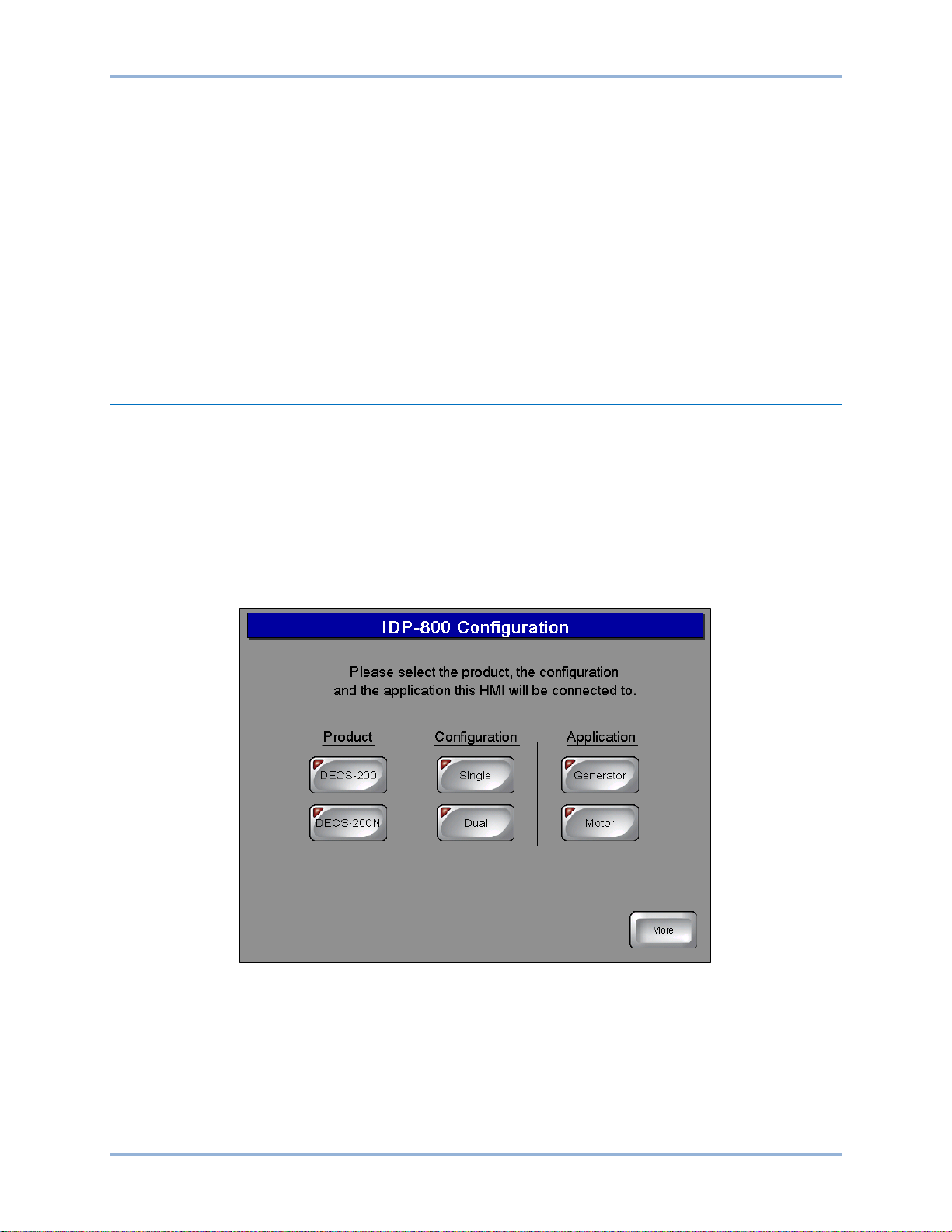

IDP-800 Configuration

Upon initial power-up, the IDP-800 displays the IDP-800 Configuration screen (Figure 4) where your

product, product configuration, and application must be selected before proceeding to other IDP-800

screens. Failure to make the proper selections may cause the IDP-800 to annunciate false alarms.

Figure 4. IDP-800 Configuration Screen

Screen Configuration

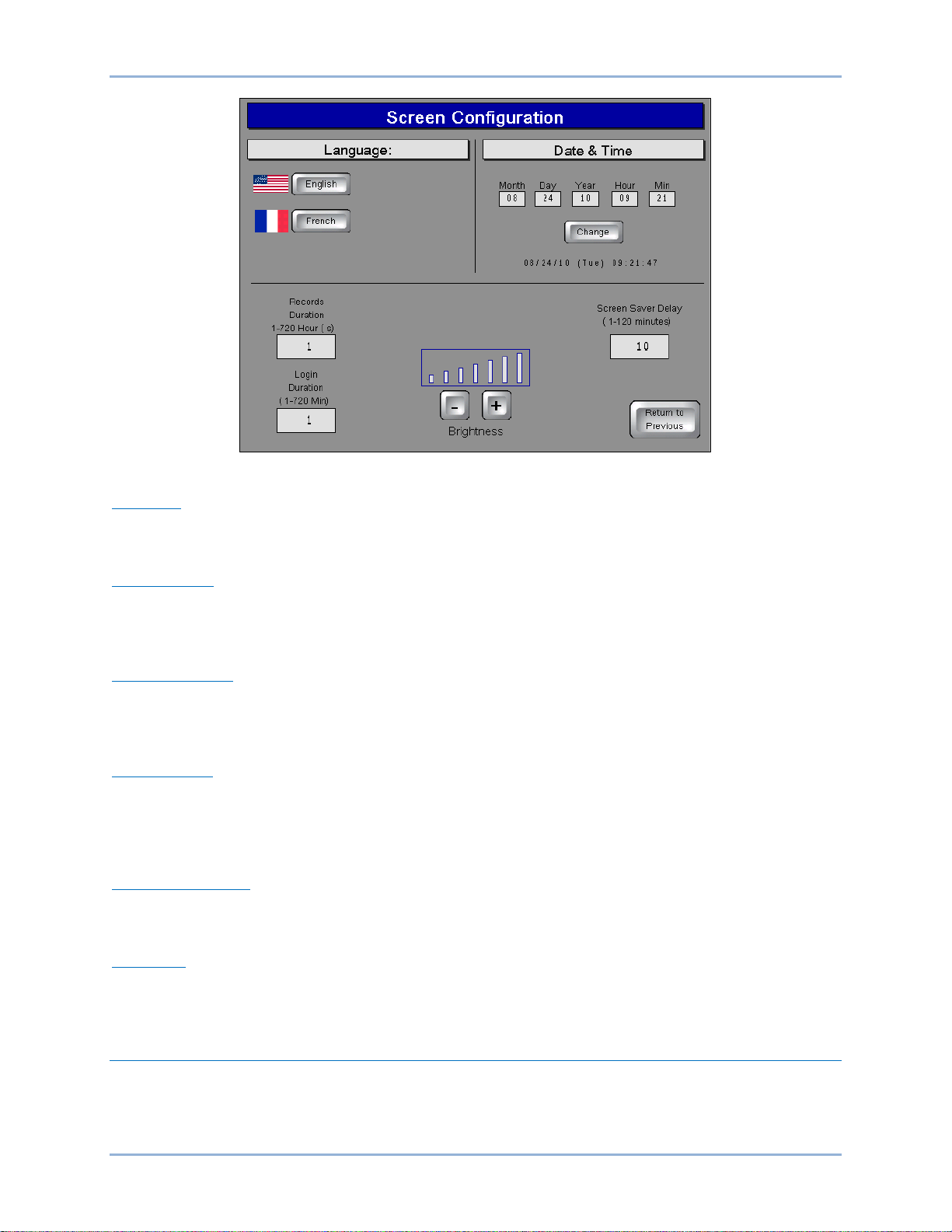

Pressing the More button on the IDP-800 Configuration screen accesses the Screen Configuration screen

(Figure 5) which enables selection of the IDP-800 language, date and time, and other IDP-800 operating

preferences. Individual screen functions are described in the following paragraphs.

IDP-800 IDP-800-A Operation

Page 14

8 9437600990 Rev F

Figure 5. Screen Configuration

Language

Pressing the English (or Anglais) button selects English as the IDP-800 disp lay language. Pressing the

French (or Francais) button selects French as the display language.

Date and Time

The date and time of the IDP-800 must be set manually to match the date and time of the connected

DECS. Enter the desired values in the date and time fields and press the Change button to save the

values.

Records Duration

Trending records saved by the IDP-800 retain up to six variables per record with each record consisting of

2,400 data points. Trending records saved by the IDP-800 can have a user-defined duration ranging from

1 hour to 720 hours (30 days). Note: requires installation of a compact flash memory card.

Login Duration

Following login, the length of time that pass wor d acc es s is available (if no butt on pres s es occ ur) is limited

by the value of this setting. If no button presses are received for the duration of the setting, password

access is lost and the user must log in again to make changes requiring password access. Login Duration

is adjustable over the range of 1 to 720 minutes (12 hours).

Screen Saver Delay

A screensaver activates if no button presses are received at the display panel for the length of time

specified by the Screen Saver Delay. A setting of 1 to 120 minutes may be entered.

Brightness

Display panel brightness can be adjusted by pressing the “+” and “–“ buttons. A bar graph above the

buttons serves as a reference for adjusting the display brightness .

Main View Screen

This screen (Figure 6) serves as a gateway to the IDP-800 status and control screens. It also provides

access to file transfer functions and a screen lock to enable panel cleaning. The Login button can be used

to enter the appropriate password and gain access to the configuration screens.

IDP-800-A Operation IDP-800

Page 15

9437600990 Rev F 9

Access to the control screens is possible only when logged into the IDP-800 w ith the correct password.

As a result, the Control button is visible only when logged into the IDP-800.

Figure 6. Main View Screen

IDP-800 Passwords

Four passwords protect the IDP-800 from unauthorized settings changes, control commands, and

transfers offline.

Two of the passwords are used when transferring the IDP-800 offline. When taking the IDP-800 offline,

the offline and system passwords are used. The IDP-800 is del iver ed with a system password of “4376”

and an offline mode access password of “basler”.

A factory-default password of “IDP8” gives access to IDP-800 configuration and control functions.

A factory-default password of “DECS2” gives access to only the IDP-800 control functions.

Password access remains in effect based on display panel activity and the limit set by the Login Duration

setting (Screen Configuration screen).

Gaining Password Access

The following example describes the process for using a password to gain configuration and control

access.

1. Press the Login button on the Main View screen.

2. Use the alphanumeric keypad to enter the appropriate password and press the Enter button. The

factory-default password is IDP8 and is case-sensitive.

Once the correct password is entered, the Main View screen is displayed with a Control button that

provides access to the control screens and a Configure button that provides access to the configuration

screens.

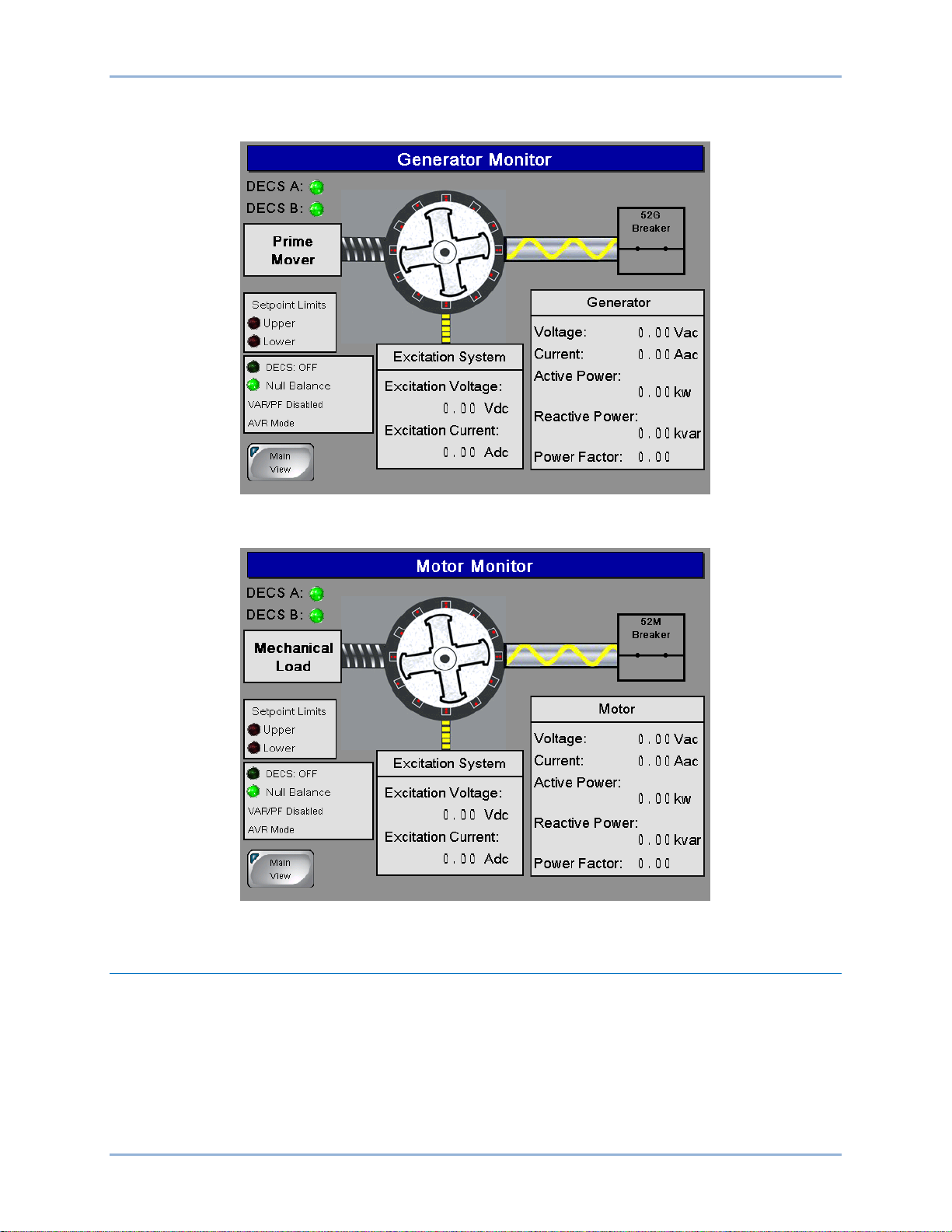

Generator/Motor Monitor

Depending upon the application selected on the IDP-800 Configuration screen, either the Generator

Monitor screen or the Motor Monitor screen is accessed by pressing the Generator Monitor button or

Motor Monitor button of the Main View screen. The Generator Monitor or Motor Monitor screen graphically

illustrates generator/motor and excitation system status/activity. Generator and motor parameters include

output voltage, output current, active (true) power, reactive power, and power factor. Excitation system

IDP-800 IDP-800-A Operation

Page 16

10 9437600990 Rev F

parameters include field voltage, field current, and excitation on/off status. The Generator Monitor screen

is shown in Figure 7 and the Motor Monitor screen is shown in Figure 8.

Figure 7. Generator Monitor Screen

Figure 8. Motor Monitor Screen

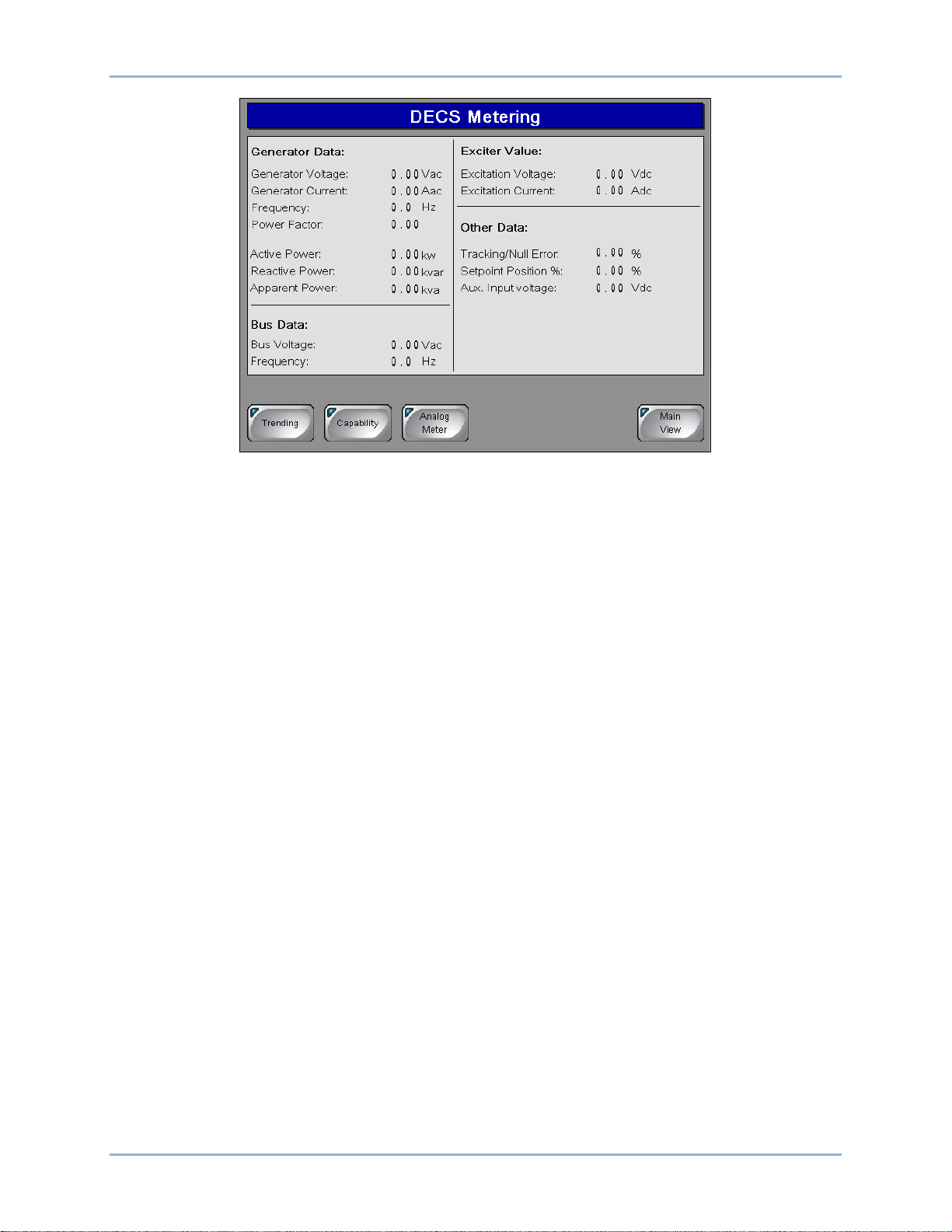

DECS Metering Screen

This screen (Figure 9) is accessed by pressing the Metering button of the Main View screen. The DECS

Metering screen displays digital metering values for the generator or motor, bus, and exciter field as well

as the excitation setpoint position and control values.

Access to the Trending and Capability Curve screens is also provided through the Trending and

Capability buttons on the DECS Metering screen.

IDP-800-A Operation IDP-800

Page 17

9437600990 Rev F 11

Figure 9. DECS Metering Screen

Analog Metering

Pressing the Analog Meter button accesses the analog representations of the digital values displayed on

the DECS Metering screen. Analog metering values are divided among three screens accessed through

buttons labeled Generator Values, Generator Power, and Exciter Values. Each p ar amet er is repres e nte d

by an analog meter along with the digital version of the metered value.

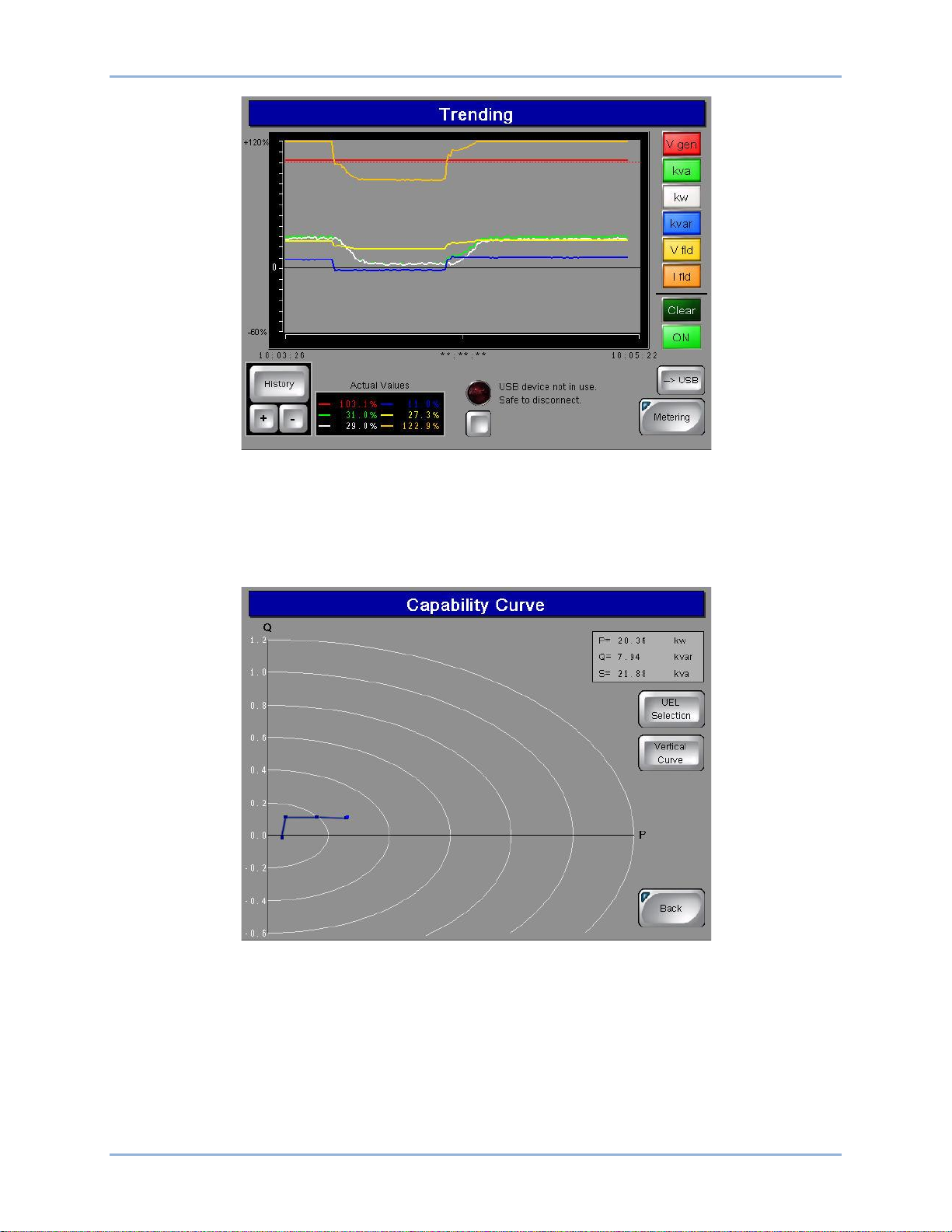

Trending

The Trending screen (Figure 10) is accessed by pressing the Trending button of the DECS Metering

screen. Several system parameters can be selected and monitored over time in an amplitude-versus-time

window. Buttons on the Trending screen enable selection of the parameters to be monitored. Available

parameters include generator voltage (Vgen), apparent power (kVA), true power (kW), reactive power

(kvar), field voltage (Vexc), and field current (Iexc). Parameters are plotted in a color that matches the

color of the parameter buttons. Pressing the History button displays additional controls and a display for

manipulating the cursor position within a data plot. Pressing the USB button transfers the trending data to

a connected USB memory device. Storage of trending information requires the installation of a compact

flash memory card.

IDP-800 IDP-800-A Operation

Page 18

12 9437600990 Rev F

Figure 10. Trending Screen

Capability

This screen (Figure 11) is accessed by pressing the Capability button on the DECS Metering screen. By

default, a horizontal curve is displayed. Pressing the Vertical Curve button selects a vertical curve

orientation.

Figure 11. Capability Curve Screen

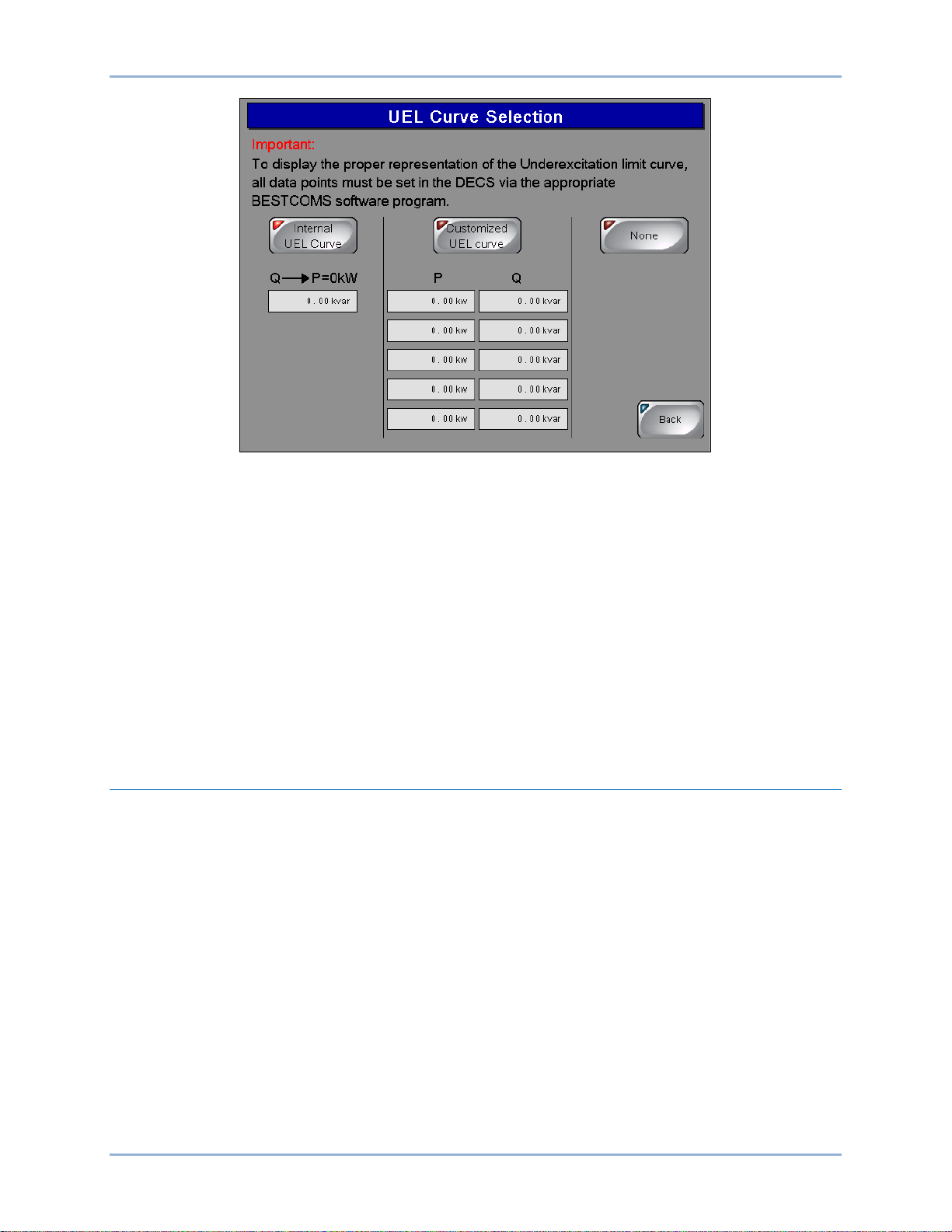

If a plot of the underexcitation limiter (UEL) curve is desired, the UEL Selection button can be pressed to

access the UEL Curve Selection screen (Figure 12). Here, the internal DECS UEL curve can be selected

or a customized, three-point, four-point, or five-point curve can be selected and configured. UEL curve

points must be selected in the DECS BESTCOMS software for an accurate representation on the

IDP-800. Pressing the None button disables the display of UEL curves.

IDP-800-A Operation IDP-800

Page 19

9437600990 Rev F 13

Figure 12. UEL Curve Selection Screen

DECS Analog Metering

Analog representations of the digital metering values shown on the DECS Metering screen (Figure 9) can

be accessed by pressing the Analog Meter button. Pressing this button accesses the Generator Values or

Motor Values screen which displays analog representations of the generator/motor voltage, current,

frequency, and power factor. Each analog representation displays the digital equivalent in the upper, left

corner. The remaining analog metering values are divided between two screens: the Generator Power or

Motor Power screen and the Exciter values screen. The Generator Power or Motor Power screen is

accessed from the Generator/Motor Values screen or Exciter Values screen by pressing the Generator

Power or Motor Power button. This screen displays analog representations of the generator/motor active

power, reactive power, and apparent power. The Exciter Values screen is accessed from the

Generator/Motor Values screen or Generator/Motor Power screen by pressing the Exciter Values butt on.

This screen displays analog representations of the excitation voltage and current. A Digital Meter button,

on each analog metering screen, can be pressed to return to the DECS (digital) Metering screen.

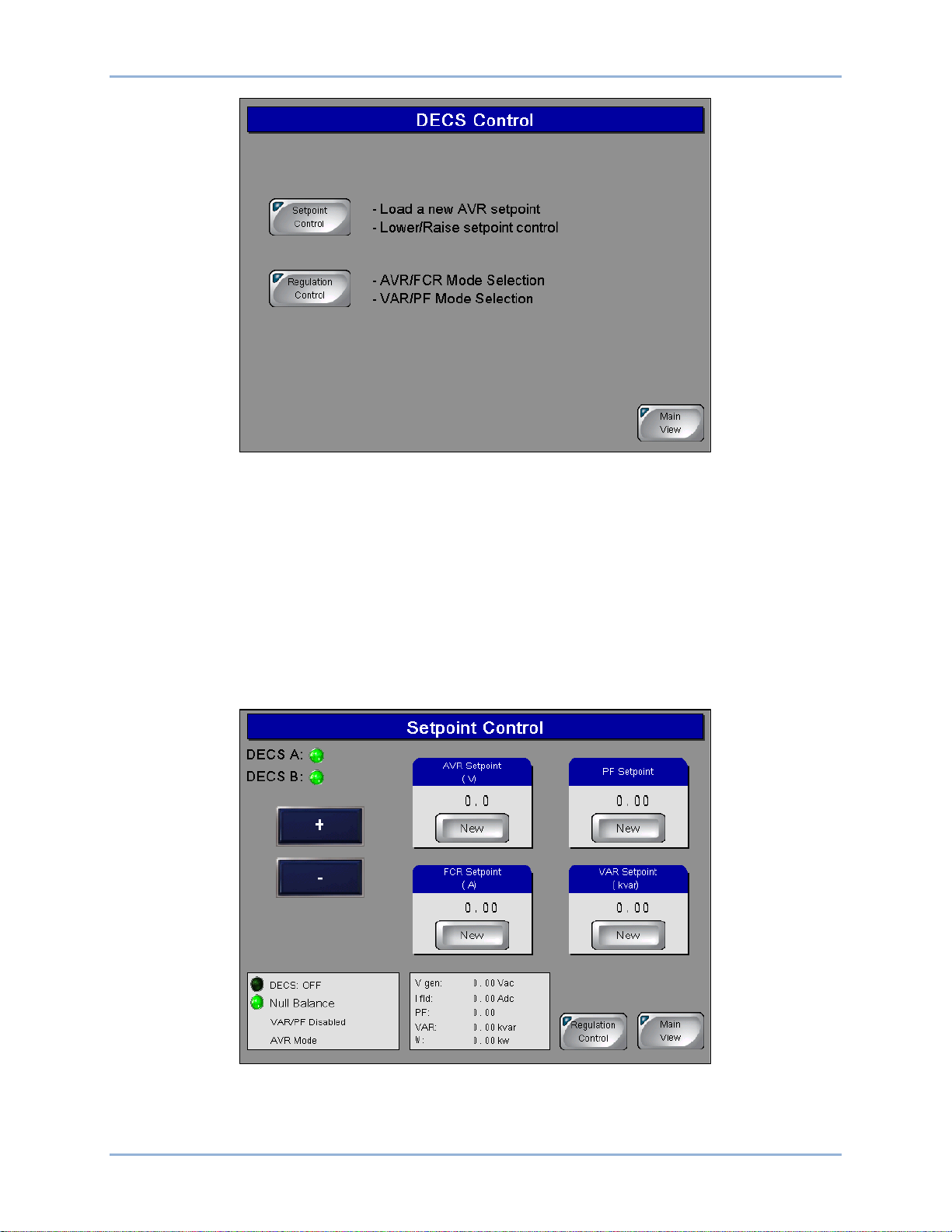

DECS Control

Access to the DECS Control screen is possible only when logged in with the appropriate password. When

logged in, a Control button on the Main View screen provides access to the DECS Control screen

illustrated in Figure 13. DECS control functions are divided between two screens: Setpoint Control and

Regulation Control.

IDP-800 IDP-800-A Operation

Page 20

14 9437600990 Rev F

Figure 13. DECS Control Screen

Setpoint Control

Pressing the Setpoint Control button accesses the Setpoint Control screen (Figure 14). This screen

displays the DECS-200/200N AVR, FCR, power factor, and var setpoints and provides two methods of

setpoint adjustment. The “+” and “–“ buttons can be pressed to increment and decrement the active

setpoint. A specific setpoint can be entered for any of the four setpoints. Pressing the New button

associated with the setpoint to be changed accesses a Setpoint Adjustment screen that displays the

current setpoint value along with the minimum and maximum limits for the setting. Touching the setting

field area displays a numeric keypad where the new value can be entered.

The Setpoint Control screen also has system status indicators and a metering display for generator and

excitation system parameters.

Figure 14. Setpoint Control Screen

IDP-800-A Operation IDP-800

Page 21

9437600990 Rev F 15

Regulation Control

Pressing the Regulation Control button accesses the Regulation Control screen (Figure 15). This screen

enables selection of the active regulation mode. The MAN/AVR button toggles between Manual and Auto

modes. When operating in AVR mode, the Off, PF, and VAR buttons can be used to enable or disable

regulation of vars or power factor. Each change to the regulation mode requires a confirmation via an

accept/reject dialog box.

The Regulation Control screen also has system status indicators and a metering display for

generator/motor and excitation system parameters.

Figure 15. Regulation Control Screen

Alarms and Status

Two screens annunciate the state of DECS alarms, functions, limiters, and relay outputs. Depending upon

the annunciation, active indicators change to amber, green, or red when active.

Pressing the Alarms/Status button of the Main View screen displays the Alarms and Status screen (Figure

16). This screen has indicators for alarms, limiter states, and DECS functions/conditions. An Alarms

Reset button can be pressed to clear alarm annunciations. (An alarm cannot be reset unless the condition

causing the alarm has been cleared.) Pressing the History button accesses the Alarms History screen

which lists the alarms captured by the DECS. Buttons are provided for scrolling through the alarms list,

clearing selected alarms, and clearing all listed alarms. A USB button enables the transfer of selected

alarm records to a memory device plugged into the IDP-800 U SB po rt .

IDP-800 IDP-800-A Operation

Page 22

16 9437600990 Rev F

Figure 16. Alarms and Status Screen

Pressing the Relay Status button on the Alarms and Status screen displays the DECS Relay Status

screen (Figure 17). This screen has indicators for DECS relay output contacts status (open or closed) and

a matrix of indicators showing each relay output and the condition causing the relay output to energize.

Pressing the Back button returns the display to the Alarms and Status screen.

Figure 17. DECS Relay Status Screen

IDP-800-A Operation IDP-800

Page 23

9437600990 Rev F 17

IDP-800-B Operation

The IDP-800-B is applied in applications using the DECS-400. The IDP-800-A is applied in applications

using the DECS-200 and DECS-200N. The IDP-800-C is applied in applications using the DECS-250 and

DECS-250N. See Figure 1 for IDP-800 style definitions. This chapter describes IDP-800-B operation and

screen navigation. For DECS-200 and DECS-200N applications, see the IDP-800-A Operation chapter.

For DECS-250 and DECS-250N applications, see the IDP-800-C Operation chapter.

IDP-800 screen appearance and availability will vary according to the type of DECS used and the

configuration of the DECS system (single or dual DECS and generator or motor control).

DECS and generator/motor system parameters are viewed and controlled through interactive screens

displayed by the IDP-800. Screens are organized according to function. Navigation between screens and

control of functions are achieved by touching “buttons” on the IDP-800 screens.

Configuration Screens

Two configuration screens establish DECS and IDP-800 o perat ing mo des : IDP-800 Configuration and

Screen Configuration. These configuration screens are available upon initial power-up of the IDP-800.

After initial configuration, these screens can be accessed through the Main View screen by entering the

appropriate password.

IDP-800 Configuration

Upon initial power-up, the IDP-800 displays the IDP-800 Configuration screen (Figure 18) where your

product, product configuration, application, and communication method must be selected before

proceeding to other IDP-800 screens. Failure to make the proper selections may cause the IDP-800 to

annunciate false alarms.

Figure 18. IDP-800 Configuration Screen

Screen Configuration

Pressing the More button on the IDP-800 Configuration screen accesses the Screen Configuration screen

(Figure 19) which enables selection of the IDP-800 language and other operating preferences. Individual

screen preferences are described in the f ol low ing para gr aphs.

IDP-800 IDP-800-B Operation

Page 24

18 9437600990 Rev F

Language

Pressing the English (or Anglais) button selects English as the IDP-800 disp lay language. Pressing the

French (or Francais) button selects French as the display language.

Date and Time

The date and time of an IDP-800 connected to a DECS-400 is automatically synchronized with the date

(month, day, and year) and time (hours and minutes) maintained by the DECS-400.

52L/M Input Switch Number

These buttons configure the IDP-800 to monitor the same contact inputs that the DECS-400 is monitoring

for the 52L/M contact input. Pressing the Standard Logic button configures the IDP-800 to monitor contact

input 3 for 52L/M contact status, which is the default assignment in standard DECS-400 logic. Pressing

the Customized Logic button enables the user to configure the IDP-800 to monitor the 52L/M contact

input as configured in the customized DECS-400 logic.

Records Duration

Trending records saved by the IDP-800 retain up to six variables per record with each record consisting of

2,400 data points. Trending records saved by the IDP-800 can have a user-defined duration ranging from

1 hour to 720 hours (30 days). Note: requires installation of a compact flash memory card.

Figure 19. Screen Configuration Screen

Login Duration

Following login, the length of time that pass wor d acc es s is available (if no butt on pres s es occ ur) is limited

by the value of this setting. If no button presses are received for the duration of the setting, password

access is lost and the user must log in again to make changes requiring password access. Login Duration

is adjustable over the range of 1 to 720 minutes (12 hours).

Screen Saver Delay

A screensaver activates if no button presses are received at the display panel for the length of time

specified by the Screen Saver Delay. A setting of 1 to 120 minutes may be entered.

Brightness

Display panel brightness can be increased and reduced by pressing the “+” and “–“ buttons. A bar graph

above the buttons serves as a reference for adjusting the display brightness.

IDP-800-B Operation IDP-800

Page 25

9437600990 Rev F 19

Main View Screen

This screen (Figure 20) serves as a gateway to the IDP-800 status and control screens. It also provides

access to file transfer functions and a screen lock to enable panel cleaning. The Login button can be used

to enter the appropriate password and gain access to the configuration screens.

Figure 20. Main View Screen

Access to the Control button (and control screens) is possible only when logged into the IDP-800 with the

correct password.

IDP-800 Passwords

Four passwords protect the IDP-800 from unauthorized settings changes, control commands, and

transfers offline.

Two of the passwords are used when transferring the IDP-800 offline. When taking the IDP-800 offline,

the offline and system passwords are used. The IDP-800 is delivered with a system password of “4376”

and an offline mode access password of “basler”.

A factory-default password of “IDP8” gives access to IDP-800 configuration and control functions.

A factory-default password of “DECS4” gives access to only the IDP-800 control functions.

Password access remains in effect based on display panel activity and the limit set by the Login Duration

setting (Screen Configuration screen).

Gaining Password Access

The following example describes the process for using a password to gain configuration and control

access.

1. Press the Login button on the Main View screen.

2. Use the alphanumeric keypad to enter the appropriate password and press the Enter button. The

factory-default password is IDP8 and is case-sensitive.

Once the correct password is entered, the Main View screen is displayed with a Control button that

provides access to the control screens and a Configure button that provides access to the configuration

screens.

IDP-800 IDP-800-B Operation

Page 26

20 9437600990 Rev F

Generator/Motor Monitor

Depending upon the application selected on the IDP-800 Configuration screen, either the Generator

Monitor screen or Motor Monitor screen is accessed by pressing the Generator Monitor button or Motor

Monitor button of the Main View screen. The Generator Monitor or Motor Monitor screen graphically

illustrates generator/motor and excitation system status/activity. Generator and motor parameters include

output voltage, output current, active (true) power, reactive power, and power factor. Excitation system

parameters include field voltage, field current, and excitation on/off status. The Generator Monitor screen

is shown in Figure 21 and the Motor Monitor screen is shown in Figure 22.

Figure 21. Generator Monitor Screen

Figure 22. Motor Monitor Screen

IDP-800-B Operation IDP-800

Page 27

9437600990 Rev F 21

DECS Metering Screen

Access the DECS Metering screen (Figure 23) by pressing the Metering button of the Main View screen.

The DECS Metering screen displays digital metering values for the generator or motor, bus, and exciter

field as well as the excitation setpoint position and control values.

Figure 23. DECS Metering Screen

Analog Metering

Pressing the Analog Meter button accesses the analog representations of the digital values displayed on

the DECS Metering screen. Analog metering values are divided among three screens accessed through

buttons labeled Generator Values, Generator Power, and Exciter Values. Each parameter is represented

by an analog meter along with the digital version of the metered value.

Trending

Access to the Trending and Capability Curve screens is also provided through the Trending and

Capability buttons on the DECS Metering screen.

The Trending screen (Figure 24) is accessed by pressing the Trending button of the DECS Metering

screen. Several system parameters can be selected and monitored over time in an amplitude-versus-time

window. Buttons on the Trending screen enable selection of the parameters to be monitored. Available

parameters include generator voltage (Vgen), apparent power (kVA), true power (kW), reactive power

(kvar), field voltage (Vexc), and field current (Iexc). Parameters are plotted in a color that matches the

color of the parameter buttons. Pressing the History button displays additional controls and a display for

manipulating the cursor position within a data plot. Pressing the USB button accesses the Memory

Transfer screen where the data from a trending plot can be transferred to USB memory device. Storage

of trending information requires the installation of a compact flash memory card.

IDP-800 IDP-800-B Operation

Page 28

22 9437600990 Rev F

Figure 24. Trending Screen

Capability

Access the Capability screen (Figure 25) by pressing the Capability button on the DECS Metering screen.

By default, a horizontal curve is displayed. Pressing the Vertical Curve button selects a vertical curve

orientation.

Figure 25. Capability Curve Screen

If a plot of the underexcitation limiter (UEL) curves is desired, the Internal UEL Curve button can be

pressed to access the UEL Curve Selection screen (Figure 26). Here, the internal DECS UEL curve can

be selected or a customized, three-, four-, or five-point curve can be selected and configured. UEL curve

points must be selected in the DECS BESTCOMS software for an accurate representation on the

IDP-800. Pressing the None button disables the display of UEL curves.

IDP-800-B Operation IDP-800

Page 29

9437600990 Rev F 23

Figure 26. UEL Curve Selection Screen

DECS Analog Metering

Analog representations of the digital metering values shown on the DECS Metering screen (Figure 23)

can be accessed by pressing the Analog Meter button. Pressing this button accesses the Generator

Values or Motor Values screen which displays analog representations of the generator/motor voltage,

current, frequency, and power factor. Each analog representation displays the digital equivalent in the

upper, left corner. The remaining analog metering values are divided between two screens: the Generator

Power or Motor Power screen and the Exciter values screen. The Generator Power or Motor Power

screen is accessed from the Generator/Motor Values screen or Exciter Values screen by pressing the

Generator Power or Motor Power button. This screen displays analog representations of the

generator/motor active power, reactive power, and apparent power. The Exciter Values screen is

accessed from the Generator/Motor Values screen or Generator/Motor Power screen by pressing the

Exciter Values button. This screen displays analog representations of the excitation voltage and current.

A Digital Meter button, on each analog metering screen, can be pressed to return to the DECS (digital)

Metering screen.

DECS Control

Access to the DECS Control screen is possible only when logged in with the appropriate password. When

logged in, a Control button on the Main View screen provides access to the DECS Control screen

illustrated in Figure 27. This screen has two buttons: a Setpoint Control button and a Regulation Control

button.

IDP-800 IDP-800-B Operation

Page 30

24 9437600990 Rev F

Figure 27. DECS Control Screen

Setpoint Control

Pressing the Setpoint Control button accesses the Setpoint Control screen (Figure 28). This screen

displays the DECS-400 AVR, FCR, power factor, and var setpoints and provides two methods of setpoint

adjustment. The “+” and “–“ buttons can be pressed to increment and decrement the active setpoint. A

specific setpoint can be entered for any of the four setpoints. Pressing the New button associated with the

setpoint can be entered for any of the four setpoints. Pressing the New button associated with the

setpoint to be changed accesses a Setpoint Adjustment screen that displays the current setpoint value

along with the minimum and maximum limits for the setting. Touching the setting field area displays a

numeric keypad where the new value can be entered.

The Setpoint Control screen also has system status indicators and a metering display for generator and

excitation system parameters.

Figure 28. Setpoint Control Screen

IDP-800-B Operation IDP-800

Page 31

9437600990 Rev F 25

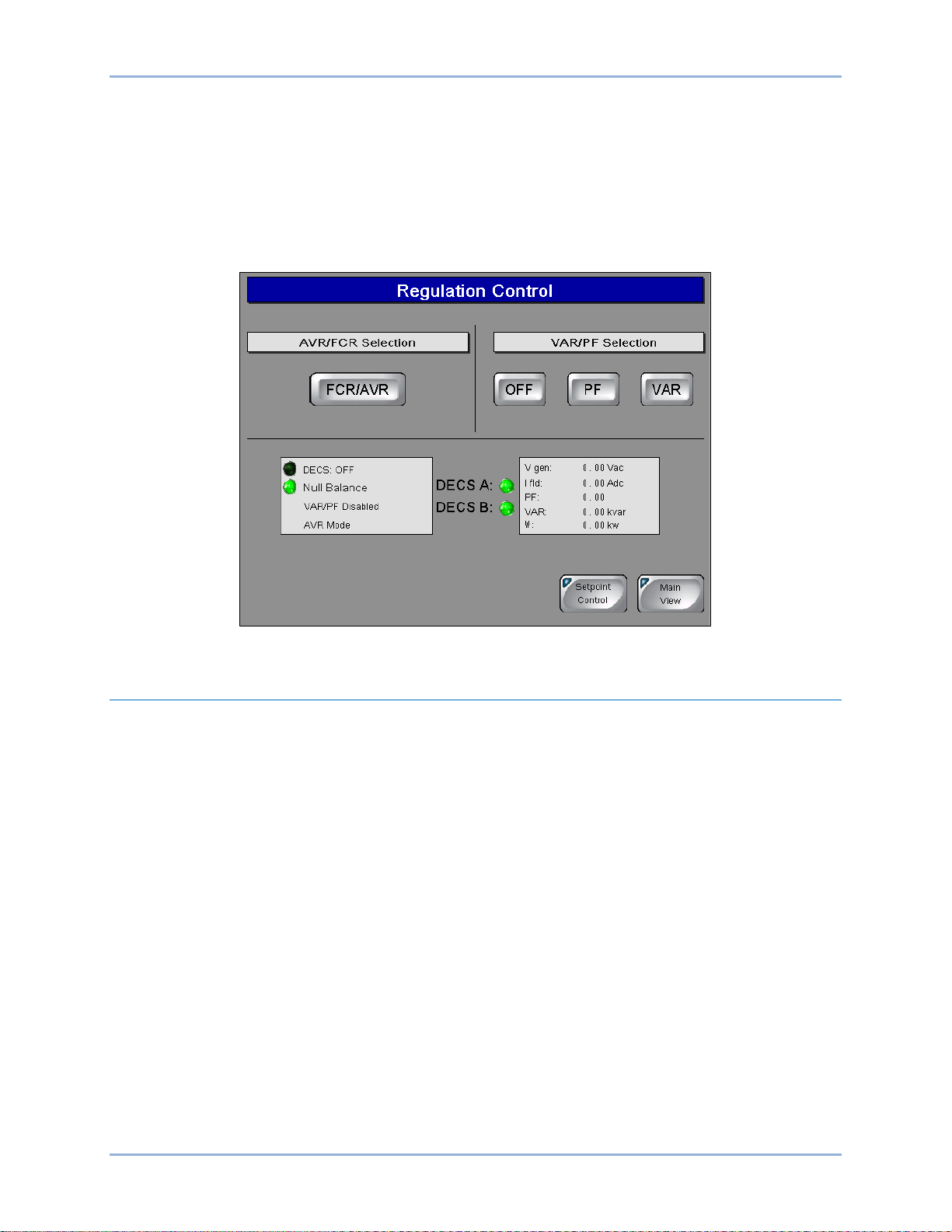

Regulation Control

Pressing the Regulation Control button accesses the Regulation Control screen (Figure 29). This screen

enables selection of the active regulation mode. The MAN/AVR button toggles between Manual and Auto

modes. When operating in AVR mode, the OFF, PF, and VAR buttons can be used to enable or disable

regulation of vars or power factor. Each change to the regulation mode requires a confirmation via an

accept/reject dialog box.

The Regulation Control screen also has system status indicators and a metering display for

generator/motor and excitation system parameters.

Figure 29. Regulation Control Screen

Alarms and Status

Three screens annunciate the state of DECS-400 alarms, functions, limiters, and relay outputs.

Depending upon the annunciation, active indicators change to amber, green, or red when active.

The Activated Alarms screen (Figure 30) is accessed from the Main View screen by pressing the

Alarm/Status button. It can also be accessed from the DECS Status screen by pressing the Alarms

button. This screen has indicators for active DECS-400 alarms, power system stabilizer status, and

IDP-800 inputs and clock status. An Alarms Reset button can be pressed to clear alarm annunciations.

(An alarm cannot be cleared unless the condition causing the alarm has been cleared.) Pressing the

History button accesses the Alarms History screen which lists the alarms captured by the DECS-400.

Buttons are provided for scrolling through the alarms list, clearing selected alarms, and clearing all listed

alarms. A USB button enables the transfer of selected alarm records to a memory device plugged into

the IDP-800 USB port.

IDP-800 IDP-800-B Operation

Page 32

26 9437600990 Rev F

Figure 30. Activated Alarms Screen

The DECS I/O Status screen (Figure 31) is accessed from the Activated Alarms screen or the DECS

Status screen by pressing the I/O Status button. This screen has indicators for the status of the

DECS-400 contact inputs and relay outputs.

Figure 31. DECS I/O Status Screen

The DECS Status screen (Figure 32) is accessed from the Activated Alarms screen by pressing the

Status button. This screen has indicators for DECS-400 operating conditions, DECS-400 setting groups,

and DECS-400 limiters.

IDP-800-B Operation IDP-800

Page 33

9437600990 Rev F 27

Figure 32. DECS Status Screen

IDP-800 IDP-800-B Operation

Page 34

28 9437600990 Rev F

IDP-800-B Operation IDP-800

Page 35

9437600990 Rev F 29

IDP-800-C Operation

The IDP-800-C is applied in applications using the DECS-250 or DECS-250N. The IDP-800-A is applied

in applications using the DECS-200 or DECS-200N. The IDP-800-B is applied in applications us ing the

DECS-400. See Figure 1 for IDP-800 style definitions. This chapter describes IDP-800-C operation and

screen navigation. For DECS-200 and DECS-200N applications, see the IDP-800-A Operation chapter.

For DECS-400 applications, see the IDP-800-B Operation chapter.

IDP-800 screen appearance and availability will vary according to the type of DECS used and the

configuration of the DECS system (single or dual DECS and generator or motor control).

DECS and generator/motor system parameters are viewed and controlled through interactive screens

displayed by the IDP-800. Screens are organized according to function. Navigation between screens and

control of functions are achieved by touching “buttons” on the IDP-800 screens.

Configuration Screens

Two configuration screens establish DECS and IDP-800 o perat ing mo des : IDP-800 Configuration and

Screen Configuration. These configuration screens are available upon initial power-up of the IDP-800.

After initial configuration, these screens can be accessed through the Main View screen by entering the

appropriate password.

IDP-800 Configuration

Upon initial power-up, the IDP-800 displays the IDP-800 Configuration screen (Figure 33) where your

product, product configuration, and application must be selected before proceeding to other IDP-800

screens. Failure to make the proper selections may cause the IDP-800 to annunciate false alarms.

Figure 33. IDP-800 Configuration Screen

Screen Configuration

Pressing the More button on the IDP-800 Configuration screen accesses the Screen Configuration screen

(Figure 34) which enables selection of the IDP-800 date and time, and other IDP-800 operating

preferences. Individual screen functions are described in the following paragraphs.

IDP-800 IDP-800-C Operation

Page 36

30 9437600990 Rev F

Figure 34. Screen Configuration

Date and Time

The date and time of the IDP-800 must be set manually to match the date and time of the connected

DECS. Enter the desired values in the date and time fields and press the Change button to save the

values.

Records Duration

Trending records saved by the IDP-800 retain up to six variables per record with each record consisting of

2,400 data points. Trending records saved by the IDP-800 can have a user-defined duration ranging from

1 hour to 720 hours (30 days). Note: requires installation of a compact flash memory card.

Login Duration

Following login, the length of time that pass wor d acc es s is available (if no butt on pres s es occ ur) is limited

by the value of this setting. If no button presses are received for the duration of the setting, password

access is lost and the user must log in again to make changes requiring password access. Login Duration

is adjustable over the range of 1 to 720 minutes (12 hours).

Screen Saver Delay

A screensaver activates if no button presses are received at the display panel for the length of time

specified by the Screen Saver Delay. A setting of 1 to 120 minutes may be entered.

Brightness

Display panel brightness can be adjusted by pressing the “+” and “–“ buttons. A bar graph above the

buttons serves as a reference for adjusting the display brightness.

Main View Screen

The Main View screen (Figure 35) serves as a gateway to the IDP-800 status and control screens. It also

provides access to file transfer functions and a screen lock to enable panel cleaning. The Login button

can be used to enter the appropriate password and gain access to the configuration screens.

Access to the control screens is possible only when logged into the IDP-800 with the correct password.

As a result, the Control button is visible only when logged into the IDP-800.

IDP-800-C Operation IDP-800

Page 37

9437600990 Rev F 31

Figure 35. Main View Screen

IDP-800 Passwords

Four passwords protect the IDP-800 from unauthorized settings changes, control commands, and

transfers offline.

Two of the passwords are used when transferring the IDP-800 offline. When taking the IDP-800 offline,

the offline and system passwords are used. The IDP-800 is delivered with a system password of “4376”

and an offline mode access password of “basler”.

A factory-default password of “IDP8” gives access to IDP-800 configuration and control functions.

A factory-default password of “DECS2” gives access to only the IDP-800 control functions.

Password access remains in effect based on display panel activity and the limit set by the Login Duration

setting (Screen Configuration screen).

Gaining Password Access

The following example describes the process for using a password to gain configuration and control

access.

1. Press the Login button on the Main View screen.

2. Use the alphanumeric keypad to enter the appropriate password and press the Enter button. The

factory-default password is IDP8 and is case-sensitive.

Once the correct password is entered, the Main View screen is displayed with a Control button that

provides access to the control screens and a Configure button that provides access to the configuration

screens.

Generator/Motor Monitor

Depending upon the application selected on the IDP-800 Configuration screen, either the Generator

Monitor screen or the Motor Monitor screen is accessed by pressing the Generator Monitor button or

Motor Monitor button of the Main View screen. The Generator Monitor or Motor Monitor screen graphically

illustrates generator/motor and excitation system status/activity. Generator and motor parameters include

output voltage, output current, active (true) power, reactive power, and power factor. Excitation system

parameters include field voltage, field current, and excitation on/off status. The Generator Monitor screen

is shown in Figure 36 and the Motor Monitor screen is shown in Figure 37.

IDP-800 IDP-800-C Operation

Page 38

32 9437600990 Rev F

Figure 36. Generator Monitor Screen

Figure 37. Motor Monitor Screen

DECS Metering Screen

The DECS Metering screen (Figure 38) is accessed by pressing the Metering button of the Main View

screen. The DECS Metering screen displays digital metering values for the generator or motor, bus, and

exciter field as well as the excitation setpoint position and control values.

Access to the Trending, Capability Curve, Analog Meter, and DECS Status screens is also provided

through the buttons at the bottom of the DECS Metering screen.

IDP-800-C Operation IDP-800

Page 39

9437600990 Rev F 33

Figure 38. DECS Metering Screen

Trending

The Trending screen (Figure 39) is accessed by pressing the Trending button of the DECS Metering

screen. Several system parameters can be selected and monitored over time in an amplitude-versus-time

window. Buttons on the Trending screen enable selection of the parameters to be monitored. Available

parameters include generator voltage (Vgen), apparent power (kVA), true power (kW), reactive power

(kvar), field voltage (Vexc), and field current (Iexc). Parameters are plotted in a color that matches the

color of the parameter buttons. Pressing the History button displays additional controls and a display for

manipulating the cursor position within a data plot. Pressing the USB button transfers the trending data to

a connected USB memory device. Storage of trending information requires the installation of a compact

flash memory card.

Figure 39. Trending Screen

IDP-800 IDP-800-C Operation

Page 40

34 9437600990 Rev F

Capability

The Capability screen (Figure 40) is accessed by pressing the Capability button on the DECS Metering

screen. By default, a horizontal curve is displayed. Pressing the Vertical Curve button selects a vertical

curve orientation.

Figure 40. Capability Curve Screen

If a plot of the underexcitation limiter (UEL) curve is desired, the UEL Selection button can be pressed to

access the UEL Curve Selection screen (Figure 41). Here, the internal DECS UEL curve can be selected

or a customized, three-point, four-point, or five-point curve can be selected and configured. UEL curve

points must be selected in BESTCOMSPlus® software for an accurate representation on the

IDP-800. Pressing the None button disa bles the display of UEL curves.

Figure 41. UEL Curve Selection Screen

Analog Metering

Analog representations of the digital metering values shown on the DECS Metering screen (Figure 38)

can be accessed by pressing the Analog Meter button. Pressing this button accesses the Generator

IDP-800-C Operation IDP-800

Page 41

9437600990 Rev F 35

Values or Motor Values screen (Figure 42) which displays analog representations of the generator/motor

voltage, current, frequency, and power factor.

Figure 42. Generator Values Screen

Each analog representation displays the digital equivalent in the upper, left corner. The remaining analog

metering values are divided between two screens: the Generator Power or Motor Power screen and the

Exciter values screen.

The Generator Power or Motor Power screen is accessed from the Generator/Motor Values screen or

Exciter Values screen by pressing the Generator Power or Motor Power button. This screen displays

analog representations of the generator/motor active power, reactive power, and apparent power.

The Exciter Values screen is accessed from the Generator/Motor Values screen or Generator/Motor

Power screen by pressing the Exciter Values button. This screen displays analog representations of the

excitation voltage and current. A Digital Meter button, on each analog metering screen, can be pressed to

return to the DECS (digital) Metering screen.

Status, I/O, and Alarm Screens

The Status Index screen (Figure 43) is accessed by pressing the Status Index button of the Main View

screen. This screen provides access to alarms, alarm history, input/output status, DECS status,

configurable protection, and AEM inputs.

IDP-800 IDP-800-C Operation

Page 42

36 9437600990 Rev F

Figure 43. Status Index Screen

Alarm Status

The Alarm Status screen (Figure 44) shows active protection alarms and general alarms. Depending

upon the annunciation, active indicators change to amber, green, or red when active. An Alarms Reset

button can be pressed to clear alarm annunciations. (An alarm cannot be reset unless the condition

causing the alarm has been cleared.)

Figure 44. Alarm Status Screen

Alarms History

Pressing the History button accesses the Alarms History screen (Figure 45) which lists the alarms

captured by the DECS. Buttons are provided for scrolling through the alarms list, clearing selected

alarms, and clearing all listed alarms. A USB button enables the transfer of selected alarm records to a

memory device plugged into the IDP-800 USB port.

IDP-800-C Operation IDP-800

Page 43

9437600990 Rev F 37

Figure 45. Alarms History Screen

Programmable Alarms

The Programmable Alarms screen (Figure 46) shows active programmable alarms. An Alarms Reset

button can be pressed to clear alarm annunciations. (An alarm cannot be reset unless the condition

causing the alarm has been cleared.)

Figure 46. Programmable Alarms Screen

Configurable Protection

The Configurable Protection screen (Figure 47) shows configurable protection alarms. An alarm is active

when the configurable protection threshold has been exceeded. An Alarms Reset button can be pressed

to clear alarm annunciations. (An alarm cannot be reset unless the condition causing the alarm has been

cleared.)

IDP-800 IDP-800-C Operation

Page 44

38 9437600990 Rev F

Figure 47. Configurable Protection Screen

DECS Status

The Status screen (Figure 48) shows active DECS operating modes, status, PSS status, and limiting

status.

Figure 48. Status Screen

Status Page 2

The Status Page 2 screen (Figure 49) shows the secondary group status, setpoint pre-position, setpoint

limit alarms, and AEM alarms.

IDP-800-C Operation IDP-800

Page 45

9437600990 Rev F 39

Figure 49. Status Page 2 Screen

I/O Status

The I/O Status screen (Figure 50) has indicators for DECS contact input status and relay output status

(open or closed). CEM input and output status is also shown on this screen.

Figure 50. I/O Status Screen

AEM Inputs

The AEM Inputs screen (Figure 51) has indicators for analog inputs and alarms.

IDP-800 IDP-800-C Operation

Page 46

40 9437600990 Rev F

Figure 51. AEM Inputs Screen

RTD Inputs

The RTD Inputs screen (Figure 52) has indicators for RTD inputs and alarms.

Figure 52. RTD Inputs Screen

Remote Thermocouple Inputs

The Remote Thermocouple Inputs screen (Figure 52) has indicators for RTD inputs.

IDP-800-C Operation IDP-800

Page 47

9437600990 Rev F 41

Figure 53. Remote Thermocouple Inputs Screen

DECS Control

Access to the DECS Control screen is possible only when logged in with the appropriate password. When

logged in, a Control button on the Main View screen provides access to the DECS Control screen

illustrated in Figure 54. DECS control functions are divided between two screens: Setpoint Control and

Regulation Control.

Figure 54. DECS Control Screen

Setpoint Control

Pressing the Setpoint Control button accesses the Setpoint Control screen (Figure 55). This screen

displays the DECS AVR, FCR, power factor, and var setpoints and provides two methods of setpoint

adjustment. The “+” and “–“ buttons can be pressed to increment and decrement the active setpoint. A

specific setpoint can be entered for any of the four setpoints. Pressing the New button associated with the

setpoint to be changed accesses a Setpoint Adjustment screen that displays the current setpoint value

IDP-800 IDP-800-C Operation

Page 48

42 9437600990 Rev F

along with the minimum and maximum limits for the setting. Touching the setting field area displays a

numeric keypad where the new value can be entered.

The Setpoint Control screen also has system status indicators and a metering display for generator and

excitation system parameters.

Figure 55. Setpoint Control Screen

Regulation Control

Pressing the Regulation Control button accesses the Regulation Control screen (Figure 56). This screen

enables selection of the active regulation mode. The AUTO and MANUAL buttons toggle between Auto

and Manual modes. When operating in AVR mode, the Off, PF, and VAR buttons can be used to enable

or disable regulation of vars or power factor. Each change to the regulation mode requires a confirmation

via an accept/reject dialog box.

The Regulation Control screen also has system status indicators and a metering display for

generator/motor and excitation system parameters.

Figure 56. Regulation Control Screen

IDP-800-C Operation IDP-800

Page 49

9437600990 Rev F 43

Register

Data Description

Access

Data Format

47715

New FCR setpoint

register 47723 at 1

W-

R32_23

47717

New AVR setpoint

register 47724 at 1

W-

R32_23

47719

New VAR setpoint

register 47725 at 1

W-

R32_23

47721

New PF setpoint

register 47726 at 1

W-

R32_23

47723

Load new FCR setpoint to AVR

0= No change ; 1=change

W-

UI16

47724

Load new AVR setpoint to AVR

0= No change ; 1=change

W-

UI16

47725

Load new VAR setpoint to AVR

0= No change ; 1=change

W-

UI16

47726

Load new PF setpoint to AVR

0= No change ; 1=change

W-

UI16

Modbus™ Communication

When DECS-400 controllers are connected (through an Ethernet switch or hub) to an Ethernet network,

all Modbus registers of each DECS-400 can be int err ogate d directly through the LAN. For a complete list

of DECS-400 Modbus holding register assignments, refer to the DECS-400 instruction manual (Basler

publication 9369700990).

The Modbus holding registers of a DECS-200/DECS-200N can be interrogated through the IDP-800-A

and the holding registers of a DECS-250/DECS-250N can be interrogated through the IDP-800-C. The

amount of information (registers) available through the IDP-800-A and IDP-800-C is limited to three

categories: metering, operating modes, and setpoints.

This chapter lists the assignments and descriptions of the Modbus holding registers accessible through

the IDP-800-A (DECS-200 and DECS-200N) and IDP-800-C (DECS-250 and DE CS-250N). The following

conventions apply in the register tables. In the Access column, “R” represents read access and “W”

represents write access. Data formats are described as follows.

Data Type UI6

Corresponding Built-In Data Type: UINT16, unsigned short integer

Data Range: 0 to 65,535

Data Size in Bytes: 2

Total Number of Modbus Registers to Hold Data: 1

Data Type R32_23

Corresponding Built-In Data Type: FLOAT, floating point number

Data Range: from approximately 8.43 × 10

Data Size in Bytes: 4

Total Number of Modbus Registers to Hold Data: 2

-37

to 3.38 × 1038

IDP-800 Register Table

Data transmitted via Modbus is identified by holding registers. Table 2 lists the holding register

assignments and descriptions for the IDP-800-A and IDP-800-C. In the Access column of Table 2, “W-”

indicates write-access.

Table 2. IDP-800 Register Table

To load this new setpoint in the AVR, it is necessary to pass

To load this new setpoint in the AVR, it is necessary to pass

To load this new setpoint in the AVR, it is necessary to pass

To load this new setpoint in the AVR, it is necessary to pass

IDP-800 Modbus™ Communication

Page 50

44 9437600990 Rev F

Register

Data Description

Access

Data Format

47727

Virtual toggle switch for changing control mode from comm.

Holding register 47573 contains Control mode status.

W-

UI16

47728

Switch for changing operating mode via comm. port to one of

pass the register 47729 at 1

W-

UI16

47729

Load new operation mode to the AVR

0= No change ; 1=change

W-

UI16

47730

Raise input enable status from comm. port:

0 = Off / 1 = On

W-

UI16

47731

Lower input enable status from comm. port:

0 = Off / 1 = On

W-

UI16

Register

Data Description

Access

Data Format

47257-58

Average of the 3 rms line-to-line voltages

R-

R32_23

47259-60

Phase B generator current in amps

R-

R32_23

47261-62

Generator apparent power in kVA

R-

R32_23

47263-64

Generator real power in kW

R-

R32_23

47265-66

Generator reactive power in kvar

R-

R32_23

47267-68

Power factor

R-

R32_23

47269-70

Generator frequency in hertz

R-

R32_23

47271-72

Bus frequency in Hz

R-

R32_23

47273-74

RMS bus voltage in volts

R-

R32_23

47275-76

Field voltage in volts

R-

R32_23

47277-78

Field current in amps

R-

R32_23

47283-84

Auxiliary input in volts (PSS input)

R-

R32_23

47287-88

Null balance (tracking error) in percent

R-

R32_23

47295

Status of the Front panel LEDs (bit flags, where 0=off, 1=on for all

b3=Upper Limit, b4=Lower Limit, b5=Edit, b6-b15=unassigned

R-

UI16

47296

Voltage matching status: 0=off / 1=on

R-

UI16

47297

Protection status bit flags (0=cl ear, 1=co ndition present):

b3=gen. overvoltage, b4=underfrequency, b5=in OEL, b6=in UEL,

lower limit, b10=setpoint at upper limit, b11=gen. failed to build

R-

UI16

Port between AVR and FCR:

0 = no change / 1 = change state.

three modes.

0=OFF / 1=PF / 2=var.

Holding register 47571 contains Operating mode status.

To change the operating mode in the AVR, it is necessary to

DECS-200, DECS-250, and DECS-250N Register Tabl es

Three categories of DECS-200, DECS-250, and DECS-250N information can be accessed through the

IDP-800 using the Modbus communication protocol: C2 (metering), C5 (operating modes), and C6

(setpoints).

DECS-200, DECS-250, and DECS-250N Metering Information Category C2

Category C2 holding register assignments and descriptions are listed in Table 3.

Table 3. DECS-200/DECS-250/DECS-250N Metering Information Category C2

LEDs except Null Balance and Internal Tracking which are

reversed): b0=Null Balance, b1=Tracking, b2=Pre-position,

b0=field overvoltage, b1=field overcurrent, b2=gen. Undervoltage,

b7=in FCR mode, b8=loss of sensing voltage, b9=setpoint at

Modbus™ Communication IDP-800

Page 51

9437600990 Rev F 45

Register

Data Description

Access

Data Format

up, b12= gen. below 10Hz, b13=unassigned, b14=exciter diode

open, b15=exciter diode shorted.

47300-01

The active operating setpoint expressed as a percent of its

present adjustment range.

R-

R32_23

47302

The state of some contact inputs: b0 = 52JK, b1 = 52LM, b2 =

Automatic transfer, b3 = External Tracking Enable

R-

UI16

47303

Annunciation status bit flags (0=clear, 1=annunciation present):

b3=gen. overvoltage, b4=underfrequency, b5=in OEL, b6=in UEL,

open, b15=exciter diode shorted..

R-

UI16

47306

Protection status bit flags (0 = clear, 1 = condition present)

b0 = loss of field, b1 = in SCL, b2 – b15 are unassigned

R-

UI16

47307

Annunciation status bit flags (0 = clear, 1 = condition present)

b0 = loss of field, b1 = in SCL, b2 – b15 are unassi gned

R-

UI16

Register

Data Description

Access

Data Format

47571

Operating mode: 0 = Off / 1 = PF Control / 2 = var Control

R-

UI16

47572

Unit mode status: 0 = Stop / 1 = Start

R-

UI16

47573

Control mode status: 1 = FCR / 2 = AVR

R-

UI16

Register

Data Description

Access

Data Format

47621-22

RW

R32_23

47623-24

AVR (automatic voltage regulator) mode setpoint; adjustment

range is determined by registers (47701-02) and (47709-10)

RW

R32_23

47625-26

Var mode setpoint (in kvar); adjustment range is determined by

registers (47703-04) and (47711-12)

RW

R32_23

47627-28

PF mode setpoint; adjustment range is determined by registers

(47705-06) and (47713-14)

RW

R32_23

47699-700

FCR minimum setpoint (in amps) = % of nominal x rated field

current:(regs. 47655-56) x (regs. 47529-30) / 100

R-

R32_23

47701-02

AVR minimum setpoint (in volts) = % of nominal x rated gen.

voltage:(regs. 47657-58) x (regs. 47525-26) / 100

R-

R32_23

47703-04

Var minimum setpoint (in kvar) = % of nominal x rated generator

VA:(regs. 47659-60) x rated VA / 100

R-

R32_23

47705-06

PF minimum setpoint = registers 47661-62

R-

R32_23

47707-08

FCR maximum setpoint (in amps) = % of nominal x rated field

current:(regs. 47663-64) x (regs. 47529-30) / 100

R-

R32_23

47709-10

AVR maximum setpoint (in volts) = % of nominal x rated gen.

Voltage:(regs. 47665-66) x (regs. 47525-26) / 100

R-

R32_23

b0=field overvoltage, b1=field overcurrent, b2=gen. undervoltage,

b7=in FCR mode, b8=loss of sensing voltage, b9=setpoint at

lower limit, b10=setpoint at upper limit, b11=gen. failed to build

up, b12= gen. below 10Hz, b13=unassigned, b14=exciter diode

DECS-200, DECS-250, and DECS-250N Operating Mode Information Category C5

Category CT holding register assignments and descriptions are listed in Table 4.

Table 4. DECS-200/DECS-250/DECS-250N Operating Mode Information Category C5

DECS-200, DECS-250, and DECS-250N Setpoints Information Category C6

Category C6 holding register assignments and descriptions are listed in Table 5.

Table 5. DECS-200/DECS-250/DECS-250N Setpoints Information Category C6

FCR (field current regulator) mode setpoint; adjustment range is

determined by registers (47699-700) and (47707-08)

IDP-800 Modbus™ Communication

Page 52

46 9437600990 Rev F

Register

Data Description

Access

Data Format

47711-12

Var maximum setpoint (in kvar) = % of nominal x rated gen.

VA:(regs. 47667-68) x rated VA / 100

R-

R32_23

47713-14

PF maximum setpoint = registers 47669-70

R-

R32_23

Register

Data Description

Access

Data Format

47257-58

Average of the three rms line-to-line voltages

R-

R32_23

47259-60

Generator current Ib in amps

R-

R32_23

47261-62

Generator apparent power in kVA

R-

R32_23

47263-64

Generator real power in kW

R-

R32_23

47265-66

Generator reactive power in kvar

R-

R32_23

47267-68

Power factor

R-

R32_23

47269-70

Generator frequency in hertz

R-

R32_23

47271-72

Bus frequency in hertz

R-

R32_23

47273-74

RMS bus voltage in volts

R-

R32_23

47275-76

Field voltage in volts

R-

R32_23

47277-78

Field current in amps

R-

R32_23

47283-84

Auxiliary input in volts (PSS input)

R-

R32_23

47287-88

Null balance (tracking error) in percent

R-

R32_23

47295

Status of the Front panel LEDs:

b3=Upper Limit, b4=Lower Limit, b5=Edit Button

R-

UI16

47296

Voltage matching status: 0=off/1=on

R-

UI16

47297

Protection status bit flags (0=cl ear, 1=co ndition present):

generator below 10Hz, b12=exciter diode open, b13=exciter diode

shorted, b14=loss of field, b15=in stator current limiting.

R-

UI16

47300-01

The active operating setpoint expressed as a percent of its

adjustment range.

R-

R32_23

47302

The state of some contact inputs: b0=52JK, b1=52LM , b2 =A uto

Transfer, b3=Ext. Tracking Enable

R-

UI16

47303

Annunciation status bit flags (0=clear, 1=annunciation present):

diode shorted, b14=loss of field, b15=in stator current limiting.

R-

UI16

DECS-200N Register Tables

Three categories of DECS-200N information can be accessed through the IDP-800 using the Modbus

communication protocol: C2 (metering), C5 (operating modes), and C6 (setpoints).

DECS-200N Metering Information Category C2

Category C2 holding register assignments and descriptions are listed in Table 6.

Table 6. DECS-200N Metering Information Category C2

b0=Null Balance, b1=Internal Tracking, b2=Pre-Position,

b0=field over-voltage, b1=field over-current, b2=generator undervoltage, b3=generator over-vo l tage, b4=under-frequency, b5=in

OEL, b6=in UEL, b7=in FCR mode, b8=loss of sensing voltage,

b9=setpoint at lower limit, b10=setpoint at upper limit, b11=

b0=field over-voltage, b1=field over-current, b2=generator undervoltage, b3=generator over-vo l tage, b4=under-frequency, b5=in

OEL, b6=in UEL, b7=in FCR mode, b8=loss of sensing voltage,

b9=setpoint at lower limit, b10=setpoint at upper limit, b11=

generator below 10 Hz, b12=exciter diode open, b13=exciter

Modbus™ Communication IDP-800

Page 53

9437600990 Rev F 47

Register

Data Description

Access

Data Format

47306

Protection status bit flags (0 = clear, 1 = condition present):

failure, b3 = crowbar activated, b4 - b15 are unassigned.

R-

UI16

47307

Annunciation status bit flags (0 = clear, 1 = condition present)

failure, b3 = crowbar activated, b4– b15 are unassi gned .

R-

UI16

Register

Data Description

Access

Data Format

47571

Operating mode ( 0=OFF/ 1=PF/ 2=VAR)

R

UI16

47572

Unit mode status (1=START, 0=STOP)

R

UI16

47573

Control mode status (1=FCR, 2=AVR)

R

UI16

Register

Data Description

Access

Data Format

47621-22

FCR mode (field current) setpoint

RW

R32_23

47623-24

AVR mode (generator voltage) setpoint

RW

R32_23

47625-26

Var mode setpoint in kvar

RW

R32_23

47627-28

PF mode setpoint

RW

R32_23

47699-700

FCR minimum setpoint

R-

R32_23

47701-02

AVR minimum setpoint

R-

R32_23

47703-04

Var minimum setpoint in kvar

R-

R32_23

47705-06

PF minimum setpoint

R-

R32_23

47707-08

FCR maximum setpoint

R-

R32_23

47709-10

AVR maximum setpoint

R-

R32_23

47711-12

Var maximum setpoint in kvar

R-

R32_23

47713-14

PF maximum setpoint

R-

R32_23

b0=failed to build up, b1=build-up activated, b2= power input

b0=failed to build up, b1=build-up activated, b2= power input

DECS-200N Operating Mode Information Category C5

Category C5 holding register assignments and descriptions are listed in Table 7.

Table 7. DECS-200N Operating Mode Information Category C5

DECS-200N Setpoints Information Category C6

Category C6 holding register assignments and descriptions are listed in Table 8.

Table 8. DECS-200N Setpoints Information Category C6

IDP-800 Modbus™ Communication

Page 54

48 9437600990 Rev F

Modbus™ Communication IDP-800

Page 55

9437600990 Rev F 49

Mounting

IDP-800 mounting consists of selecting a suitable mounting location, cutting the panel opening, and

securing the display to the panel.

Warning!

The control panel/equipment enclosure where the IDP-800 will be

installed must be removed from service and all related operating and

control power de-energized before proceeding with IDP-800

installation.

Mounting Considera t ions

The IDP-800 is intended for mounting in a cutout on a vertical panel in an environment where the ambient

temperature does not exceed the temperature range of 0 to 50°C (32 to 122°F). Observe the following

considerations and guidelines when preparing to mount the IDP-800.

Location and Environmental Considerations

The IDP-800 is intended for mounting in a vertical panel. If mounting the IDP-800 in a slanted panel, the

panel should not deviate more than thirty degrees from vertical. If the panel slants more than thirty

degrees, you must ensure that the ambient temperature surrounding the IDP-800 does not exceed 40°C

(104°F). This may require the use of external cooling equipment (such as a fan or air conditioner). To

enhance ventilation and maintenance, the IDP-800 should be installed no closer than 4 inches (10

centimeters) from adjacent equipment. Heat created by nearby equipment must not cause the ambient

temperature surrounding the IDP-800 to exceed its maximum operating temperature.