Page 1

INSTRUCTION MANUA L

FOR

IDP-1200

Interactive Display Panel

Publication: 9437200990

Revision: C Mar-15

Page 2

Page 3

9437200990 Rev C i

Caution

Note

Preface

This instruction manual provides information about the installation and operation of the IDP-1200

Interactive Display Panel. To accomplish this, the following information is provided:

• Mounting and connections

• Communication requirements

• Display operation and screen navigation

• Product specifications

Conventions Used in this Ma nua l

Important safety and procedural information is emphasized and presented in this manual through

warning, caution, and note boxes. Each type is illustrated and defined as follows.

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note boxes emphasize important information pertaining to installation

or operation.

IDP-1200 Preface

Page 4

ii 9437200990 Rev C

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It is loaned for

manual.

The English-language version of this manual serves as the only approved manual version.

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2015 by Basler E lectric

All rights reserved

First printing: May 2009

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the IDP-1200

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Only qualified personnel should install, operate, or service this system.

Failure to follow warning and cautionary labels may result in personal injury or property damage.

Exercise caution at all times.

To prevent personal injury or equipment damage, only qualified personnel should install, operate, or

service this system.

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

confidential use, subject to return on request, and with the mutual understanding that it will not be used in any

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intentio n of this ma nual to cover all detai ls and va riatio ns in equi pm ent, nor doe s this man ual prov ide

data for every possible contingency regarding installation or operation. The availability and design of all features

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

Preface IDP-1200

Page 5

9437200990 Rev C iii

Contents

Introduction ................................................................................................................................................. 1

Hardware ................................................................................................................................................... 1

Accessories ............................................................................................................................................ 1

Communication ........................................................................................................................................... 3

IDP-1200 Ethernet Settings ....................................................................................................................... 3

Control System Peripheral Settings .......................................................................................................... 3

IDP-1200 Operation with ECS2100 and ECS/RW ..................................................................................... 5

Initial Screen .............................................................................................................................................. 5

Index Button ........................................................................................................................................... 5

Get Page Button and Screen .................................................................................................................... 5

Alarms Banner ........................................................................................................................................... 8

System Configuration Screen .................................................................................................................... 8

Additional Configuration Screen ............................................................................................................ 9

File Manager .......................................................................................................................................... 9

General Index .......................................................................................................................................... 10

Metering Index ......................................................................................................................................... 10

Analog Meter Config Button ................................................................................................................. 11

Main Analog Meter, Redundant Analog Meter, and Supervisory Analog Meter Buttons .................... 12

Gen Analog Meter Config Button ......................................................................................................... 13

Generator Analog Meter Button ........................................................................................................... 13

Channel Compare Button .................................................................................................................... 14

Main Meter Panel, Redundant Meter Panel, and Supervisory Meter Panel Buttons .......................... 15

Trending Index ......................................................................................................................................... 15

Trending Config Button ........................................................................................................................ 16

Trending Data Buttons ......................................................................................................................... 17

Trending Graph Buttons ...................................................................................................................... 17

Temperature Trending and Tempera tur e Data But t ons ...................................................................... 18

Limiters and Trips .................................................................................................................................... 18

Alarm Status ............................................................................................................................................ 19

Active Alarms/Faults ................................................................................................................................ 20

Alarms/Faults History .............................................................................................................................. 20

Bridge Status ........................................................................................................................................... 21

Fan Control and Temperature Monitor .................................................................................................... 22

Transfer Control ....................................................................................................................................... 23

Power System Stabilizer.......................................................................................................................... 23

Field Ground ............................................................................................................................................ 24

Var ........................................................................................................................................................... 25

Output Control ......................................................................................................................................... 25

Controls ................................................................................................................................................ 26

Status Indicators .................................................................................................................................. 26

Metering ............................................................................................................................................... 26

Generator Simulation ............................................................................................................................... 27

Generator Monitor ................................................................................................................................... 27

Voltage Match .......................................................................................................................................... 28

Capability Curves .................................................................................................................................... 29

Task Guide .............................................................................................................................................. 29

Password Settings ................................................................................................................................... 30

Updating IDP-1200 Configuration Files from Basler Electric .................................................................. 30

Updating IDP-1200 Configuration Files from Documentation CD ........................................................... 31

IDP-1200 Operation with DECS-2100 and DECS/RW ............................................................................. 33

Initial Screen ............................................................................................................................................ 33

Index Button ......................................................................................................................................... 33

Get Page Button and Screen .................................................................................................................. 33

Alarms Banner ......................................................................................................................................... 36

IDP-1200 Contents

Page 6

iv 9437200990 Rev C

System Configuration Screen .................................................................................................................. 36

File Manager ........................................................................................................................................ 37

General Index .......................................................................................................................................... 38

Metering Index ......................................................................................................................................... 38

Analog Meter Config Button ................................................................................................................. 39

Main Analog Meter, Redundant Analog Meter, and Supervisory Analog Meter Buttons .................... 40

Gen Analog Meter Config Button ......................................................................................................... 40

Generator Analog Meter Button ........................................................................................................... 41

Channel Compare Button .................................................................................................................... 41

Main Meter Panel, Redundant Meter Pan el, and Super v is ory Meter Panel Butt ons .......................... 42

Trending Index ......................................................................................................................................... 43

Trending Config Button ........................................................................................................................ 43

Trending Data Buttons ......................................................................................................................... 44

Trending Graph Buttons ...................................................................................................................... 45

Temperature Trending and Tempera tur e Data But t ons ...................................................................... 45

Limiters and Trips .................................................................................................................................... 45

Alarm Status ............................................................................................................................................ 46

Active Alarms/Faults ................................................................................................................................ 47

Alarms/Faults History .............................................................................................................................. 48

Bridge Status ........................................................................................................................................... 48

Fan Control and Temperature Monitor .................................................................................................... 49

Transfer Control ....................................................................................................................................... 50

Power System Stabilizer.......................................................................................................................... 50

Field Ground ............................................................................................................................................ 51

Var ........................................................................................................................................................... 52

Power Factor ........................................................................................................................................... 52

Output Control ......................................................................................................................................... 53

Controls ................................................................................................................................................ 53

Status Indicators .................................................................................................................................. 54

Metering ............................................................................................................................................... 54

Generator Simulation ............................................................................................................................... 54

Generator Monitor ................................................................................................................................... 55

Synchronizer ............................................................................................................................................ 55

Synchronizer Display ............................................................................................................................... 56

Capability Curves .................................................................................................................................... 56

Task Guide .............................................................................................................................................. 57

Password Settings ................................................................................................................................... 57

Updating IDP-1200 Configuration Files from Basler Electric .................................................................. 58

Updating IDP-1200 Configuration Files from Documentation CD ........................................................... 59

Mounting .................................................................................................................................................... 61

Mounting the IDP-1200............................................................................................................................ 61

Mounting Considerations ..................................................................................................................... 61

Retrofit Installations ............................................................................................................................. 61

New Installations .................................................................................................................................. 72

Mounting the Ethernet Switc h ................................................................................................................. 72

Connections .............................................................................................................................................. 73

IDP-1200 Control Power.......................................................................................................................... 73

Ethernet Switch Control Power ............................................................................................................... 73

Communication Connections .................................................................................................................. 73

Maintenance and Troubleshooting ......................................................................................................... 75

Maintenance ............................................................................................................................................ 75

Troubleshooting ....................................................................................................................................... 75

Status LED ........................................................................................................................................... 75

Blank Indication Fields ......................................................................................................................... 75

Capability Curve Fails to Display MEL Curve ...................................................................................... 75

Storage .................................................................................................................................................... 75

Contents IDP-1200

Page 7

9437200990 Rev C v

Specifications ............................................................................................................................................ 77

Control Power .......................................................................................................................................... 77

Display ..................................................................................................................................................... 77

Communication Interfaces ....................................................................................................................... 77

Ethernet ............................................................................................................................................... 77

USB ...................................................................................................................................................... 77

Environment ............................................................................................................................................ 77

Vibration and Shock Resistance ............................................................................................................. 77

Vibration ............................................................................................................................................... 77

Shock ................................................................................................................................................... 77

ESD Immunity .......................................................................................................................................... 78

Weight...................................................................................................................................................... 78

Revision History ........................................................................................................................................ 79

IDP-1200 Contents

Page 8

vi 9437200990 Rev C

Contents IDP-1200

Page 9

9437200990 Rev C 1

Introduction

The IDP-1200 Interactive Display Panel is a high-resolution, 12.1 inch/31 centimeter (measured

diagonally) color touch screen interface that enables a user to monitor and control an ECS2100,

ECS/RW, DECS-2100, or DECS/RW excitation system. IDP-1200 monitoring and control features include

excitation system status, system control operations, and routine adjustments of the excitation setpoint. An

additional IDP-1200 can be mounted remotely, such as, in the control room.

Excitation system and generator system parameters are viewed and controlled through interactive pages

displayed by the IDP-1200. Pages are organized by function. Navigation between pages and control of

functions is achieved by touching buttons located on the IDP-1200 pages.

Communication between the IDP-1200 and the control system is facilitated through the Ethernet port of

the IDP-1200 and the Ethernet port of the excitation control modules.

Hardware

The IDP-1200 is supplied with the following hardware:

• Ethernet switch, 8 ports, Basler P/N 41133

• Instruction manual (Basler publication 9437200990)

Accessories

The following optional accessories are available for use with the IDP-1200:

• Power supply, 24 Vdc, 31 W, Basler P/N 933 450 310 1

• DIN mounting rail for Ethernet switch, Basler P/N 9323900001

IDP-1200 Introduction

Page 10

2 9437200990 Rev C

Introduction IDP-1200

Page 11

9437200990 Rev C 3

Communication

IDP-1200 communication with the control system cannot take place until the Ethernet communication

settings are configured for the IDP-1200 and the control system peripheral devices. The following

procedures describe how to configure the communication settings for the IDP-1200 and peripheral

devices.

IDP-1200 Ethernet Settings

Perform the following steps to configure the local Ethernet settings for the IDP-1200.

1. Press the Index button on any IDP-1200 page to access the General Index page.

2. Press the Setup button on the General Index page to access the System Configuration page.

3. Press the Offline Mode button.

4. Press the Main Unit Settings button located at the top of the page.

5. Press the Ethernet Local Settings button located at the right of page center.

6. Tap on the Local Name box and enter a local name for the main (IDP-1200) unit.

7. Enter the IP Address, Subnet Mask, Port, and Gateway as assigned by the network administrator.

8. Press the Back button located at the bottom of the page.

9. Press the Save button located at the bottom of the page.

10. Press the Yes button when prompted to save the current settings.

Control System Periphe ra l Se t ti ngs

Perform the following steps to configure the control system peripherals for communication with the main

(IDP-1200) unit.

1. Press the Index button on any IDP-1200 page to access the General Index page.

2. Press the Setup button on the General Index page to access the System Configuration page.

3. Press the Offline Mode button.

4. Press the Peripheral Settings button located at the top of the page

5. Press the Device/PLC Settings button located at the left of page center.

6. Press the Schneider Electric Industries button in the center of the page.

7. Press the Device button located at the top of the page.

8. Enter the IP Address, Port, and Unit ID for each of the following devices as assigned by the

network administrator. Your system may not contain all of the devices listed here.

a. em (ECM Main)

b. fm (FCIM Main)

c. er (ECM Redundant)

d. fr (FCIM Redundant)

e. es (ECM Supervisory)

f. fs (FCIM Supervisory)

9. Note that em and fm share the same IP address, er and fr share the same IP address, and es

and fs share the same IP address.

IDP-1200 Communication

Page 12

4 9437200990 Rev C

10. Press the Back button located at the bottom of the page.

11. Press the Digital Electronics Corporation button in the center of the page.

12. Press the Right Arrow button in the lower, right corner of the page.

13. Set control area address 1 to match the value entered for “em” in step 8

14. Set control area address 2 to match the value entered for “er” in step 8.

15. Press the Back button.

16. Press the Save button located at the bottom of the page.

17. Press the Yes button when prompted to save the current settings.

Communication IDP-1200

Page 13

9437200990 Rev C 5

IDP-1200 Operation with ECS2100 and ECS/RW

Control system and generator system parameters are viewed and controlled through interactive screens

displayed by the IDP-1200. Screens are organized by function. Navigation between screens and control

of functions are achieved by pressing buttons located on the IDP-1200 screens.

This chapter illustrates and describes IDP-1200 screen navigation and usage. The available IDP-1200

screens and their appearance will vary according to the number of control channels and rectifier bridges

utilized in a particular control system.

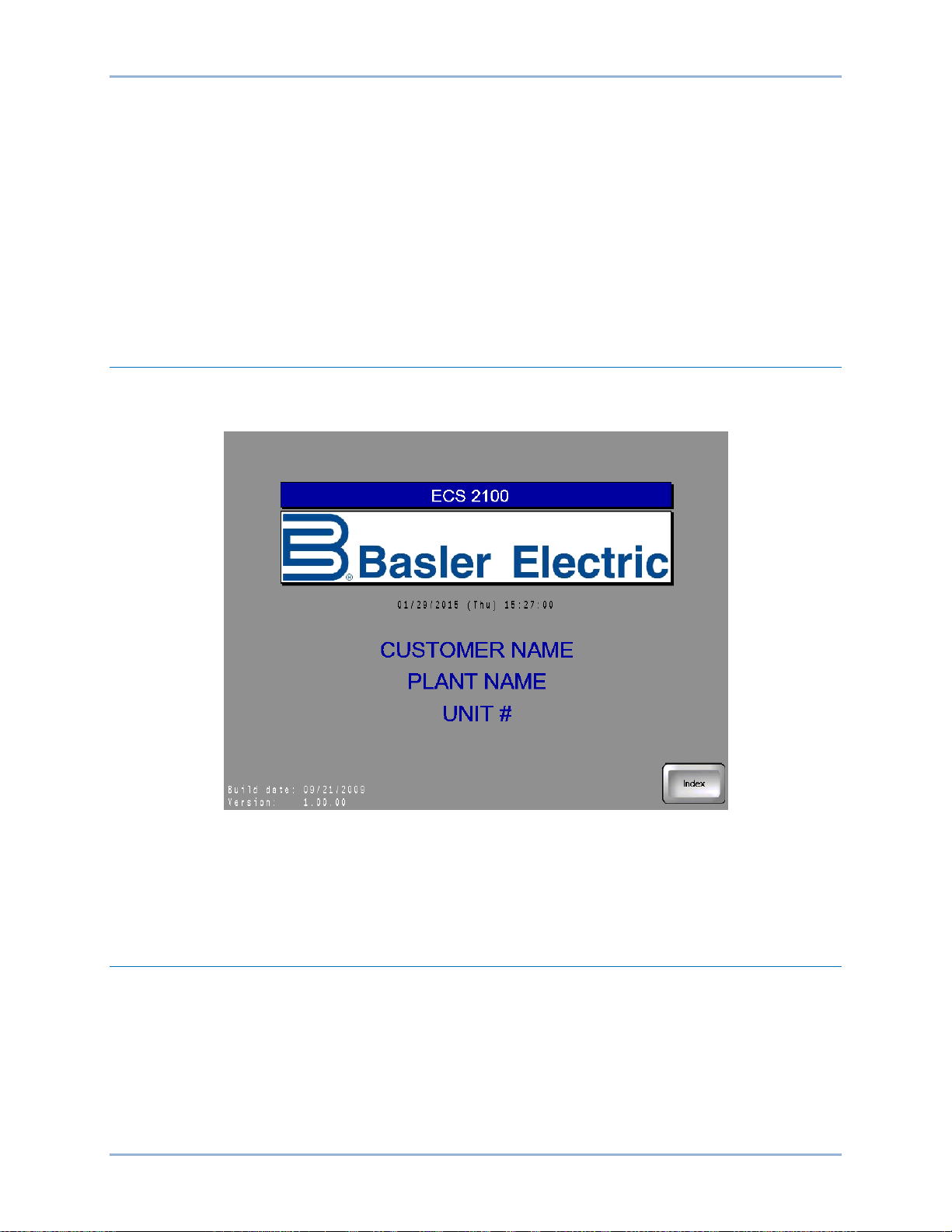

Initial Screen

The Initial screen (Figure 1) is displayed upon power-up of the IDP-1200. The initial screen lists the

number of control system channels and the version of the IDP-1200 firmware.

Figure 1. Initial Screen

Index Button

Most screens have an Index button that, when pressed, accesses the General Index screen. The General

Index screen provides quick navigation to any other IDP-1200 screen.

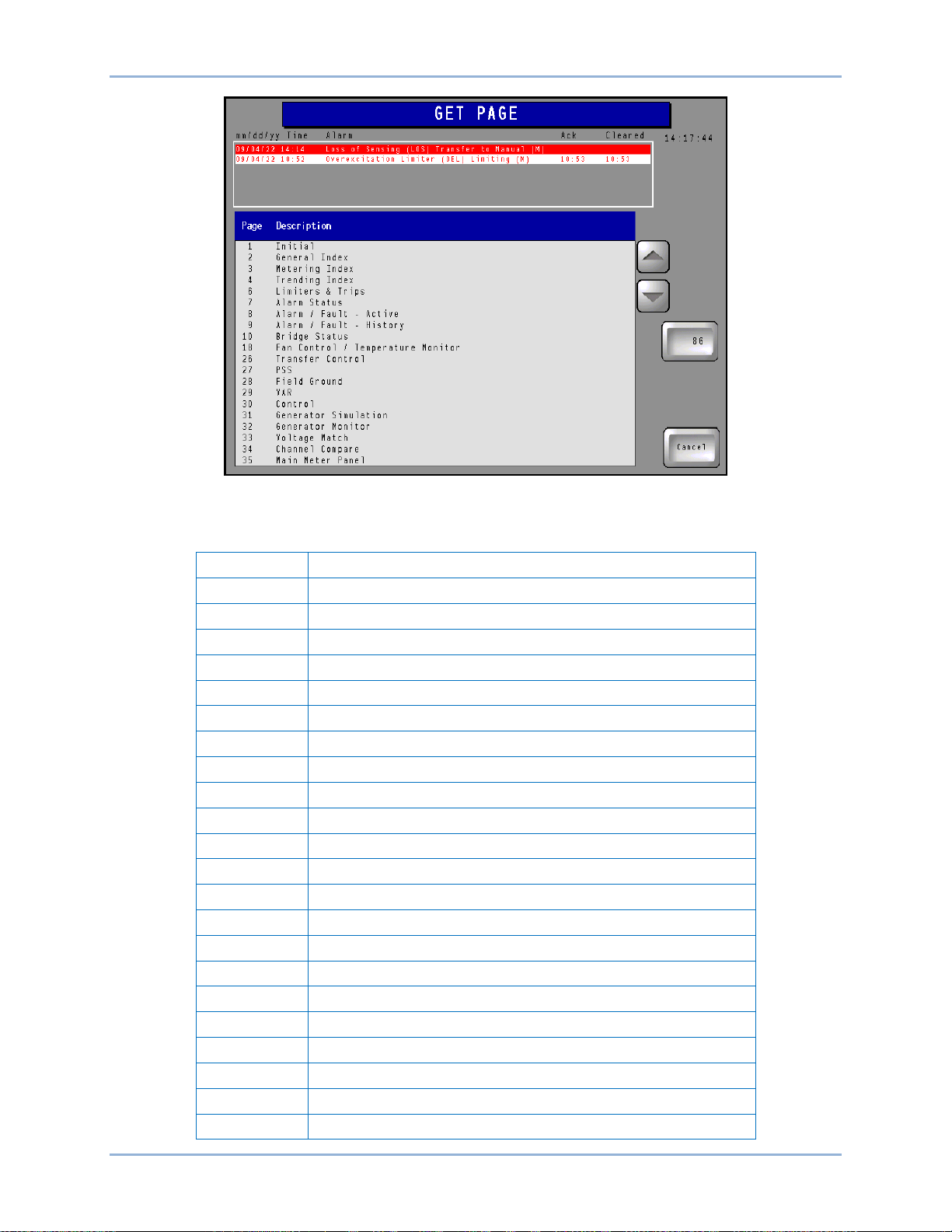

Get Page Button and Screen

Most screens have a Get Page button that accesses the Get Page screen illustrated in Figure 2. This

screen lists all screens and provides navigation to each screen. To navigate to a screen, the user scrolls

through the screen description list by using the up and down scrolling buttons until the desired screen and

screen number are found. The screen number is entered in a numeric keypad accessed by pressing the

86 button. (This button displays the number of the Get Page screen, which is 86.) Entering the screen

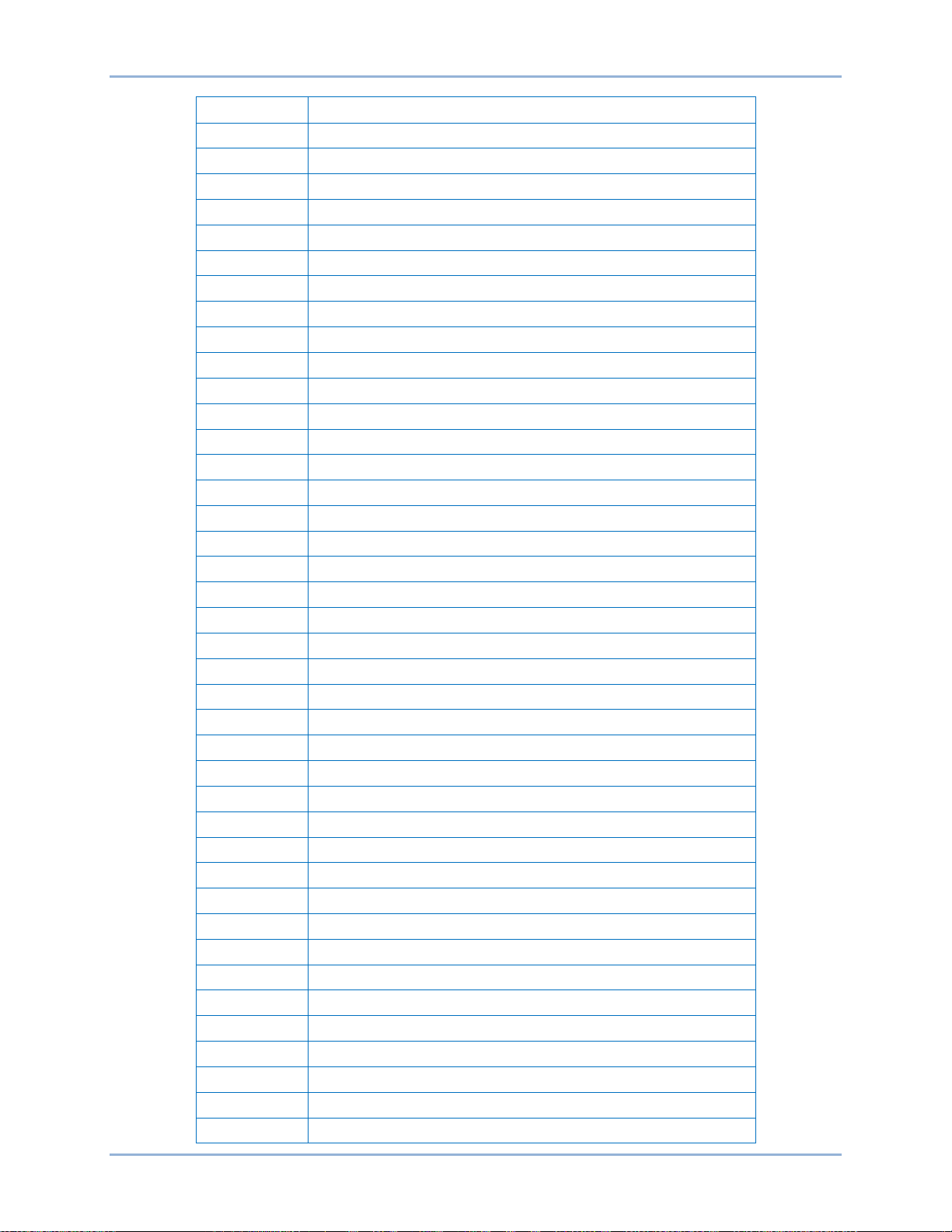

number followed by the Enter (ENT) button takes the user to the requested screen. A complete list of IDP1200 screens is provided in Table 1. Typically, your system/IDP-1200 will not have all of the

equipment/screens listed here.

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 14

6 9437200990 Rev C

Page

Description

1

Initial

2

General Index

3

Metering Index

4

Trending Index

6

Limiters and Trips

7

Alarm Status

8

Alarm/Fault – Active

9

Alarm/Fault – History

10

Bridge 00, 01 Status

11

Bridge 02, 03 Status

12

Bridge 04, 05 Status

13

Bridge 06, 07 Status

14

Bridge 08, 09 Status

15

Bridge 10, 11 Status

16

Bridge 12, 13 Status

17

Bridge 14, 15 Status

18

Fan Control/Temperature Monitor

26

Transfer Control

27

Power System Stabilizer

28

Field Ground

29

Reactive Power

30

Output Control

Figure 2. Get Page Screen

Table 1. IDP-1200 Screens

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 15

9437200990 Rev C 7

Page

Description

31

Generator Simulation

32

Generator Monitor

33

Voltage Matching

34

Channel Comparison

35

Main Meter Panel

36

Redundant Meter Panel

37

Supervisory Meter Panel

38

Main Meter Panel – Analog

39

Redundant Meter Panel – Analog

40

Supervisory Meter Panel – Analog

41

Meter Panel – Analog Configuration

42

Generator Meter Panel – Analog

43

Generator Meter Panel – Analog Configuration

44

Meter Trending Graph – Main

45

Meter Trending Data – Main

46

Meter Trending Graph – Redundant

47

Meter Trending Data – Redundant

48

Meter Trending Configuration

49

Bridge 00 Temperature Trending Graph

50

Bridge 00 Temperature Trending Data

51

Bridge 01 Temperature Trending Graph

52

Bridge 01 Temperature Trending Data

53

Bridge 02 Temperature Trending Graph

54

Bridge 02 Temperature Trending Data

55

Bridge 03 Temperature Trending Graph

56

Bridge 03 Temperature Trending Data

57

Bridge 04 Temperature Trending Graph

58

Bridge 04 Temperature Trending Data

59

Bridge 05 Temperature Trending Graph

60

Bridge 05 Temperature Trending Data

61

Bridge 06 Temperature Trending Graph

62

Bridge 06 Temperature Trending Data

63

Bridge 07 Temperature Trending Graph

64

Bridge 07 Temperature Trending Data

65

Bridge 08 Temperature Trending Graph

66

Bridge 08 Temperature Trending Data

67

Bridge 09 Temperature Trending Graph

68

Bridge 09 Temperature Trending Data

69

Bridge 10 Temperature Trending Graph

70

Bridge 10 Temperature Trending Data

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 16

8 9437200990 Rev C

Page

Description

71

Bridge 11 Temperature Trending Graph

72

Bridge 11 Temperature Trending Data

73

Bridge 12 Temperature Trending Graph

74

Bridge 12 Temperature Trending Data

75

Bridge 13 Temperature Trending Graph

76

Bridge 13 Temperature Trending Data

77

Bridge 14 Temperature Trending Graph

78

Bridge 14 Temperature Trending Data

79

Bridge 15 Temperature Trending Graph

80

Bridge 15 Temperature Trending Data

81

Horizontal Capability Curve

82

Vertical Capability Curve

83

System Configuration

84

Cleaning Lock

85

Screen Saver

86

Get Page

87

System Configuration 2

Alarms Banner

Most screens display an alarms banner that lists the six most recent system alarms. Each alarm is

labeled with a description and the date and time of the alarm. The timestamp for acknowledgement and

clearing (if applicable) of alarms is also displayed. Active alarms are displayed as white text on a red

background. Acknowledged alarms are displayed as yellow text on a black background. Cleared alarms

are displayed as red text on a white background.

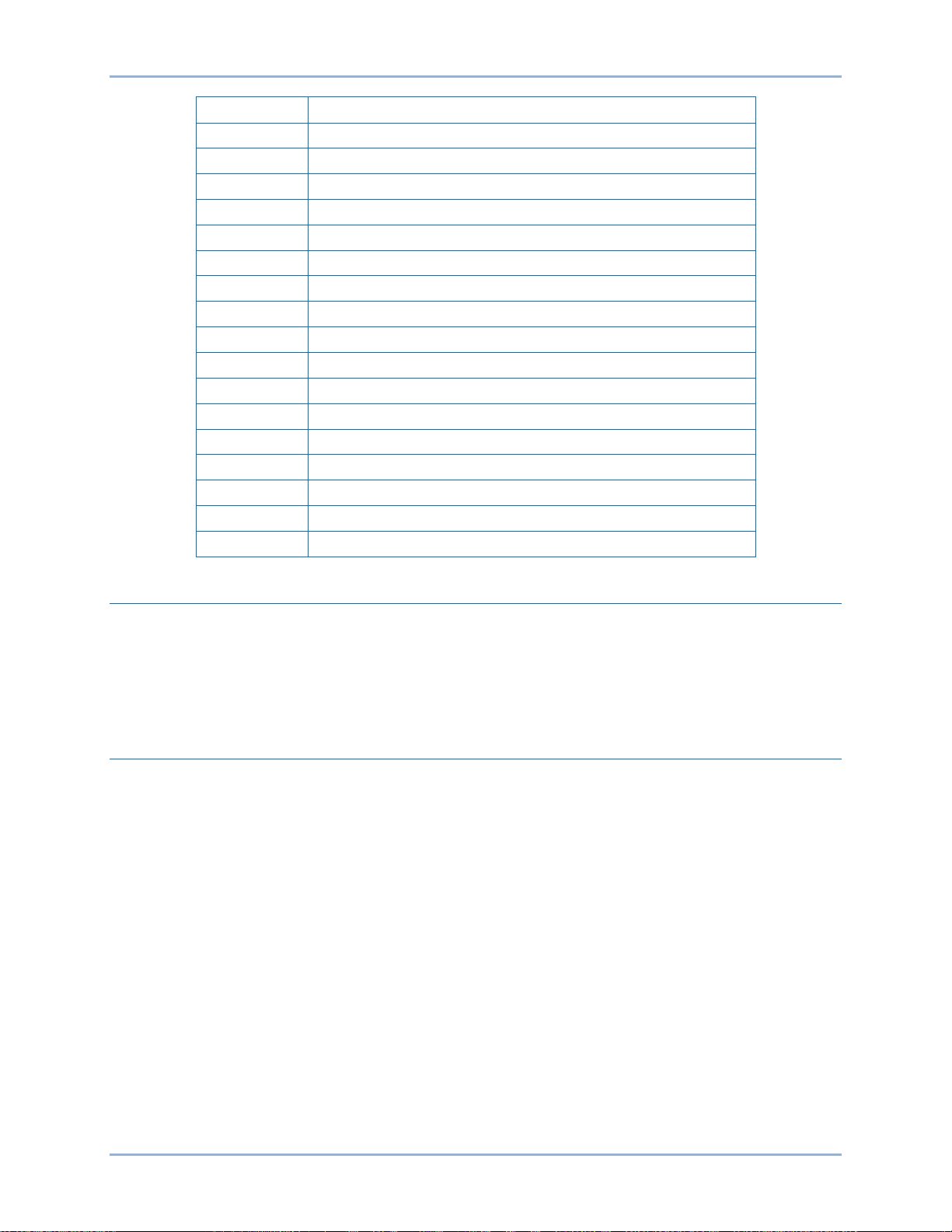

System Configuration Screen

This screen (Figure 3) has provisions for adjusting the screen saver time delay, adjusting the display

brightness, and selecting the display language.

An indicator turns red to indicate the connection of a USB device to the IDP-1200. A button below the

indicator can be pressed to de-energize the IDP-1200 USB port for safe removal of a USB device from

the IDP-1200.

If the IDP-1200 panel requires cleaning, the Lock for Cleaning button can be pressed to enable cleaning

of the screen without inadvertently pressing buttons.

A Log In button accesses an alphanumeric keypad where the appropriate password can be entered to log

in and make IDP-1200 settings changes. The IDP-1200 is delivered with a level 1 password of “1234” and

a level 2 password of “4321”. The proper, level 1 password is required to select the IDP-1200 display

language. The proper level 2 password is required to configure the IDP-1200 as a local or remote display

or to change passwords. Instructions for changing the password are provided in Password Settings.

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 17

9437200990 Rev C 9

Figure 3. System Configuration Screen

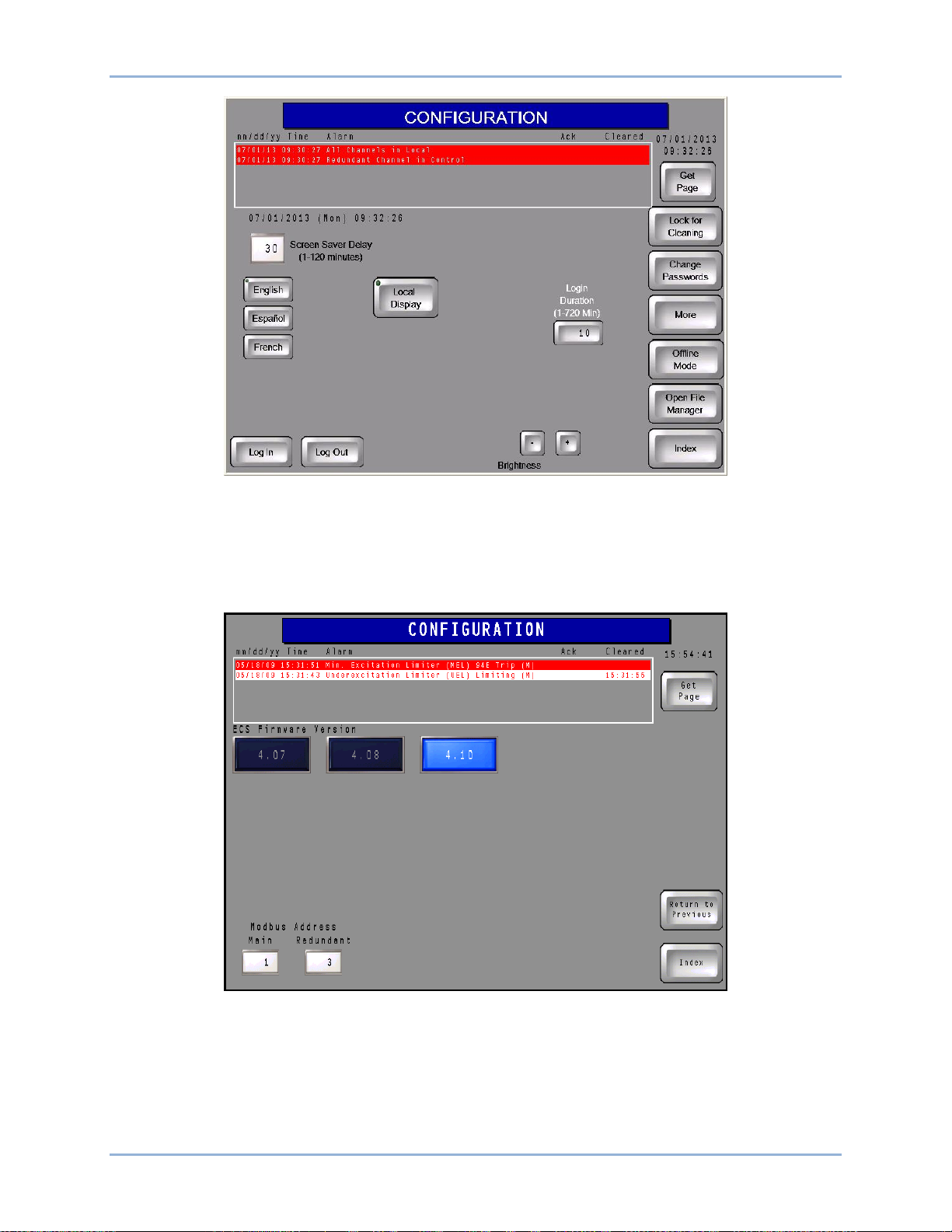

Additional Configuration Screen

Pressing the More button acc ess es a second Config uratio n sc reen, il lustr at ed in Figure 4. This screen

enables selection of the firmware version being used by the control system and the Modbus address of

the main and redundant channels.

Figure 4. Firmware and Modbus Address Configuration Screen

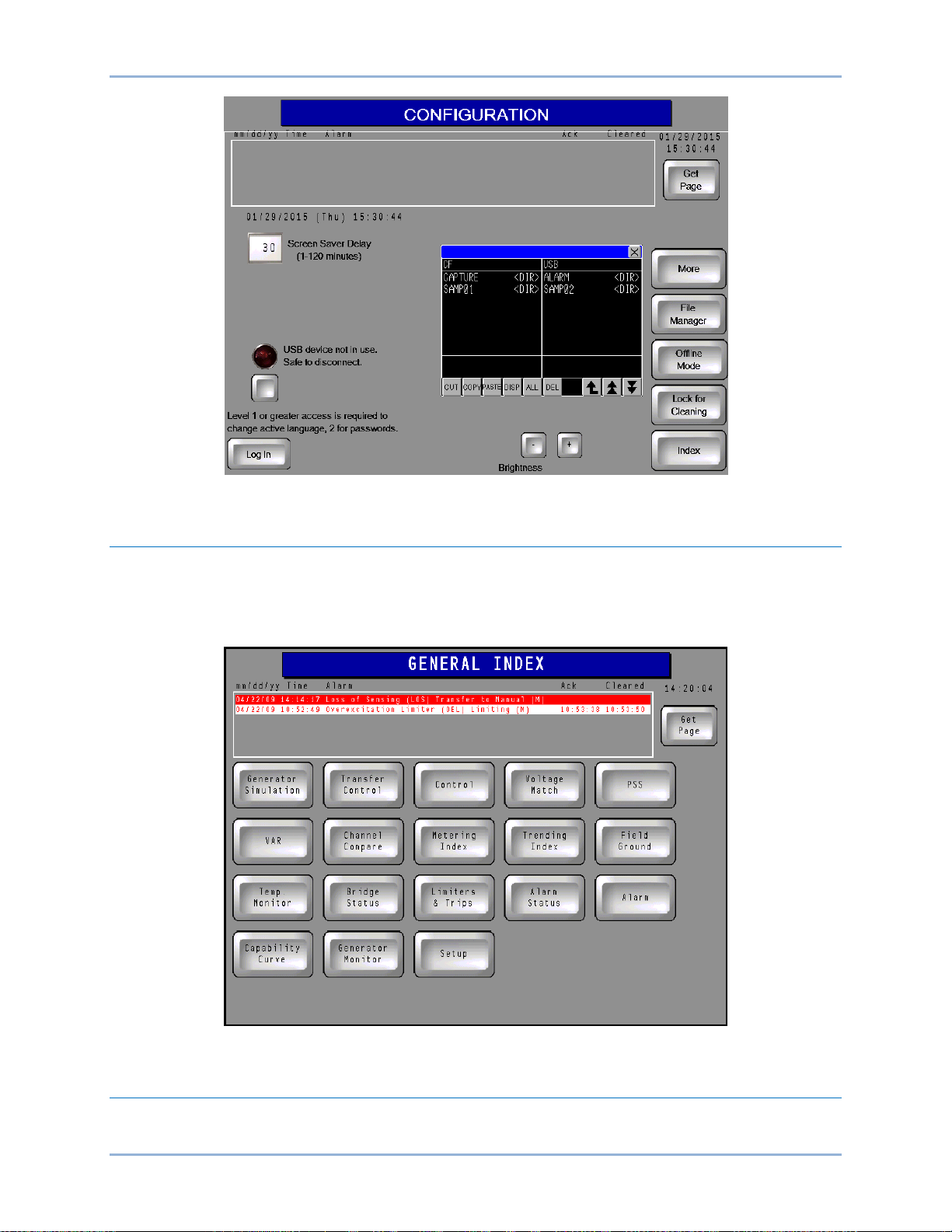

File Manager

The Open File Manager button accesses the file manager which lists the files present on an inserted

compact flash card and connected USB device. Files can be copied or moved from one storage device to

the other or deleted.

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 18

10 9437200990 Rev C

Figure 5. File Manager Screen

General Index

The General Index screen (Figure 6) is accessed by pressing the Index button, located in the lower right

corner of any other IDP-1200 screen. The General Index screen provides two methods of access to other

screens within the IDP-1200. Buttons on the General Index page provide quick access to 18 frequently

used IDP-1200 screens.

Figure 6. General Index Screen

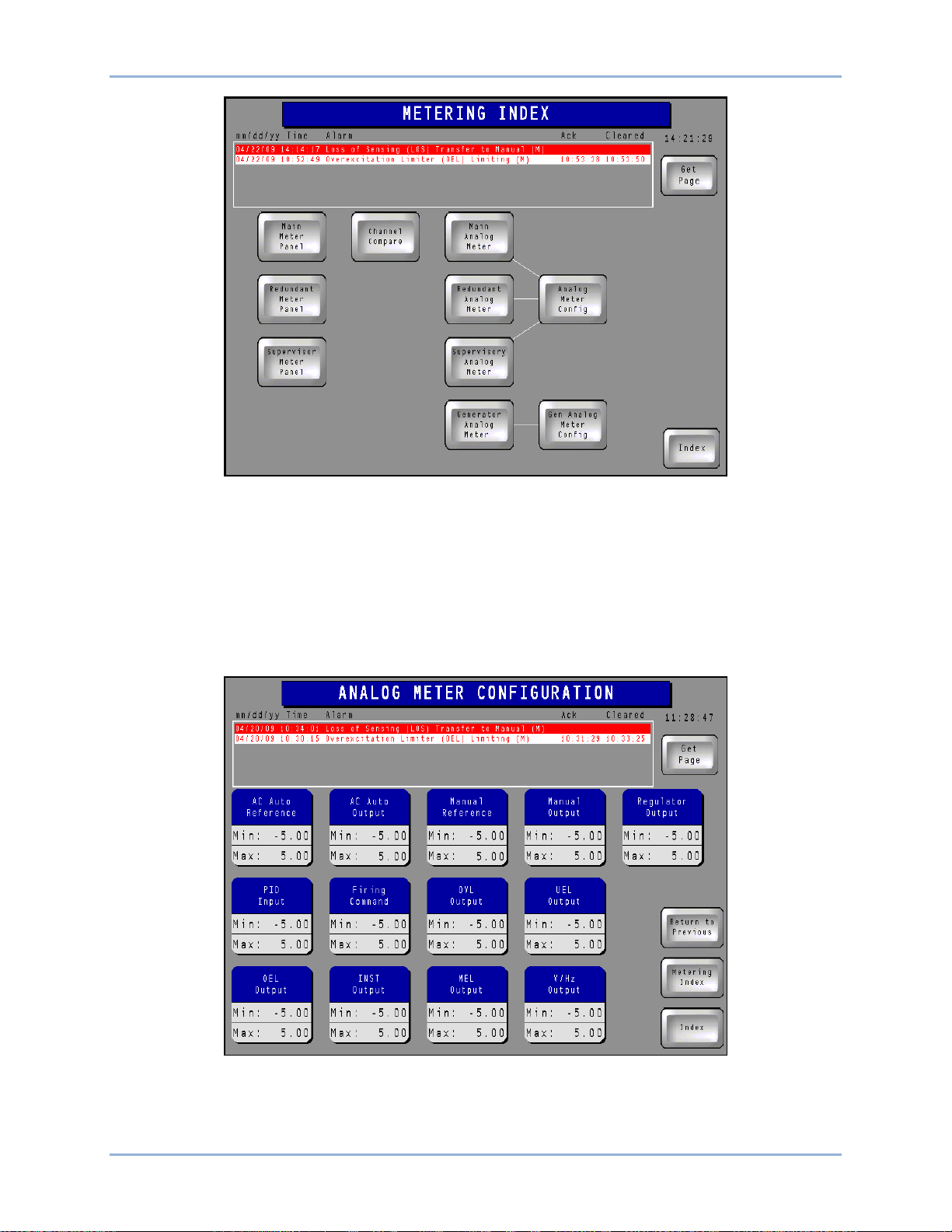

Metering Index

Buttons on the Metering Index screen (Figure 7) are pressed to access the screens used to scale and

display system metering values.

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 19

9437200990 Rev C 11

Figure 7. Metering Index Screen

Analog Meter Config Button

Pressing this Metering Index screen button accesses the Analog Meter Configuration screen (Figure 8)

which sets the range of the metering values displayed on the Main, Redundant, and Supervisory Metering

Panels (if so equipped). The minimum and maximum per-unit values for a metered parameter is changed

by pressing the corresponding value. This displays a keypad which is then used to assign the desired

metering limit. A per-unit value of –5.00 to 5.00 may be entered. Pr ess ing the En te r (ENT) button saves

the value.

Figure 8. Analog Meter Configuration Screen

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 20

12 9437200990 Rev C

Parameter

Minimum

Maximum

Field Current

0

10000

Field Voltage

–1500

1500

Generator Current

0

30000

Generator Voltage

0

30000

Generator Megavars

–1500

1500

Generator Megawatts

0

1500

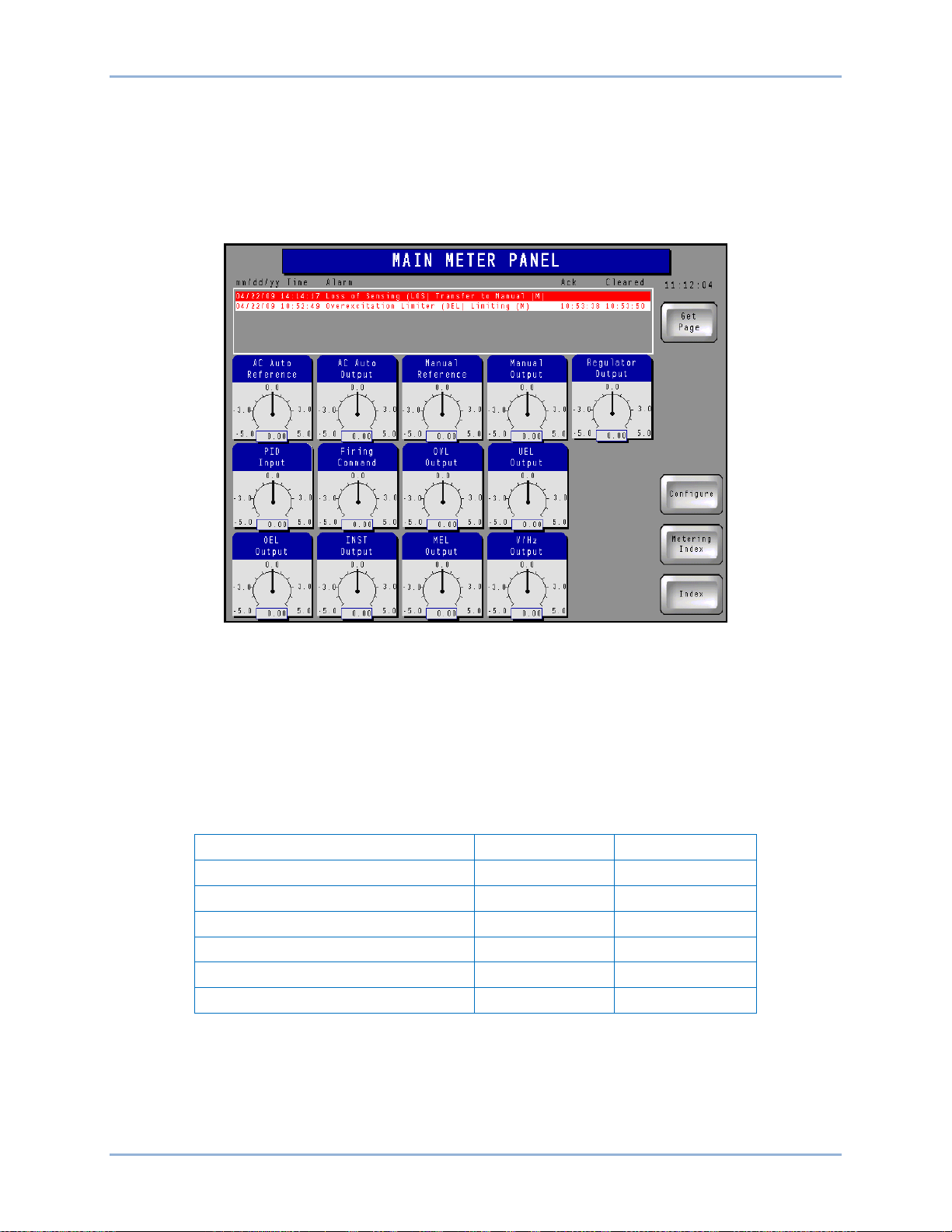

Main Analog Meter, Redundant Analog Meter, and Supervisory Analog Meter Buttons

Pressing one of these Metering Index screen buttons (if so equipped) accesses the corresponding

metering page which displays the parameters illustrated in Figure 9. (Only the Main Meter Panel is shown

here; the Redundant and Supervisory Meter Panels are similar.) The value of each parameter is

graphically shown on an analog scale and also displayed in digital format. The minimum and maximum

values established on the Analog Meter Configuration screen determine the metering ranges shown on

this screen.

Figure 9. Main Meter Panel

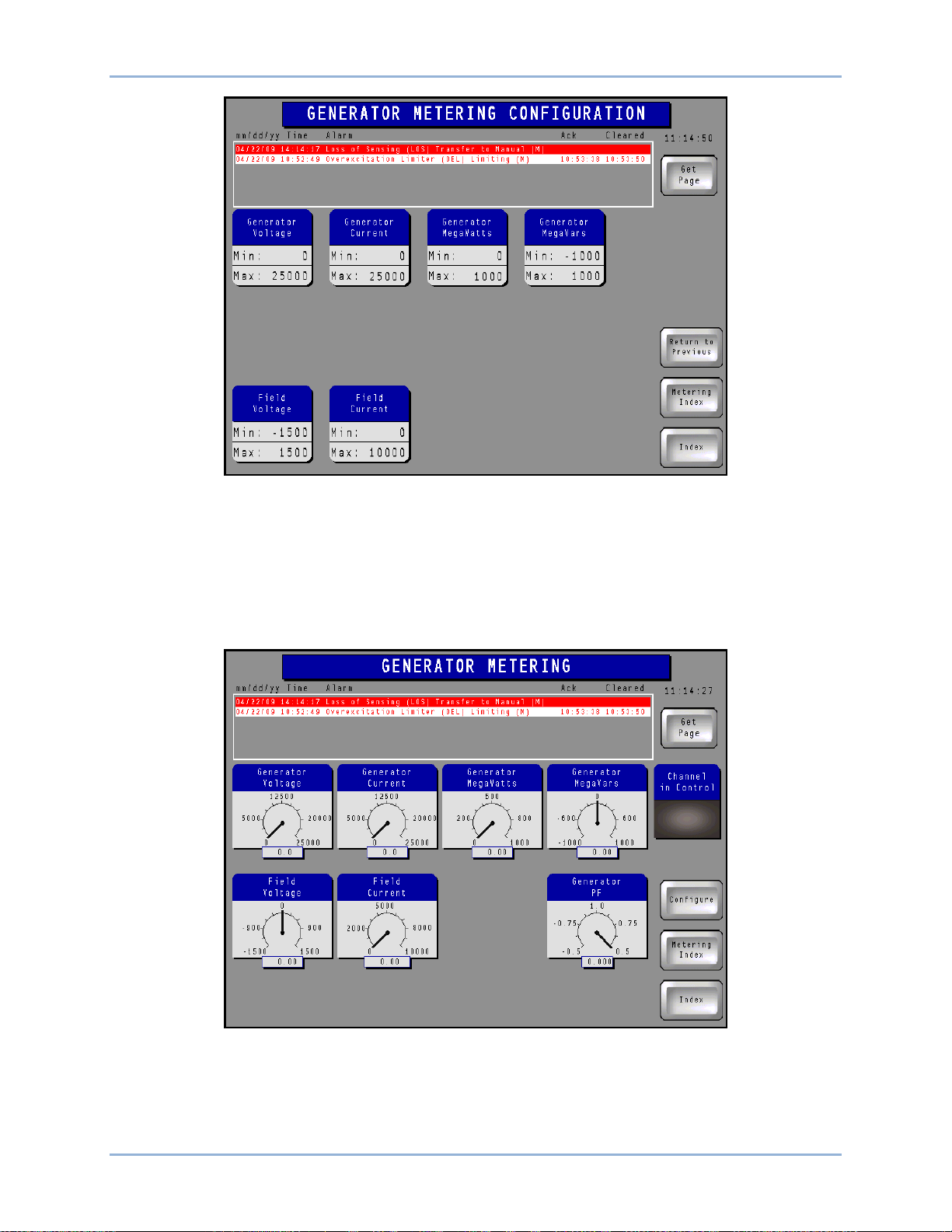

Gen Analog Meter Config Button

Pressing this Metering Index screen button accesses the Generator Metering Configuration screen

(Figure 10) which sets the range of the generator metering values displayed on the Generator Metering

screen. The generator power factor metering range is fixed so no adjustment is provided. The minimum

and maximum value for a metered parameter is changed by pressing the corresponding value. This

displays a keypad which is then used to assign the desired metering limit. Pressing the Enter (ENT)

button saves the value. Minimum and maximum metering parameter ranges are listed in Table 2.

Table 2. Metering Parameter Ranges

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 21

9437200990 Rev C 13

Figure 10. Generator Metering Configuration Screen

Generator Analog Meter Button

Pressing this Metering Index screen button accesses the Generator Metering screen which displays the

parameters illustrated in Figure 11. The value of each parameter is graphically shown on an analog scale

and also displayed in digital format. The mini mum and max im um va lues es tab lishe d on the Generator

Metering Configuration screen determine the metering ranges shown on this screen. The Generator

Metering screen also indicates the control system channel that is controlling excitation.

Figure 11. Generator Metering Screen

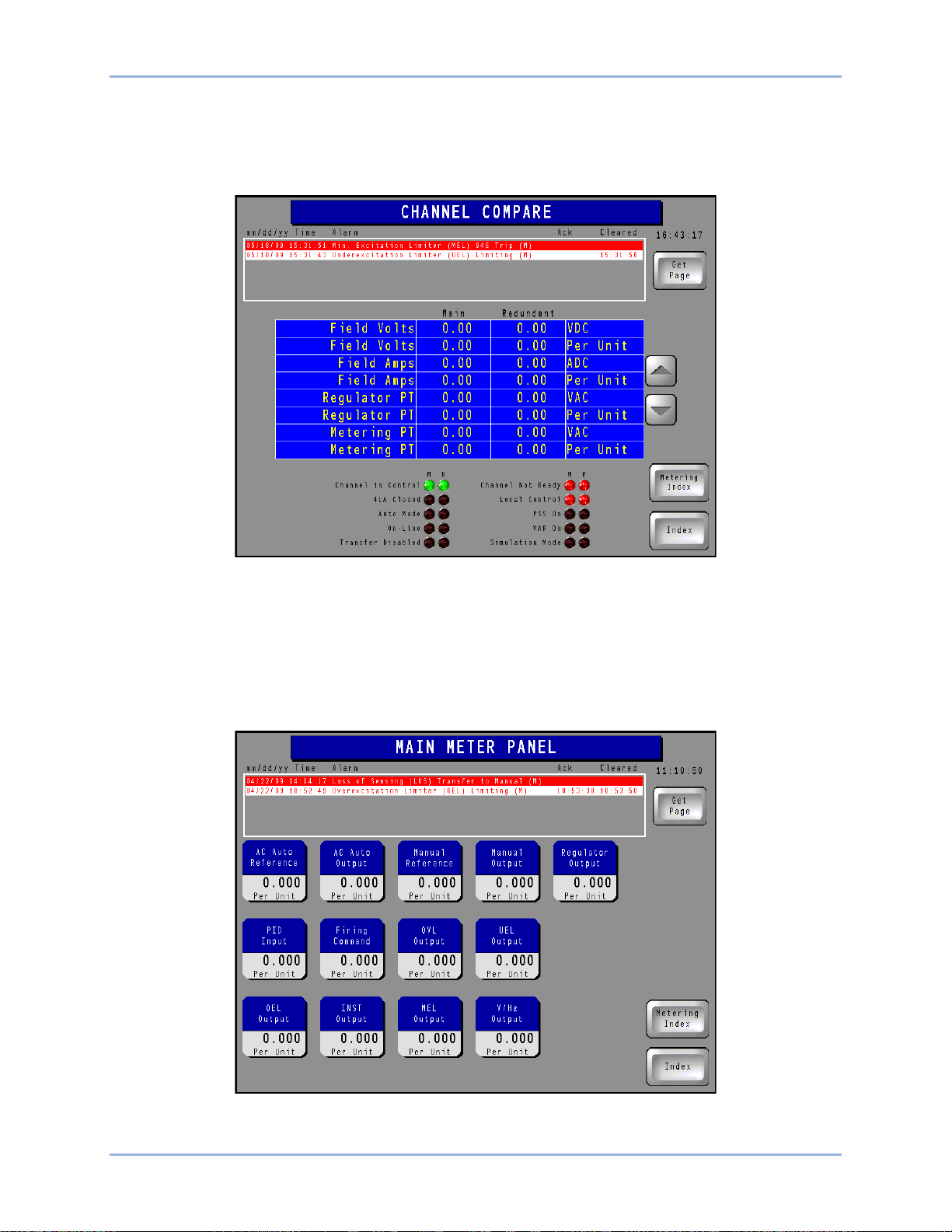

Channel Compare Button

Pressing this Metering Index screen button accesses the Channel Compare screen (Figure 12) which

displays a list of parameters metered by the control system channels. Scroll buttons, located to the right

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 22

14 9437200990 Rev C

of the list, can be used to scroll up and down through the list of parameters. (A particular system may not

be equipped with all of the channels shown here.) Three columns of indicators, located in the lower

portion of the screen, show the status of various operating modes, functions, and devices for the three

channels. The Channel in Control indicators turn green when active; all other indicators turn red when

active.

Figure 12. Channel Compare Screen

Main Meter Panel, Redundant Meter Panel, and Supervisory Meter Panel Buttons

Pressing one of these Metering Index screen buttons (if so equipped) accesses the corresponding meter

panel screen which displays the digital-only version of the parameters illustrated in Figure 9. (Only the

Main Meter Panel (Figure 13) is shown here; the Redundant and Supervisory Meter Panels are similar.)

The minimum and maximum values established on the Analog Meter Configuration page determine the

metering ranges shown on this screen.

Figure 13. Main Meter Panel Screen

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 23

9437200990 Rev C 15

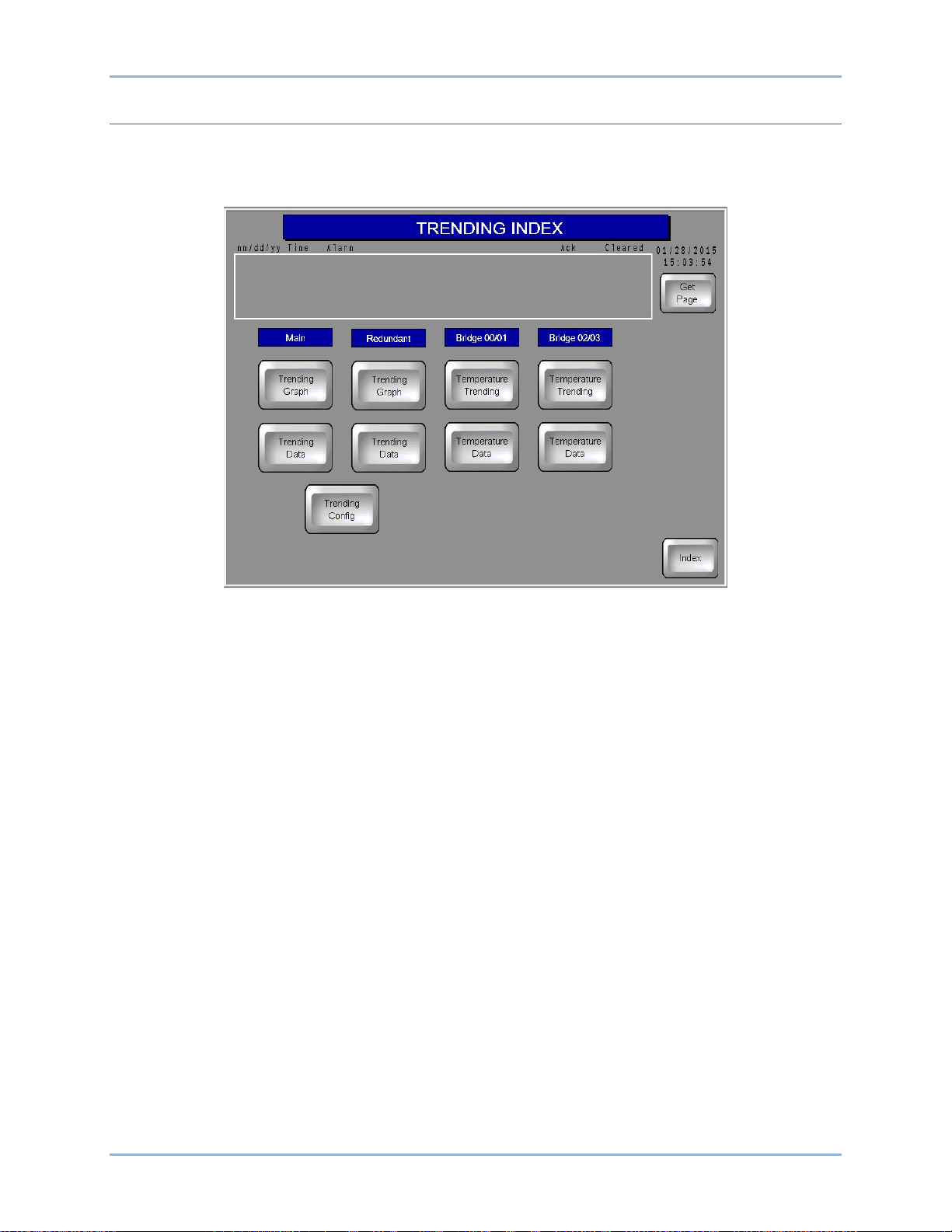

Trending Index

Buttons on the Trending Index screen (Figure 14) provide access to data lists and plots for user-selected

control system parameters and temperature data lists and plots for the excitation system rectifier bridges.

Appropriate buttons are provided based on the number of bridges included in the system.

Figure 14. Trending Index Screen

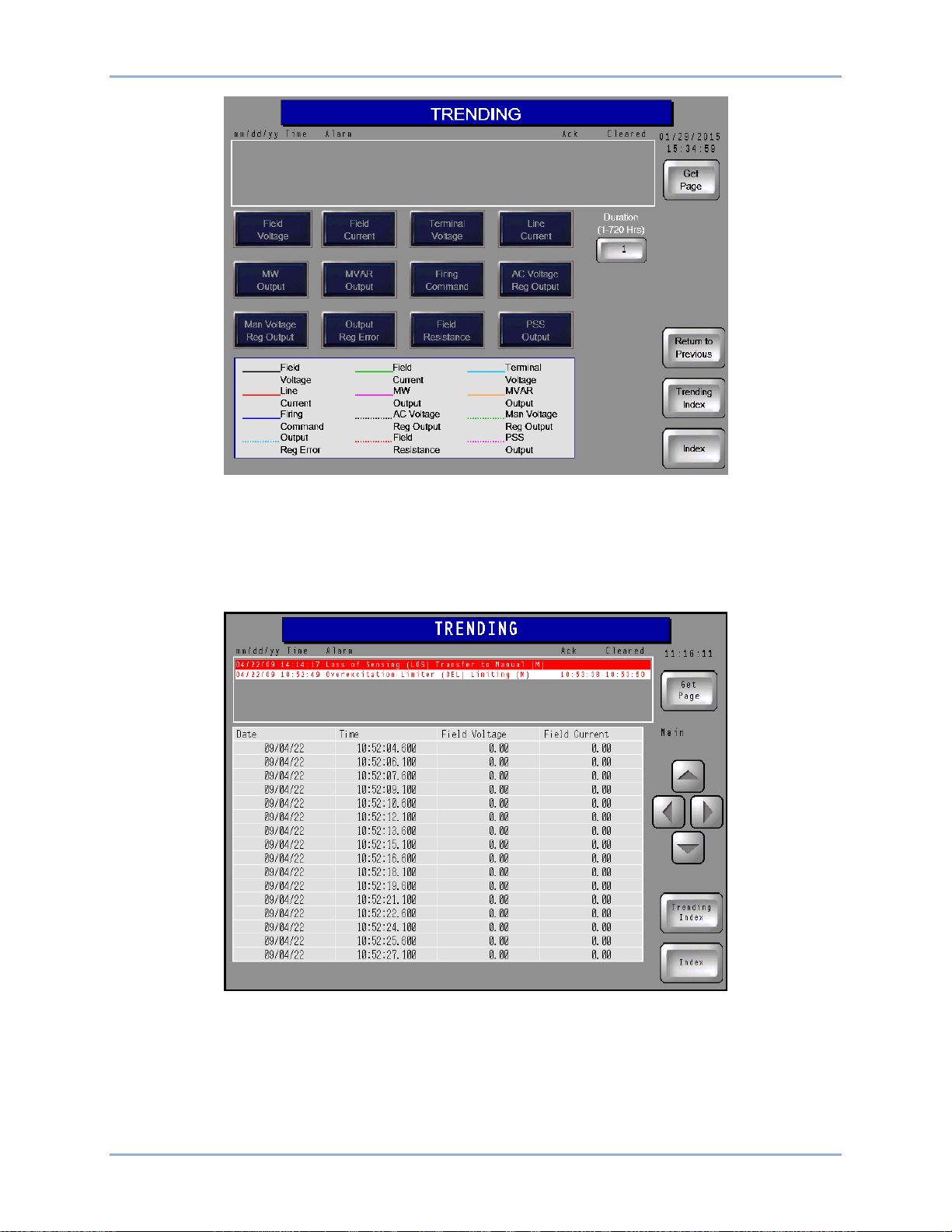

Trending Config Button

Pressing this Trending Index screen button accesses the Meter Trending Configuration screen shown in

Figure 15. Up to 12 control system channel parameters may be selected as part of a data list (accessed

through the Trending Data buttons) or data graph (accessed through the Trending Graph buttons). A

Duration button can be pressed to access a keypad where the trending length can be selected. Up to

2,400 control channel data points and 100 bridge temperature data points are maintained. A legend

indicates the line colors and patterns used when parameters are graphed.

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 24

16 9437200990 Rev C

Figure 15. Meter Trending Configuration Screen

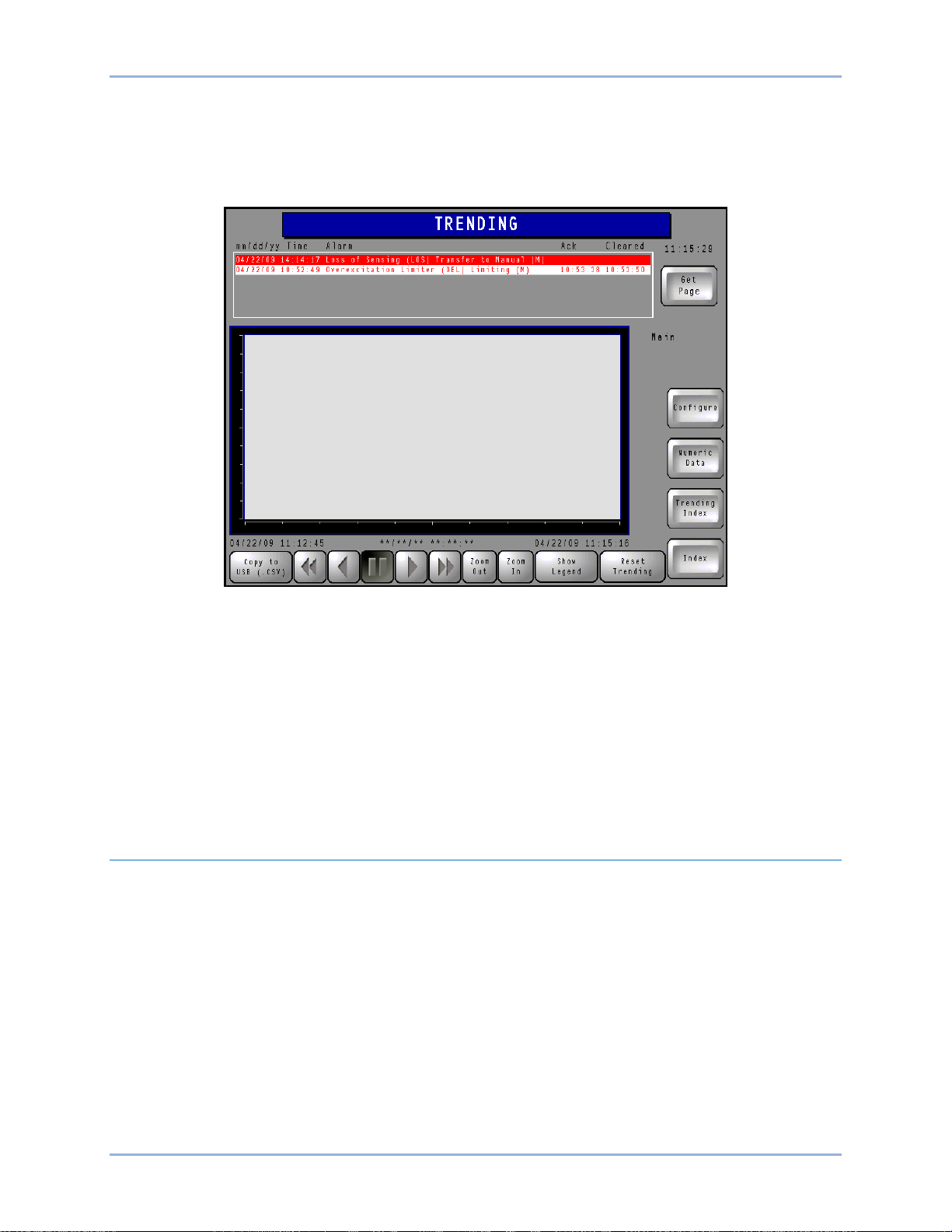

Trending Data Buttons

Pressing these Trending Index screen buttons accesses the corresponding trending page (either the Main

channel trending list or the Redundant channel trending list). The Main channel trending list screen is

shown in Figure 16; the Redundant channel trending list screen is identical in appearance.

Figure 16. Main Channel Trending Data Screen

Parameter data are listed in columns along with dates and timestamps for each row of data. Note that the

date format is yy/mm/dd. The parameters displayed are selected on the Meter Trending Configuration

screen. Scrolling buttons enable the user to move through the record and view the desired data points.

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 25

9437200990 Rev C 17

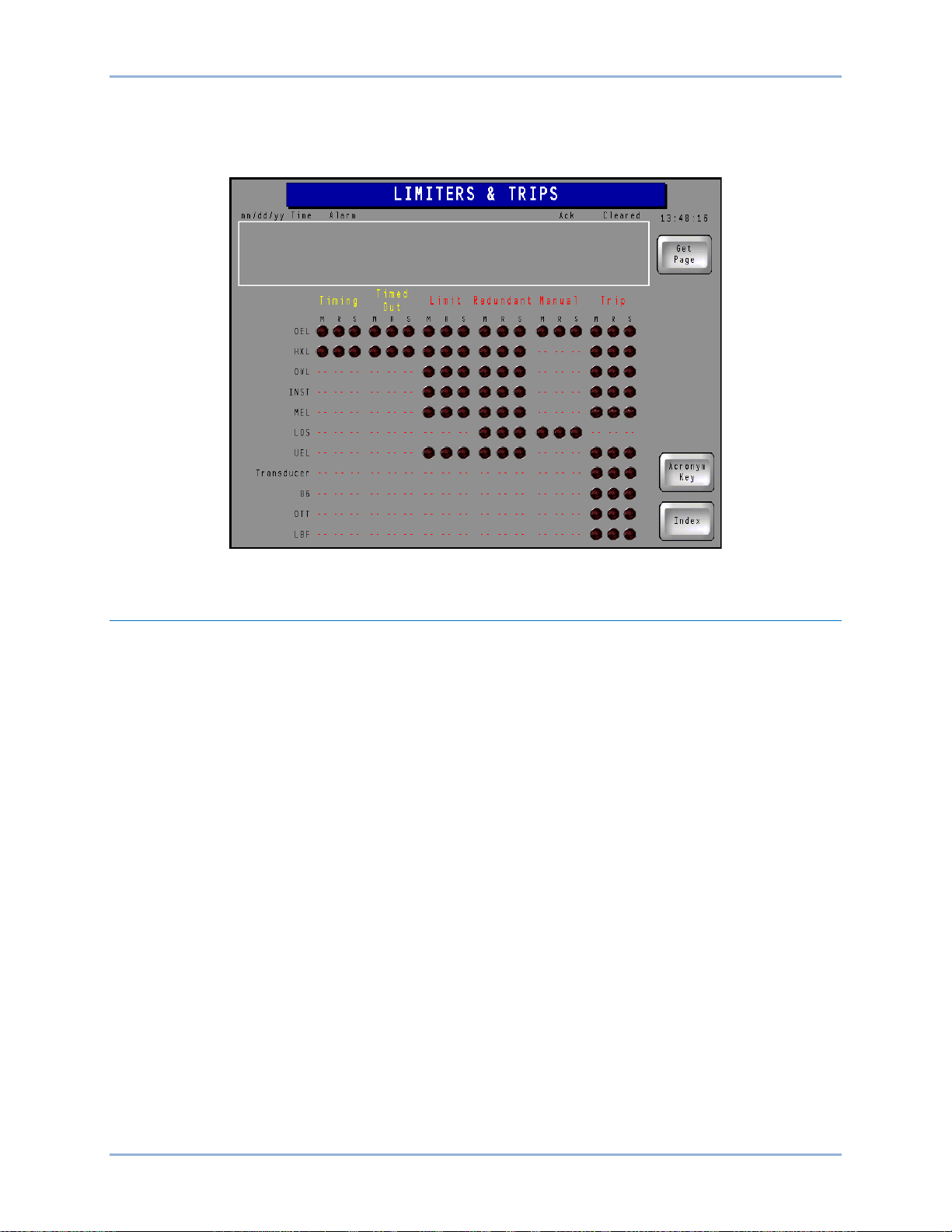

Trending Graph Buttons

Pressing these Trending Index screen buttons accesses the corresponding trending graph page (either

the Main channel trending graph or the Redundant channel trending graph). The Main channel trending

graph screen (Figure 17) is shown here; the Redundant channel trending graph screen is identical in

appearance.

Figure 17. Main Channel Trending Graph Screen

Each trending graph screen has a graph window with buttons that are used to move forward and

backward through the plot, zoom in and out, and reset the plot. Plotted parameters are selected on the

Meter Trending Configuration screen. Pressing the Show Legend button displays a legend indicating the

line colors and patterns used in the trending graph. A Copy to USB button provides the ability to export

the plot data to the IDP-1200’s USB port in a comma-separated-values file format.

Temperature Trending and Temperature Data Buttons

These Trending Index screen buttons are pressed to access a plot or list of temperature data for the

rectifier bridges. Display and control layout of these pages are identical to that of the trending data and

trending graph screens for the control system channels.

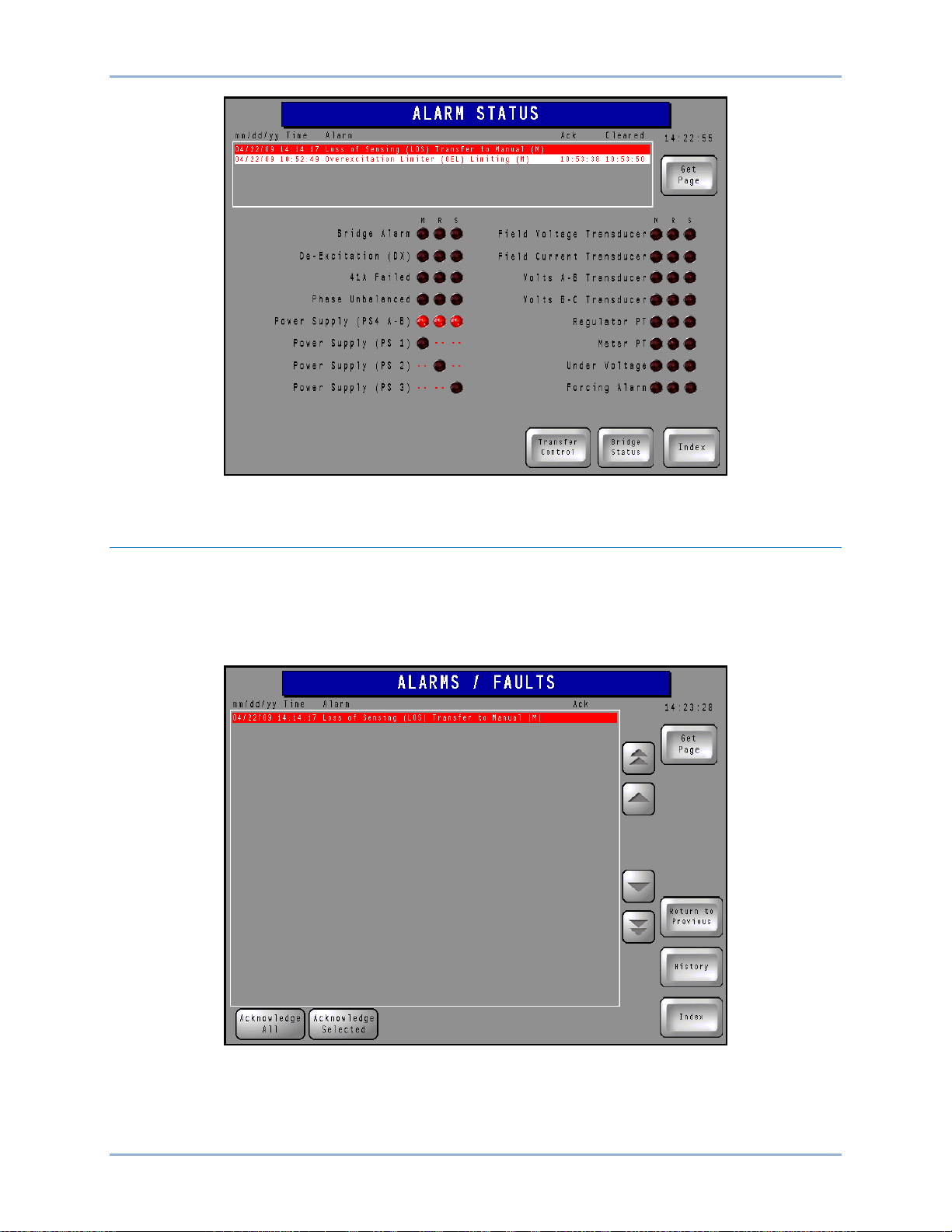

Limiters and Trips

This page (Figure 18) indicates the status of the following limiters and trip actions:

• Overexcitation (OEL)

• Volts per Hertz (HXL)

• Overvoltage (OVL)

• Instantaneous (INST)

• Minimum Excitation (MEL)

• Underexcitation (UEL)

• Loss of Sensing (LOS)

• External Initiated Lockout (86)

• Transformer Overtemperature (OTT)

• Loss of Both Cooling Fans (LBF)

Pressing the Acronym Key button displays a list of acronym definitions for the Limiters & Trips page.

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 26

18 9437200990 Rev C

Limiter/trip status is indicated by up to three columns of red (active) or black (inactive) indicators labeled

M (main channel), R (redundant channel), and S (supervisory channel). The meaning of a red indicator

depends upon the column it is located in. Indication categories (columns) are Timing, Timed Out, Limit,

Redundant, Manual, and Trip.

Figure 18. Limiters and Trips Screen

Alarm Status

The Alarm Status screen (Figure 19) lists control system parameters, conditions, and modules along with

their alarm status. Alarm status is displayed by three columns of indicators that are either black (no alarm)

or red (alarm). Depending upon the features of the control system, each parameter has up to three alarm

indicators labeled M (main channel), R (redundant channel), and S (supervisory channel). An active alarm

is annunciated by a red indicator and is listed in the alarms banner along the top of the page. More

information about how alarms are displayed is provided in the description for the Alarms/Faults screen.

Navigation to the Index, Bridge Status, and Transfer Control screen is available through buttons located in

the lower, right portion of the Alarm Status screen.

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 27

9437200990 Rev C 19

Figure 19. Alarm Status Screen

Active Alarms/Faults

This screen (Figure 20) lists only alarms that are active. Scrolling buttons along the right side of the list

enable the user to navigate through the list of alarms. Individual alarms can be acknowledged by

selecting the alarm and then pressing the Acknowledge Selected button. All alarms in the list can be

acknowledged simultaneously by pressing the Acknowledge All button. The History button provides

access to the Alarms/Faults History screen.

Figure 20. Active Alarms/Faults Screen

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 28

20 9437200990 Rev C

Alarms/Faults History

This screen (Figure 21) lists all active, acknowledged, and cleared alarms. Active alarms are displayed as

white text on a red background. Alarms that have been acknowledged (but not cleared) are displayed as

yellow text on a black background. Cleared alarms are displayed as red text on a white background.

Scrolling buttons along the right side of the list enable the user to navigate through the list of alarms.

Individual alarms can be acknowledged or cleared by selecting the alarm and then pressing the

Acknowledge Selected or Clear Selected button. All alarms in the list can be simultaneously

acknowledged or cleared by pressing the Acknowledge All or Clear All button. A Copy to USB button

provides the ability to export the plot data to the IDP-1200’s USB port in a comma-separated-values file

format. The History button provides access to the Active Alarms/Faults screen.

Figure 21. Alarms/Faults History Screen

Bridge Status

The Bridge Status screen (Figure 22) displays alarm conditions associated with the excitation system

power converters. This screen indicates the status of up to two power converters; a system with more

than two power converters will have more than one Bridge Status screen.

Alarm indications are provided for open input fuses, open or non-conducting SCRs, open or shorted

RTDs, and cooling failures.

A Reset FCIM Alarms button can be used to reset any alarms associated with the Field Control Interface

Module.

The Return Bridge From Maint button must be pressed when an out-of-service power converter is ready

to be returned to service.

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 29

9437200990 Rev C 21

Figure 22. Bridge Status Screen

Fan Control and Temperature Monitor

This screen (Figure 23) displays a table of temperature data for the excitation system rectifier bridges.

Heat sink temperature data is listed for each SCR. The ambient air temperature surrounding the bridge is

also listed.

Buttons at the right side of the page enable the user to override the cooling fan logic and manually select

which fans operate.

Indicators display the operating status of the rectifier bridge cooling fans.

Figure 23. Fan Control and Temperature Monitor Screen

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 30

22 9437200990 Rev C

Transfer Control

This screen (Figure 24) is used to transfer control from one control system channel to another.

When transferring control system channel control, observe the following:

• The IDP-1200 being used must be in control.

• You must know whether the IDP-1200 being used is Local or Remote (as displayed on the

Local/Remote indicator). Note that the IDP-1200 located on the control system equipment

enclosure is considered as the Local IDP-1200. An IDP-1200 at any other location is considered

to be a Remote IDP-1200.

• Level 1 password access is required (through use of the Log In button).

• The redundant channel tracks the output of the main channel and displays the percent difference

(error) between the outputs of the redundant and main channels.

To transfer control system channel control:

1. Ensure that the Enable Transfer indicator shows “Panel Transfer Enabled”. This is achieved by

pressing the Enable Transfer button.

2. Press the Transfer indicator button and select the desired channel.

Figure 24. Transfer Control Screen

Power System Stabilizer

This page (Figure 25) displays power system stabilizer operating status and enables/disables PSS

operation. PSS metering indications for each control system channel are displayed. The PSS output for

the active channel is displayed adjacent to the Channel in Control indicator.

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 31

9437200990 Rev C 23

Figure 25. Power System Stabilizer Screen

Field Ground

This is an indications-only screen (Figure 26) that displays the field-to-ground resistance and calculated

field temperature as measured/calculated by each channel. If the level of the field-to-ground resistance is

detected as less than system variable FLDGND_RMIN, an alarm condition exists and is displayed in the

Field Ground indicator(s).

Figure 26. Field Ground Screen

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 32

24 9437200990 Rev C

Var

This screen (Figure 27) is available only on systems equipped with var control.

Control of reactive power is enabled and disabled by the VAR Control button. When this button is

pressed, Enable and Disable buttons will appear and enable the user to turn control of vars on and off.

Var balance is adjusted by pressing the VAR Adjuster button. When the button is pressed, Raise and

Lower buttons will appear and enable the user to raise and lower the level of reactive power.

The 70BC-CS Manual button can be used to raise or lower the balance or manual reference. When the

button is pressed, Raise and Lower buttons will appear and enable the user to raise and lower the voltage

while operating in Manual mode.

Similarly, the 90DV-CS Auto button can be used to raise or lower the voltage while operating in Auto

mode.

Generator and excitation system values are displayed and controls are provided for control of the ac

(41A) breaker.

Figure 27. Var Screen

Output Control

This screen (Figure 28) provides system control, status indication, and metering of generator and

excitation system parameters.

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 33

9437200990 Rev C 25

Figure 28. Output Control Screen

Controls

Controls include opening and closing of the ac (41A) breaker, selection of auto- or manual-mode

regulation, and adjustment of the gener at or volt age in Manu al or Auto mod e.

Control of the 41A breaker is provided through the AC Breaker button. When this button is pressed, Trip

and Close buttons will appear and enable the user to open and close the ac breaker.

Selection of auto- or manual-mode regulation is provided through the Mode Select button. When this

button is pressed, Put Reg in Auto and Put Reg in Manual buttons wil l appear and enab le the us er to

select either auto or manual regulation.

The 70BC-CS Manual button can be used to raise or lower the balance or manual reference. When the

button is pressed, Raise and Lower buttons will appear and enable the user to raise and lower the voltage

while operating in Manual mode.

Similarly, the 90DV-CS Auto button can be used to raise or lower the voltage while operating in Auto

mode.

Status Indicators

The System Status indicator displays the readiness of the control system channels.

The Channel in Control indicator displays which of the control system channels is actively controlling the

excitation level.

The Generator Breaker indicator displays whether the generator breaker is open or closed.

The Local/Remote indicator displays the local/remote control status of all control system channels. When

logged in with the Log In button and the proper password, this indicator is converted to a control button

that can be used to select either local or remote control. When pressed, Local Control and Remote

Control buttons appear and enable the user to select the operating mode. During proper operation, the

control mode of all channels should match. That is, all channels should be under local control or all

channels should be under remote control.

Metering

Metering indications are provided for generator voltage, current, watts, vars, and power factor. Metering

indications are also provided for field voltage and current, the SCR firing command percentage, and

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 34

26 9437200990 Rev C

manual/auto setpoint balance. Metering indications with two values display the actual reading in the upper

row of numbers and the per-unit (PU) value in the lower row of numbers.

Generator Simulation

This screen (Figure 29) gives the user the ability to test a group of settings offline. Controls are provided

for enabling and disabling generator simulation (Simulation Enable), raising and lowering the Auto

setpoint (Raise/Lower Volts), raising and lowering the output power (Turbine Control), toggling between

Auto and Manual modes (Mode Select), and tripping and closing the 41A breaker (AC Breaker). Metering

indicators are provided for common generator and excitation system parameters.

Figure 29. Generator Simulation Screen

Generator Monitor

The Generator Monitor screen (Figure 30) graphically illustrates excitation system and generator status.

Excitation system indicators are provided for ac breaker and PSS status and field voltage and current

levels. Generator voltage, current, watts, vars, and power factor are also displayed.

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 35

9437200990 Rev C 27

Figure 30. Generator Monitor Screen

Voltage Match

The Voltage Match scr een ( Figure 31) toggles voltage matching on and off (Voltage Match Enable

control) and monitors voltage matching progress through generator and line voltage metering values. A

Voltage Match indicator annunciates when the generator voltage level matches the level of line voltage.

Figure 31. Voltage Match Screen

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 36

28 9437200990 Rev C

Task

Screen

Close ac breaker

Control

Flash the field

N/A, field is flashed automatically

when ac field breaker is closed.

Place regulator in Auto or Manual

mode

Control

Raise or lower voltage

Control

Var

Change the controlling channel

Transfer Control

Change Local/Remote control

Control

View alarms

Any page

Acknowledge alarms

Alarm/Fault – Active

Alarm/Fault – History

Capability Curves

This screen displays the generator minimum excitation limit (MEL) capability curve in per- unit values and

is superimposed on the actual excitation values. The horizontal capability curve screen is shown in Figure

32. A vertical curve is also available. For proper display of plotted values, the version of control system

firmware, resident in the Excitation Control Module (ECM) must be selected on the Capability Curve

Configuration screen. This screen is accessed by pressing the Configure button.

Figure 32. Capability Curve Screen

Task Guide

Table 3 lists common tasks along with the IDP-1200 pages that provide the controls for performing the

tasks.

Table 3. Tasks and Screens Cross-Reference

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 37

9437200990 Rev C 29

Mode

PS

Level

Password

1

New

2

New

3

4 5

6 7 8 9

10 11

12 13 14 15

12345

Password Settings

The default, level 2 password is “4321”. Use the following procedure to change the security password. A

USB flash drive is required to change the password.

1. Create a CSV (comma-separated values) file named “Security.csv” that has its content structured

as shown in Table 4. Place the new password where “New” is shown in the table. Passwords are

case sensitive and have a maximum length of eight alphanumeric characters. It is not necessary

to enter a password for levels 3 through 14. The default level 15 password is “12345” and should

not be changed.

2. Insert the USB flash drive into any available USB port on your PC.

®

3. Use normal Windows

4. Copy the CSV file created in Step 1 inside the “Security” directory on the flash drive.

5. Insert the USB flash drive into one of the USB ports on the side of the IDP-1200.

6. Press the Index button on any IDP-1200 page.

7. Press the Setup button on the General Index page.

8. Press the Login button at the bottom of the page.

9. Enter the default security password (4321).

techniques to create a root directory on the flash drive named “Security”.

10. Press the Change Passw ord s button located on the right side of the page.

11. If successful, the unit will display “Password change successful” to the left of the Change

Passwords button.

12. If the unit displays “Password file not found”, verify that the CSV file is valid, named correctly, and

located in the proper directory on the flash drive.

Table 4. Security.csv File Structure

Updating IDP-1200 Configur a t ion Files from Basler Electric

Use the following procedure to upload an IDP-1200 settings/software file provided by Basler Electric.

1. Copy the configuration file (*.cml) onto a USB flash drive in the root directory.

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 38

30 9437200990 Rev C

2. Open the IDP Loader folder and copy the /prj001 folder and boot.cfg file onto the USB flash drive

in the root directory.

3. Insert the drive into one of the USB ports on the side of the IDP-1200

4. Press the Index button on any IDP-1200 page to access the General Index page.

5. Tap in the upper, left corner of the page and, within one second, tap in the lower right corner of

the page. If done correctly, a menu should appear at the bottom of the page.

6. Press the CF/USB button at the bottom of the page.

7. Press the USB_Starting button at the bottom of the page.

8. Tap on the language box in the center of the page and select the desired language.

9. Press the Download (USB=>Display) button located to the right of the page center.

10. Select the configuration file (*.cml) file from the file list.

11. Tap on the password box in the center of the page and enter the appropriate password. (The

default password is “5678”. On the popup control, use the Down arrow to toggle between letters

and numbers.)

12. Press the Start button located in the center of the page.

13. Press the Yes button when asked to download the data. Downloading settings from a USB flash

drive to the IDP-1200 takes approximately three minutes.

14. After completion of the download, press the Back button located at the bottom of the page.

15. Press the Back button again.

16. Press the Exit button at the bottom of the page.

17. Press the Yes button when prompted to restart the system.

Updating IDP-1200 Configur a t ion Files from Documentation CD

Configuration files are included on the documentation CD that accompanies the manual for this excitation

system. If replacement of a display panel becomes necessary, the provided files enable you to program

the new IDP-1200 to ensure proper functionality with your system or application.

Use the following procedure to upload an IDP-1200 configuration file provided by Basler Electric.

1. Open the Configuration Files folder on the documentation CD and copy the configuration file

(*.cml) onto a USB flash drive in the root directory.

2. Open the IDP Loader folder and copy the /prj001 folder and boot.cfg file onto the USB flash drive

in the root directory.

3. Insert the drive into one of the USB ports on the side of the IDP-1200.

4. Press the Index button on any IDP-1200 page to access the General Index page.

5. Tap in the upper, left corner of the page and, within one second, tap in the lower right corner of

the page. If done correctly, a menu should appear at the bottom of the page.

6. Press the CF/USB button at the bottom of the page.

7. Press the USB_Starting button at the bottom of the page.

8. Tap on the language box in the center of the page and select the desired language.

9. Press the Download (USB=>Display) button located to the right of the page center.

10. Select the configuration file (*.cml) file from the file list.

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 39

9437200990 Rev C 31

11. Tap on the password box in the center of the page and enter the appropriate password. (The

default password is “5678”. On the popup control, use the Down arrow to toggle between letters

and numbers.)

12. Press the Start button located in the center of the page.

13. Press the Yes button when asked to download the data. Downloading settings from a USB flash

drive to the IDP-1200 takes approximately three minutes.

14. After completion of the download, press the Back button located at the bottom of the page.

15. Press the Back button again.

16. Press the Exit button at the bottom of the page.

17. Press the Yes button when prompted to restart the system.

IDP-1200 IDP-1200 Operation with ECS2100 and ECS/RW

Page 40

32 9437200990 Rev C

IDP-1200 Operation with ECS2100 and ECS/RW IDP-1200

Page 41

9437200990 Rev C 33

IDP-1200 Operation with DECS-2100 and DECS/RW

Control system and generator system parameters are viewed and controlled through interactive screens

displayed by the IDP-1200. Screens are organized by function. Navigation between screens and control

of functions are achieved by pressing buttons located on the IDP-1200 screens.

This chapter illustrates and describes IDP-1200 screen navigation and usage. The available IDP-1200

screens and their appearance will vary according to the number of control channels and rectifier bridges

utilized in a particular control system.

Initial Screen

The Initial screen (Figure 33) is displayed upon power-up of the IDP-1200. The initial screen lists the

version of the IDP-1200 firmware.

Figure 33. Initial Screen

Index Button

Most screens have an Index button that, when pressed, accesses the General Index screen. The General

Index screen provides quick navigation to any other IDP-1200 screen.

Get Page Button and Screen

Most screens have a Get Page button that accesses the Get Page screen illustrated in Figure 34. This

screen lists all screens and provides navigation to each screen. To navigate to a screen, the user scrolls

through the screen description list by using the up and down scrolling buttons until the desired screen and

screen number are found. The screen number is entered in a numeric keypad accessed by pressing the

86 button. (This button displays the number of the Get Page screen, which is 86.) Entering the screen

number followed by the Enter (ENT) button takes the user to the requested screen. A complete list of IDP1200 screens is provided in Table 5. Typically, your system/IDP-1200 will not have all of the

equipment/screens listed here.

IDP-1200 IDP-1200 Operation with DECS-2100 and DECS/RW

Page 42

34 9437200990 Rev C

Page

Description

1

Initial

2

General Index

3

Metering Index

4

Trending Index

6

Limiters and Trips

7

Alarm Status

8

Alarm/Fault – Active

9

Alarm/Fault – History

10

Bridge 00, 01 Status

11

Bridge 02, 03 Status

12

Bridge 04, 05 Status

13

Bridge 06, 07 Status

14

Bridge 08, 09 Status

15

Bridge 10, 11 Status

16

Bridge 12, 13 Status

17

Bridge 14, 15 Status

18

Fan Control/Temperature Monitor

19

Fan Control/Temperature Monitor

22

Voltage Match

23

Power Factor

24

Synchronizer

25

Synchronizer Display

Figure 34. Get Page Screen

Table 5. IDP-1200 Screens

IDP-1200 Operation with DECS-2100 and DECS/RW IDP-1200

Page 43

9437200990 Rev C 35

Page

Description

26

Transfer Control

27

Power System Stabilizer

28

Field Ground

29

Reactive Power

30

Output Control

31

Generator Simulation

32

Generator Monitor

34

Channel Comparison

35

Main Meter Panel

36

Redundant Meter Panel

38

Main Meter Panel – Analog

39

Redundant Meter Panel – Analog

41

Meter Panel – Analog Configuration

42

Generator Meter Panel – Analog

43

Generator Meter Panel – Analog Configuration

44

Meter Trending Graph – Main

45

Meter Trending Data – Main

46

Meter Trending Graph – Redundant

47

Meter Trending Data – Redundant

48

Meter Trending Configuration

49

Bridge 00 Temperature Trending Graph

50

Bridge 00 Temperature Trending Data

51

Bridge 01 Temperature Trending Graph

52

Bridge 01 Temperature Trending Data

53

Bridge 02 Temperature Trending Graph

54

Bridge 02 Temperature Trending Data

55

Bridge 03 Temperature Trending Graph

56

Bridge 03 Temperature Trending Data

57

Bridge 04 Temperature Trending Graph

58

Bridge 04 Temperature Trending Data

59

Bridge 05 Temperature Trending Graph

60

Bridge 05 Temperature Trending Data

61

Bridge 06 Temperature Trending Graph

62

Bridge 06 Temperature Trending Data

63

Bridge 07 Temperature Trending Graph

64

Bridge 07 Temperature Trending Data

65

Bridge 08 Temperature Trending Graph

66

Bridge 08 Temperature Trending Data

67

Bridge 09 Temperature Trending Graph

68

Bridge 09 Temperature Trending Data

IDP-1200 IDP-1200 Operation with DECS-2100 and DECS/RW

Page 44

36 9437200990 Rev C

Page

Description

69

Bridge 10 Temperature Trending Graph

70

Bridge 10 Temperature Trending Data

71

Bridge 11 Temperature Trending Graph

72

Bridge 11 Temperature Trending Data

73

Bridge 12 Temperature Trending Graph

74

Bridge 12 Temperature Trending Data

75

Bridge 13 Temperature Trending Graph

76

Bridge 13 Temperature Trending Data

77

Bridge 14 Temperature Trending Graph

78

Bridge 14 Temperature Trending Data

79

Bridge 15 Temperature Trending Graph

80

Bridge 15 Temperature Trending Data

81

Horizontal Capability Curve

82

Vertical Capability Curve

83

System Configuration

84

Cleaning Lock

85

Screen Saver

86

Get Page

88

File Manager

Alarms Banner

Most screens display an alarms banner that lists the six most recent system alarms. Each alarm is

labeled with a description and the date and time of the alarm. The timestamp for acknowledgement and

clearing (if applicable) of alarms is also displayed. Active alarms are displayed as white text on a red

background. Acknowledged alarms are displayed as yellow text on a black background. Cleared alarms

are displayed as red text on a white background.

System Configuration Screen

This screen (Figure 35) has provisions for adjusting the screen saver time delay, adjusting the display

brightness, and selecting the display language.

If the IDP-1200 panel requires cleaning, the Lock for Cleaning button can be pressed to enable cleaning

of the screen without inadvertently pressing buttons.

A Log In button accesses an alphanumeric keypad where the appropriate password can be entered to log

in and make IDP-1200 settings changes. The IDP-1200 is delivered with a level 1 password of “1234” and

a level 2 password of “4321”. The proper, level 1 password is required to select the IDP-1200 display

language. The proper level 2 password is required to configure the IDP-1200 as a local or remote display

or to change passwords. Instructions for changing the password are provided in Password Settings.

IDP-1200 Operation with DECS-2100 and DECS/RW IDP-1200

Page 45

9437200990 Rev C 37

Figure 35. System Configuration Screen

File Manager

The Open File Manager button accesses the file manager which lists the files present on an inserted

compact flash card and connected USB device. Files can be copied or moved from one storage device to

the other or deleted. This button also accesses the file manager where you can download event records.

See Figure 36.

Figure 36. File Manager Screen

An indicator turns red to indicate the connection of a USB device to the IDP-1200. A button below the

indicator can be pressed to de-energize the IDP-1200 USB port for safe removal of a USB device from

the IDP-1200.

IDP-1200 IDP-1200 Operation with DECS-2100 and DECS/RW

Page 46

38 9437200990 Rev C

Downloading Event Records

The following procedure is used to download event records.

Step 1. Insert a USB drive into the USB 2 port on the front of the ECM-2 (Main).

Step 2. Using the IDP-1200, navigate to the General Index screen.

Step 3. Press Setup to enter the Configuration screen.

Step 4. On the Configuration screen, select Open File Manager.

Step 5. Verify that the M (Main) indicator next to “USB Device Ready” is illuminate d .

Step 6. Press the “Download Data From Controller” button under M (Main).

Step 7. Wait until the M (Main) indicator next to “USB Download Complete” illuminates.

Step 8. Press the “Push to Safely Remove USB Device” button under M (Main).

Step 9. Wait until the M (Main) indicator next to “USB Device Not In Use.” illuminates.

Step 10. Remove the USB drive.

General Index

The General Index screen (Figure 37) is accessed by pressing the Index button, located in the lower right

corner of any other IDP-1200 screen. The General Index screen provides two methods of access to other

screens within the IDP-1200. Buttons on the General Index page provide quick access to 20 frequently

used IDP-1200 screens.

Figure 37. General Index Screen

Metering Index

Buttons on the Metering Index screen (Figure 38) are pressed to access the screens used to scale and

display system metering values.

IDP-1200 Operation with DECS-2100 and DECS/RW IDP-1200

Page 47

9437200990 Rev C 39

Figure 38. Metering Index Screen

Analog Meter Config Button

Pressing this Metering Index screen button accesses the Analog Meter Configuration screen (Figure 39)

which sets the range of the metering values displayed on the Main, Redundant, and Supervisory Metering

Panels (if so equipped). The minimum and maximum per-unit values for a metered parameter is changed

by pressing the corresponding value. This displays a keypad which is then used to assign the desired

metering limit. A per-unit value of –5.00 to 5.00 may be entered. Pr ess ing the En ter (ENT) button saves

the value.

Figure 39. Analog Meter Configuration Screen

IDP-1200 IDP-1200 Operation with DECS-2100 and DECS/RW

Page 48

40 9437200990 Rev C

Parameter

Minimum

Maximum

Field Current

0

10000

Field Voltage

–1500

1500

Generator Current

0

30000

Generator Voltage

0

30000

Generator Megavars

–1500

1500

Generator Megawatts

0

1500

Main Analog Meter, Redundant Analog Meter, and Supervisory Analog Meter Buttons

Pressing one of these Metering Index screen buttons (if so equipped) accesses the corresponding

metering page which displays the parameters illustrated in Figure 40. (Only the Main Meter Panel is

shown here; the Redundant and Supervisory Meter Panels are similar.) The value of each parameter is

graphically shown on an analog scale and also displayed in digital format. The minimum and maximum

values established on the Analog Meter Configuration screen determine the metering ranges shown on

this screen.

Figure 40. Main Meter Panel

Gen Analog Meter Config Button

Pressing this Metering Index screen button accesses the Generator Metering Configuration screen

(Figure 41) which sets the range of the generator metering values displayed on the Generator Metering

screen. The generator power factor metering range is fixed so no adjustment is provided. The minimum

and maximum value for a metered parameter is changed by pressing the corresponding value. This

displays a keypad which is then used to assign the desired metering limit. Pressing the Enter (ENT)

button saves the value. Minimum and maximum metering parameter ranges are listed in Table 6.

Table 6. Metering Parameter Rang es

IDP-1200 Operation with DECS-2100 and DECS/RW IDP-1200

Page 49

9437200990 Rev C 41

Figure 41. Generator Metering Configuration Screen

Generator Analog Meter Button

Pressing this Metering Index screen button accesses the Generator Metering screen which displays the

parameters illustrated in Figure 42. The value of each parameter is graphically shown on an analog scale

and also displayed in digital format. The mini mum and max im um va lues es tab lishe d on the Generator

Metering Configuration screen determine the metering ranges shown on this screen. The Generator

Metering screen also indicates the control system channel that is controlling excitation.

Figure 42. Generator Metering Screen

Channel Compare Button

Pressing this Metering Index screen button accesses the Channel Compare screen (Figure 43) which

displays a list of parameters metered by the control system channels. Scroll buttons, located to the right

IDP-1200 IDP-1200 Operation with DECS-2100 and DECS/RW

Page 50

42 9437200990 Rev C

of the list, can be used to scroll up and down through the list of parameters. (A particular system may not

be equipped with all of the channels shown here.) Three columns of indicators, located in the lower

portion of the screen, show the status of various operating modes, functions, and devices for the three

channels. The Channel in Control indicators turn green when active; all other indicators turn red when

active.

Figure 43. Channel Compare Screen

Main Meter Panel, Redundant Meter Panel, and Supervisory Meter Panel Buttons

Pressing one of these Metering Index screen buttons (if so equipped) accesses the corresponding meter

panel screen which displays the digital-only version of the parameters illustrated in Figure 40. (Only the

Main Meter Panel (Figure 44) is shown here; the Redundant and Supervisory Meter Panels are similar.)

The minimum and maximum values established on the Analog Meter Configuration page determine the

metering ranges shown on this screen.

IDP-1200 Operation with DECS-2100 and DECS/RW IDP-1200

Page 51

9437200990 Rev C 43

Figure 44. Main Meter Panel Screen

Trending Index

Buttons on the Trending Index screen (Figure 45) provide access to data lists and plots for user-selected

control system parameters and temperature data lists and plots for the excitation system rectifier bridges.

Appropriate buttons are provided based on the number of bridges included in the system.

Figure 45. Trending Index Screen

Trending Config Button

Pressing this Trending Index screen button accesses the Meter Trending Configuration screen shown in