Page 1

INSTRUCTION MANUA L

FOR

DGC-2020HD

DIGITAL GENSET CONTROLLE R

Publication: 9469300990

Revision: B Mar-14

Page 2

Page 3

9469300990 Rev B i

Caution

Note

Preface

This instruction manual provides information about the installation and operation of the DGC-2020HD

Digital Genset Controller. To accomplish this, the following information is provided:

• Controls and indicators

• Inputs and outputs

• Protection and control functions

• Reporting and alarms information

• Mounting and connection diagrams

• BESTCOMSPlus

• Communication and security

• Maintenance and troublesh ooting pr oc edures

• Specifications

• AEM-2020

• CEM-2020

• MTU Fault Codes

• Exhaust Treatment

• Diagnostic Trouble Codes

Conventions Used in this Ma nua l

®

software

Important safety and procedural information is emphasized and presented in this manual through

Warning, Caution, and Note boxes. Each type is illustrated and defined as follows.

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note boxes emphasize important information pertaining to Digital

Genset Controller installation or operation.

Digital Genset Controller Preface

Page 4

ii 9469300990 Rev B

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

This product contains, in part, open source software (software licensed in a way that ensures freedom to run,

terms of either the GNU General Public License or GNU Lesser General Public License. The licenses, at the time

documentation from us, including our End User License Agreement, places any additional restrictions on what you

corresponding source code for the version of the programs distributed to you will be sent upon request (contact

The source code is distributed in the hope that it will be useful, but WITHOUT ANY REPRESENTATION or

Review the software website for the latest version of the software documentation.

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide

manual.

The English-language version of this manual serves as the only approved manual version.

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2014 by Basler E lectric

All rights reserved

First printing: November 2013

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the DGC-2020HD.

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Only qualified personnel should install, operate, or service this system.

Failure to follow warning and cautionary labels may result in personal injury or property damage.

Exercise caution at all times.

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

copy, distribute, study, change, and improve the software) and you are granted a license to that software under the

of sale of the product, allow you to freely copy, modify, and redistribute that software and no other statement or

may do with that software.

For at least three (3) years from the date of distribution of this product, a machine-readable copy of the complete

information is provided above). A fee of no more than our cost of physically performing the source code distribution

is charged.

WARRANTY or even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE.

Refer to the source code distribution for additional restrictions regarding warranty and copyrights.

For a complete copy of GNU GENERAL PUBLIC LICENSE Version 2, June 1991 or GNU LESSER GENERAL

PUBLIC LICENSE Version 2.1, February 1999 refer to www.gnu.org or contact Basler Electric. You, as a Basler

Electric Company customer, agree to abide by the terms and conditions of GNU GENERAL PUBLIC LICENSE

Version 2, June 1991 or GNU LESSER GENERAL PUBLIC LICENSE Version 2.1, February 1999, and as such

hold Basler Electric Company harmless related to any open source software incorporated in this product. Basler

Electric Company disclaims any and all liability associated with the open source software and the user agrees to

defend and indemnify Basler Electric Company, its directors, officers, and employees from and against any and all

losses, claims, attorneys' fees, and expenses arising from the use, sharing, or redistribution of the software.

data for every possible contingency regarding installation or operation. The availability and design of all features

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

Preface DGC-2020HD

Page 5

9469300990 Rev B iii

Contents

Introduction ................................................................................................................................................. 1

Features and Functions ............................................................................................................................. 1

Style Number ............................................................................................................................................. 4

Optional Features and Capabilities ........................................................................................................... 4

Specifications .............................................................................................................................................. 5

Operating Power ........................................................................................................................................ 5

Battery Ride Through ................................................................................................................................ 5

Current Sensing ......................................................................................................................................... 5

Voltage Sensing ........................................................................................................................................ 5

Analog Sensing ......................................................................................................................................... 6

Contact Sensing ........................................................................................................................................ 6

Engine System Inputs................................................................................................................................ 7

Output Contacts ......................................................................................................................................... 7

Metering ..................................................................................................................................................... 8

Generator Protection Functions .............................................................................................................. 10

Logic Timers ............................................................................................................................................ 11

Communication Interface......................................................................................................................... 11

Real-Time Clock ...................................................................................................................................... 12

LCD Heater .............................................................................................................................................. 13

Type Tests ............................................................................................................................................... 13

Environment ............................................................................................................................................ 13

UL Approval ............................................................................................................................................. 14

CSA Certification ..................................................................................................................................... 14

NFPA Compliance ................................................................................................................................... 14

CE Compliance ........................................................................................................................................ 14

Physical ................................................................................................................................................... 14

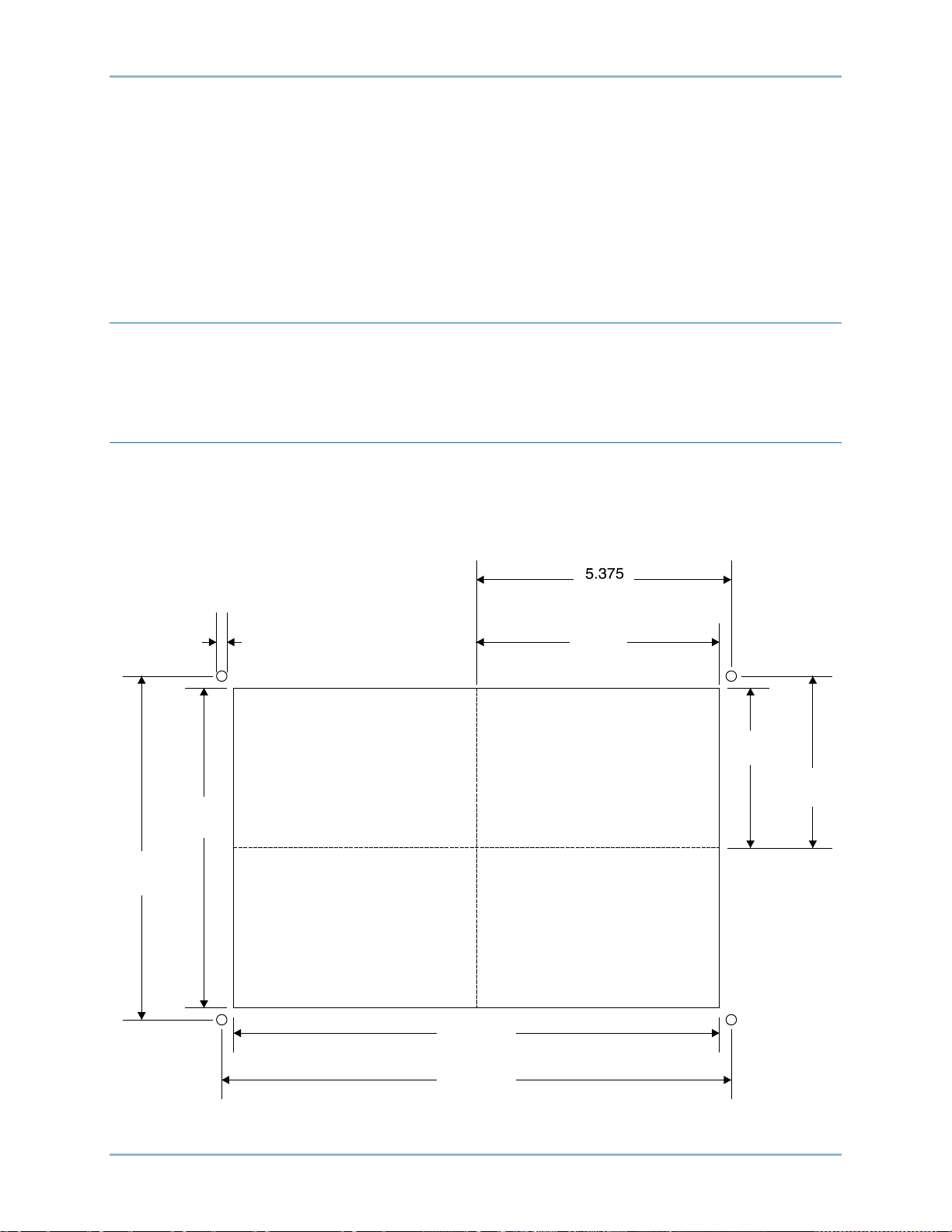

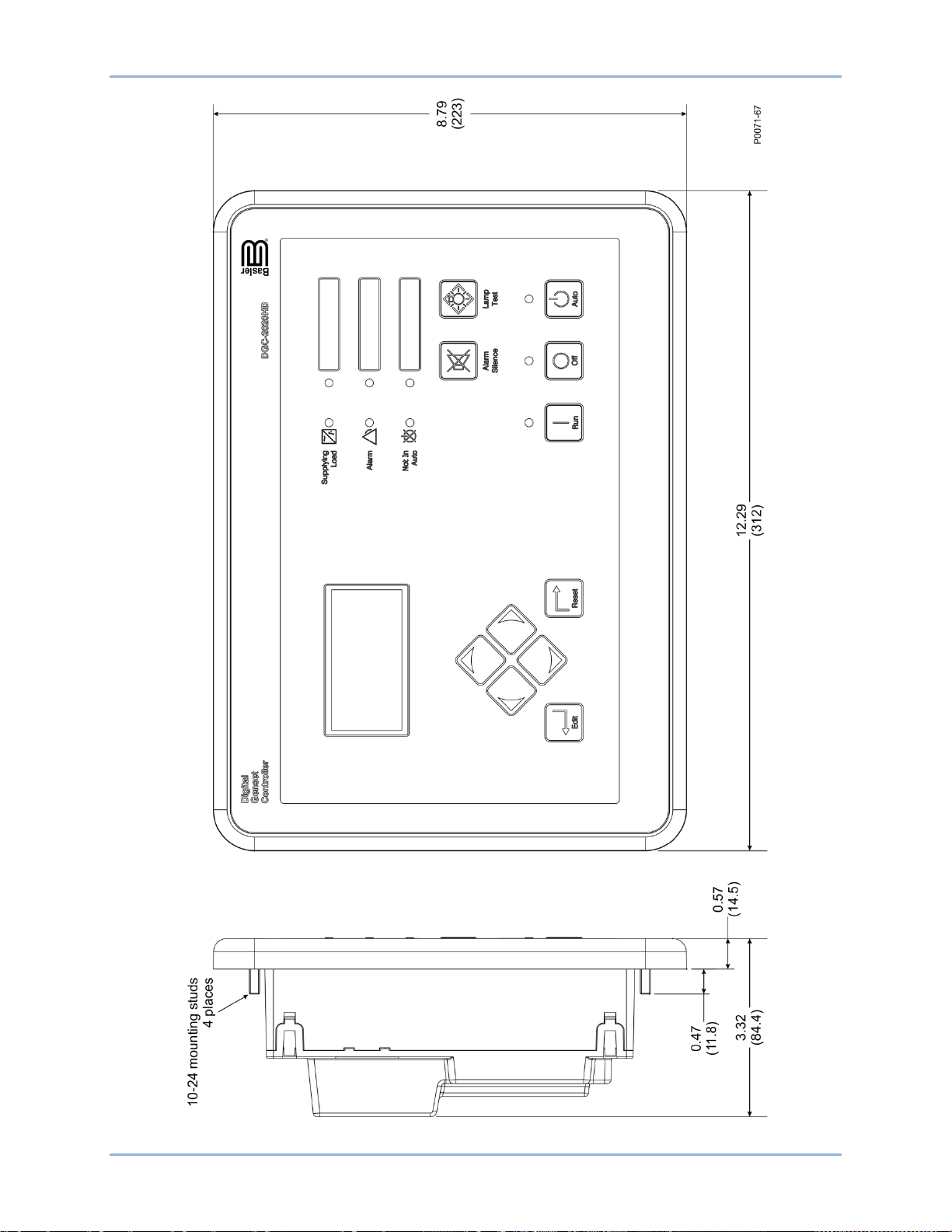

Mounting .................................................................................................................................................... 15

Hardware ................................................................................................................................................. 15

Dimensions .............................................................................................................................................. 15

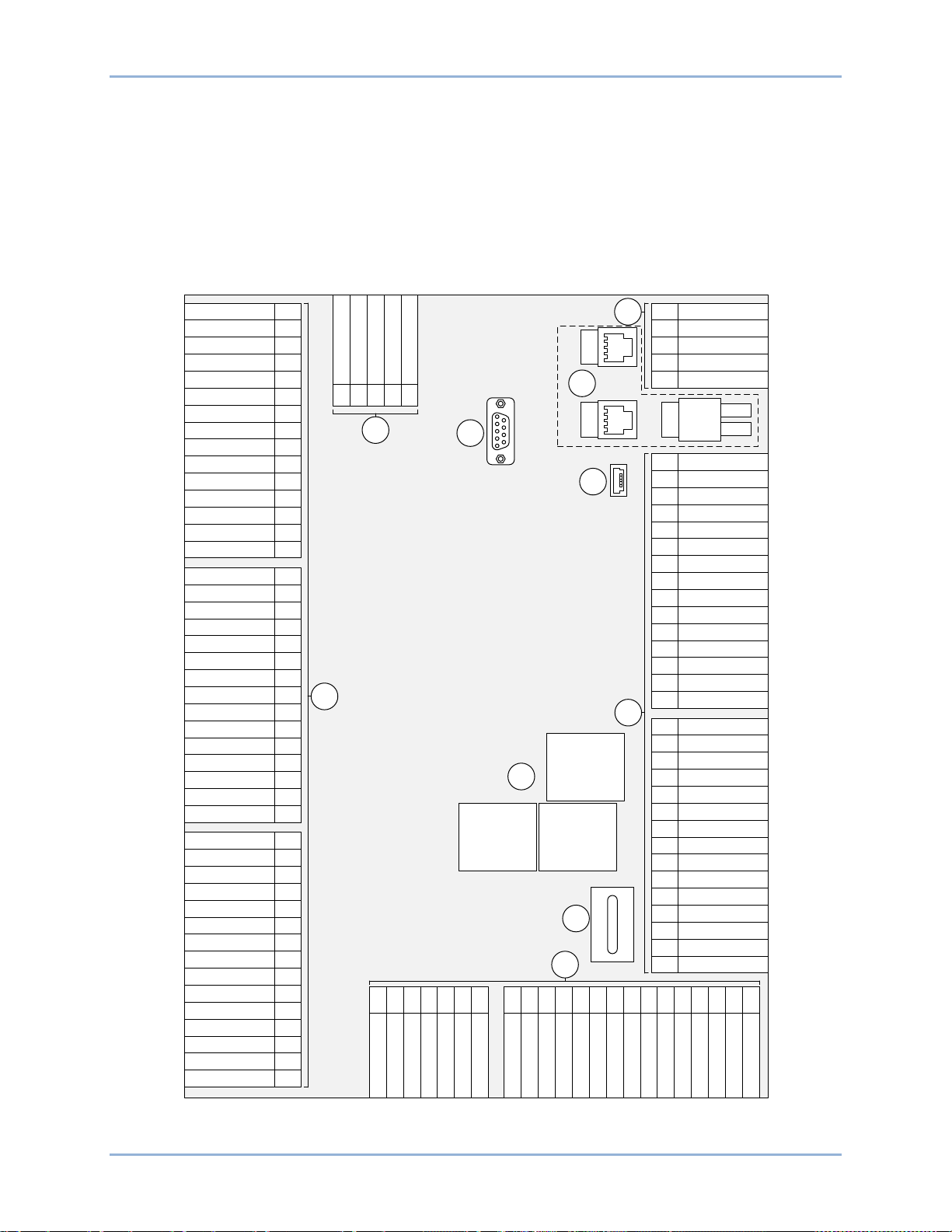

Terminals and Connectors ....................................................................................................................... 17

Terminals ................................................................................................................................................. 18

Connectors .............................................................................................................................................. 25

Typical Applications ................................................................................................................................. 27

Connections for Typical Applications ...................................................................................................... 27

Connections for Load Sharing ................................................................................................................. 32

Analog Input Connections ....................................................................................................................... 33

CAN Connections .................................................................................................................................... 33

Expansion Module Connections (CAN 1) ................................................................................................ 35

Installation for CE Systems ..................................................................................................................... 35

Controls and Indicators ............................................................................................................................ 37

Programmable Indicator Configuration .................................................................................................... 39

Display Operation and Navigation ........................................................................................................... 40

Display Setup .......................................................................................................................................... 48

Power Input ................................................................................................................................................ 51

Nominal Voltage Input and Acceptable Range of Input Voltage ............................................................. 51

Terminal Assignments ............................................................................................................................. 51

Power Consumption ................................................................................................................................ 51

Battery Ride-Through Capability ............................................................................................................. 51

Fuse Protection ....................................................................................................................................... 51

Voltage and Current Sensing ................................................................................................................... 53

Generator Voltage ................................................................................................................................... 53

DGC-2020HD Contents

Page 6

iv 9469300990 Rev B

Bus Voltage ............................................................................................................................................. 53

Generator and Bus Current ..................................................................................................................... 53

Engine Sender Inputs ............................................................................................................................... 55

Connections ............................................................................................................................................. 55

Compatibility ............................................................................................................................................ 55

Operation ................................................................................................................................................. 55

Programmability ....................................................................................................................................... 55

Characteristic Curves .............................................................................................................................. 55

Sender Failure Detection ......................................................................................................................... 59

Speed Signal Inputs .................................................................................................................................. 61

Magnetic Pickup ...................................................................................................................................... 61

Generator Sensing Voltage ..................................................................................................................... 61

Contact Inputs ........................................................................................................................................... 63

Programmable Contact Inputs ................................................................................................................. 63

Analog Inputs ............................................................................................................................................ 67

Input Setup .............................................................................................................................................. 67

Ranges .................................................................................................................................................... 67

Thresholds ............................................................................................................................................... 67

Operational Settings ................................................................................................................................ 68

Logic Connections ................................................................................................................................... 69

Contact Outputs ........................................................................................................................................ 71

Prestart .................................................................................................................................................... 71

Start ......................................................................................................................................................... 71

Run .......................................................................................................................................................... 71

Relay Control ........................................................................................................................................... 71

Programmable Contact Outputs .............................................................................................................. 72

Operating Modes ....................................................................................................................................... 75

Off ............................................................................................................................................................ 75

Run .......................................................................................................................................................... 75

Auto ......................................................................................................................................................... 75

Operating Mode Control .......................................................................................................................... 75

Breaker Management ................................................................................................................................ 77

Breaker Status ......................................................................................................................................... 77

System Breaker Configuration ................................................................................................................ 77

Breaker Operation ................................................................................................................................... 88

Synchronizer ............................................................................................................................................. 97

Operation ................................................................................................................................................. 97

Configuration ........................................................................................................................................... 99

Bias Control ............................................................................................................................................. 113

AVR Bias Control Settings .................................................................................................................... 113

Governor Bias Control Settings ............................................................................................................. 115

Multiple Generator Management ........................................................................................................... 119

AVR Output ........................................................................................................................................... 119

Governor Output .................................................................................................................................... 120

Load Share Output ................................................................................................................................ 121

Parameter Selection .............................................................................................................................. 121

Demand Start/Stop ................................................................................................................................ 121

Generator Sequencing .......................................................................................................................... 123

Network Configuration ........................................................................................................................... 125

Generator Protection .............................................................................................................................. 127

Undervoltage (27) .................................................................................................................................. 127

Overvoltage (59) .................................................................................................................................... 129

Contents DGC-2020HD

Page 7

9469300990 Rev B v

Phase Voltage Imbalance (47) .............................................................................................................. 131

Vector Shift (78) ..................................................................................................................................... 133

Frequency (81) ...................................................................................................................................... 135

Overcurrent (51) .................................................................................................................................... 138

Power (32) ............................................................................................................................................. 144

Loss of Excitation (40Q) ........................................................................................................................ 147

Setting Groups ....................................................................................................................................... 149

Configurable Protection ......................................................................................................................... 151

Element Setup ....................................................................................................................................... 151

Thresholds ............................................................................................................................................. 153

Logic Connections ................................................................................................................................. 154

Operational Settings .............................................................................................................................. 154

Metering ................................................................................................................................................... 157

Metering Explorer .................................................................................................................................. 157

Engine.................................................................................................................................................... 158

Generator .............................................................................................................................................. 159

Bus 1 and Optional Bus 2 ...................................................................................................................... 159

Bias Control ........................................................................................................................................... 160

Power..................................................................................................................................................... 160

Run Statistics ......................................................................................................................................... 161

Synchronization ..................................................................................................................................... 161

Status Indication .................................................................................................................................... 162

Inputs ..................................................................................................................................................... 162

Outputs .................................................................................................................................................. 167

Configurable Protection ......................................................................................................................... 169

J1939 ECU ............................................................................................................................................ 169

MTU ....................................................................................................................................................... 171

Summary ............................................................................................................................................... 172

Control Panel ......................................................................................................................................... 174

Generator Network Status ..................................................................................................................... 174

Generator Sequencing .......................................................................................................................... 175

Diagnostics ............................................................................................................................................ 176

Analysis ................................................................................................................................................. 176

Reporting and Alarms ............................................................................................................................. 179

Event Logging ........................................................................................................................................ 179

Sequence of Events .............................................................................................................................. 179

Data Logging ......................................................................................................................................... 180

Trending ................................................................................................................................................ 181

Alarms.................................................................................................................................................... 182

BESTCOMSPlus® Software .................................................................................................................... 193

System Recommendations ................................................................................................................... 194

Installation ............................................................................................................................................. 194

Activate the DGC-2020HD Plugin for BESTCOMSPlus® ...................................................................... 194

Menu Bars ............................................................................................................................................. 198

Settings Explorer ................................................................................................................................... 199

Metering Explorer .................................................................................................................................. 200

BESTspace™ ......................................................................................................................................... 200

Settings File Management ..................................................................................................................... 201

Auto Export Metering ............................................................................................................................. 202

BESTCOMSPlus® Updates ................................................................................................................... 203

Firmware Updates ................................................................................................................................. 203

BESTlogic™Plus ...................................................................................................................................... 205

Overview of BESTlogic™Plus ................................................................................................................ 205

BESTlogic™Plus Composition ............................................................................................................... 206

Logic Schemes ...................................................................................................................................... 234

DGC-2020HD Contents

Page 8

vi 9469300990 Rev B

Programming BESTlogic ™Plus.............................................................................................................. 235

Offline Logic Simulator .......................................................................................................................... 236

BESTlogic™Plus File Management ....................................................................................................... 236

BESTlogic™Plus Ex amp les ................................................................................................................... 237

Communication ....................................................................................................................................... 239

USB ....................................................................................................................................................... 239

Ethernet ................................................................................................................................................. 239

CAN ....................................................................................................................................................... 243

RS-232 .................................................................................................................................................. 253

RS-485 .................................................................................................................................................. 256

Modbus™ Setup ..................................................................................................................................... 256

Remote Display Panel (optional) ........................................................................................................... 257

Configuration ........................................................................................................................................... 259

System Settings ..................................................................................................................................... 259

Rated Data ............................................................................................................................................ 262

Remote Module Setup ........................................................................................................................... 267

Crank Settings ....................................................................................................................................... 267

Automatic Restart Settings .................................................................................................................... 269

Exercise Timer Settings......................................................................................................................... 270

Sensing Transformer Ratings ................................................................................................................ 271

Relay Control Settings ........................................................................................................................... 272

System Configuration Detection Settings .............................................................................................. 273

Device Information .................................................................................................................................. 275

Style Number ......................................................................................................................................... 275

Device Info ............................................................................................................................................. 275

Firmware Updates ................................................................................................................................. 276

Security .................................................................................................................................................... 281

Access Levels ........................................................................................................................................ 281

User Name Setup .................................................................................................................................. 281

Port Access Setup ................................................................................................................................. 283

Access Control ...................................................................................................................................... 283

Timekeeping ............................................................................................................................................ 285

Clock Setup ........................................................................................................................................... 285

Setting the Time and Date ..................................................................................................................... 287

IRIG Port ................................................................................................................................................ 287

Real-Time Clock Specificat ions ............................................................................................................. 288

Backup Battery for the Real-Time Clock ............................................................................................... 288

Maintenance and Troubleshooting ....................................................................................................... 289

Maintenance .......................................................................................................................................... 289

Storage .................................................................................................................................................. 289

Troubleshooting ..................................................................................................................................... 289

AEM-2020 ................................................................................................................................................. 303

Features ................................................................................................................................................ 303

Specifications ........................................................................................................................................ 303

Functional Description ........................................................................................................................... 305

Mounting ................................................................................................................................................ 305

Connections ........................................................................................................................................... 306

AEM-2020 Configuration ....................................................................................................................... 312

Remote Analog Inputs Configuration .................................................................................................... 312

Remote RTD Inputs Configuration ........................................................................................................ 315

Remote Thermocouple Inputs Configuration ........................................................................................ 317

Remote Analog Outputs Configuration .................................................................................................. 319

Firmware Updates ................................................................................................................................. 322

Repair .................................................................................................................................................... 322

Contents DGC-2020HD

Page 9

9469300990 Rev B vii

Maintenance .......................................................................................................................................... 322

Storage .................................................................................................................................................. 323

CEM-2020 ................................................................................................................................................. 325

Features ................................................................................................................................................ 325

Specifications ........................................................................................................................................ 325

Functional Description ........................................................................................................................... 327

Mounting ................................................................................................................................................ 327

Connections ........................................................................................................................................... 329

CEM-2020 Configuration ....................................................................................................................... 334

Remote Contact Inputs Configuration ................................................................................................... 334

Remote Contact Outputs Configuration ................................................................................................ 336

Firmware Updates ................................................................................................................................. 336

Repair .................................................................................................................................................... 336

Maintenance .......................................................................................................................................... 337

Storage .................................................................................................................................................. 337

Time Curve Characteristics.................................................................................................................... 339

Curve Specifications .............................................................................................................................. 339

Time Overcurrent Characteristic Curve Graphs .................................................................................... 340

Tuning PID Settings ................................................................................................................................ 361

Voltage and Speed Controllers ............................................................................................................. 361

kW Load Controller ................................................................................................................................ 361

Var/PF Controller ................................................................................................................................... 361

Speed Trim Function ............................................................................................................................. 361

Tuning Parameters ................................................................................................................................ 361

Tuning Procedures ................................................................................................................................ 362

Generic Gains for Multiple Machine Types ........................................................................................... 366

MTU Fault Codes ..................................................................................................................................... 367

Exhaust Treatment .................................................................................................................................. 377

Diesel Particulate Filter (DPF) ............................................................................................................... 377

Exhaust After-Treatment Systems (EATS)............................................................................................ 379

Diagnostic Trouble Codes ...................................................................................................................... 381

Revision History ...................................................................................................................................... 391

DGC-2020HD Contents

Page 10

viii 9469300990 Rev B

Contents DGC-2020HD

Page 11

9469300990 Rev B 1

Introduction

The DGC-2020HD Digital Genset Controller provides integrated engine-genset control, protection, and

metering in a single package. Microprocessor based technology allows for exact measurement, setpoint

adjustment, and timing functions. Front panel controls and indicators enable quick and simple DGC2020HD operation. A backlit liquid crystal display (LCD) can be viewed under a wide range of ambient

light and temperature conditions. Basler Electric communication software (BESTCOMSPlus®) allows units

to be easily customized for each application. Because of the low sensing burden in the DGC-2020HD,

dedicated potential transformers (PTs) are not required.

Features and Functions

The DGC-2020HD Digital Genset Controller has the following features:

• Local and remote generator control

• Engine, generator, and loss of mains protection (optional)

• Automatic transfer switch control (mains failure)

• Automatic generator configuration detection

• Generator sequencing

• Generator soft loading/unloading

• Auto synchronizing (optional)

• Programmable analog engine senders

• 16 programmable contact inputs

• Three programmable front panel LEDs, with labels

• Up to four local analog inputs

• A ramping function to load and unload generator smoothly

• Demand start/stop and generator sequencing

• kW and kvar load control

• kW and kvar load sharing via Ethernet or analog load share lines

• Programmable logic

• Exercise timer

• ECU communications via SAE J1939

• Marathon DVR2000E+ voltage regulator control via SAE J1939

• Integrated USB, RS485, and Ethernet communication

• Two J1939 CAN Bus ports

• Additional modules available to expand the capabilities of the DGC-2020HD

An overview of DGC-2020HD Digital Genset Controller functions is provided in the following paragraphs.

Generator and Bus Protection and Metering

Multifunction protection guards against overvoltage, undervoltage, excessive forward and reverse power,

underfrequency, and overfrequency. Overcurrent, phase imbalance, loss of mains, and frequency rate-ofchange protection are available as an option. Each protection function has an adjustable pickup and time

delay setting. Sixteen inverse time curves, in addition to user-programmable curves, enable the DGC2020HD to offer overcurrent protection in a variety of applications. Each protective element can be

assigned to the generator, bus 1 or bus 2.

Metered generator and bus parameters include voltage, current, real power (watts), apparent power (VA),

and power factor (PF).

Engine Protection and Metering

Engine protection features include oil pressure and coolant temperature monitoring, overcrank protection,

ECU-specific protection elements, and diagnostic reporting.

Metered engine parameters include oil pressure, coolant temperature, battery voltage, speed, fuel level,

engine load, coolant level (from ECU), ECU-specific parameters, and run-time statistics.

DGC-2020HD Introduction

Page 12

2 9469300990 Rev B

Load Sharing

The DGC-2020HD provides analog outputs to the power system in the form of analog bias signals to the

voltage regulator and speed governor. A pulse width modulated (PWM) speed bias output is also

available. When the generator breaker is closed and load sharing is enabled, the DGC-2020HD shares

the real power load proportionally with other generators in the system. Load sharing can be implemented

on the Analog Load Share Line or through Ethernet communications. Reactive power (kvar) sharing is

accomplished through Ethernet communications.

Event Recording

A history of system events are logged in nonvolatile memory. The DGC-2020HD retains records for 128

unique types of events. Each record tracks the number of times that an event has occurred and records a

time stamp of the first and last occurrences.

A Sequence of Events (SER) log is also available. This log tracks the internal and external status of the

DGC-2020HD. Events are scanned at five millisecond intervals with 1,023 events stored per record. All

changes of state that occur during each scan are time- and date-stamped. Sequences of Events reports

are available through BESTCOMSPlus. Over 1,000 records can be retained in nonvolatile memory. When

the SER memory becomes full, the oldest record is replaced by the latest one acquired.

Data Logging

The data logging function of the DGC-2020HD records up to six records of user-selectable, real-time

parameter data. For more information, see the Reporting and Alarms chapter.

Contact Inputs and Outputs

DGC-2020HD controllers have 16 programmable contact inputs. All contact inputs recognize dry contacts.

The programmable inputs can be configured to initiate a pre-alarm or alarm condition. A programmable

input can be programmed to receive a contact input from an automatic transfer switch (ATS). In addition,

a programmable Battle Override function allows overriding of DGC-2020HD alarms and protection

functions. Each programmable input can be assigned a user-defined name for easy identification at the

front panel display and in fault records.

Output contacts include three dedicated relays for energizing an engine’s glow plugs, fuel solenoid, and

starter solenoid. An additional twelve programmable output contacts are provided.

Additional contact inputs and output contacts can be accommodated with an optional CEM-2020 Contact

Expansion Module. Contact Basler Electric for ordering information.

Automatic Transfer Switch Control (Mains Failure)

The DGC-2020HD has the ability to detect a mains failure via a single- or three-phase Bus input. A mains

failure is established when any one of the following conditions are met:

• Any phase of bus voltage falls below the dead bus threshold

• Any phase of bus voltage is unstable due to overvoltage or undervoltage

• Any phase of bus voltage is unstable due to overfrequency or underfrequency

At this time, the DGC-2020HD starts the genset and, when ready, applies power to the load from the

genset. The DGC-2020HD implements open or closed breaker transitions to and from the mains. When

the mains returns and is considered stable, the DGC-2020HD will transfer the load back to the mains and

stop the engine. During closed breaker transitions, the optional Auto Synchronizer can synchronize the

generator to the mains before transferring the load from generator power to utility power.

Device Security

Passwords provide access security for six distinct functional access areas: Read, Control, Operator,

Settings, Design, and Administrator. Each username/password is assigned an access area with access to

that area and each area below it. An administrator password provides access to all six of the functional

areas.

Introduction DGC-2020HD

Page 13

9469300990 Rev B 3

A second dimension of security is provided by the ability to restrict access for any of the access areas to

only specific communication ports. For example, you could set up security to deny access to control

commands through an Ethernet port.

Security settings affect read and write access. Refer to the Security chapter for more information.

Communication

DGC-2020HD communication features include a mini-B USB port, RS-485 port, two copper Ethernet ports

or one fiber optic Ethernet port (optional), and SAE J1939 interface.

USB Port

The USB communication port can be used with BESTCOMSPlus® software to quickly configure a DGC2020HD with the desired settings or retrieve metering values and event log records.

RS485 Port

An RS485 communication port uses the Modbus™ communication protocol and enables remote control

and monitoring of the DGC-2020HD over a polled network.

Ethernet Port(s)

Depending on style number, each DGC-2020HD is equipped with either dual copper (100BaseT) Ethernet

communication ports (style xxxxDxxxx) or a fiber optic (100BaseF) Ethernet communication port (style

xxxxFxxxx).

Ethernet ports provide communications between the DGC-2020HD and a PC via BESTCOMSPlus or

other DGC-2020HDs in a network. An Ethernet connection to a PC running BESTCOMSPlus provides

remote metering, setting, annunciation, and control of the DGC-2020HD. Ethernet communication

between DGC-2020HDs allows for generator sequencing on an islanded system.

CAN Interface

The CAN (Control Area Network) interface provides high-speed communication between the DGC2020HD and the engine control unit (ECU) on an electronically controlled engine. This interface provides

access to oil pressure, coolant temperature, and engine speed data by reading these parameters directly

from the ECU. When available, engine diagnostic data can also be accessed. The CAN interface supports

the following protocols:

• SAE J1939 Protocol - Oil pressure, coolant temperature, and engine speed data are received

from the ECU. In addition, DTCs (Diagnostic Trouble Codes) help diagnose any engine-related

failures. The engine DTCs are displayed on the front panel of the DGC-2020HD and may be

obtained using BESTCOMSPlus® software.

• MTU Protocol - A DGC-2020HD connected to a genset equipped with an MTU engine ECU

receives Oil pressure, coolant temperature, and engine speed data from the engine controller,

along with various alarms and pre-alarms that are MTU-specific. In addition, the DGC-2020HD

tracks and displays the active fault codes issued by the MTU engine ECU.

DGC-2020HD Introduction

Page 14

4 9469300990 Rev B

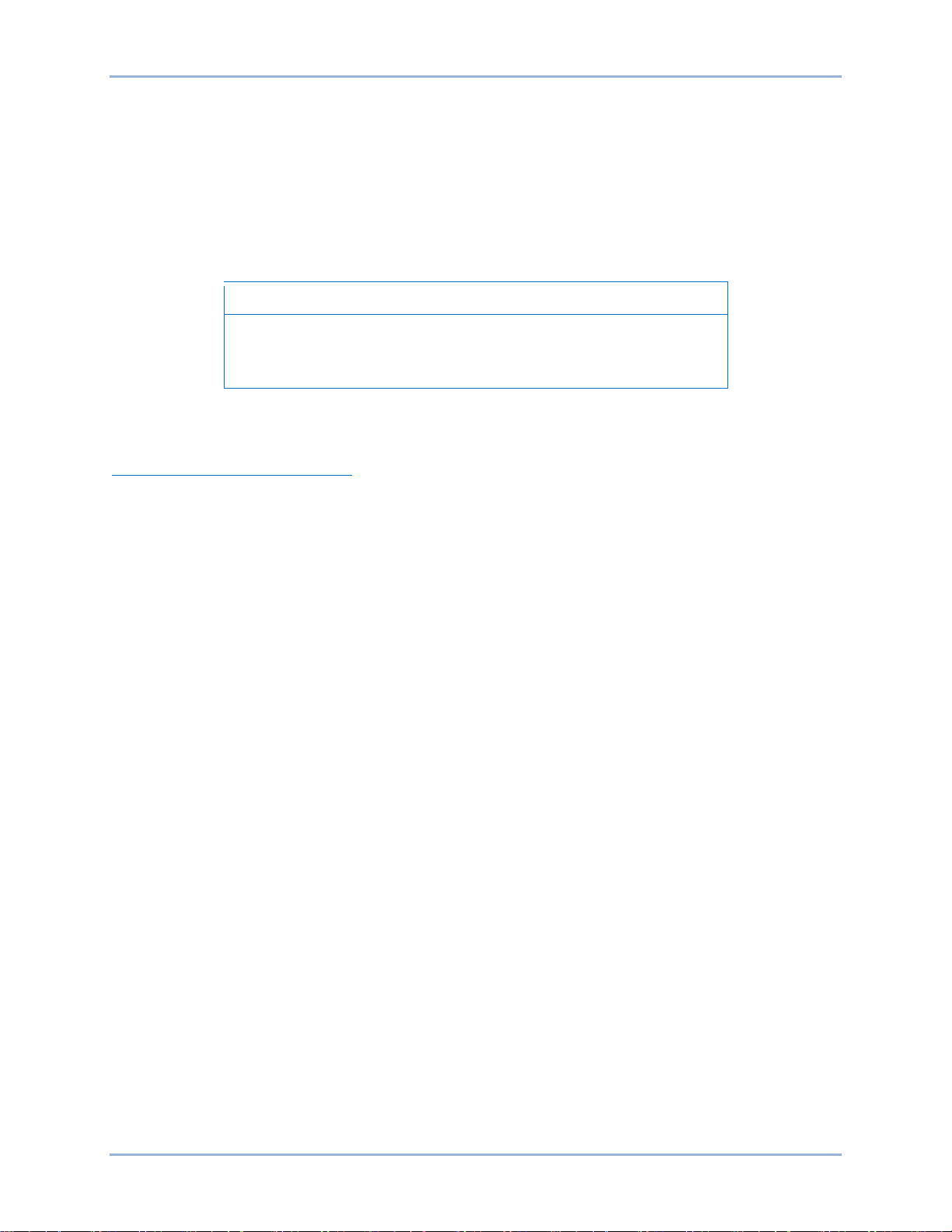

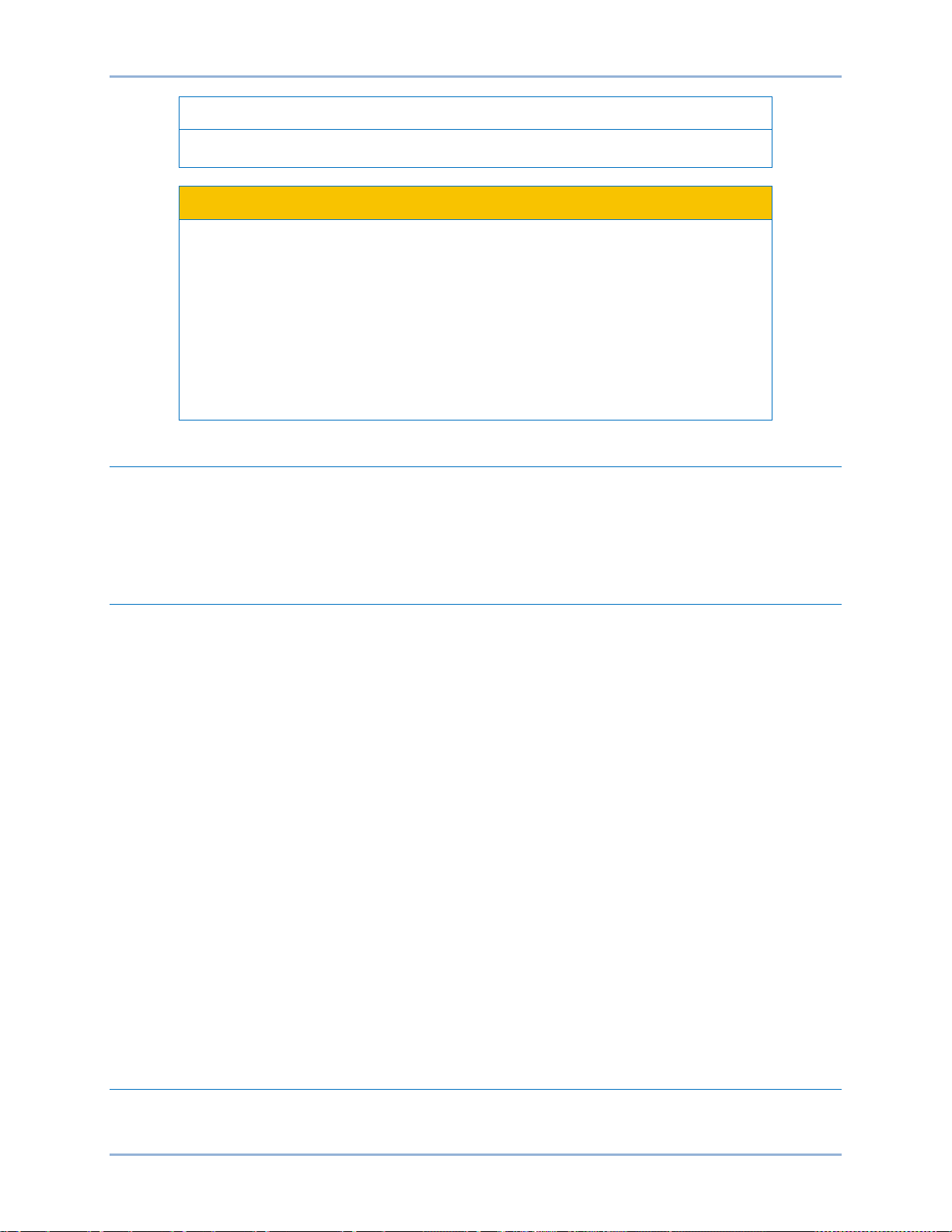

MODEL NUMBER

STYLE NUMBER

DGC – 2020HD

P0071-69

Current Sensing

5) 5A CT inputs

1) 1A CT inputs

N N

Generator Protection

,

S) Standard: 27, 32, 40Q,

59 81O, 81U

E) Enhanced: 27, 32, 40Q,

47, 51, 59, 78, 81O,

81U, 81 ROCOF

Ethernet

D) Dual 100BaseT (Copper)

F) 100BaseF (Fiber)

Terminal Type

S) Spring

Auto Synchronizer

1) No Auto Sync

2) w/ Auto Sync

The fuel level sender is always resistive and is not a programmable input.

1

Senders

A) Anal og

R) Resi st ive

1

Bus Inputs

B) Basic Sensing:

1 Bus Input, 4 CTs

E) Enhanced Sensing:

2 Bus Inputs, 7 CTs

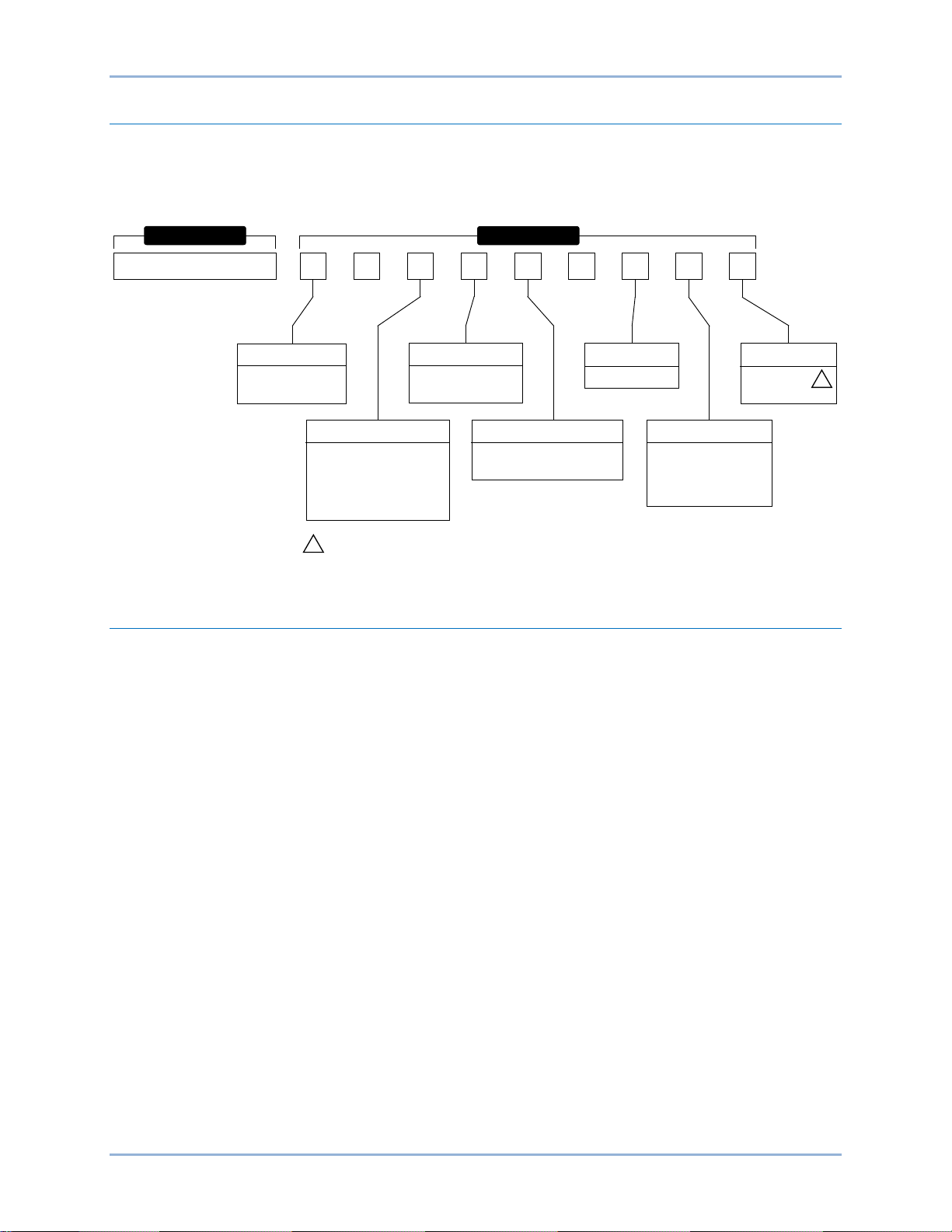

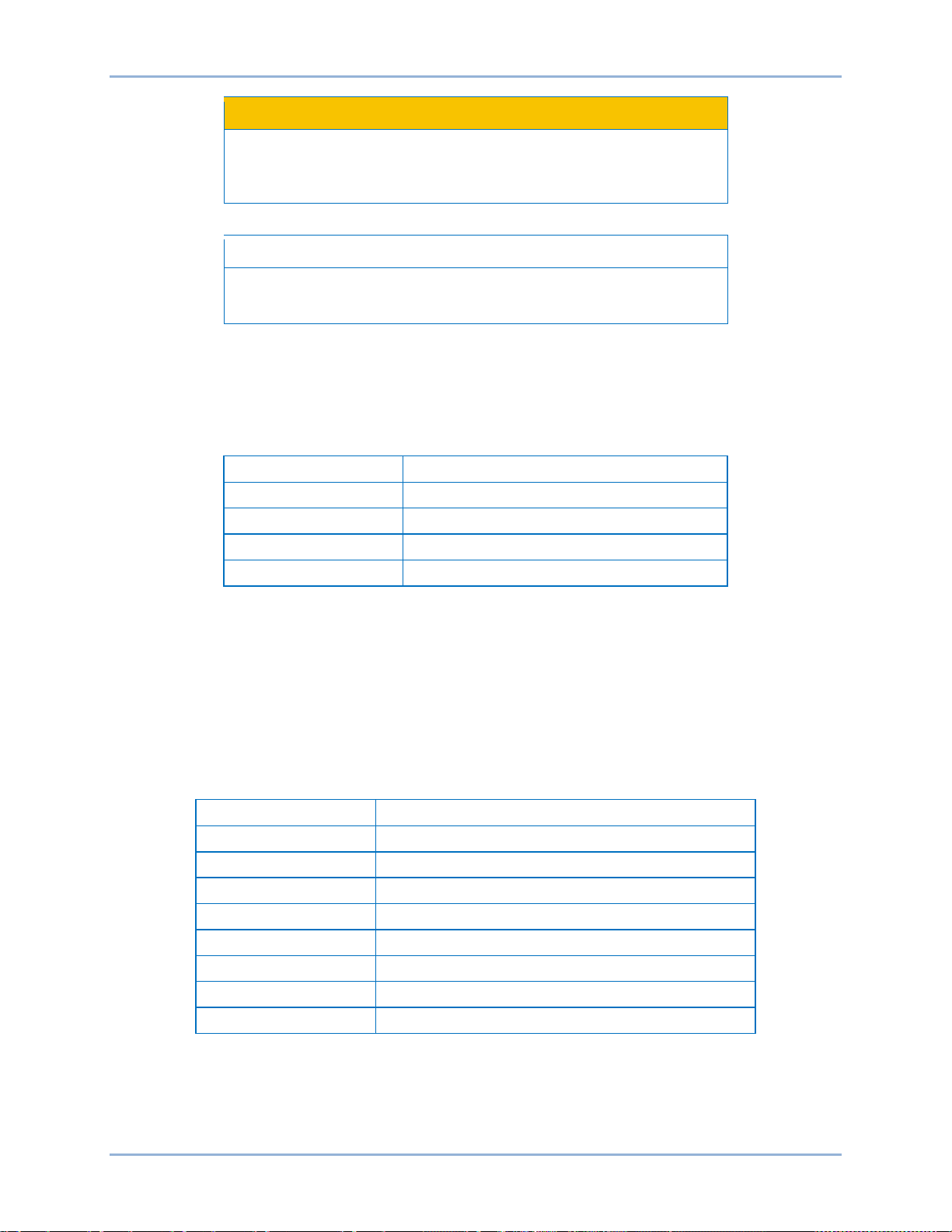

Style Number

Standard-order DGC-2020HD controllers are identified by a style number which consists of a combination

of letters and numbers that define the controller’s electrical characteristics and operational features. The

model number, together with the style number, describes the options included in a specific controller.

Figure 1 illustrates the DGC-2020HD style number identification chart.

Optional Features and Capabilities

AEM-2020 (Analog Expansion Module)

The optional AEM-2020 provides eight remote analog inputs, eight remote RTD inputs, two Type-K

remote thermocouple inputs, and four remote analog outputs to the DGC-2020HD. The AEM-2020

communicates with the DGC-2020HD through a CAN interface. Up to four AEM-2020s may be used with

one DGC-2020HD. Refer to the AEM-2020 chapter for more information.

CEM-2020 (Contact Expansion Module)

The optional CEM-2020 provides 10 additional contact inputs and 18 or 24 additional output contacts

(depending on module type) to the DGC-2020HD. The CEM-2020 communicates with the DGC-2020HD

through a CAN interface. Up to four CEM-2020s may be used with one DGC-2020HD. Refer to the CEM-

2020 chapter for more information.

Figure 1. DGC-2020HD Style Chart

Introduction DGC-2020HD

Page 15

9469300990 Rev B 5

Specifications

DGC-2020HD electrical and physical characteristics are listed in the following paragraphs.

Operating Power

Nominal ............................................ 12 or 24 Vdc

Range ............................................... 6 to 32 Vdc

Terminals.......................................... 48 (+), 49 (–), 50 (chassis ground)

Power Consumption

Sleep Mode ...................................... 12.7 W - LCD heater off, all relays de-energized, and analog outputs

disabled

Normal Operational Mode ................ 18.1 W - Run mode, LCD heater off, START and RUN relays

energized, six programmable relays energized, and analog outputs

enabled

Maximum Operational Mode ............ 25 W - Run mode, LCD heater on, all relays energized, and analog

outputs enabled

Battery Ride Through

Starting at 10 Vdc, withstands cranking ride-through down to 0 Vdc for 50 ms

Current Sensing

Burden .............................................. 1 VA

Generator CTs

Terminals.......................................... 1 (+), 2 (–) (A-phase)

3 (+), 4 (–) (B-phase)

5 (+), 6 (–) (C-phase)

Available Programmable CTs

AUX 1Terminals ............................... 7 (+), 8 (–)

AUX 2 Terminals .............................. 9 (+), 10 (–)

AUX 3 Terminals .............................. 11 (+), 12 (–)

AUX 4 Terminals .............................. 13 (+), 14 (–)

(Programmable CTs AUX 2, 3, and 4 are optional with style number xxxxxxxEx.)

1 Aac Current Sensing

Continuous Rating ............................ 0.02 to 1.5 Aac

1 Second Rating ............................... 10 Aac

5 Aac Current Sensing

Continuous Rating ............................ 0.1 to 7.5 Aac

1 Second Rating ............................... 50 Aac

Voltage Sensing

Range ............................................... 12 to 576 V rms, line-to-line

Frequency ........................................ 50/60 Hz

Frequency Range ............................. 10 to 90 Hz

Burden .............................................. 1 VA

1 Second Rating ............................... 720 V rms

DGC-2020HD Specifications

Page 16

6 9469300990 Rev B

Generator Sensing

Configuration .................................... Line-to-line or line-to-neutral

Generator Sensing Terminals .......... 86 (A-phase)

88 (B-phase)

90 (C-phase)

91 (Neutral)

Bus 1 Sensing

Configuration .................................... Line-to-line or line-to-neutral

Bus Sensing Terminals .................... 93 (A-phase)

95 (B-phase)

97 (C-phase)

98 (Neutral)

Bus 2 Sensing (Optional with style number xxxxxxxEx)

Configuration .................................... Line-to-line or line-to-neutral

Bus Sensing Terminals .................... 100 (A-phase)

101 (B-phase)

103 (C-phase)

104 (Neutral)

Analog Sensing

The DGC-2020HD contains two or four (optional) analog inputs.

Current Sensing

Rating ............................................... 4 to 20 mA

Burden .............................................. 84.25 Ω to 87.1 Ω

Voltage Sensing

Rating ............................................... –10 to 10 Vdc

Burden .............................................. 9.75 kΩ to 10.16 kΩ

Contact Sensing

Contact sensing inputs include sixteen programmable inputs. All inputs accept dry contacts. The following

contact input recognition and contact output closure times reflect the maximum possible delay.

Contact Input Recognition Time

This is the amount of time that elapses after a local contact input closes until that closure is available in

logic.

DGC-2020HD ................................... 125 ms

CEM-2020 ........................................ 185 ms

Contact Output Closure Time

This is the amount of time that elapses after a contact output closure is true in logic until that contact

output closes.

DGC-2020HD ................................... 15 ms

CEM-2020 ........................................ 125 ms

Terminals

Input 1 .............................................. 31, 49

Input 2 .............................................. 32, 49

Input 3 .............................................. 33, 49

Input 4 .............................................. 34, 49

Specifications DGC-2020HD

Page 17

9469300990 Rev B 7

Input 5 .............................................. 35, 49

Input 6 .............................................. 36, 49

Input 7 .............................................. 37, 49

Input 8 .............................................. 38, 49

Input 9 .............................................. 39, 49

Input 10 ............................................ 40, 49

Input 11 ............................................ 41, 49

Input 12 ............................................ 42, 49

Input 13 ............................................ 43, 49

Input 14 ............................................ 44, 49

Input 15 ............................................ 45, 49

Input 16 ............................................ 46, 49

Engine System Inputs

Stated accuracies are subject to the accuracy of the senders used. Values within these ranges are

deemed “good” and the DGC-2020HD will use them for the appropriate calculation and protection. Values

outside these ranges are deemed “failed” and the DGC-2020HD will begin timing towards a sender failure

condition.

Fuel Level Sensing

Resistance Range ............................ 0 to 250 Ω nominal

Terminals.......................................... 71 (FUEL +), 72 (FUEL –)

Coolant Temperature Sensing

Resistance Range ............................ 10 to 2,750 Ω nominal

Terminals.......................................... 77 (COOLANT +), 78 (COOLANT –)

Oil Pressure Sensing

Resistance Range ............................ 0 to 250 Ω nominal

Terminals.......................................... 74 (OIL +), 75 (OIL –)

Engine Speed Sensing

Magnetic Pickup

Voltage Range ................................. 3 to 35 V peak (6 to 70 V peak-peak)

Frequency Range ............................. 32 to 10,000 Hz

Terminals.......................................... 106 (MPU +), 107 (MPU –)

Generator Voltage

Range ............................................... 12 to 576 V rms

Terminals.......................................... 86 (A-phase)

88 (B-phase)

90 (C-phase)

91 (Neutral)

Output Contacts

PRE (Prestart), START, and RUN Relays

Rating ............................................... 30 Adc at 28 Vdc—General purpose, 3 A pilot duty∗

Programmable Relays (12)

Rating ............................................... 2 Adc at 30 Vdc—General purpose, 1.2 A pilot duty∗

∗The load must be in parallel with a diode rated at least 3 times the coil current and 3 times the coil

voltage.

DGC-2020HD Specifications

Page 18

8 9469300990 Rev B

Terminals

Output 1............................................ 15, 18 (common)

Output 2............................................ 16, 18 (common)

Output 3............................................ 17, 18 (common)

Output 4............................................ 19, 22 (common)

Output 5............................................ 20, 22 (common)

Output 6............................................ 21, 22 (common)

Output 7............................................ 23, 26 (common)

Output 8............................................ 24, 26 (common)

Output 9............................................ 25, 26 (common)

Output 10.......................................... 27, 30 (common)

Output 11.......................................... 28, 30 (common)

Output 12.......................................... 29, 30 (common)

The programmable relays share common terminals: terminal 18 is used for outputs 1, 2, and 3, terminal

22 is used for outputs 4, 5, and 6, terminal 26 is used for outputs 7, 8, and 9, 30 is used for outputs 10,

11, and 12.

Metering

Generator and Bus Voltage (rms)

Metering Range ................................ 0 to 576 Vac (direct measurement)

577 to 9,999 Vac (through VT using VT ratio setting)

VT Ratio Range ................................ 1:1 to 125:1 in primary increments of 1

Accuracy* ......................................... ±1.0% of programmed rated voltage or ±2 Vac

Display Resolution ........................... 1 Vac

* Voltage metering indicates 0 V when generator voltage is below 2% of the full-scale rating.

Generator Current (rms)

Generator current is measured at the secondary windings of user-supplied 1 A or 5 A CTs.

Metering Range ................................ 0 to 5,000 Aac

CT Primary Range ........................... 1 to 5,000 Aac in primary increments of 1 Aac

Accuracy* ......................................... ±1.0% of programmed rated current or ±2 Aac

Display Resolution ........................... 1 Aac

* Current metering indicates 0 A when generator current is below 2% of the full-scale rating.

Generator and Bus Frequency

Frequency is sensed through the generator and bus voltage inputs (phases A and B).

Metering Range ................................ 10 to 90 Hz

Accuracy........................................... ±0.25% or 0.05 Hz

Display Resolution ........................... 0.1 Hz

Apparent Power

Indicates total kVA and individual line kVA (4-wire, line-to-neutral or 3-wire, li ne -to-line).

Measurement/Calcula tio n Meth ods

Total ................................................. kVA = (V

4-Wire, Line-to-Neutral ..................... kVA calculated with respect to neutral

3-Wire, Line-to-Line .......................... A-phase kVA = V

B-phase kVA = V

C-phase kVA = V

Accuracy........................................... ±2% of the full-scale indication or ±2 kVA *†

× IL ×√3) ÷ 1000

L-L

× IA ÷ 1000 ÷ √3

AB

× IB ÷ 1000 ÷ √3

BC

× IC ÷ 1000 ÷ √3

CA

* kVA metering indicates 0 kVA when the generator kVA is below 2% of the full-scale rating.

† Applies when temperature is between −40°C to +70°C (–40°F to +158°F).

Specifications DGC-2020HD

Page 19

9469300990 Rev B 9

Note

Power Factor

Metering Range ................................ 0.2 leading to 0.2 lagging

Calculation Method .......................... PF = cosine of the angle between phase AB voltage (Vab) and

phase A current (Ia) *

Accuracy........................................... ±0.01 †

* In single-phase AC-connected machines, it is the cosine of the angle between phase CA voltage

(Vca) and phase C current (Ic).

† Applies when temperature is between –40°C to +70°C (–40°F to +158°F).

For the DGC-2020HD to correctly meter power factor, the generator

must be rotating in the same phase sequence as dictated by the

generator phase rotation setting.

Real Power

Indicates total kW and individual line kW (4-wire, line-to-neutral or 3-wire line-to-line)

Measurement/Calcula tio n Meth ods

Total ................................................. PF × Total kVA

4-Wire, Line-to-Neutral ..................... kW calculated with respect to neutral

3-Wire, Line-to-Line .......................... A-phase kW = V

B-phase kW = V

C-phase kW = V

Accuracy........................................... ±2% of the full-scale indication or ±2 kW *†

× IA × PF ÷ 1000 ÷ √3

AB

× IB × PF ÷ 1000 ÷ √3

BC

× IC × PF ÷ 1000 ÷ √3

CA

* kW metering indicates 0 kW when the generator kW is below 2% of the full-scale rating.

† Applies when temperature is between –40°C to +70°C (–40°F to +158°F).

Oil Pressure

Metering Range ................................ 0 to 150 psi, 0 to 10.3 bar, or 0 to 1,034 kPa

Accuracy........................................... ±2% of actual indication or ±1 psi, ±0.07 bar, or ±6.9 kPa (subject to

accuracy of sender)

Display Resolution ........................... 1 psi, 0.07 bar, or 6.9 kPa

Coolant Temperature

Metering Range ................................ 32 to 410°F or 0 to 204°C

Accuracy........................................... ±2% of actual indication or as low as ±2° (subject to accuracy of

sender)

Fuel Level

Metering Range ................................ 0 to 100%

Accuracy........................................... ±2% (subject to accuracy of sender)

Display Resolution ........................... 1.0%

Battery Voltage

Metering Range ................................ 6 to 32 Vdc

Accuracy........................................... ±2% of actual indication or as low as ±0.2 Vdc

Display Resolution ........................... 0.1 Vdc

Engine RPM

Metering Range ................................ 0 to 4,500 rpm

Accuracy* ......................................... ±2% of actual indication or as low as ±2 rpm

Display Resolution ........................... 2 rpm

* When engine speed is below 2% of full-scale, reported rpm is 0.

DGC-2020HD Specifications

Page 20

10 9469300990 Rev B

Maintenance Timer

Maintenance timer indicates the time remaining until genset service is due. Value is retained in

nonvolatile memory.

Metering Range ................................ 0 to 5,000 hours

Update Interval ................................. 0.1 hours

Accuracy........................................... ±1% of actual indication or as low as ±12 minutes

Display Resolution ........................... 1 minute

Generator Protection Func t ions

Overvoltage (59) and Undervoltage (27)

Pickup Range ................................... 0 to 576 V

Pickup Increment ............................. 1 V

Hysteresis Range ............................. 1 to 60 Vac

Inhibit Frequency Range .................. 20 to 90 Hz (27 function only)

Activation Delay Range .................... 0 to 600 s

Activation Delay Increment .............. 0.1 s

Underfrequency (81U) and Overfrequency (81O)

Pickup Range ................................... 37.5 to 66 Hz

Pickup Increment ............................. 0.01 Hz

Hysteresis Range ............................. 0.1 to 40 Hz

Activation Delay Range .................... 0 to 600 s

Activation Delay Increment .............. 0.1 s

Inhibit Voltage Range ....................... 0 to 100% of nominal voltage

Inhibit Voltage Increment ................. 1%

ROCOF (Rate of Change of Frequency) (81) (Optional)

Pickup Range ................................... 0.2 to 10 Hz/s

Pickup Increment ............................. 0.1 Hz/s

Pickup Accuracy ............................... 0.2 Hz/s

Activation Delay Range .................... 0 to 10,000 ms

Activation Delay Increment .............. 1 ms

Reverse and Forward Power (32)

Pickup Range ................................... 0 to 200% of nominal input rating

Pickup Increment ............................. 0.1%

Hysteresis Range ............................. 1 to 10%

Activation Delay Range .................... 0 to 600 s

Activation Delay Increment .............. 0.1 s

Loss of Excitation (40Q)

Pickup Range ................................... –150 to 0% of Rated kvar*

Pickup Increment ............................. 0.1%

Hysteresis Range ............................. 1 to 10%

Activation Delay Range .................... 0 to 600 s

Activation Delay Increment .............. 0.1 s

* Rated kvar is calculated on the System Settings, Rated Data s c reen in BEST COMSPlus

Overcurrent (51) (Optional)

Pickup Range ................................... 0.18 to 4 Aac (1 A current sensing)

0.9 to 20 Aac (5 A current sensing)

Hysteresis......................................... 2 %

Time Dial Range .............................. 0 to 7,200 s (fixed time curve)

0 to 9.9 (inverse curve time multiplier)

®

.

Specifications DGC-2020HD

Page 21

9469300990 Rev B 11

Caution

Notes

Time Dial Increment ......................... 0.1

Inverse Time Curves ........................ See the Time Overcurrent Characteristic Curves chapter

For 1 A current sensing, current shall not exceed 3 amperes for 30

seconds or 4 amperes for 1 second. For 5 A current sensing, current

shall not exceed 15 amperes for 30 seconds or 20 amperes for 1

second. Exceeding the above limits may result in equipment damage.

Phase Voltage Imbalance (47) (Optional)

Pickup Range ................................... 0 to 150 Vac

Pickup Increment ............................. 1 Vac

Hysteresis Range ............................. 1 to 5 Vac

Activation Delay Range .................... 0 to 600 s

Activation Delay Increment .............. 0.1 s

Vector Shift (78) (Optional)

Pickup Range ................................... 2 to 90°

Pickup Increment ............................. 1°

Hysteresis......................................... 0.5 degrees

Accuracy........................................... ±1°

Logic Timers

Hours Setting Range ........................ 0 to 250

Hours Setting Increment .................. 1

Minutes Setting Range ..................... 0 to 59

Minutes Setting Increment ............... 1

Seconds Setting Range ................... 0 to 59

Seconds Setting Increment .............. 1

Accuracy........................................... ±15 ms

Communication Interface

CAN (SAE J1939)

Differential Bus Voltage .................... 1.5 to 3 Vdc

Maximum Voltage ............................ –32 to +32 Vdc with respect to negative battery terminal

Communication Rate ........................ 250 kb/s

CAN 1 Terminals .............................. 51 (low), 52 (high), and 53 (shield)

CAN 2 Terminals .............................. 54 (low), 55 (high), and 53 (shield)

1. If the DGC-2020HD is providing one end of the J1939 bus, a 120 Ω, ½ watt

terminating resistor should be installed across terminals 51 (CAN1L) and 52

(CAN1H) and/or 54 (CAN2L) and 55 (CAN2H).

2. If the DGC-2020HD is not part of the J1939 bus, the stub connecting the DGC-

2020HD to the bus should not exceed 914 mm (3 ft) in length.

3. The maximum bus length, not including stubs, is 40 m (131 ft).

4. The J1939 drain (shield) should be grounded at one point only. If grounded

elsewhere, do not connect the drain to the DGC-2020HD.

DGC-2020HD Specifications

Page 22

12 9469300990 Rev B

Ethernet

Dual Copper (RJ-45) ........................ 10/100BASE-T (style number xxxxDxxxx)

Fiber Optic (BNC) ............................. 10/100BASE-F (style number xxxxFxxxx)

Industrial Ethernet devices des ig ned to comply with IE C 61000-4 series of specif ic ations are

recommended.

External Dial-Out Modem (RS-232)

Protocol ............................................ ASCII

Data Transmission ........................... Full Duplex

Baud ................................................. 4,800 to 115,200

Data Bits ........................................... 8

Parity ................................................ None

Stop Bits ........................................... 1

Connector Type ................................ DB-9 Connector (Male)

IRIG-B Time Synchronization

Standard: .......................................... 200-04, Format B002

Input Signal ...................................... Demodulated (dc level-shifted signal)

Logic High Level ............................... 3.5 Vdc, minimum

Logic Low Level ............................... 0.5 Vdc, maximum

Input Voltage Range ........................ –10 to +10 Vdc

Input Resistance .............................. Nonlinear, approximately 4 kΩ at 3.5 Vdc, 3 kΩ at 20 V dc

Response Time ................................ < 1 cycle

Terminals.......................................... 59 (IRIG-B +), 60 (IRIG-B –)

Modbus™ (RS-485)

Baud ................................................. 1,200 to 115,200

Data Bits ........................................... 8

Parity ................................................ None

Stop Bits ........................................... 1

Terminals.......................................... 56 (485 A), 57 (485 B), and 58 (485 shield)

RDP-110

Minimum Wire Size .......................... 20 AWG (0. 52 mm2)

Maximum Wire Length ..................... 4,000 feet (1,219 meters)

Terminals.......................................... 61 (RDP-110 TxD+), 62 (RDP-110 TxD–)

USB

Specification Compatibility USB 2.0

Connector Type Mini-B jack

Real-Time Clock

Clock has leap year and selectable daylight saving time correction. Backup battery sustains timekeeping

during losses of DGC-2020HD operating power.

Resolution ........................................ 1 s

Accuracy........................................... ±1.73 s/d at 25°C (77°F)

Clock Holdup

Battery Holdup Time ........................ Approximately 10 yrs

Battery Type ..................................... Rayovac BR2032, lithium, coin-type, 3 Vdc, 195 mAh

Basler Electric P/N 38526

Specifications DGC-2020HD

Page 23

9469300990 Rev B 13

Note

Caution

Failure to replace the battery with Basler Electric P/N 38526 may void the warranty.

Replacement of the backup battery for the real-time clock should be performed only

by qualified personnel.

Do not short-circuit the battery, reverse battery polarity, or attempt to recharge the

battery. Observe polarity markings on the battery socket while inserting a new

battery. The battery polarity must be correct in order to provide backup for the realtime clock.