Page 1

INSTRUCTION MANUA L

FOR

DGC-2020ES

DIGITAL GENSET CONTROLLE R

Publication: 9469200990

Revision: C Nov-14

Page 2

Page 3

9469200990 Rev C i

Caution

Note

Preface

This instruction manual provides information about the installation and operation of the DGC-2020ES

Digital Genset Controller. To accomplish this, the following information is provided:

• Controls and indicators

• Inputs and outputs

• Protection and control functions

• Reporting and alarms information

• Mounting and connection diagrams

• BESTCOMSPlus

• Communication and security

• Maintenance and troublesh ooting pr oc edures

• Specifications

• CEM-2020

• MTU Fault Codes

• Exhaust Treatment

• Diagnostic Trouble Codes

Conventions Used in this Ma nua l

®

software

Important safety and procedural information is emphasized and presented in this manual through

Warning, Caution, and Note boxes. Each type is illustrated and defined as follows.

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note boxes emphasize important information pertaining to Digital

Genset Controller installation or operation.

Digital Genset Controller Preface

Page 4

ii 9469200990 Rev C

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It is loaned for

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

manual.

The English-language version of this manual serves as the only approved manual version.

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2014 by Basler E lectric

All rights reserved

First printing: March 2013

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the DGC-2020ES.

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Only qualified personnel should install, operate, or service this system.

Failure to follow warning and cautionary labels may result in personal injury or property damage.

Exercise caution at all times.

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

confidential use, subject to return on request, and with the mutual understanding that it will not be used in any

data for every possible contingency regarding installation or operation. The availability and design of all features

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

Preface Digital Genset Controller

Page 5

9469200990 Rev C iii

Contents

Introduction ................................................................................................................................................. 1

Features and Functions ............................................................................................................................. 1

Style Number ............................................................................................................................................. 2

Optional Features and Capabilities ........................................................................................................... 3

Controls and Indicators .............................................................................................................................. 5

Display Operation and Navigation ............................................................................................................. 6

Display Setup .......................................................................................................................................... 23

Remote Display Panel (optional) ............................................................................................................. 24

Power Input ................................................................................................................................................ 27

Nominal Voltage Input and Acceptable Range of Input Voltage ............................................................. 27

Terminal Assignments ............................................................................................................................. 27

Power Consumption ................................................................................................................................ 27

Battery Ride-Through Capability ............................................................................................................. 27

Fuse Protection ....................................................................................................................................... 27

Voltage and Current Sensing ................................................................................................................... 29

Generator Voltage ................................................................................................................................... 29

Bus Voltage ............................................................................................................................................. 29

Generator Current ................................................................................................................................... 29

Engine Sender Inputs ............................................................................................................................... 31

Connections ............................................................................................................................................. 31

Compatible Senders ................................................................................................................................ 31

Operation ................................................................................................................................................. 31

Sender Programmability .......................................................................................................................... 31

Sender Characteristic Curves ................................................................................................................. 31

Sender Failure Detection ......................................................................................................................... 34

Speed Signal Inputs .................................................................................................................................. 37

Magnetic Pickup ...................................................................................................................................... 37

Generator Sensing Voltage ..................................................................................................................... 37

Contact Inputs ........................................................................................................................................... 39

Programmable ......................................................................................................................................... 39

Contact Outputs ........................................................................................................................................ 43

Prestart .................................................................................................................................................... 43

Start ......................................................................................................................................................... 43

Run .......................................................................................................................................................... 43

Relay Control ........................................................................................................................................... 43

Programmable ......................................................................................................................................... 44

Operating Modes ....................................................................................................................................... 47

Off ............................................................................................................................................................ 47

Run .......................................................................................................................................................... 47

Auto ......................................................................................................................................................... 47

Operating Mode Control .......................................................................................................................... 47

Breaker Management ................................................................................................................................ 49

Breaker Status ......................................................................................................................................... 49

Breaker Operation ................................................................................................................................... 49

Breaker Configuration.............................................................................................................................. 50

Generator Protection ................................................................................................................................ 55

Voltage .................................................................................................................................................... 55

Frequency ................................................................................................................................................ 58

Overcurrent .............................................................................................................................................. 59

DGC-2020ES Contents

Page 6

iv 9469200990 Rev C

Metering ..................................................................................................................................................... 61

Metering Explorer .................................................................................................................................... 61

Engine...................................................................................................................................................... 62

Generator ................................................................................................................................................ 63

Power....................................................................................................................................................... 63

Run Statistics ........................................................................................................................................... 63

Status Indication ...................................................................................................................................... 64

Inputs ....................................................................................................................................................... 65

Logic Control Relays ............................................................................................................................... 65

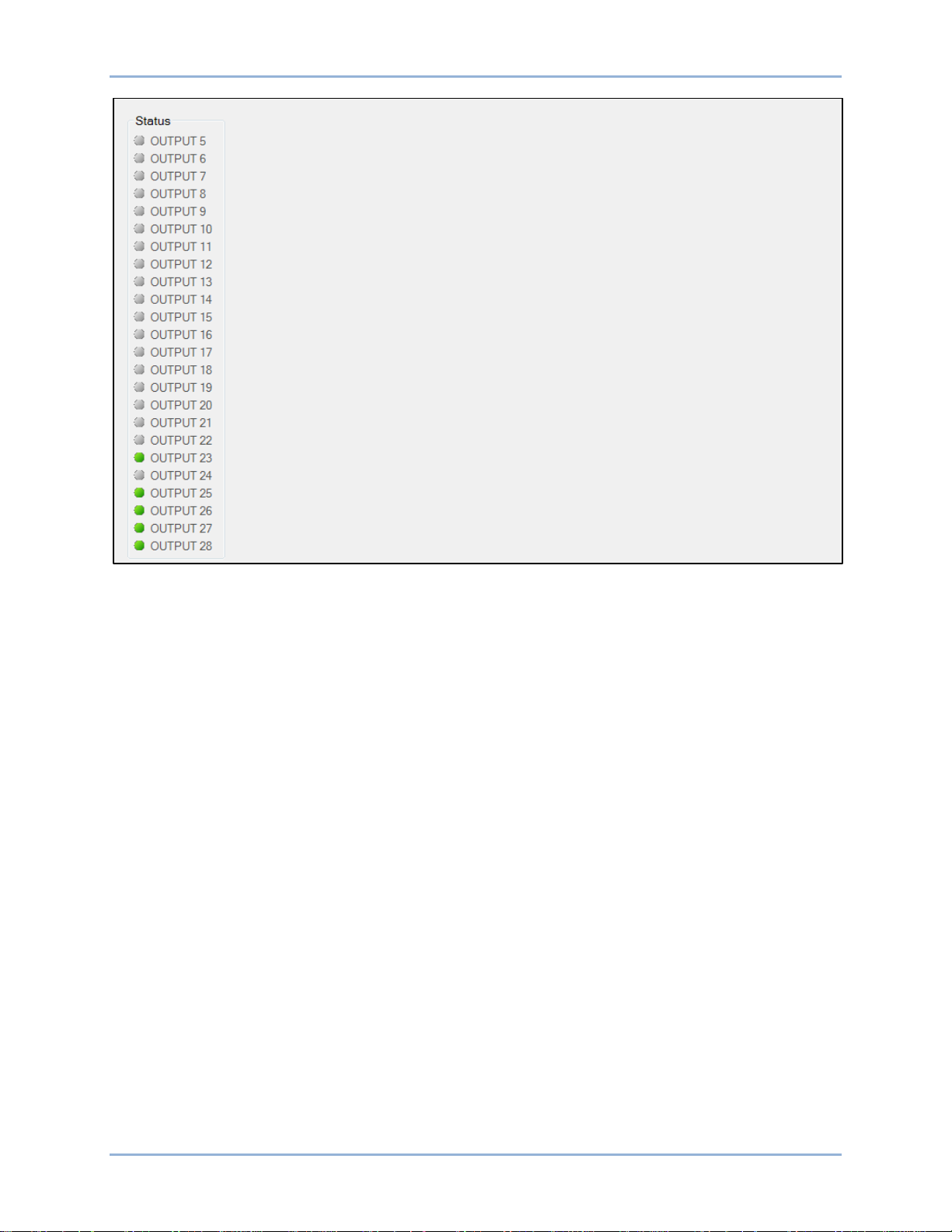

Outputs .................................................................................................................................................... 66

Control ..................................................................................................................................................... 68

Mains Fail Transfer Status ...................................................................................................................... 69

Auto Export Metering ............................................................................................................................... 70

Reporting and Alarms ............................................................................................................................... 71

Alarm Configuration ................................................................................................................................. 73

Retrieving Alarm Information ................................................................................................................... 78

Resetting Alarms and Pre-Alarms ........................................................................................................... 79

Event Recording ........................................................................................................................................ 81

Event Log ................................................................................................................................................ 81

Mounting .................................................................................................................................................... 87

Hardware ................................................................................................................................................. 87

Dimensions .............................................................................................................................................. 87

Terminals and Connectors ....................................................................................................................... 89

Connections ............................................................................................................................................. 90

Operating Power ...................................................................................................................................... 90

Generator Current Sensing ..................................................................................................................... 91

Generator Voltage Sensing ..................................................................................................................... 91

Bus Voltage Sensing ............................................................................................................................... 91

Analog Engine Sender Inputs .................................................................................................................. 92

Magnetic Pickup Input ............................................................................................................................. 92

Contact Sensing Inputs ........................................................................................................................... 92

Output Contacts ....................................................................................................................................... 93

USB Interface .......................................................................................................................................... 93

CAN Interface .......................................................................................................................................... 93

Optional Remote Display Panel Connections ......................................................................................... 94

Typical Connections ................................................................................................................................. 95

Connections for Typical Applications ...................................................................................................... 95

CAN Connections .................................................................................................................................... 99

CEM-2020 Connections ........................................................................................................................ 100

Installation for CE Systems ................................................................................................................... 100

BESTCOMSPlus® ..................................................................................................................................... 101

System Recommendations ................................................................................................................... 102

Installation ............................................................................................................................................. 102

Activation of the DGC-2020ES Plugin ................................................................................................... 102

Menu Bars ............................................................................................................................................. 105

Settings Explorer ................................................................................................................................... 107

Metering Explorer .................................................................................................................................. 107

BESTspace™ ........................................................................................................................................ 107

Settings File Management ..................................................................................................................... 108

Firmware Updates ................................................................................................................................. 110

BESTCOMSPlus® Updates .................................................................................................................... 113

BESTlogic™Plus ...................................................................................................................................... 115

Overview of BESTlogic™Plus ................................................................................................................ 115

BESTlogic™Plus Composition ............................................................................................................... 116

Contents DGC-2020ES

Page 7

9469200990 Rev C v

Logic Schemes ...................................................................................................................................... 137

Programming BESTlogic ™Plus.............................................................................................................. 138

Offline Logic Simulator .......................................................................................................................... 139

BESTlogic™Plus File Management ....................................................................................................... 140

BESTlogic™Plus Ex amp les ................................................................................................................... 141

Communication ....................................................................................................................................... 143

USB ....................................................................................................................................................... 143

CAN ....................................................................................................................................................... 143

Remote Display Panel (optional) ........................................................................................................... 151

Configuration ........................................................................................................................................... 153

System Settings ..................................................................................................................................... 153

Rated Data ............................................................................................................................................ 154

Remote Module Setup ........................................................................................................................... 156

Crank Settings ....................................................................................................................................... 157

Automatic Restart .................................................................................................................................. 159

Exercise Timer ....................................................................................................................................... 159

Sensing Transformers ........................................................................................................................... 160

Relay Control ......................................................................................................................................... 161

System Configuration Detection ............................................................................................................ 161

Security .................................................................................................................................................... 163

Changing Passwords ............................................................................................................................. 163

Saving Passwords in a DGC-2020ES Settings File .............................................................................. 163

Loading Passwords from a Settings File into the DGC-2020ES ........................................................... 165

Timekeeping ............................................................................................................................................ 167

Clock Setup ........................................................................................................................................... 167

Setting the Time and Date ..................................................................................................................... 168

Real-Time Clock Specificat ions ............................................................................................................. 168

Maintenance and Troubleshooting ....................................................................................................... 169

Maintenance .......................................................................................................................................... 169

Storage .................................................................................................................................................. 169

Troubleshooting ..................................................................................................................................... 169

Specifications .......................................................................................................................................... 175

Operating Power .................................................................................................................................... 175

Battery Ride Through ............................................................................................................................ 175

Current Sensing ..................................................................................................................................... 175

Voltage Sensing .................................................................................................................................... 175

Contact Sensing .................................................................................................................................... 176

Engine System Inputs............................................................................................................................ 176

Output Contacts ..................................................................................................................................... 177

Metering ................................................................................................................................................. 177

Generator Protection Functions ............................................................................................................ 179

Logic Timers .......................................................................................................................................... 180

Communication Interface....................................................................................................................... 180

Real-Time Clock .................................................................................................................................... 181

Liquid Crystal Display (LCD) ................................................................................................................. 181

Type Tests ............................................................................................................................................. 181

Environment .......................................................................................................................................... 182

UL Approval ........................................................................................................................................... 182

CSA Certification ................................................................................................................................... 182

NFPA Compliance ................................................................................................................................. 182

CE Compliance ...................................................................................................................................... 182

Physical ................................................................................................................................................. 183

CEM-2020 ................................................................................................................................................. 185

General Information ............................................................................................................................... 185

DGC-2020ES Contents

Page 8

vi 9469200990 Rev C

Features ................................................................................................................................................ 185

Specifications ........................................................................................................................................ 185

Functional Description ........................................................................................................................... 187

BESTCOMSPlus® Software ................................................................................................................... 187

Installation ............................................................................................................................................. 188

Remote Contact Input Configuration ..................................................................................................... 194

Remote Contact Output Configuration .................................................................................................. 194

Maintenance .......................................................................................................................................... 195

MTU Fault Codes ..................................................................................................................................... 197

Exhaust Treatment .................................................................................................................................. 219

Diesel Particulate Filter (DPF) ............................................................................................................... 219

Exhaust After-Treatment Systems (EATS)............................................................................................ 221

Diagnostic Trouble Codes ...................................................................................................................... 223

Revision History ...................................................................................................................................... 239

Contents DGC-2020ES

Page 9

9469200990 Rev C 1

Introduction

The DGC-2020ES Digital Genset Controller provides integrated engine-genset control, protection, and

metering in a rugged and economical package. Its features set make the DGC-2020ES ideal for

standalone genset applications where paralleling or load sharing is not required. Microprocessor based

technology allows for exact measurement, setpoint adjustment, and timing functions. Front panel controls

and indicators enable quick and simple DGC-2020ES operation. Basler Electric communication software

(BESTCOMSPlus

burden in the DGC-2020ES, dedicated potential transformers (PTs) are not required. A liquid crystal

display (LCD) with backlighting can be viewed under a wide range of ambient light and temperature

conditions.

Features and Functions

The DGC-2020ES Digital Genset Controller has the following features:

• Generator Control

• Engine and Generator Pr ot ect ion

• Automatic Transfer Switch Control (Mains Failure)

• Automatic Generator Configuration Detection

• Programmable Analog Engine Senders

• Seven Programmable Contact Inputs

• Programmable Logic

• Exercise Timer

• ECU Communications via SAE J1939

• Additional contact input/output module available to expand the capabilities of the DGC-2020ES

®

) allows units to be easily customized for each application. Because of the low sensing

DGC-2020ES Digital Genset Controllers perform the following functions:

Generator Protection and Metering

Multifunction generator protection guards against generator overvoltage, undervoltage, reverse power,

loss of excitation, underfrequency, overfrequency, and overcurrent. Each generator protection function

has an adjustable pickup and time delay setting.

Metered generator parameters include voltage, current, real power (watts), apparent power (VA), and

power factor (PF).

Engine Protection and Metering

Engine protection features include oil pressure and coolant temperature monitoring, overcrank protection,

ECU specific protection elements, and diagnostic rep o rt ing.

Metered engine parameters include oil pressure, coolant temperature, battery voltage, speed, fuel level,

engine load, coolant level (from ECU), ECU specific parameters, and run-time statistics.

Event Recording

An event log retains a history of system events in nonvolatile memory. Up to 30 event types are retained

and each record contains a time stamp of the first and last occurrence, and the number of occurrences for

each event. For more information, see the Event Recording chapter.

Contact Inputs and Outputs

DGC-2020ES controllers have seven programmable contact inputs. All contact inputs recognize dry

contacts. The programmable inputs can be configured to initiate a pre-alarm or alarm. An input can be

programmed to receive an input from an automatic transfer switch. Inputs can also be programmed to

override DGC-2020ES alarms and protection functions. Each input can be assigned a user-defined name

for easy identification at the front panel display and in fault records.

DGC-2020ES Introduction

Page 10

2 9469200990 Rev C

Output contacts include three dedicated relays for energizing an engine’s glow plugs, fuel solenoid, and

starter solenoid. Four additional user-programmable output contacts are provided.

Additional contact inputs and output contact requirements can be accommodated with an optional CEM2020 (Contact Expansion Module). Contact Basler Electric for ordering information.

Automatic Transfer Switch Control (Mains Failure)

The DGC-2020ES can detect a mains failure via a single- or three-phase bus input. A mains failure is

established when any one of the following conditions are met:

• Any phase of bus voltage falls below dead the bus threshold

• Any phase of bus voltage is unstable due to overvoltage or undervoltage

• Any phase of bus voltage is unstable due to overfrequency or underfrequency

At this time, the DGC-2020ES will start the genset and when ready, apply power to the load via the

genset. The DGC-2020ES implements open transitions to and from the mains. When the mains returns

and is considered stable, the DGC-2020ES will transfer the load back to the mains.

Communication

DGC-2020ES communication features include a standard USB port for local (and temporary)

communication, SAE J1939 interface for remote communication, and RS-485 interface for communication

with an optional Remote Display Panel.

USB Port

The USB communication port can be used with BESTCOMSPlus software to quickly configure a DGC2020ES with the desired settings or retrieve metering values and event log records.

CAN Interface

The CAN interface provides high-speed communication between the DGC-2020ES and the engine control

unit (ECU) on an electronically controlled engine. This interface provides access to oil pressure, coolant

temperature, and engine speed data by reading these parameters directly from the ECU. When available,

engine diagnostic data can also be accessed. The CAN interface supports the following protocols:

• SAE J1939 Protocol - Oil pressure, coolant temperature, and engine speed data are received

from the ECU. In addition, DTCs (Diagnostic Trouble Codes) help diagnose any engine or related

failures. The engine DTCs are displayed on the front panel of the DGC-2020ES and may be

obtained using BESTCOMSPlus® software.

• MTU Protocol - A DGC-2020ES connected to a genset equipped with an MTU ECU receives oil

pressure, coolant temperature, and engine speed data from the engine controller, along with

various alarms and pre-alarms that are MTU specific. In addition, the DGC-2020ES tracks and

displays the active fault codes issued by the MTU engine ECU.

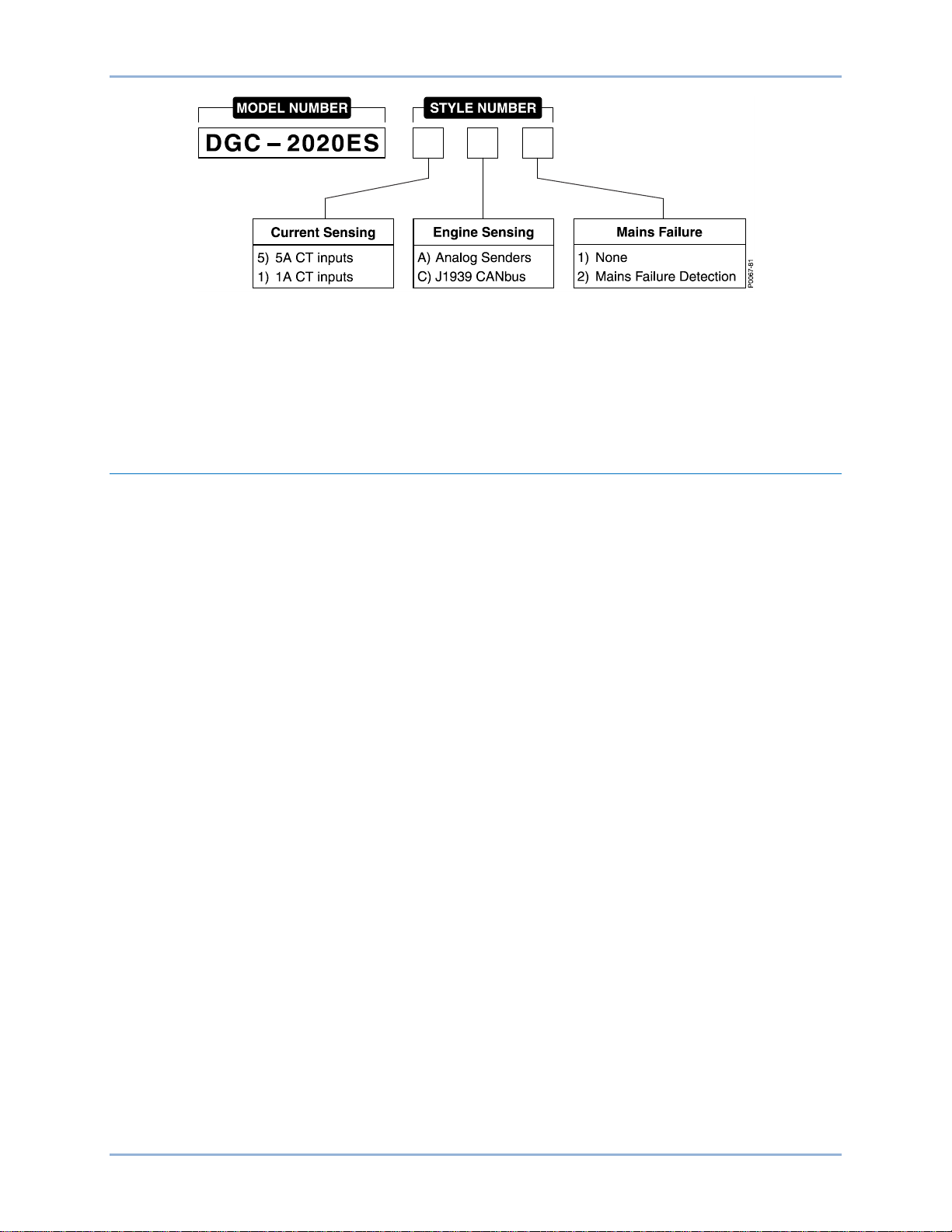

Style Number

Standard-order DGC-2020ES controllers are identified by a style number which consists of a combination

of letters and numbers that define the controller’s electrical characteristics and operational features. The

model number, together with the style number, describes the options included in a specific controller.

Figure 1 illustrates the DGC-2020ES style number identification chart.

Introduction DGC-2020ES

Page 11

9469200990 Rev C 3

Figure 1. DGC-2020ES Style Chart

For example, a DGC-2020ES with style number 5A2, has the following characteristics and features.

5 5 Aac Current Sensing Inputs

A Analog Senders

2 Mains Failure Detection

Optional Features and Capa bilities

CEM-2020 (Contact Expansion Module)

The optional CEM-2020 provides 10 additional contact inputs and 18 or 24 additional output contacts

(depending on module type) to the DGC-2020ES. The CEM-2020 communic a tes with the DGC-2020ES

through a CAN interface. Refer to the CEM-2020 chapter for more information.

Remote Display Panel

The optional Remote Display Panel provides remote indication of many pre-alarm and alarm conditions.

The DGC-2020ES communicates with the Remote Display Panel through an RS-485 interface. Refer to

the Controls and Indicators chapter for more information.

DGC-2020ES Introduction

Page 12

4 9469200990 Rev C

Introduction DGC-2020ES

Page 13

9469200990 Rev C 5

®

DGC-2020ES

Not In

Auto

Alarm

Supplying

Load

Auto

Off

Run

Back

Edit

Digital

Genset

Controller

P0067-97

G

A

H

B

I

C

J

D

K

E

L

F

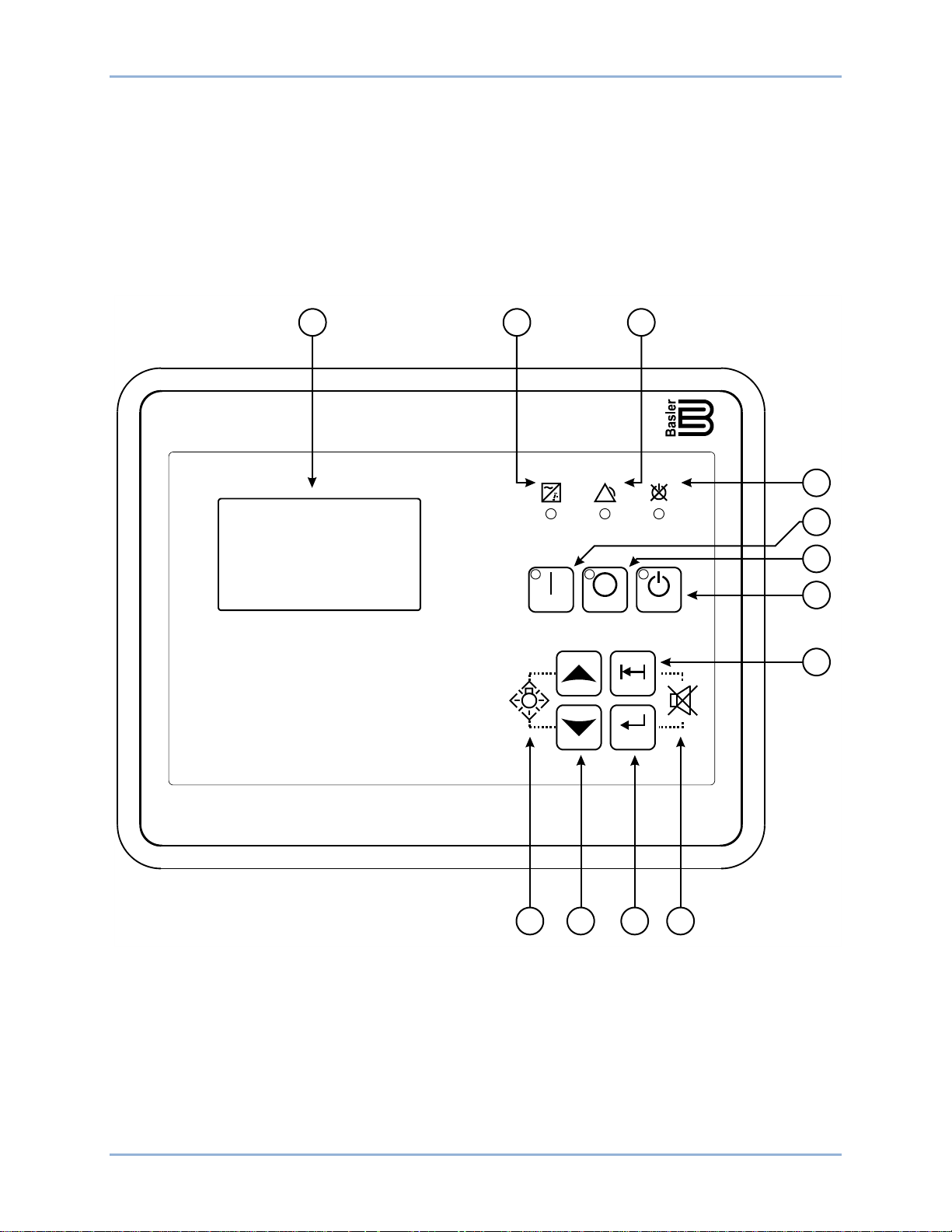

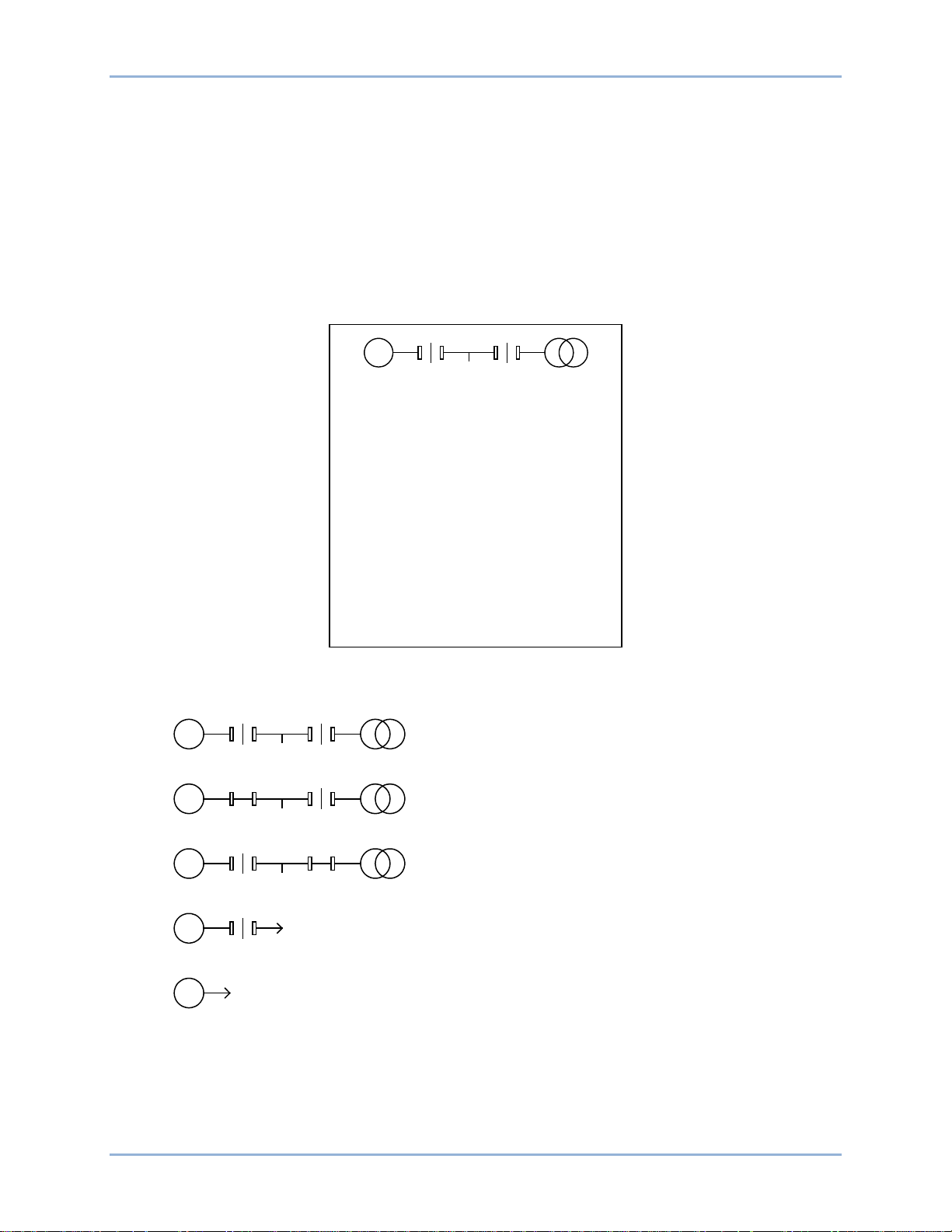

Controls and Indicators

DGC-2020ES controls and indicators are located on the front panel and are intended for local control and

monitoring of DGC-2020ES operation. Front panel controls consist of pushbuttons. Front panel indicators

consist of LED (light emitting diode) indicators and a backlit LCD (liquid crystal display).

DGC-2020ES controls and ind icator s are illustr at ed in Figure 2. Lettered locators in Figure 2 correspond

to the control and indicator descriptions of Table 1.

Figure 2. Front Panel

DGC-2020ES Controls and Indicators

Page 14

6 9469200990 Rev C

Locator

Description

A

Liquid Crystal Display. The backlit, 64 by 128 pixel LCD serves as the local information

maintained at −40°C.

B

Supplying Load Indicator. This green LED lights when the generator current is greater

than Emergency Power Supply (EPS) threshold current.

C

Alarm Indicator. This red LED lights continuously during alarm conditions and flashes

during pre-alarm conditions.

D

Not in Auto Indicator. This red LED lights when the DGC-2020ES is not operating in Auto

mode. When the DGC-2020ES is operating in Run or Off mode, this LED is on.

E

Run Pushbutton and Mode Indicator. Pressing this button places the DGC-2020ES in

Run mode. The green Run mode LED lights when Run mode is active.

F

Off Pushbutton and Mode Indicator. Pressing this button places the DGC-2020ES in Off

also resets the Breaker Management Pre-Alarms and all MTU ECU Alarms.

G

Auto Pushbutton and Mode Indicator. Pres sing the Au t o butt on plac es the DGC-2020ES

in Auto mode. The green Auto mode LED lights when Auto mode is active.

H

Back Pushbutton. This button is pressed to cancel a settings editing session and discard

Maintenance or Maintenance Due Pre-Alarm.

I

Alarm Silence Pushbutton Combination. Simultaneously pressing both the Back and Edit

buttons opens the relay output programmed as the horn output.

J

Edit Pushbutton. Pressing this button starts an editing session and enables changes to

Edit twice to submit the string.

K

Arrow Pushbuttons. These two buttons are used to navigate through the front panel

lower the value of the selected setting.

L

Lamp Test Pushbutton Combination. Simultaneo us ly pressing both the Up- and Downall LEDs for as long as both buttons are held.

Table 1. Front Panel HMI Descriptions

source for metering, alarms, pre-alarms, and protective functions. Display operation is

mode. The red Off mode LED lights when the DGC-2020ES is in Off mode. This button

any settings changes. When navigating through menus, pressing this button moves

upward a level. When pressed momentarily, this button also resets the Breaker

Management Pre-Alarms and all MTU ECU Alarms. This button is also used to reset the

Maintenance Interval when pressed for 10 seconds while viewing Hours Until

DGC-2020ES settings. At the conclusion of an editing session, the Edit pushbutton is

pressed again to save the setting changes. When navigating through menus, pressing

this button moves downward one level. When entering a string, such as a password, this

button locks the selected character and moves to the next position. When finished, press

display menus and modify settings. Within a level, the up- and down-arrow buttons are

used to move among items within the menu level. Pressing the down-arrow button moves

to items lower in the list. Pressing the up-arrow button moves to items higher in the list.

During a settings editing session, the up- and down-arrow buttons are used to raise and

arrow buttons tests the DGC-2020ES indicators by exercising all LCD pixels and lighting

Display Operation and Navigation

The front panel display is used to make settings changes and display metering values. Refer to locators

H, J, and K in Table 1 for information on changing settings through the front panel and navigating through

the Metering screens.

Login and Permissions

To login, navigate to the SETTINGS, ENTER PASSWORD screen and press the Edit key. Use the

Up/Down arrow keys to scroll through the characters. Use the Edit key to accept a character and move to

Controls and Indicators DGC-2020ES

Page 15

9469200990 Rev C 7

• GEN VBN

• kW TOT

the next space. Once the password has been entered, press the Edit key again to login. A LOGOUT

selection now appears in the list of SETTINGS. To log out, nav igat e to SETTIN G S > LOGOUT and press

the Edit key. The LOGOUT selection is removed from the SETTINGS list.

If communication access is active through the USB port, the front panel will display REMOTE COMMS,

FRONT PANEL IS READ ONLY, and the summary screen. This informs the user that the front panel can

only be used for viewing metering data and settings information. USB port access must be ended before

modifying settings through the front panel.

If a front-panel key is not pressed for more than 15 minutes, the user is automatically logged out.

Summary Screen and Configurable Metering

The summary screen can be set to standard or scrolling. When set to standard, only the following

parameters are displayed:

• VOLT∗

• AMP∗

• PH∗

• Hz

• OIL

• FUEL

• TEMP

• BATT

∗ When set to standard, individual phase information can be automatically toggled at a rate set by the

Phase Toggle Delay setting. Navigate to the SETTINGS > GENERAL SETTINGS > FRO N T PANEL HMI

screen and edit PH TOG DELAY. When the Phase Toggle Delay is set to zero, information for each

phase is obtained by pressing the Up or Down arrow keys on the front panel HMI. When it is set to a

number other than zero, the display will toggle through the phases automatically at the rate specified by

the Phase Toggle Delay Setting.

When the summary screen is set to scrolling, you can select/configure the metering values that are

displayed. Up to 20 values can be displayed and these values will scroll at a delay time specified by the

user. To select a standard or scrolling summary, navigate to the SETTINGS > GENERAL SETTINGS >

FRONT PANEL HMI screen and edit the SUMMARY VIEW. The SCROLL DELAY setting is also found on

this screen.

To select the scrolling values, navigate to the SETTINGS > GENERAL SETTINGS > FRONT PANEL HMI

screen and edit the CONFIGURABLE METERING. The following parameters may be placed in the

scrolling summary:

• BATT V

• BLANK (Shows nothing on this line)

• BOOST PRESS

• BUS Hz

• BUS VAB

• BUS VBC

• BUS VCA

• CHRG AIR TMP

• COOLANT PRESS

• DEF1 %

• DEF2 %

• ENGINE % LOAD

• ENG INTCLR TEMP

• ENG OIL TEMP

• FUEL

• FUEL DELV P

• FUEL RATE

• FUEL TEMP

• GEN VCA

• GEN VCN

• INJ RAIL PRS

• INTAK MNFLD TMP

• kVA A

• kVA B

• kVA C

• kVA TOT

• kvar A

• kvar B

• kvar C

• kvar TOTAL

• kW A

• kW B

• kW C

• kW LD%

• kWh

DGC-2020ES Controls and Indicators

Page 16

8 9469200990 Rev C

• GEN Hz

• GEN VBC

• NONE (Removes a line from the scrolling list)

G

L

P

0067-82

ENGINE

GENERATOR

POWER

RUN STATISTICS

ALARMS-STATUS

DIAGNOSTICS

METERING

• GEN IA

• GEN IB

• GEN IC

• GEN PF

• GEN VAB

• GEN VAN

• OIL P

• RPM

• RPM SRC

• RUN HRS

• TEMP

• TOTAL FUEL USED

Sleep Mode

Sleep mode de-energizes the LCD backlight and heater when no pushbutton activity is detected for 15

minutes and the DGC-2020ES is operating in OFF mode or Auto mode with the engine not running.

Normal display operation resumes when any pushbutton is pressed or the genset is started remotely via

the ATS input. Sleep mode will not be entered while an alarm is active. Sleep mode can be permanently

disabled through BESTCOMSPlus

®

or the front panel.

Changing a Setting

To change a setting, navigate to the setting you want to change and press the Edit key. If you are not

already logged in, you will be prompted for your password. Use the Up/Down arrow key to raise or lower

the value. Press the Edit key again when finished.

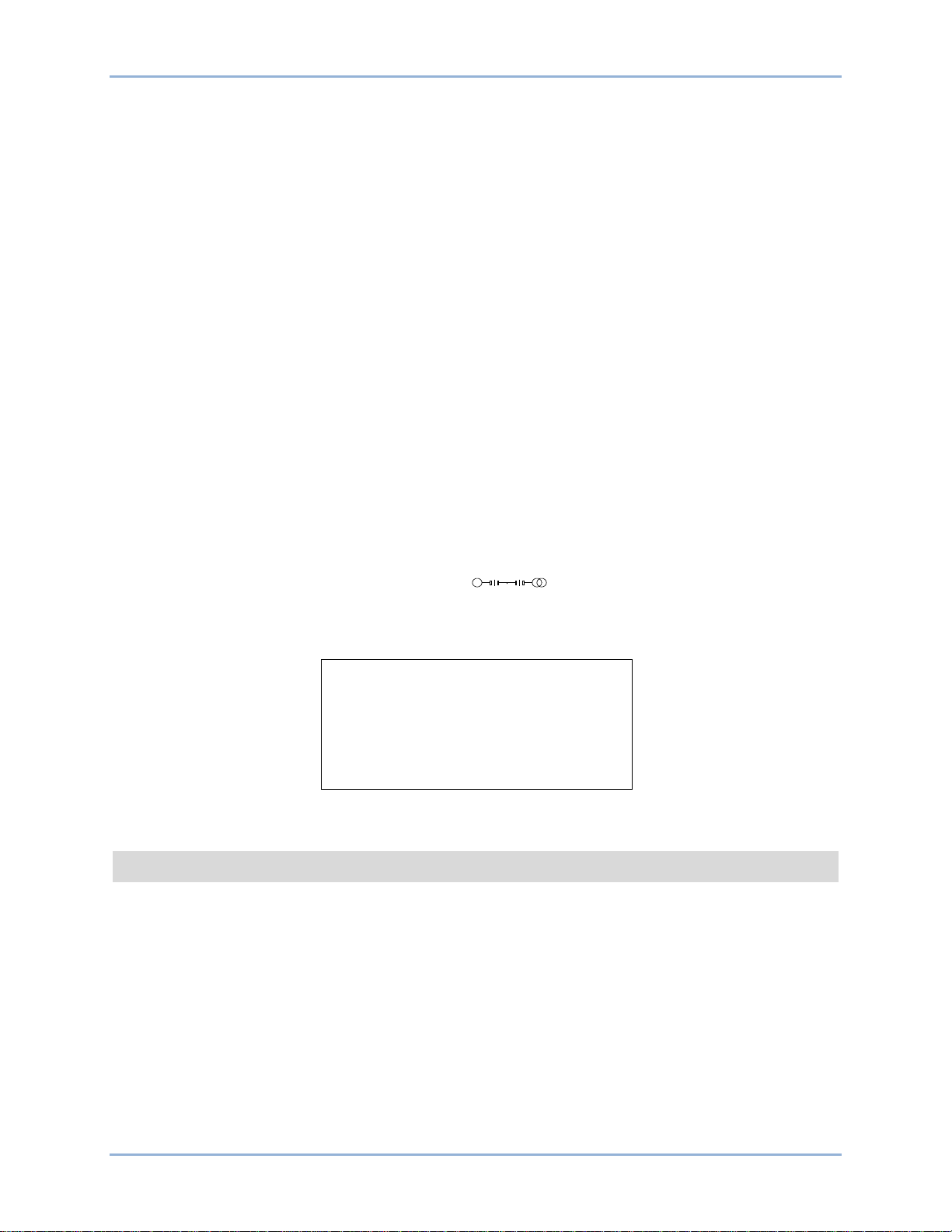

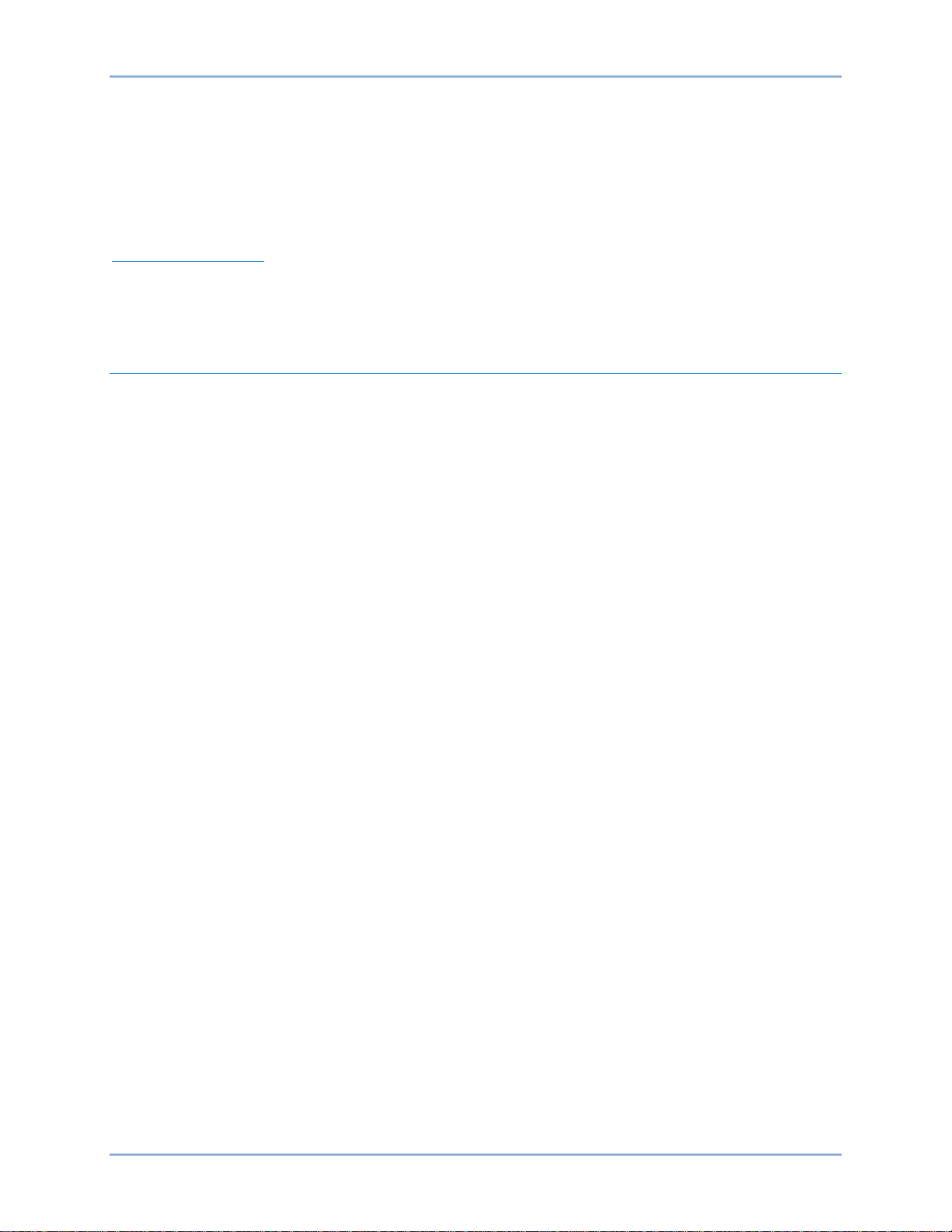

Front Panel Display Structure

The front panel display structure begins with the SUM MAR Y SCRE EN. Press in g the Edit key opens the

MAIN MENU screen. The MAIN MENU screen consists of METERING, SETTINGS and, when enabled,

the ONE-LINE DIAGRAM, indicated by this symbol: . The METERING screen branches are

shown in Figure 3. Details of the METERING screen branches follow Figure 3. The SETTINGS screen

branches are shown in Figure 4. Details of the SETTINGS screen branches follow Figure 4. The ONELINE DIAGRAM screen options are shown in Figure 5.

● OIL PRESSURE

● COOLANT TMP

● BATTERY VOLT

● RPM

● SPEED SRC

● FUEL LEVEL

● ENGINE LOAD

● COOLANT LEVL (Visible when CAN Bus is enabled.)

● TOTAL RUN TM

● HRS TO MAINT

● DEF TANK 1 LVL % (Visible when CAN Bus is enabled.)

● DEF TANK 2 LVL % (Visible when CAN Bus is enabled.)

Controls and Indicators DGC-2020ES

Figure 3. Metering Screen Branches

ENGINE

Page 17

9469200990 Rev C 9

GENERATOR

POWER

RUN STATISTICS

● GEN CONNECT

● GEN VAB

● GEN VBC

● GEN VCA

● GEN VAN

● GEN VBN

● GEN VCN

● GEN FREQ

● GEN AMPS A

● GEN AMPS B

● GEN AMPS C

● BUS CONNECT

● BUS VAB

● BUS FREQ

● kW A

● kW B

● kW C

● kW TOTAL

● kVA A

● kVA B

● kVA C

● kVA TOTAL

● kvar A

● kvar B

● kvar C

● kvar TOTAL

● PF

● CUMULATIVE

○ CUMULATIVE

○ TOTAL RUN TIME

○ LOADED RUN TIME

○ UNLOADED RUN TIME

● SESSION

○ SESSION

○ TOTAL RUN TIME

○ LOADED RUN TIME

○ UNLOADED RUN TIME

■ START

■ # STARTS

■ HRS TO MAINT

■ kW-HRS

■ HOURS

■ MINUTES

■ HOURS

■ MINUTES

■ HOURS

■ MINUTES

■ START

■ kW-HRS

■ HOURS

■ MINUTES

■ HOURS

■ MINUTES

■ HOURS

■ MINUTES

DGC-2020ES Controls and Indicators

Page 18

10 9469200990 Rev C

ALARMS-STATUS

● ACTIVE ALARMS

● ACTIVE PRE-ALARMS

● MTU FAULT CODES (Visible when ECU is configured for MTU MDEC, MTU ADEC, MTU ECU7/ECU8 or MTU

Smart Connect.)

● MTU STATUS (Visible when ECU is configured for MTU MDEC, MTU ADEC, MTU ECU7/ECU8, or MTU Smart

Connect.)

○ NMT-ALIVE STATUS (Visible when ECU is configured for MTU MDEC or MTU ECU7/ECU8.)

■ SPS_NODE

■ SW_TYP

■ SW_VAR

■ SW_ED1

■ SW_ED2

■ REV

■ SW_MOD

○ TRIP FUEL (Visible when ECU is configured for MTU ECU7/ECU8.)

■ TRIP HRS

■ TRIP IDLE HRS

■ FUEL RATE

■ TRIP FL RATE

■ TOTAL RUN TM

■ DAILY FUEL

■ TOTAL FUEL

○ FUEL (Visible when ECU is configured for MTU ADEC.)

■ DAY TANK LVL

■ STORE TANK LVL

○ ENGINE STATUS (Visible when ECU is configured for MTU ADEC, MTU ECU7/ECU8, or MTU Smart

Connect.)

■ MTU FAULT CODES

■ ENG RUNNING

■ CYL CUTOUT

■ ENG OPTIMIZED (Visible when ECU is configured for MTU ADEC or MTU ECU7/ECU8.)

■ PREHT NT RCHD (Visible when ECU is configured for MTU ADEC or MTU ECU7/ECU8.)

■ SPEC TORQUE (Visible when ECU is configured for MTU ADEC or MTU ECU7/ECU8.)

■ SPD DMD FL MD (Visible when ECU is configured for MTU ADEC.)

■ CURR P DEGREE (Visible when ECU is configured for MTU ADEC.)

■ LOAD GEN ON (Visible when ECU is configured for MTU ADEC, MTU ECU7/ECU8, or MTU

Smart Connect.)

■ PRIME PUMP ON (Visible when ECU is configured for MTU ADEC.)

■ RUNUP SPD LO (Visible when ECU is configured for MTU ADEC.)

■ IDLE SPD LO (Visible when ECU is configured for MTU ADEC.)

■ CYL CUTOUT CD (Visible when ECU is configured for MTU ECU7/ECU8.)

■ RPM (Visible when ECU is configured for MTU ECU7/ECU8.)

■ DROOP % (Visible when ECU is configured for MTU ECU7/ECU8 or MTU Smart Connect.)

■ ENG COOL TEMP (Visible when ECU is c onfigured for MTU ECU7/ECU8.)

■ CHRG AIR TMP (Visible when ECU is configured for MTU ECU7/ECU8.)

■ INTRCOOLR TEMP (Visible when ECU is configured for MTU ECU7/ECU8.)

■ ENG OIL TEMP (Visible when ECU is configured for MTU ECU7/ECU8.)

■ FUEL TEMP (Visible when ECU is configured for MTU ECU7/ECU8.)

■ ECU TEMP (Visible when ECU is configured for MTU ECU7/ECU8.)

■ OIL PRESSURE (Visible when ECU is configured for MTU ECU7/ECU8.)

■ CHG AIR P (Visible when ECU is configured for MTU ECU7/ECU8.)

■ FUEL DELV P (Visible when ECU is configured for MTU ECU7/ECU8.)

■ FL RAIL P (Visible when ECU is configured for MTU ECU7/ECU8.)

■ CAMSHAFT RPM (Visible when ECU is configured for MTU ECU7/ECU8.)

■ IDLE RPM (Visible when ECU is configured for MTU ECU7/ECU8.)

■ ECU SHUTDOWN (Visible when ECU is configured for MTU ECU7/ECU8.)

■ TOTAL RUN TM (Visible when ECU is configured for MTU ECU7/ECU8.)

■ ECU SUPP VOLTS (Visible when ECU is configured for MTU ECU7/ECU8.)

■ INJCT DBR % (Visible when ECU is configured for MTU ECU7/ECU8.)

■ RATED RPM (Visible when ECU is configured for MTU ECU7/ECU8.)

■ INJCT QTY (Visible when ECU is configured for MTU ECU7/ECU8.)

■ RATED KW (Visible when ECU is configured for MTU ECU7/ECU8.)

Controls and Indicators DGC-2020ES

Page 19

9469200990 Rev C 11

■ RESRV PWR % (Visible when ECU is configured for MTU ECU7/ECU8.)

■ START SEQ (Visible when ECU is configured for MTU ECU7/ECU8 or MTU Smart Connect.)

■ ECU OVRD FDBK (Visible when ECU is configured for MTU Smart Connect.)

■ COOLNT PRHT DONE (Visible when ECU is configured for MTU Smart Connect.)

■ REQ TORQUE (Visible when ECU is configured for MTU Smart Connect.)

■ EXT STOP (Visible when ECU is configured for MTU Smart Connect.)

■ OPERATING MODE (Visible when ECU is configured for MTU Smart Connect.)

○ SPEED (Visible when ECU is co nfigured for MTU ADEC, MTU ECU7/ECU8, or MTU Smart Connect.)

■ SPD DMD SRC

■ CAN SPD DMD

■ ANLG SPD DMD

■ SPEED DEMAND (Visible when ECU is configured for MTU Smart Connect.)

■ SEL SPD DMD (Visible when ECU is configured for MTU ADEC or MTU ECU7/ECU8.)

■ EFF SET SPEED (Visible when ECU is configured for MTU ADEC or MTU ECU7/ECU8.)

■ SPD DMD FL MD (Visible when ECU is configured for MTU ECU7/ECU8 or MTU Smart

Connect.)

■ RATED RPM (Visible when ECU is configured for MTU ECU7/ECU8.)

■ RPM (Visible when ECU is configured for MTU ECU7/ECU8.)

■ CAMSHAFT RPM (Visible when ECU is configured for MTU ECU7/ECU8.)

■ IDLE RPM (Visible when ECU is configured for MTU ECU7/ECU8.)

■ FREQ RPM DMD (Visible when ECU is c onfigured for MTU ECU7/ECU8.)

○ SIGNL FEEDBK (Visible when ECU is configured for MTU ADEC, MTU ECU7/ECU8, or MTU Smart

Connect.)

■ ECU_OVRD_FDBK

■ EXT STOP

■ SPD UP IN

■ SPD DN IN

■ CAN MODE FDBK (Visible when ECU is configured for MTU ADEC or MTU ECU7/ECU8.)

■ CYL CUTOUT (Visible when ECU is configured for MTU ECU7/ECU8.)

○ DIAGNOSTICS (Visible when ECU is configured for MTU ECU7/ECU8.)

■ AL PWR AMP 1

■ AL PWR AMP 2

■ XSTR OUT AL

■ XSTR OUT STS

■ ECU SHUTDOWN

○ CAN BUS (Visible when ECU is configured for MTU ECU7/ECU8.)

■ CAN MODE FDBK

■ CAN NODES

■ LOST NODES

○ LIMITS (Visible when ECU is configured for MTU ECU7/ECU8.)

■ OIL PRESSURE

■ LO LIM OILP

■ LOLOLIM OILP

■ ENG COOL TEMP

■ CLNT LMT HI

■ CLNT LMT HIHI

■ CHRG AIR TMP

■ CHG AIR LMT HI

■ ECU SUPP VOLTS

■ L1L ECU VOLTS

■ L2L ECU VOLTS

■ U1L ECU VOLTS

■ U2l ECU VOLTS

■ INTRCOOLR TMP

■ INTCLR LMT HI

● STATUS

○ AUTO XFER SWITCH (Visible when the Auto Transfer Switch programmable function is configured to

be driven by an input.)

○ EPS SUPP. LOAD

○ GEN BREAKER

○ MAINS BREAKER

○ BATTLE OVERRIDE (Visible when the Battle Override programmable function is configured to be

driven by an input.)

○ LOW LINE OVERRIDE (Visible when the Low Line Override programmable function is conf i gur ed to be

driven by an input.)

DGC-2020ES Controls and Indicators

Page 20

12 9469200990 Rev C

○ LOW COOL LEVEL (Visible when the Low Coolant Level programmable function is configured to be

driven by an input.)

○ LOW FUEL LEVEL (Visible when the Low Coolant Level programmable function is configured to be

driven by an input.)

○ BATT CHRG FAIL (Visible when the Battery Charger Fail programmable function is configured to be

driven by an input.)

○ FUEL LEAK DETECT (Visible when the Fuel Leak Detect programmable function is configured to be

driven by an input.)

○ GRND DELTA O-RIDE (Visible when Generator Connection is configured for Delta and the Grounded

Delta Override programmable function is configured to be driven by an input.)

○ 1 PHASE O-RIDE (Visible when the 1-Phase Override programmable function is configured to be driven

by an input.)

○ BUS DEAD

○ BUS STABLE

○ BUS FAILED

○ GEN DEAD

○ GEN STABLE

○ GEN FAILED

○ ENG RUNNING

○ CLDN TMR ACTVE

○ OFF MODE COOLDN

○ COOLDN REQ

○ COOL & STOP REQ

○ EXT START DEL

○ START DEL BYPASS

○ ALT FRQ O-RIDE

○ RESET

○ ALARM SILENCE

○ LAMP TEST

○ IDLE REQUEST

○ MAINS FAIL TEST

○ CEM CONNECTED

● INPUTS

○ INPUT X (X = 1 to 7 (8 to 17 optional))

● OUTPUTS

○ START

○ RUN

○ PRESTART

○ OUTPUT X (X = 1 to 4 (5 to 28 optional))

● LOGIC CTL RELAYS

○ LCR X (X = 1 to 16)

● CONF ELEMENTS

○ CONFIG ELEMENT X (X = 1 to 8)

● EVENT LOG

○ [EVENT NAME]

■ ACTIVE

■ OCCURRENCE COUNT

■ FIRST DATE

■ FIRST TIME

■ LAST DATE

■ LAST TIME

■ FIRST ENG HRS

■ LAST ENG HRS

■ DETAILS

□ OCCURRENCE (Use the Edit/Up/Down keys to change the occurrence.)

□ DATE

□ TIME

□ ENG HRS

■ CLEAR EVENT (Visible when logged in through the front panel.)

● J1939 DATA (Visible when CAN bus is enabled and ECU is configured for Standard, Volvo Penta, MTU ADEC,

GM/Doosan, Cummins, MTU Smart Connect, Scania, or John Deere.)

○ THROTTLE POSITN

○ LOAD @ CRNT RPM

○ ACTUAL ENG TORQ

○ ENGINE SPEED

Controls and Indicators DGC-2020ES

Page 21

9469200990 Rev C 13

○ DESIRED SPEED

○ INJ CNTRL PRESS

○ INJ RAIL PRS

○ ENGINE HOURS

○ TRIP FUEL

○ TRIP AVE FL RT

○ TOTAL FUEL USED

○ ENG COOLANT TEMP

○ COOLNT PRHT DONE

○ FUEL TEMP

○ ENG OIL TEMP

○ ENG INTCLR TEMP

○ INTRCR CLNT LVL

○ FUEL DELV P

○ ENG OIL LEVEL

○ ENG OIL PRESS

○ COOLANT PRESS

○ COOLANT LEVEL

○ FUEL RATE

○ BAROMETRIC PRESS

○ AMB AIR TEMP

○ AIR INLET TEMP

○ BOOST PRESS

○ INTAK MNFLD TEMP

○ INTAK MNFLD1 ABS PRESS

○ AIR FLTR DIF PRS

○ EXHAUST GAS TEMP

○ BATTERY VOLTAGE

○ ECU INPUT VOLTS

○ TRANS OIL PRESS

○ TRANS OIL TEMP

○ WINDG 1 TEMP

○ WINDG 2 TEMP

○ WINDG 3 TEMP

○ ECU TEMP

○ AUX PRESSURE1

○ AUX PRESSURE2

○ RATED KW

○ RATED RPM

○ EXHAUST TMP A

○ EXHAUST TMP B

○ CHRG AIR TMP

○ FUEL 1 LEAK

○ FUEL 2 LEAK

○ ALARM RST FDBK

○ ECU SHUTDOWN

○ DEF TANK 1 LVL %

○ DEF TANK 2 LVL %

● J1939 ENGINE CONFIG (Visible when CAN bus is enabled and ECU is configured for Standard, Volv o Penta,

MTU ADEC, GM/Doosan, Cummins, or MTU Smart Connect.)

○ SPD @ IDLE PNT 1

○ TRQ @ IDLE PNT 1

○ SPD @ PNT 2

○ TRQ @ PNT 2

○ SPD @ PNT 3

○ TRQ @ PNT 3

○ SPD @ PNT 4

○ TRQ @ PNT 4

○ SPD @ PNT 5

○ TRQ @ PNT 5

○ SPD @ PNT 6

○ ENDSPEED GOV KP

○ REF ENG TORQUE

○ O-RIDE SPD PNT 7

○ O-RIDE TIME LMT

DGC-2020ES Controls and Indicators

Page 22

14 9469200990 Rev C

P0067-83

GENERAL SETTINGS

COMMUNICATIONS

SYSTEM PARAMS

PROGRAMMABLE INPUTS

PROGRAMMABLE OUTPUTS

ALARM CONFIGURATION

GENERATOR PROTECTION

BREAKER MANAGEMENT

LOGIC TIMERS

ENTER PASSWORD

SETTINGS

○ SPEED LOWER LMT

○ SPEED UPPER LMT

○ TORQUE LOWER LMT

○ TORQUE UPPER LMT

● MAINS FAIL TRANSFER (Visible when DGC-2020ES style number is xx2 and Mains Fail Transfer is enabled.)

○ MAINSFAIL XFER STATE

■ DISABLED ( The possible mains fail transfer states are as follows: Power From Mains,

Transfer Timer Active, Transferring to Gens, Power From Gens, Return Timer Active,

Transferring to Mains, Disabled (when DGC is in OFF or RUN modes, or in the alarm state))

○ TRANSFER DELAY (Visible when actively counting and relevant to mains fail transfer.)

○ RETURN DELAY (Visible when actively counting and rel evant to mains fail transfer.)

○ MAX TRANSFER TIME (Visible when actively counting and relevant to mains fail transfer.)

DIAGNOSTICS

● FLASH WR

● FRONT PANEL HMI

● CONFIGURE DATE/TIME

● VIEW DATE/TIME

● VERSION INFO

Controls and Indicators DGC-2020ES

Figure 4. Settings Screen Branches

GENERAL SETTINGS

○ SUMMARY VIEW

○ SCROLL DELAY

○ PH TOG DELAY

○ LCD CONTRAST

○ SLEEP MODE

○ LANGUAGE

○ CONFIGURABLE METERING

■ ITEM X (X = 1 to 20)

○ ONE LINE DIAGRAM

○ YEAR

○ MONTH

○ DAY

○ HOURS

○ MINUTES

○ SECONDS

○ UTC OFFSET

○ DST ENABLED

○ CLK NOT SET WRN

○ DGC-2020ES

■ FIRMWARE VERSION

■ BOOT CODE VERSION

■ SERIAL NUMBER

■ PART NUMBER

■ MODEL NUMBER

■ LANGUAGE VERSION

■ LANGUAGE PART NUM

Page 23

9469200990 Rev C 15

■ STYLE CODE

○ CEM-2020 (Visible when CEM-2020 is enabled.)

■ FIRMWARE VERSION

■ BOOT CODE VERSION

■ SERIAL NUMBER

■ PART NUMBER

■ MODEL NUMBER

■ BUILD DATE

COMMUNICATIONS∗

∗(Visible when the optional J1939 CAN bus is enabled, style code xCx.)

● CAN BUS SETUP

○ CAN BUS SETUP

■ CAN BUS ENABLE

■ DTC ENABLE (Visible when CAN BUS is enabled.)

■ SPN CONV METHOD (Visib le when CAN BUS is enabled.)

■ CAN BUS ADDR (Visible wh en CAN B US is enabled.)

■ ECU OPT SLCT (Visible when CAN BUS is enabled.)

■ ECU PULSING (Visible when CAN BUS is enabled.)

■ ENG SHTDN TM (Visible when CAN BUS is enabled.)

■ PLS CYCL TM (Visible when CAN BUS is enabled.)

■ ECU SET TM (Visible when CAN BUS is enabled.)

■ RESP TIMEOUT (Visible when CAN BUS is enabled.)

○ ECU SETUP (Visible when CAN BUS is enabled.)

■ ECU CONF

■ GEN DATA TRANSMIT

■ ENGINE PARAM XMT

■ TRIP RESET (Visible when ECU is configured for Standard, Volvo Penta, MTU ADEC,

GM/Doosan, Cummins, or MTU Smart Connect.)

■ DPF REGENRATE SETUP (Visible when ECU is configured for Standard, Volvo Penta, MTU

ADEC, GM/Doosan, Cummins, or MTU Smart Connect.)

□ DPF MANUAL REGEN

□ DPF REGEN DISABLE

■ SPEED SELECT (Visible when ECU is configured for Volvo Penta.)

■ ACCEL POSITION (Visible when ECU is configured for Volvo Penta.)

■ MODULE TYPE (Visible when ECU is configured for MTU MDEC or MTU ECU7/ECU8.)

■ ALIVE MSG (Visible when ECU is configured for MTU MDEC or MTU ECU7/ECU8.)

■ SPEED SETUP

□ J1939 RPM ENABLE (Visible when ECU is configured for Standard, Volvo Penta,

MTU ADEC, GM/Doosan, Cummins, or MTU Smart Connect.)

□ ENGINE RPM

□ RPM BAND WIDTH

□ IDLE RPM

□ SPEED UP (Visible when ECU is configured for MTU ADEC, MTU MDEC 304, MTU

ECU7/ECU8, or MTU Smart Connect.)

□ SPEED DN (Visible when ECU is configured for MTU ADEC, MTU MDEC 304, MTU

ECU7/ECU8, or MTU Smart Connect.)

□ TEST OVRSPEED (Visible when ECU is configured for MTU ADEC, MTU MDEC

304, MTU ECU7/ECU8, or MTU Smart Connect.)

□ SPD DMAND SRC (Visible when ECU is configured for MTU ADEC, MTU MDEC

304, MTU ECU7/ECU8, or MTU Smart Connect.)

□ IDLE REQUEST (Visible when ECU is configured for MTU MDEC 304, MTU

ECU7/ECU8, or MTU Smart Connect.)

□ INCREASE IDLE (Visible when ECU is configured for MTU MDEC 304, or MTU

ECU7/ECU8.)

■ ECU SETUP (Visible when ECU is configured for MTU ADEC, MTU MDEC 304, MTU

ECU7/ECU8, or MTU Smart Connect.)

□ TRIP RESET (Visible when ECU is configured for MTU MDEC 304, or MTU

ECU7/ECU8.)

□ INT OIL PRIME

□ GOV PRM SW (Visible when ECU is configured for MTU ADEC or MTU Smart

Connect.)

DGC-2020ES Controls and Indicators

Page 24

16 9469200990 Rev C

□ ENG STRT PRIME (Visible when ECU is configured for MTU MDEC 304, or MTU

ECU7/ECU8.)

□ FAN OVERRIDE (Visible when ECU is configured for MTU MDEC 304, or MTU

ECU7/ECU8.)

□ MODE SWITCH (Visible when ECU is configured for MTU MDEC 304, or MTU

ECU7/ECU8.)

□ GOV PARAM SET (Visible when ECU is configured for MTU ECU7/ECU8.)

□ CAN RATING SW 1 (Visible when ECU is configured for MTU ECU7/ECU8.)

□ CAN RATING SW 2 (Visible when ECU is configured for MTU ECU7/ECU8.)

□ DIS CYL CUT 1 (Visible when ECU is configured for MTU MDEC 304, or MTU

ECU7/ECU8.)

□ DIS CYL CUT 2 (Visible when ECU is configured for MTU MDEC 304, MTU

ECU7/ECU8 or MTU Smart Connect.)

□ OPERATING MODE (Visible when ECU is configured for MTU Smart Connect.)

SYSTEM PARAMS

● SYSTEM SETTINGS

○ GEN CONNECT

○ BUS CONNECT

○ RATED kW

○ RATED VOLTS

○ RATED FREQ

○ ALTRNATE FRQ

○ RATED RPM

○ RATED PF

○ ROTATION

○ EPS

■ EPS THRESHLD

■ LOW LINE SF (Visible when an input is selected for the Low Line Override progr am m abl e

function.)

○ FUEL LVL TYP

○ SYSTEM UNITS

○ PRESSURE UNITS (Visible when Metric is selected for System Units.)

○ BATTERY VOLT

○ FLYWHL TEETH

○ SPEED SOURCE

○ MAINT RESET

○ NFPA LEVEL

○ POWER UP DELAY

● REMOTE MODULE SETUP

○ CEM SETUP

■ ENABLE

■ OUTPUTS (Visible when CEM-2020 is enabled.)

■ CAN BUS ADDR (Visible wh en CEM-2020 is enabled.)

■ VERSION INFO (Visible when CEM-2020 is enabled.)

□ FIRMWARE VERSION

□ BOOT CODE VERSION

□ SERIAL NUMBER

□ PART NUMBER

□ MODEL NUMBER

□ BUILD DATE

■ CEM DEBUG MENU (Visible when CEM-2020 is enabled.)

□ DGC TO CEM BP

□ CEM TO DGC BP

● CRANK SETTINGS

○ DISCNCT LMIT

○ PRECRNK DELY

○ PRESTRT CNTCT

○ STYLE

○ # CYCLES (Visible when Cycle is s elected for Cranking Style.)

○ CONT TIME (Visible when Continuous is selected for Cranking Style.)

○ CYCLE TIME

○ COOLDWN TIME

○ OFF MODE COOLDN

Controls and Indicators DGC-2020ES

Page 25

9469200990 Rev C 17

○ PRESTART REST CONFIG

■ CONF

○ OIL PRS CRANK DISC

■ ENABLE

■ CRANK DISC PRS

● AUTOMATIC RESTART

○ ENABLE

○ ATTEMPTS

○ INTERVAL

● EXERCISE TIMER

○ MODE

○ RUN WITH LOAD

○ START HOUR

○ START MINUTE

○ RUN HOURS

○ RUN MINUTES

● SENSING TRANS

○ GEN PT PRI V

○ GEN PT SEC V

○ GEN CT PRI A

○ CT LOW LINE SF (Visible when an input is selected for the Low Line Override programmable function.)

○ BUS PT PRI V

○ BUS PT SEC V

● RELAY CONTROL

○ START

○ RUN

○ PRESTART

● AUTO CONFIG DETECT

○ ENABLE

○ LOW LINE THRESH

○ 1-PH THRESH

● ENGINE STATISTICS

○ START YEAR

○ START MONTH

○ START DAY

○ # STARTS

○ HRS TO MAINT

○ kW-HRS

○ TOTAL HRS

○ LOADED HRS

○ UNLOADED HRS

PROGRAMMABLE INPUTS

● CONFIGURABLE INPUTS

○ INPUT X (X = 1 to 7)

■ ALARM CONFIG

■ ACTIVATN DLY

■ RECOGNITION

● PROG FUNCTIONS

○ EMERGENCY STOP

■ INPUT

○ AUTO XFER SWITCH

■ INPUT

■ RECOGNITION (Visible when an INPUT is selected.)

○ GRND DELTA O-RIDE

■ INPUT

■ RECOGNITION (Visible when an INPUT is selected.)

○ BATTLE OVERRIDE

■ INPUT

■ RECOGNITION (Visible when an INPUT is selected.)

○ LOW LINE OVERRIDE

■ INPUT

■ RECOGNITION (Visible when an INPUT is selected.)

DGC-2020ES Controls and Indicators

Page 26

18 9469200990 Rev C

○ 1 PHASE O-RIDE

■ INPUT

■ RECOGNITION (Visible when an INPUT is selected.)

○ BATT CHRG FAIL

■ INPUT

■ ALARM CONFIG (Visible when an INPUT is selected.)

■ ACTIVATN DLY (Visible when an INPUT is selected.)

■ RECOGNITION (Visible when an INPUT is selected.)

○ LOW COOL LEVEL

■ INPUT

■ ALARM CONFIG (Visible when an INPUT is selected.)

■ ACTIVATN DLY (Visible when an INPUT is selected.)

■ RECOGNITION (Visible when an INPUT is selected.)

○ LOW FUEL LEVEL

■ INPUT

■ ALARM CONFIG (Visible when an INPUT is selected.)

■ ACTIVATN DLY (Visible when an INPUT is selected.)

■ RECOGNITION (Visible when an INPUT is selected.)

○ FUEL LEAK DETECT

■ INPUT

■ ALARM CONFIG (Visible when an INPUT is selected.)

■ ACTIVATN DLY (Visible when an INPUT is selected.)

■ RECOGNITION (Visible when an INPUT is selected.)

PROGRAMMABLE OUTPUTS

● CONFIG ELEMENTS

○ CONFIG ELEMENT X (X = 1 to 8)

■ ALARM CONFIG

■ ACTIVATN DLY

■ RECOGNITION

● HORN CONFIGURATION

○ HORN

○ NOT IN AUTO HORN

● PRE-ALARMS

○ HIGH COOLANT TEMP

■ ENABLE

■ THRESHOLD

○ LOW COOLANT TEMP

■ ENABLE

■ THRESHOLD

○ LOW OIL PRESSURE

■ ENABLE

■ THRESHOLD

○ LOW FUEL LEVEL

■ ENABLE

■ THRESHOLD

○ MAINTENANCE INTERVAL

■ ENABLE

■ THRESHOLD

○ BATTERY OVERVOLTAGE

■ ENABLE

■ THRESHOLD

○ LOW BATTERY VOLTAGE

■ ENABLE

■ THRESHOLD

■ ACTIVATN DLY

○ WEAK BATTERY VOLTAGE

■ ENABLE

■ THRESHOLD

■ ACTIVATN DLY

ALARM CONFIGURATION

Controls and Indicators DGC-2020ES

Page 27

9469200990 Rev C 19

Note

The HIGH COOLANT TEMP and LOW OIL PRESSURE alarms have

after engine startup.

○ HIGH FUEL LEVEL

■ ENABLE

■ THRESHOLD

■ ACTIVATN DLY

○ ACTIVE DTC (Visible when DTC is enabled.)

■ ENABLE

○ ECU COMMS FAIL (Visible when CAN BUS is enabled.)

■ ENABLE

○ COOLANT LEVEL (Visible when CAN BUS is enabled.)

■ ENABLE

■ THRESHOLD

○ CEM COMM FAIL (Visible when CEM-2020 is enabled.)

■ ENABLE

○ CHECKSUM FAIL

■ ENABLE

○ BRK CLOSE FAIL PALM

■ ENABLE

○ BRK OPEN FAIL PALM

■ ENABLE

• ALARMS

○ HIGH COOLANT TEMP

■ ENABLE

■ THRESHOLD

■ ARMING DELAY

○ LOW OIL PRESSURE

■ ENABLE

■ THRESHOLD

■ ARMING DELAY

○ LOW FUEL LEVEL

■ ENABLE

■ THRESHOLD

■ ACTIVATN DLY

○ OVERSPEED

■ ENABLE

■ THRESHOLD

■ ACTIVATN DLY

○ COOLANT LEVEL (Visible when CAN bus is enabled.)

■ ENABLE

■ THRESHOLD

an ARMING DLY setting that disables the alarm for the specified time

● SENDER FAIL

○ COOL TEMP SENDR FAIL

■ CONFIG TYPE

■ ACTIVATN DLY

○ OIL PRESS SENDR FAIL

■ CONFIG TYPE

■ ACTIVATN DLY

○ FUEL LEVL SENDR FAIL

■ CONFIG TYPE

■ ACTIVATN DLY

○ VOLTAGE SENSE FAIL

■ CONFIG TYPE

■ ACTIVATN DLY

○ SPEED SENDR FAIL

■ TIME DELAY

DGC-2020ES Controls and Indicators

Page 28

20 9469200990 Rev C

GENERATOR PROTECTION

BREAKER MANAGEMENT

● 27 UNDERVOLTAGE

○ LOW LINE SF (Visible when an input is selected for the Low Line Override programmable function.)

○ 3 / 1 PHASE SETTINGS

■ PICKUP

■ HYSTERESIS

■ TIME DELAY

■ FREQ INHIBIT

■ ALARM CONFIG

● 59 OVERVOLTAGE

○ LOW LINE SF (Visible when an input is selected for the Low Line Override programmable function.)

○ 3 / 1 PHASE SETTINGS

■ PICKUP

■ HYSTERESIS

■ TIME DELAY

■ ALARM CONFIG

● 47 PHASE IMBALANCE

○ PICKUP

○ HYSTERESIS

○ TIME DELAY

○ ALARM CONFIG

○ LOW LINE SF (Visible when an input is selected for the Low Line Override programmable function.)

● 81 O/U FREQUENCY

○ UNDERFREQUENCY

■ INHIBIT VOLTS

■ PICKUP

■ HYSTERESIS

■ TIME DELAY

■ ALARM CONFIG

○ OVERFREQUENCY

■ PICKUP

■ HYSTERESIS

■ TIME DELAY

■ ALARM CONFIG

○ ALTRNT FRQ SCALE FCTR

■ ALT FREQ SF

● 50 OVERCURRENT

○ LOW LINE SF (Visible when an input is selected for the Low Line Override programmable function.)

○ 3 / 1 PHASE SETTINGS

■ PICKUP

■ TIME DELAY

■ ALARM CONFIG

● BREAKER HARDWARE

○ MAINS FAIL TRANSFER

■ ENABLE

■ RETURN DELAY

■ TRANSFER DELAY

■ MAX TRANSFER TIME

○ CLOSE WAIT TIME

■ TIME

○ GEN BREAKER

■ CONTINUOUS

■ CLOSING TIME

■ OPEN CMD

■ CLOSE CMD

○ MAINS BREAKER

■ CONFIGURED

■ CONTINUOUS (Visible when configured.)

■ CLOSING TIME (Visible when configured.)

Controls and Indicators DGC-2020ES

Page 29

9469200990 Rev C 21

LOGIC TIMERS

ENTER PASSWORD

■ OPEN CMD (Visible when configured.)

■ CLOSE CMD (Visible when configured.)

○ BRK CLOSE FAIL PALM

○ BRK OPEN FAIL PALM

● BUS CONDITION DETECT

○ GEN DEAD

■ THRESHOLD

■ TIME DELAY

○ GEN STABLE

■ OV PICKUP

■ OV DROPOUT

■ UV PICKUP

■ UV DROPOUT

■ OF PICKUP

■ OF DROPOUT

■ UF PICKUP

■ UF DROPOUT

■ TIME DELAY

■ LOW LINE SF (Visible when an input is selected for the Low Line Override programmable

function.)

■ ALT FREQ SF

○ GEN FAILED

■ TIME DELAY

○ BUS DEAD

■ THRESHOLD

■ TIME DELAY

○ BUS STABLE

■ OV PICKUP

■ OV DROPOUT

■ UV PICKUP

■ UV DROPOUT

■ OF PICKUP

■ OF DROPOUT

■ UF PICKUP

■ UF DROPOUT

■ TIME DELAY

■ LOW LINE SF (Visible when an input is selected for the Low Line Override programmable

function.)

■ ALT FREQ SF

○ BUS FAILED

■ TIME DELAY

● TIMER X (X = 1 to 10)

○ HOURS

○ MINUTES

○ SECONDS

LOGOUT (Visible when logged in through the front panel.)

One-Line Diagram

A one-line diagram of the breaker hardware configuration can be displayed on the front panel. This

diagram changes in real time to reflect the current state of the configured breakers. The one-line diagram

is disabled by default. To display the one-line diagram using front panel controls, nav igat e to Sett ings >

General Settings > Fr ont P ane l HMI > One-Line Diagram and enable the setting. If using

BESTCOMSPlus, navigate to Settings Explorer, General Settings, Front Panel HMI and select Enable on

the One-Line Diagram setting.

DGC-2020ES Controls and Indicators

Page 30

22 9469200990 Rev C

Generator and mains breakers are configured and

Generator and mains breakers are configured. The

Generator and mains breakers are configured. The

Generator breaker is configur ed and open.

0 VLL 0 VLN

0.0 Hz 0 A

0 kW 0 KVar

PF 1.00 LEAD

BUS 0 VLL 0.0 Hz

G

L

GN BRK OPN CMD OFF

GN BRK CLS CMD OFF

MN BRK OPN CMD OFF

MN BRK CLS CMD OFF

P0071-89

MAINSFAIL XFER STATE

DISABLED

G

L

G

L

G

L

G L

G

L

P0071-88

Once enabled, the one-line diagram appears on both the front panel Summary and Main Menu screens.

The One-Line Diagram Menu screen provides metering for mains fail transfer, generator and bus

parameters as well as breaker controls. To access the One-Line Diagram Menu screen, go to the Main

Menu and select the one-line diagram as you would a normal menu option and press the Edit pushbutton.

The one-line diagram, mains fail transfer state (if enabled), generator and bus parameters, and breaker

controls are displayed respectively from the top of the menu.

Further mains fail transfer state metering is available by selecting the “MAINSFAIL XFER STATE” and

pressing the Edit pushbutton. Mains fail transfer state, transfer delay, return delay, and max transfer time

are displayed.

To issue a breaker open or breaker close command, select the appropriat e menu opti on, pr es s Edit and

select ON.

Figure 5. One-Line Diagram Menu Options (Available when One-Line Diagram is Enabled)

Mains Fail Transfer Status Display

Mains Fail Transfer Status can be viewed from three locations; however, the DGC-2020ES must be

equipped with Mains Fail Transfer (style number xx2) and Mains Fail Transfer must be enabled.

Figure 6. One-Line Diagram: Breaker Hardware Status Indication

Controls and Indicators DGC-2020ES

both breakers are open.

generator breaker is closed and the mains breaker

is open.

generator breaker is open and the mains breaker is

closed.

No breakers are configured.

Page 31

9469200990 Rev C 23

Note

To enable Mains Fail Transfer, navigate to Settings > Breaker Management > Breaker Hardware > Mains

Fail Transfer using the front panel controls or Settings Explorer, Breaker Management, Mains Fail using

BESTCOMSPlus.

Mains Fail Transfer Status is displayed on the front panel in Metering > Alarms-Status > Mains Fail

Transfer and also on the Breaker Hardware One-Line Diagram screen. It is displayed in BESTCOMSPlus

on the Metering Explorer, Mains Fail Transfer Status screen.

These screens display the Mains Fail Transfer State and any timers relevant to the mains fail transfer

process. These parameters are listed below.

Mains Fail Transfer State: The different mains fail transfer states are described below.

Power From Mains: Power is being supplied to the load from the mains bus.

Transfer Timer Active: Transfer Delay timer is actively counting.

Transferring to Gens: Load is being transferred to the generator bus.

Power From Gens: Power is being supplied to the load from the generator bus.

Return Timer Active: Return Delay timer is actively counting.

Transferring to Mains: Load is being transferred to the mains bus.

Disabled: DGC-2020 is in the OFF or RUN operating mode or in the alarm state.

Transfer Delay: Displays the current timer value in seconds.

Return Delay: Displays the current timer value in seconds.

Max Transfer Time: Displays the current timer value in seconds.

The Mains Fail Transfer screen found at Metering > Alarms-Status >