Page 1

INSTRUCTION MANUA L

FOR

DIGITAL GENSET CONTRO LL ER

DGC-2020

Publication: 9400200990

Revision: X Oct-14

Page 2

Page 3

INTRODUCTION

WARNING!

2020 settings. Instructions for changing passwords are

This instruction manu al pro vides inform ation abo ut the operation and inst allation of the DGC-2020 Digital

Genset Controller. To accomplish this, the following information is provided:

• General Information and Specifications

• Controls and Indicators

• Functional Description

• Graphical User Interface Operation

• Installation

• Setup

• Maintenance and Troubleshooting

To avoid personal injury or equipment damage, only qualified personnel should

perform the procedures in this manual.

NOTES

Check for the latest version of this instruction manual at www.basler.com

DGC-2020 controllers are moun ted using th e four permane ntly-at tached 10-24

studs and the provided self-locking nuts. Failure to use the proper 10-24

locking nuts may da mage t he stu d thr eads and/or impr operly s ecure the DG C-

2020.

Be sure that the control ler is hard-wired to earth grou nd with no smaller than

12 AWG copper wire attach ed to the c hass is groun d terminal on the rear of the

unit. When the controller is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

The DGC-2020 utilizes pas sword protection that guards against unauthorized

changing of DGCprovided in Section 4, BESTCOMSPlus® Software, General Settings, Device

Security Setup. The default passwords are listed below.

• OEM access level: OEM

• Settings access level: SET

• Operator access level: OP

• LSM-2020 (Load Share Module)

• CEM-2020 (Contact Expansion Module)

• AEM-2020 (Analog Expans ion Mod ule)

• Time Overcurrent Characteristic Curves

• Modbus™ Communication

• PID Tuning Settings

• MTU Fault Codes

.

BOX DEFINITIONS

WARNING!

A warning box indicates a potentially hazardous situa tion which co uld result in

death or injury.

CAUTION

A caution box indicates a potentially hazar dous situation which could result in

equipment or property damage.

NOTE

A note box provides helpful information.

9400200990 Rev X DGC-2020 Introduction i

Page 4

First Printing: November 2006

OR STATUTORY WARRANTY, INCLUDING BUT NOT LIMITED TO

any products or services supplied or Web sites maintained or provided by third parties and/or

Printed in USA

Copyright © 2014 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

October 2014

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use,

subject to return on request, and with the mutual understanding th at it will not

be used in any manner detrimental to the interest of Basler Electric.

Disclaimer of Liability and Warranty

Basler Electric provides links to third-party Web sites and references to third party products and

services as a convenience in locating relative information, products, and serv ices for our users. The

existence of these links an d referenc es is not to be c onstrued as an endors ement by Basler Electric of

the content of any of these third-party sites, produc ts or services. BASLER ELECTRIC MAKES NO

EXPRESS, IMPLIED,

WARRANTY OF MERCHANTABILITY, WARRANTY OF FITNESS FOR A PAR TICULAR PURPOSE,

WARRANTY OF NONINFRINGEMENT OR THE LIKE, OR WARRANTY OF TITLE. Basler Electric

makes no representatio n of fr eedo m fr om computer viruses or of the ac cur ac y of the in forma ti on an d/or

the quality of products or services provided by thes e referenc ed products or advertis ed on these thirdparty Web sites. Basl er El ectric d i scl aim s, to th e fullest extent permi ssible by applicable law, an y

and all liability and respo nsibility for any claims o r damage that may ari se as a result of use of

linked to the Basler Electric W eb site. Basler El ectric advises site visitors that link s to Web sites not

controlled by Basler Electr ic are not subject to the privacy notice as sociated with the Basler Electric

Web site and, therefore, are advised to read the privacy policies of any third-party sites accessed

through this site.

It is not the intent ion of th is manual to cover a ll detai ls and variat ions in equipme nt, nor do es this m anual

provide data for every pos s ible c ont ing enc y regar di ng i nstal lat ion or operation. The avai labil ity and design

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

For terms of service relati ng to this product and software, see the Commercial Ter ms of Products and

Services document available at www.basler.com/terms

.

Basler Electric

12570 State Route 143

Highland IL 62249-1074 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii DGC-2020 Introduction 9400200990 Rev X

Page 5

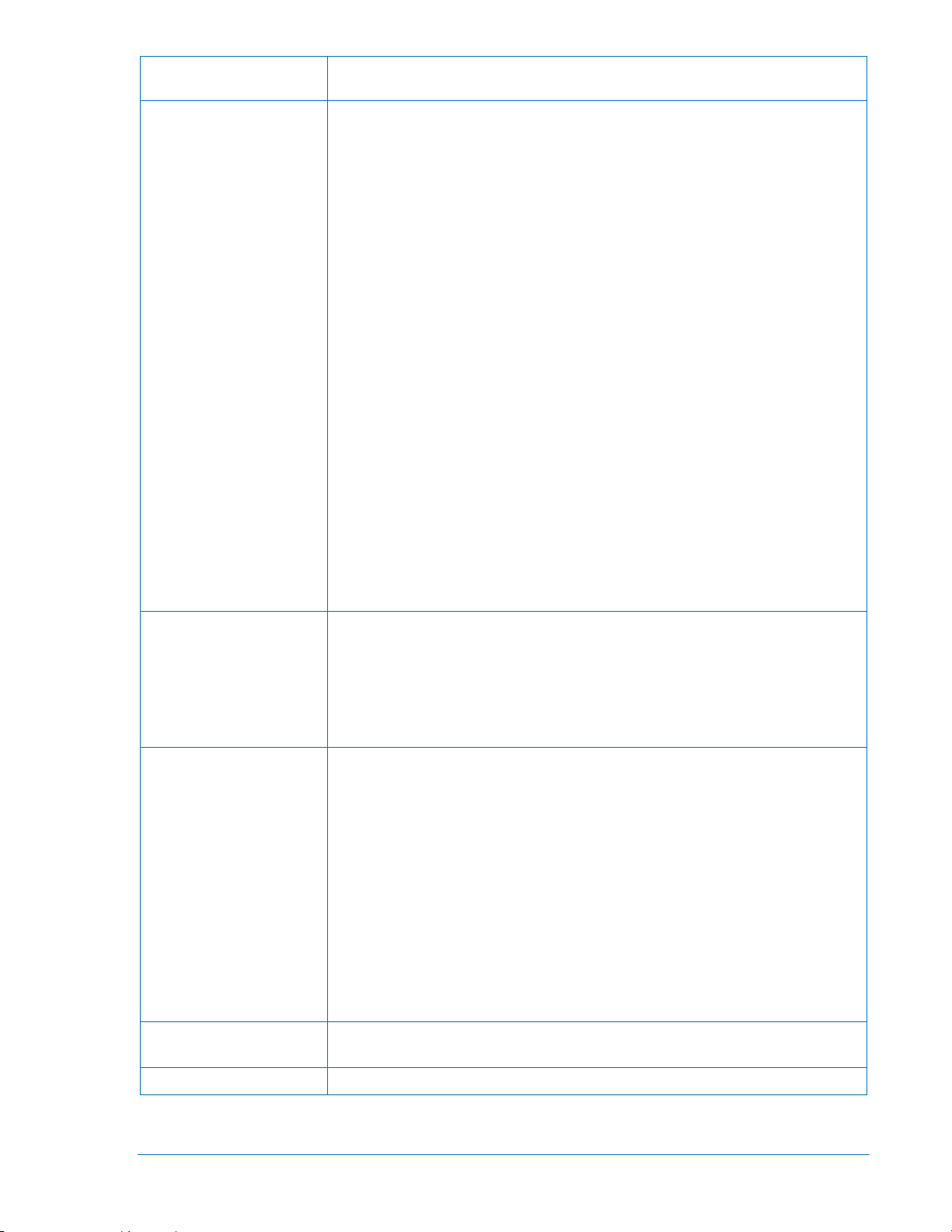

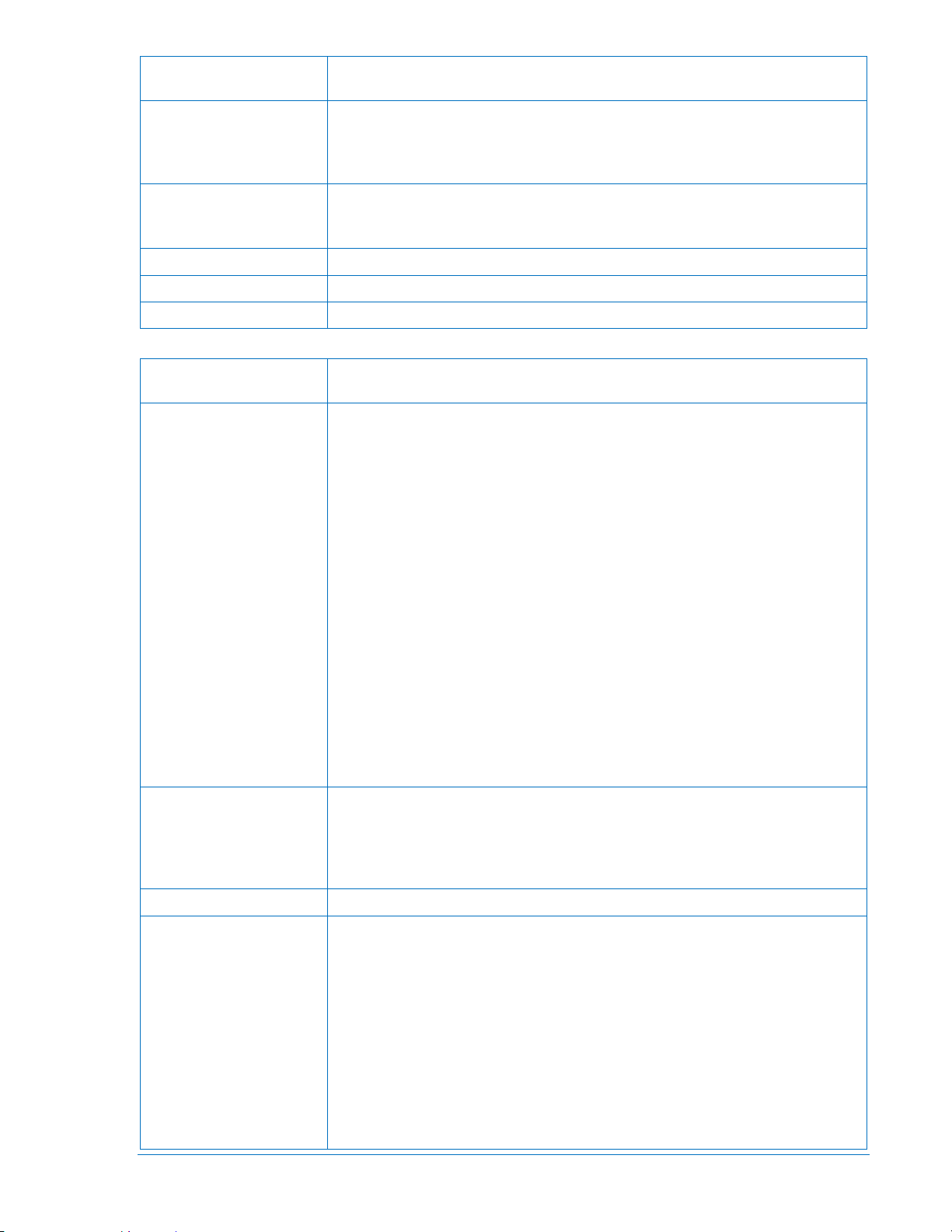

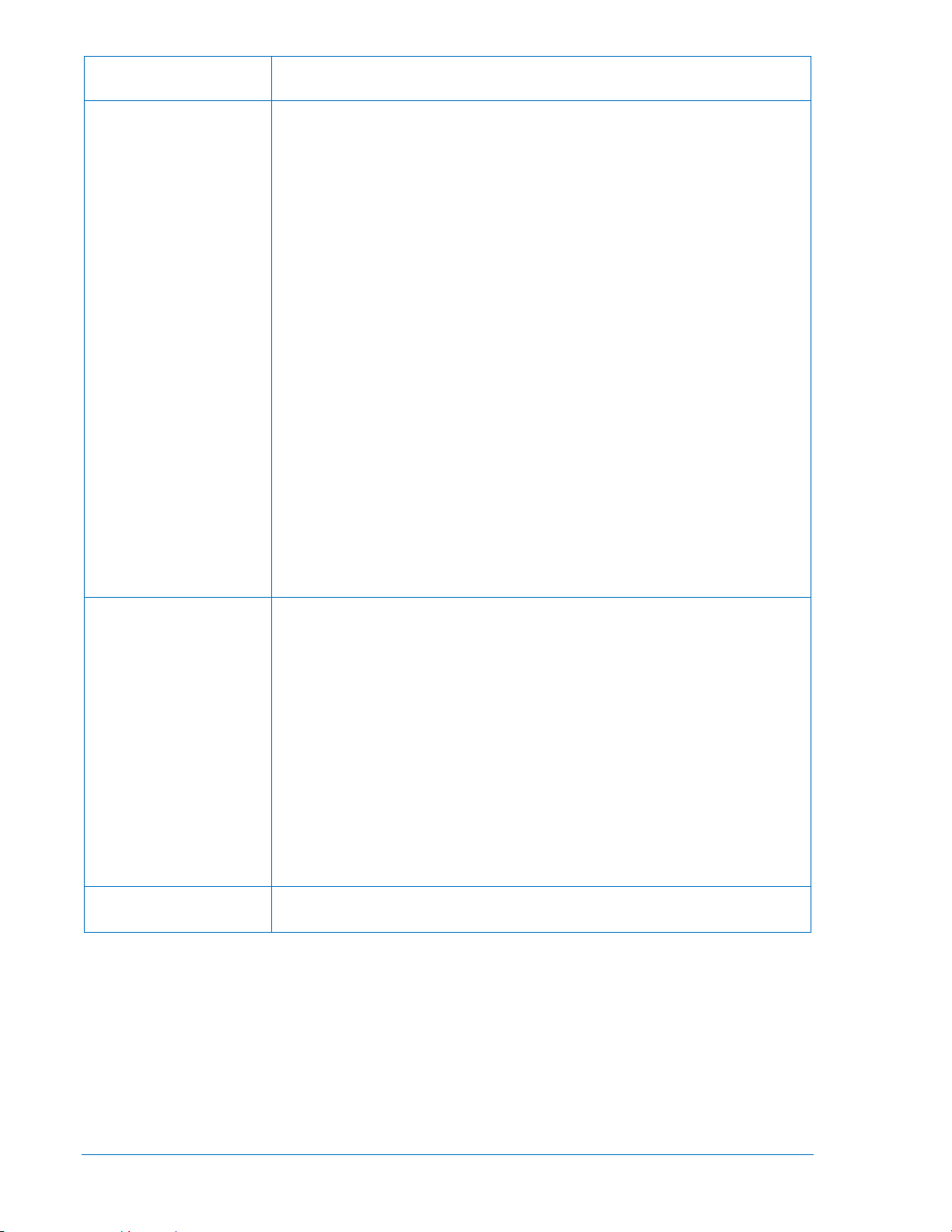

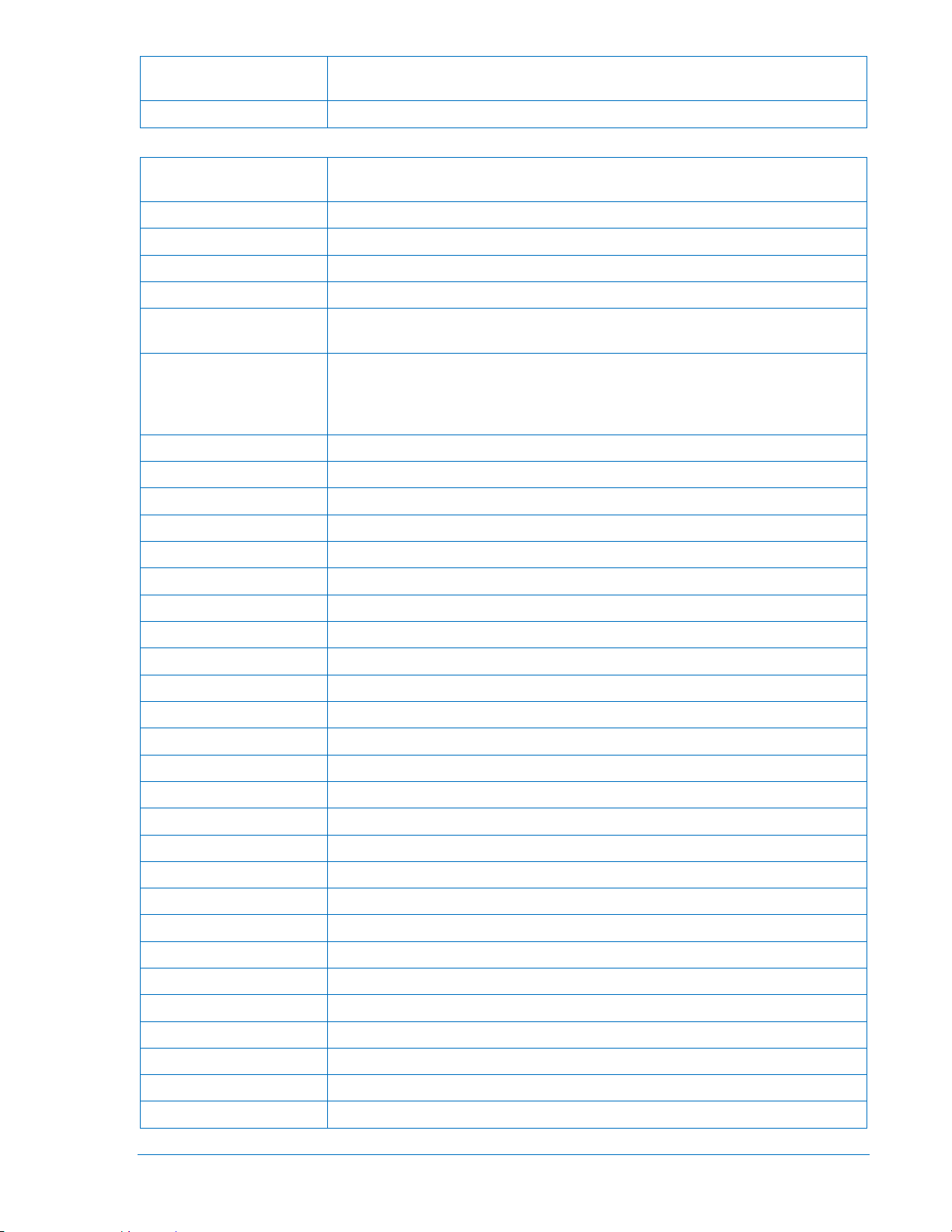

REVISION HISTORY

Manual

Revision and Date

X, 10/14

• Revised to support firmware package version 1.19.00 (see firmware

• Minor text edits throughout manual.

W, 04/14

• Added German and Portuguese language support.

• Increased unique recorded events to 50 from 30.

V, 03/14

• Added features of DGC-2020 hardware version 3.

• This revision was released in English language only.

U, 03/13

• Revised to support firmware package version 1.17.02 (see firmware

• Minor text edits

T, 01/13

• Revised to support firmware package version 1.17.00 (see firmware

package version history).

S, 05/12

• Revised to support firmware package version 1.15.00 (see firmware

• Added Appendix E • EXHAUST TREATMENT.

R, 10/11

• Added Disclaimer of Liability and Warranty in Introduction.

Q

• This revision letter not used.

The following inform ation provides a h istorical summary of th e changes made to this instruction manual

(9400200990), BESTCOMSPlus® software, firmware package, and hardwar e of the DGC-2020.

Change

package version history) and BESTCOMSPlus version 3.07.00 (see

BESTCOMSPlus revision history).

• Added Diagnostics under Metering Explorer in Section 4.

• Added Offline Logic Simulator in Section 5.

• Improvements to Appendix C, Tuning PID Settings.

• Replaced several BESTCOMSPlus screenshots where the layout

changed throughout manual.

• Added DGC-2000 legacy Modbus option and register table.

• Added Breaker configuration one-line diagram (front panel only) and

mains fail transfer status screen.

• Added Windows 8 compatibility and updated system recommendations

for BESTCOMSPlus and .NET framework.

• Expansion modules (AEM-2020, CEM-2020, and LSM-2020) now

have gold-plated communication terminals for increased signal

integrity.

• Removed product registration information.

• Added EMC wiring requirements for the LSM-2020 BATT and GOV

terminals.

• Minor text edits.

package version history).

• Added new breaker hardware and mains fail transfer settings

package version history).

• Enhanced description of DTCs (diagnostic trouble codes).

• Added Tables 3-5 DTCs Displayed by the DGC-2020 (FMI Strings)

and 3-6 DTCs Displayed by the DGC-2020.

• Removed Setup from Section 6 • Installation, and created separate

Section 7 • Setup.

9400200990 Rev X DGC-2020 Introduction iii

Page 6

Manual

Revision and Date

Change

P, 08/11

• Revised to support firmware package version 1.13.04 (see firmware

• Improved Figure 8-9, Typical LSM-2020 Interconnection Diagram.

O

• This revision letter not used.

N, 04/10

• Revised to support firmware package version 1.10.00 (see firmware

• Added Table 4-2, Generator Parameter Transmit.

M, 11/09

• Section 1: Under Specifications, Metering, Power Factor, changed

45754.

package version history) and BESTCOMSPlus version 2.10.02 (see

BESTCOMSPlus version history).

• Added LCD Heater specifications in Section 1.

• Added Analog Input Burden data in Section 10.

• Updated Activation of DGC-2020 Plugin for BESTCOMSPlus and

Communication in Secti on 4.

package version history) and BESTCOMSPlus version 2.07.01 (see

BESTCOMSPlus version history).

• Changed Battery Backup for Real-Time Clock to a standard feature.

• Added Table 3-3, J1939 Data Transmitted from the DGC-2020.

calculation method from “PF = P (3-phase average) / S (3-phase

average)” to “PF = Cosine of the Angle between Phase AB voltage

(Vab) and Phase A current (Ia)”.

• Added “Diagnostics” to Figure 2-2, Metering Screen Branches.

• Section 3: Updated MTU Fault Code list.

• Added description for Logic Control Relays in Table 5-1.

• Updated cutout dimensions in Figure 6-1, Panel Cutting and Drilling

Dimensions.

• Section 6: Added Setting Up DGC-2020 Programmable Inputs and

Outputs, Synchronizer, and Setting up a DGC-2020 and LSM-2020 for

a Load Sharing and kW Control Application.

• Section 10: Added Maximum Consumption under Specifications,

Operating Power.

• Appendix B: Improved description for registers 40020, 43750, and

iv DGC-2020 Introduction 9400200990 Rev X

Page 7

Manual

Revision and Date

Change

L, 05/09

• Added information for CEM-2020H in Sec t ion 9.

B, Modbus Communication.

K, 01/09

• Updated manual to support firmware package 1.08.01 changes and

40476.

J, 08/08

• Added Section 10, AEM-2020 (Anal og Ex pans ion Mo d ule) .

• Added Appendix C, Tu ni ng PID Sett in gs .

I, 07/08

• Changed Output Contacts 13 through 24 rating from 2 Adc to 1 Adc.

Changed Output Contacts 25 through 36 rating from 10 Adc to 4 Adc.

H, 02/08

• Added Section 9, CEM-2020 (Contact Expansion Module).

• Added CSA Certification in Sections 1 (DGC-2020), 8 (LSM-2020), 9

(CEM-2020), and 10 (AEM-2020).

• Added DGC-2020 Setup in Section 6, Installation.

• Added description of special strings displayed (NC, SF, NS, NA, UF)

under DGC-2020 Function Blocks, Communication Ports, CANbus in

Section 3.

• Improved procedure for upgrading firmware in Section 4.

• Expanded explanation of configurable elements in Section 4.

• Added “P” (programmable) curves for overcurrent protection in Section

4.

• Added Figure 4-51, Sy nchronizer Screen, and re-numbered remaining

figures.

• Clarified low-line scale factor on Bus Condition Detection and Pre-

Alarms in Section 4.

• Added “1/2 watt” for resistor in #1 in NOTE box for CANbus in Sections

1, 6, 8, 9, and 10.

• In Figure 8-7, corrected LSM-2020 terminal numbering for AVR & GOV

inputs.

• Added Figure 8-9, additional method for interfacing an external control

device with a DGC-2020 - LSM-2020 system.

• Added “P” curve to Tables A-1 and A-2 in Appendix A, Time

Overcurrent Curves.

• Corrected bit numbering for registers 44812 through 45572 and added

missing bits in Appendix B, Modbus Communication.

• Added registers 44936 through 44946, 44982, and 44984 in Appendix

BESTCOMSPlus version 2.03.00 changes. (See firmware package

and BESTCOMSPlus revision history below for details.)

• Removed duplicate Speed Controller Tuning Procedure from Appendix

C.

• In Appendix B, added additional information for registers 40436 -

• Added information for Automatic Generator Detection in Section 4.

• Improved CAN bus diagrams and notes throughout manual.

• Added information for Integrating Reset func t ion in Sec tion 4.

• Added information for Configurab le Protec t ion in Section 4.

• Improved definition of Emergency Stop Input in Section 6.

• Added installation diagrams for MTU MDEC ECU in Section 6.

• Added Typical LSM-2020 Interconnection Diagram in Section 8.

• Enhanced Section 7, Maintenance and Troubleshooting.

• Added Synchronizer Operation under Breaker Management in Sect ion

3.

• Improved Communication in Section 4.

• Added Bits 6 through 10 to register 44822 in Appendix B.

•

9400200990 Rev X DGC-2020 Introduction v

Page 8

Manual

Revision and Date

Change

G, 11/07

• Added Section 8, LSM-2020 (Load Share Module).

Added BESTCOM SPlus Multigen Management screens.

F, 08/07

• Updated manual to support firmware package 1.02.00 changes and

and BESTCOMSPlus revision history below for details.)

E, 05/07

• Added description of Clock Setup screen in BESTCO M SPlus.

• Increased Low Coolant Temp Pre-Alarm range to 30 - 150°F.

D, 03/07

• Removed International Modem option from Style Chart in Section 1.

• Added coverage of part numbers 9400200105 and 9400200106.

C, 02/07

• Added Event Recording in Section 3, Function al Desc r ipt ion.

• Minor text edits throug hout manual.

B, 11/06

• Initial release

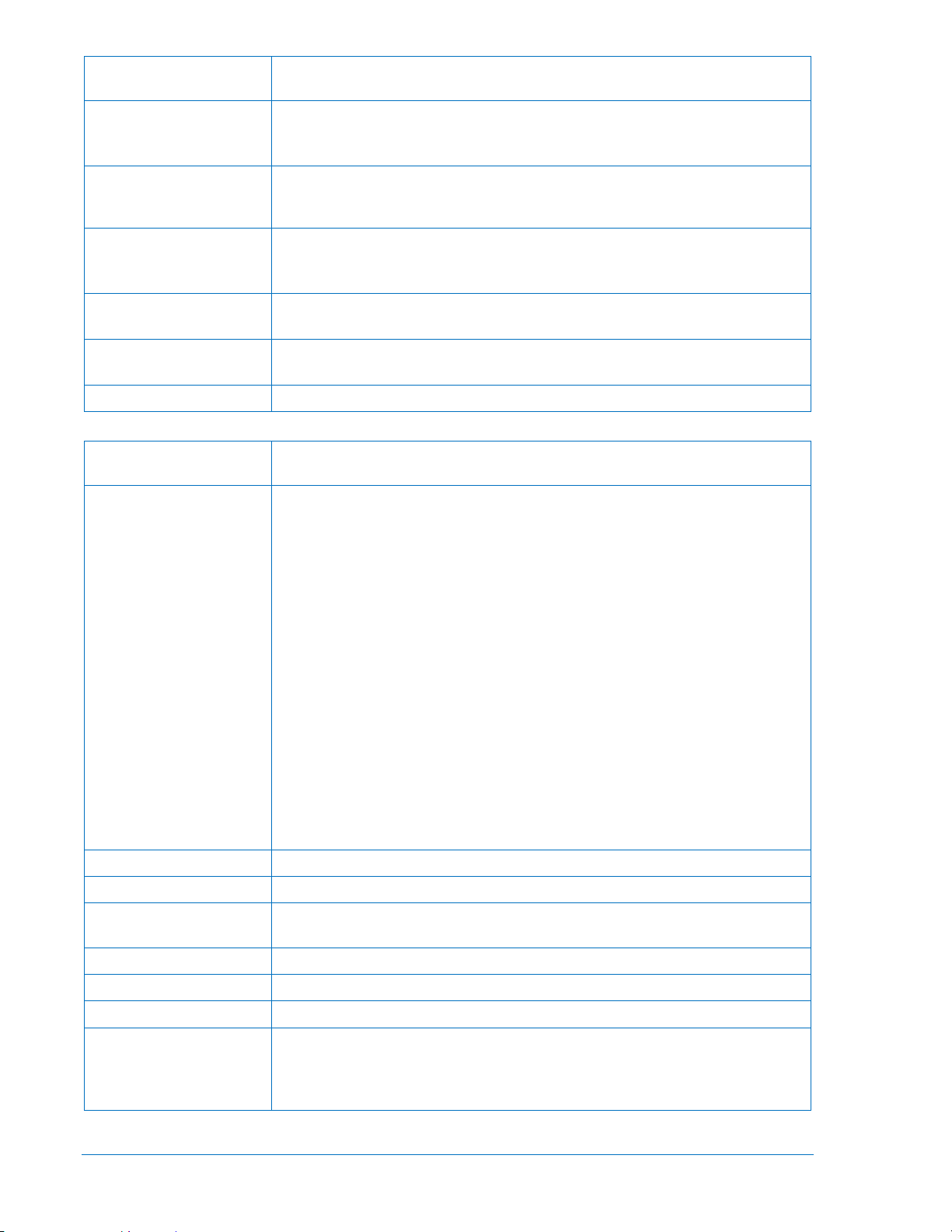

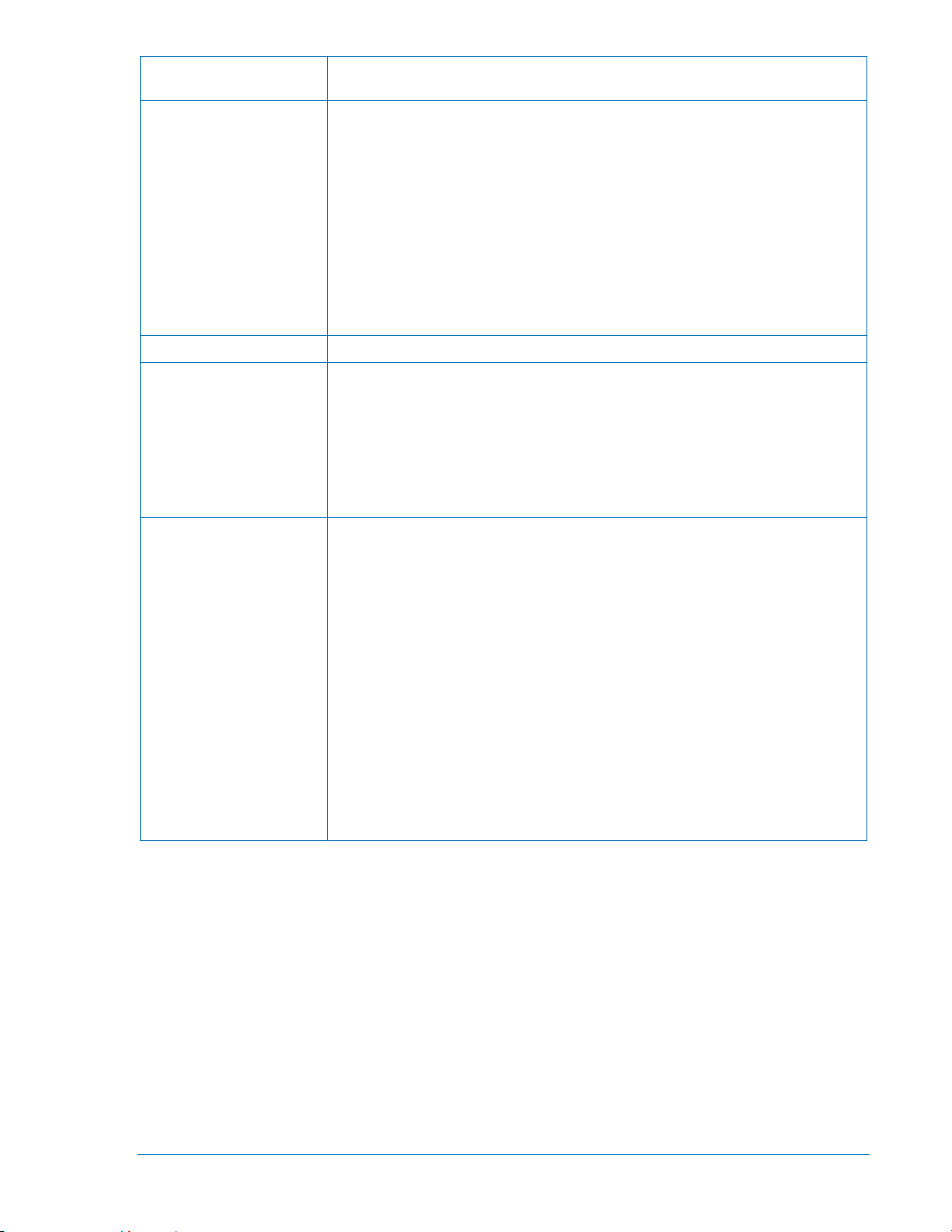

BESTCOMSPlus®

Version and Date

3.07.00, 10/14

• Updated to support firmware package 1.19.00 (see firmware package

• Changed to make BESTlogicPlus status LEDs report all logic errors.

3.06.00, 04/14

• Maintenance release (BE1-11 changes)

3.05.03, 03/14

• Maintenance release (DECS-250N changes)

3.05.02, 01/14

• Updated to support firmware package 1.18.00 (see firmware package

version history).

3.04.01. 10/13

• Maintenance release (BE1-11 changes)

3.04.00, 08/13

• Maintenance release (BE1-11 changes)

3.03.03, 06/13

• Maintenance release (BE1-11 changes)

3.03.00, 03/13

• Updated to support firmware package 1.17.02 (see firmware package

• Added new mains fail transfer screen.

• Updated HMI screens layout in Section 2.

•

BESTCOMSPlus version 1.03.00 changes. (See firmware package

• Updated several BESTCOMSPlus screen shots.

Change

version history).

• Added Load Share and Control Diagnostics screens.

• Changed to allow the Metering Status screen to open before a

connection is made.

• Removed duplicate results in the device discovery list.

• Improvements to device directory on Connection screen.

• Changed how the LSM-2020 model number is reported on the Device

Info screen.

• Changed to allow a comma in the Device ID.

• Changed to annunciate a connection failure message when a device is

not present on a selected port.

• Improved prompts to save settings when choosing to close all open

views.

• Changed to hide security settings for the LSM-2020 when opening a

settings file.

• Changed to allow the middle mouse button to close the security view.

• Improved display of raw analog input currents.

version history).

• Added breaker hardware settings.

vi DGC-2020 Introduction 9400200990 Rev X

Page 9

BESTCOMSPlus®

Version and Date

Change

3.02.00, 01/13

• Updated to support firmware package 1.17.00 (see firmware package

• Increased number of logic gates per level from 10 to 20.

3.01.01, 11/12

• Maintenance release (DECS-250 changes)

3.00.02, 09/12

• Maintenance release (BE1-11 changes)

2.14.00, 07/12

• Maintenance release (BE1-11 changes)

2.13.01, 05/12

• Updated to support firmware package 1.15.00 (see firmware package

version history).

2.13.00, 04/12

• Changes invisible to the user.

2.11.02, 12/11

• Added a Cancel button on the Rated Data dialog.

• Improved workspace files.

2.11.01, 11/11

• Changed Manual Regeneration setting to use a button instead of a

• Enhanced settings file printout.

2.10.02, 06/11

• Updated to support firmware package version 1.13.04 (see firmware

• Enhanced BESTlogic™Plus.

2.08.01, 10/10

• Improved off-page logic.

2.08.00, 08/10

• Updated to support firmware package version 1.11.00 (see firmware

package version history).

2.07.03, 06/10

• Changes invisible to the user.

2.07.01, 03/10

• Updated to support firmware package version 1.10.00 (see firmware

compatibility.

2.06.02, 01/10

• Changes invisible to the user.

2.06.01, 12/09

• Added Total Engine Run Time Minutes on Engine and Summary

• Added Windows 7 32-bit compatibility.

version history).

• Added Windows® 8 compatibility.

• Added the ability to disable settings download after reconnect or initial

connect on the Advanced Properties dialog in the DGC-2020

Connection screen.

drop-down menu on the ECU Setup screen.

package version history).

• Settings for generator protection, battery voltage protection, and

configurable protection can now be entered in secondary or per unit

values.

• Added the ability to set IP Address of LSM-2020 through device

discovery.

• Added the ability to select what data to view/export from the Preview

Metering and Export Metering buttons.

• Added the ability to save workspace.

• Added the ability to auto reconnect when connection is lost.

• Added the ability to close multiple views.

package version history).

• Added Export Metering.

• Added Windows® 7 64-bit compatib il ity and rem ov ed Window s 200 0

9400200990 Rev X DGC-2020 Introduction vii

screens in the Metering Explorer.

• BESTCOMSPlus shell enhancements.

Page 10

BESTCOMSPlus®

Version and Date

2.05.00, 07/09

• Made a correction to announce a message that logic will not be saved

logic control relay outputs in the logic diagram.

2.04.01, 05/09

• Changes invisible to the user.

2.03.01, 02/09

• Added “P” (programmable) curve selection for the 51 function.

Metering Explorer.

2.03.00, 12/08

• Added support for CEM-2020H.

screen.

2.02.01, 10/08

• Maintenance release (BE1-11 changes)

2.01.00, 05/08

• Added settings for AEM-2020.

• Added settings for Configurable Protection.

2.00.01, 03/08

• Added settings for CEM-2020.

1.04.01, 11/07

• Added settings for LSM-2020.

Change

if the maximum number of logic gates on any one level has been

exceeded.

• On the Breaker Management, Breaker Hardware screen, changed the

Gen and Mains Breaker Closing Time from 0.1-600 in increments of

0.1 to 0-800 in increments of 5.

• Corrected Settings Compare error when there are remote outputs or

• Improvement to allow spaces in Initializing Message 1 & 2 on General

Settings, Front Panel HMI screen in the Settings Explorer.

• Improved backwards compatibility.

• Improved Commission Date setting on Run Stat is tics screen in the

• Added Export to File feature.

• Added settings for Phase Toggle and Initializing Messages on General

Settings, Front Panel HMI screen.

• Re-arranged CANbus Setup screen and added ECU Setup screen

under Communications.

• Added settings for 51-3 element under Generator Protection, Current.

• Added setting for Off Mode Cooldown on System Parameters, System

Settings screen.

• Added Remote Module Setup screen under System Parameters.

• Added Remote LSM Inputs settings and metering screens under

Programmable Inputs.

• Added settings to Bias Control screens for Var/PF control.

• Added kvar A, B, C, and Total to Power and Summary metering

screens.

• Re-arranged MTU metering screens.

• Added MTU Status scr een and MTU Engine Status screen.

• Added BESTlogicPlus Input Objects for Configurable Elements,

Configurable Protection, Front Panel Buttons, PF Mode Active, Pre

Start Input, and Run Input.

• Added BESTlogicPlus Pre-Alarms for Checksum Fail and CEM

Hardware Mismatch.

• Added BESTlogicPlus Elements for 51-3, COOLSTOPREQ,

COOLDOWNREQ, EXTSTARTDEL, PRESTARTOUT, RUNOUTPUT,

STARTDELBYP, and STARTOUTPUT.

• Added Relay Control settings on System Param eter s, Sys tem Sett ings

• Added settings for Automatic Generator Protection.

• Added settings for Integrating Reset on 51 function.

viii DGC-2020 Introduction 9400200990 Rev X

Page 11

BESTCOMSPlus®

Version and Date

Change

1.03.00, 08/07

• Added/Updated screens to support firmware package version 1.03.00.

• Made all status LEDs available as inputs for PLC logic.

1.02.00, 05/07

• Added Spanish language support.

• Changed layout of several screens.

1.01.02, 04/07

• Removed International Modem option from Style Chart.

1.01.01, 02/07

• Added Chinese language support.

1.00.07, 11/06

• Initial release

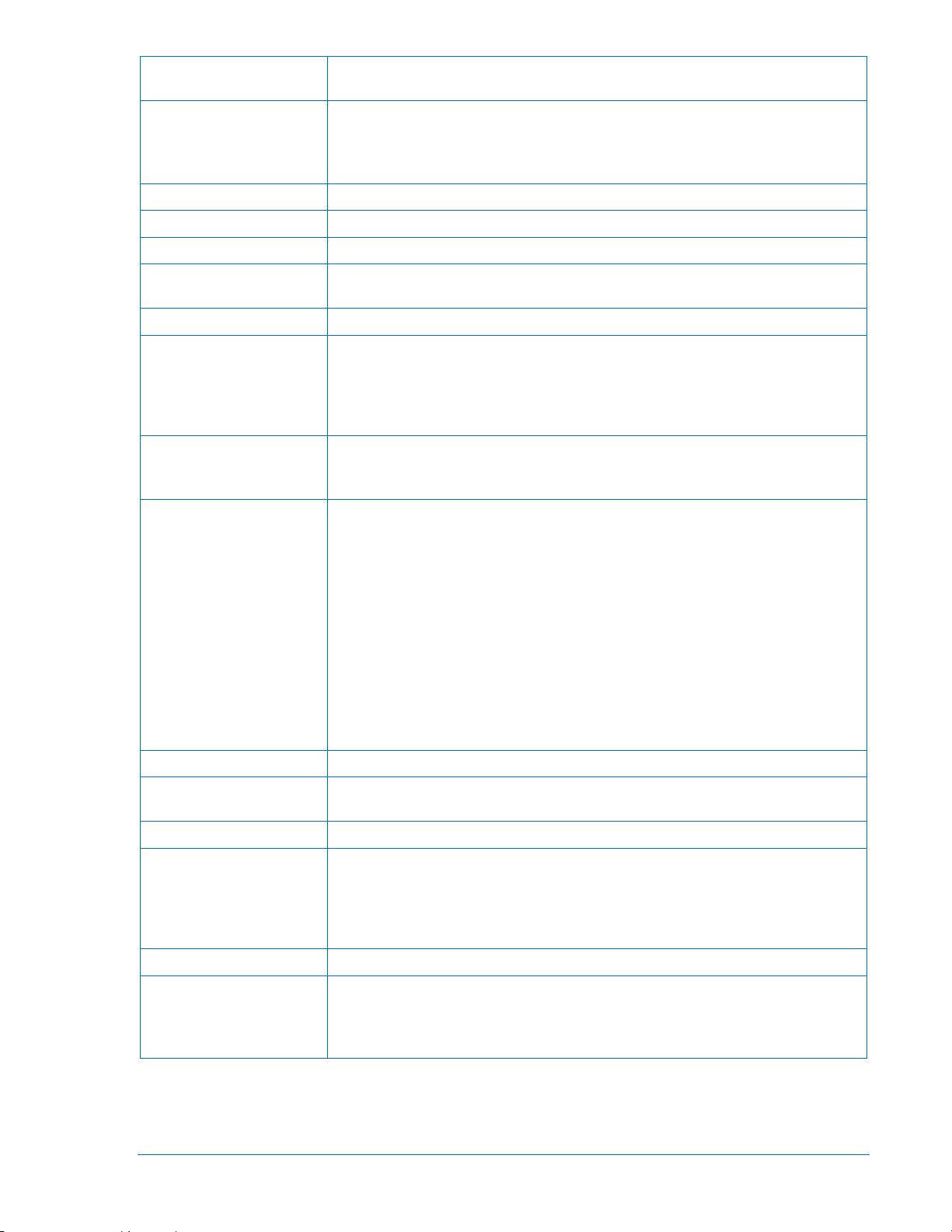

Firmware Package

Version and Date

1.19.00, 10/14

• Modified Voltage Trim function to support paralleling of reconfigurable

• Added ECU9 Fault Code list for MTU.

1.18.02, 04/14

• Added German and Portuguese language support.

• Increased unique recorded events to 50 from 30.

1.17.07, 05/13

• Minor firmware improvements

1.17.02, 03/13

• Added new breaker hardware and mains fail transfer settings.

units.

(See firmware package version history for details.)

• Added password protection for portions of the programmable logic.

• Added Clock Setup screen.

Change

machines.

• Added MTU Speed Demand Switch setting from logic capability.

• Added a rest timer for cyclic cranking.

• Added Mains Fail Return Fail pre-alarm and Mains Fail Max Return

Time setting.

• Added a deadband setting for speed trim and voltage trim.

• Added Parallel to Mains Gain Factor for mains parallel operation.

• Added System kW Generation in percent to Gen Status screen and

configurable protection.

• Added System Total Capacity on Generator Network Status screen.

• Added DPF Outlet Gas Temperature to J1939 metering and

configurable protection.

• Added John Deere to list of ECU configurations.

• Added AEM thermal protection settings to Modbus.

• Changed DEF EMPTY pre-alarm to DEF LOW SEVERE.

• Changed DEF ENGINE DERATE pre-alarm to DEF INDUCEMENT.

• Added descriptive text for Diagnostic Trouble Codes (DTC’s)

broadcast by Mercedes, PSI, and MTU-ECU9 engine ECU’s.

• Added DGC-2000 legacy Modbus option.

• Added Breaker configuration one-line diagram and mains fail transfer

9400200990 Rev X DGC-2020 Introduction ix

status screen to front panel.

• Improved breaker hardware, synch check, and mains fail logic.

• Added a logic element which allows the EPS Supplying Load front

panel LED to be driven via logic.

• Improved event log processing rate.

• Improved CAN transmit processing rate.

• Added single-phase AC bus sensing configuration option.

• Corrected battle override function preventing engine shut-off in rare

cases.

• Corrected DTCs not clearing when receiving a “no active” DTC frame.

• Corrected frequency settings reverting to 60 Hz on startup for 400 Hz

Page 12

Firmware Package

Version and Date

Change

1.17.00, 01/13

• Added French language support.

scenarios.

1.15.00, 06/12

• Added Russian language support.

RDP-110.

1.13.08, 11/11

• Made Diesel Particulate Filter Regeneration Request momentary.

• Minor firmware improvements.

• Increased the number of gates per logic level to 20.

• Allow Grounded Delta Override to be effective regardless of configured

generator connection.

• Increased the number of logic latches to 10.

• Added phase rotation checks and pre-alarms.

• Remote speed trim bias adjustable from analog input.

• Added speed bias range in units of percent.

• Added sequencing status display.

• Added Ethernet kW and kvar sharing.

• Phase Imbalance (47) disables in singl e-phase mode.

• Improved response during Modbus writes.

• Increased available configurable protection parameters.

• Added system status display.

• Modified breaker reset function so that breakers are only reset if

locked out, sync failed, or failed to open.

• Added a setting to breaker fail pre-alarm to be active on transitions

only or always.

• Modified sequencing to operate correctly when units are operating due

to external ATS.

• Corrected handling of Combined Code Red Al arm on EC U7/ ECU 8

engines.

• Modified speed raise/lower so no change occurs if both conditions are

true.

• Corrected potential settings loss in weak battery and emergency stop

• Added Auto Breaker Operation Inhibit, Mains Fail Transfer Inhibit, and

Closed Transition Override logic elements.

• Added Restart Delay setting.

• Added SPN Conversion Method

• Increased Max on Weak Battery and Low Battery Pre-alarms. 14 V for

12 V systems and 28 V for 24 V systems.

• Added DPF Soot Level Pre-Alarms

• Added DEF Fluid Level and Inducement Pre-Alarms

• Added Unexpected Shutdown Alarm

• Added function which disables the front panel buttons Run, Off, and

Auto when logic elements Run Mode, Off Mode, and Auto Mode are

set true.

• Added 4 logic elements which override control of 4 LEDs on the

x DGC-2020 Introduction 9400200990 Rev X

Page 13

Firmware Package

Version and Date

Change

1.13.04, 07/11

• Enhanced configurable protection.

• Improved detection of Intergenset Communications failures.

1.11.02, 11/10

• Improved time dials for fixed time curves of the 51 function.

1.11.00, 08/10

• Changed synchronizer slip frequency to have minimum slip rate of

State.

1.10.00, 03/10

• Added Loss of Mains Protection (78 Vector Shift and 81 ROCOF).

Detection, and Relay Control for organizational purposes.

• Enhanced synchronizer.

• Enhanced J1939.

• Added Q parameter to 51 programmable curve equation.

• Added Sequenced System Startup logic element.

• Added Low Fuel logic element.

• Added Last Unit Shutdown enable/disable setting for generator

sequencing.

• Added the ability to set IP Address of LSM-2020 through the front

panel.

• Added governor load sharing over J1939.

0.01 in increments of 0.01.

• Added pre-alarms logic for Mains Fail Transfer Fail, Gen Breaker Sync

Fail, Gen Breaker Fail to Close, Gen Breaker Fail to Open, Mains

Breaker Sync Fail, Mains Breaker Fail to Close, and Mains Breaker

Fail to Open.

• Added status logic for Mains Fail Transfer Complete and Unloading

• Added Dead Bus Breaker Close Arbitrati on.

• Added GM and Cummins as settings for ECU type.

• Added CAN settings for MTU 50/60 Hz Switch, NMT Alive Transmit

Rate, Generator Parameter Transmit, and Diesel Particulate Filter.

• Added Modem Setup through the Front Panel HMI.

• Added settings for Clock Not Set Warning, Gen CT Low Line Scale

Factor, Horn Enable, Not in Auto Horn Enable, Low Line Scale Factor

for 47 function, Alternate Frequency Scale Factors, Alternate

Frequency, Metric Pressure Units, and Dead Gen Close Enable.

• Added logic for Idle Request, Alternate Frequency Override, Mains Fail

Test, Load Take Over, Alarm Silence, Lamp Test, Generator

Protection, DPF Regeneration Disabled, DPF Regeneration Required,

and High Exhaust Temperature.

• Added ranges for hours and minutes of Logic Timers.

• Moved Engine Cooldown, Horn, Sin gl e-Phase Override, Auto Config

9400200990 Rev X DGC-2020 Introduction xi

Page 14

Firmware Package

Version and Date

Change

1.09.00, 07/09

• Corrected transmittal of parameters to engine for MDEC module types

a dead generator was not possible.

1.08.01, 01/09

• Added support for CEM-2020H.

• Added “P” (programmable) curve selection for the 51 function.

1.07.02, 09/08

• Finalized settings for AEM-2020.

1.06.00, 07/08

• Added settings for AEM-2020.

Added settings for Configurable Protection.

1.05.00, 04/08

• Added settings for CEM-2020.

1.04.00, 12/07

• Added settings for LSM-2020.

1.03.00, 08/07

• Added 32 and 40Q protection functions.

• Changed the Low-Coolant Temp Pre-Alarm range to 32-150 F.

1.02.00, 05/07

• Added Spanish language support.

1.00.08, 03/07

• Minor firmware improvements.

1.00.07, 01/07

• Added Chinese language support.

201, 302, and 303.

• Implemented most recent MTU fault codes.

• Engine Total Run Time in metering now displays hours and minutes.

Engine Total Run Time previously displayed hours only.

• Added front panel diagnostics to show Modbus Read Count, Modbus

Write Count, and Serial Flash Write Count.

• Modbus legacy registers 40019 and 40020 are now read/write.

Previously these registers were write only.

• Improved MCS5 parameter handling.

• Fixed spurious High Charge Air Temp Pre-Alarm every time engine

starts on MTU-ECU7 mach i nes .

• Accelerator pedal position is now sent to Volvo ECU for load sharing.

• Modified generator breaker logic to allow closure of generator breaker

from a dead gen to a dead bus (if Dead Bus Close Enable is selected).

In previous versions of firmware, closure of the generator breaker from

• Changed time dial range of 51 element fixed time curve from 0-30 s to

0-7,200 s.

• Added Phase Toggle Delay setting for front panel HMI.

• Added Off Mode Cooldown feature.

• Added 51-3 element.

• Added Var/PF control.

• Added LSM Input settings.

• Added Checksum Fail and CEM Hardwar e Mismatc h p r e-alarms.

• Added kvar A, B, C, and Total metering.

• Added several MTU items to metering.

• Re-arranged CANbus Setup screens and added ECU Setu p screens

on front panel HMI.

• Added settings for Automatic Generator Detection.

• Added settings for Integrating Reset on 51 function.

•

• Added Automatic Restart function and Exercise Timer.

xii DGC-2020 Introduction 9400200990 Rev X

• Added dual settings for 51, 27, and 59 functions.

• Added Oil Pressure Crank Disconnect Enabl e.

• Modified Prestart operation during rest cycle.

• Added 2 additional Engine kW Overload Pre-Alarms.

• Added Low Line Scale Factor for EPS Supplying Load and Engine kW

Overload Pre-Alarms.

• Changed the metering range of coolant temperature to 32-410 F.

Page 15

Firmware Package

Version and Date

Change

1.00.06, 11/06

• Initial release

DGC-2020 Hardware

Revision and Date

AK, 10/14

• Released firmware package 1.19.00 and BESTCOMSPlus 3.07.00.

AJ, 07/14

• Updated internal documentation.

AH, 04/14

• Released firmware package 1.18.02.

AG, 04/14

• Updated internal documentation.

AF, 11/13

• Improved membrane venting to prevent moisture accumulation in LCD

window.

AE, 11/13

• Released DGC-2020 rev 3 hardware: Three-phase bus sensing

• Expanded panel cutout dimensions for easier fit.

AD, 07/13

• Improved LCD heater cable routing.

AC, 06/13

• Upgraded injection mold tool.

AB, 05/13

• Released firmware package 1.17.07

AA, 03/13

• Released firmware package 1.17.02 and BESTCOMSPlus 3.03.00

Z, 01/13

• Released firmware package 1.17.00 and BESTCOMSPlus 3.02.00.

Y, 06/12

• Released firmware package 1.15.00 and BESTCOMSPlus 2.13.01.

X, 06/12

• Changed PCB to enhance product.

W, 09/11

• Released firmware package 1.13.04 and BESTCOMSPlus 2.10.02.

V, 02/11

• Released firmware package 1.11.02.

U, 04/10

• Released firmware package 1.10.00 and BESTCOMSPlus 2.07.01.

T, 01/10

• Improved panel gasket.

S, 10/09

• Improved transient protection.

R, 07/09

• Added ribbon cable slot for front overlay to prevent cable damage.

P, 01/09

• Released firmware package 1.08.01 and BESTCOMSPlus 2.03.00.

N, 09/08

• Released firmware package 1.07.02.

M, 07/08

• Released firmware package 1.06.00 and BESTCOMSPlus 2.01.00.

L, 04/08

• Released firmware package 1.05.00 and BESTCOMSPlus 2.00.01.

K, 01/08

• Added definition of emergency stop input terminals.

J, 12/07

• Released firmware package 1.04.00 and BESTCOMSPlus 1.04.01.

H, 12/07

• Switched LCD heater types for manufacturability.

G, 08/07

• Released firmware package 1.03.00 and BESTCOMSPlus 1.03.00.

F, 04/07

• Released BESTCOMSPlus 1.02.00.

E, 03/07

• Released firmware 1.00.08 and changed LCD heater.

D, 02/07

• LCD heater and battery holder made as a standard feature.

C, 01/07

• Deleted, added, or changed components to enhance product.

B, 11/06

• Initial release

Change

capability, RS-232 port, enhanced microprocessor for expanded

programmable logic, greatly increased mini-B USB transfer rate

9400200990 Rev X DGC-2020 Introduction xiii

Page 16

xiv DGC-2020 Introduction 9400200990 Rev X

Page 17

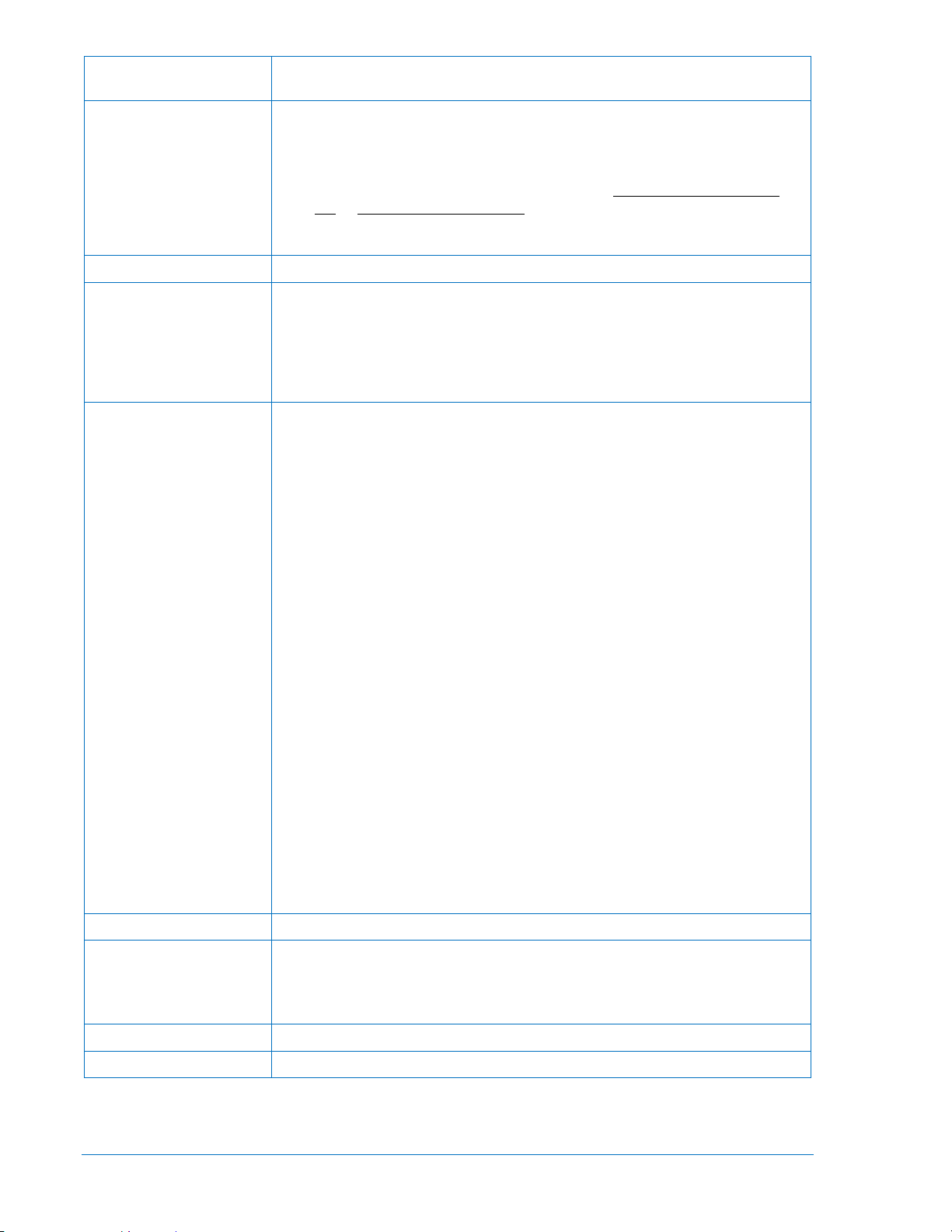

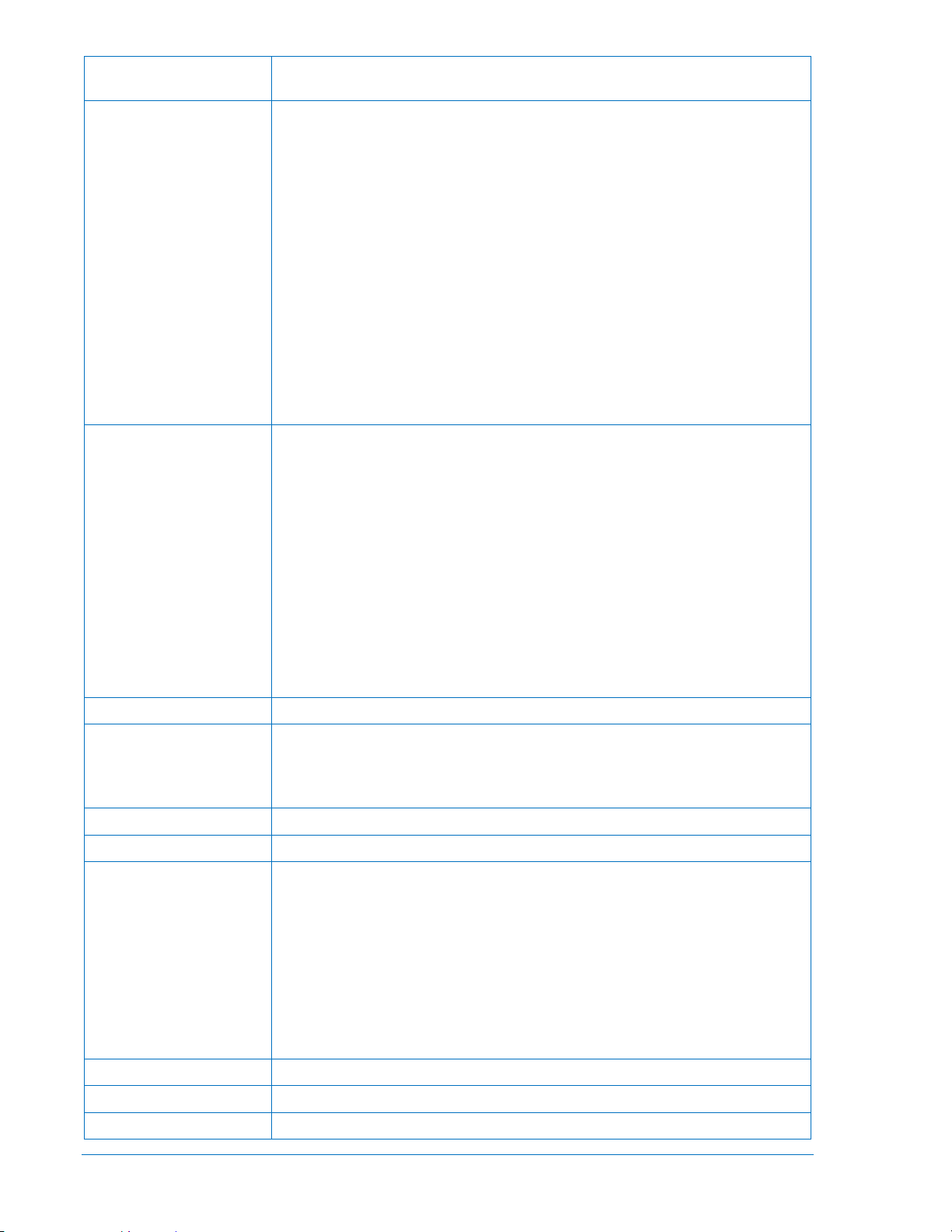

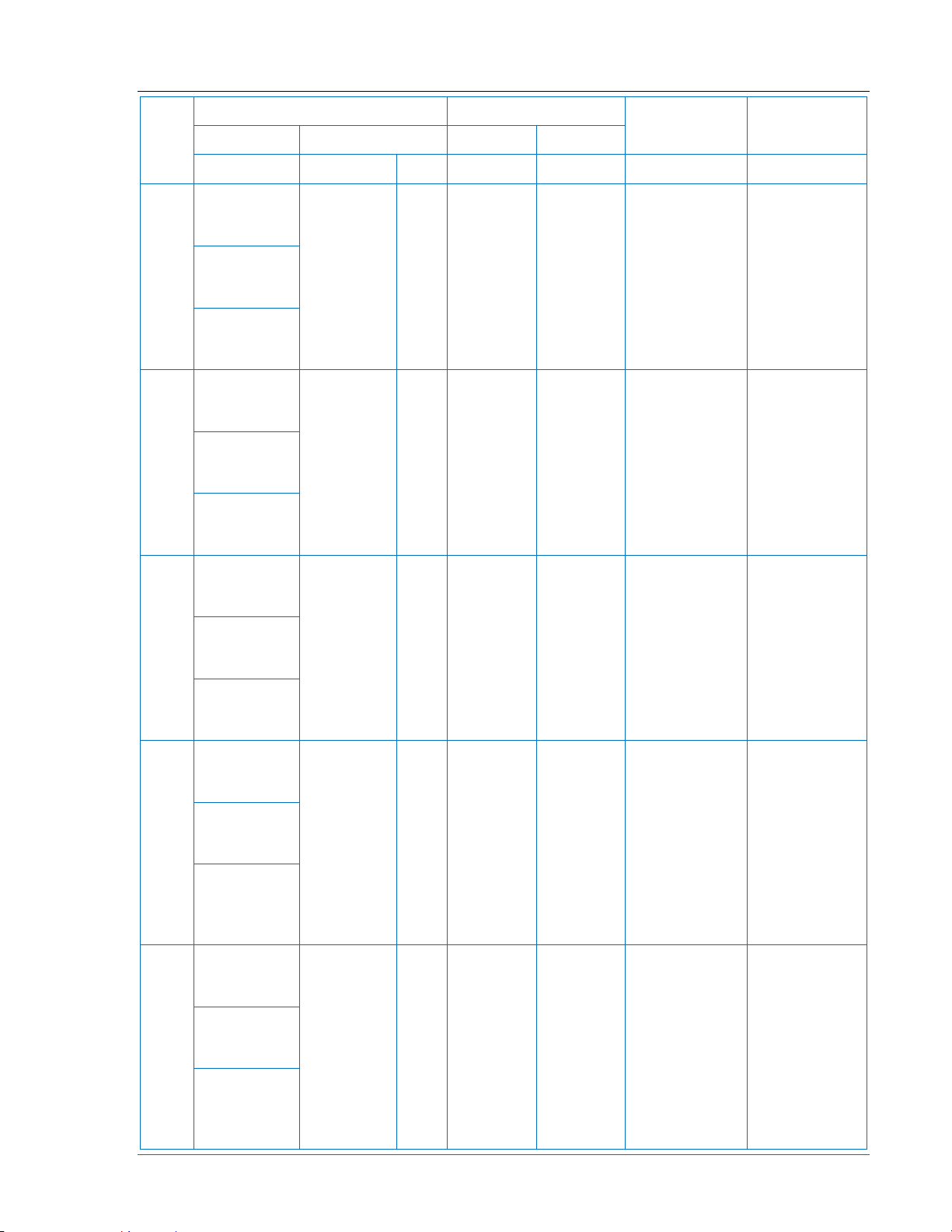

DETAILED FIRMWARE REL E AS E HISTORY

Pkg.

File

Ver.

1.19.00

1.18.02

1.17.07

1.17.02

1.17.00

Digital Genset Controller (DGC-2020) Load Share Module (LSM-2020)

Application Code Flash Language Module CANBus App. Ethernet App.

Version & P/N Version & P/N Lang.* Version & P/N Version & P/N Version & P/N Version & P/N

3.18.00

10/16/14

9400209013/-14

2.18.00

10/16/14

9400206035/-36

1.18.00

10/16/14

9400201087/-88

3.17.02

04/25/14

9400209011/-12

2.17.02

04/25/14

9400206033/-34

1.17.02

04/25/14

9400201085/-86

3.16.07

05/09/13

9400209009/-010

2.16.07

05/09/13

9400206029/-030

1.16.07

05/09/13

9400201082/-083

3.16.02

03/13/13

9400209005/-006

2.16.02

03/13/13

9400206022/-023

1.16.02

03/13/13

9400201076/-077

3.16.00

11/16/12

9400209002/-03

2.16.00

11/16/12

9400206015/-016

1.16.00

11/16/12

9400201070/-071

5.06.00

9/18/14

9400201089

5.05.01

02/04/14

9400201081

5.04.03

05/08/13

9400201084

5.04.01

02/20/13

9400201078

5.04.00

11/16/12

9400201072

C,E,F,

G,P,R,

S

C,E,F,

G,P,R,

S

C,E,F

R,S

C,E,F

R,S

C,E,F

R,S

1.04.00

08/20/14

9417501031

1.03.02

10/28/13

9417501029

1.03.01

03/15/13

9417501024

1.03.01

03/13/13

9417501024

1.03.00

11/07/12

9417501022

1.04.00

08/20/14

9417501032

1.03.02

10/28/13

9417501030

1.03.01

03/15/13

9417501025

1.03.01

03/13/13

9417501025

1.03.00

11/07/12

9417501023

Contact Expansion

Module

(CEM-2020/H)

1.01.04

02/14/13

9421001014

1.01.04

02/14/13

9421001014

1.01.04

02/14/13

9421001014

1.01.04

02/14/13

9421001014

1.01.03

03/29/12

9421001013

Analog Expansion

Module

(AEM-2020)

1.00.05

02/14/13

9421103002

1.00.05

02/14/13

9421103002

1.00.05

02/14/13

9421103002

1.00.05

02/14/13

9421103002

1.00.04

03/29/12

9421103001

9400200990 Rev X DGC-2020 Introduction xv

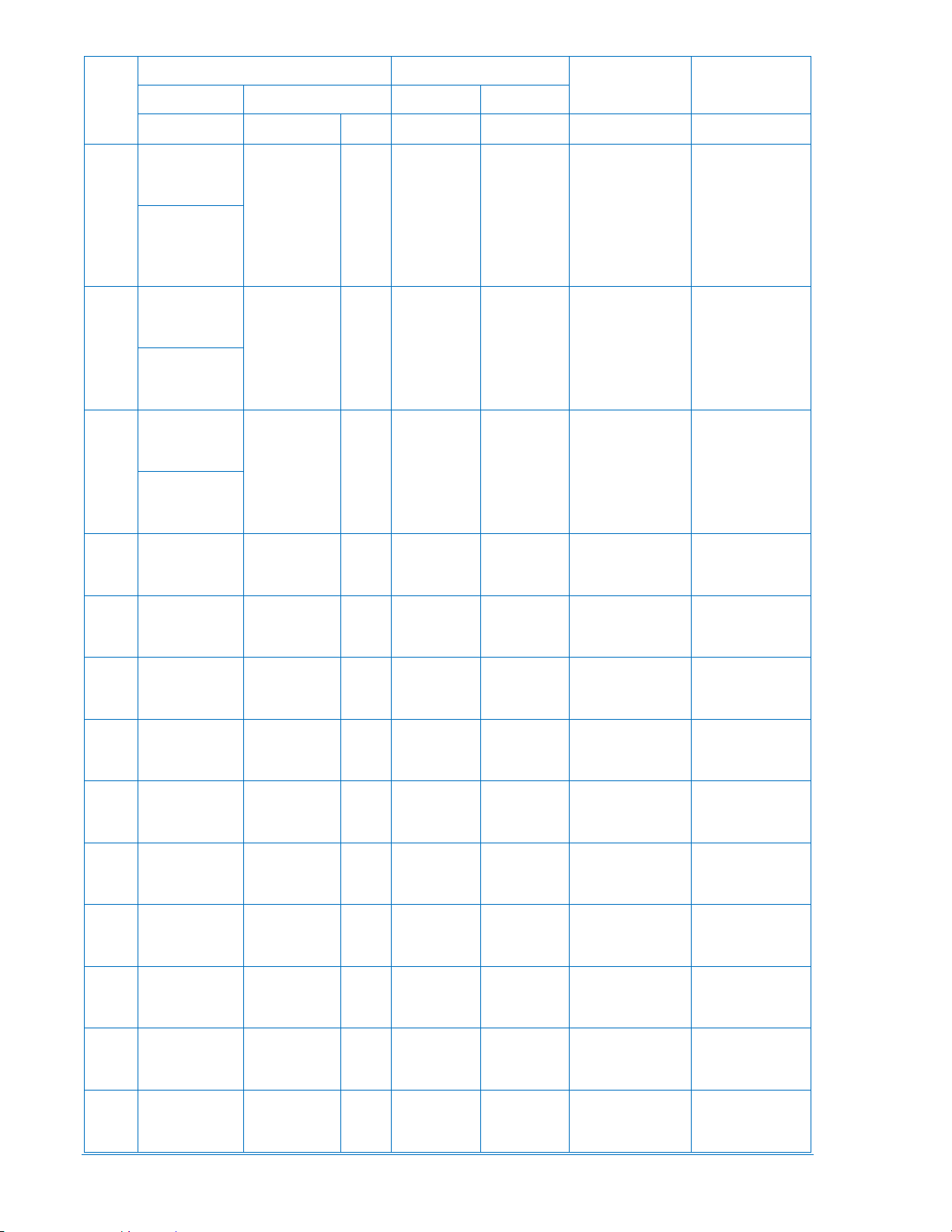

Page 18

Pkg.

File

Ver.

1.15.00

1.13.08

1.13.04

1.11.02

1.11.00

1.10.00

1.09.00

1.08.01

1.07.02

1.06.00

1.05.00

1.04.00

1.03.00

Digital Genset Controller (DGC-2020) Load Share Module (LSM-2020)

Application Code Flash Language Module CANBus App. Ethernet App.

Version & P/N Version & P/N Lang.* Version & P/N Version & P/N Version & P/N Version & P/N

2.14.00

08/13/12

9400206009/-010

1.14.00

08/13/12

9400201065/-066

2.12.08

11/10/11

9400206003/-004

1.12.08

11/10/11

9400201058/-059

2.12.04

07/01/11

9400206001/-002

1.12.04

07/01/11

9400201051/-054

1.10.00

07/09/10

9400201046/-052

1.10.00

07/09/10

9400201046/-047

1.09.00

03/05/10

9400201043/-044

1.08.00

06/24/09

9400201039/-040

1.07.01

01/14/09

9400201036/-035

1.06.01

07/5/08

9400201030

1.05.00

05/19/08

9400201028

1.04.00

01/15/08

9400201025

1.03.00

11/21/07

9400201022

1.02.00

08/14/07

9400201020

5.02.00

06/18/12

9400201064

4.06.05

11/04/11

9400201060

4.06.03

07/01/11

9400201055

4.04.01

11/24/10

9400201053

4.04.00

08/02/10

9400201048

4.03.00

03/05/10

9400201045

4.02.00

06/24/09

9400201041

4.00.01

01/14/09

9400201037

3.00.03

07/16/08

9400201031

3.00.00

05/19/08

9400201029

2.03.00

01/15/08

9400201026

2.01.00

11/15/07

9400201023

2.01.00

08/09/07

9400201021

C,E,

R,S

C,E,S

C,E,S

C,E,S

C,E,S

C,E,S

C,E,S

C,E,S

C,E,S

C,E,S

C,E,S

C,E,S

C,E,S N/A N/A N/A N/A

1.02.05

06/12/12

9417501020

1.02.03

07/21/11

9417501016

1.02.03

07/21/11

9417501016

1.01.00

02/04/10

9417501014

1.01.00

02/04/10

9417501014

1.01.00

02/04/10

9417501014

1.00.05

12/09/08

9417501012

1.00.05

12/09/08

9417501012

1.00.04

07/22/08

9417501010

1.00.03

05/19/08

9417501008

1.00.02

01/02/08

9417501006

1.00.00

11/21/07

9417501005

1.02.05

06/12/12

9417501021

1.02.03

07/21/11

9417501017

1.02.03

07/21/10

9417501017

1.01.00

02/04/10

9417501015

1.01.00

02/04/10

9417501015

1.01.00

02/04/10

9417501015

1.00.05

12/09/08

9417501013

1.00.05

12/09/08

9417501013

1.00.04

07/22/08

9417501011

1.00.03

05/19/08

9417501009

1.00.02

01/02/08

9417501007

1.00.00

11/21/07

9417501004

Contact Expansion

Module

(CEM-2020/H)

1.01.03

03/29/12

9421001013

1.01.02

06/06/11

9421001012

1.01.02

06/06/11

9421001012

1.01.00

12/09/08

9421001009

1.01.00

12/09/08

9421001009

1.01.00

12/09/08

9421001009

1.01.00

12/09/08

9421001009

1.01.00

12/09/08

9421001009

1.00.03

07/22/08

9421001007

1.00.01

05/19/08

9421001005

1.00.00

01/02/08

9421001004

N/A N/A

Analog Expansion

Module

(AEM-2020)

1.00.04

03/29/12

9421103001

1.00.03

06/06/11

9421101012

1.00.03

06/06/11

9421101012

1.00.01

12/09/08

9421101009

1.00.01

12/09/08

9421101009

1.00.01

12/09/08

9421101009

1.00.01

12/09/08

9421101009

1.00.01

12/09/08

9421101009

1.00.00

07/22/08

9421101007

N/A

N/A

xvi DGC-2020 Introduction 9400200990 Rev X

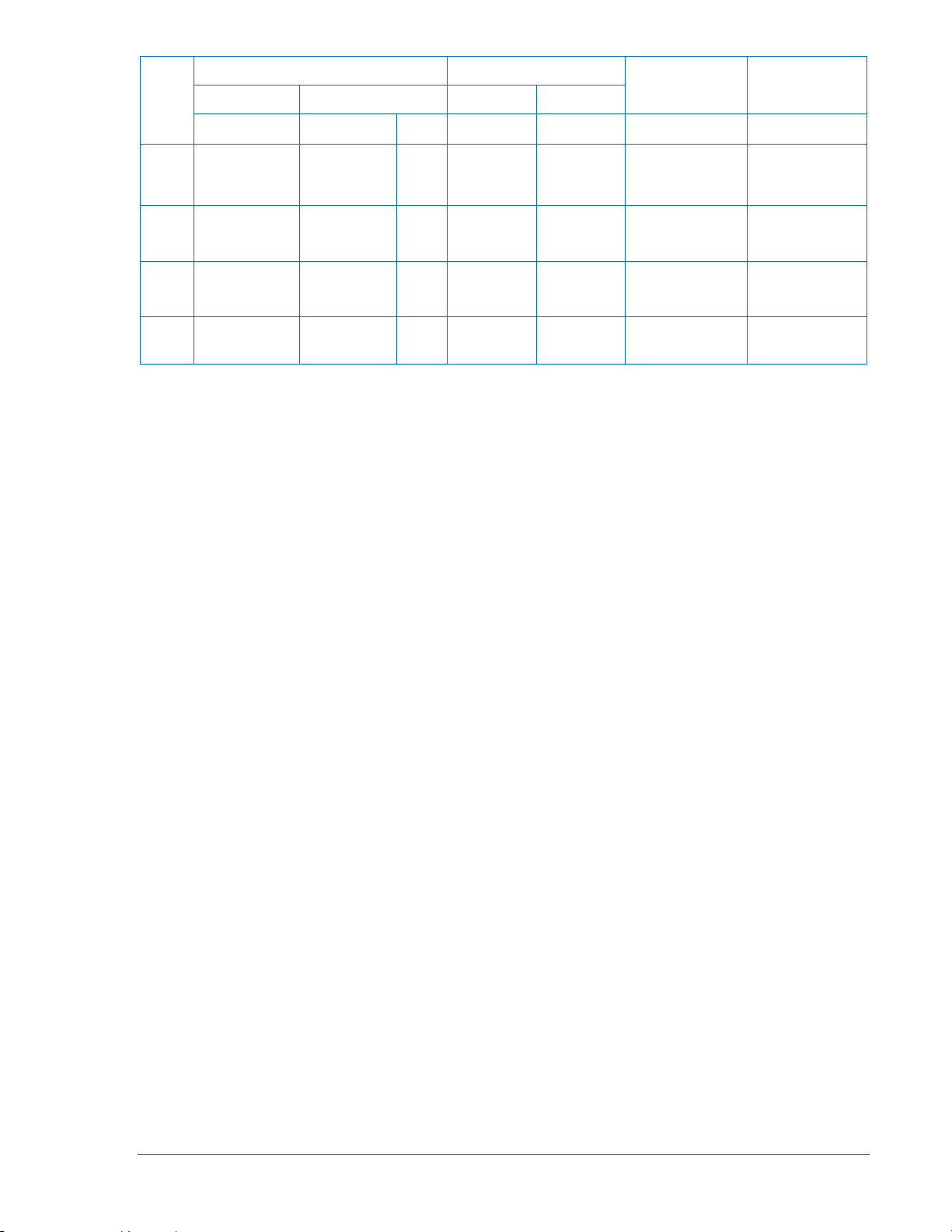

Page 19

Pkg.

File

Ver.

Digital Genset Controller (DGC-2020) Load Share Module (LSM-2020)

Application Code Flash Language Module CANBus App. Ethernet App.

Version & P/N Version & P/N Lang.* Version & P/N Version & P/N Version & P/N Version & P/N

Contact Expansion

Module

(CEM-2020/H)

Analog Expansion

Module

(AEM-2020)

2.00.00

05/01/07

9400201017

1.00.00/1.00.00

9400201011/-

012

1.00.00/1.00.00

9400201011/-

012

N/A N/A N/A N/A N/A N/A

C,E,S N/A N/A N/A N/A

C,E N/A N/A N/A N/A

C,E N/A N/A N/A N/A

1.02.00

N/A

N/A

N/A

1.01.00

05/02/07

9400201016

1.00.08

9400201015

1.00.07

9400201013

1.00.06

9400201008

* C = Chinese, E = English, F = French, G = German, P = Portuguese, R = Russian, S = Spanish

Note: For firmware upgrade procedure, refer to Section 4, BESTCOMSPlus® Software.

9400200990 Rev X DGC-2020 Introduction xvii

Page 20

xviii DGC-2020 Introduction 9400200990 Rev X

Page 21

CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

SECTION 2 • HUMAN-MACHINE INTERFACE ....................................................................................... 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

SECTION 4 • BESTCOMSPlus® SOFTWARE ......................................................................................... 4-1

SECTION 5 • BESTlogic™Plus PROGRAMMABLE LOGIC .................................................................... 5-1

SECTION 6 • INSTALLATION .................................................................................................................. 6-1

SECTION 7 • SETUP ................................................................................................................................ 7-1

SECTION 8 • MAINTENANCE AND TROUBLESHOOTING ................................................................... 8-1

SECTION 9 • LSM-2020 (LOAD SHARE MODULE) ................................................................................ 9-1

SECTION 10 • CEM-2020 (CONTACT EXPANSION MODULE) ........................................................... 10-1

SECTION 11 • AEM-2020 (ANALOG EXPANSION MODULE) .............................................................. 11-1

APPENDIX A • TIME OVERCURRENT CHARACTERISTIC CURVES ................................................... A-1

APPENDIX B • MODBUS™ COMMUNICATION ...................................................................................... B-1

APPENDIX C • TUNING PID SETTINGS ................................................................................................. C-1

APPENDIX D • MTU FAULT CODES ....................................................................................................... D-1

APPENDIX E • EXHAUST TREATMEN T ................................................................................................. E-1

9400200990 Rev X DGC-2020 Introduction xix

Page 22

xx DGC-2020 Introduction 9400200990 Rev X

Page 23

SECTION 1 • GENERAL INFORMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

Description ............................................................................................................................................. 1-1

Hardware Versions ................................................................................................................................ 1-1

Identifying DGC-2020 Vers i on ............................................................................................................ 1-1

Features ................................................................................................................................................. 1-1

Functions ................................................................................................................................................ 1-2

Generator Protection and Meter ing .................................................................................................... 1-2

Engine Protection and Metering ......................................................................................................... 1-2

Event Recording ................................................................................................................................. 1-2

Auto-Synchronizer .............................................................................................................................. 1-2

Contact Inputs and Output Contacts .................................................................................................. 1-2

Automatic Transfer Switch Control (Mains Failure)............................................................................ 1-2

Communication .................................................................................................................................. 1-2

USB Port ......................................................................................................................................... 1-3

CAN Bus Interface .......................................................................................................................... 1-3

External Dial-Out Modem Port ........................................................................................................ 1-3

RS-485 Port .................................................................................................................................... 1-3

AEM-2020 (Analog Expans ion Mod ule) ................................................................................................. 1-3

CEM-2020 (Contact Expansion Module) ............................................................................................... 1-3

LSM-2020 (Load Share Module) ............................................................................................................ 1-3

Style Number ......................................................................................................................................... 1-3

Specifications ......................................................................................................................................... 1-5

Operating Power ................................................................................................................................ 1-5

Power Consumption ....................................................................................................................... 1-5

Battery Ride Through ......................................................................................................................... 1-5

Current Sensing ................................................................................................................................. 1-5

1 Aac Current Sensing .................................................................................................................... 1-5

5 Aac Current Sensing .................................................................................................................... 1-5

Voltage Sensing ................................................................................................................................. 1-5

Contact Sensing ................................................................................................................................. 1-5

Terminals ........................................................................................................................................ 1-6

Engine System Inputs ........................................................................................................................ 1-6

Fuel Level Sensing ......................................................................................................................... 1-6

Coolant Temperature Sensing ........................................................................................................ 1-6

Oil Pressure Sensing ...................................................................................................................... 1-6

Engine Speed Sensing ................................................................................................................... 1-6

Output Contacts ................................................................................................................................. 1-7

PRESTART, START, and RUN Relays .......................................................................................... 1-7

Programmable Relays (12) ............................................................................................................. 1-7

Metering .............................................................................................................................................. 1-7

Generator and Bus Voltage (rms) ................................................................................................... 1-7

Generator Current (rms) ................................................................................................................. 1-7

Generator and Bus Frequency ....................................................................................................... 1-7

Apparent Power .............................................................................................................................. 1-7

Power Factor .................................................................................................................................. 1-8

Real Power ..................................................................................................................................... 1-8

Oil Pressure .................................................................................................................................... 1-8

Coolant Temperature ...................................................................................................................... 1-8

Battery Voltage ............................................................................................................................... 1-8

Engine RPM .................................................................................................................................... 1-9

Engine Run Time ............................................................................................................................ 1-9

Maintenance Timer ......................................................................................................................... 1-9

Fuel Level ....................................................................................................................................... 1-9

Generator Protection Functions ......................................................................................................... 1-9

Overvoltage (59) and Undervoltage (27) ........................................................................................ 1-9

9400200990 Rev X DGC-2020 General Information i

Page 24

Underfrequency (81U) and Overfrequency (81O) .......................................................................... 1-9

Reverse Power (32) ........................................................................................................................ 1-9

Loss of Excitation (40Q) ............................................................................................................... 1-10

Overcurrent (51) (Optional) ........................................................................................................... 1-10

Phase Imbalance (47) (Optional) .................................................................................................. 1-10

ROCOF (Rate of Change of Frequency) (81) (Optional) .............................................................. 1-10

Vector Shift (78) (Optional) ........................................................................................................... 1-10

Logic Timers ..................................................................................................................................... 1-10

Communication Interface ................................................................................................................. 1-10

USB ............................................................................................................................................... 1-10

External Dial-Out Modem (Optional)............................................................................................. 1-10

RS-485 (Optional) ......................................................................................................................... 1-10

RDP-110 ....................................................................................................................................... 1-11

CAN .............................................................................................................................................. 1-11

Real-Time Clock ............................................................................................................................... 1-11

Clock Holdup................................................................................................................................. 1-11

LCD Heater ....................................................................................................................................... 1-12

Type Tests ........................................................................................................................................ 1-12

Shock ............................................................................................................................................ 1-12

Vibration ........................................................................................................................................ 1-12

Radio Interference ........................................................................................................................ 1-12

HALT (Highly Accelerated Life Testing) ....................................................................................... 1-12

Ignition System ............................................................................................................................. 1-12

Environment ..................................................................................................................................... 1-12

UL Recognition ................................................................................................................................. 1-12

CSA Certification .............................................................................................................................. 1-13

NFPA Compliance ............................................................................................................................ 1-13

CE Compliance................................................................................................................................. 1-13

GOST-R Certification ....................................................................................................................... 1-13

Physical ............................................................................................................................................ 1-13

Figures

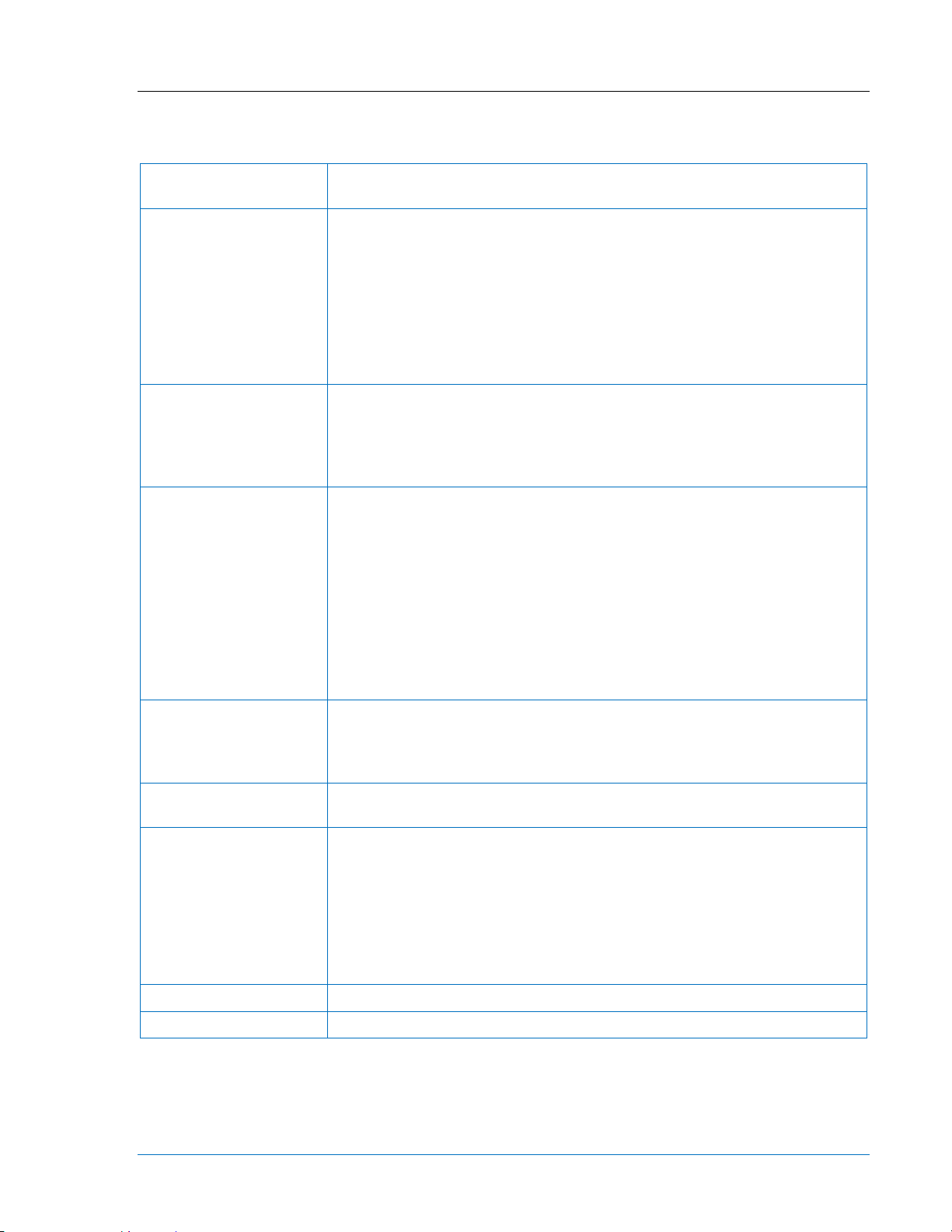

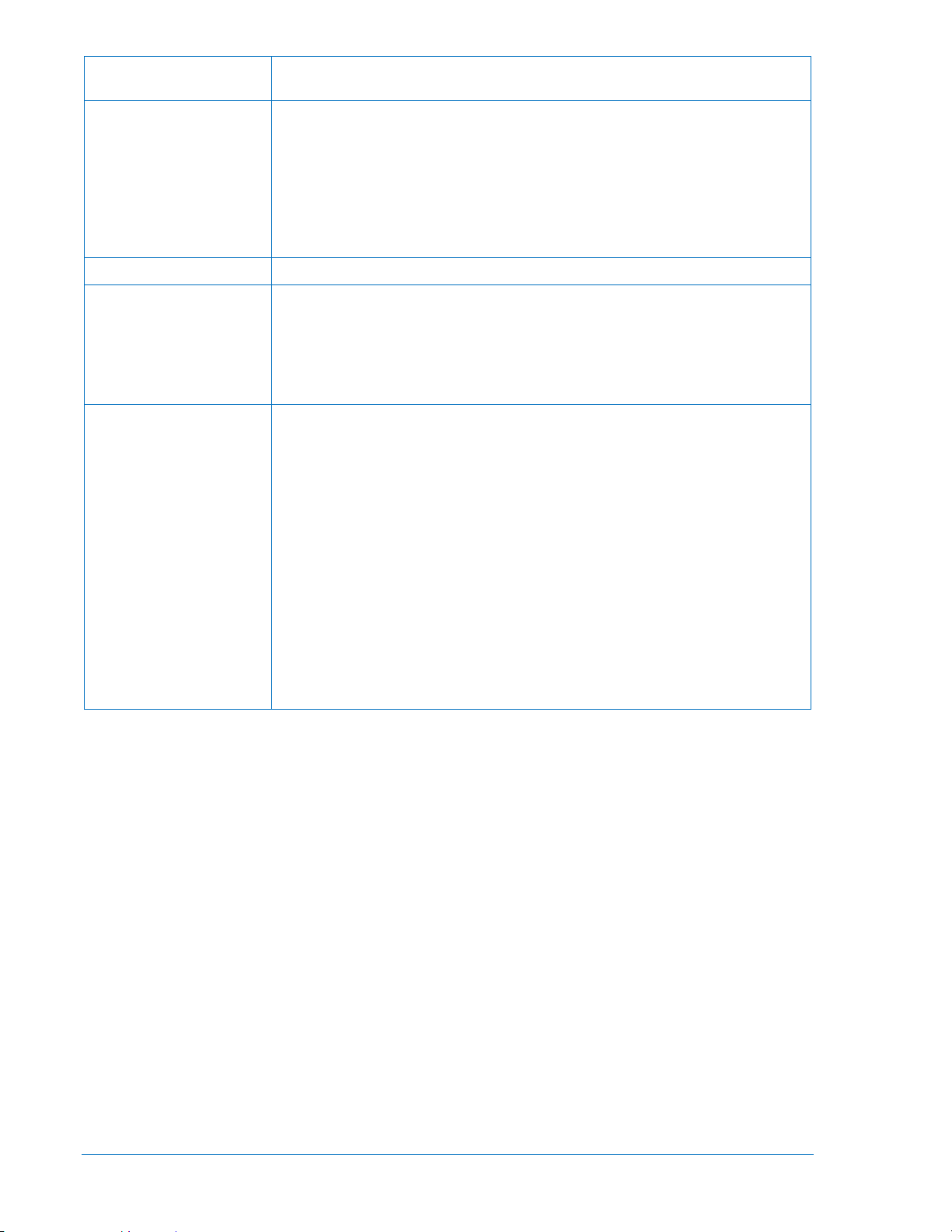

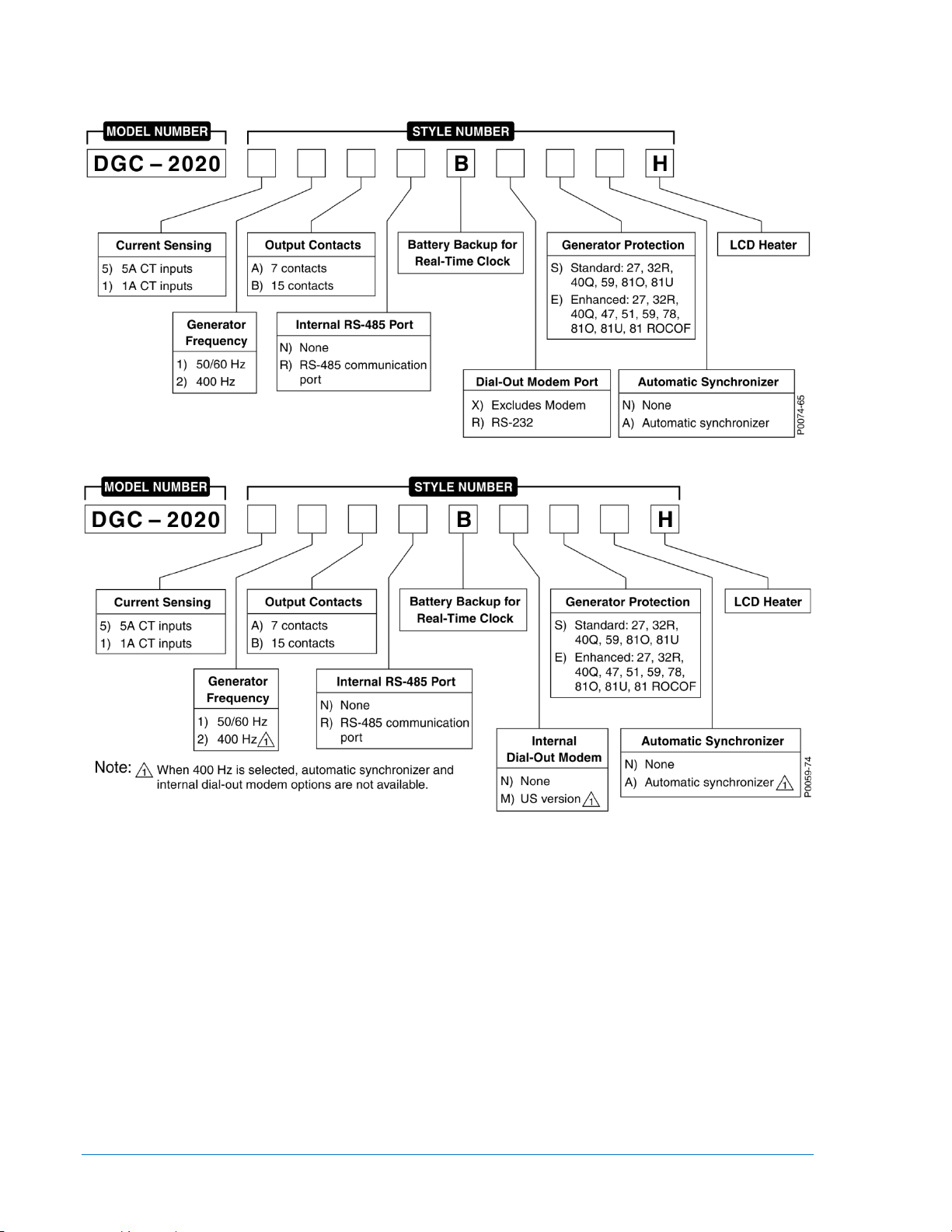

Figure 1-1. DGC-2020 Style Chart for Hardware Version 3 ...................................................................... 1-4

Figure 1-2. DGC-2020 Style Chart for Hardware Versions 1 and 2 .......................................................... 1-4

ii DGC-2020 General Information 9400200990 Rev X

Page 25

SECTION 1 • GENERAL INFORMATION

Feature

Versions 1 and 2∗

Version 3

Three-phase bus sensing

Single-phase bus sensing only

Available

Optional RS-232 port for

communication with external modem

Optional RJ-11 jack for internal

modem communication only

Description

The DGC-2020 Digital Genset Controller provides integrated engine-genset control, protection, and

metering in a single package. M icroprocessor based tec hnology allows for exact measur ement, setpoint

adjustment, and ti ming func tions. Front panel co ntrols and indica tors enab le quick and simp le DGC-2020

operation. Basler Electric communication software (BESTCOMSPlus®) allows units to be easily

customized for each application. Because of the low sensing burden in the DGC-2020, dedicated

potential transformers (PTs) are not required. A wi de temperature-ran ge liquid crys tal display (LCD) wit h

backlighting can be viewed under a wide range of ambient light and temperature conditions.

Hardware Versions

This instruction manu al covers all hardware versions of the DGC-2020. Differences between hardware

versions are listed in Table 1-1 below, and noted throughout this publication where applicable.

Table 1-1. DGC-2020 Hardware Version Differences

Available

∗Versions 1 and 2 are no longer available for ordering.

Identifying DGC-2020 Version

DGC-2020 version inform ation can be f ound throu gh the front-panel inter face an d via connec tion to a PC

running BESTCOMSPlus software.

Version information is displayed on t he front panel LC D immediately aft er applying operat ing power and

on the Version Info screen. To view the Version Info screen, navigate to Setting s > General Settings >

Version Info > DGC-2 020 > Firmware version. The f irmware version number c onsists of five digits. The

first digit is the hard ware version number. Re fer to Section 2, Controls and Indicators for inf ormation on

using the front panel.

In BESTCOMSPlus, th e DGC-2020 har dware vers ion is found on t he Device Inf o screen. Connect to t he

DGC-2020 and download setti ngs and logic. Using t he Settings Explorer , open G eneral Settings , Device

Info. The hardware version of the DGC-2020 is shown in the Application Version field. The a pplication

version number consis ts of five di gits. The first d igit is the hardwar e version num ber. Refer to Secti on 4,

BESTCOMSPlus Software for details on installing and using BESTCOMSPlus.

Features

DGC-2020 Digital Genset Controllers have the following features:

• Local and Remote Generator Control

• Engine, Generator, and Loss of Mains Protection

• Automatic Transfer Switch Control (Mains Failure)

• Automatic Generator Configuration Detection

• Generator Sequencing

• Generator Soft Loading/Unloading

• Auto Synchronizing

• Programmable Analog Engine Senders

• 16 Programmable Contact Inputs

• Programmable Logic

• Exercise Timer

• ECU Communications via SAE J1939

• Marathon DVR2000E+ Voltage Regulator Control via SAE J1939

• Integrated RS485 communication (optional)

• Dial-Out Modem communication (optional)

• Additional modules available to expand the capabilities of the DGC-2020

9400200990 Rev X DGC-2020 General Information 1-1

Page 26

Functions

DGC-2020 Digital Genset Controllers perform the following functions:

Generator Protection and Metering

Multifunction generator protection guards against generator overvoltage, undervoltage, reverse power,

loss of excitation, underfre quency, and overfreque ncy. Overcurrent, phase imb alance, and loss of mains

protection are available as an o ption. Each generator protection f unction has an adjustable pickup and

time delay setting. Sixteen invers e time curves en able the DGC-20 20 to offer ov ercurrent prot ection in a

variety of applications.

Metered generator parameters include voltage, current, real power (watts), apparent power (VA), and

power factor (PF).

Engine Protection and Metering

Engine protection fe atures inc lude o il press ure a nd coola nt temp eratur e mo nitorin g, overc rank pr otec tion,

ECU specific protection elements, and diagnostic reporting.

Metered engine param eters include oil press ure, coolant temperature, battery voltage, speed, f uel level,

engine load, coolant level (from ECU), ECU specific parameters, and run-time statistics.

Event Recording

An event log retains a histo ry of system events in n onvolatile mem ory. Up to 30 event ty pes are retained

and each record contains a time stamp of the first and last occurrence, a nd the number of occ ur renc es for

each event. For more informati on, se e Sec ti on 3, Fun ctiona l Des c riptio n, Ev ent Rec ordin g.

Auto-Synchronizer

An optional automatic synchronizer monitors the bus and generator voltages and supplies discrete

raise/lower correcti on signals to sy nchronize the ge nerator v oltage, frequenc y, and slip angle with that o f

the bus.

Contact Inputs and Output Contacts

DGC-2020 controllers have one, dedicated emergency stop contact input and 16 program mable contact

inputs. All contact inputs re cognize dry contacts. T he program mable inpu ts can be config ured to initiat e a

pre-alarm or alarm. A programmable input can be programmed to receive an input from an automatic

transfer switch or over ride DGC-2020 alarms and protec tion functions. Each programmable in put can be

assigned a user-defined name for easy identification at the front panel display and in fault records.

Output contacts include thr ee dedicated relays for ener gizing an engine’s glow plugs, fuel s olenoid, and

starter solenoid. An additional four user -progr amma ble outp ut cont acts are provided i f the style number is

xxAxxxxxx. If the style number is xxBxxxxxx, an additional twelve output contacts are provided.

Additional contact inputs and output contacts can be accommodated with an o ptio nal CEM-2020 (Contact

Expansion Module). Contact Basler Electric for ordering information.

Automatic Transfer Switch Control (Mains Failure)

The DGC-2020 has the ab ility to detect a mains failur e via a single- or three-phase Bus input. A mains

failure is established when any one of the following conditions are met:

• Any phase of bus voltage falls below dead bus threshold

• Any phase of bus voltage unstable due to overvoltage or undervoltage

• Any phase of bus voltage unstable due to overfrequency or underfrequency

At this time, the DGC-2 020 will start the genset and when ready , apply power to the loa d via the gens et.

The DGC-2020 impleme nts open or closed transitio ns to and from the mains. Whe n the mains returns

and is considered sta ble, the DG C-2020 w ill transf er the load back to t he mains. When closed transitions

are required, the Auto Synchronizer option of the DGC-2020 is required in order to synchronize the

generator to the mains when transferring a load from generator power to utility power.

Communication

Standard DGC-2020 communication features include a standard USB port and SAE J1939 interface.

Optional communicat ion features include an RS-232 port for conn ection with an external dial-out modem

1-2 DGC-2020 General Information 9400200990 Rev X

Page 27

and RS-485 communication port. BESTCOMSPlus® can communicate with the DGC-2020 through

Ethernet via an optional LSM-2020 (Load Share Module). Contact Basler Electric for ordering information.

USB Port

A USB communication port can be used with BESTCOMSPlus® software to quickly configure a DGC2020 with the desired settings or retrieve metering values and event log records.

CAN Bus Interface

A CAN bus interface provides high-spee d commu nication b etween the DGC-2020 and the eng ine contro l

unit (ECU) on an e lectronically contr olled engine. Th is interface provid es access to oil pres sure, coolant

temperature, and engine s peed data by reading thes e parameter s direc tly from th e ECU. When av aila ble,

engine diagnostic data can also be accessed.

The CAN bus interface also provides communication between the DGC-2020 and the Marathon

DVR2000E+ voltage regulator. Voltage setpoint and underfrequency knee-point settings can be sent

directly to the DVR2000E+ from the DGC-2020.

The CAN bus interface supports the following protocols:

• SAE J1939 Protocol - Oil pressure, coolant temperature, and engine speed data are

received from the ECU. In addition, DTCs (D iagnostic Trouble Codes) help diag nose any engine

or related failures. The eng ine DTCs are displayed on the front panel of the DGC -2020 and may

be obtained using BESTCOMSPlus® software.

• MTU Protocol - A DG C-2 020 c onnected to a gense t e quip ped wit h an MTU engine ECU receives

Oil pressure, coolant temperature, and en gine speed data from the engine con troller, along with

various alarms and pre-alarms that are MTU specific. In addition, the DGC-2020 tracks and

displays the active fault codes issued by the MTU engine ECU.

External Dial-Out Modem Port

An optional RS-232 comm unication port uses the ASCII protocol to communicate with a user-supplied

external modem. Th e opti onal ex terna l dial-out modem enables r emote contro l, mon itoring, an d sett ing of

the DGC-2020. When an alarm or pre-alarm condition occurs, the DGC-2020 can dial up to four

telephone numbers, in sequence, until an answer is received and the condition is annunciated.

RS-485 Port

An optional RS-485 com municatio n port uses the Modbus™ communicati on protocol a nd enables remot e

control and monitoring of the DGC-2020 over a polled network.

AEM-2020 (Analog Expansion Module)

The optional AEM-2020 provides eight remote analog inputs, eight remote RTD inputs, two remote

thermocouple inputs, an d four remote analog outputs t o the DGC-2020. The AEM-2020 communicates

with the DGC-2020 through a CAN bus interface. Refer to Section 11, AEM-2020 (Analog Expansion

Module), for more information.

CEM-2020 (Contact Expansion Module)

The optional CEM-2020 provides 10 additional contact inputs and 18 or 24 additional output contacts

(depending on module type) to the DGC-2020. The CEM-2020 communicates with the DGC-2020 through

a CAN bus interface. Refer to Section 10, CEM-2020 (Contact Expansion Module), for more information.

LSM-2020 (Load Share Module)

The optional LSM-2020 in conjunction with the DGC-2020 provides load sharing between governors

through an analog load sh are line. The LSM-2020 commu nicates through an Et hernet port and provides

access to the DGC-2020 via Ethernet. Refer to Section 9, LSM-2020 (Load Share Module), for more

information.

Style Number

Standard-order DGC-20 20 contr ollers are identifie d by a sty le number w hich cons ists of a co mbinatio n of

letters and numbers that define the controller’s electrical characteristics and operational features. The

9400200990 Rev X DGC-2020 General Information 1-3

Page 28

model number, together with the style number, describes the options included in a specific controller.

Figure 1-1 i llustrates the DGC-2020 styl e number identification ch art for hardware ver sion 3. Figure 1-2

illustrates the DGC-2020 style number identification chart for hardware versions 1 and 2.

Figure 1-1. DGC-2020 Style Chart for Hardware Version 3

Figure 1-2. DGC-2020 Style Chart for Hardware Versions 1 and 2

For example, if a DGC-2020 (hardw are version 3) style num ber were 51BNBREAH, the con troller would

have the following characteristics and operating features.

5 5 Aac current sensing inputs

1 50/60 hertz nominal generator frequency

B Three fixed-function output contacts and 12 programmable output contacts

N No RS-485 communication port

B Battery backup for real-time clock during losses of control power

R External dial-out modem port

E Enhanc ed gen er ator pr otection (27 undervoltage, 32R reverse power, 40Q loss of excitation, 47

phase imbalance, 51 overcurrent, 59 overvoltage, 78 vector shift, 81O overfrequency, 81U

underfrequency, and 81 ROCOF)

A Auto-synchronizer

H LCD heater

1-4 DGC-2020 General Information 9400200990 Rev X

Page 29

Specifications

Operating Power

Nominal ............................................. 12 or 24 Vdc

Range ............................................... 6 to 32 Vdc

Terminals .......................................... 3 (+), 2 (–), 1 (chassis ground)

Power Consumption

Sleep Mode ....................................... 5W with all relays non-energized

Normal Operational Mode ................ 7.9W - Run mode, LCD heater off, 3 relays energized

Maximum Operational Mod e ............ 14.2W - Run mode, LCD heater on, 6 relays energized

Battery Ride Through

Withstands cranking ride-through down to 0 V for 50 ms, starting at 10 Vdc.

Current Sensing

Burden .............................................. 1 VA

Terminals .......................................... 68, 69 (A-phase)

71, 72 (B-phase)

74, 75 (C-phase)

1 Aac Current Sensing

Continuous Rating ............................ 0.02 to 1.0 Aac

1 Second Rating ............................... 2 Aac

5 Aac Current Sensing

Continuous Rating ............................ 0.1 to 5.0 Aac

1 Second Rating ............................... 10 Aac

Voltage Sensing

Generator Configuration ................... Line-to-line or line-to-neutral

Bus Configuration ............................. Line-to-line

Range ............................................... 12 to 576 V rms, line-to-line

Frequency ......................................... Style selectable, 50/60 Hz or 400 Hz

Frequency Range ............................. 10 to 72 Hz for 50/60 style and 10 to 480 Hz for 400 Hz style

Burden ............................................. 1 VA

1 Second Rating ............................... 720 V rms

Generator Sensing Terminals ........... 41 (A-phase)

39 (B-phase)

37 (C-phase)

35 (Neutral)

Bus Sensing Terminals

Hardware Version 3 .......................... 76, 45 (A-phase)∗

78, 43 (B-phase)∗

80 (C-phase)

Hardware Versions 1 and 2 .............. 45 (A-phase)

43 (B-phase)

∗ In version 3 hardware, terminal 45 is internally tied to 76 and terminal 43 is internally tied to 78. This

accommodates the use of connectors wired for legacy DGC-2020 versions.

Contact Sensing

Contact sensing inputs incl ude 1 emergency stop input and 16 programmable inputs. All inputs accept dry

contacts.

Time from a DGC-2020 input application to:

Shutdown the generator via an alarm = 490 ms max

Close a relay on board the DGC-2020 = 215 ms max

Close a relay on board the CEM-2020 = 400 ms max

9400200990 Rev X DGC-2020 General Information 1-5

Page 30

A contact i nput is true (on) if the input is connected t o battery ground with a

resistance of less than 240 ohms.

The maximum length of wire that can be accommodated depends on the

resistance of the w ire, and the resist ance of the conta cts of the device driving

the input at the far end of the wire.

The maximum wire length can be calculated as follows:

L

= (240 – R

max

)/(Resistance per Foot of Desired Wire)

device

Terminals

Emergency Stop ............................... 46, 47

Programmable

Input 1 ............................................... 30, 2

Input 2 ............................................... 29, 2

Input 3 ............................................... 28, 2

Input 4 ............................................... 27, 2

Input 5 ............................................... 26, 2

Input 6 ............................................... 25, 2

Input 7 ............................................... 24, 2

Input 8 ............................................... 23, 2

Input 9 ............................................... 22, 2

Input 10 ............................................. 21, 2

Input 11 ............................................. 20, 2

Input 12 ............................................. 19, 2

Input 13 ............................................. 18, 2

Input 14 ............................................. 17, 2

Input 15 ............................................. 16, 2

Input 16 ............................................. 15, 2

NOTES

Engine System Inputs

Stated accuracies are subject to the accuracy of the senders used. Values within these ranges are

deemed “good” and the DGC-2020 will use them for the appropriate calculation and protection. Values

outside these ranges are deemed “bad” and the DGC-2020 will begin timing towards a sender failure

condition.

Fuel Level Sensing

Resistance Range ............................ 0 to 250 Ω nominal

Terminals .......................................... 9, 11 (sender common)

Coolant Temperature Sensing

Resistance Range ............................ 10 to 2,750 Ω nominal

Terminals .......................................... 10, 11 (sender common)

Oil Pressure Sensing

Resistance Range ............................ 0 to 250 Ω nominal

Terminals .......................................... 8, 11 (sender common)

Engine Speed Sensing

Magnetic Pickup

Voltage Range .................................. 3 to 35 V peak (6 to 70 V peak-peak)

Frequency Range ............................. 32 to 10,000 Hz

Terminals .......................................... 31 (+), 32 (–)

Generator Voltage

Range ............................................. 12 to 576 V rms

Terminals .......................................... 41 (A-phase)

39 (B-phase)

37 (C-phase)

1-6 DGC-2020 General Information 9400200990 Rev X

Page 31

Output Contacts

PRESTART, START, and RUN Relays

Rating ............................................... 30 Adc at 28 Vdc - General purpose, 3 A pilot duty∗

Programmable Relays (12)

Rating ............................................... 2 Adc at 28 Vdc - General purpose, 1.2 A pilot duty∗

∗ The load mus t be in parallel with a diode rated at least 3 tim es the coil current and 3 times the coil

voltage.

Terminals†

Output 1 ............................................ 52, 51 (common)

Output 2 ............................................ 53, 51 (common)

Output 3 ............................................ 54, 51 (common)

Output 4 ............................................ 56, 55 (common)

Output 5 ............................................ 57, 55 (common)

Output 6 ............................................ 58, 55 (common)

Output 7 ............................................ 60, 59 (common)

Output 8 ............................................ 61, 59 (common)

Output 9 ............................................ 62, 59 (common)

Output 10 .......................................... 64, 63 (common)

Output 11 .......................................... 65, 63 (common)

Output 12 .......................................... 66, 63 (common)

† The number of programmable output contacts provided is determined by the output contacts

character of the DGC-2020 style number. Controllers with output contacts option A have 4 programmable outputs (Outputs 1, 2, 3, and 4). Controllers with output contacts option B have 12

programmable outputs.

The programmable relays share common terminals: terminal 51 is used for outputs 1, 2, and 3,

terminal 55 is us ed for out puts 4, 5, and 6, ter minal 59 is used for outputs 7, 8, and 9, 63 is used for

outputs 10, 11, and 12.

Metering

Generator and Bus Voltage (rms)

Metering Range ................................ 0 to 576 Vac (direct measurement)

577 to 9,999 Vac (through VT using VT ratio setting)